Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

360results about How to "Not easy to warp" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

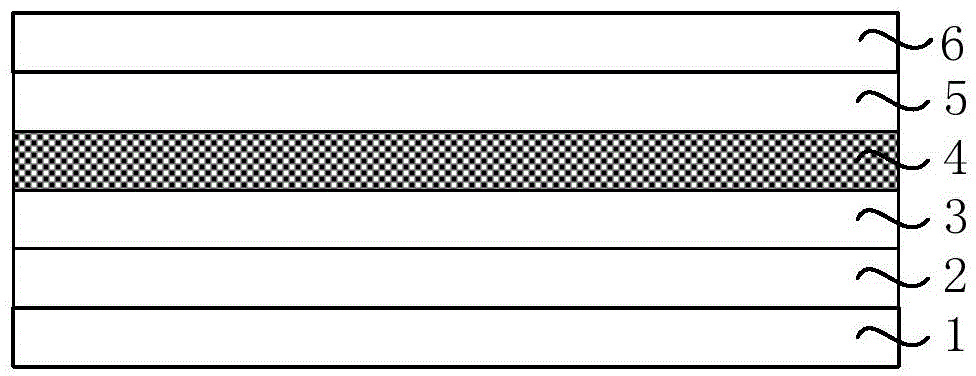

Terrestrial heat composite floor and manufacturing method thereof

ActiveCN101412238AEasy constructionDoes not affect strengthWood working apparatusFlooringHardnessWear resistance

The invention relates to a terrestrial heat composite floor board and a method for manufacturing the same. The method comprises the following processing steps: step A, preparation of face veneer, which is to process face veneer raw materials into sheets, and dry and balance the sheets; step B, preparation of middle veneer, which is to process middle veneer raw materials into sheets, and dry and balance the sheets; step C, preparation of bottom veneer, which is to process bottom veneer raw material into sheets, and dry and balance the sheets; step D, glue spreading; step E, blank assembling, which is to arrange the face veneer, the middle veneer, and the bottom veneer longitudinally, transversely, and longitudinally respectively according to wood grains; step F, hot pressing, which is to put the face veneer, the middle veneer, and the bottom veneer into a hot press to perform hot pressing; step G, conditioning, which is to put the floor board after the hot pressing and gluing into a balancing storeroom with constant temperature and humidity to keep stand and perform balance conditioning; step H, securing thickness and sanding; step I, mortice opening; step J, back trough opening; and step K, surface finishing, which is to adopt a roll painting process to lacquer the glued floor board. The composite floor board manufactured by the method has the characteristics of beautiful surface, hardness, wear resistance, good heat conductivity, high flexibility, and humiture change resistance.

Owner:FUSONG JINQIU WOOD CO LTD

Long fiber reinforced polypropylene/PPE alloy material and its prepn and application

The long fiber reinforced polypropylene / PPE alloy material has oriented fibers in the length over 4 mm and in netted configuration, and thus greatly raised shock resistance, rigidity, creeping resistance and size stability. What is more important is that the material may be mixed with many kinds of other material and thus has wide application range. The material may be prepared through powder soaking process, smelting soaking process, etc. The long fiber reinforced polypropylene / PPE alloy material of the present invention has excellent tensile, bending and anti-shocking performance, and may be used in manufacturing automobile part, pipe, valve part, electric tool, etc.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

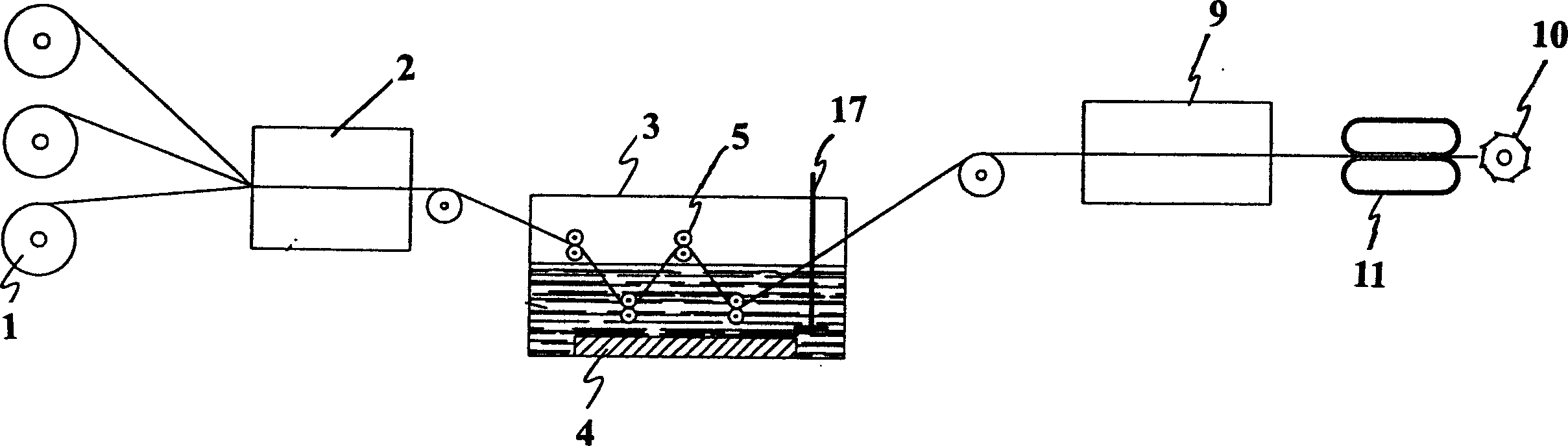

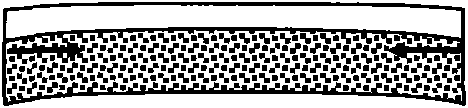

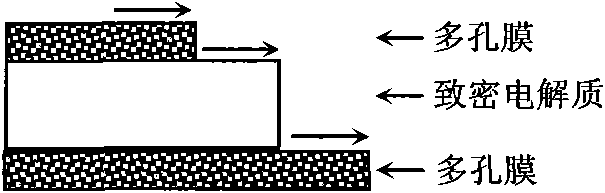

Method for preparing solid oxide fuel cell and entire cell thereof at low temperature

InactiveCN101577341ANot easy to warpLower sintering temperatureCell electrodesSolid electrolyte fuel cellsElectrical conductorEntire cell

The invention discloses a method for preparing a solid oxide fuel cell and an entire cell thereof at low temperature, which comprises the steps of: firstly conducting tape casting layer by layer for three times or stratified tape casting co-decompression, then obtaining a porous membrane / dense electrolyte / porous three-layer membrane by co-firing at low temperature, and then impregnating anode materials at one side and cathode materials at the other side, and finally obtaining the entire cell by sintering at low temperature. The relative density of a YSZ / GDC dense electrolyte in the three-layer membrane is higher than 96 percent and the porosity of the porous layer is greater than 60 percent. The impregnating mass fraction of the composite anodes of a NiO / CuO isoelectronic conductance phase and a doped ZrO2 / CeO2 plasma ion conductance phase reaches 40-70wt percent; and the impregnating mass fraction of the composite cathodes of an ion-electron mixed conductor or ion and electron reaches 40-60wt percent. The preparation method has the advantages of fewer processes, wide application of technology to the industry, low cost and good industrial prospects. The intensity of the obtained entire cell is relatively high, and the shape and size thereof are stable and reliable in preparation process and running.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

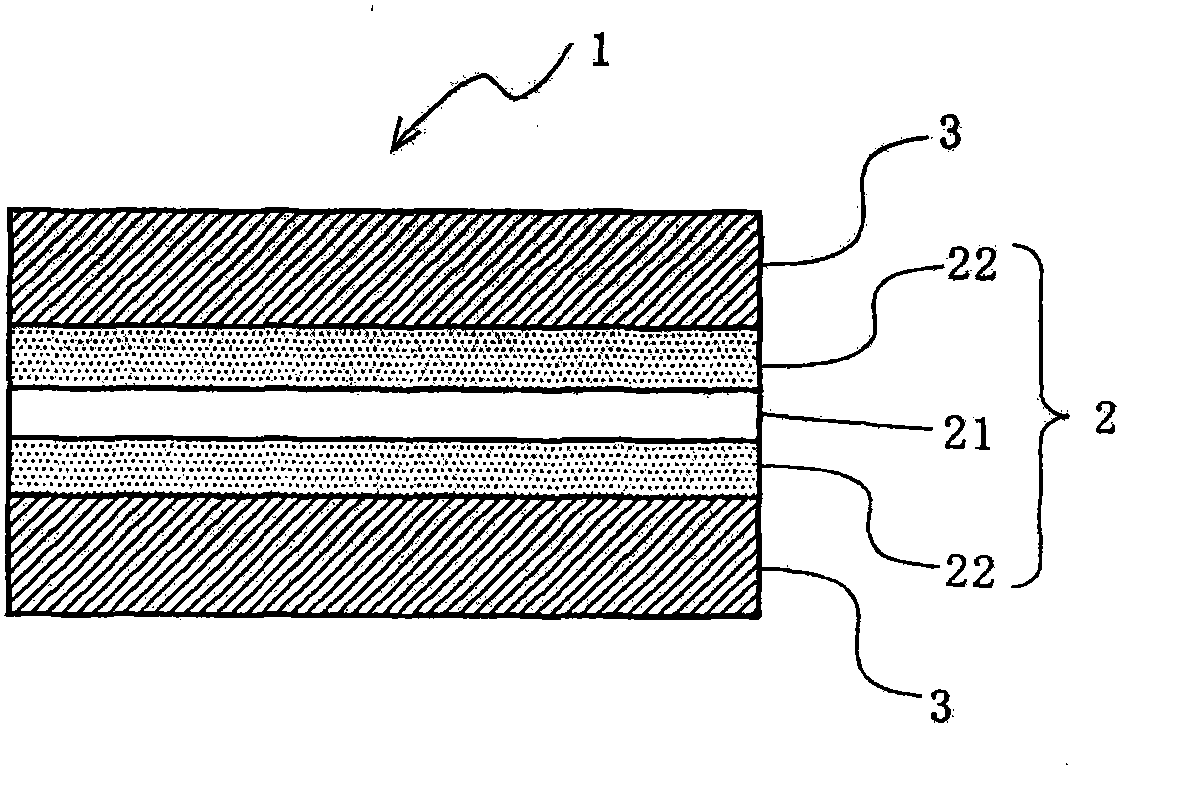

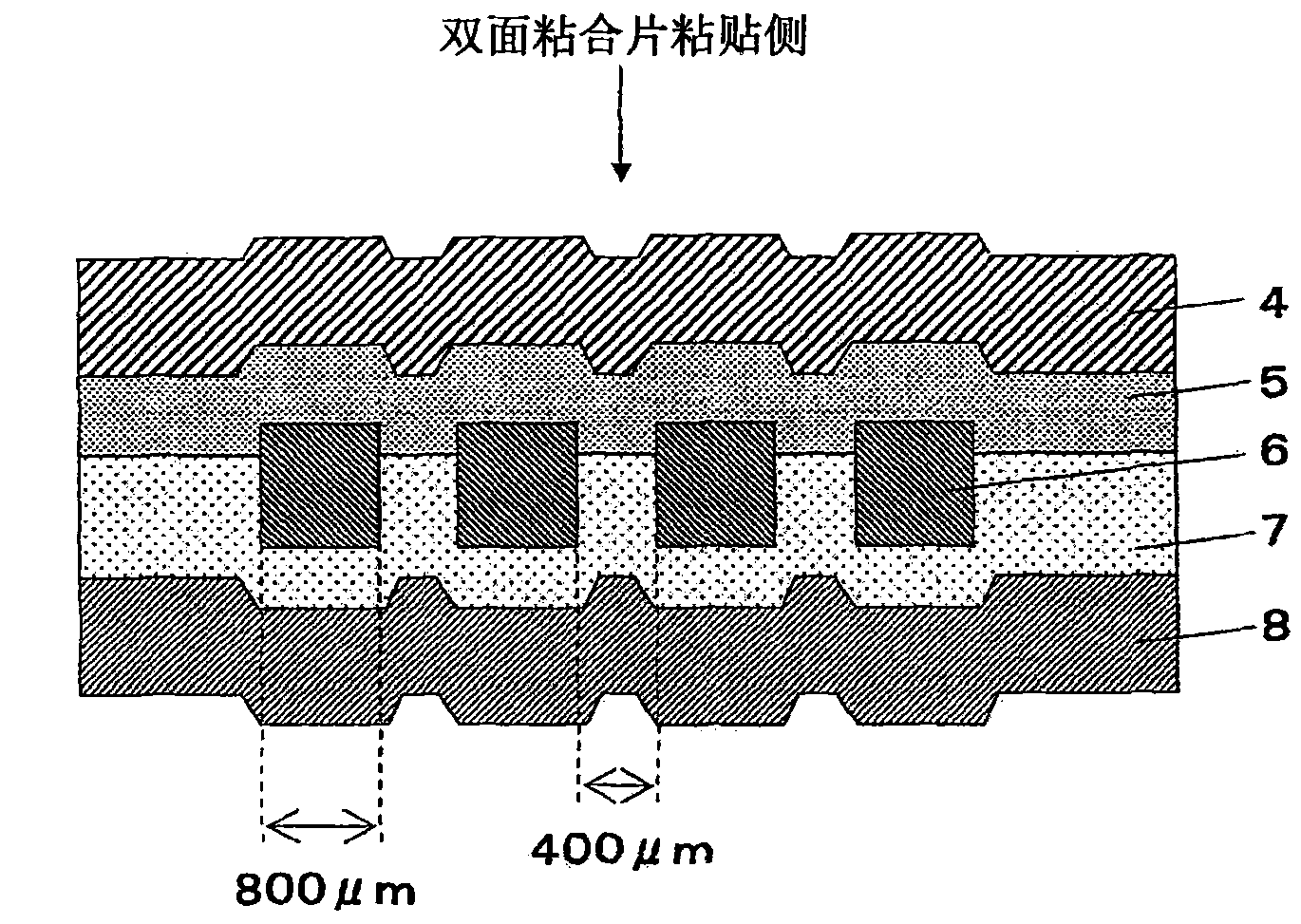

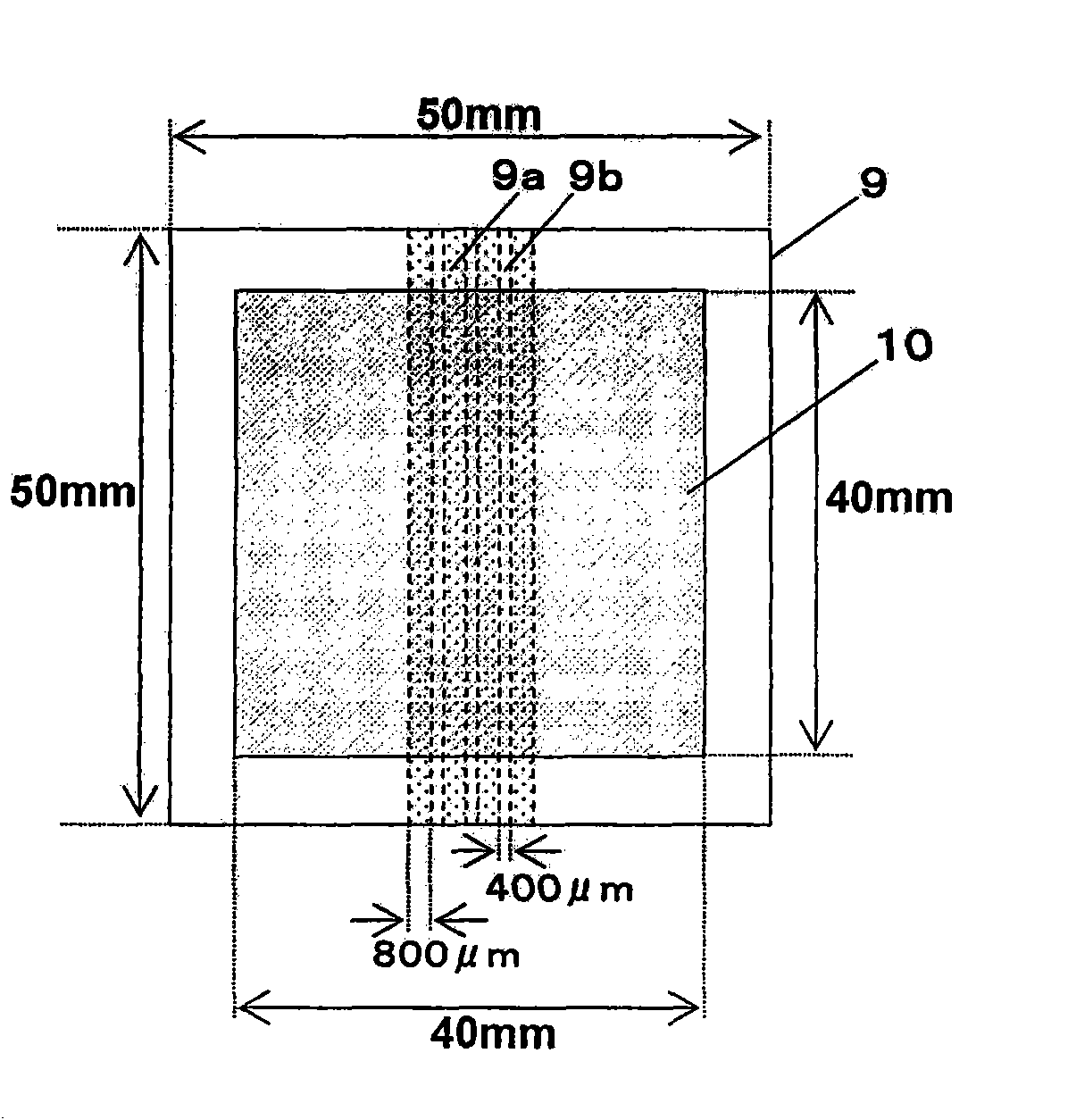

Double-coated pressure sensitive adhesive sheet for fixing flexible printed circuit board

InactiveCN101781529AImprove productivityImprove qualityLaminating printed circuit boardsSolid-state devicesMeth-Electrical polarity

Disclosed is a double-coated pressure-sensitive adhesive sheet for fixing a flexible printed circuit board, which includes at least a pressure-sensitive adhesive unit including a plastic base film having a thickness of 13 [mu]m or less, and pressure-sensitive adhesive layers on both sides of the plastic base film. The pressure-sensitive adhesive layers are formed from an acrylic polymer containing, as essential monomer components, a polar-group-containing monomer and an alkyl (meth)acrylate whose alkyl moiety being a linear or branched-chain alkyl group having 2 to 14 carbon atoms. The pressure-sensitive adhesive unit has a thickness of 60 [mu]m or less, the double-coated pressure-sensitive adhesive sheet shows an outgassing of 1 [mu]g / cm2 or less when heated at 120 DEG C. for 10 minutes, and shows a split distance (lifting) of 1.5 mm or less.

Owner:NITTO DENKO CORP

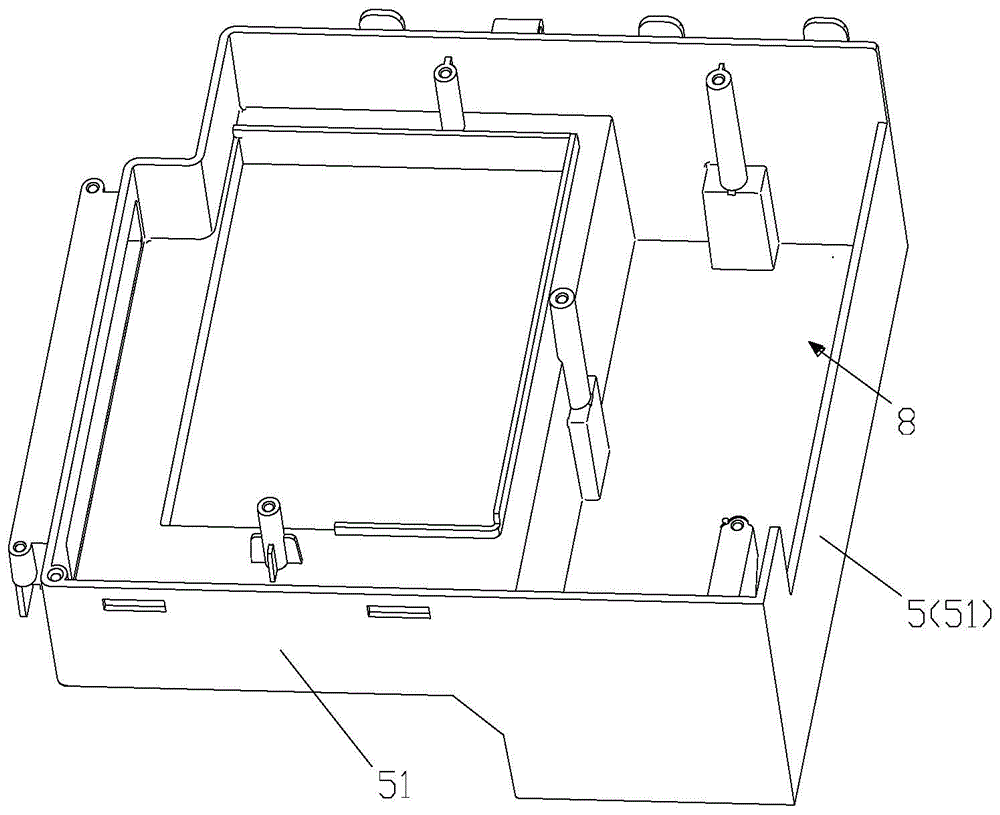

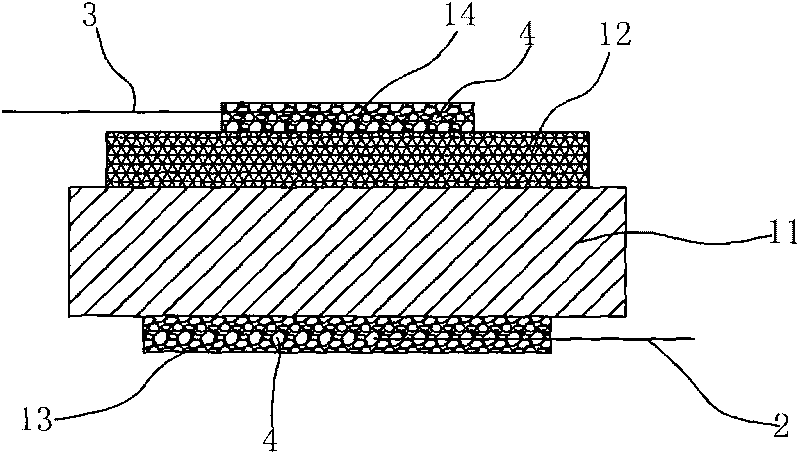

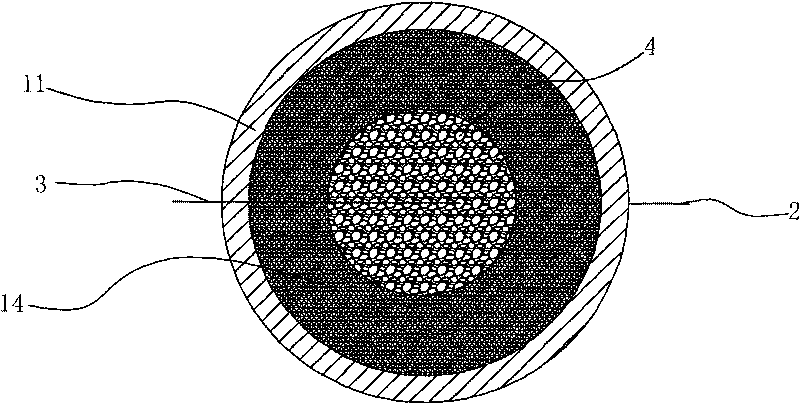

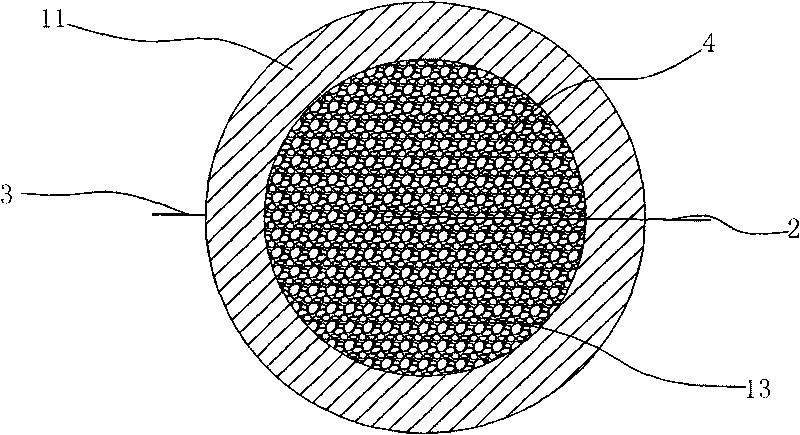

Heat radiation structure of circuit module and outdoor unit of variable-frequency air conditioner

ActiveCN104697077AImprove surface heat dissipationNot easy to gatherLighting and heating apparatusAir conditioning systemsComputer moduleElectric control

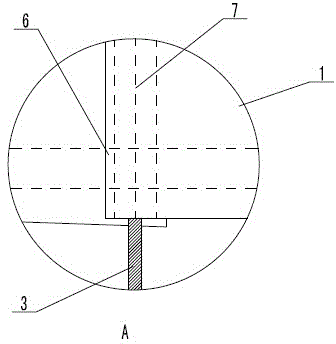

The invention discloses a heat radiation structure of a circuit module and an outdoor unit of a variable-frequency air conditioner. The heat radiation structure comprises a circuit board (1), a mounting support (2), electronic devices (3) and a heat radiator (4), wherein the electronic devices penetrate one side of the mounting support to be connected with a circuit board on the other side, and the heat radiator is abutted against the surfaces of the electronic devices; a zigzag structure (21) used for reducing mutual contact area is formed on the contact surface between the circuit board and the mounting support. Furthermore, the heat radiation structure comprises an electric control box (5), various parts are sequentially stacked in the electric control box, the heat radiator extends out of the electric control box, and an air inlet passage (7) facing the heat radiator is formed on the electric control box. The heat radiation structure is mounted in a case (9) via the electric control box and close to an air wheel (12) of the outdoor unit. With the zigzag structure, water accumulation is well prevented; with the mounting structure and the air passage, heat radiation effect of the heat radiator is well improved so as to radiate heat on the surface of the circuit board.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

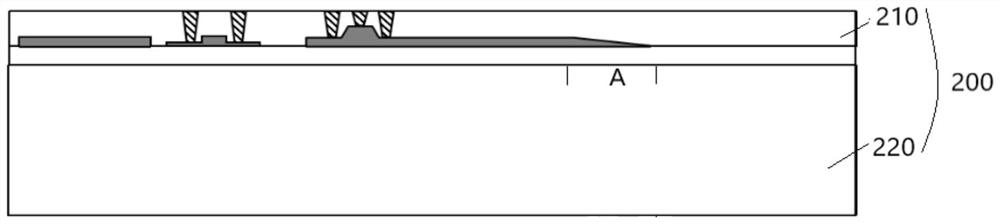

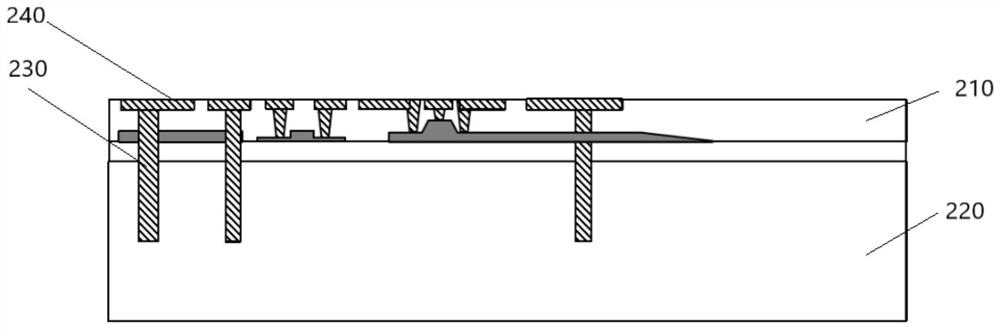

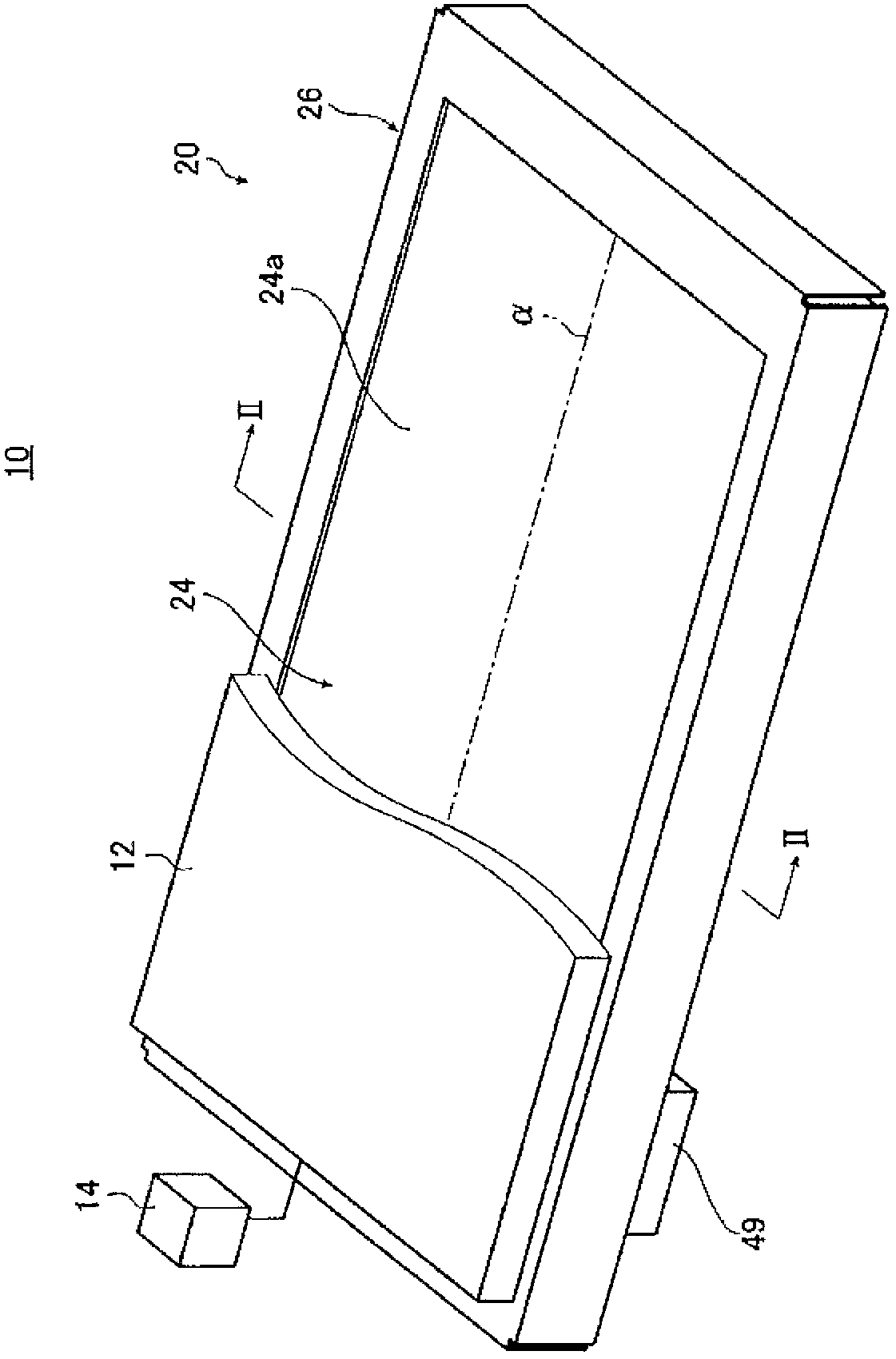

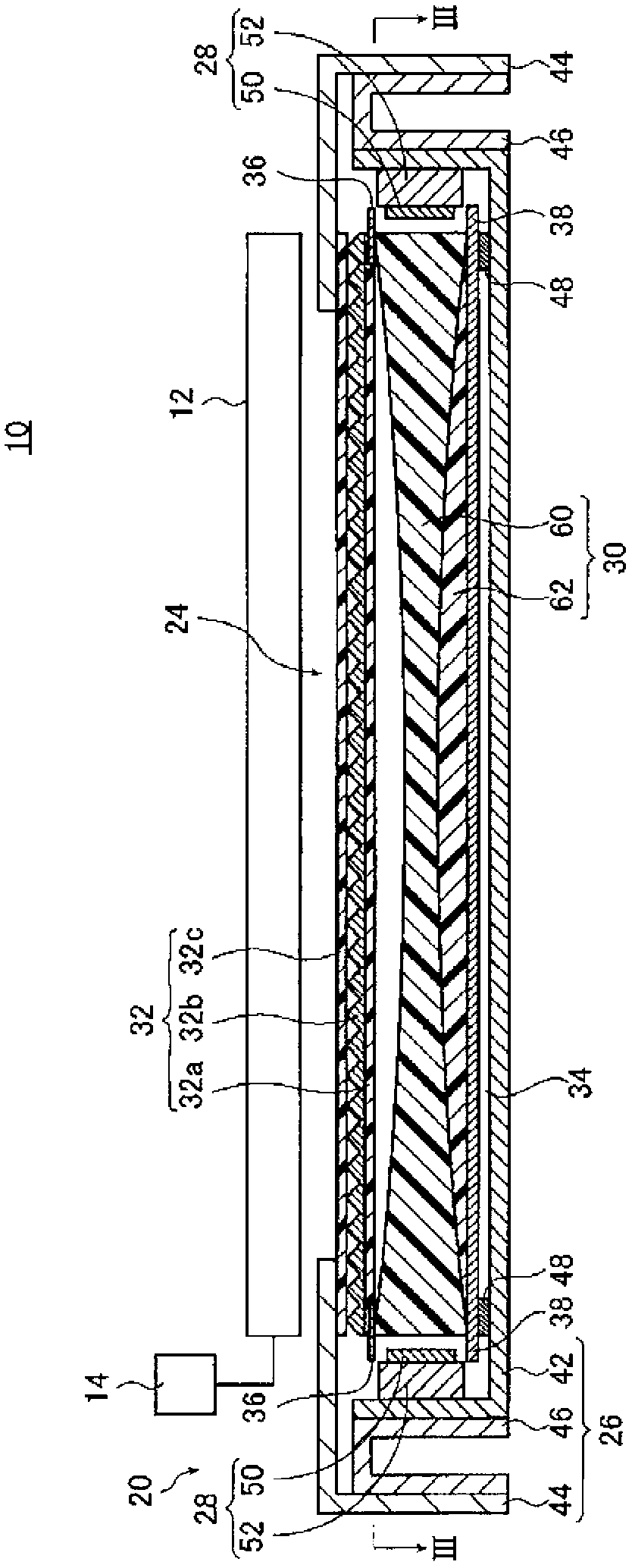

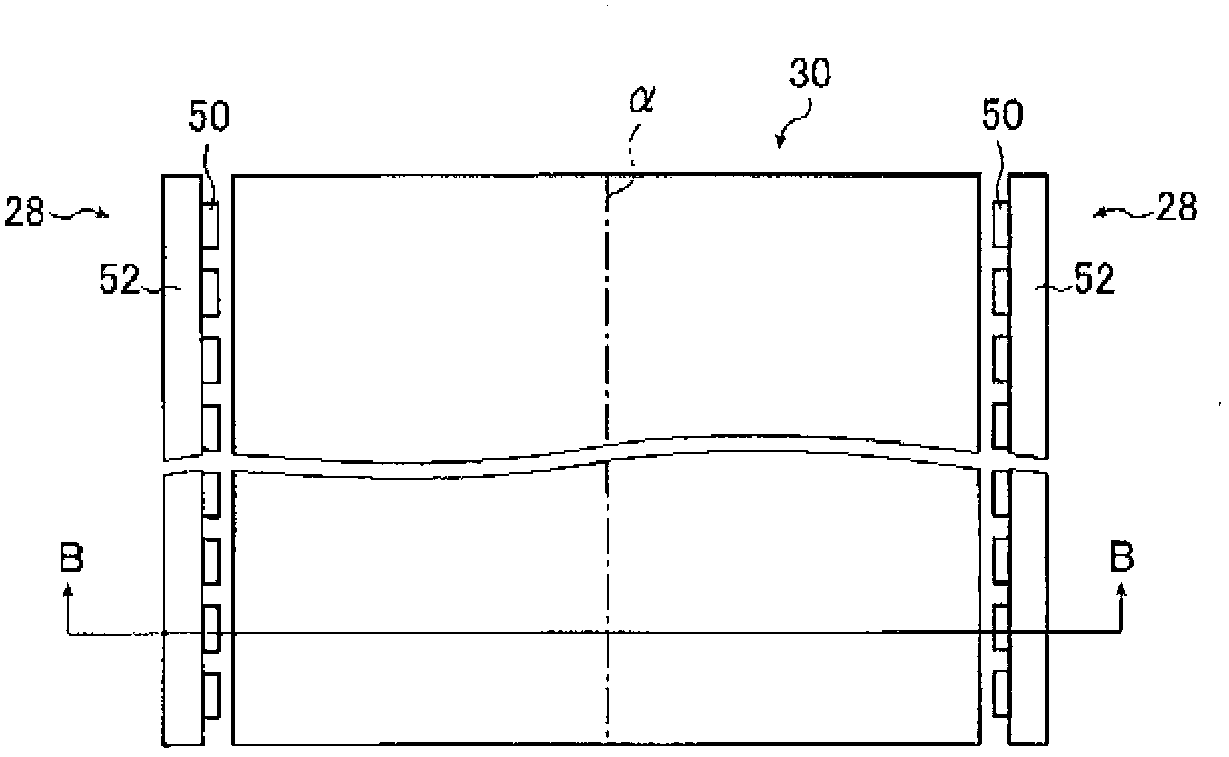

Backlight and manufacturing method thereof, and display device

ActiveCN109116626AImprove yieldReduce the chance of poor contactStatic indicating devicesCasings with display/control unitsElectricityDisplay device

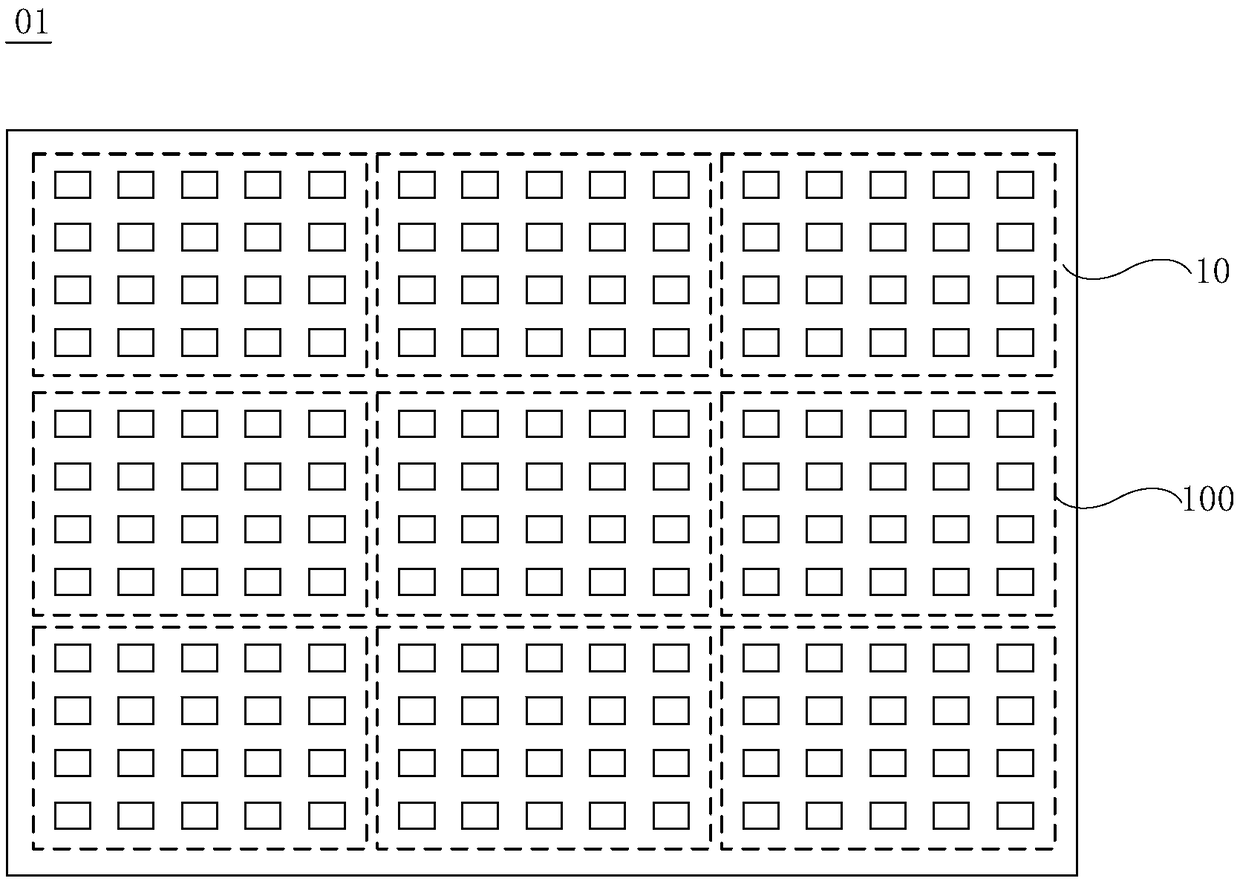

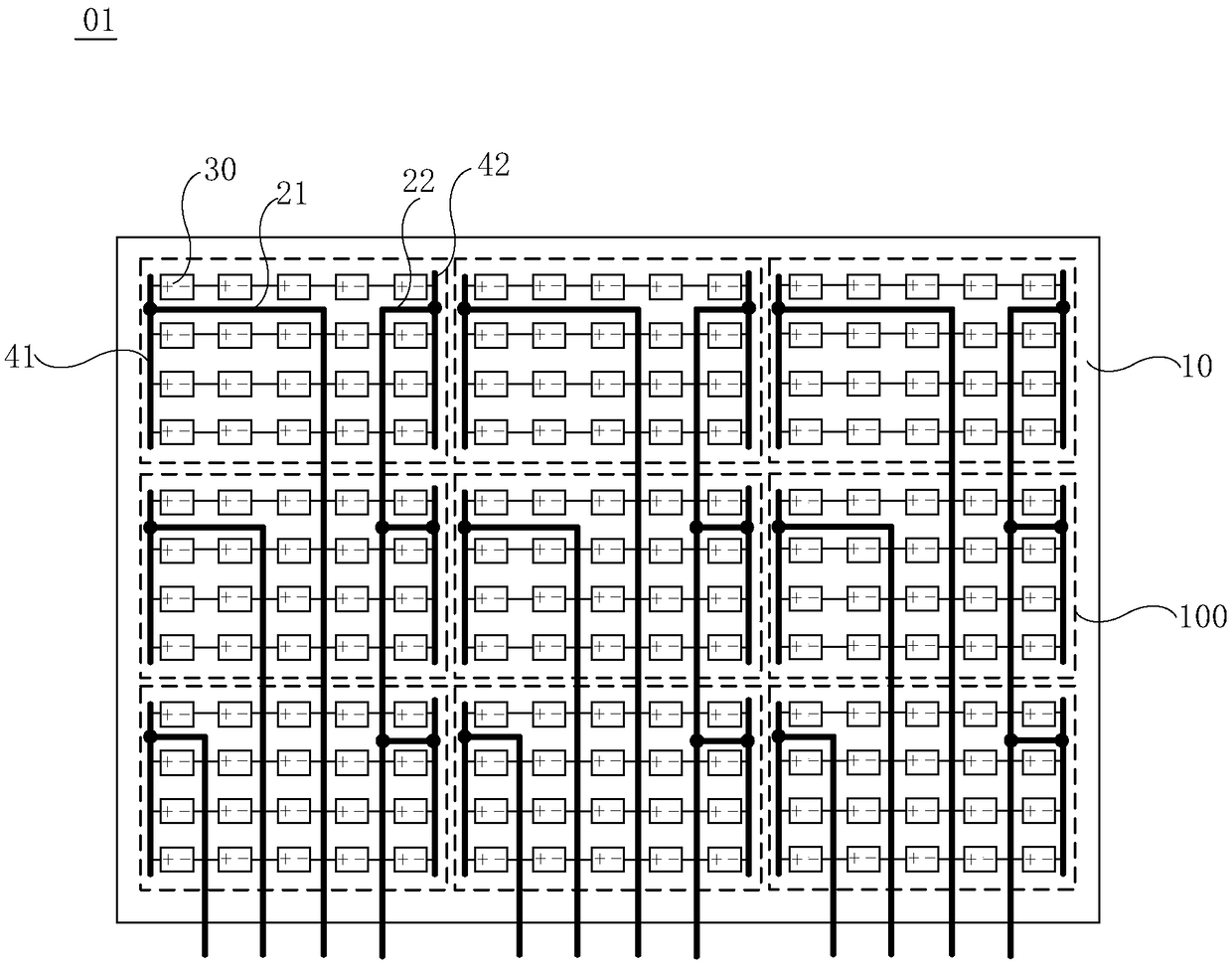

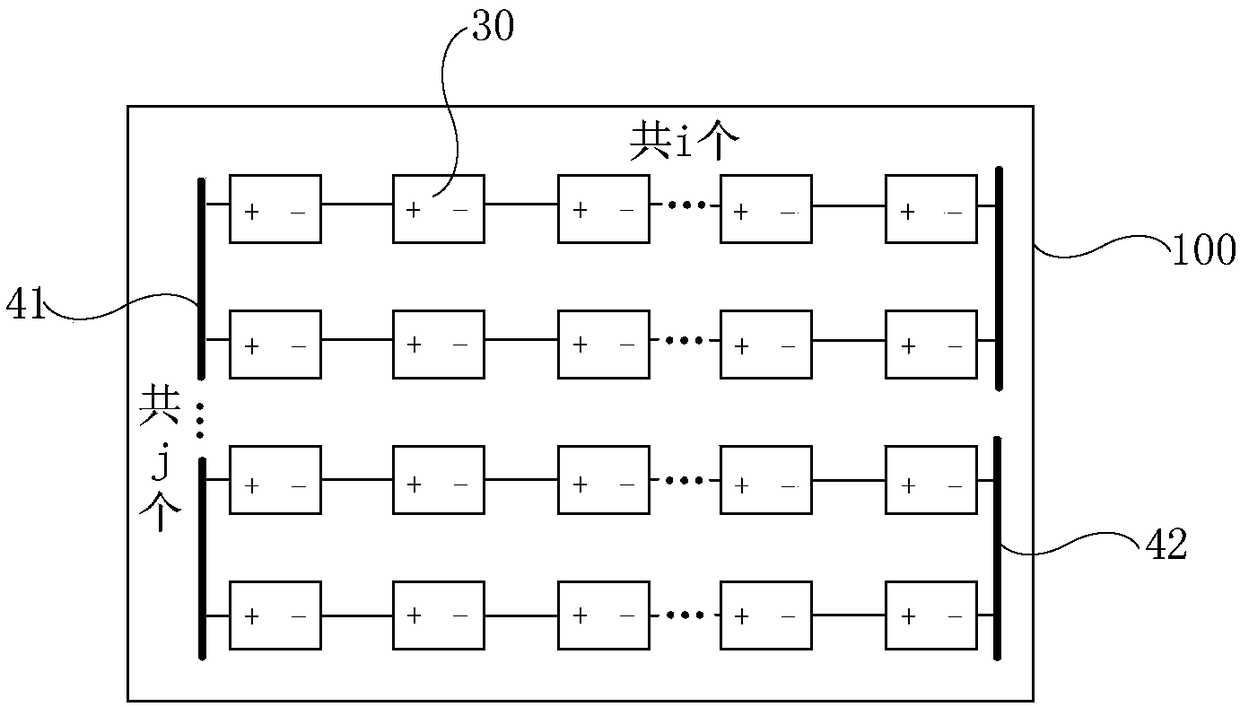

The embodiment of the invention provides a backlight and a manufacturing method thereof, and a display device, and relates to the technical field of display. The problem that an FPC or a PCB in a direct type backlight module is warped, such that some light emitting devices cannot emit light is solved. The backlight comprises a substrate, and a plurality of dimming areas are divided on the substrate. The backlight further comprises a plurality of first routes, a plurality of second routes, a plurality of miniature light emitting devices located in the dimming areas, first common polar lines andsecond common polar lines, which are arranged on the substrate. The first electrodes of the plurality of miniature light emitting devices located in the same dimming areas are electrically connectedwith the first common polar lines, and the second electrodes are electrically connected with the second common polar lines. The first common polar lines of any two dimming areas are electrically connected with different first routes. The second common polar lines of the plurality of dimming areas are electrically connected with the same second route.

Owner:BOE TECH GRP CO LTD +1

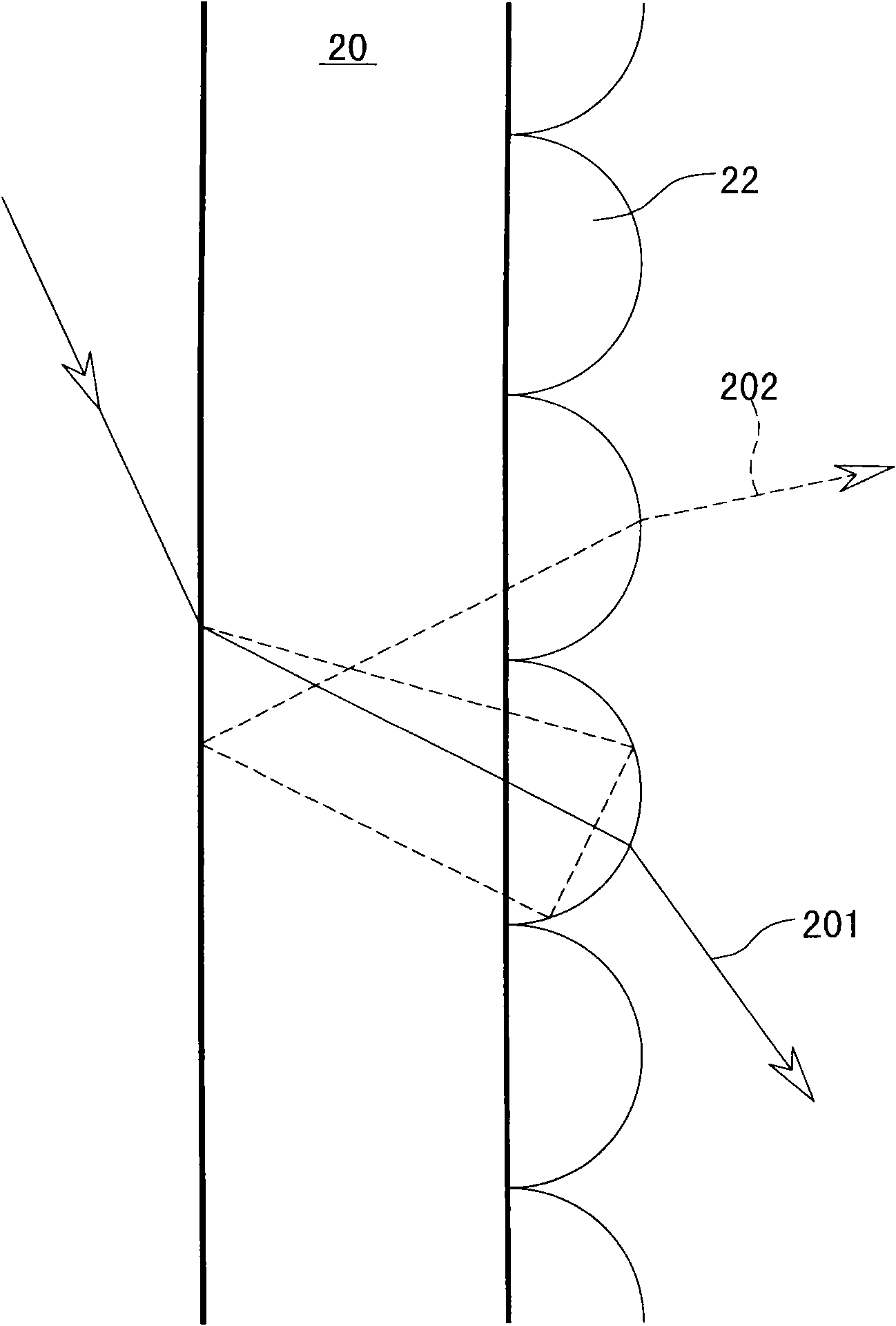

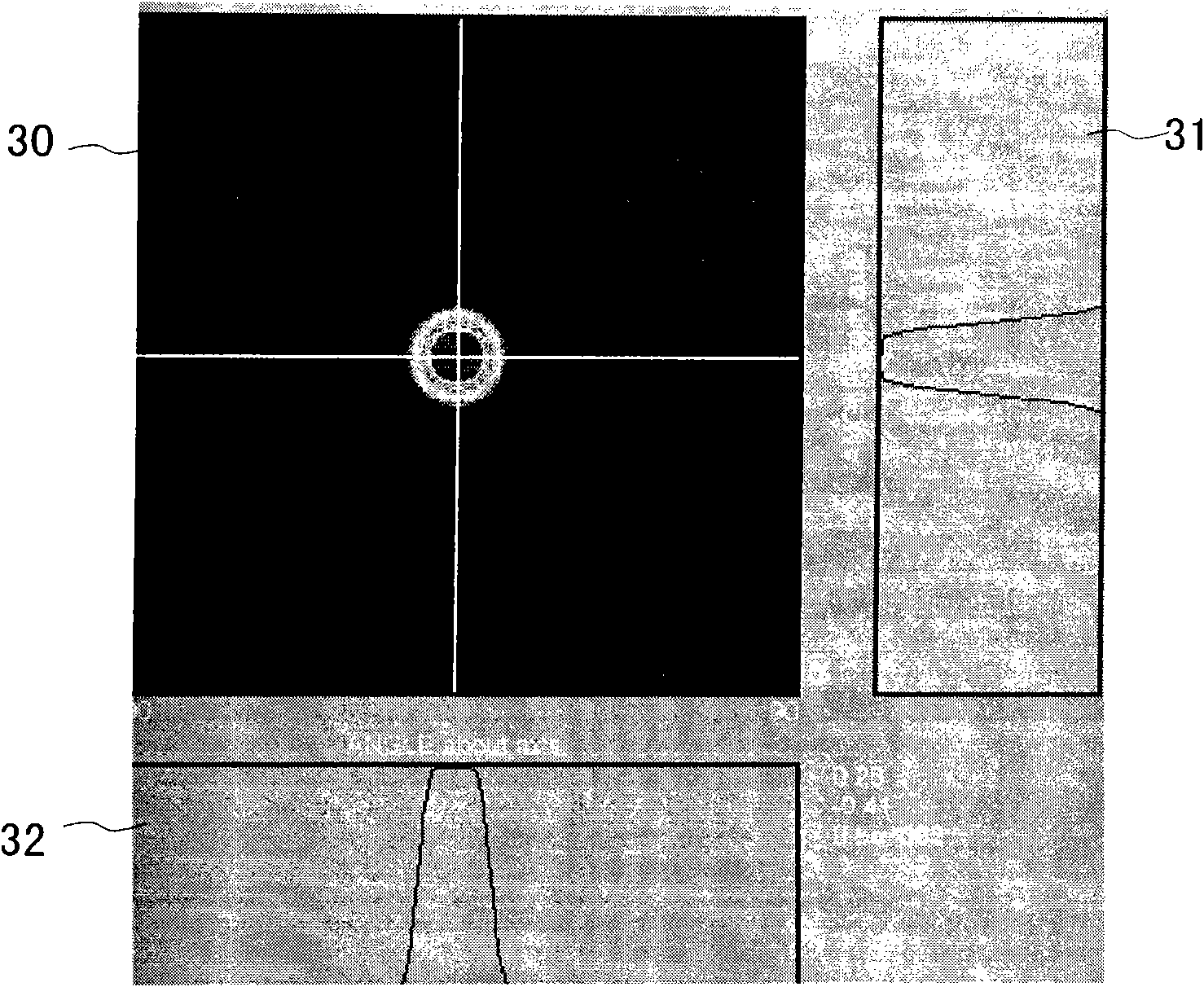

Asymmetrical light diffusion element and manufacturing method thereof

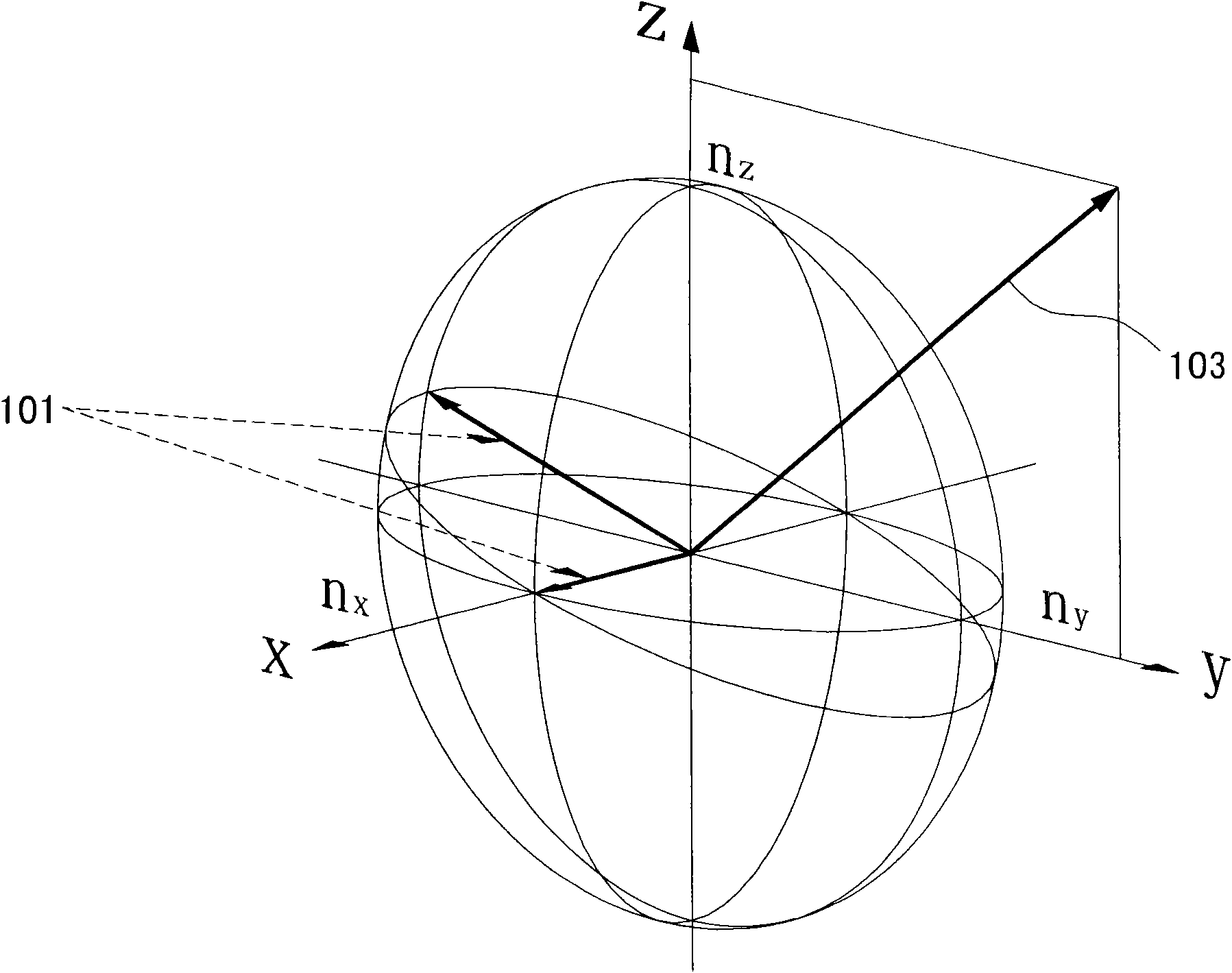

InactiveCN101602254ALarge difference in refractive indexHighly asymmetric diffusion propertiesDiffusing elementsOptical articlesMicro structureNon symmetric

The invention discloses an asymmetrical light diffusion element and a manufacturing method thereof, wherein the diffusion element is a light transmission film subject to stress extension, and the material of a substrate is mixed with diffusion grains made of different materials; an anisotropic film layer is formed by means of the process of stress extension and has the property of birefractive diffusion; an asymmetrical up-and-down structure is formed on the surface structure of the film layer by means of extrusion or multi-layer co-extrusion and extension, therefore, light passing through the diffusion element is diffused and then forms uniform light, has an anisotropic refractive index difference and can generate the effect of partial polarized scattering; wherein a better embodiment of the diffusion element comprises: a mould is prepared to be used for manufacturing the basic surface structure needed by the asymmetrical diffusion element, the body of the substrate with a surface micro-structure is manufactured by means of a roller wheel transfer printing process, and the body of the substrate undergoes the change of refractive index and the deformation of the basic structure by means of the stress extension process.

Owner:ENTIRE TECH CO LTD

Light wall plate

InactiveCN1803697AHigh strengthAvoid deformationSolid waste managementCeramic shaping apparatusGlass fiberPolyvinyl acetate

The manufacture method for a light wallboard comprises: selecting the material by weight ratio as 30~40 coal ash, 15~25MgO, 10~20 MgCl2, 3~10 lime or cement, 5~15 gypsum / plant powder, and 1~5 glass fiber, as well as the additive contained 0.5~1.5 FeSO4 / oxalic acid, 0.1~1 Na3PO4, 0.1~1 sodium hexametaphosphate, and 1~2 polyvinyl acetate; stirring the MgCl2 in water evenly to prepare the solution with Baume degree as 18~25; adding former additive to stir evenly, putting the material into the solution to prepare the slurry; pouring the slurry into a mould to the half height, then annular spreading the glass fiber and pouring slurry; finally, tamping to form, demolding, and drying. This product has high strength with hard deformation and other merits.

Owner:范景红

Method of manufacturing semiconductor device

InactiveCN101752273ANot easy to warpSemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

First, a trench formed in parts of a semiconductor wafer, a sealing film and others corresponding to a dicing street and both sides thereof. In this state, the semiconductor wafer is separated into silicon substrates by the formation of the trench. Then, a resin protective film is formed on the bottom surface of each silicon substrate including the inner part of the trench. In this case, the semiconductor wafer is separated into the silicon substrates. However, a support plate is affixed to the upper surfaces of the columnar electrode and the sealing film via an adhesive layer. Therefore, when the resin protective film is formed, it is possible to prevent the entirety including the separated silicon substrates from being easily warped.

Owner:TERAMIKROS INC

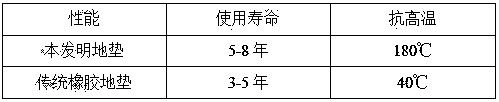

Colorful rubber floor mat and manufacturing method of colorful rubber floor mat

ActiveCN104000463AAvoid deformationExtended service lifeSynthetic resin layered productsLaminationPolymer scienceAdhesive

The invention discloses a colorful rubber floor mat and a manufacturing method of the colorful rubber floor mat. The manufacturing method of the colorful rubber floor mat includes the steps that waste rubber is smashed to serve as bottom-layer particles, then the smashed waste rubber and adhesives are evenly mixed, and a molded bottom layer is formed in a heated and pressurized mode; raw materials including ethylene-propylene-diene monomer, rubber oil, toner, white carbon black, ultraviolet-resistant agents, accelerants, zinc oxide, antioxidants, calcium carbonate and the like are evenly mixed, banburying and open milling are sequentially carried out, rubber is cut into pieces, the rubber pieces are cooled and smashed to serve as face-layer particles, then the smashed rubber pieces and adhesives are evenly mixed, and a molded face layer is formed in a heated and pressurized mode; finally the bottom layer and the face layer are bonded with the hot mold technology. The service life of the colorful rubber floor mat manufactured with the manufacturing method is as long as 5 years-8 years; the colorful rubber floor mat can be resistant to the 180-DEG C high temperature; the buffering performance is good; a slightly-protruding particle feeling is achieved on the surface, a special soft feeling is achieved during treading, and the colorful rubber floor mat has the elasticity and is resistant to sliding; no harmful matter is contained; the colorful rubber floor mat is basically free of influences of expansion caused by heat and contraction caused by cold, and is safe, comfortable, durable and attractive in appearance.

Owner:QINGYUAN CHUANAO HI TECH MATERIAL CO LTD

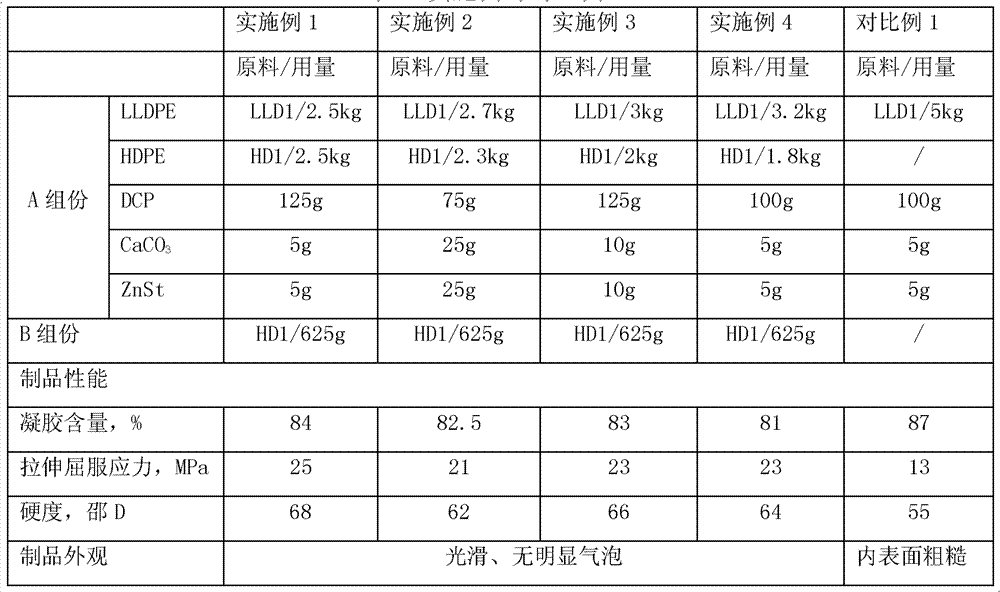

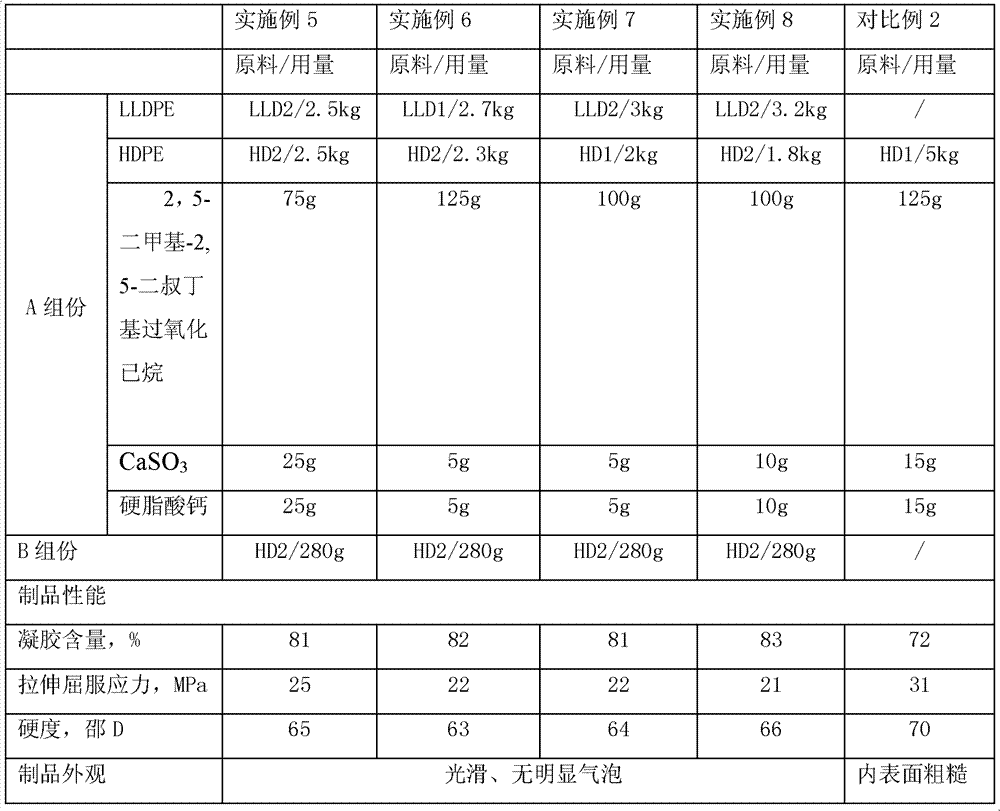

Cross-linked polyolefin composition for rotational molding and preparation method thereof

The invention relates to a cross-linked polyolefin composition for rotational molding and a preparation method thereof, belonging to the field of cross-linked polyolefin composition for rotational molding. The cross-linked polyolefin composition comprises a component A and a component B, wherein the component A comprises 100 weight parts of linear low density polyethylene (LLDPE), 50-100 weight parts of high density polyethylene (HDPE), 2-5 weight parts of cross-linking agent, 0.2-1.0 weight parts of nucleating agent, and 0.2-1.0 weight parts of lubricant; and the component B is high density polyethylene, and the ratio of the component A to the component B is 90:10-95:5. According to the invention, optimum crosslinking degree is achieved and high hardness and difficulty in warpage are guaranteed by selecting the basic resin, and the addition of the nucleating agent is beneficial for reducing product bubbles; products produced by using the composition of the invention has smooth internal and external surface, easiness in mold stripping, high crosslinking degree, and good comprehensive properties.

Owner:CHINA PETROLEUM & CHEM CORP

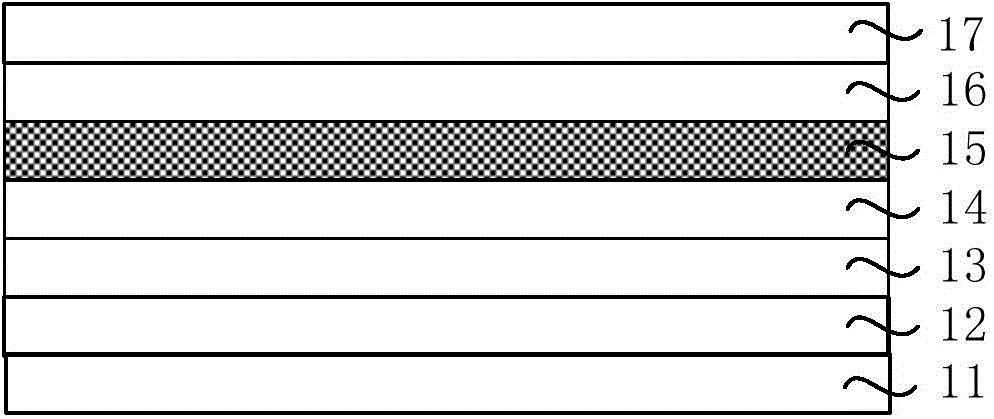

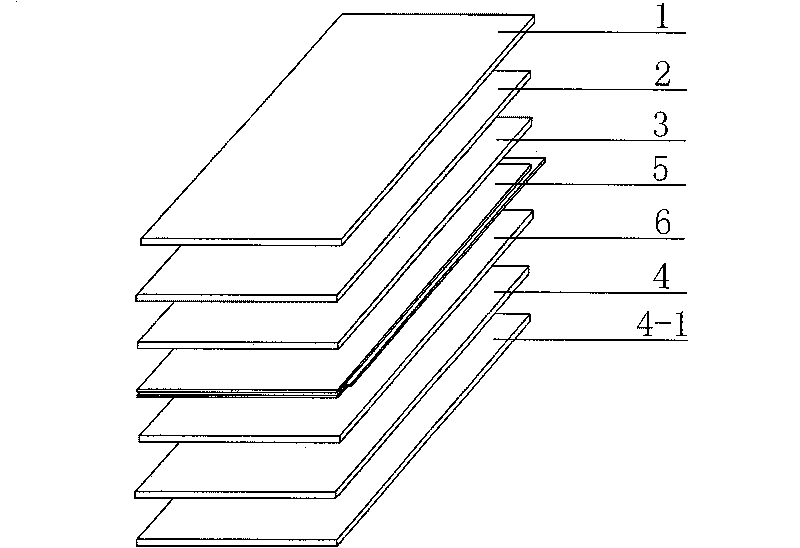

Polarizer and manufacturing method thereof, display panel and display device

ActiveCN104570186ADoes not affect the optical effectNot easy to warpPolarising elementsNon-linear opticsOrganic layerDisplay device

The invention describes a polarizer and a manufacturing method thereof, a display panel comprising the polarizer and a display device. According to the embodiment of the invention, the polarizer provided by the invention comprises a first transparent layer, a second transparent layer arranged opposite to the first transparent layer, a polarizing layer arranged between the first transparent layer and the second transparent layer, and a first organic layer arranged between the first transparent layer and the polarizing layer, or a second organic layer arranged between the second transparent layer and the polarizing layer, wherein the shrinkage stress direction of the first organic layer or the second organic layer is vertical to that of the polarizing layer. The polarizer provided by the embodiment of the invention comprises the polarizing layer and the organic layer, wherein the shrinkage stress direction of the organic layer is vertical to that of the polarizing layer; when the outer surface of the display panel is attached with two polarizers, the shrinkage stresses of the upper polarizer and the lower polarizer are balanced, so that the display panel is less likely to warp.

Owner:XIAMEN TIANMA MICRO ELECTRONICS +1

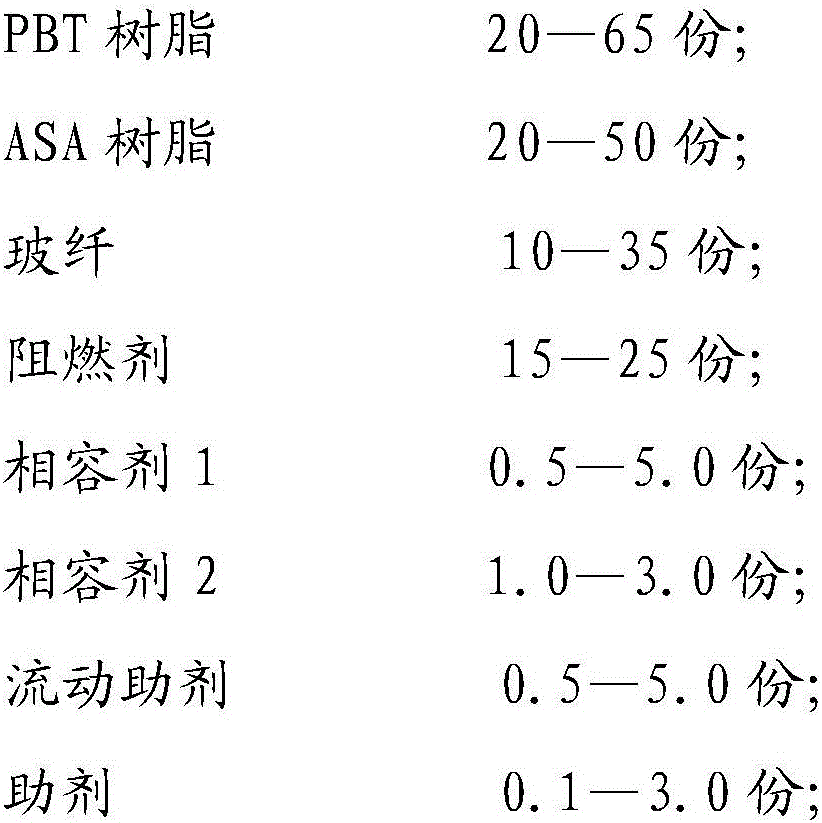

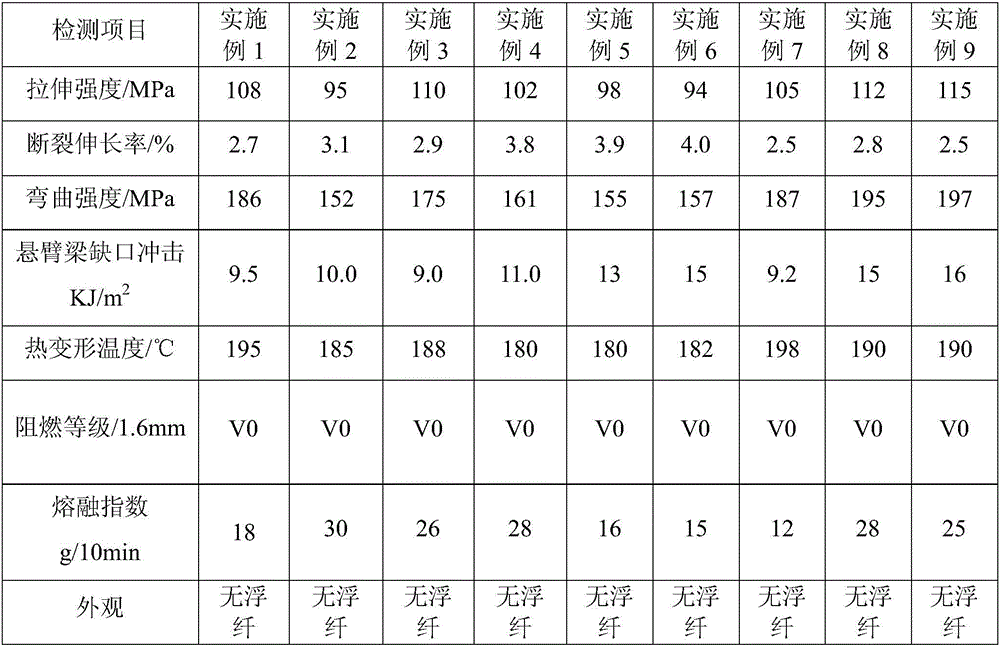

PBT/ASA alloy material and preparing method thereof

ActiveCN106589844AImprove flame retardant performanceImprove impact resistanceGlass fiberPolystyrene

The invention discloses a PBT / ASA alloy material and a preparing method thereof. The alloy material is prepared from, by weight, 20-65 parts of PBT resin, 20-50 parts of ASA resin, 10-35 parts of glass fiber, 15-25 parts of fire retardant, 0.5-5.0 parts of first compatilizer, 1.0-3.0 parts of second compatilizer, 0.5-5.0 parts of a flow promoting agent and 0.1-3.0 parts of auxiliary, wherein the fire retardant is compounded by main fire retardant brominated polystyrene and fire retardant synergist sodium antimonite according to a mass ratio of (10-20):(4-5), the first compatilizer is a styrene copolymer, and the second compatilizer is bisphenol A type epoxy resin with an epoxy value of 0.5-1.5. The prepared PBT / ASA alloy material has the functions of both flame retardancy and resistance to shocks at the same time, and the material is not prone to warpage and good in comprehensive mechanical performance.

Owner:GUANGZHOU KEYUAN INNOVATIVE MATERIALS

All-solid mixed-potential NOx sensor and preparation method thereof

InactiveCN101706470ASolve the peeling problemStable working signalMaterial analysis by electric/magnetic meansScreen printingRepeatability

The invention discloses an all-solid mixed-potential NOx sensor prepared on the basis of spark plasma sintering technology. The NOx sensor consists of an electrolyte layer, a sensing electrode layer, a reference electrode and a working electrode, wherein the multilayer composite consisting of the electrolyte layer and the sensing electrode layer is directly sintered by the spark plasma sintering technology; and the reference electrode layer and the working electrode layer, which have screen pores, are directly printed in the centers of the upper and lower surfaces of the composite by screen printing. As the NOx sensor is manufactured by the spark plasma sintering technology, the sensing electrode layer and the electrolyte layer of the sensor are well combined without problems of flying up, cracking and the like and have the characteristics of good repeatability, stable performance, simple manufacturing process, short manufacturing period, small volume, quick response and the like. The NOx sensor of the invention can detect NOx concentration ranging from 1 to 75 percent and give a response within 2 minutes and is suitable for the detection of the NOx concentration in a wide range.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Self-adhesion cork floor board

The invention relates to the field of architectural decoration materials, in particular to a self-adhesion cork floor board which comprises a wear-resistant layer, a decorative cork layer and a cork base layer, wherein the cork base layer is a mounting layer; and a pressure-sensitive adhesive layer with transfer protective paper is adhered to the mounting surface of the cork base layer. The invention also relates to a suspension type self-adhesion cork floor board based on the same concept, which comprises a wear-resistant layer, a decorative cork layer, a cork base layer, a fiber board tongue-and-groove layer and a cork balancing layer, wherein the cork balancing layer is a mounting layer, and a pressure-sensitive adhesive layer with transfer protective paper is adhered to the mounting surface of the cork balancing layer. The floor board or wallboard in the invention has the advantages of accurate positioning during installation, high convenience and speed, labor saving, time saving and high efficiency; the invention does not need to coat adhesive on site, thereby having the advantages of environmental protection and sanitation and having little effect on construction sites and household environment; the invention can not easily contaminate the board surface in the mounting process, and the board surface can be easily cleaned and maintained; and the invention can not easily deform, tilt or crack in the use process, thereby having the advantage of long service life.

Owner:羌炳顺

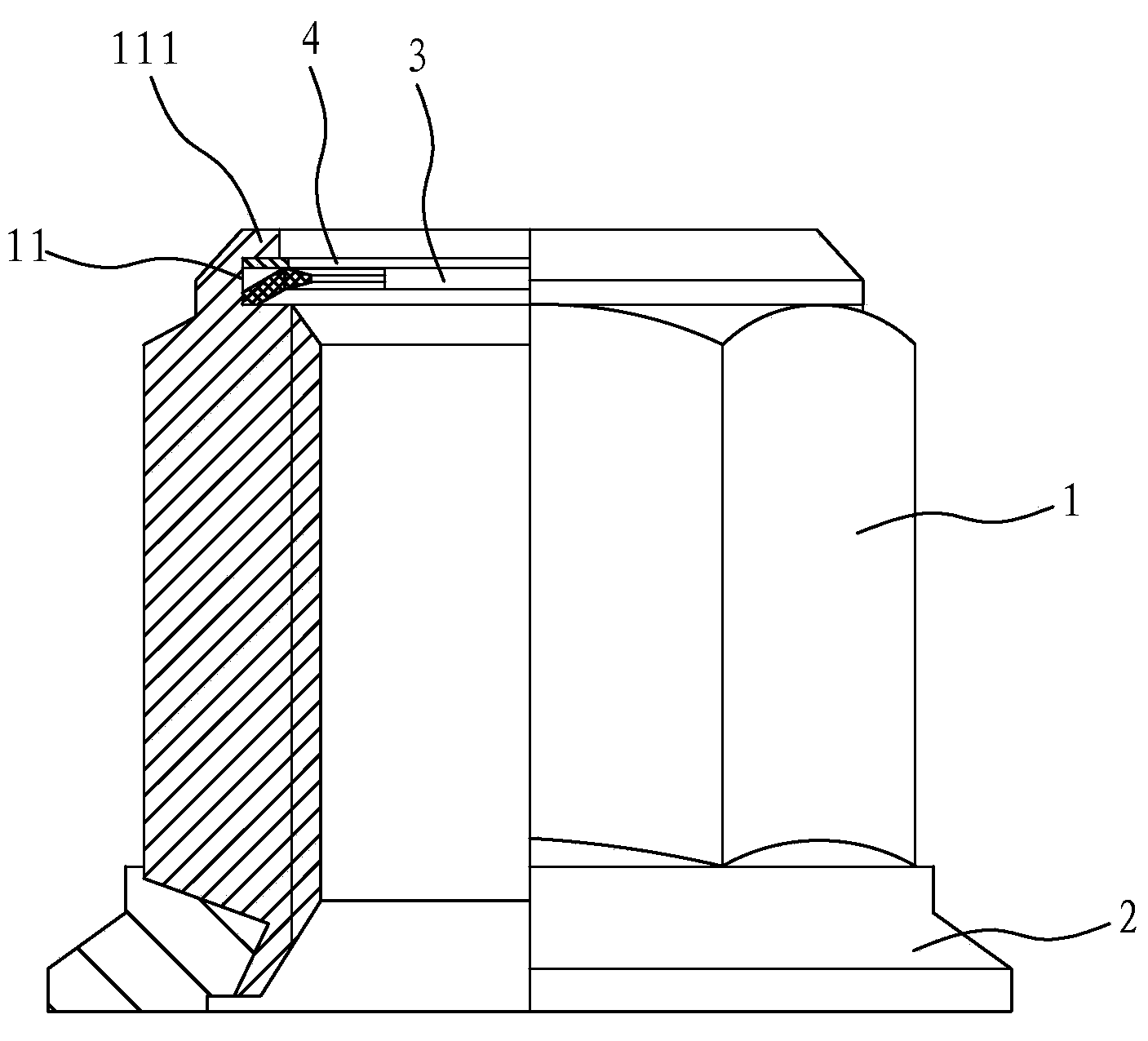

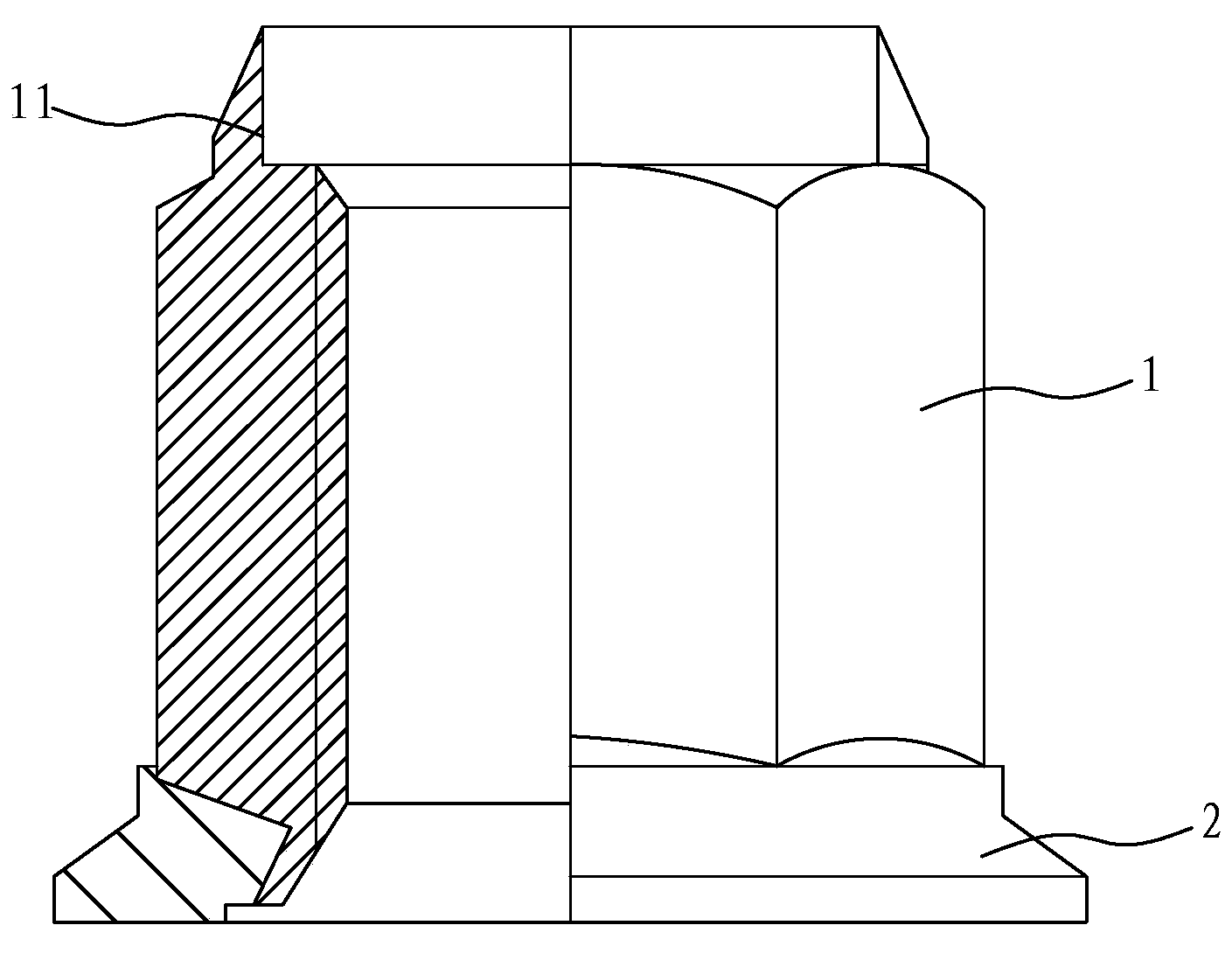

Anti-loose self-locking nut and production method thereof

The invention relates to the field of manufacturing of automobile parts, in particular to an anti-loose self-locking nut simple in structure, capable of effectively preventing the nut from falling off, convenient to mount and dismount and capable of being reused. The anti-loose self-locking nut comprises a nut body and a nut collar rotatably arranged at the lower end of the nut body, a threaded hole is penetratingly arranged in the middle of the nut body, a stepped groove is formed in the upper end of the nut body, a spring steel piece is placed in the stepped groove, a bending portion used for clamping the spring steel piece in the stepped groove is arranged on the upper portion of the stepped groove, the spring steel piece comprises an annular piece and more than two clamping pieces evenly arranged at the upper end of the annular piece and protruding along the radial direction, the annular piece is formed by a tilt surface rotating and scanning around the axis of the threaded hole, the clamping piece protrudes inwardly to extend into the threaded hole of the nut body, and the extending length of the clamping piece is located between the inner diameter and outer diameter of the threaded hole. The invention further comprises a production method of the anti-loose self-locking nut.

Owner:QUANZHOU JINQI MACHINERY PARTS

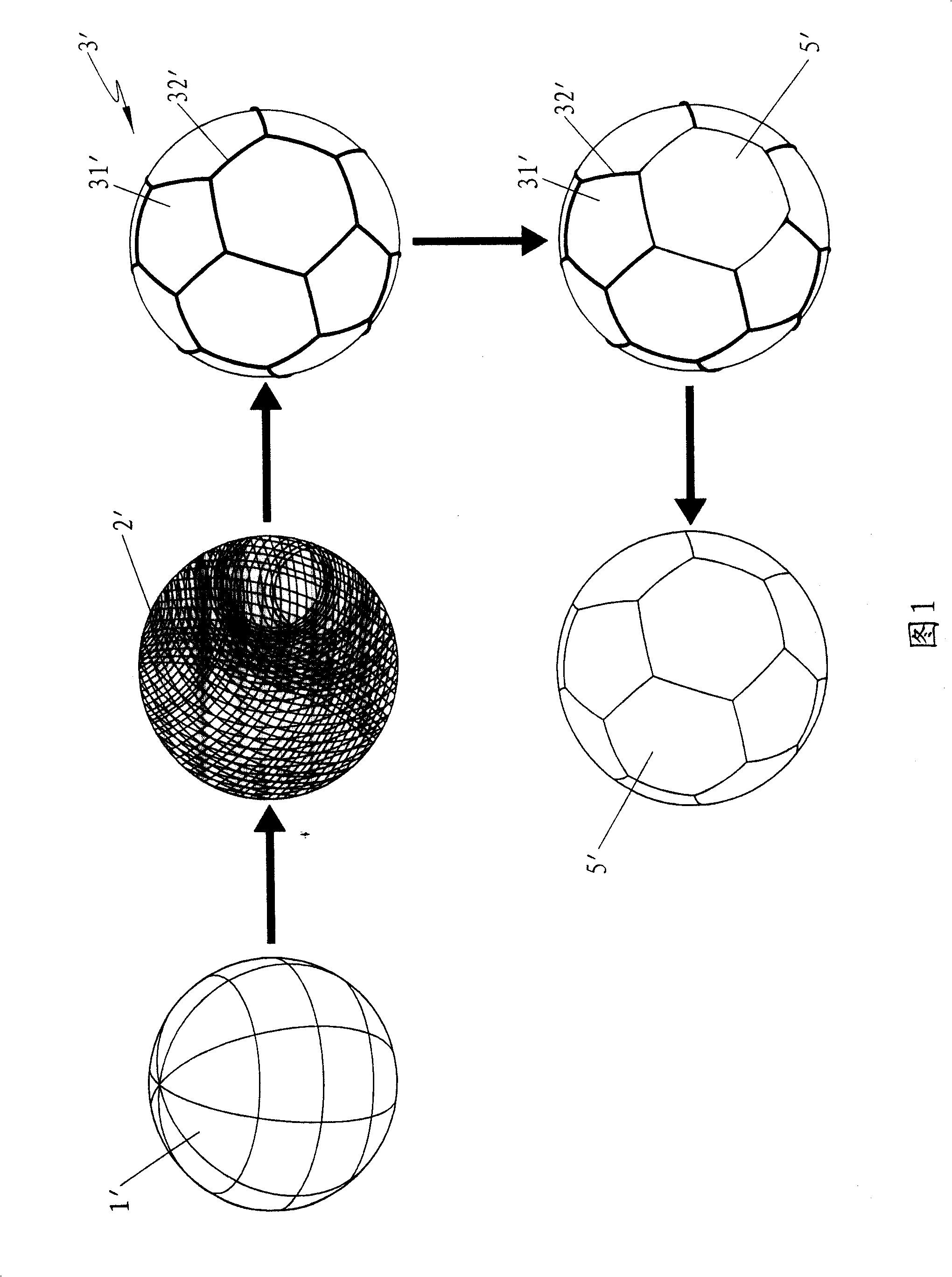

Leather ball producing technique

InactiveCN101244327AButt edge tidyBeautiful butt edgeHollow inflatable ballsSkin graftingInternal pressure

The invention discloses a manufacturing technique of leather ball, which comprises making inner tubes, wrapping filament, forming middle pneumatic, sizing, sticking skin, printing pattern and other steps; wherein, a protuberant boundary line is arranged on the position of the middle pneumatic adding sulfur die cavity which is matched with the middle pneumatic film edge in the process of forming middle pneumatic; a concave groove is formed on the vulcanized middle pneumatic; the skin graft edge is pressed into the groove in the process of sticking skin; a protuberant blank holder is arranged on the position of the printing pattern mold which is matched with the skin graft edge via printing pattern by printing pattern mold; the blank holder is extended into the joint and extruded in the action of finished ball internal pressure, which makes the joint tight; the skin graft edge is uneasy to tilt as the skin graft edge is extended into the groove formed on the middle pneumatic; the butt-mounted edges of each skin graft are more even and without gaps, which makes the connection of pattern printed on the skin graft smooth; the approximately vertical radian among the skin grafts makes the leather ball the same stereoperception as hand sewn leather ball.

Owner:XIAMEN PULSA SPORTING GOODS CO LTD

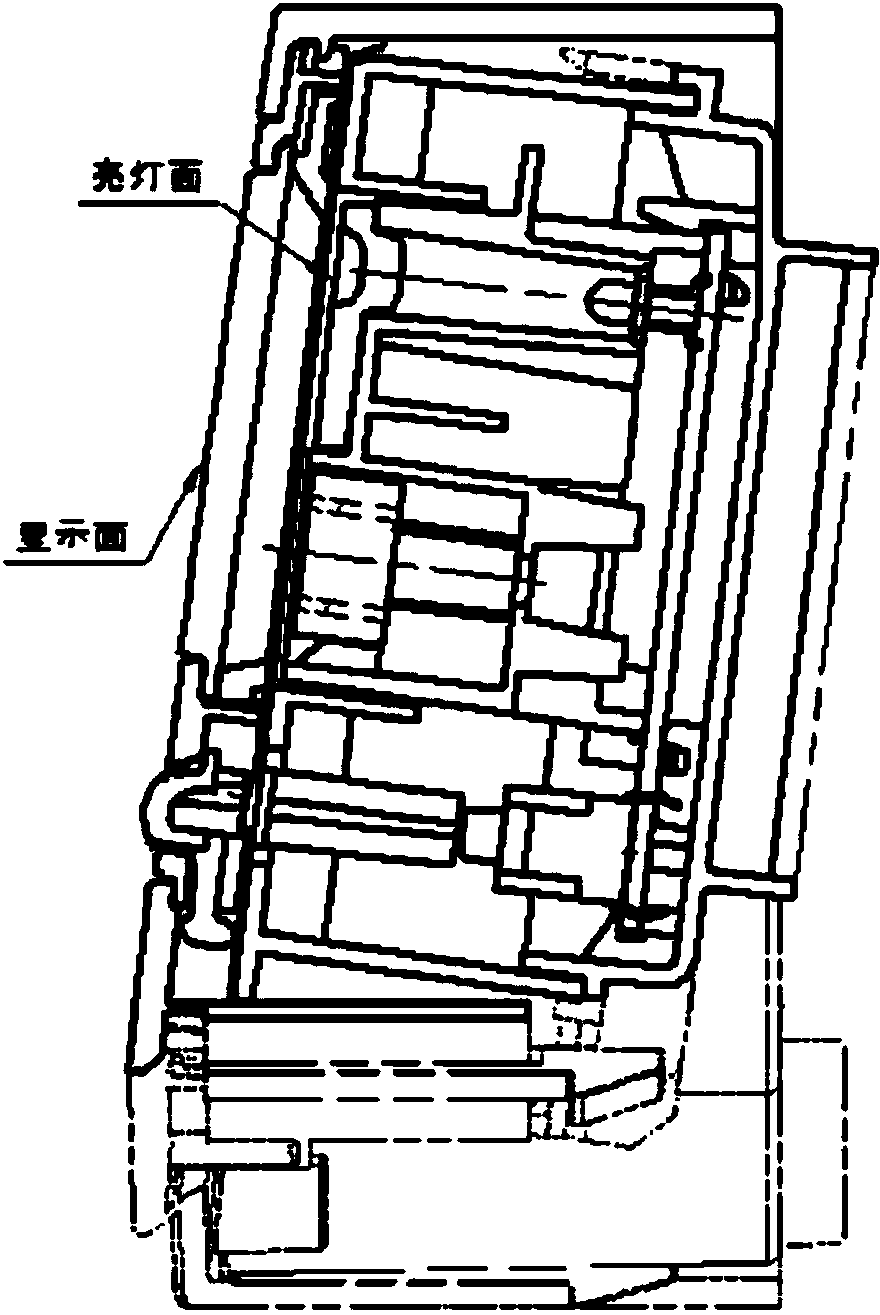

Washing machine operation panel and washing machine

InactiveCN103441011AReduce the sense of differenceImprove visual effectsOther washing machinesElectric switchesElectrical and Electronics engineeringSurface plate

The invention discloses a washing machine operation panel. The washing machine operation panel comprises a panel body, a display panel and buttons, the display panel comprises a main light-transmitting part and a plurality of button installation grooves formed in the edge of the main light-transmitting part, the outer side wall surface of the panel body is provided with a subsidence platform used for installing the display panel, the subsidence platform is provided with a plurality of light-transmitting holes and a linkage part used for controlling a corresponding switch on a PCB, the surface of one side of the subsidence platform is provided with thin transparent paster sealing the light-transmitting holes, a seal ring is further arranged between the display panel and the subsidence platform, and the seal ring surrounds the edge of the surface of the inner side of the main light-transmitting part. According to the scheme, the structure is more concise, the display effect is optimized, assembly is more convenient, and a water mist environment is prevented from being formed. The invention further discloses a washing machine utilizing the washing machine operation panel.

Owner:PANASONIC HOME APPLIANCES R&D CENT HANGZHOU +1

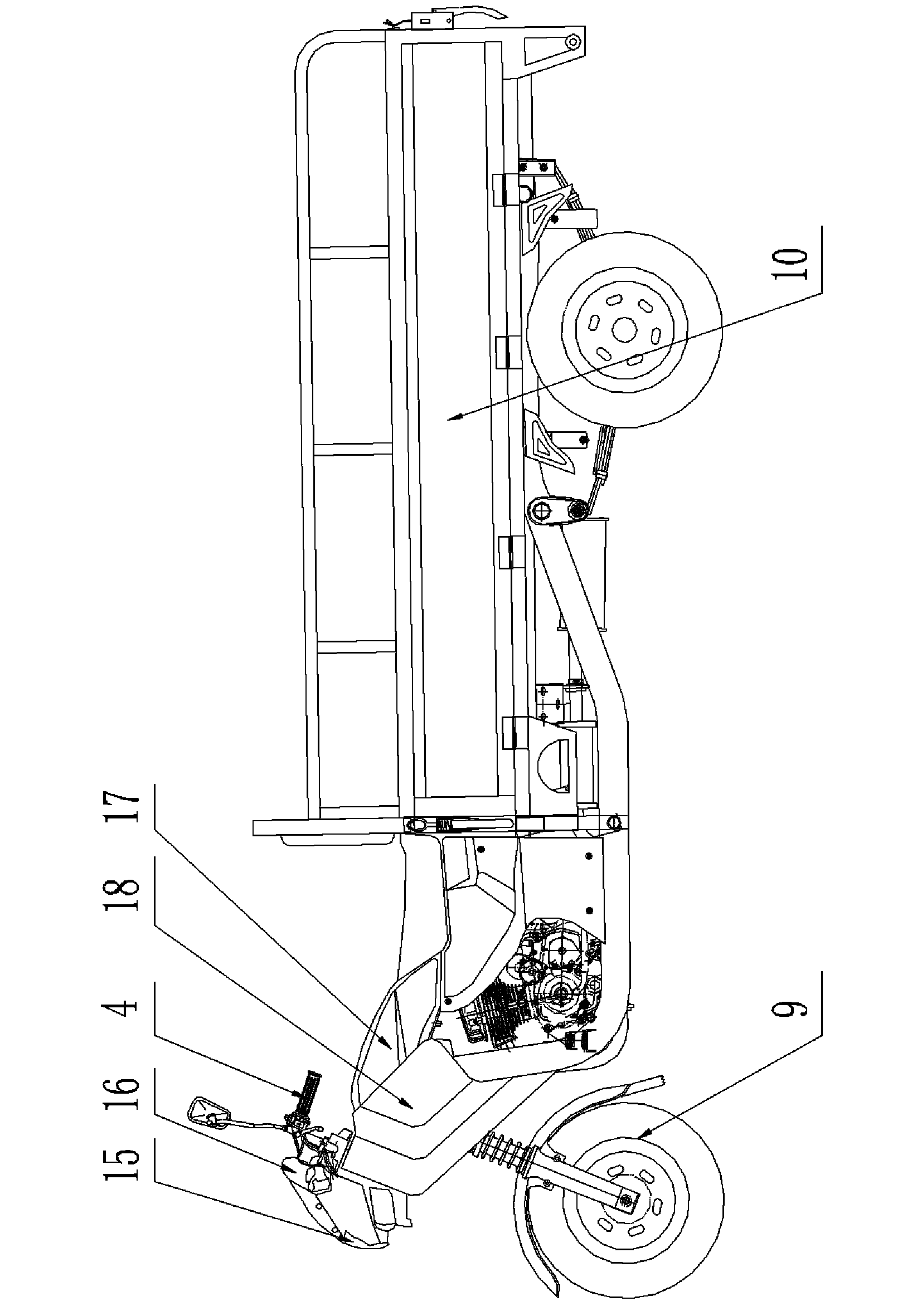

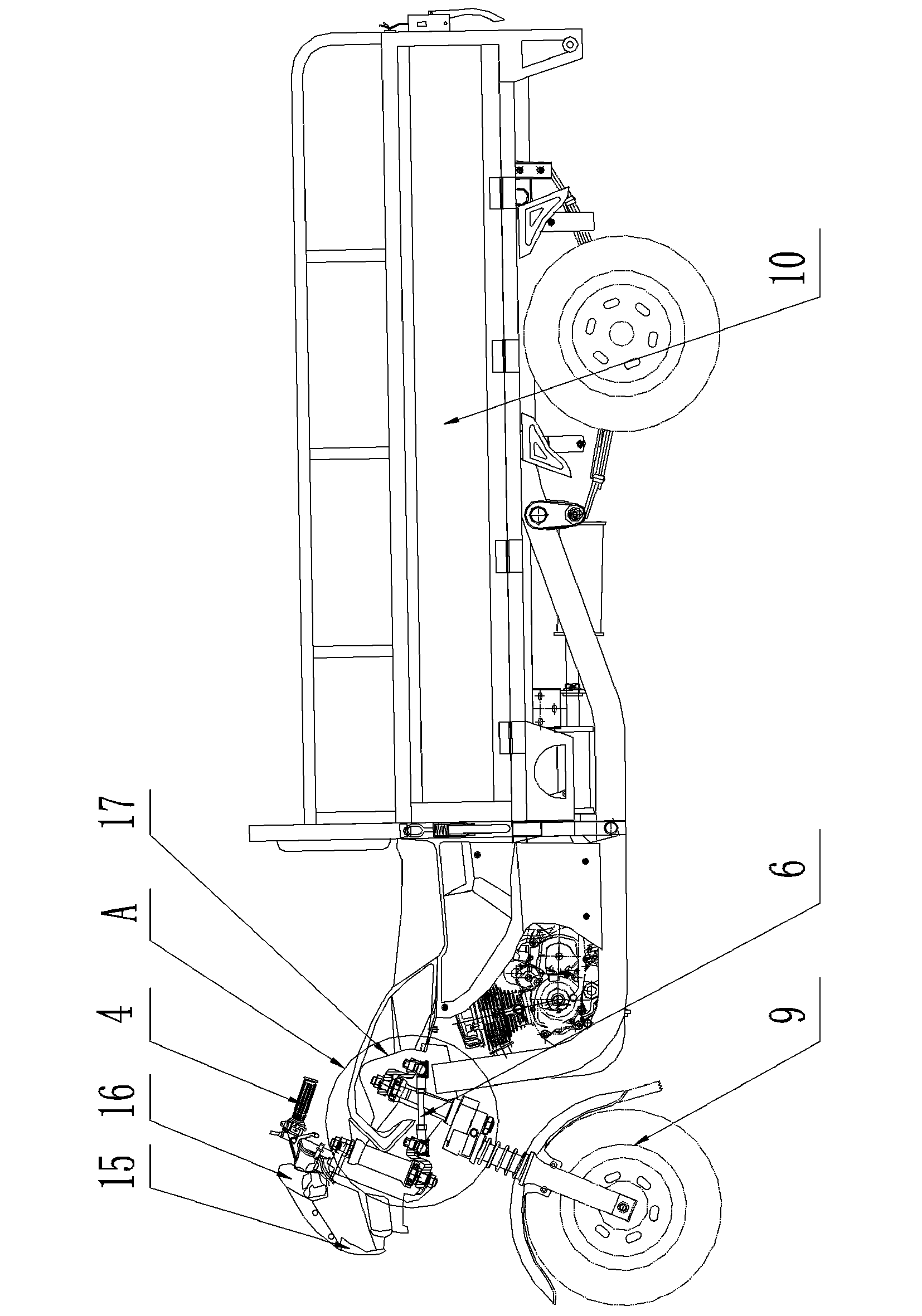

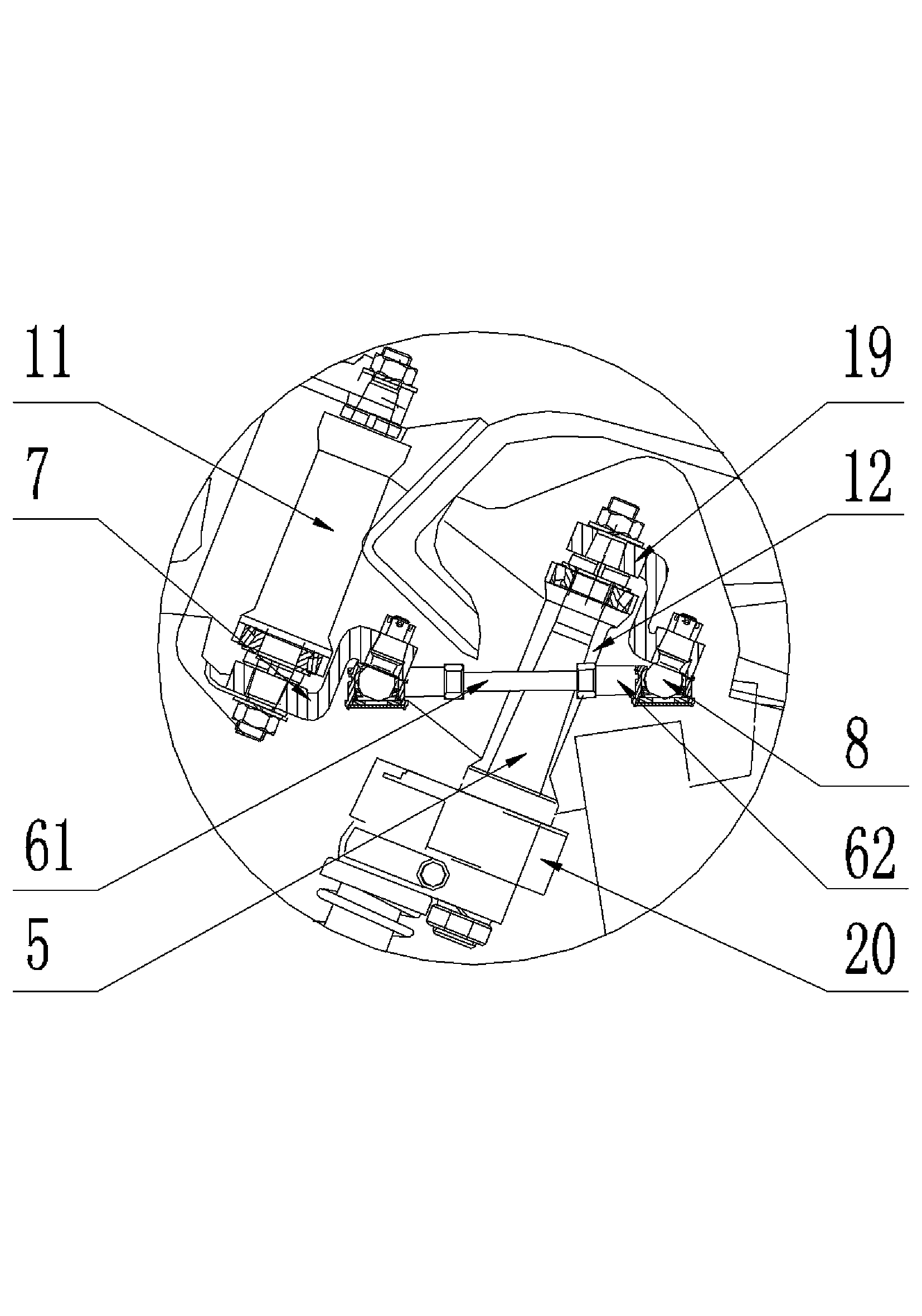

Right three-wheeled motorcycle

ActiveCN103192917AShorten invalid lengthConducive to driving safetyPassenger cyclesChain/belt transmissionVehicle frameControl engineering

The invention discloses a right three-wheeled motorcycle. The right three-wheeled motorcycle comprises a frame with a main beam and a container support beam, wherein a headstock stand pipe for installing a steering post is welded at the front end of the main beam; a handle pipe steering post for installing a handle pipe is rotatably matched in the headstock stand pipe; a handle pipe is arranged at the upper end of the handle pipe steering post; a front fork stand pipe for installing a front fork steering post is welded on the main beam at the back of the headstock stand pipe; a front fork steering post is rotatably matched in the front fork stand pipe; and the handle pipe steering post is connected with the front fork steering post through a linkage device. Compared with a conventional right three-wheeled motorcycle, the front fork steering post of the motorcycle moves backward, so that the invalid length between the front end of a front wheel and the front end of a head lamp of the right three-wheeled motorcycle is shortened; and therefore, a container of the right three-wheeled motorcycle can be lengthened within the specified overall length of the motorcycle, the transportation efficiency can be improved, and the requirements of customers can be met.

Owner:CHONGQING ASTRONAUTIC BASHAN MOTORCYCLE MFG

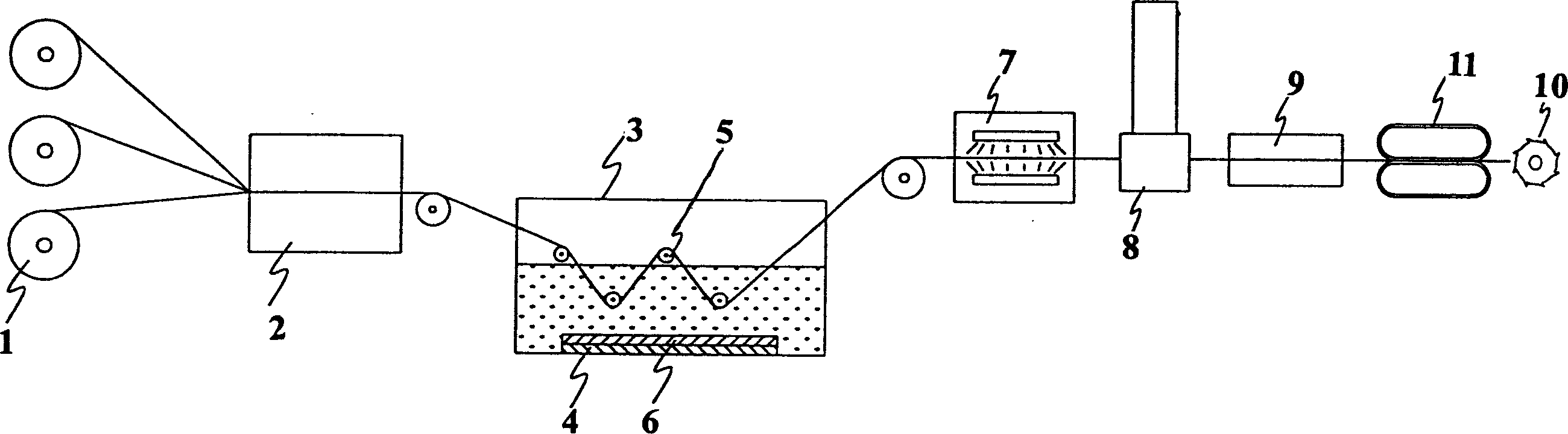

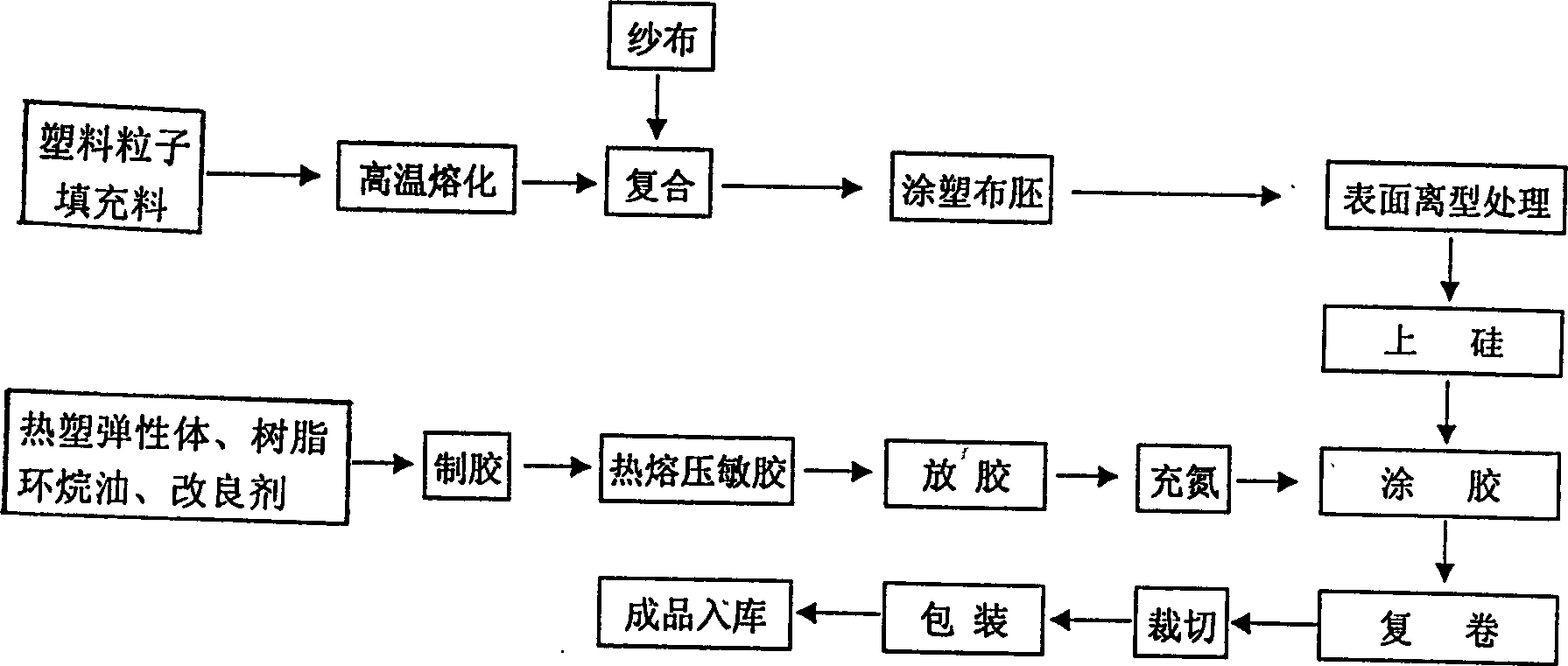

Process for making hot-melt pressure sensitive adhesive type fabric base adhesive tape

The manufacturing engineering for melten pressure-sensitive adhesive cloth-based belt belongs to manufacturing technique sphere of gel products. The method is characterized in that mixing and melting the PE plastic particles and filling materials; scoring with the gauze to produce plastic-coated cloth embryo; evenly daubing a non-silicon on the plastic-coated face of the plastic-coated cloth embryo; mixing and stirring thermoplastic elastomer, resin, naphthenic oil and modifying agent to prepare melten pressure-sensitive belt; inflowing into the gelholder filled with nitrogen; evenly covering the gel on the gaze cloth of the silicon-coated cloth embryo. The invention adds partial regenerative cotton into the pure polyester to obtain the product, which is of more adequate raw materials compared with pure polyester gauze and of moderate price, at the same time, adding mineral filler into PE largely reduces the cost of manufacture, and is of good suppleness, can not easily cock and can fast seal; the melten pressure-sensitive gel adopted by new cloth-based (pipe) gel is pure solid glue and is hard to burn, the industrial process can not produce any gaseous effluent and can not produce damage to people and environment, which belongs to a safety and environment-friendly type glue.

Owner:SHANGHAI YONGGUAN ADHESIVE PROD CORP LTD

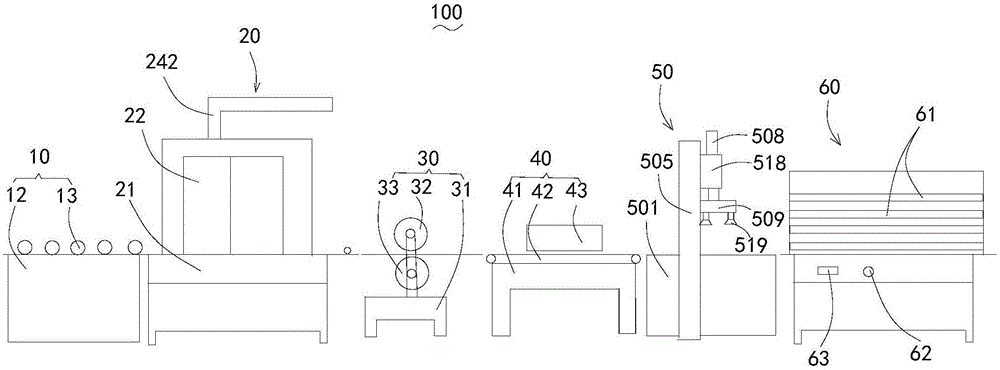

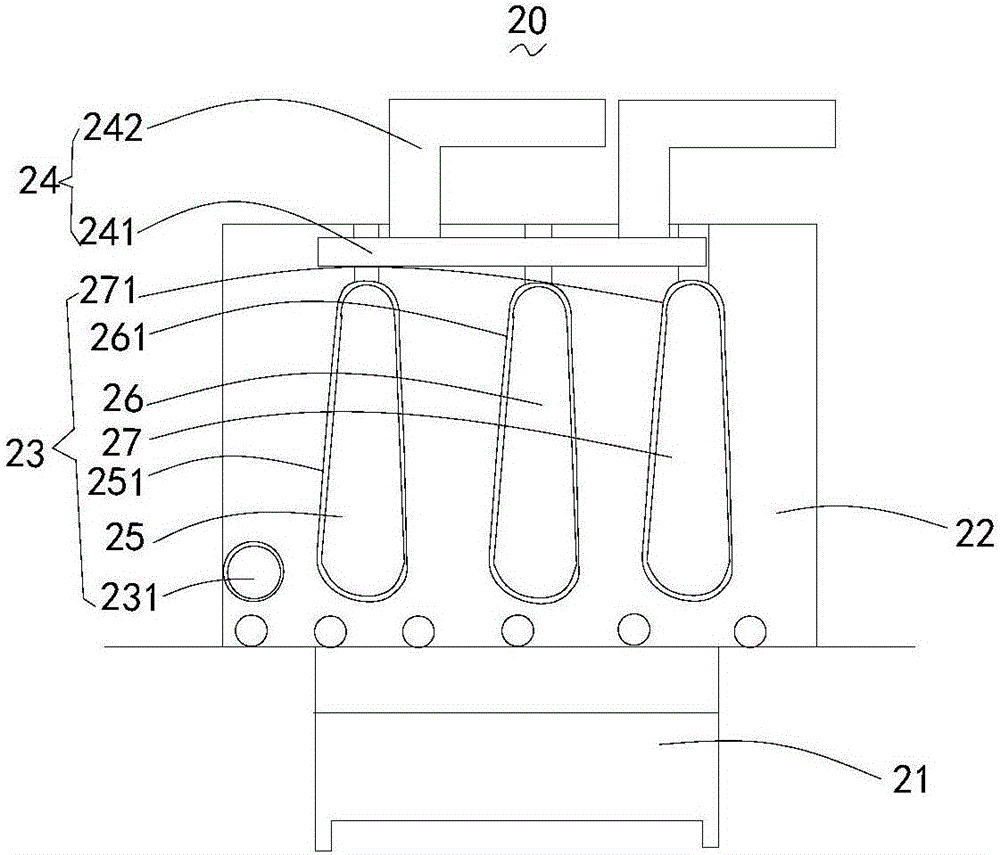

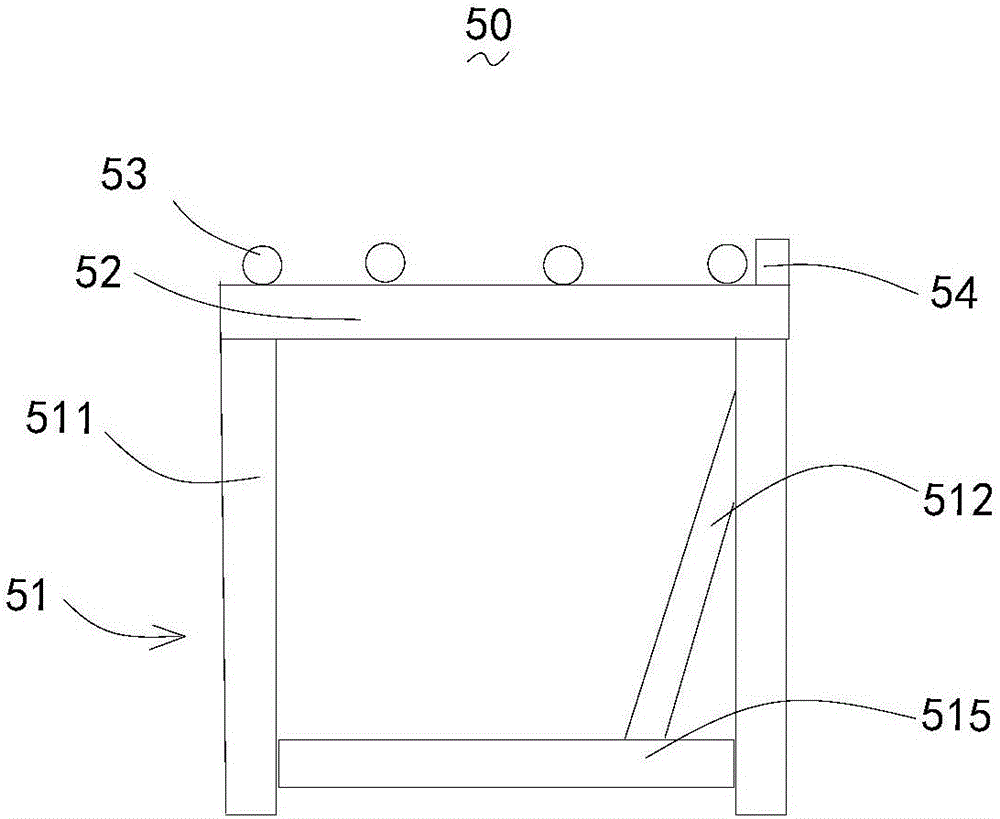

Production device of environment-friendly magnesium oxide decorative plate

ActiveCN106078382AStable structureNot easy to peel offCovering/liningsLayered product treatmentEngineeringPortal frame

The invention discloses a production device of an environment-friendly magnesium oxide decorative plate. The device comprises a conveying mechanism, a sanding mechanism, a gluing mechanism, a baking mechanism, a stacking mechanism and a hot pressing mechanism, wherein the sanding mechanism comprises a sanding rack, a cabinet arranged on the sanding rack, a sanding component installed in the cabinet and a dust exhaust component communicated with the interior of the cabinet; the gluing mechanism comprises a gluing rack, an upper roller and a lower roller which are positioned on the gluing rack; the baking mechanism comprises a baking rack, a baking conveying belt and an oven which are positioned on the baking rack; the stacking mechanism comprises a stacking rack, a portal frame and a material sucking component which are stridden at the stacking rack, and a material wheel is arranged on the stacking rack; the portal frame comprises upright posts which are arranged on both sides of the stacking rack and a cross post which is connected with the upright posts, and a sliding rail is arranged on the cross post. The device has the advantages of simple structure and low cost, and the produced magnesium oxide decorative plate has the advantages of stable structure and good decorative performance and cannot be stripped or warped after being used for a long time.

Owner:东莞市华富立装饰建材有限公司

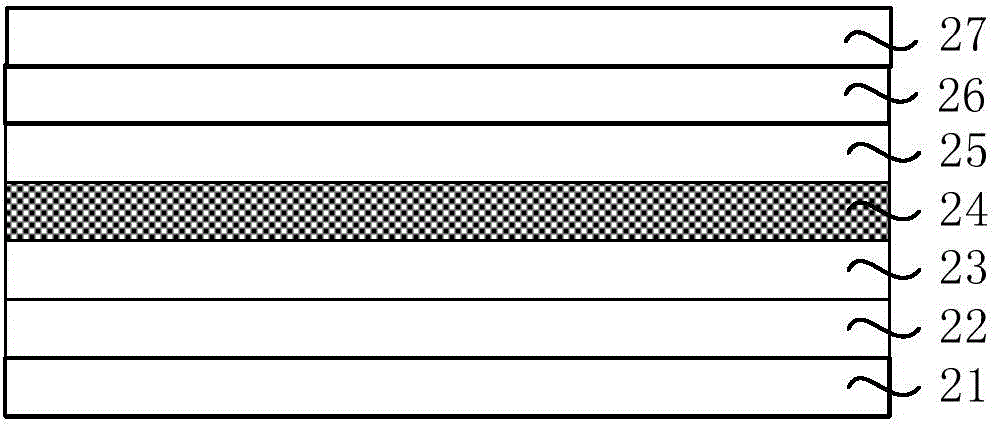

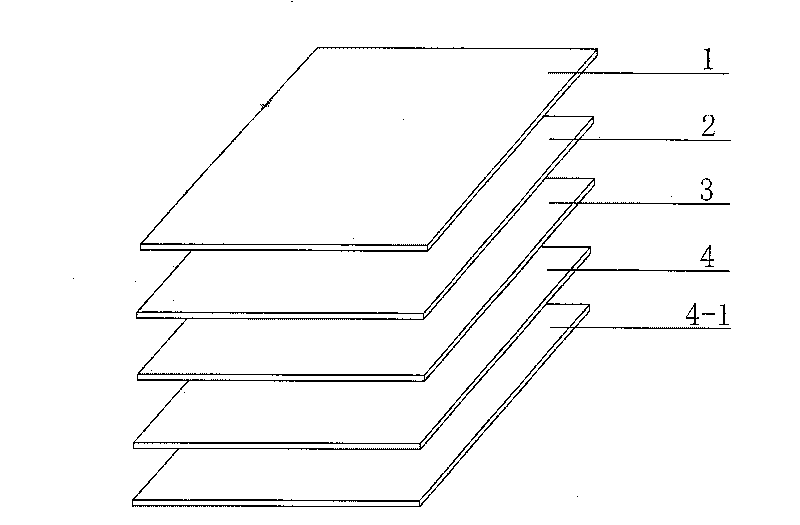

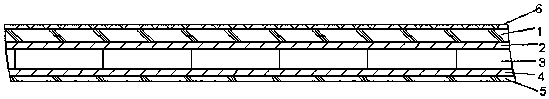

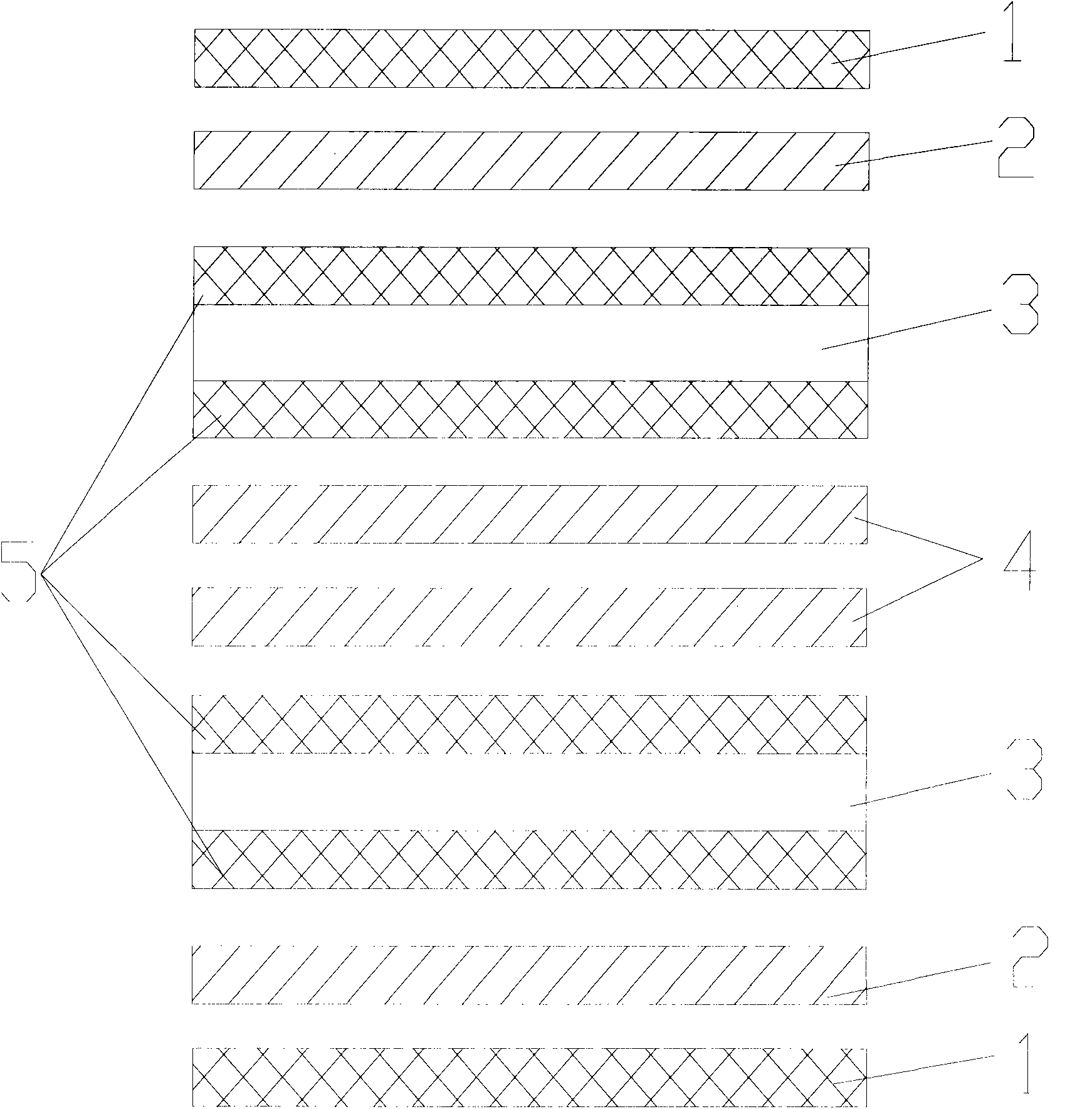

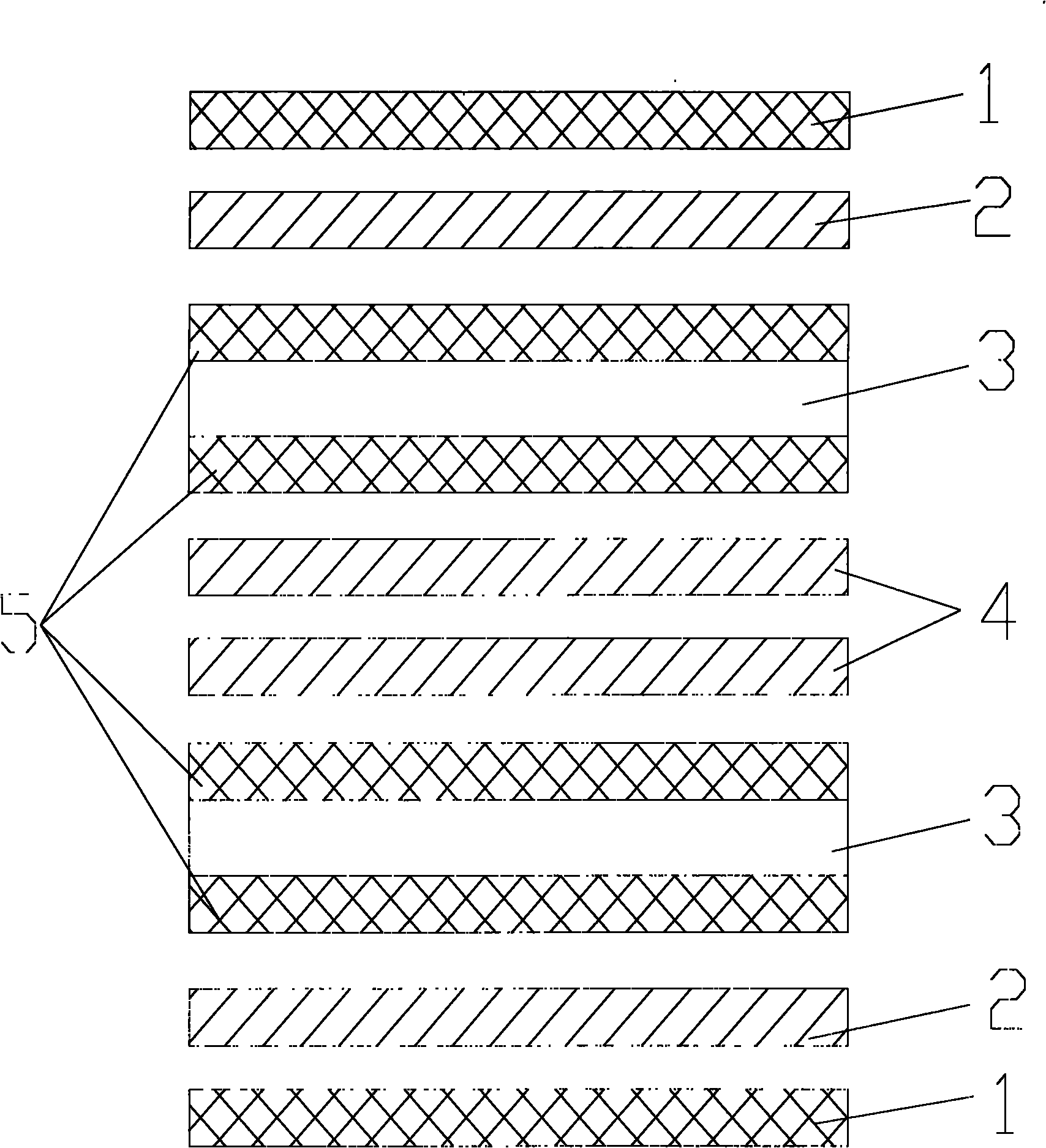

Solid wood composite cork floor and making method thereof

InactiveCN107816193AAvoid deformationSolution to short lifeWood veneer joiningConstructions elementsSolid woodEngineering

The invention belongs to the technical field of wood floor, relates to a solid wood composite floor, and particularly relates to a solid wood composite cork floor and a making method thereof. The solid wood composite cork floor disclosed by the invention sequentially comprises a coating layer, an upper cork composite layer, an upper balancing layer, a middle layer, a lower balancing layer and a lower cork layer, wherein a solid wood composite material layer is arranged between the upper and lower cork layers, the lower surface of the coating layer is laminated to the upper surface of the uppercork layer, the lower surface of the upper cork layer is laminated to the upper surface of the upper balancing layer, the lower surface of the upper balancing layer is laminated to the upper surfaceof the middle layer, the lower surface of the middle layer is laminated to the upper surface of the lower balancing layer, and the lower balancing layer is laminated to the upper surface of the lowercork layer. The invention also discloses a making method of the floor. The invention solves the characteristic of easy deformation of solid wood, overcomes relatively poor mechanical property of cork,adopts a gluing manner of two times of assembly, and effectively solves the problems of poor quality and poor gluing property caused by deformation, lamination dislocation and compression performancedifference of different layers.

Owner:DAYA JIANGSU FLOOR

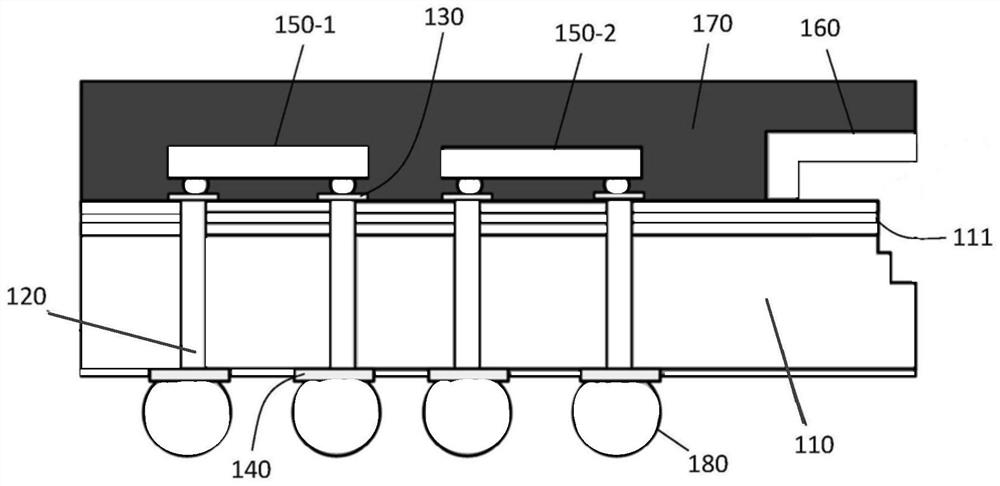

Photoelectric chip packaging structure and packaging method thereof

ActiveCN112034567APrevent leakageImprove performanceCoupling light guidesOptical waveguide light guideRefractive indexOptical coupling

The invention discloses a photoelectric chip packaging structure and a packaging method thereof. The photoelectric chip packaging structure comprises an optical chip and a protection structure; the optical chip comprises an optical dielectric layer; the edge region of one side of the optical dielectric layer is an optical coupling region; the protection structure is located on the front face of the optical chip and makes contact with the surface of the optical coupling region; the refractive index of the protection structure is smaller than that of the optical medium layer. The packaging reliability of the photoelectric chip packaging structure is improved, and light leakage is reduced.

Owner:NAT CENT FOR ADVANCED PACKAGING

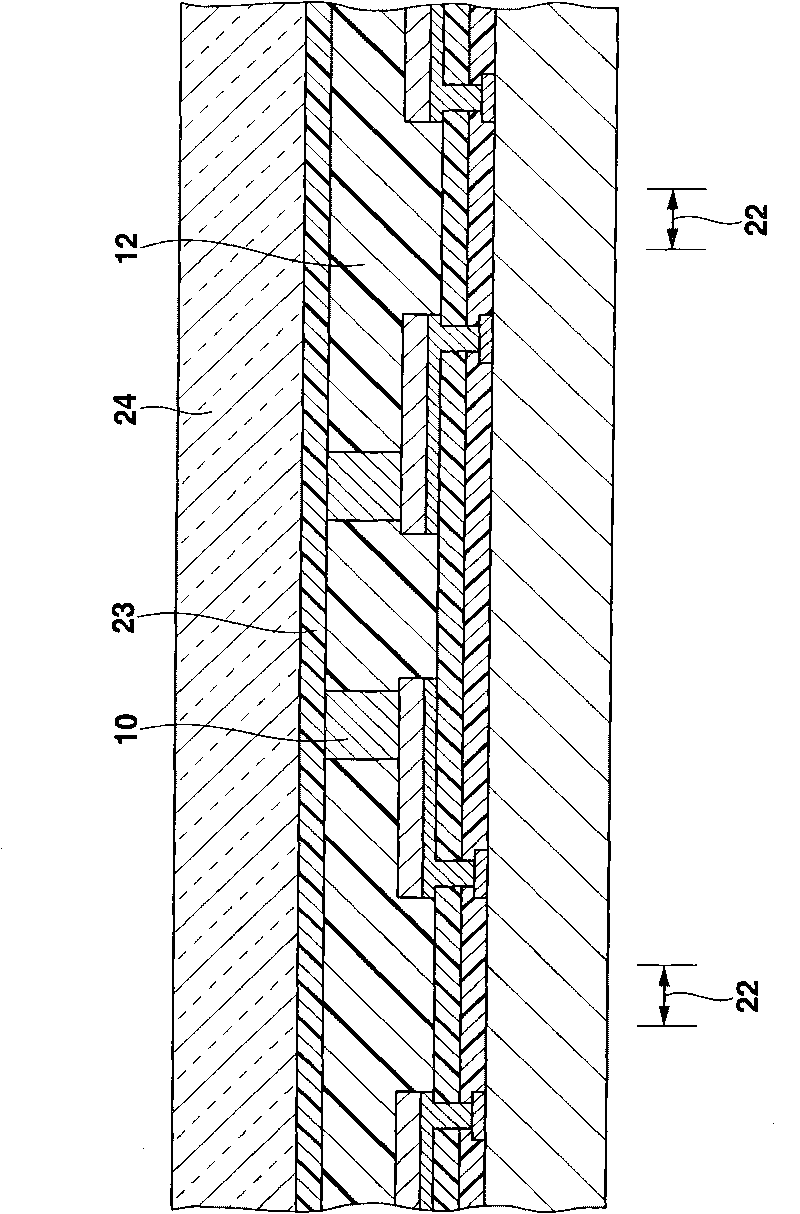

Printed circuit board(PCB) with thicker inner-layer baseplates

The invention discloses a Printed circuit board(PCB) with thicker inner-layer baseplates, relating to the technical field of printed circuit board. The Printed circuit board(PCB) comprises two outer-layer copper foils at the outermost side and two outer-layer PPs arranged at the inner side of the two outer-layer copper foils, and the outer-layer pps are made of PP1080. The Printed circuit board(PCB) is characterized by further comprising two inner-layer baseplates and inner-layer PPs, the inner sides of the two outer-layer PPs are provided with two inner-layer baseplates, and the inner-layer baseplates have the thickness of 4 mil. The two sides of each inner-layer baseplate are provided with inner-layer foils, the inner sides of the two inner-layer baseplates are provided with inner-layer PPs, the inner-layer PPs comprise two layers of PP, and the two layers of PP are made of PP7630. The invention solves the problem that in the prior art, when DES wires are arranged and multibond wires are pressed, the corners of the inner-layer baseplates can be warped easily, and the inner-layer baseplates can be blocked easily when being arranged directly. The invention provides the PCB which has simple structure, and the inner-layer baseplates of the PCB are thicker and can not be blocked easily when being arranged.

Owner:昆山元茂电子科技有限公司

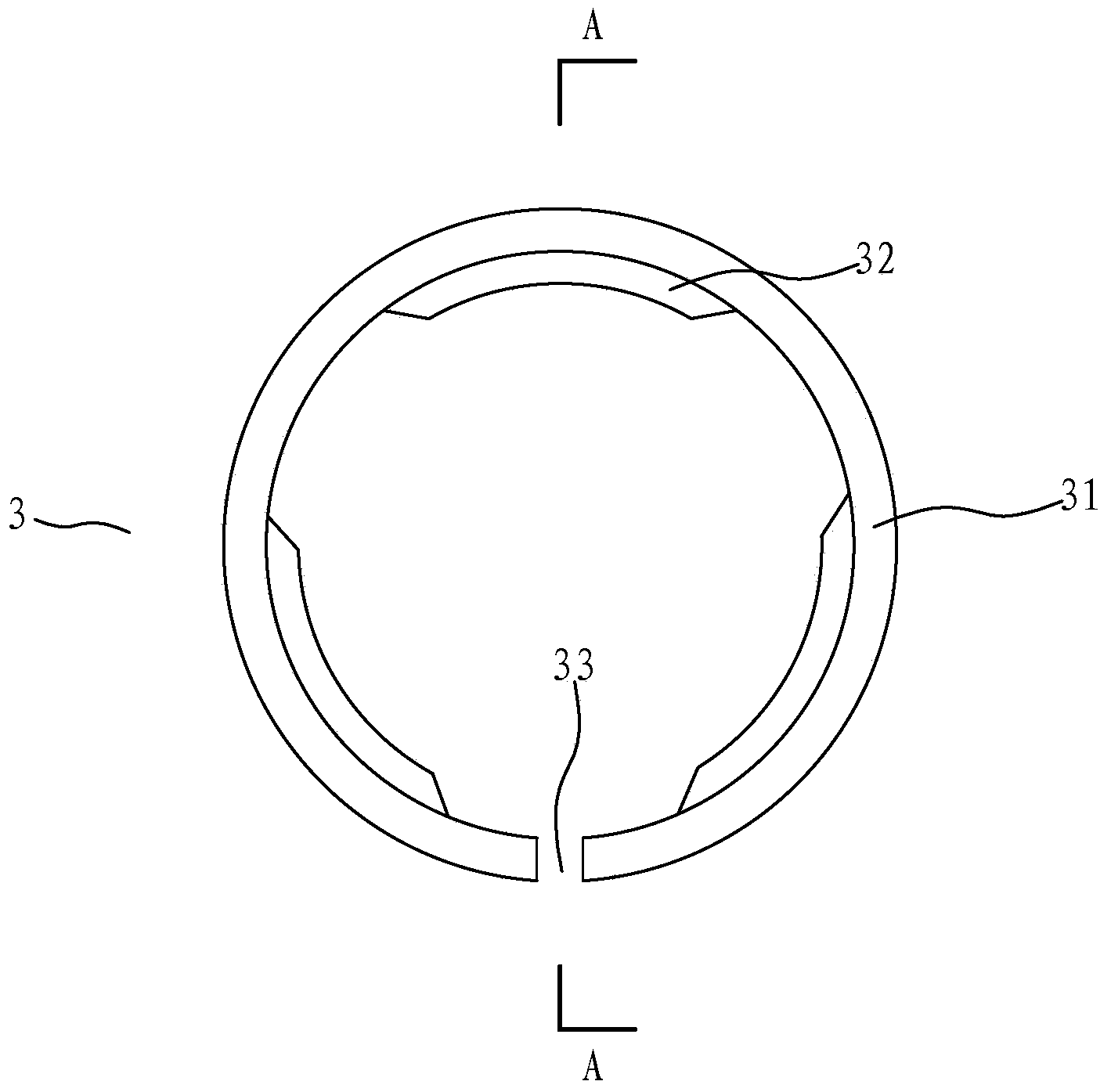

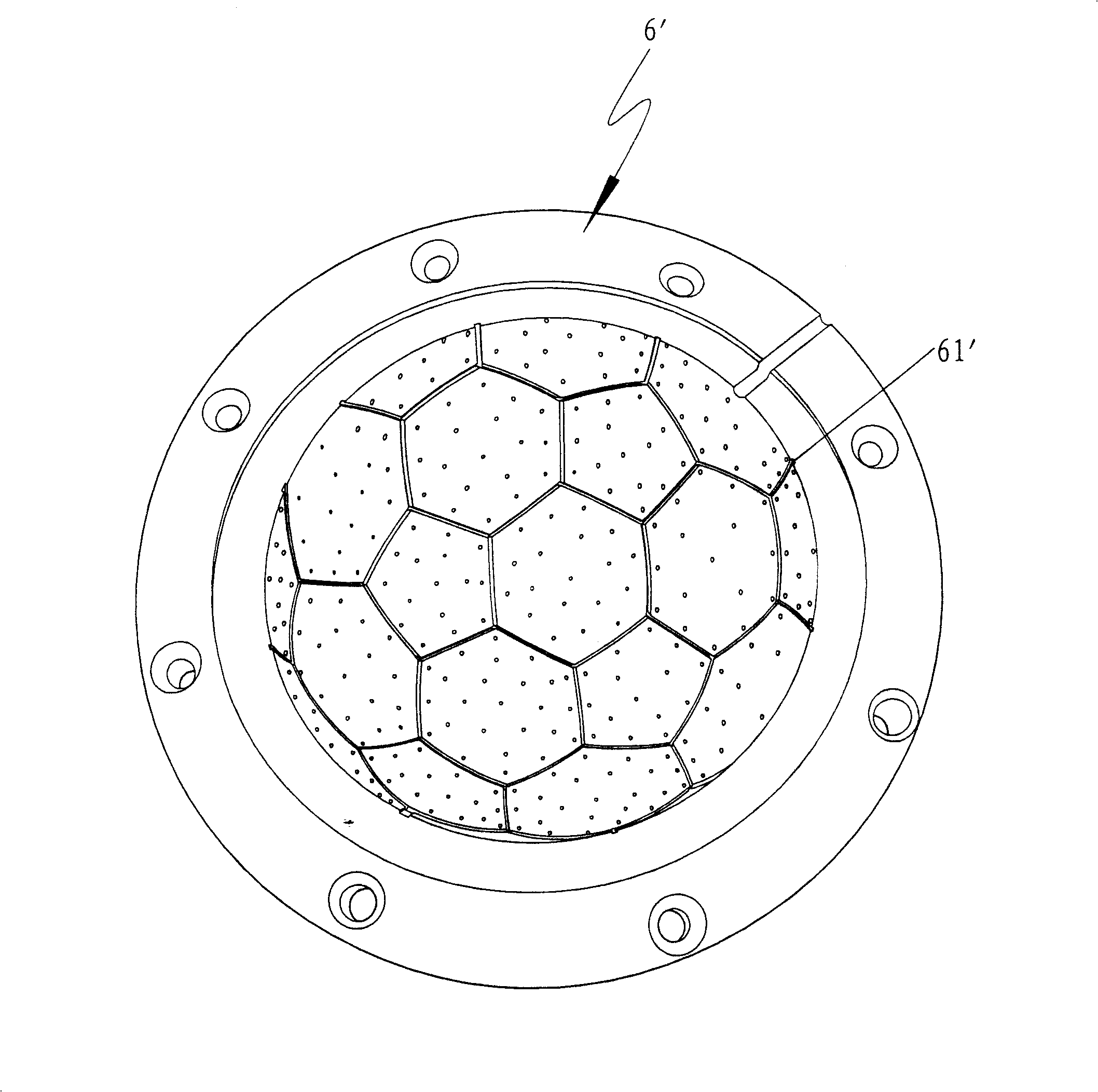

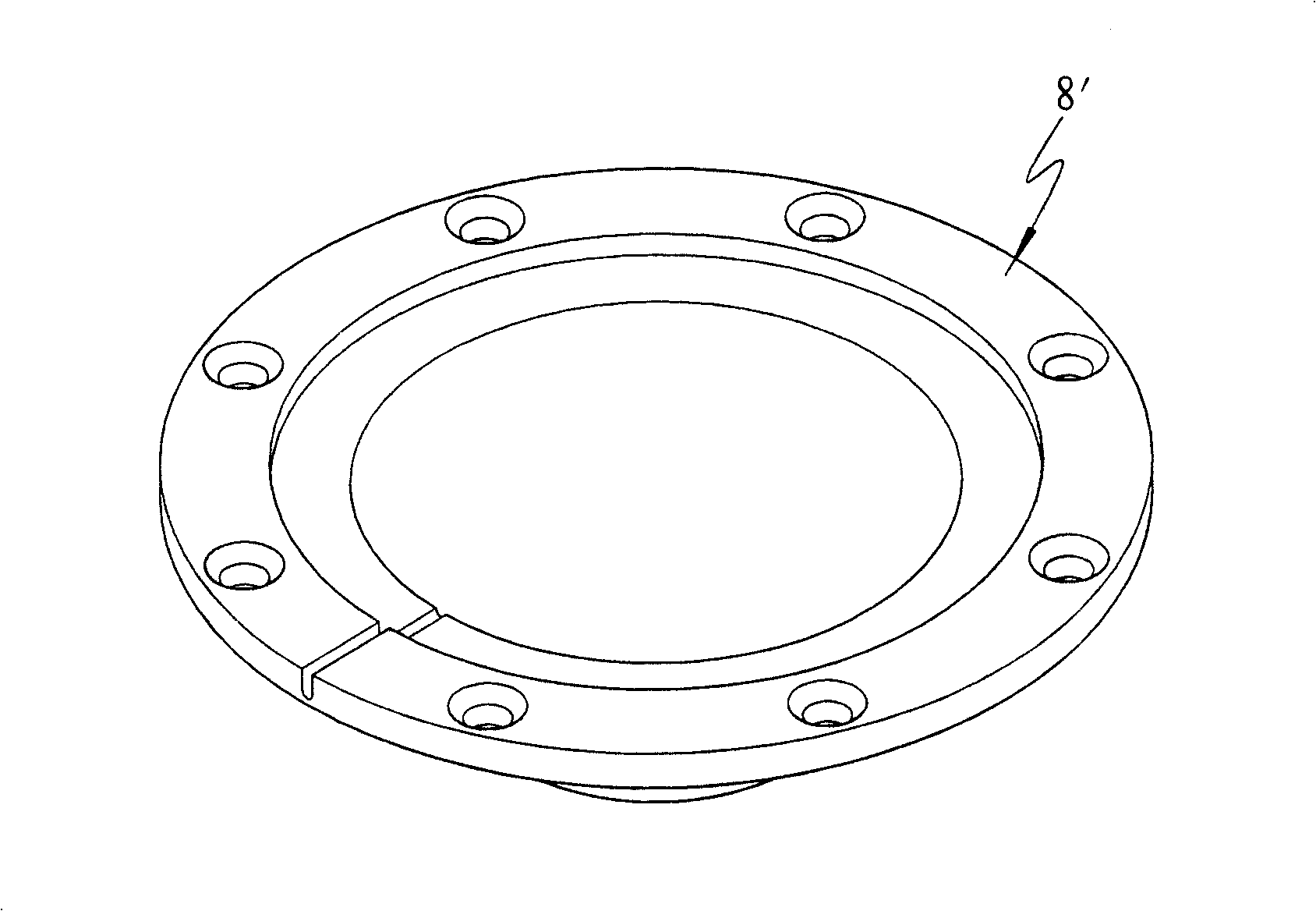

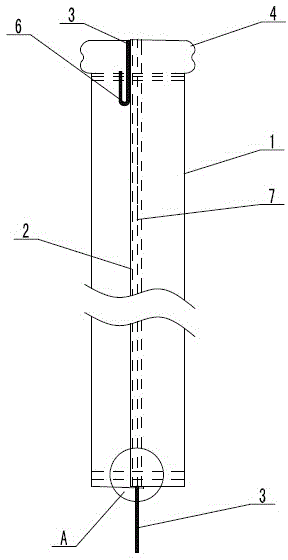

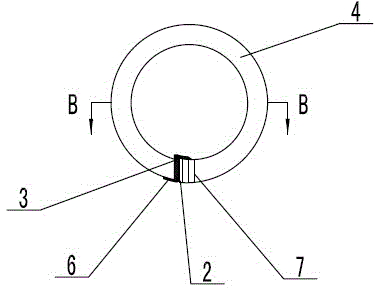

Electrically conductive filter bag and production method thereof

ActiveCN105854442AEasy to installDoes not affect filteringDispersed particle filtrationMechanical engineeringElectrical and Electronics engineering

An electrically conductive filter bag and a production method thereof belong to the technical field of electrically conductive bag. The electrically conductive filter bag includes a bag body (1) and q bag bottom sewn at the bottom of the bag body (1); the bag body (1) is provided with a double-layer edge for sewing (2); the double-layer edge (2) is internally provided with a conductive strip (3); the conductive strip (3) is fixed by suture (7) sewn on the double-layer edge; the upper end of the bag body (1) is provided with an annular skeleton; the top of the conductive strip (3) exposes from the top of the double-layer edge (2), and winds from the inside of the bag body (1) to the outside of the bag body (1), and is then fixed below the annular skeleton onto the bag body (1); and the bottom end of the conductive strip (3) exposes from the bottom of the double-layer edge and is placed outside the bag body (1). The electrically conductive filter bag has good conductive effect, prevents conductive failure caused by collision of the keel and the conductive strip in the bag body. The production method completes sewing of the bag body and the conductive strip in one step, and improves the production efficiency of the electrically conductive filter bag.

Owner:山东兴国新力环保科技股份有限公司

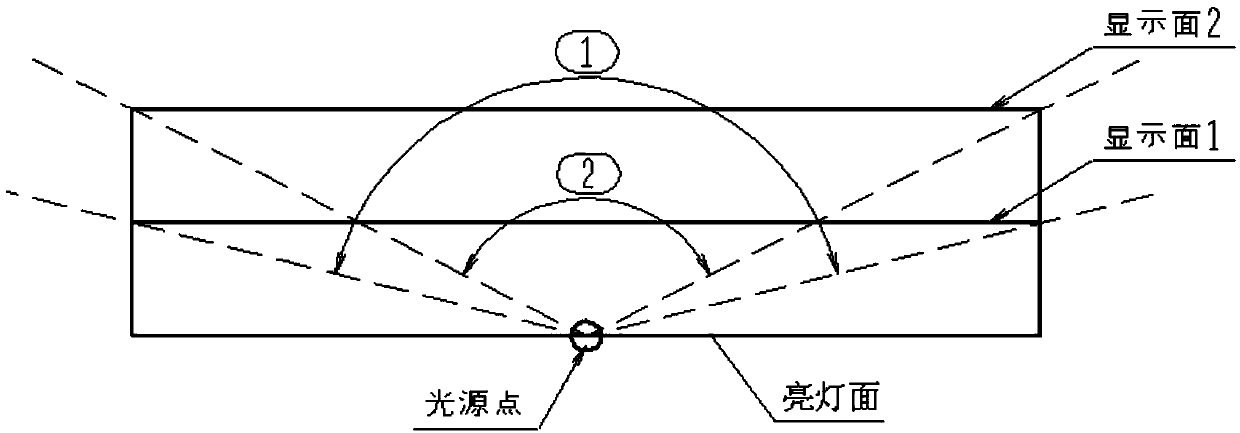

Light guide plate, surface illuminating device, and liquid crystal display device

InactiveCN102713417AImprove utilization efficiencyLess ejaculationPoint-like light sourceElectric lightingLiquid-crystal displaySection plane

Disclosed is a light guide plate wherein the utilization efficiency of light is high, light with less luminance variation can be output, and a distribution such that the central part of the screen is brighter than the peripheral part can be achieved. The light guide plate comprises a rectangular light output surface, a light input surface through which light traveling in a direction approximately parallel to the light output surface is allowed to enter, a back surface on opposite side to the light output surface, and scattering particles dispersed inside. The light guide plate is so configured that the light guide plate has two or more layers which are stacked in a direction approximately perpendicular to the light output surface and which have particle densities of the scattering particles different from one another, the layers include a first layer which is on the light output surface side and the particle density of which is Npo and a second layer which is nearer to the back surface than the first layer and the particle density of which is Npr, the relation Npo<Npr is satisfied, the shape of the cross section taken in a direction perpendicular to the light input surface on the light output surface side is concave, the thicknesses of the first and second layers in a direction approximately perpendicular to the light output surfaces are varied from each other, and thereby the combined particle density of the light guide plate in a direction perpendicular to the light input surface is varied.

Owner:FUJIFILM CORP

Blue-light-proof film and preparation method thereof

InactiveCN109553790AGood flexibilityImprove adhesionPolyurea/polyurethane coatingsUV curingOptical coating

The invention provides a blue-light-proof film which comprises a thermoplastic base material and a functional coating arranged on the thermoplastic base material; a blue-light-proof coating is arranged on one surface, opposite to the functional coating, of the thermoplastic base material, and / or, the blue-light-proof coating is arranged between the thermoplastic base material and the functional coating. Compared with the prior art, two UV-cured optical coatings are arranged on the thermoplastic base material, the two UV-cured optical coatings are the blue-light-proof coating and the functional coating respectively; by mixing the ratio of components in a reactive diluent, the blue-light-proof coating has good flexibility and re-coating adhesive force, and interlayer separation is not easyto occur; no blue light blocking agent is contained in the functional coating, the influence of the blue light blocking agent on the UV curing condition is eliminated, the functional coating can be easily endowed with other properties, by mixing the types and proportions of main body resin and the reactive diluent, the functional coating has good flexibility, and cracking and falling of the coating cannot be caused in the hot-pressing molding process.

Owner:安徽屹珹新材料科技有限公司

Manufacturing method of weather-resistant, waterproof and high-quality special paper for printing

InactiveCN108914675AReduce pollutionReduce dependencePaper coatingPaper/cardboardFiberPulp and paper industry

The invention relates to the field of preparation of consumables of printing products, in particular to a manufacturing method of weather-resistant, waterproof and high-quality special paper for printing. The manufacturing method comprises the following steps of preparation of initial paper pulp, preparation of a toughening additive, preparation of papercopying pulp, preparation of paper blanks, preparation of an adhesive film solution, and applying of the adhesive film layer. The prepared paper has the advantages that the strength is high, and the printing effect is excellent; the water-resistant, oil-resistant, chemical-resistant and aging-resistant properties are realized; the heat insulation property is good; the certain flame-retardant effect is realized; the paper is flat in surface,is difficult to warp, and is suitable for drum printing; by adopting a large amount of waste paper pulp fiber, the resource is saved, the weight of the paper is light, and the certain fluorescent property is realized; when the paper is used as the advertisement paper, the vision effect is improved; the good bacteria-inhibiting and insect-preventing effects are realized; the added components are free from poison and harm, the safe and environment-friendly effects are realized, and the higher practical value and good application prospect are realized.

Owner:安徽古耐家居有限公司

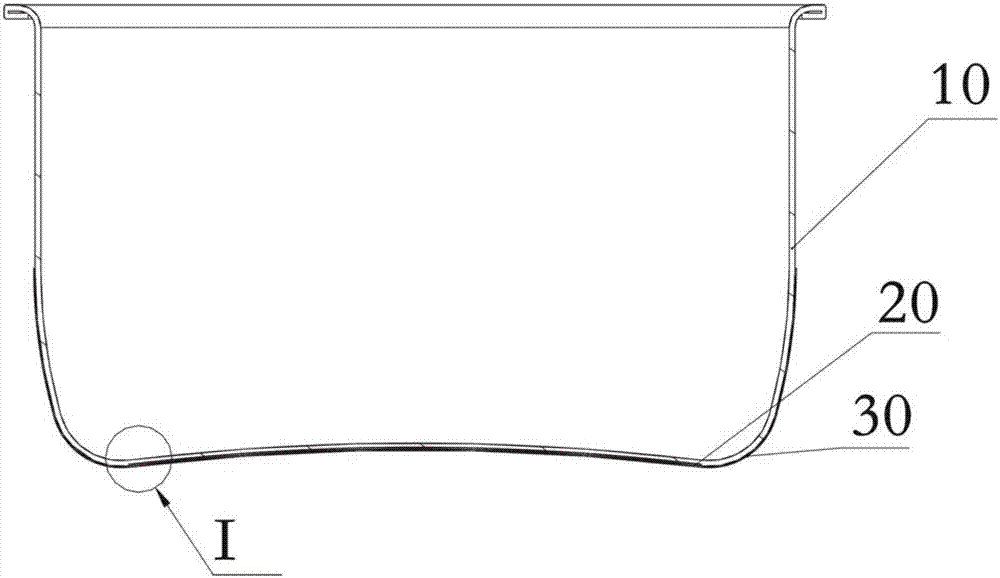

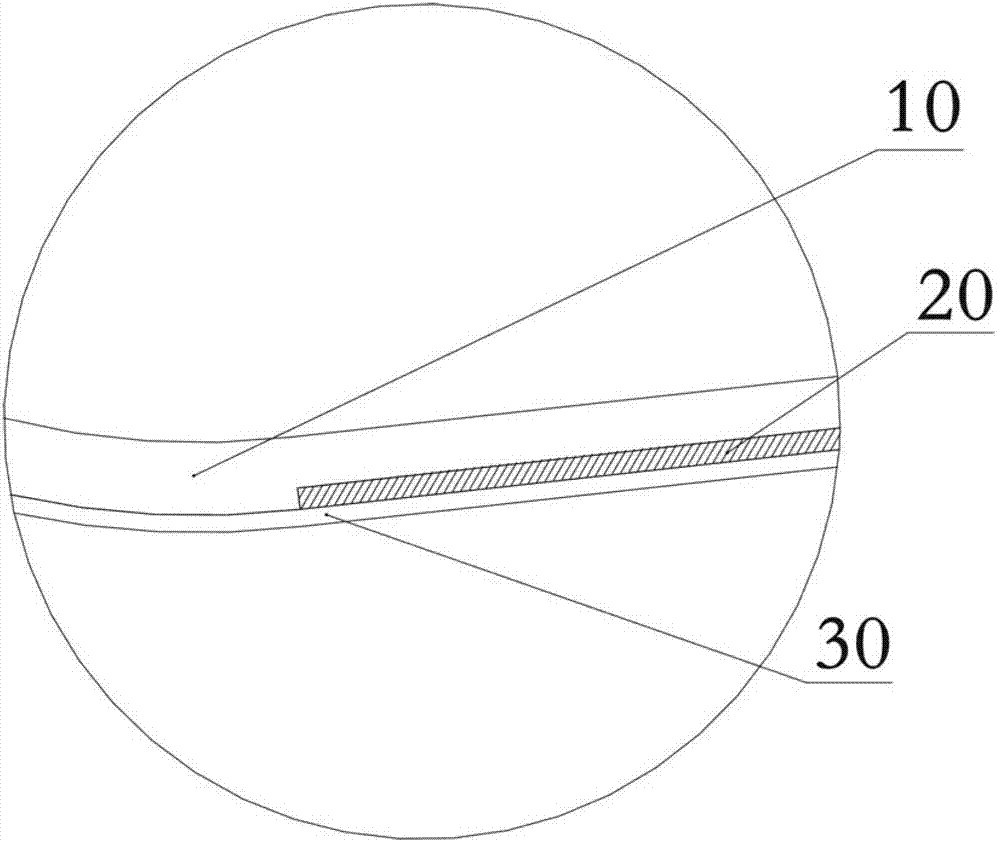

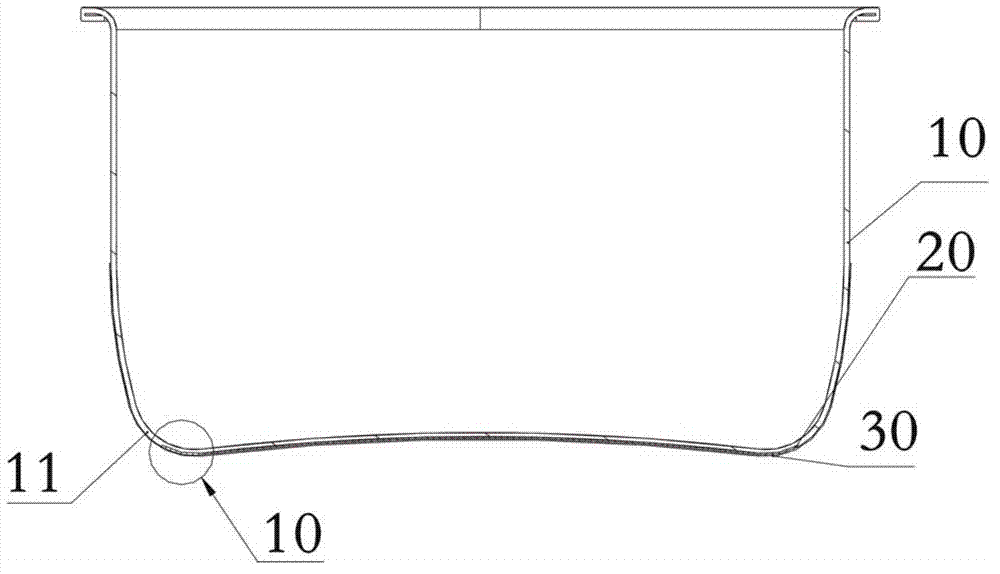

Inner pot for electromagnetic induction heating cooker and processing method thereof

The invention discloses an inner pot for an electromagnetic induction heating cooker and a processing method thereof, relates to the technical field of electromagnetic induction heating cooking and solves the problem in the prior art of low magnetism conduction efficiency. The inner pot for the electromagnetic induction heating cooker comprises a pot body of the inner pot, wherein a magnetism conduction sheet is composited at the bottom on the outer side of the pot body. Meshes are arranged on the magnetism conduction sheet, pot body materials are deformed and extruded into the meshes, the magnetism conduction sheet is fixedly composited at the bottom of the pot body, a joint is formed between the edge of the magnetism conduction sheet and the pot body, a magnetism conduction layer is arranged outside the pot body and the magnetism conduction sheet, formed in high temperature meltallizing mode and covered on the joint position, and the magnetism conduction sheet at the joint position is tightly embedded into the pot body in the high temperature meltallizing process. The inner pot for the electromagnetic induction heating cooker is mainly used in the electromagnetic induction heating cookers, in particular to electric pressure cookers, electric cooker, electric saucepans and the like which are in electromagnetic induction heating.

Owner:JOYOUNG CO LTD

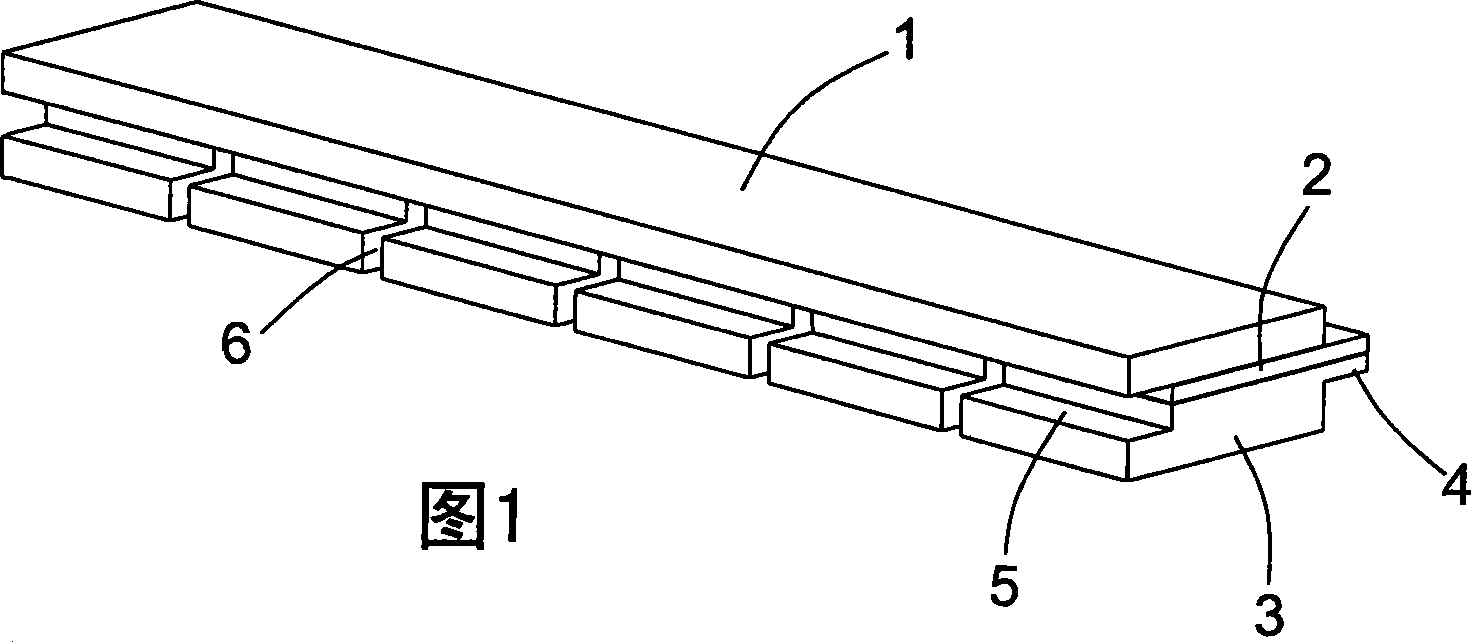

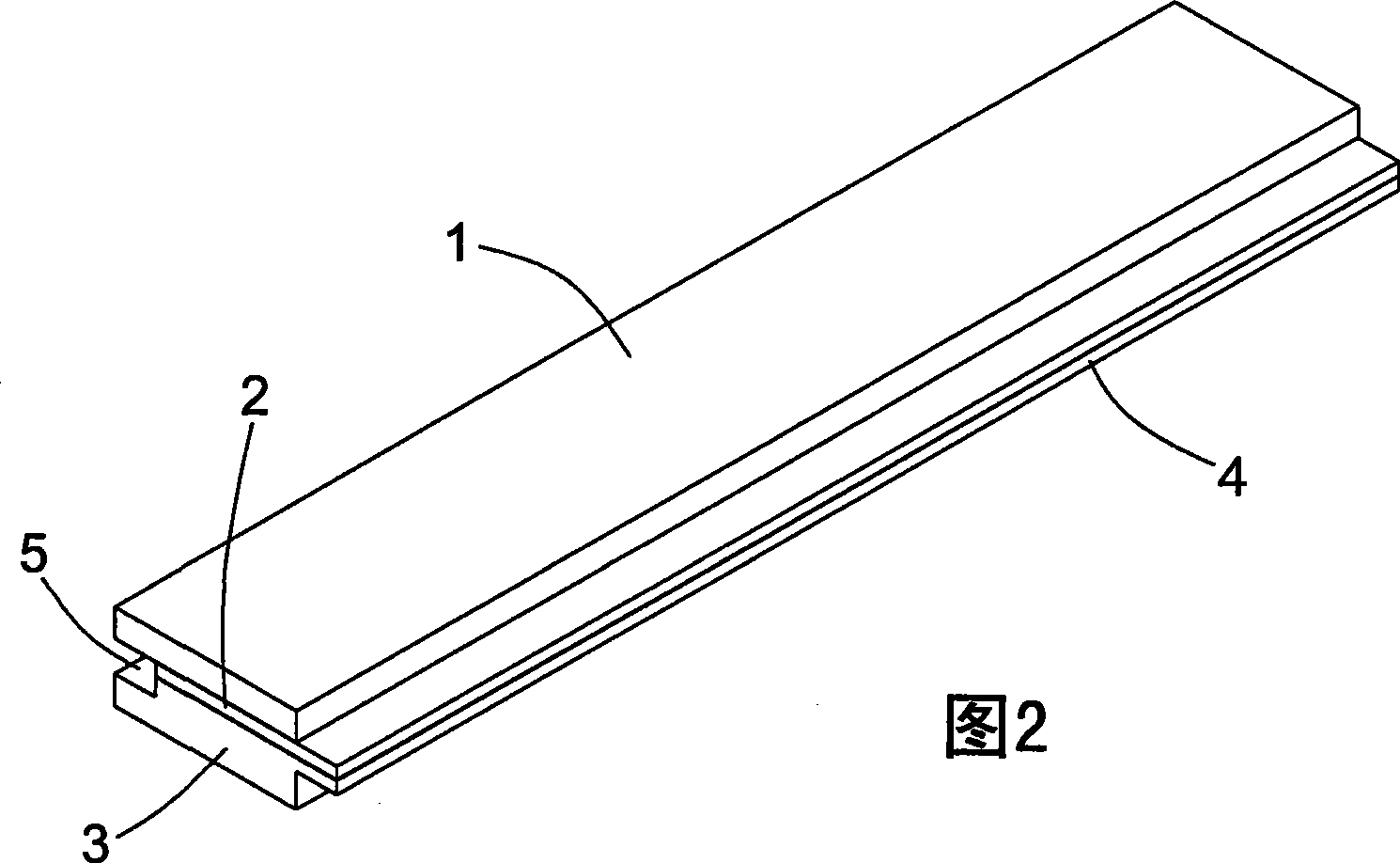

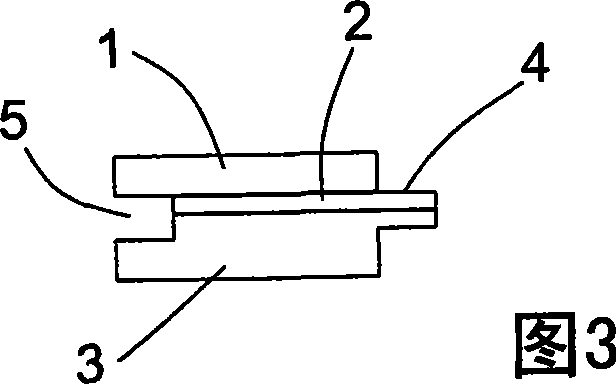

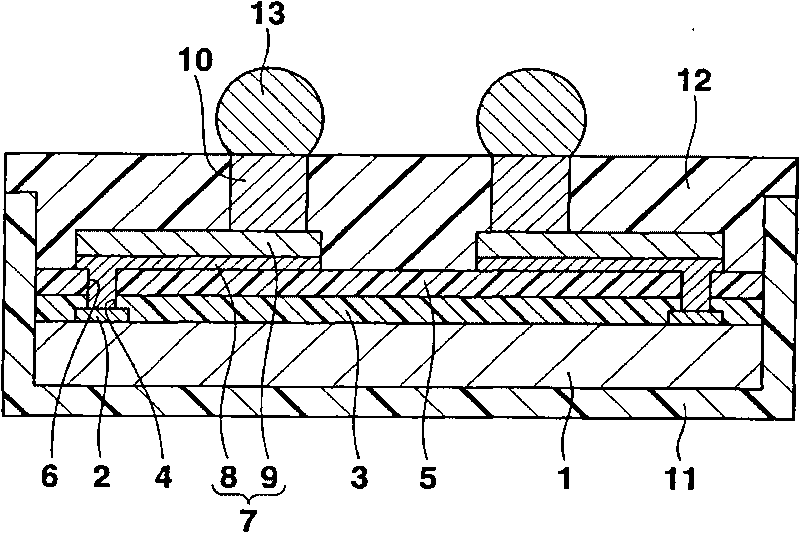

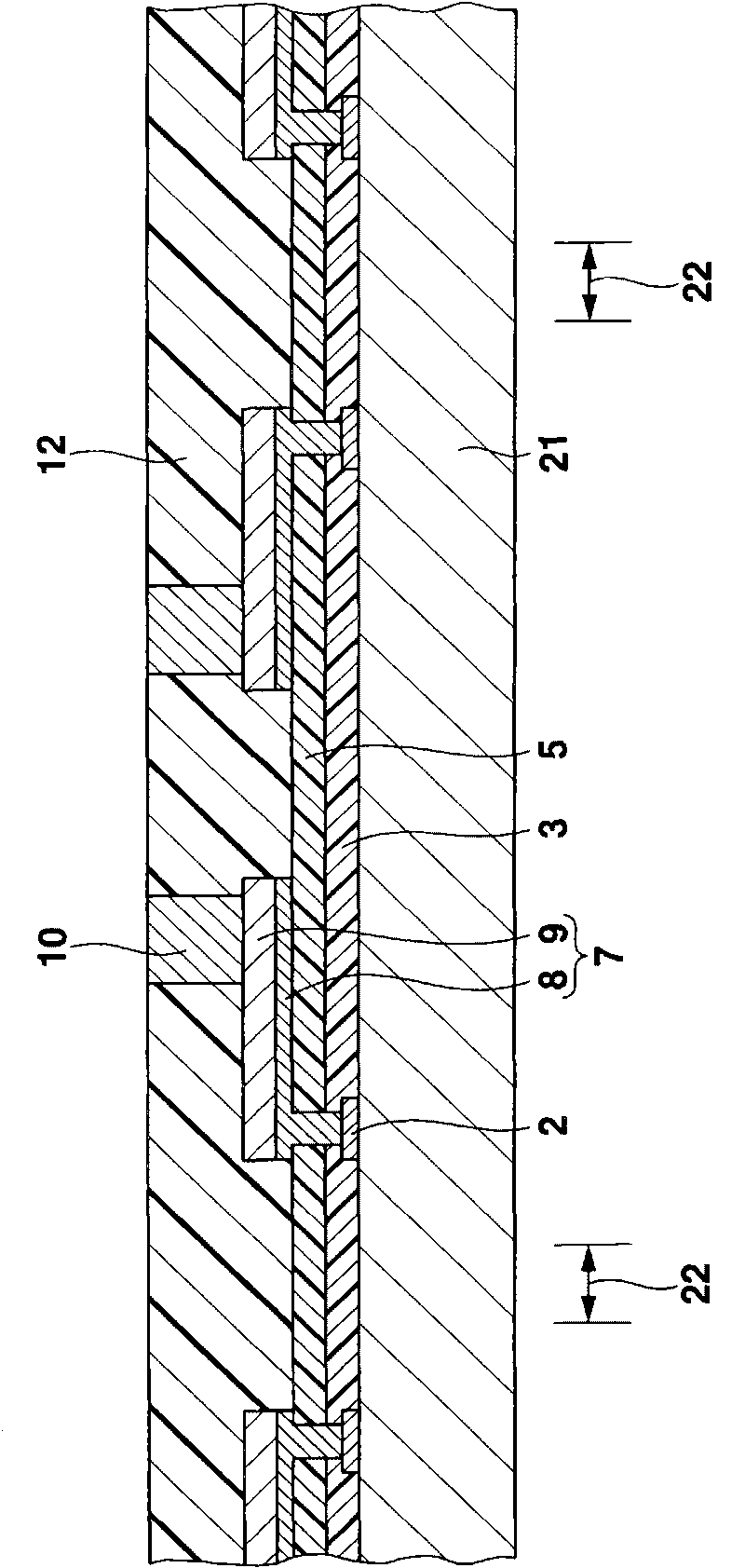

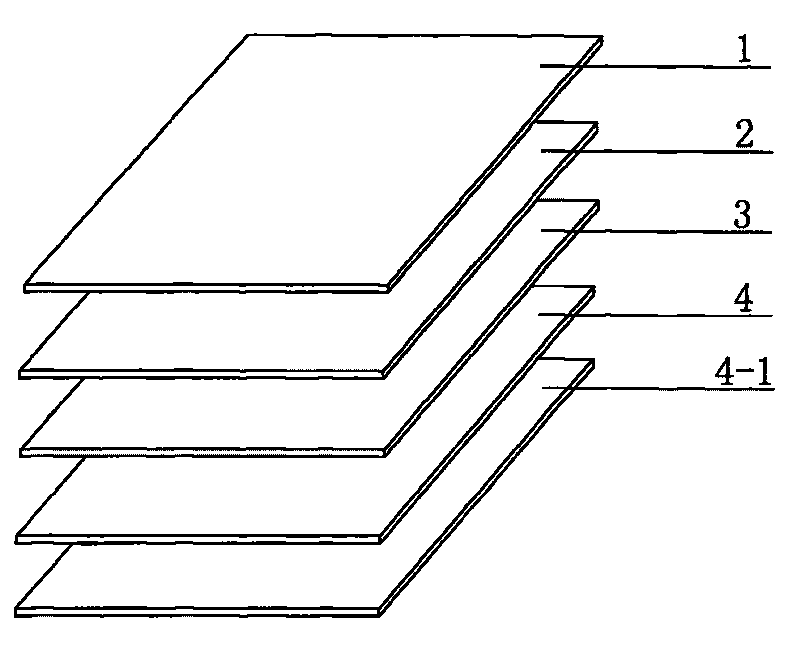

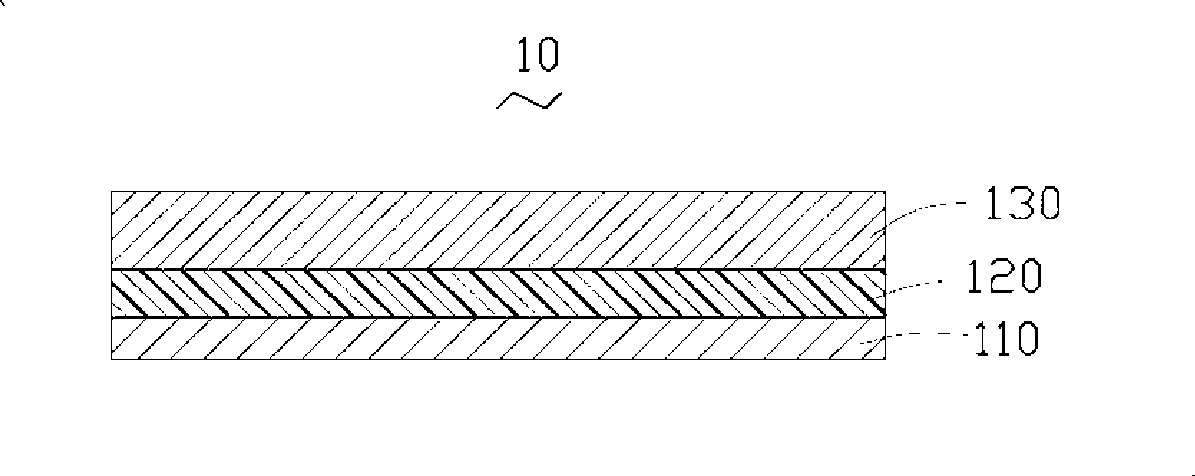

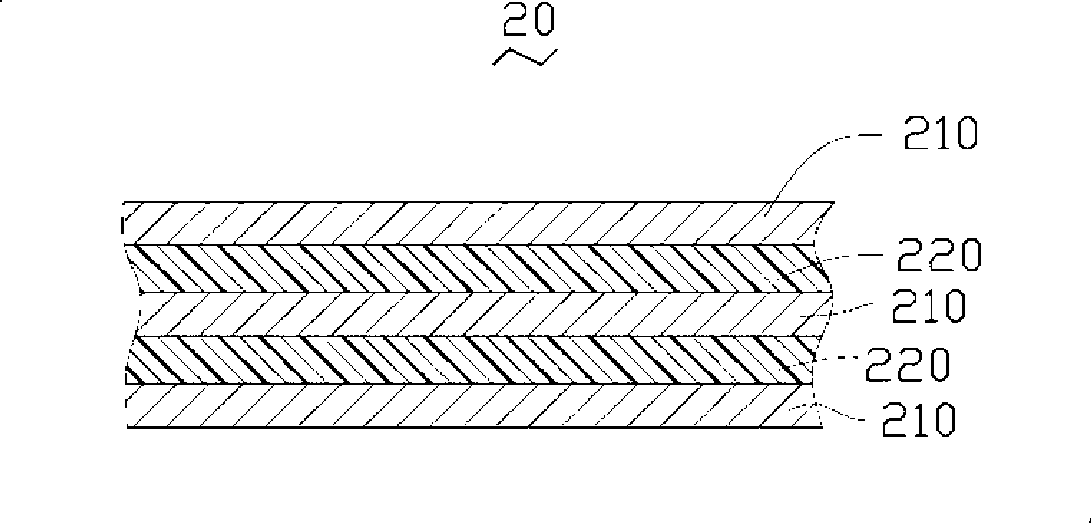

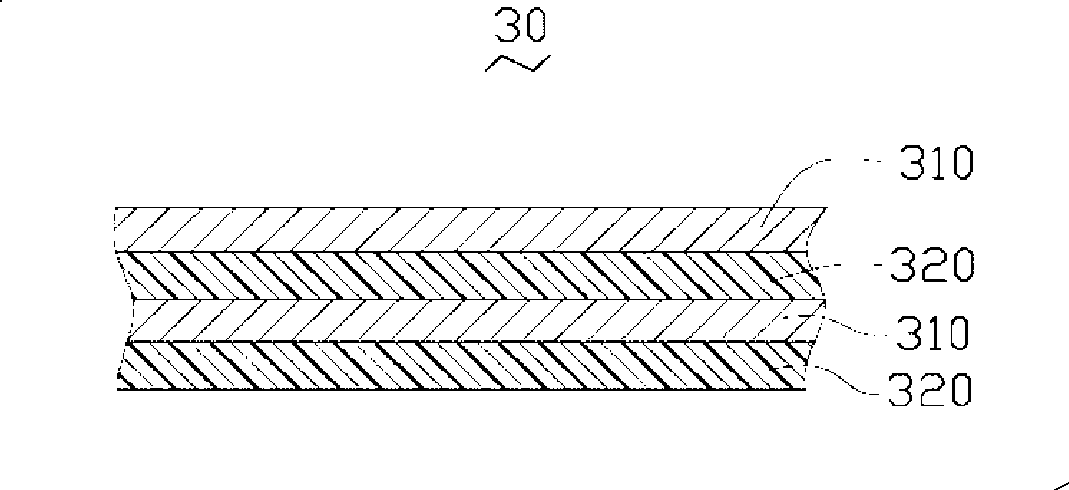

Reinforcing plate and reinforced flexible circuit board including the same

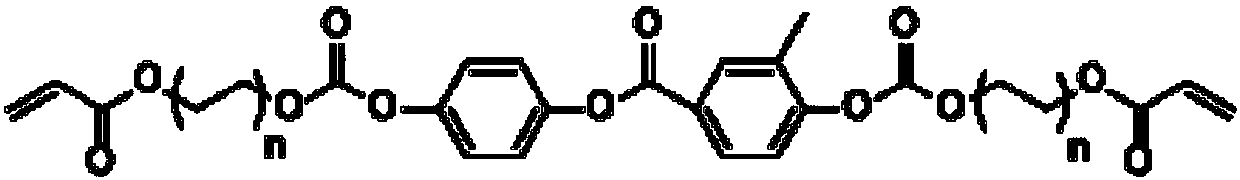

ActiveCN101472390ANot easy to warpImprove structural stabilitySynthetic resin layered productsPrinted circuit aspectsImidePolyetherimide

The invention provides a stiffening plate, which is formed by at least a layer of polyimide and at least a layer of polyetherimide which are in alternative arrangement. The polyetherimide layer is made of a polyetherimide material; and the general formula of the structure of the polyetherimide material is A. The invention further provides a stiffening flexible circuit board comprising the stiffening plate. The stiffening flexible circuit board has the advantages of little possibility of warping and better structural stability.

Owner:AVARY HLDG (SHENZHEN) CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com