Vertical plastic pipe bending device

A technology for pipe bending equipment and plastic pipes, applied in the field of profile processing, can solve problems such as low efficiency, achieve smooth inner and outer surfaces, obvious effects, and great promotion value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

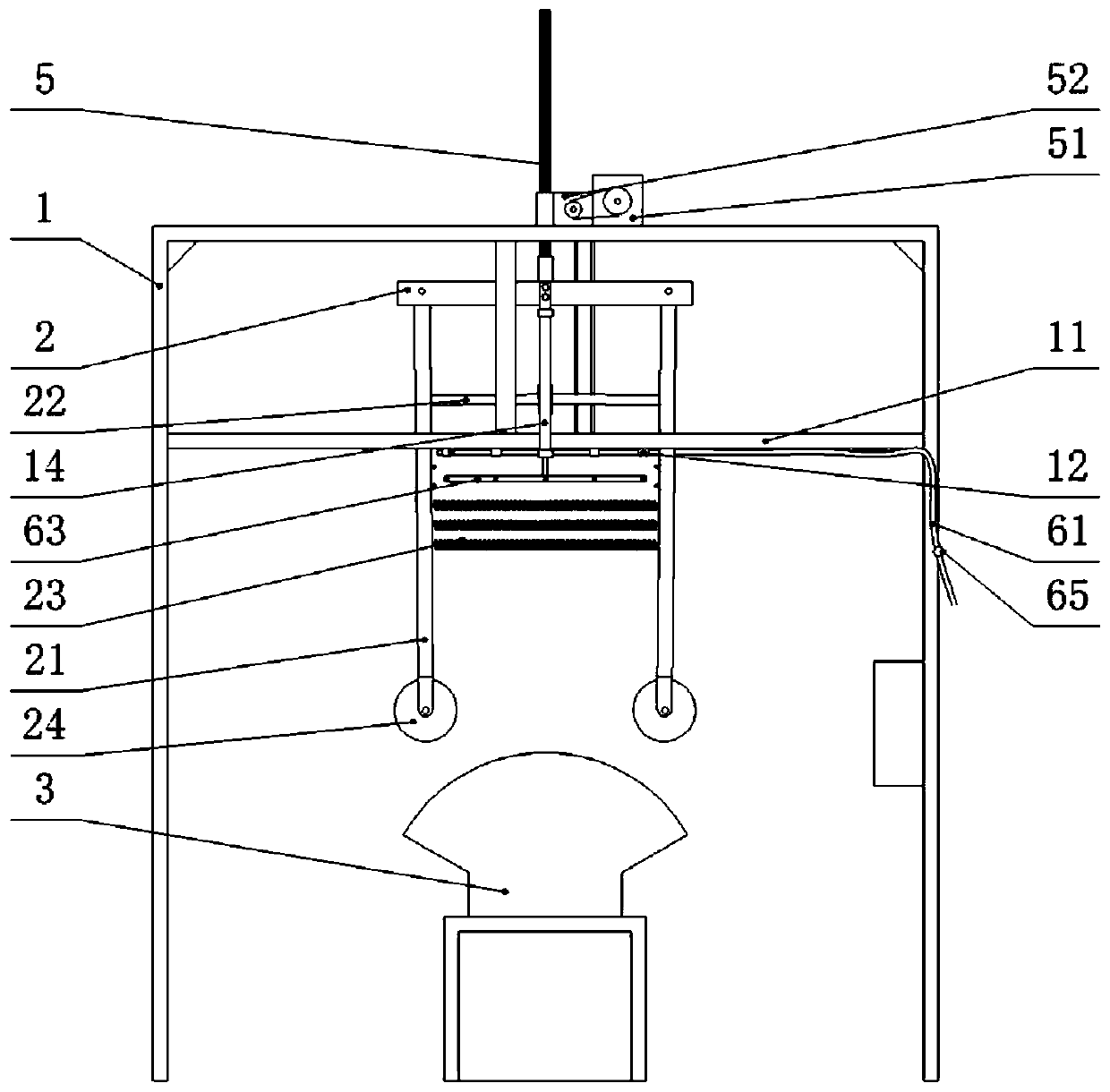

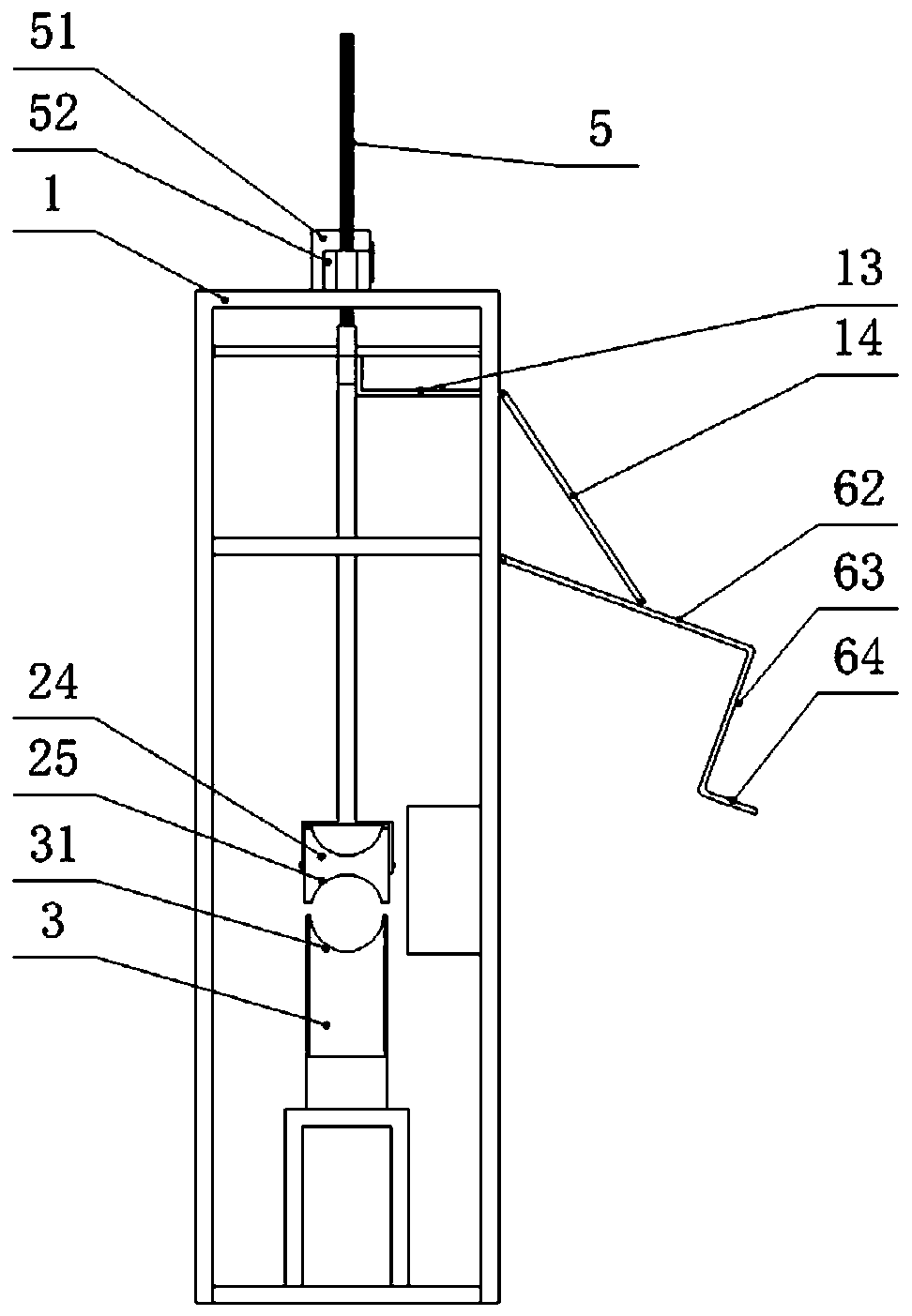

[0025] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

[0026] A preferred embodiment of the vertical plastic pipe bending equipment provided by the present invention is as follows: Figure 1 to Figure 3 Shown: a vertical plastic pipe bending equipment, including a frame 1 and a driving device, the frame 1 is provided with a pressure component and a concave mold 3 in sequence, the concave mold 3 is set on the bracket 1, and the pressure component includes an upper part The crossbeam 2, the left and right push rods 21 are movably connected to the two sides of the crossbeam 2 respectively, and the left and right push rods 21 are respectively connected with push rods 22, and the other ends of the left and right push rods 22 are pushed together in the middle of the left and right push rods...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com