Cross-linked polyolefin composition for rotational molding and preparation method thereof

A technology of cross-linking polyolefin and composition, applied in the direction of coating, etc., can solve the problems of easy generation of air bubbles, poor product hardness, lower density, etc., and achieve the effect of reducing product air bubbles, good plasticization, and easy demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

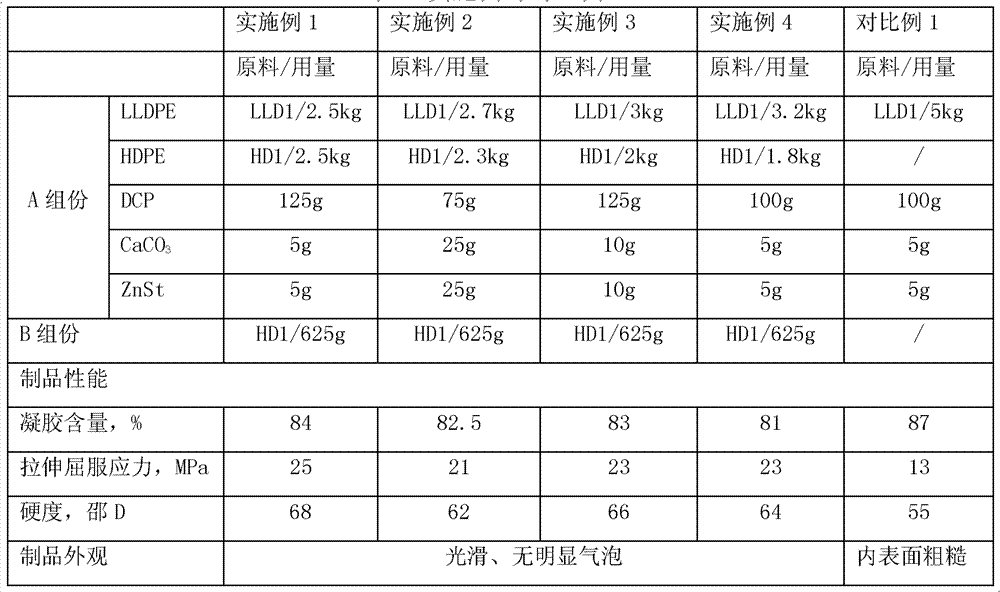

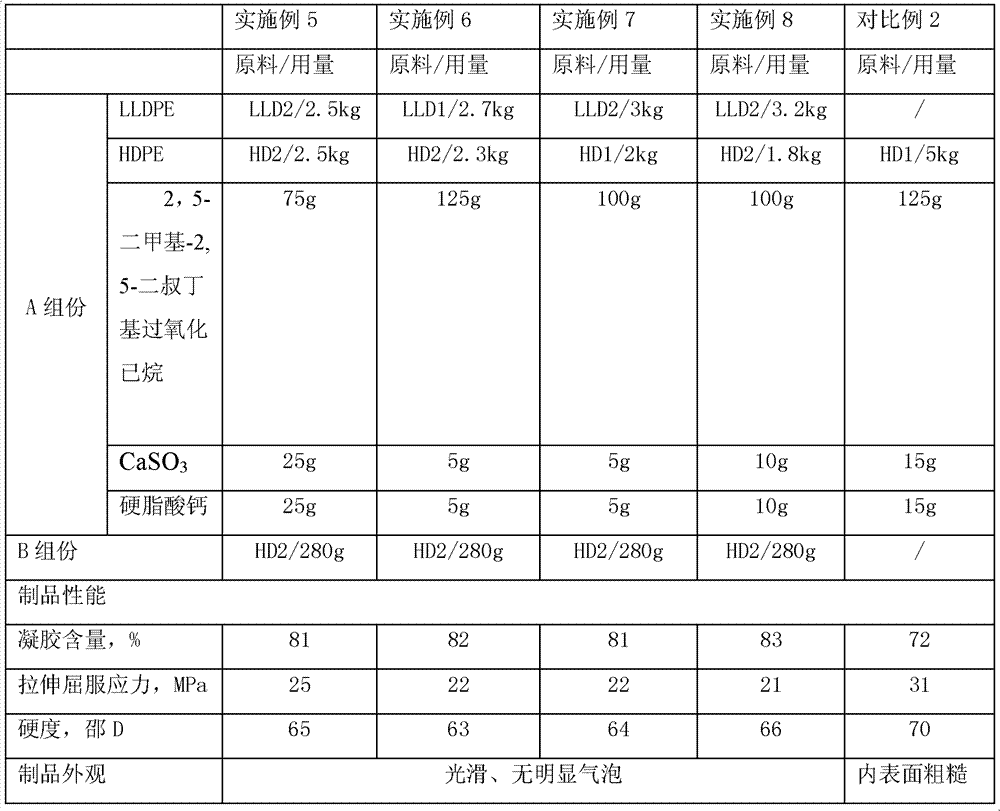

Embodiment 1~8

[0034] Raw materials used:

[0035] Linear Low Density Polyethylene 1 (LLD1): Melt mass flow rate (190°C, 2.16kg) is 6g / 10min, density 0.938g / cm 3

[0036] Linear low density polyethylene 2 (LLD2): Melt mass flow rate (190°C, 2.16kg) is 4g / 10min, density 0.936g / cm 3

[0037] High-density polyethylene 1 (HD1): Melt mass flow rate (190°C, 2.16kg) is 6.5g / 10min, density 0.954g / cm 3

[0038] High-density polyethylene 2 (HD2): Melt mass flow rate (190°C, 2.16kg) is 7.5g / 10min, density 0.958g / cm 3

[0039] Cross-linking agent: dicumyl peroxide (DCP) or 2,5-dimethyl-2,5-di-tert-butylperoxyhexane

[0040] Nucleating agent: 2000 mesh calcium carbonate (CaCO 3 ) or 2500 mesh calcium sulfate (CaSO 3 )

Embodiment

[0042] Embodiment preparation technology:

[0043] The various raw materials of component A are mixed according to the proportion and then granulated. The mixing speed is 1000 rpm, the mixing temperature is 25°C, and the mixing time is 4 minutes. Single-screw extruder or twin-screw extruder is used. Granulate at a temperature of 130-170° C., and then grind into fine powder. Examples 1-4 are ground into 35-mesh fine powder. Embodiment 5-Example 8 are ground into 45-mesh fine powder. Comparative Example 1 is ground into 35-mesh fine powder. Fine powder, Comparative Example 2 was ground into 45 mesh fine powder.

[0044] Grind high-density polyethylene 1 and high-density polyethylene 2 directly into powder, as component B, grind into 20-mesh fine powder in Example 1-Example 4, and grind into 30-mesh fine powder in Example 5-Example 8 .

[0045] Mix the grinding powder of component A and the grinding powder of component B according to the proportion for rotomolding. When the tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com