Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1110results about How to "Reduce scrap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

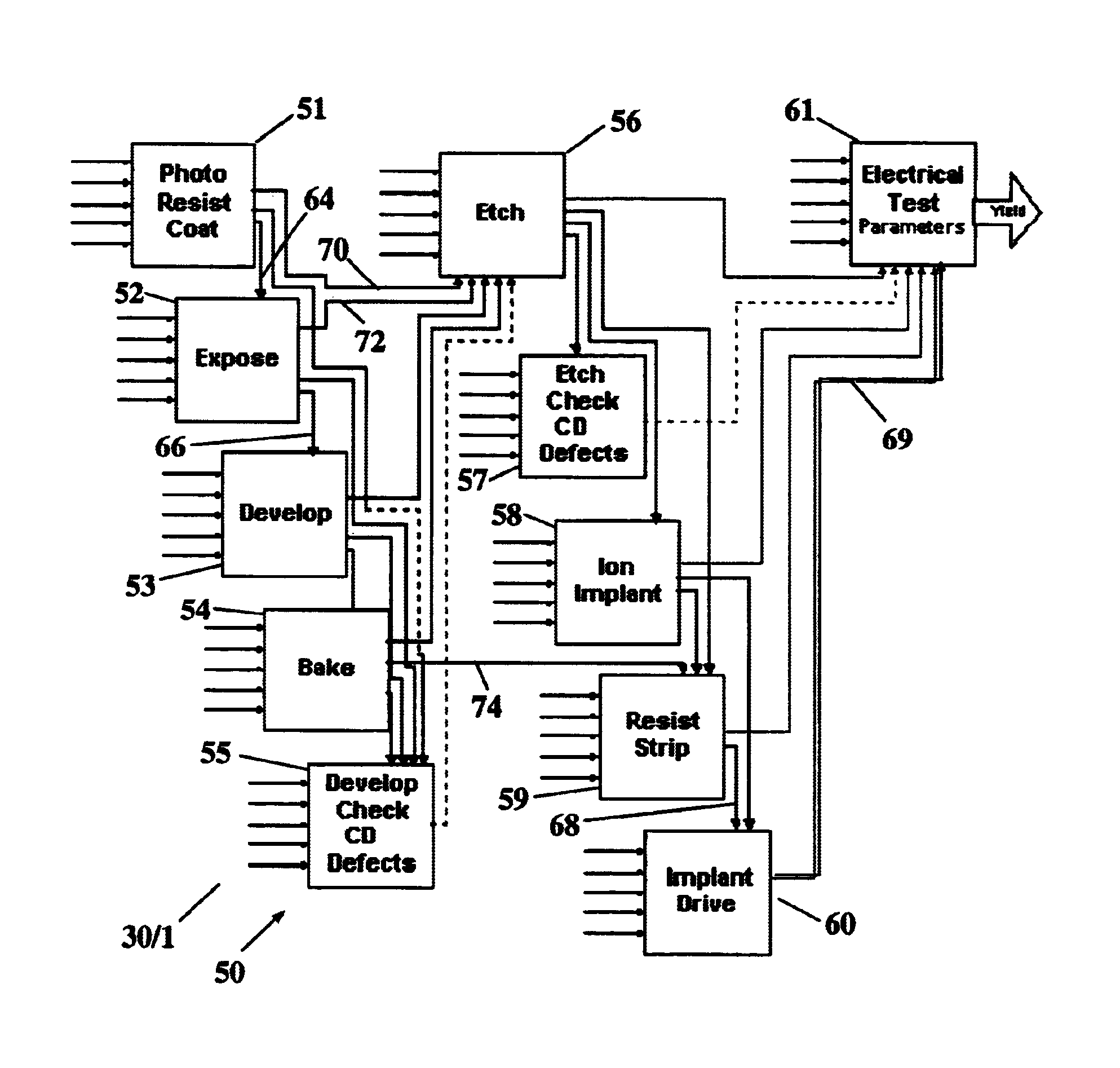

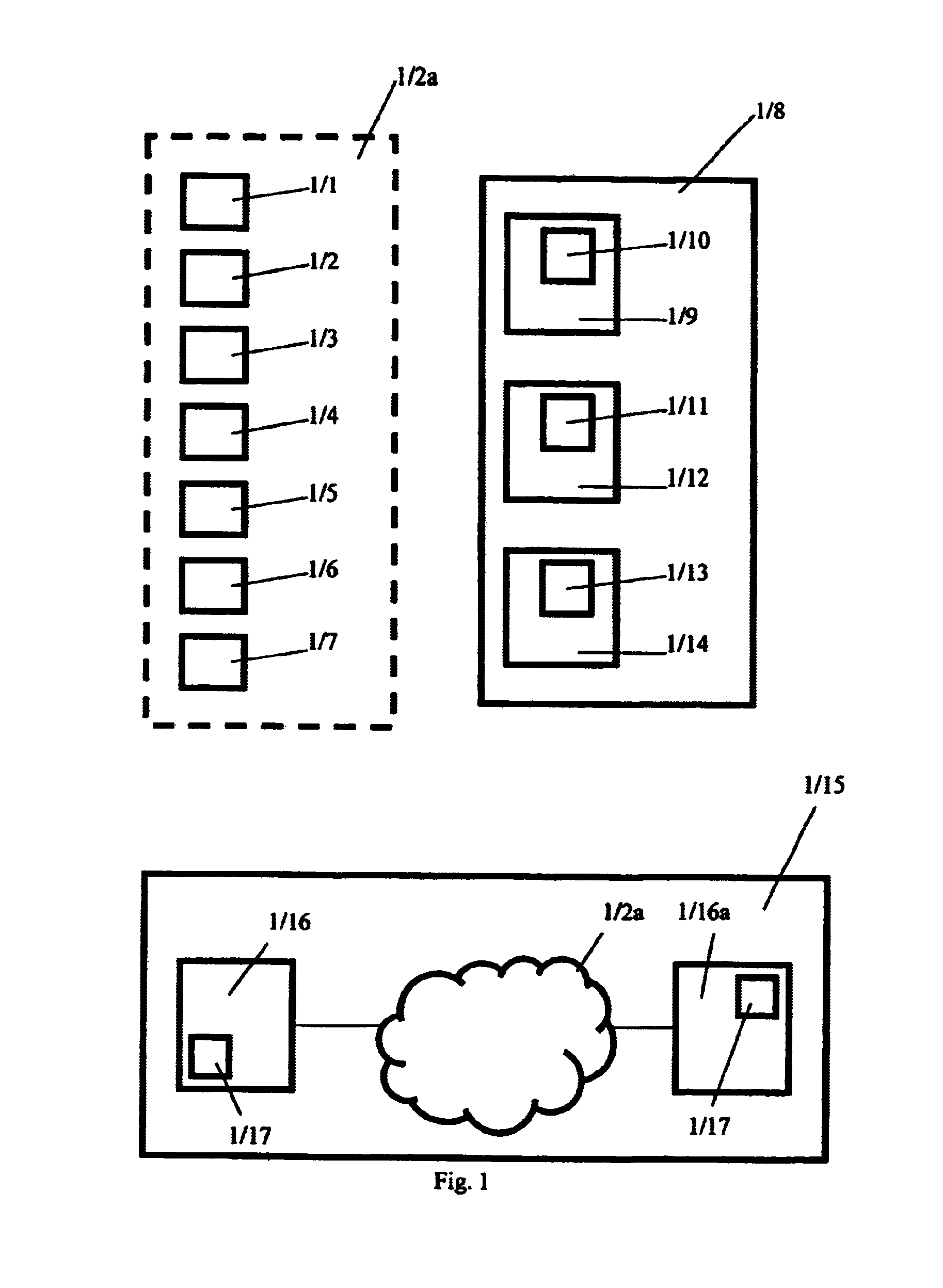

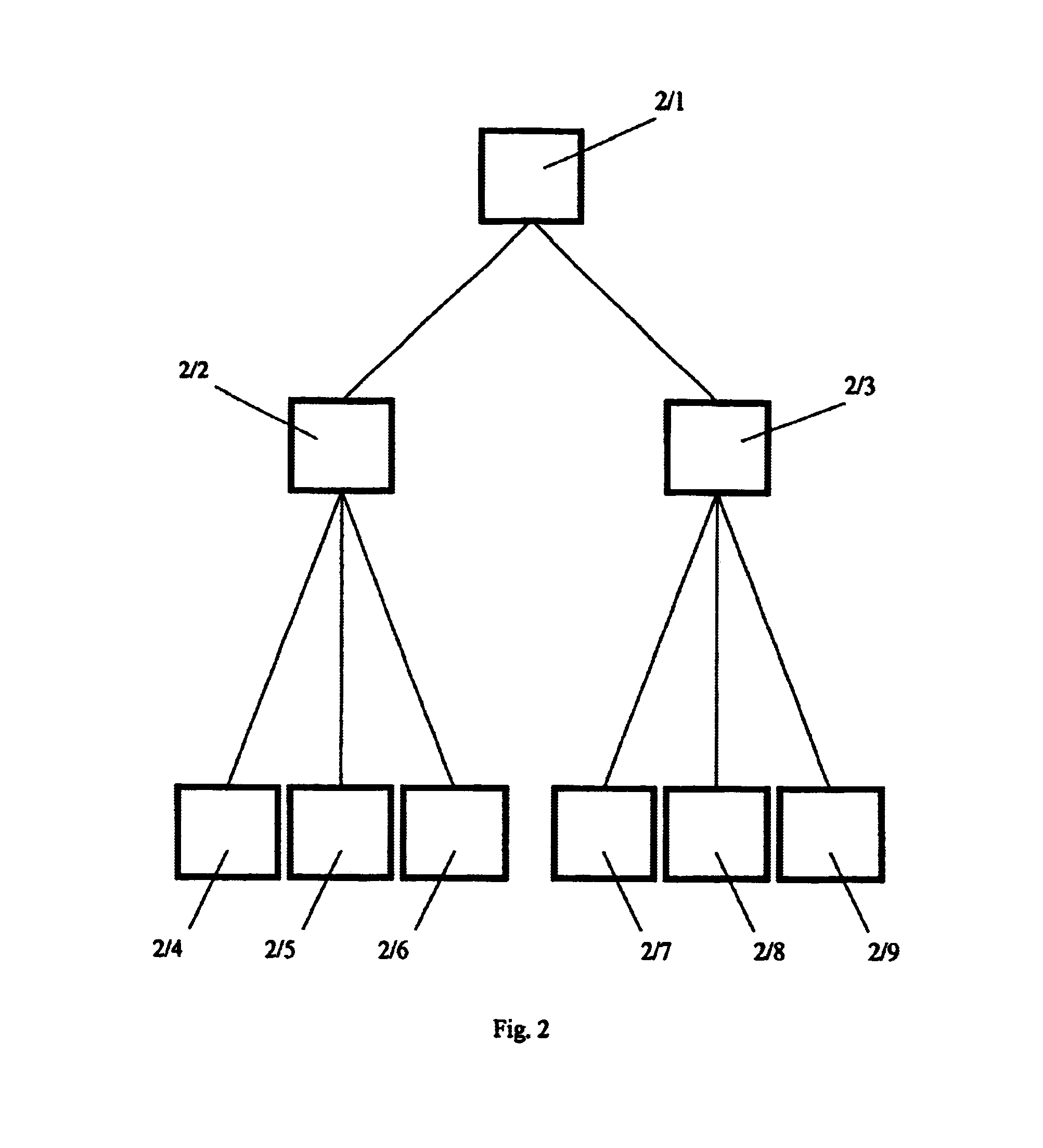

Knowledge-engineering protocol-suite

InactiveUS6952688B1Improve efficiencyExtension of timeKnowledge representationSpecial data processing applicationsEnsemble simulationControl communications

A Knowledge-Engineering Protocol-Suite is presented that generally includes methods and systems, apparatus for search-space organizational validation, and appurtenances for use therewith. The protocol-suite includes a search-space organizational validation method for synergistically combining knowledge bases of disparate resolution data-sets, such as by actual or simulated integrating of lower resolution expert-experience based model-like templates to higher resolution empirical data-capture dense quantitative search-spaces. Furthermore, from alternative technological vantages, the suite relates to situations where this synergetic combining is beneficially accomplished, such as in control systems, command control systems, command control communications systems, computational apparatus associated with the aforesaid, and to quantitative modeling and measuring tools used therewith. The protocol-suite also includes facile algorithmic tools for use with the method and a process-modeling computer for use in a distributed asynchronous system of process modeling computers.

Owner:ADA ANALYTICS ISRAEL

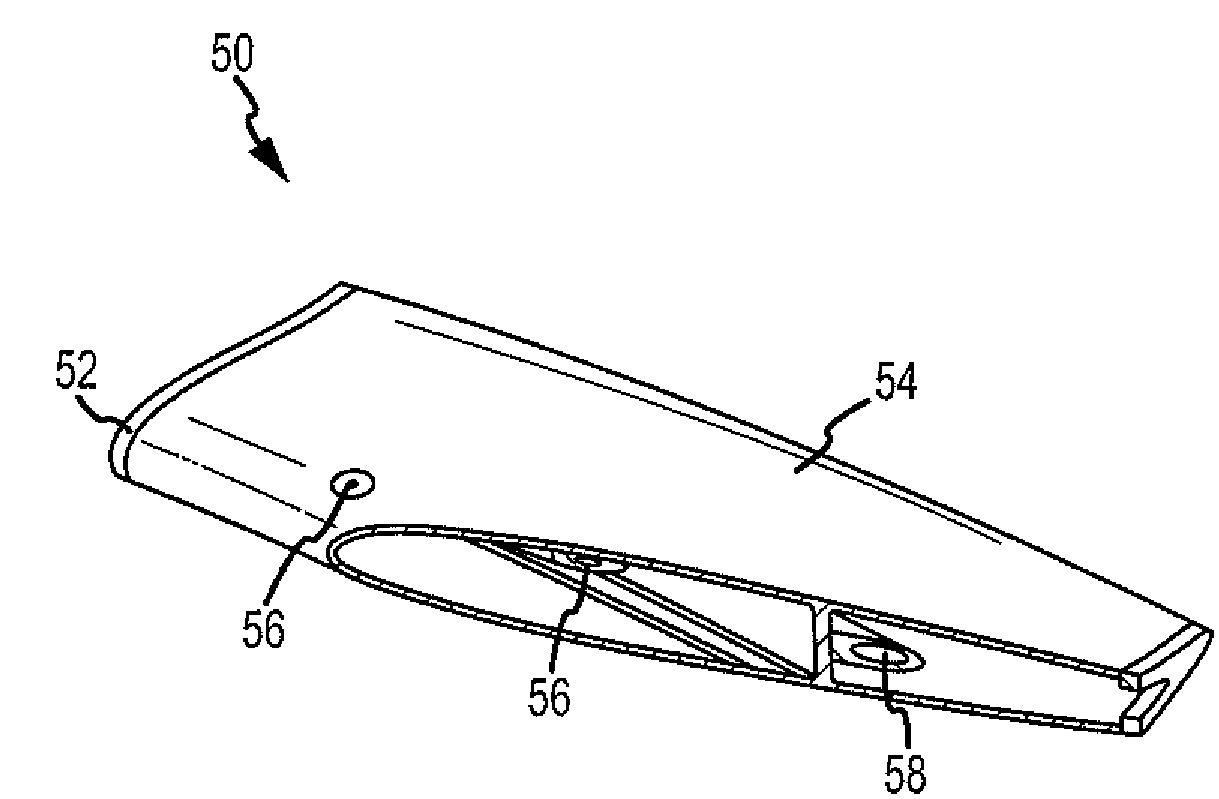

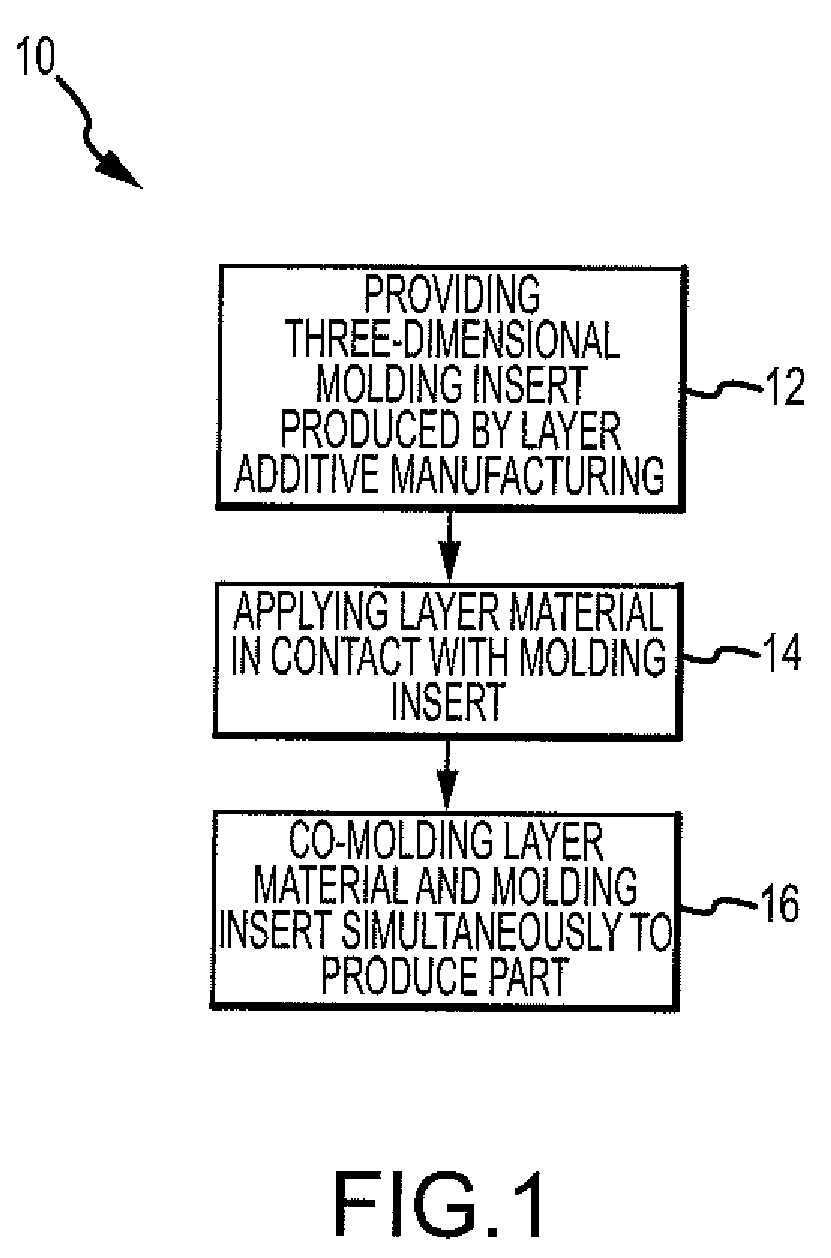

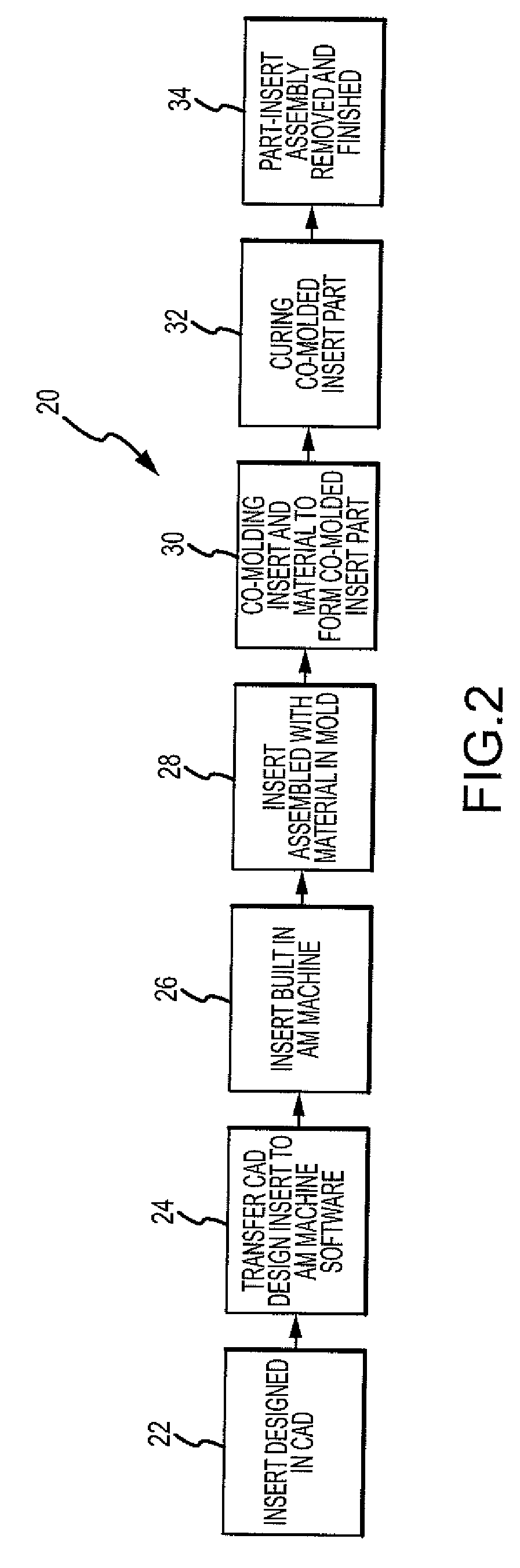

Method of manufacturing co-molded inserts

ActiveUS8383028B2Little costsLittle timeAdditive manufacturing apparatusLamination ancillary operationsMaterials scienceMetal

A method for manufacturing a co-molded insert part for use in composite, plastic, or metal parts is disclosed. The method comprises the step of providing a three-dimensional molding insert produced by a layer additive manufacturing process. The method further comprises the step of applying a layer material in contact with at least a portion of the molding insert. The method further comprises the step of co-molding the layer material and the molding insert simultaneously to produce a co-molded insert part.

Owner:THE BOEING CO

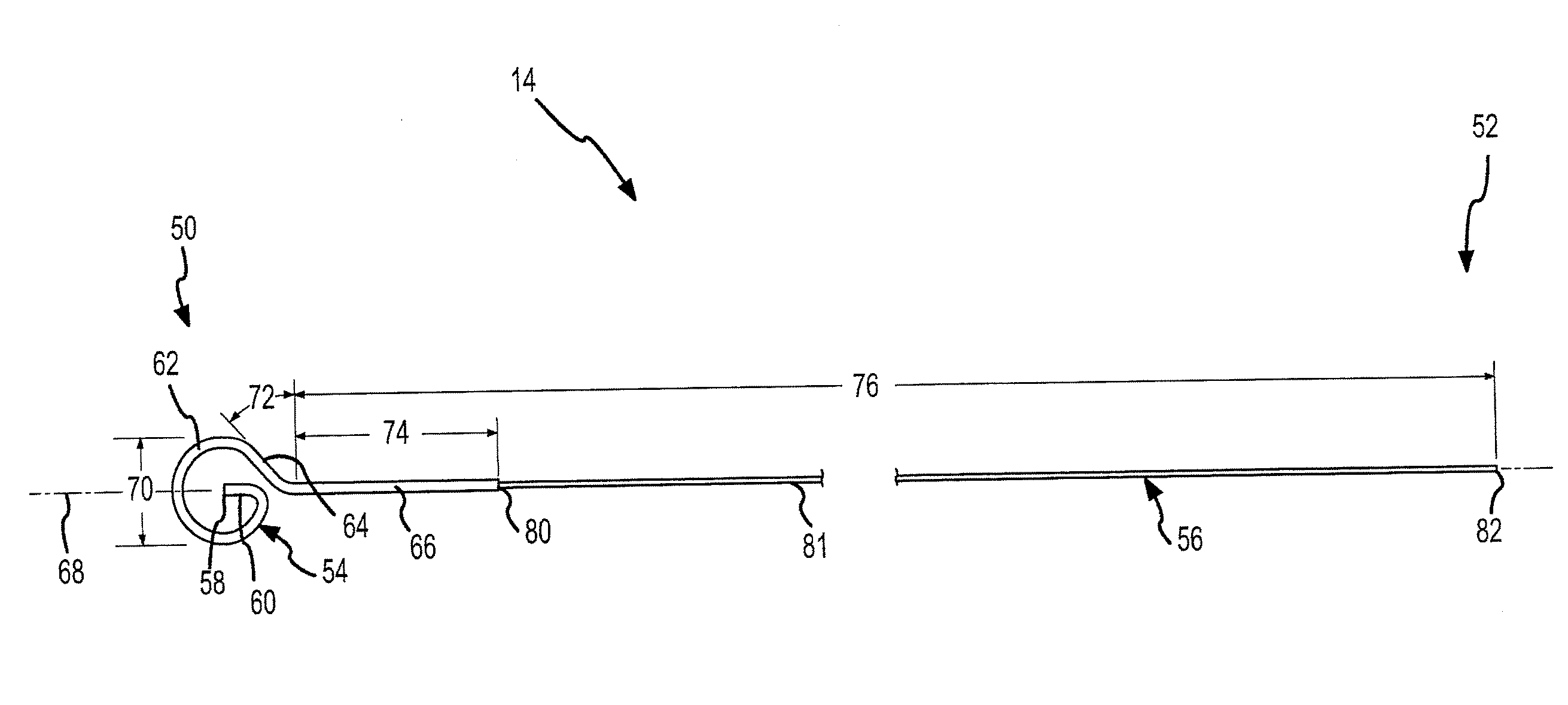

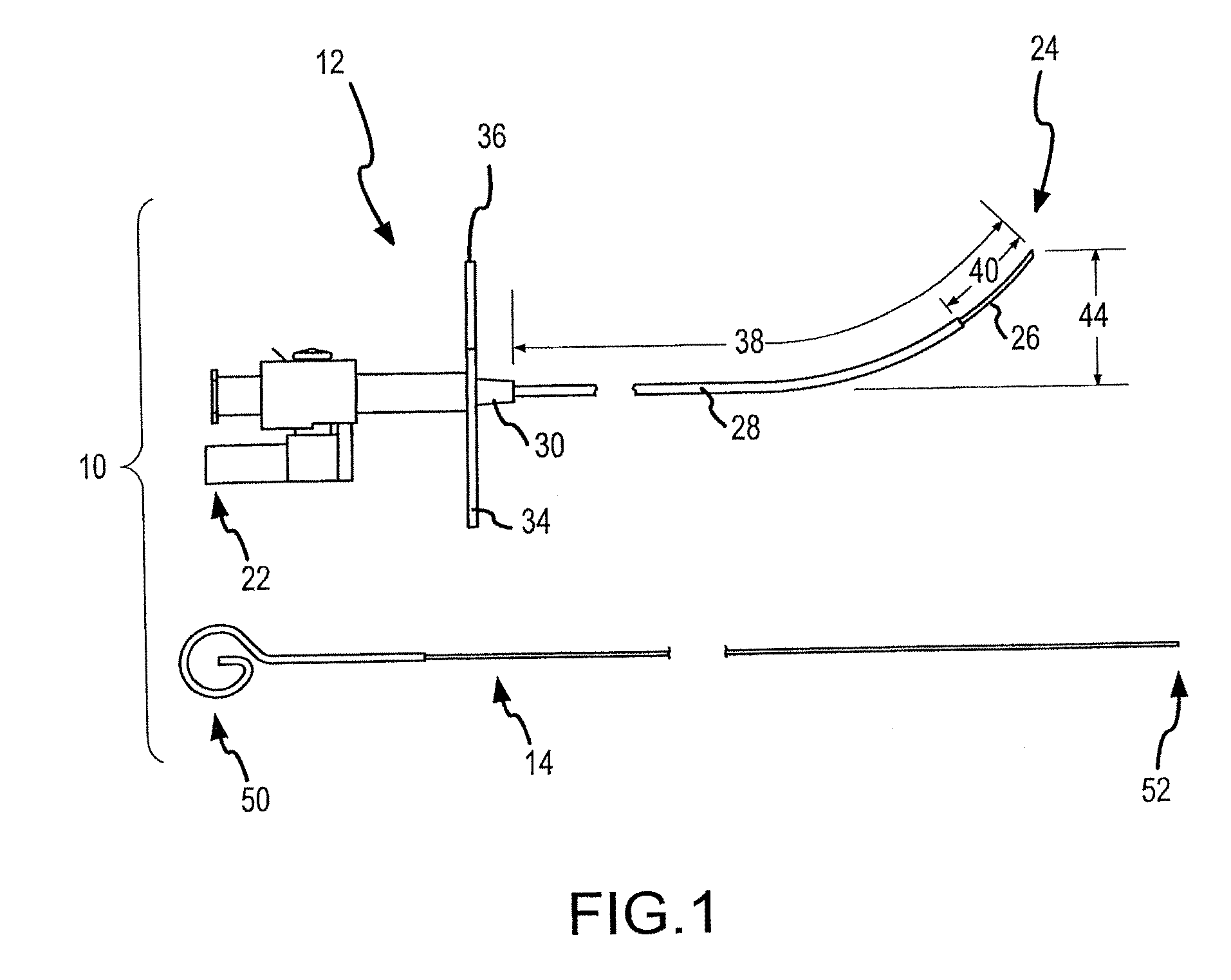

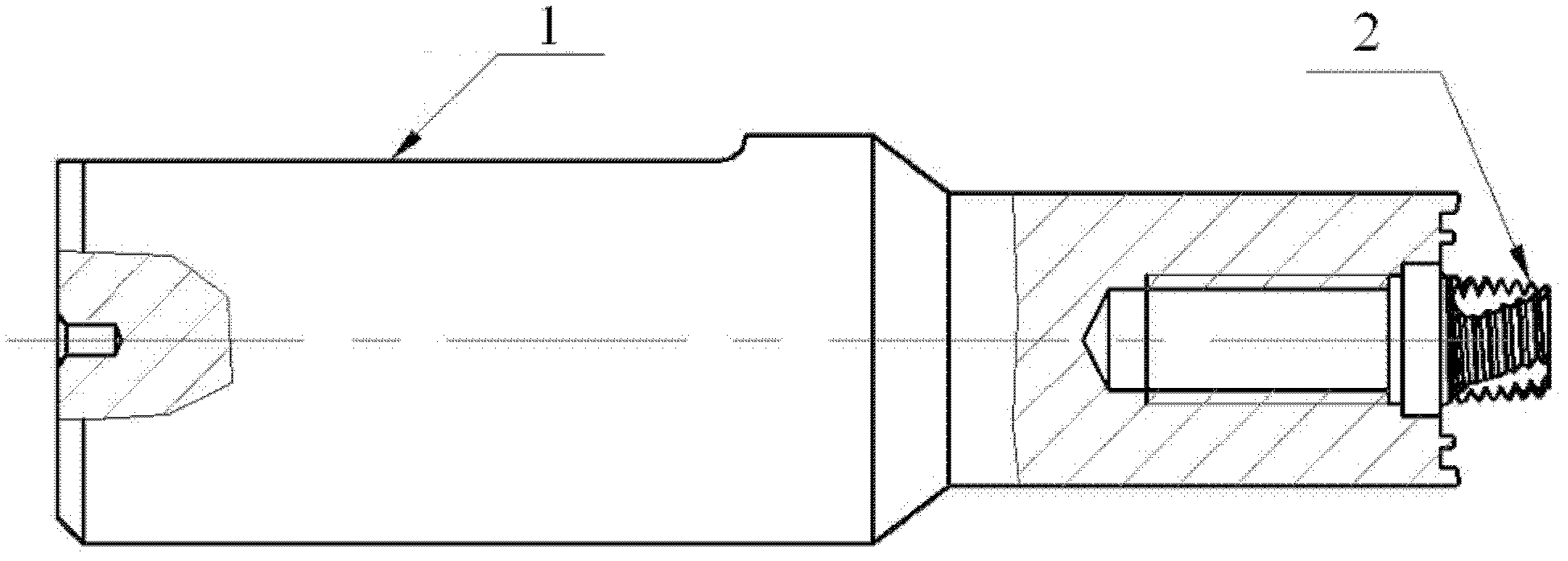

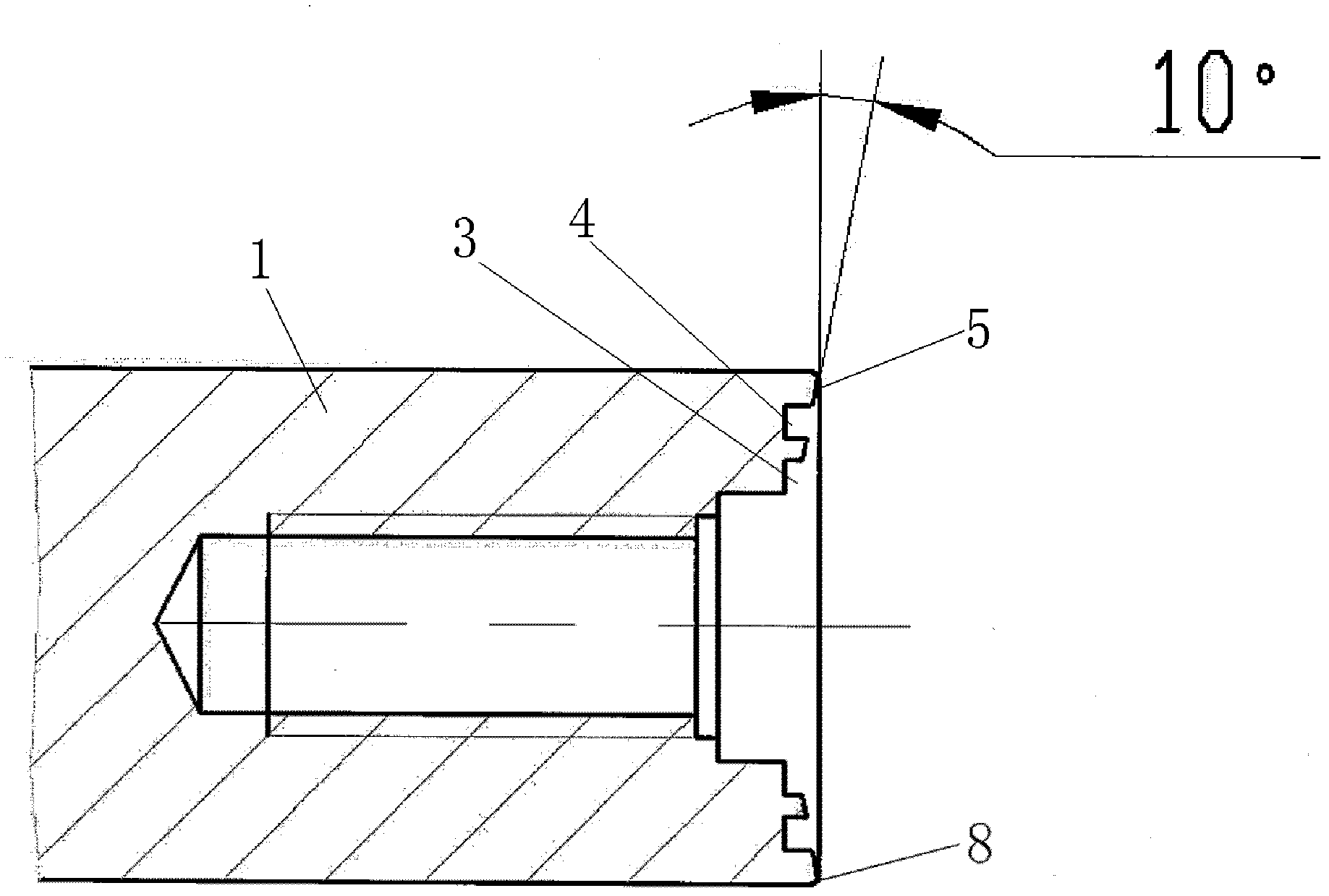

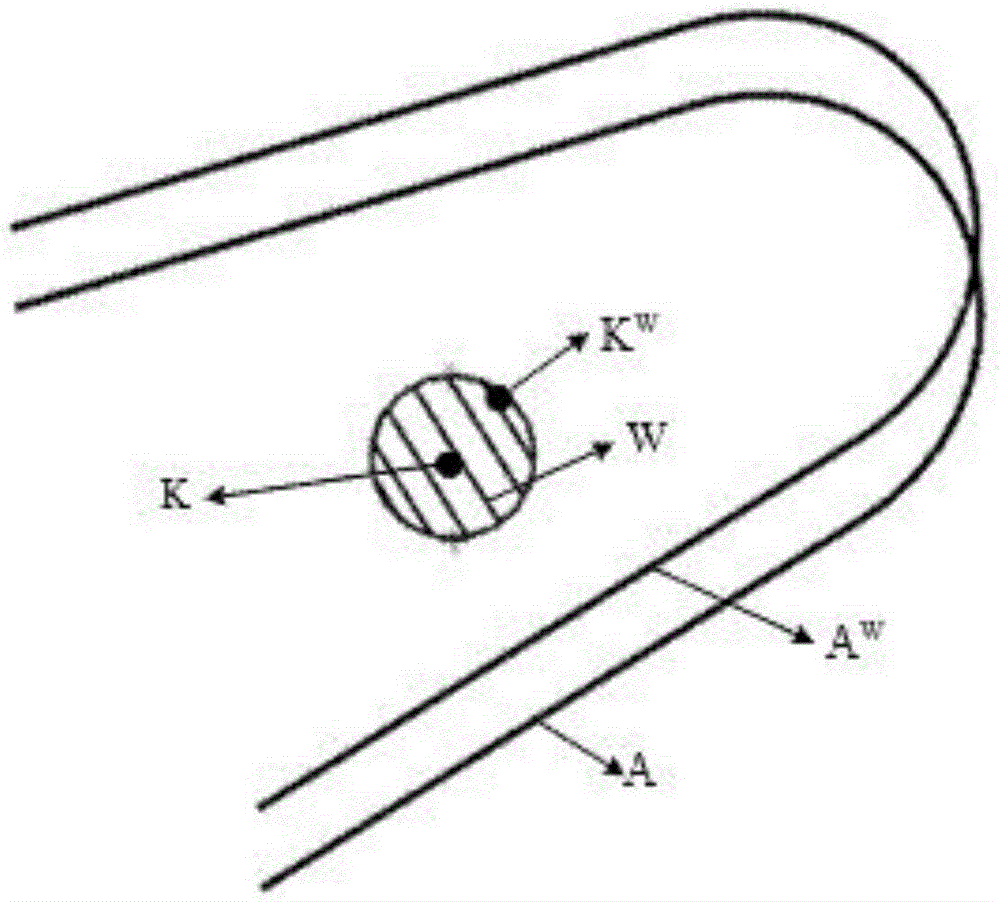

Transseptal Puncture Needle and Needle Assemblies

ActiveUS20090171276A1Lower insertion forceRisk minimizationGuide needlesDiagnosticsWedge angleProximate

A transseptal needle includes an elongate needle body having a distal end and a proximal end and a cannular needle tip located proximate the distal end of the needle body. The needle tip has a distal segment, a proximal segment, and a longitudinal axis. An inner surface of the needle tip defines a passageway spanning at least a portion of the needle tip, and an outer surface of the needle tip defines a wall with the inner surface. The distal segment of the needle tip also includes a wedge surface and a dome-shaped region. The wedge surface forms a wedge angle of other than 90 degrees relative to the longitudinal axis. The dome-shaped region, which intersects the wedge surface, includes at least two bevels that intersect the wedge surface and that intersect each other at one or more points on the needle tip.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

Production process of honey peach CZ diamond

InactiveCN102838277ANo pollution damagePlay a role in fluxingGlass furnace apparatusGlass productionMachine toolKiln

The invention relates to a production process of a honey peach CZ diamond. The honey peach CZ diamond comprises the following raw materials in parts by weight: 60-70 parts of SiO2, 0.5-1.5 parts of Al2O3, 0.5-2.5 parts of BaO, 1.5-5 parts of ZnO, 1.0-2.5 parts of B2O3, 3-8 parts of K2O3, 8-15 parts of Na2O, 0.5-1.5 parts of CaO, 0.3-1.5 parts of Se and 0.03-0.3 parts of S. The production process comprises the following steps of: smelting by a hot smelting kiln and classifying; discharging to obtain a CZ diamond bead blank; sequentially carrying out fire polishing by a fire polishing furnace, and grinding by a grinding machine; and grinding a plurality of cutting surfaces of the CZ diamond by a multi-faced grinding machine tool and chemically plating to obtain a CZ diamond finished product.

Owner:JIANGSU JINCHENG GRP TECH

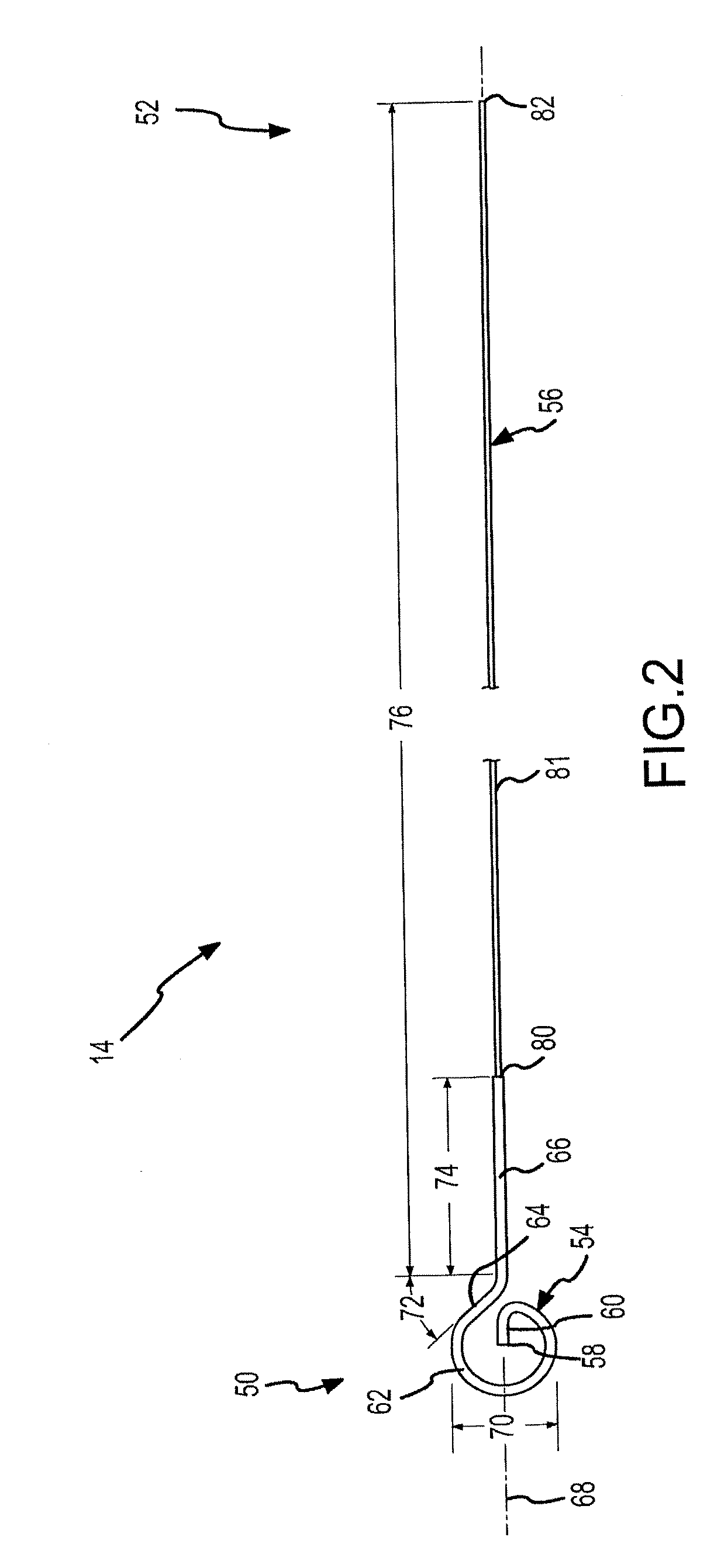

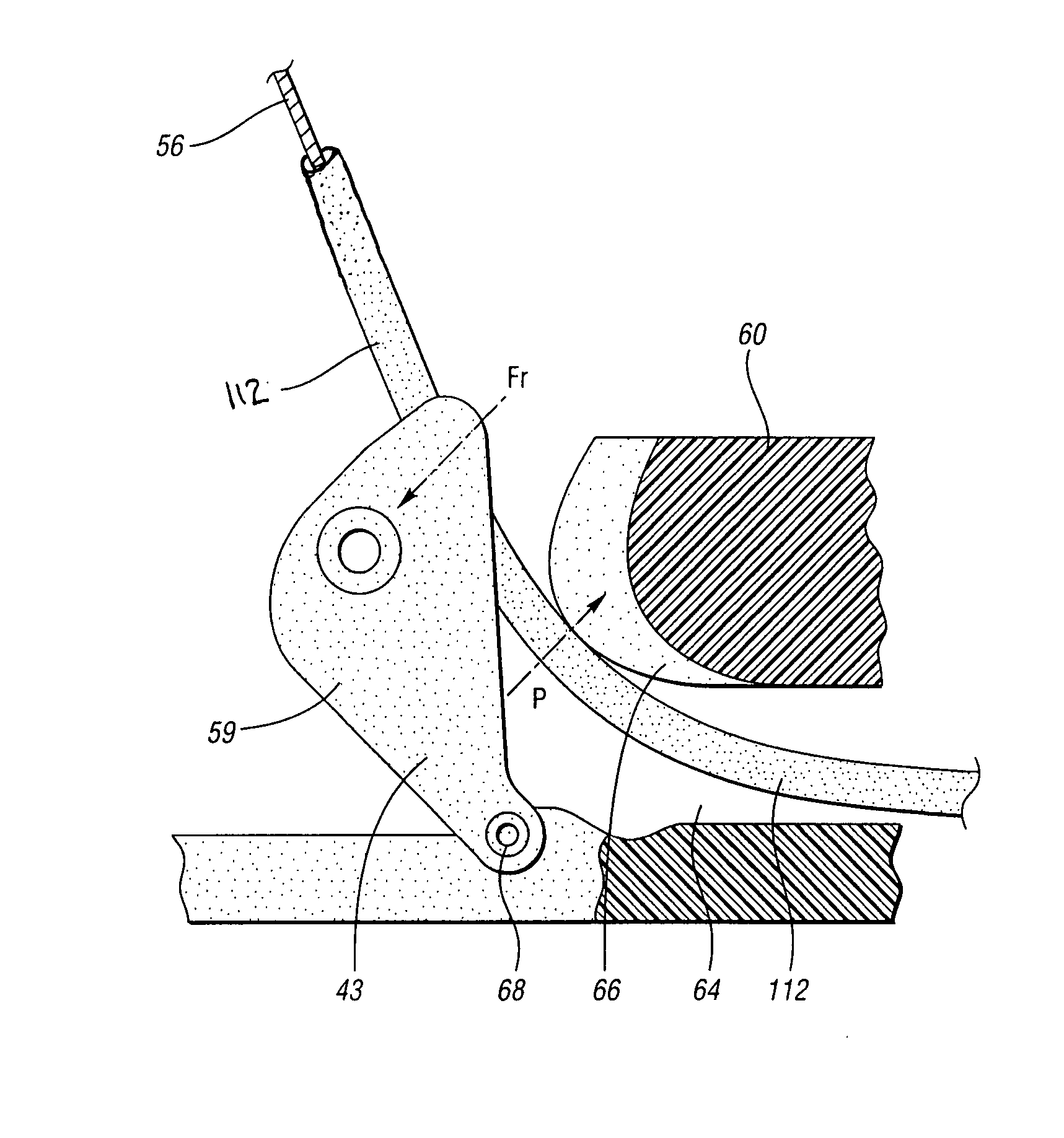

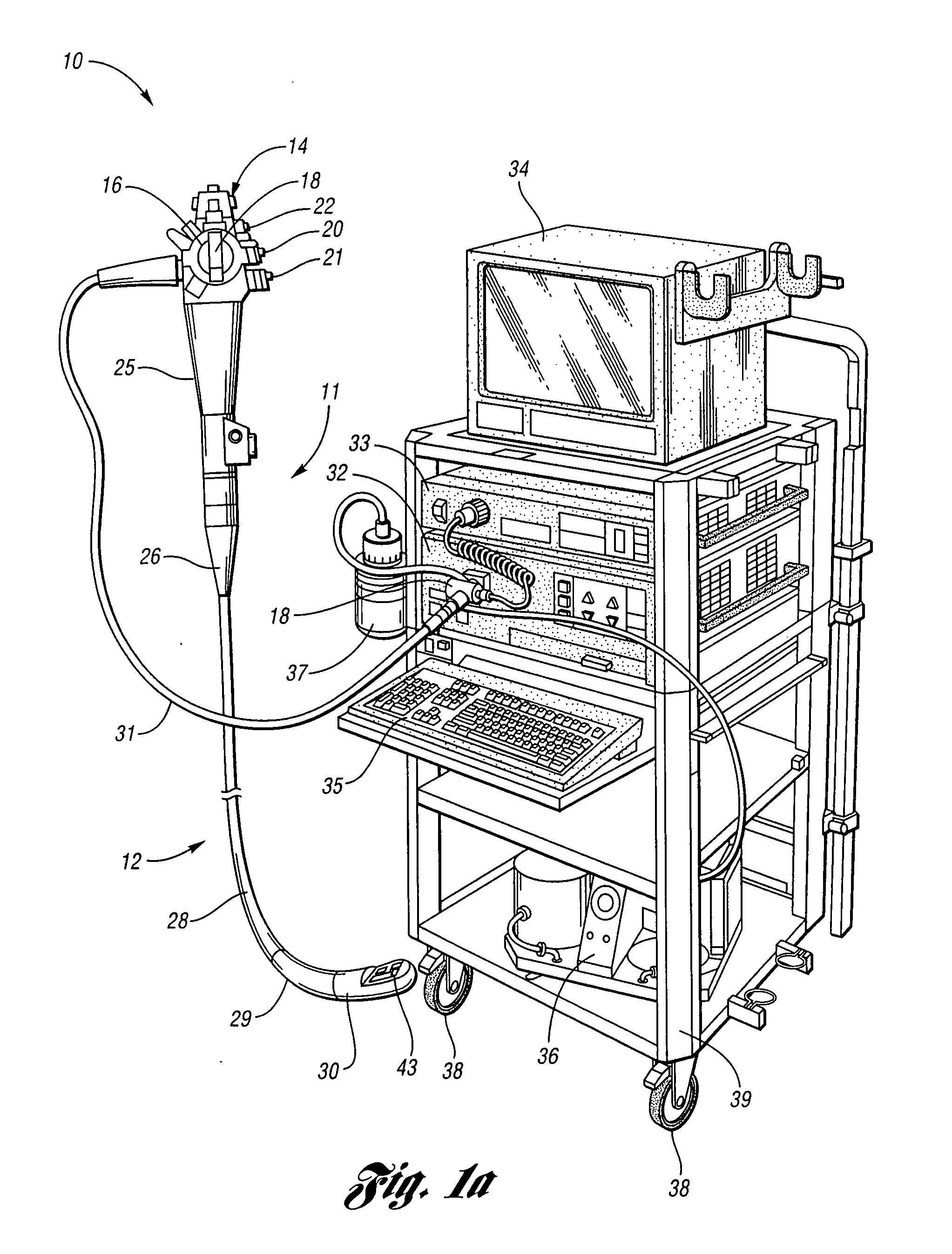

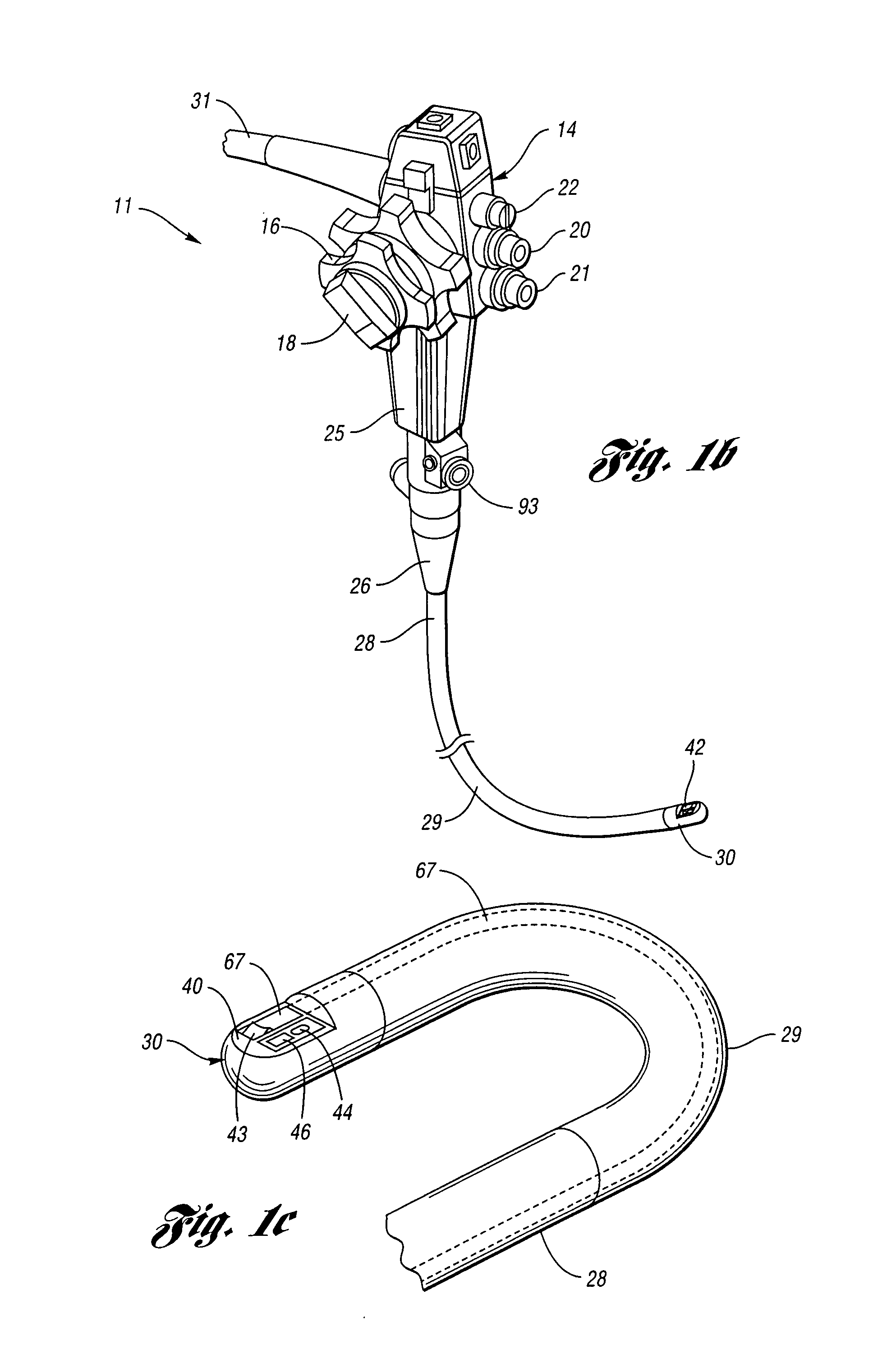

Endoscopic elevator apparatus

An endoscopic elevator apparatus cooperable with an insertion tube extending to a distal tip and having enhanced grasping and reduced scraping of an elongate medical device is disclosed. The apparatus comprises an elevator movably attached to the distal tip. The elevator has an inner side formed thereon defining a grasping slot for engagement with the endoscope. The elevator has a surface projection disposed thereon for inhibiting damage to the elongate medical device.

Owner:COOK MEDICAL TECH LLC

Linear suspension spring

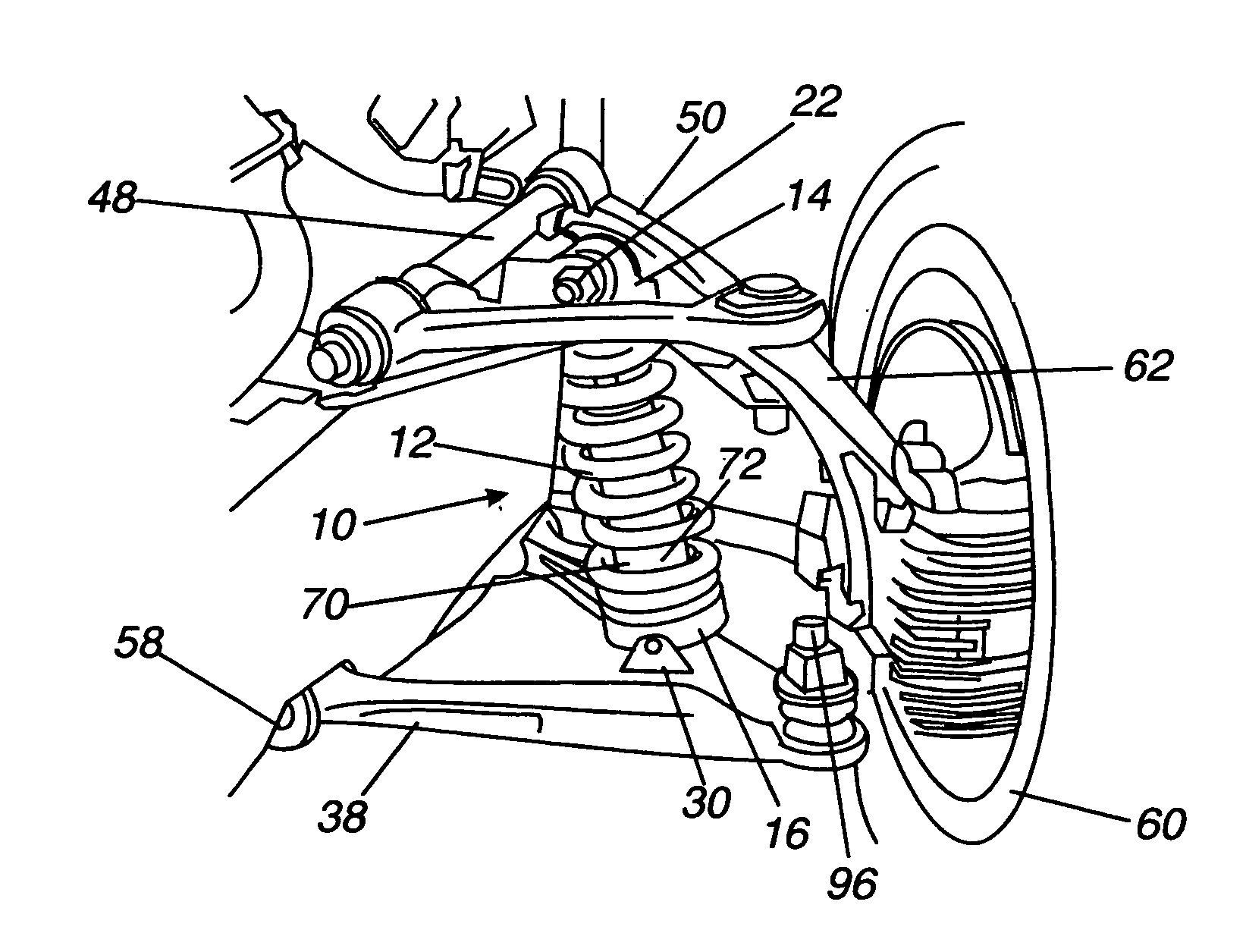

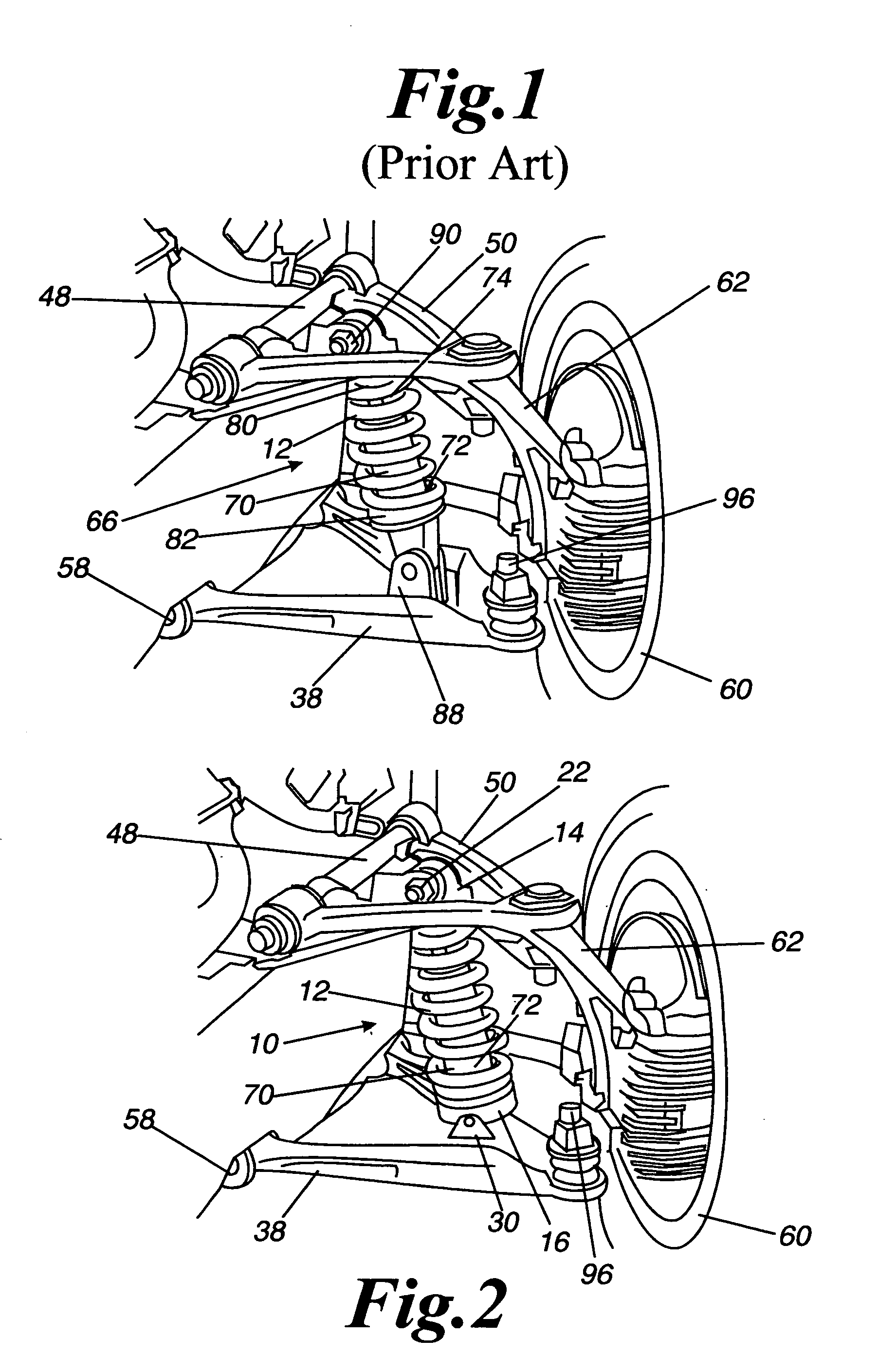

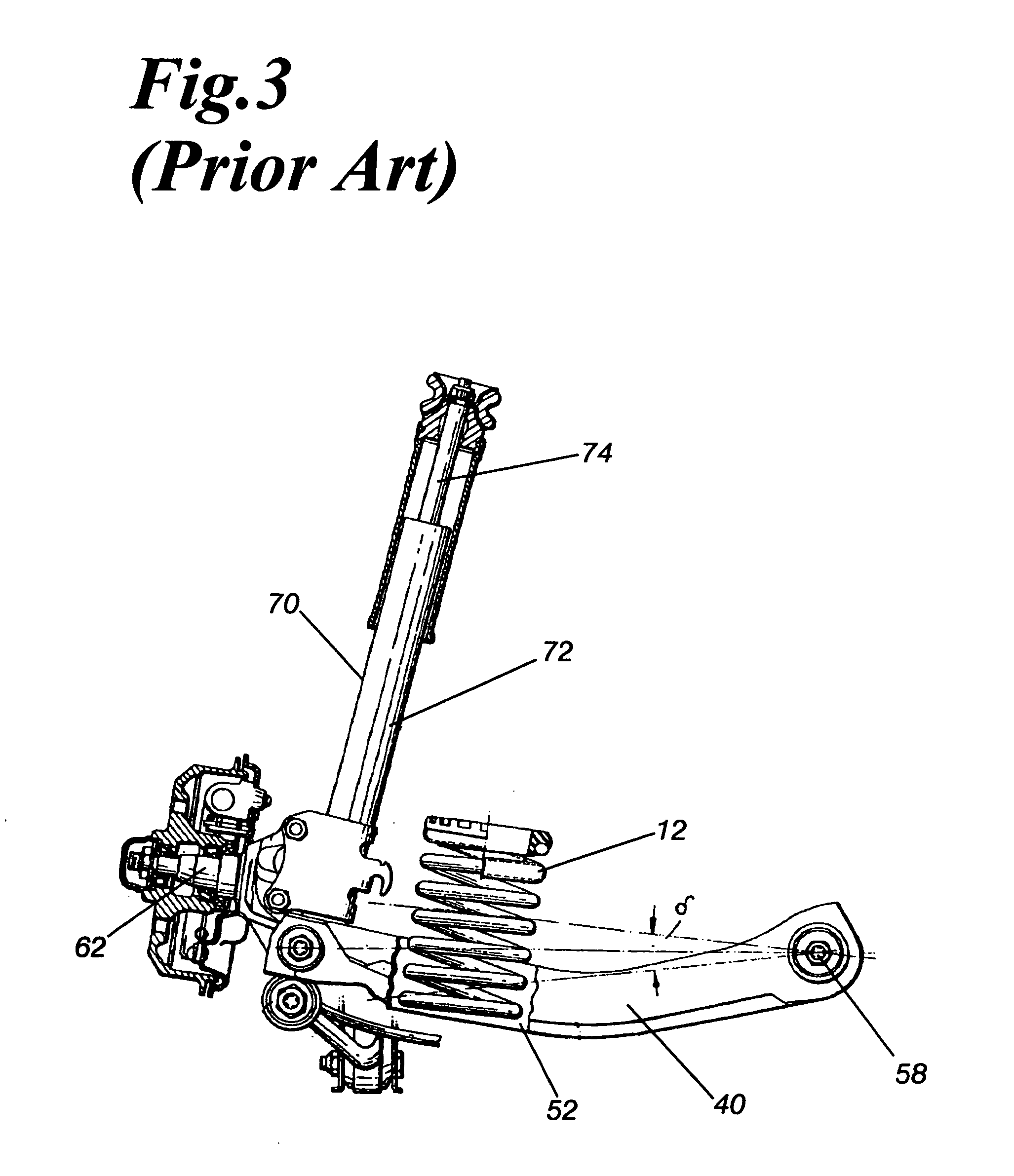

InactiveUS7185903B2Suppress noiseReduce scrapResilient suspensionsPivoted suspension armsControl armEngineering

The invention is a suspension spring apparatus for a vehicle wherein the suspension spring maintains a linear alignment irrespective of the position of the articulating strut, where the articulating strut is selected from the group consisting of: control arms, axle arms, solid axles, adjustable spring tensioning devices, and longitudinal struts. The apparatus is comprised of a compression spring mounted between a pivoting lower seat and a pivoting upper seat, where the pivoting lower seat is coupled to the articulating strut and the pivoting upper seat is coupled to a support element. The support element is static, and serves to support the suspension system, and to distribute the forces generated by the suspension system. The pivoting lower seat and the pivoting upper seat can, in combination, pivot through substantially the same plane as the articulating strut, such that when there is a change in angle of the articulating strut with respect to the support element there is a commensurate change in the pivoting lower seat and the pivoting upper seat. The compensation maintains the compression spring aligned linearly between the pivoting lower seat and the pivoting upper seat. Compression and expansion occurs along the centerline of the spring, and there is no transverse curvature, or other deformation of the spring.

Owner:DOVE JASON L

Fast repairing method of internal screw

The present invention relates to mechanical repair technology, and is especially fast internal thread repairing process. The fast internal thread repairing process includes the following steps: 1. reaming the thread hole with worn thread; 2. machining internal thread sleeve with internal thread fitting the available screw bolt and outer diameter fitting the reamed hole; and 3. fixing the internal thread sleeve into reamed hole in the workpiece firmly. The said repair process can repair worn internal thread quickly and avoid discard of workpiece caused by worn internal thread.

Owner:QISHUYAN LOCOMOTIVE & ROLLING STOCK WORKS CSR

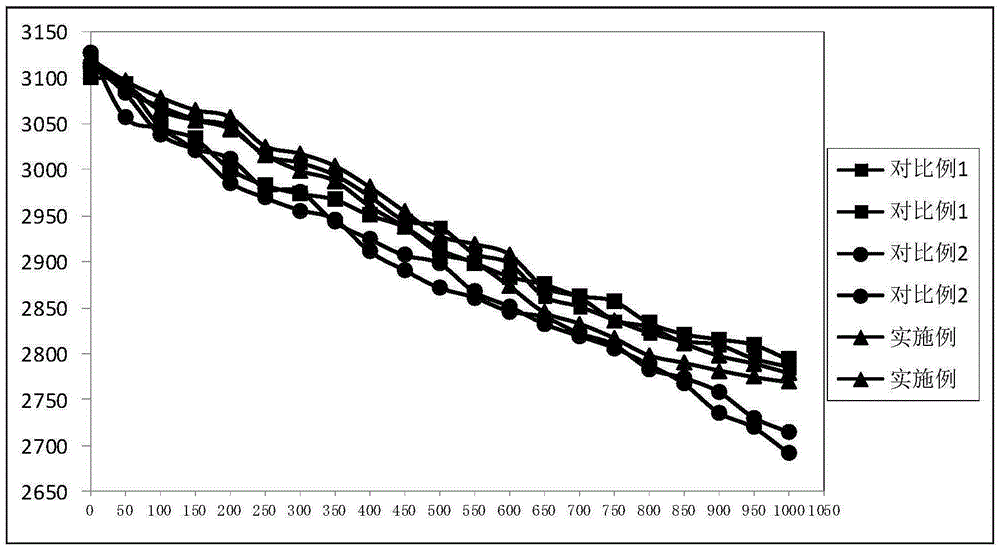

Formation method of lithium ion battery

ActiveCN105406129AConsistent thicknessReduce scrapFinal product manufactureSecondary cells charging/dischargingVacuum pumpingPower flow

A formation method of a lithium ion battery comprises the following steps of placing an aged battery in a formation device for formation in a high-temperature pressurized environment, charging by using 0.1-0.5CmA current during charging until to a cut-off voltage of 3.7V, and then charging by using 0.5-2.0CmA current until to a cut-off voltage of 4.0V; increasing the temperature and keeping the pressure unchanged, and carrying out heat preservation and pressure maintaining on the battery; reducing the temperature and the pressure, and cooling the battery; and carrying out vacuum pumping and secondary sealing on the battery subjected to cooling finish, and completing formation. According to the formation method, a battery core is placed in a high temperature and certain pressure condition for large-current charging formation, the processing time is shortened, and the production efficiency is improved; moreover, the contact of an operator to the lithium battery core is reduced, and the cost problems caused by poor appearance, damage and the like are reduced; and the consistencies on the thickness, the capacity and pole piece interface states of the battery are higher, and the cycle ability is improved.

Owner:ZHUHAI COSMX BATTERY CO LTD

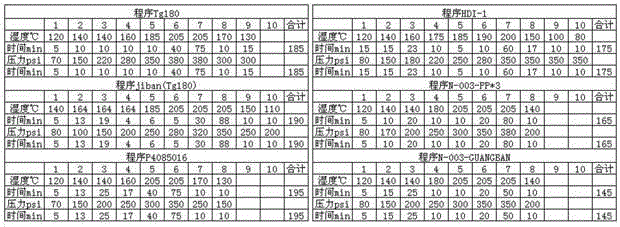

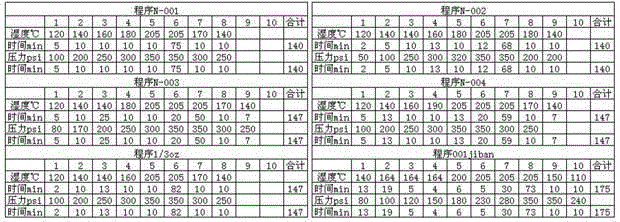

Method for controlling expansion and shrinkage of lamination of multiple layers of boards

InactiveCN103987194AIncrease profitMeet the needs of large typesetting productionMultilayer circuit manufacturePunchingX-ray

The invention relates to a method for controlling expansion and shrinkage of lamination of multiple layers of boards. The method comprises the steps that board incoming quality inspection is conducted, a dimensional stability test is conducted, and a part number is selected according to a test result; according to relevant parameters, an expansion and shrinkage library is established; inner films are produced, and measurement and statistics are conducted on the produced films; punching is conducted on multiple layers of boards which are not laminated; according to the thickness of each board, rivets with appropriate height are selected for riveting; the pattern is adjusted, the lamination conditions are set; lamination is conducted; holes are drilled through an X-RAY target drilling machine. Compared with the prior art, the method for controlling expansion and shrinkage of lamination of the multiple layers of boards has the advantages that the demand for large-composition production is met, production cost is effectively reduced, the utilization ratio of the boards is increased, the production efficiency is improved, and the rejection rate is reduced. Factors influencing control over expansion and shrinkage are controlled, the range of the influence caused by expansion and shrinkage is effectively narrowed, the error rate of drilling is effectively reduced, defective products and scrapped products caused by overall displacement of the multiple layers of boards are reduced, the drilling first-workpiece percent of pass is increased, and halt determination time is shortened.

Owner:奥士康精密电路(惠州)有限公司

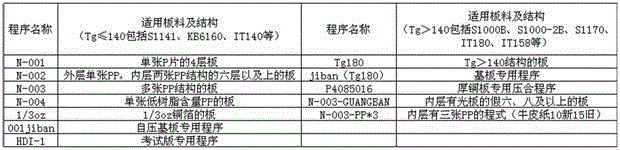

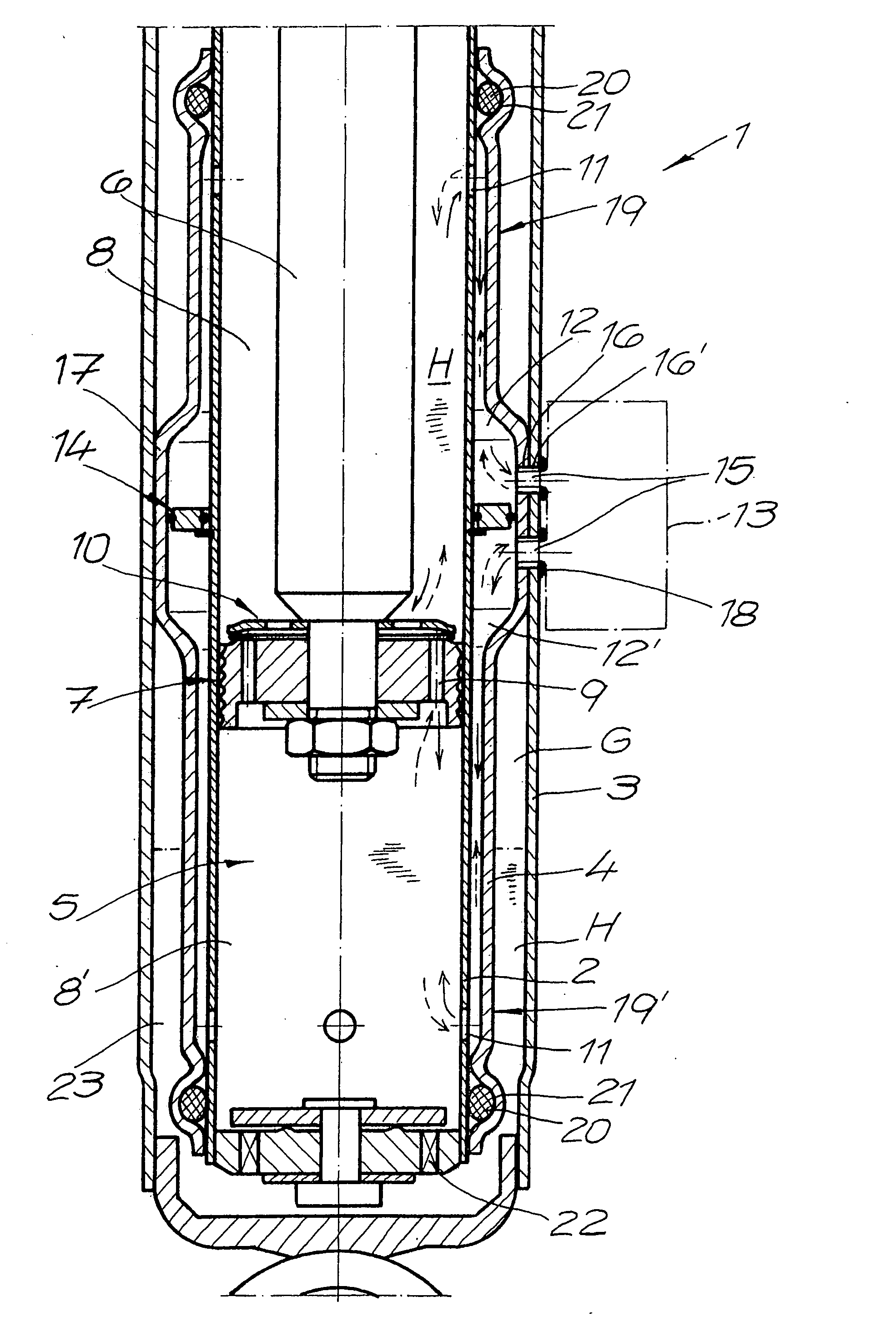

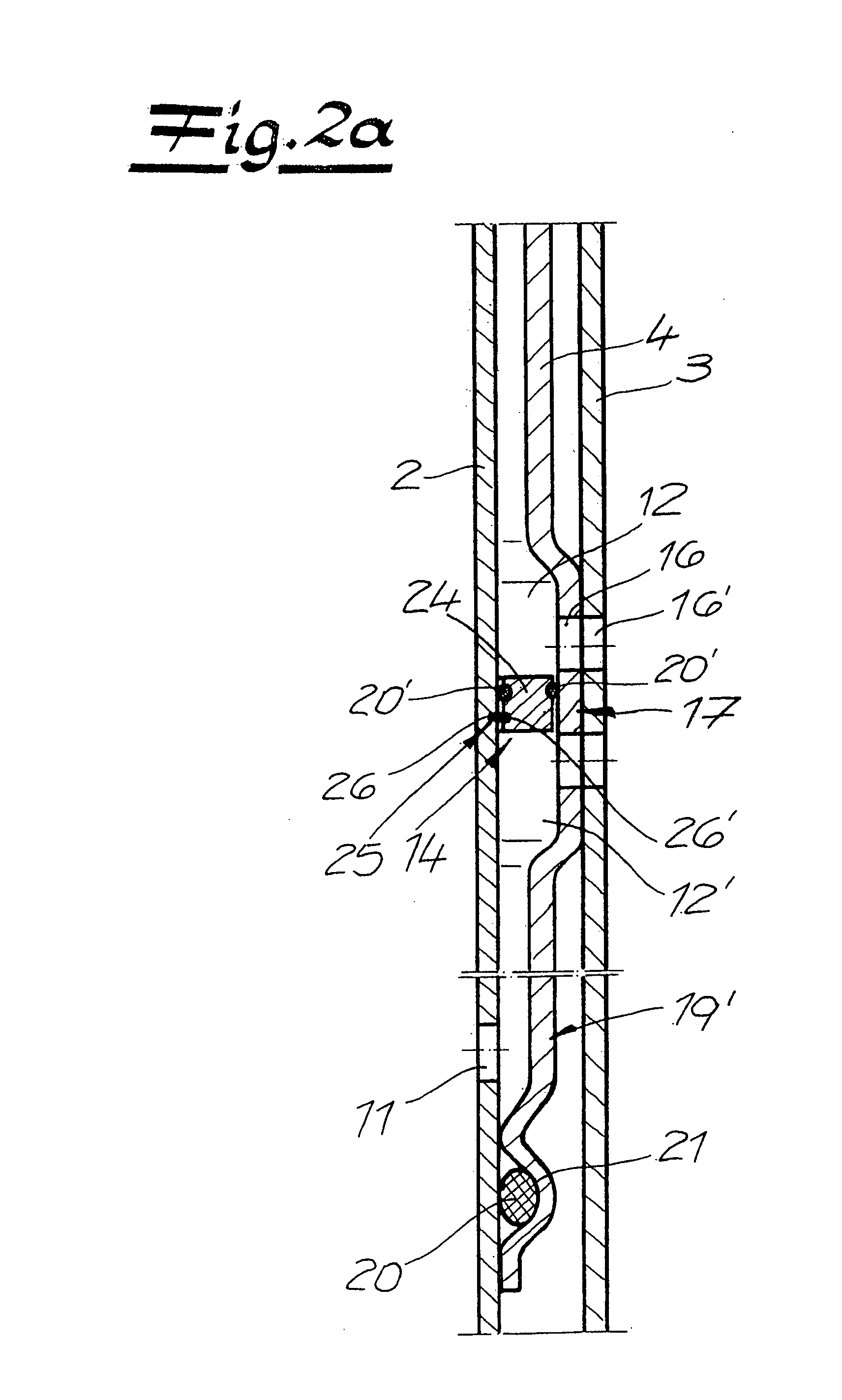

Vibration damper and method for the production of a three-pipe system for a vibration damper

InactiveUS20090120749A1Easy to produceReduce scrapSpringsResilient suspensionsPiston rodSeparation system

A hydraulic vibration damper has an inner pipe, a center pipe, and an outer pipe. A piston on a piston rod is guided to be displaceable in a working space that is formed by the inner pipe. Flow spaces that are hydraulically separated from one another and connected with a valve module are formed between inner pipe and center pipe. The center pipe has a radially projecting formed-out part, at which the center pipe is connected with the outer pipe or the inner pipe, via a press fit. The passage openings of the center pipe and of the outer pipe are disposed in the region of the formed-out part. Also, a separation system for hydraulic separation of the flow spaces is situated in the region of the formed-out part. Also provided is a method for the production of a three-pipe system for a vibration damper.

Owner:THYSSENKRUPP BILSTEIN

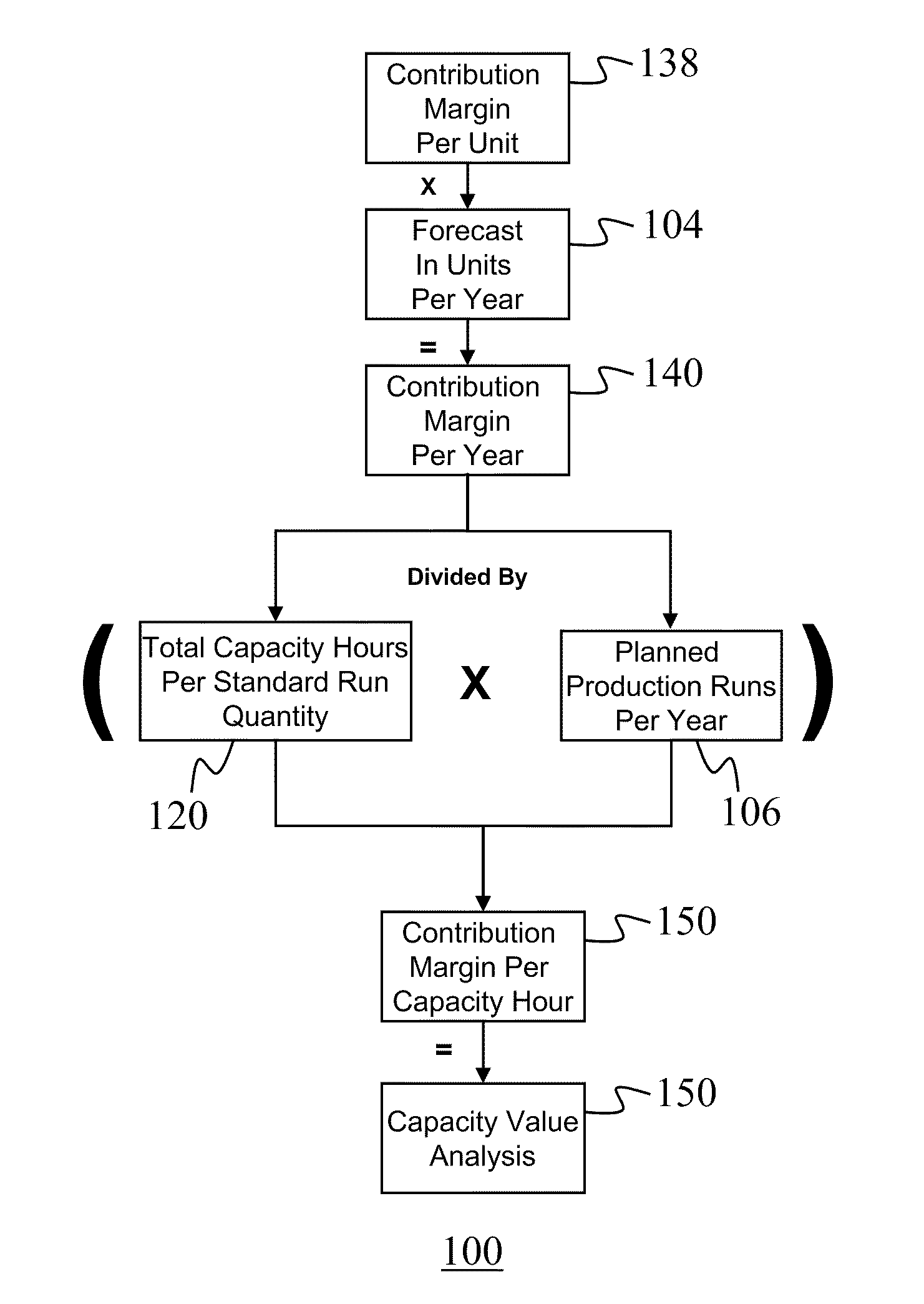

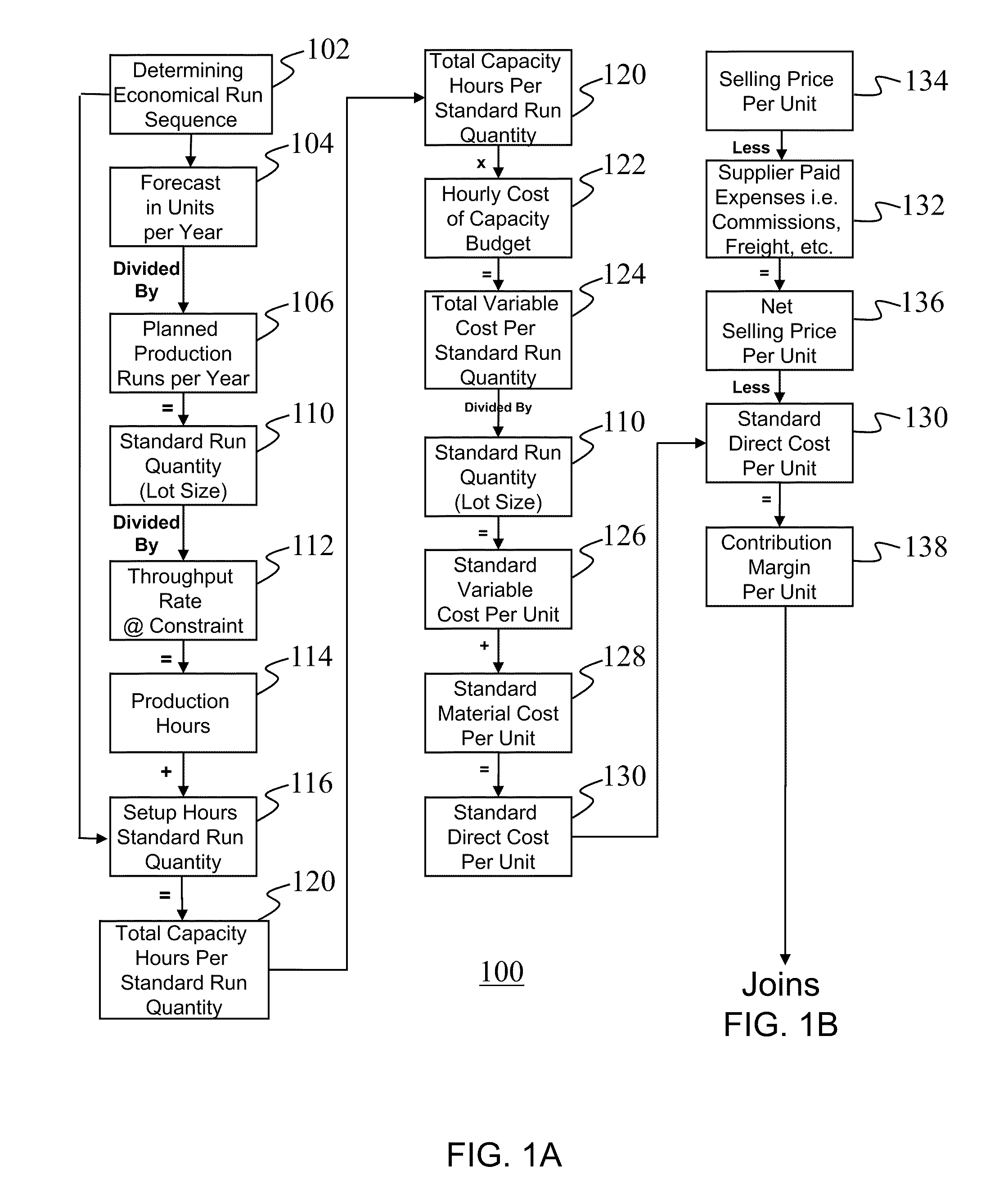

Profit optimizer

InactiveUS20100161383A1Eliminate associated fixed overhead expenseHigh capacity valueForecastingResourcesCapacity valueProfit optimization

A system and method for analyzing the profitability of a company's products and services and then maximizing that profit is provided. A contribution margin per unit 138 is multiplied times the forecast in units per year 104. The product of this contribution margin per unit 138 times the forecast in units per year 104 is divided by the product of the total capacity hours per standard run 120 quantity and the planned production runs per year 106. The result is the contribution margin per capacity hour 150 which is also defined here as the capacity value analysis 150. The capacity value analysis 150 provides for determining product rationalization, and profitable growth determination, as well as a metric for profit optimization initiatives such as eliminating constraints, customer perceived value, design for manufacturability, reduced production frequency, and reduced setup time.

Owner:BUTLER GLEN ORES

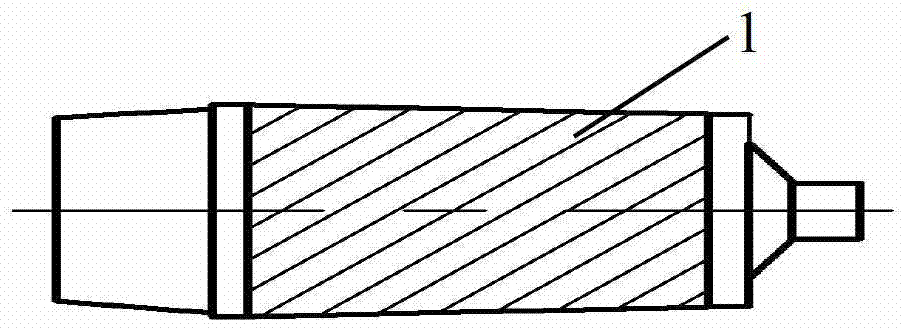

Device and method for repairing friction stir welding weld defect of storage tank for carrier rocket

ActiveCN102581476AGuarantee product qualityReduce scrapNon-electric welding apparatusFilling materialsRocket

The invention provides a device and a method for repairing a friction stir welding weld defect of a storage tank for a carrier rocket. A repair welding pin tool comprises a tool pin clamping structure and a tool pin, the end face of a shaft shoulder portion of the tool pin clamping structure is a recessed slope provided with two concentric-circle annular grooves, the front of the tool pin is of a conical thread structure, and a conical thread is circumferentially provided with three spiral grooves at intervals. The method includes the steps: firstly, manually excavating the tool pin broke at a friction stir welding weld; secondly, performing solid filling for the weld; thirdly, utilizing the repair welding pin tool to start friction stir welding from a center of the broke position of the tool pin filled with welding wires or materials to a set welding end point; and finally, continuing utilizing the repair welding pin tool to perform friction stir welding for the weld again from a welding start point to the welding end point. The method and the device are capable of guaranteeing the quality of the storage tank for the carrier rocket and decreasing scrapping of the storage tank for the carrier rocket due to the key hole type defect.

Owner:CAPITAL AEROSPACE MACHINERY +1

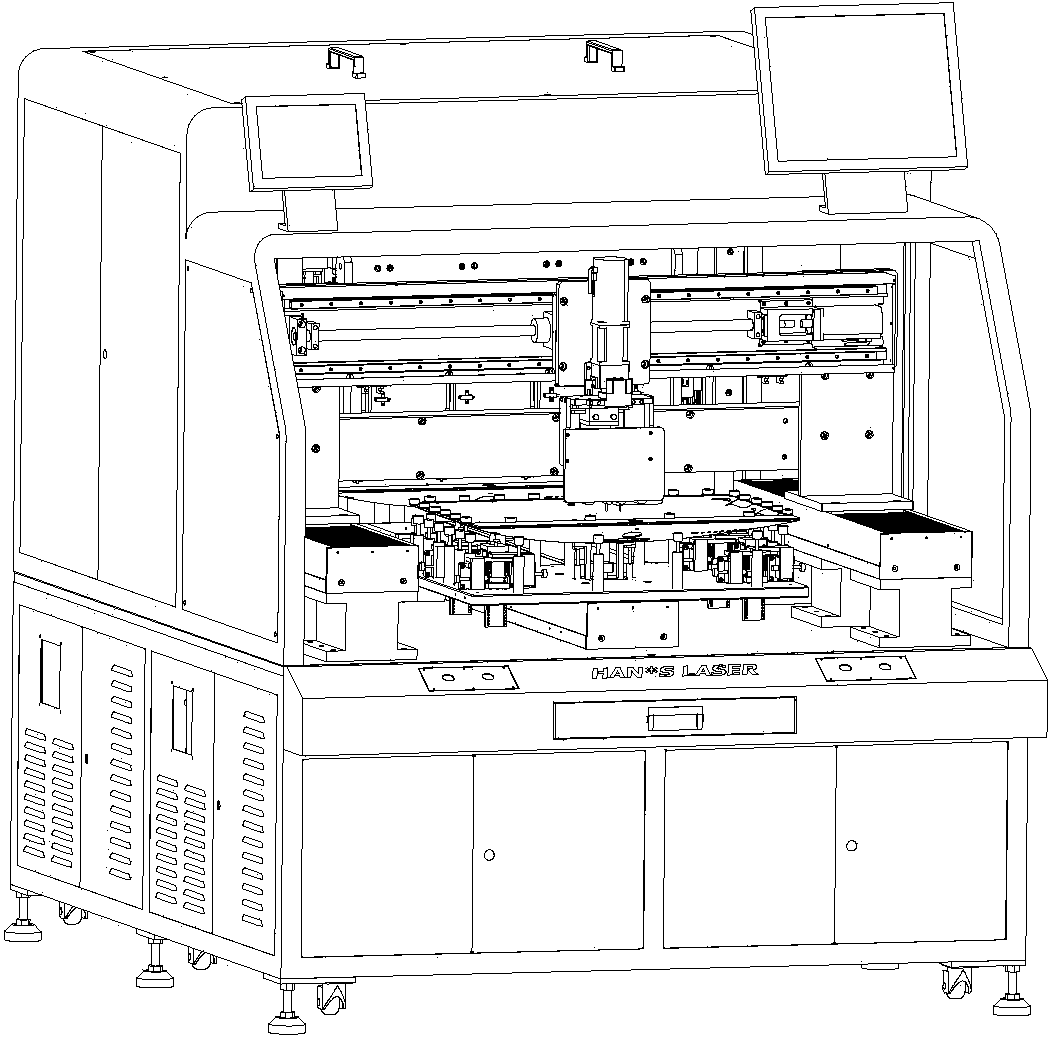

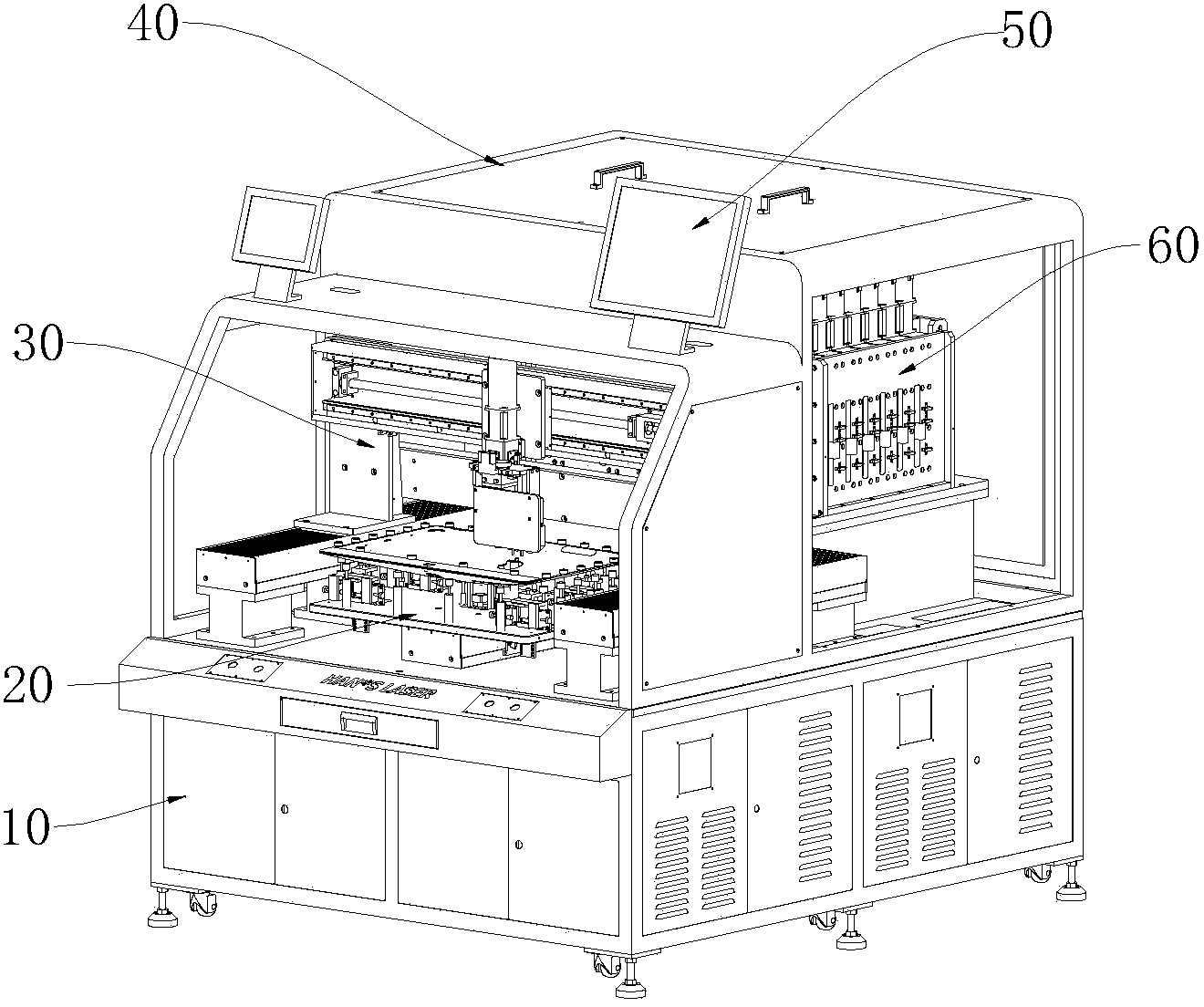

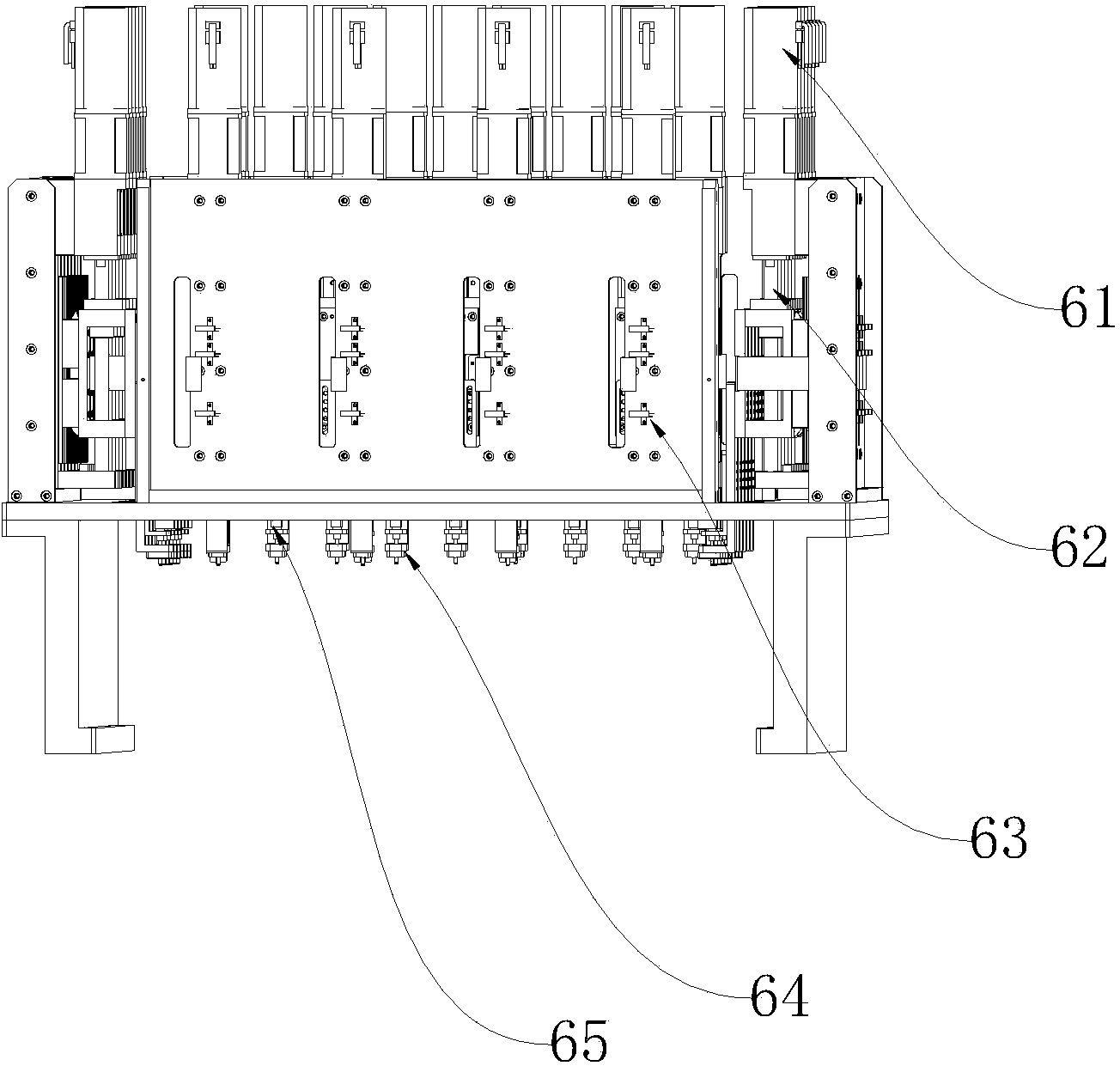

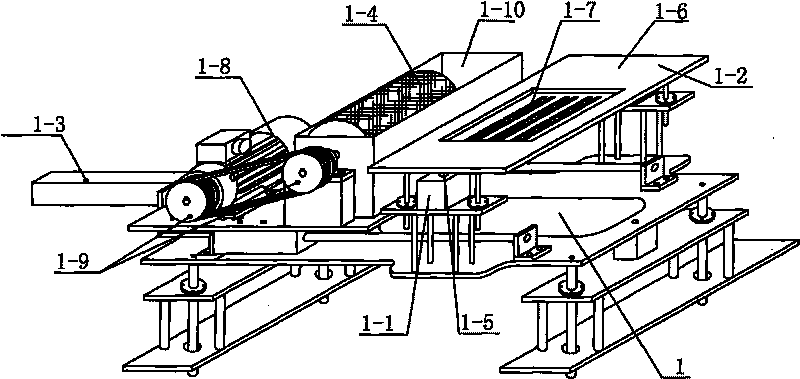

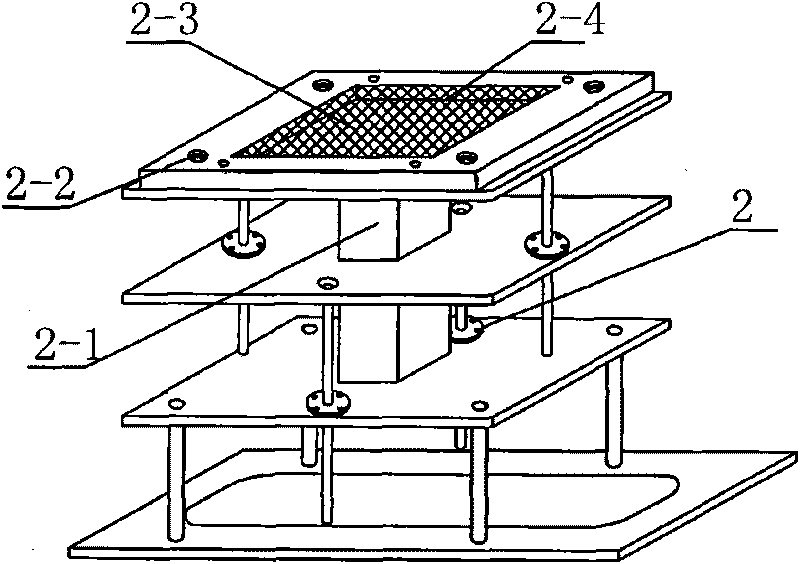

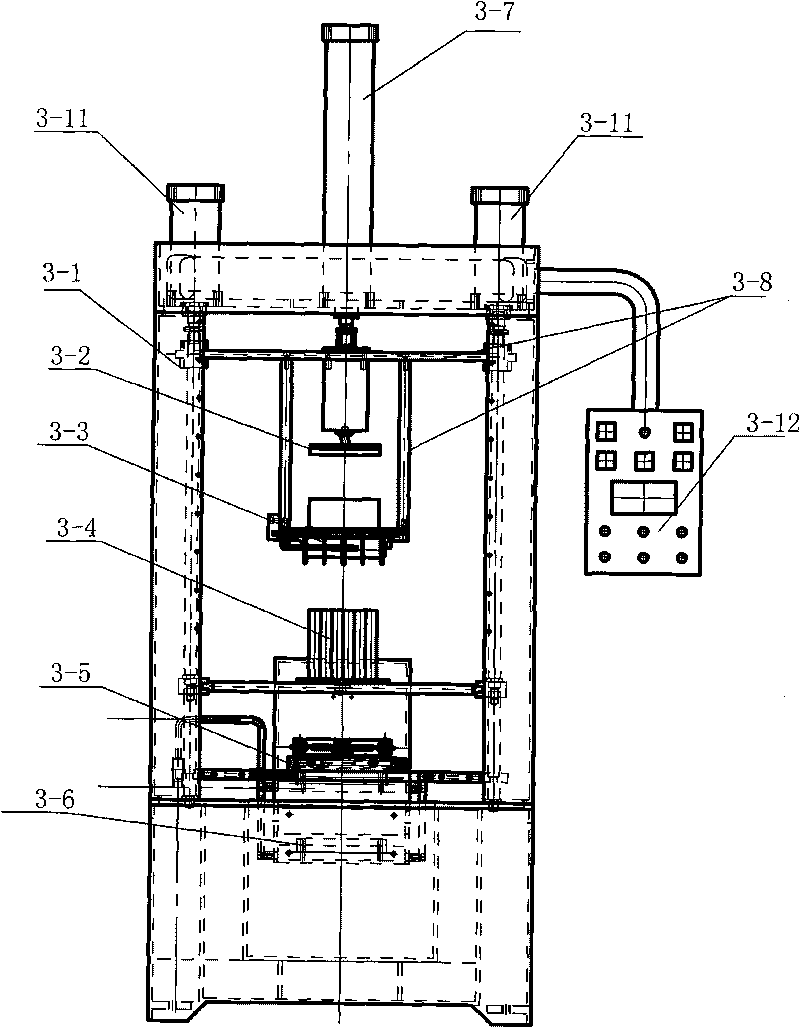

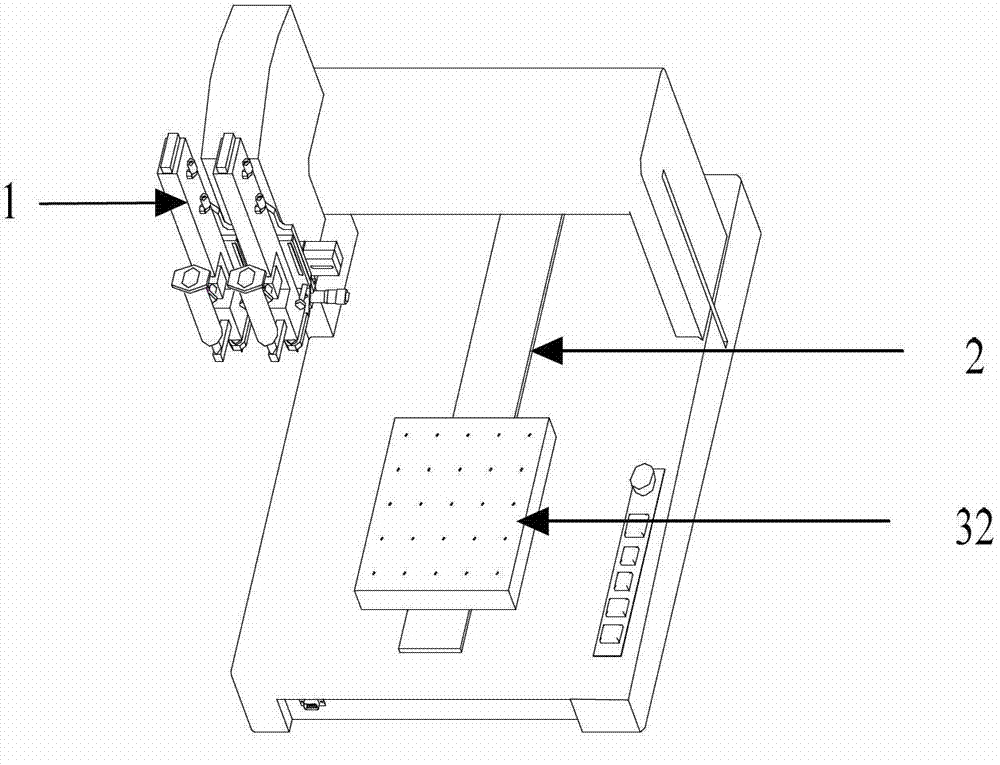

Planeness detection and correction all-in-one machine and detection and correction method

ActiveCN103453858AIncrease productivityImprove detection accuracyUsing optical meansPortal frameCorrection method

The invention relates to a planeness detection and correction all-in-one machine which comprises a machine cabinet assembly, a fixture assembly for clamping a workpiece to be detected and corrected and a control assembly for controlling the detection and correction. The all-in-one machine further comprises a detection assembly and a correction assembly, wherein the detection assembly comprises a portal frame assembly achieving moving on an X axis, a Y axis and a Z axis and a laser displacement sensor, and the correction assembly comprises a correction mechanism and a contact type digital sensor. The detection assembly and the correction assembly are connected with the control assembly to carry out information interaction to achieve the detection and the correction of the planeness. The planeness detection and correction all-in-one machine can detect whether products are qualified or not, can also carry out correction on sub-quality products, and the effects of improving production efficiency, detection precision and the product percent of pass and reducing cost are achieved.

Owner:深圳市大族半导体装备科技有限公司

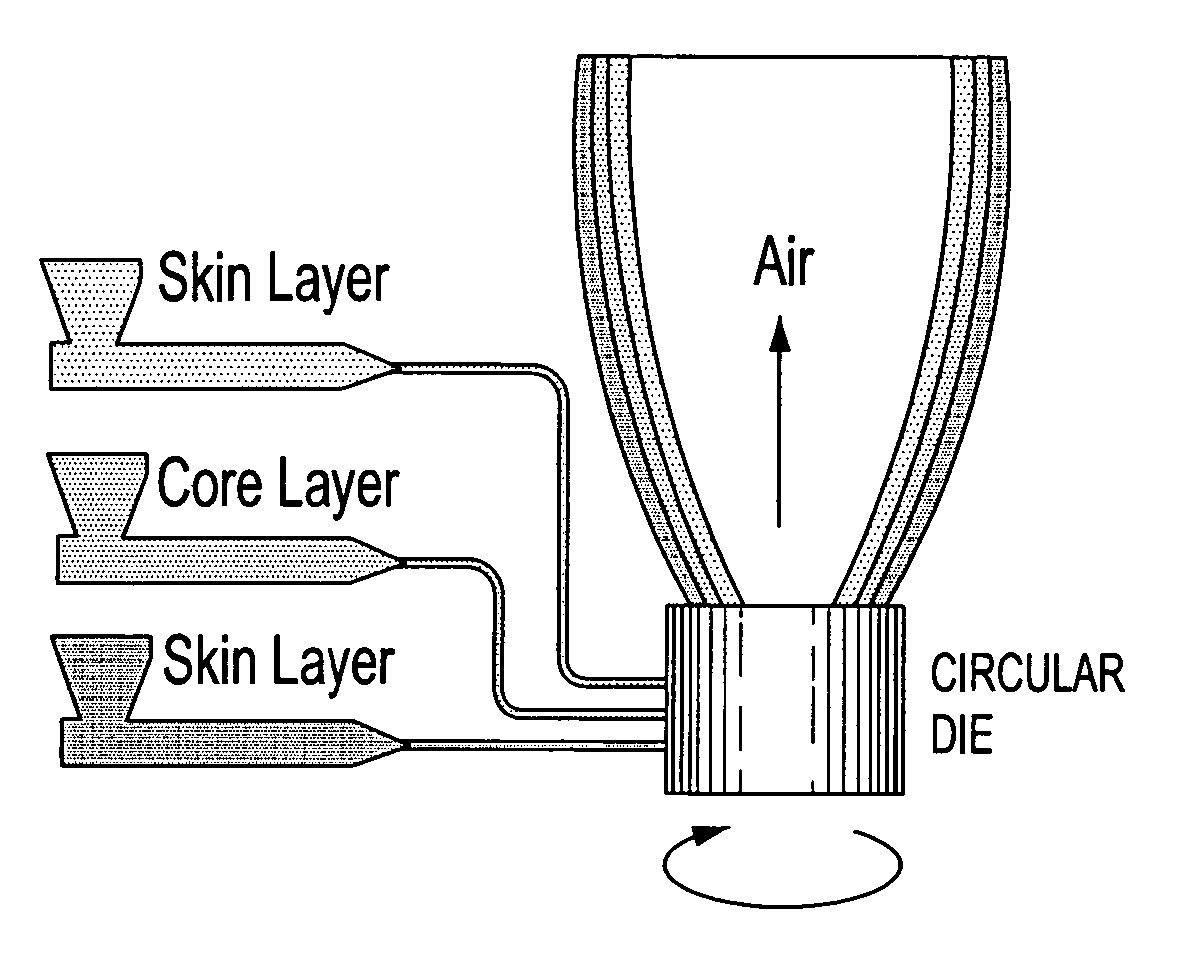

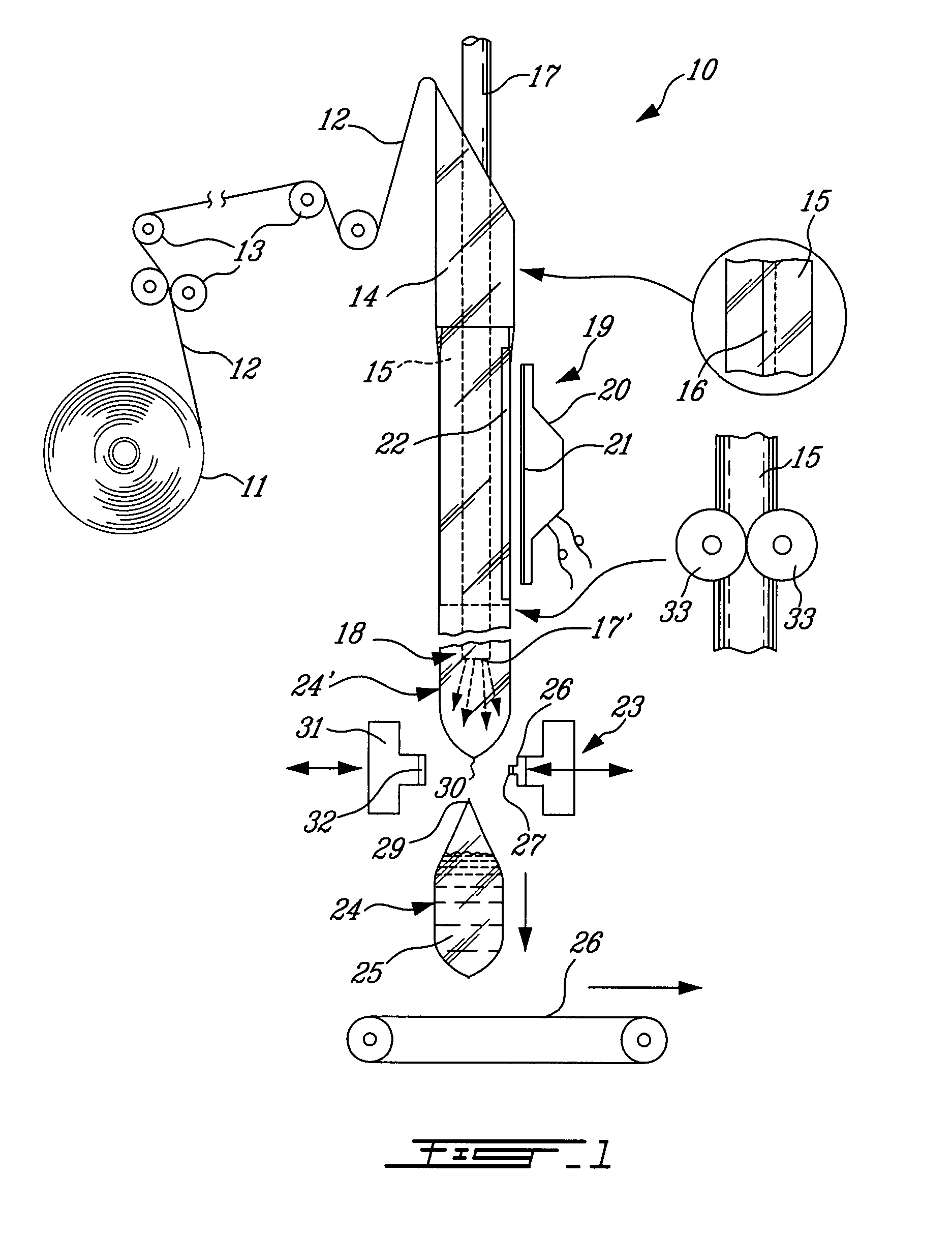

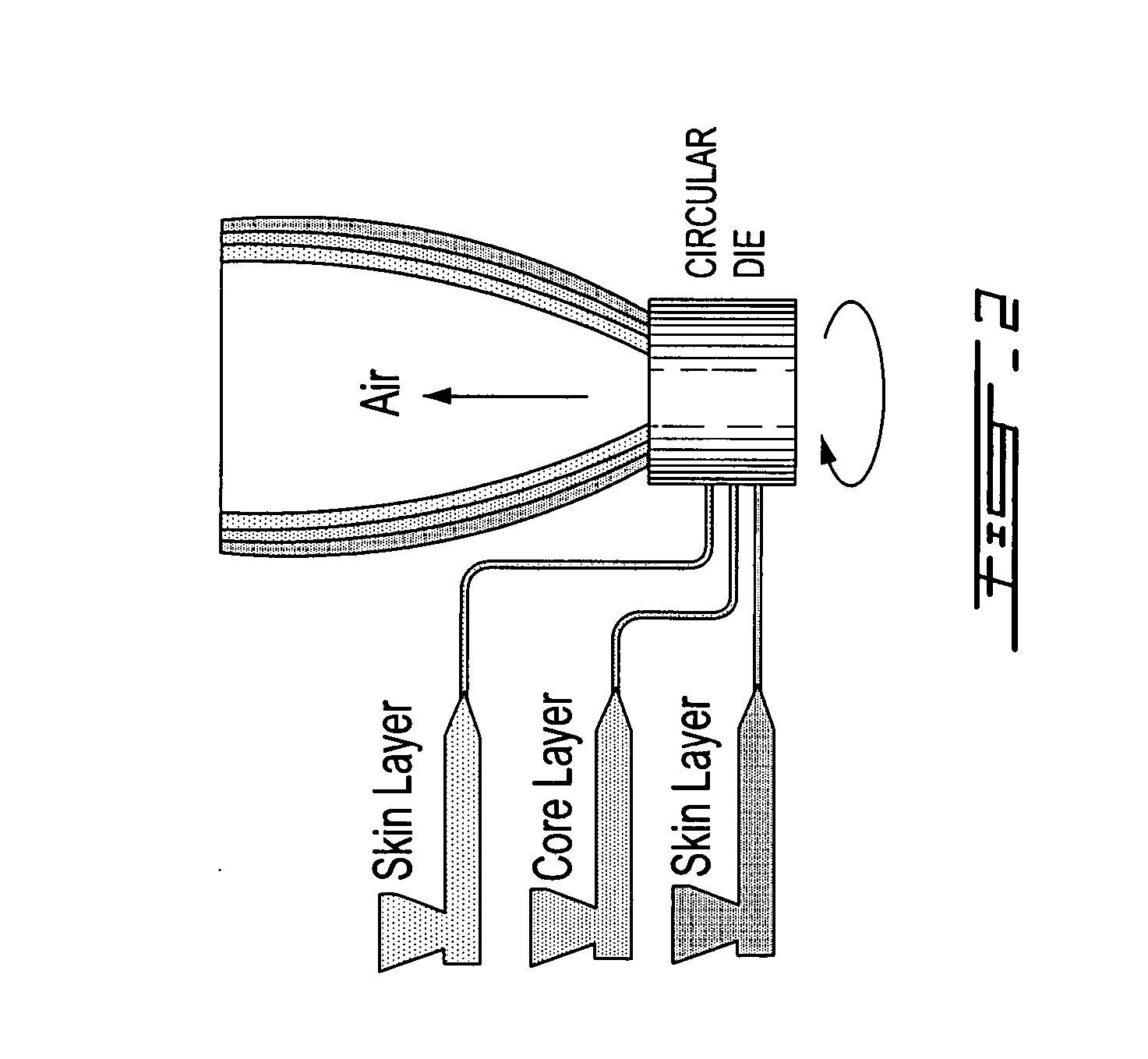

Thin film for vertical form fill and seal packaging of flowable materials

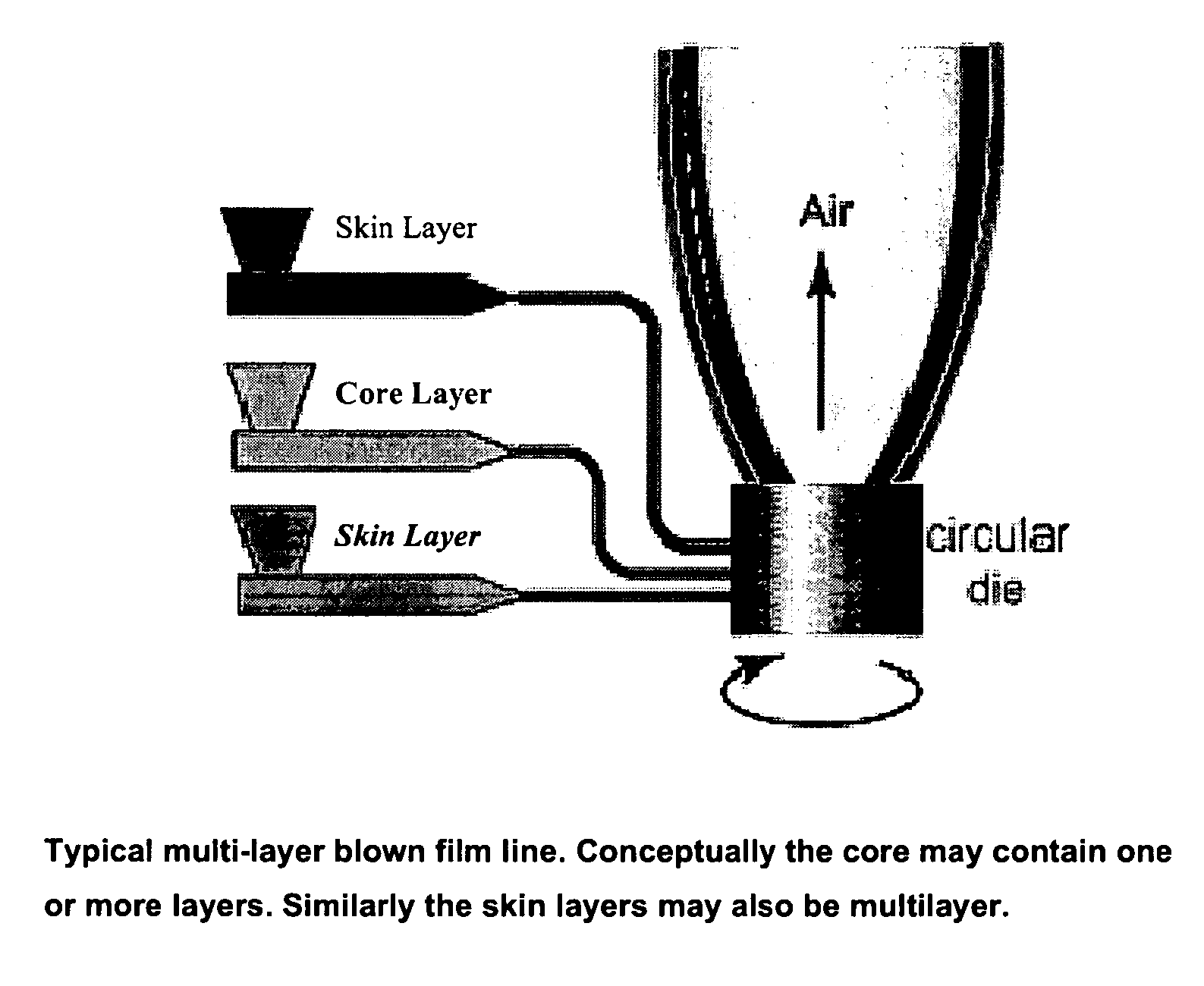

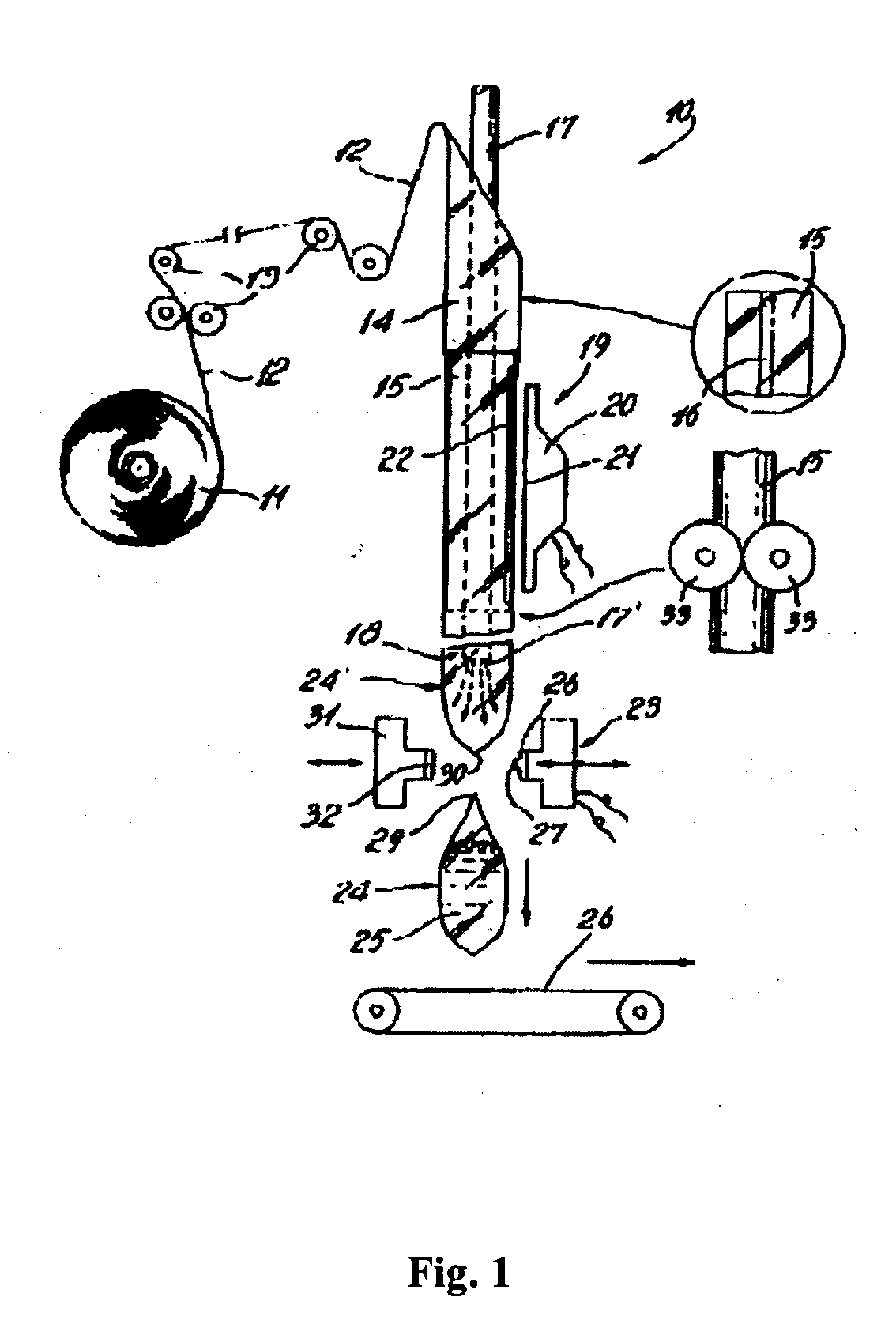

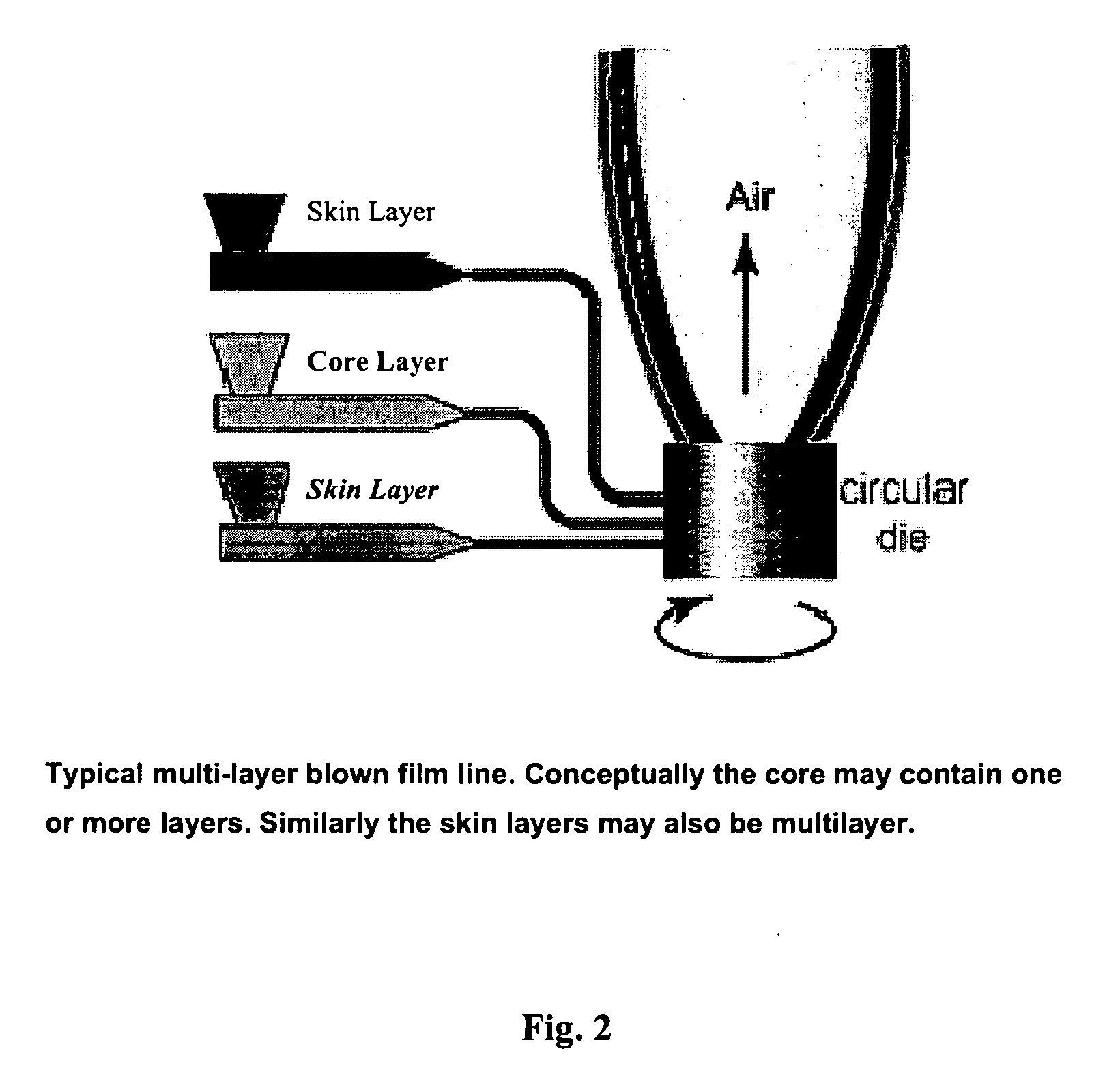

InactiveUS20070252276A1Quick sealImprove heat transfer characteristicsSemiconductor/solid-state device detailsSynthetic resin layered productsPolypropyleneLow-density polyethylene

A multi-layer film for vertical form, film and seal systems for liquid, powder, granules and / or other flowables packaging, said multi-layer comprising: an inner layer made of polyethylene, a blend of polyethylenes or ethylene copolymers; a core, comprising one or more than one layer, made from a blend of polypropylene, linear low density polyethylene, a polymer compatibilizer or tie-layer resin, and / or low density polyethylene, said core being applied against the inner layer; and an outer layer (same or different from the inner layer or the core layer) is made of a polyethylene or a blend of polyethylenes with or without ethylene copolymers, said outer layer being applied against the core and opposite the inner layer; said multi-layer film having an overall thickness of lower or equal to 2.5 mil and at least one of the properties listed hereinafter: a stiffness (as measured by 1% secant modulus in the film direction) varying from 79000 psi to 140000 psi; a tensile strength at yield of from 2100 psi to 3300 psi; (measured in film machine direction) and a tensile strength at break of from 4700 to 6700 psi (measured in film machine direction). A method of forming, sealing and filling a pouch with said film, a pouch formed with said film and use of said film to form a pouch.

Owner:LLOYD GEORGE IAN

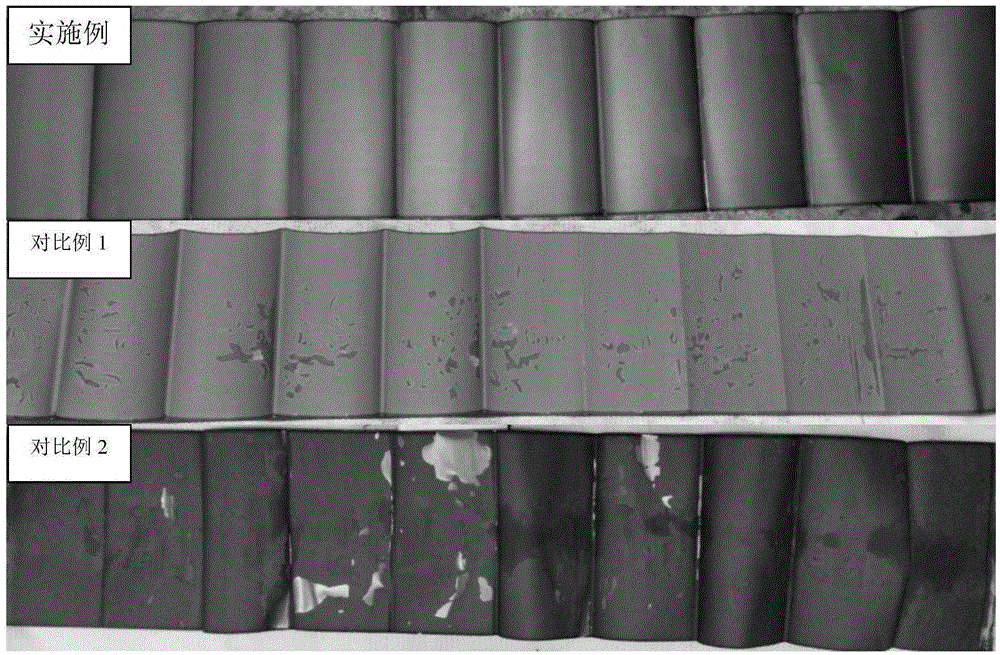

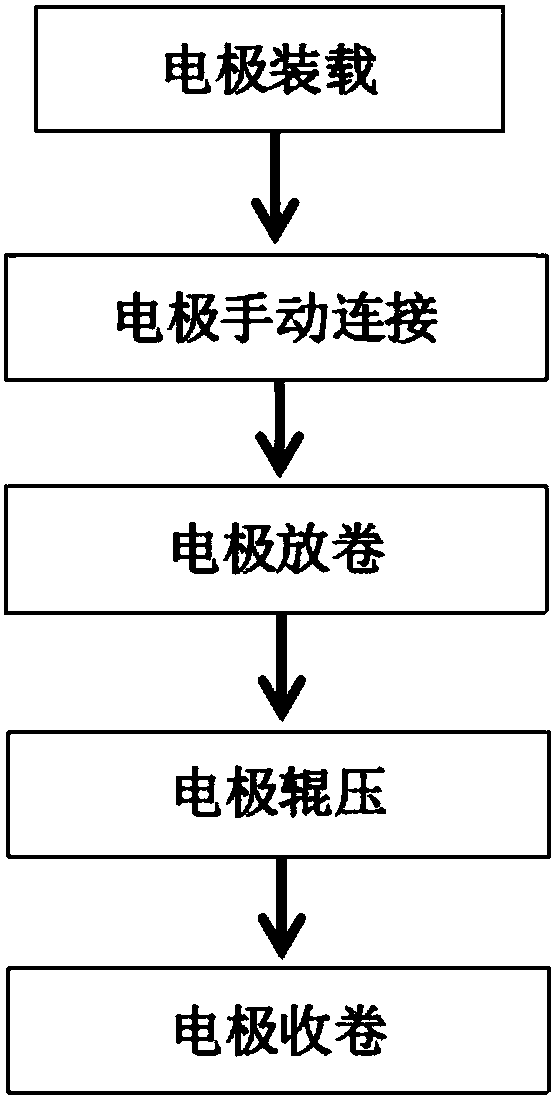

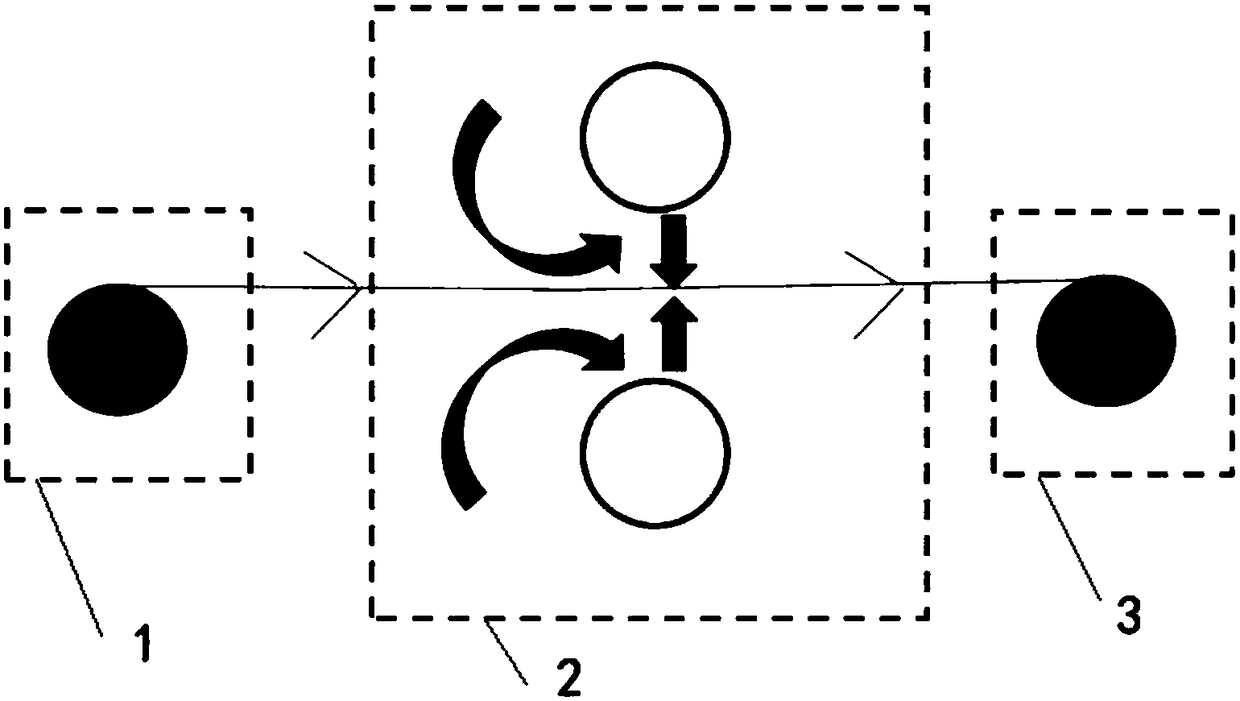

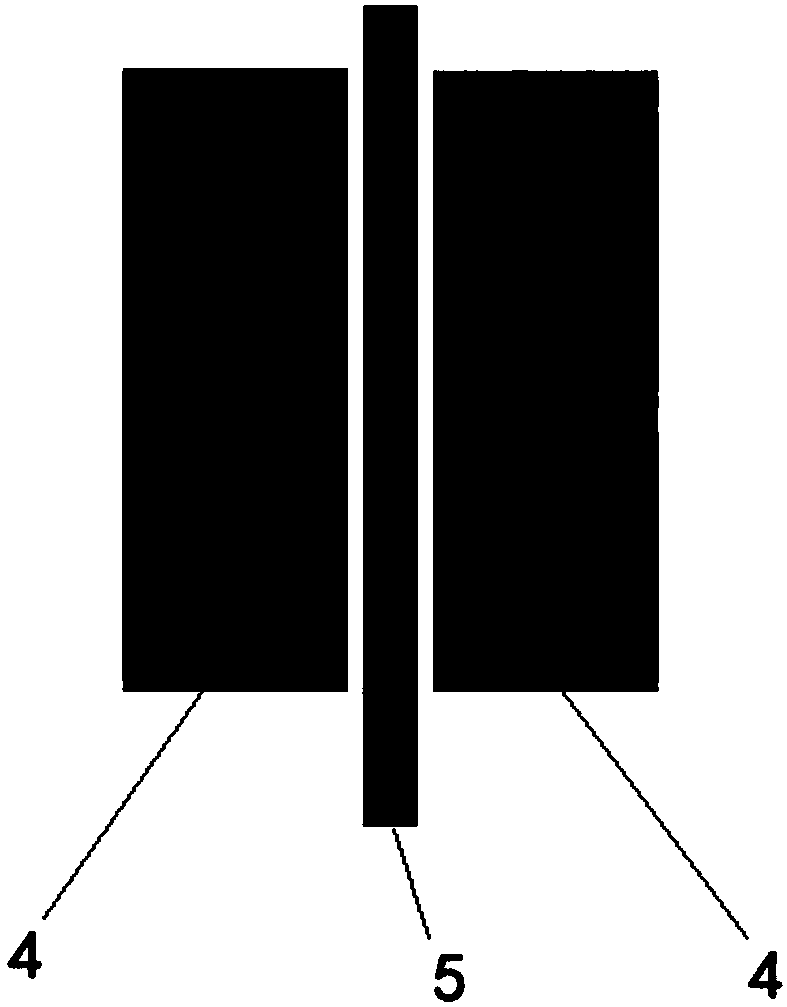

Rolling method and equipment for battery pole piece

ActiveCN108199005AImprove consistencyImprove defects such as poor snake shapeElectrode manufacturing processesElectrical batteryPole piece

The invention relates to the technical field of lithium-ion battery manufacturing, in particular to a rolling method for a battery pole piece. The method comprises the steps of making the coated and dried battery pole piece pass through a foil heating device, an electrode preheating device, an electrode rolling device and a thickness curing device in sequence; when the battery pole piece passes through the foil heating device, heating a foil area of the battery pole piece by using the foil heating device; when the battery pole piece passes through the electrode preheating device, heating a coating area of the battery pole piece by using the electrode preheating device; when the battery pole piece passes through the electrode rolling device, applying rolling force of different sizes to theedge part and the middle part of the battery pole piece by using the electrode rolling device to roll the battery pole piece; and when the battery pole piece passes through the thickness curing device, sequentially baking and cooling the battery pole piece by using the thickness curing device. The invention further provides rolling equipment for the battery pole piece. According to the rolling method and the rolling equipment, the thickness consistency of the rolled battery pole piece is effectively improved.

Owner:ZHEJIANG FOREVER NEW ENERGY TECH CO LTD +1

Thin film for vertical form fill and seal packaging of flowable materials

InactiveUS20070254119A1More sealEnhance heat transfer characteristicSynthetic resin layered productsCeramic shaping apparatusPolypropyleneEngineering

A multi-layer film for vertical form, film and seal systems for liquid, powder, granules and / or other flowables packaging, said multi-layer comprising: an inner layer made of polyethylene, a blend of polyethylenes or ethylene copolymers; a core, comprising one or more than one layer, made from a blend of polypropylene, linear low density polyethylene, a polymer compatibilizer or tie-layer resin, and / or low density polyethylene, said core being applied against the inner layer; and an outer layer (same or different from the inner layer or the core layer) is made of a polyethylene or a blend of polyethylenes with or without ethylene copolymers, said outer layer being applied against the core and opposite the inner layer; said multi-layer film having an overall thickness of lower or equal to 2.5 mil and at least one of the properties listed hereinafter: a stiffness (as measured by 1% secant modulus in the film machine direction) varying from 3500 psi to 150000 psi; a tensile strength at yield of from 1700 psi to 3300 psi; (measured in film machine direction) and a tensile strength at break of from 4300 to 7400 psi (measured in film machine direction). A method of forming, sealing and filling a pouch with said film, a pouch formed with said film and use of said film to form a pouch.

Owner:GLOPAK INC

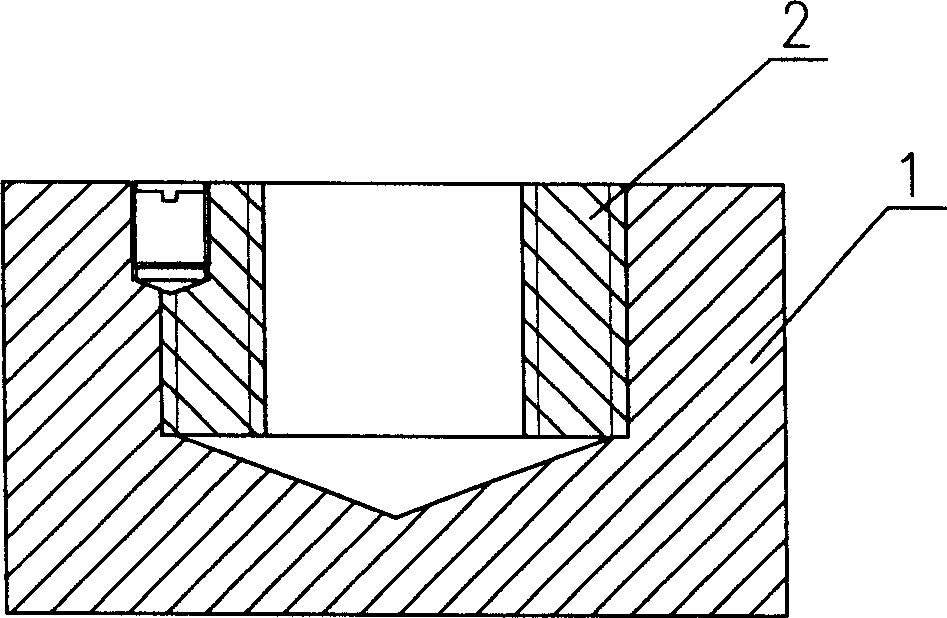

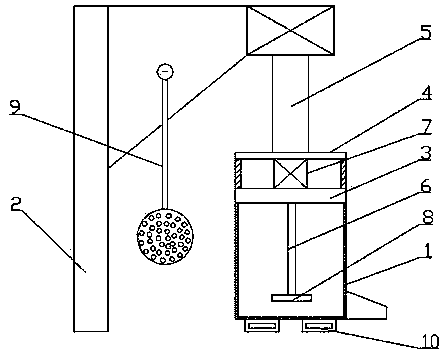

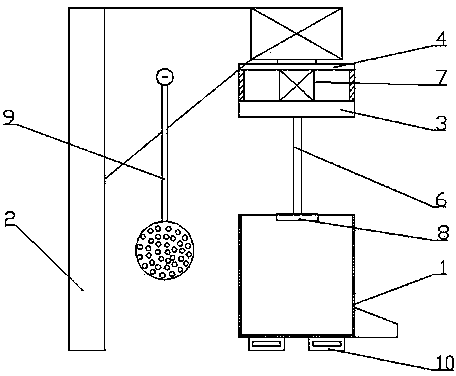

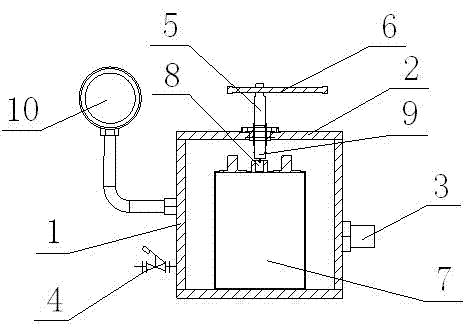

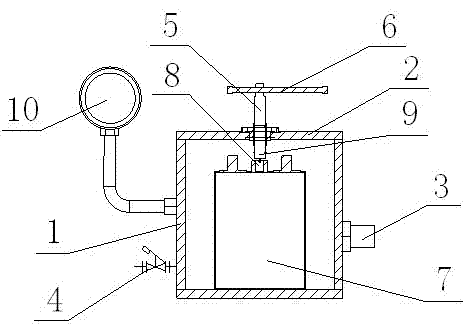

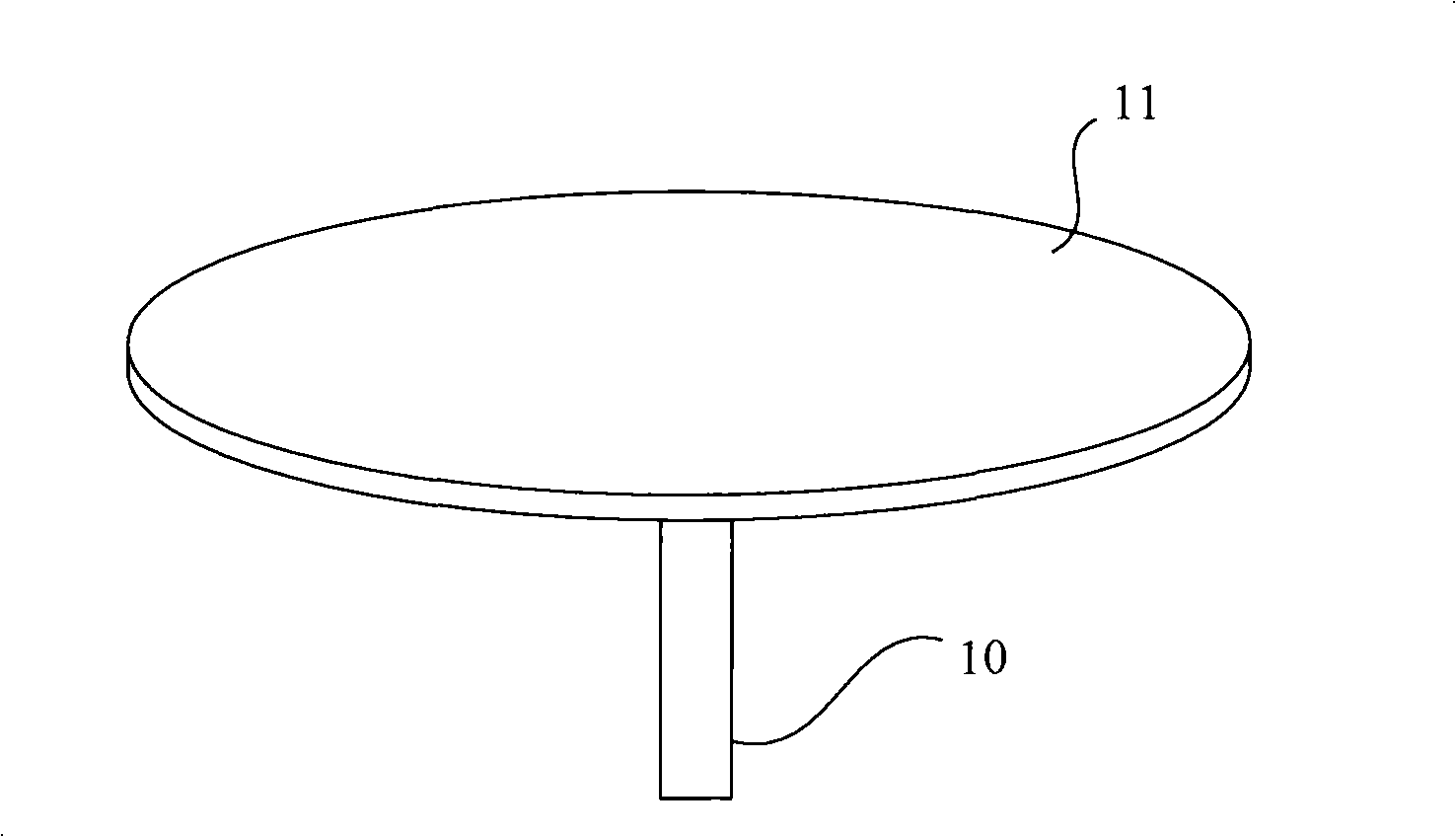

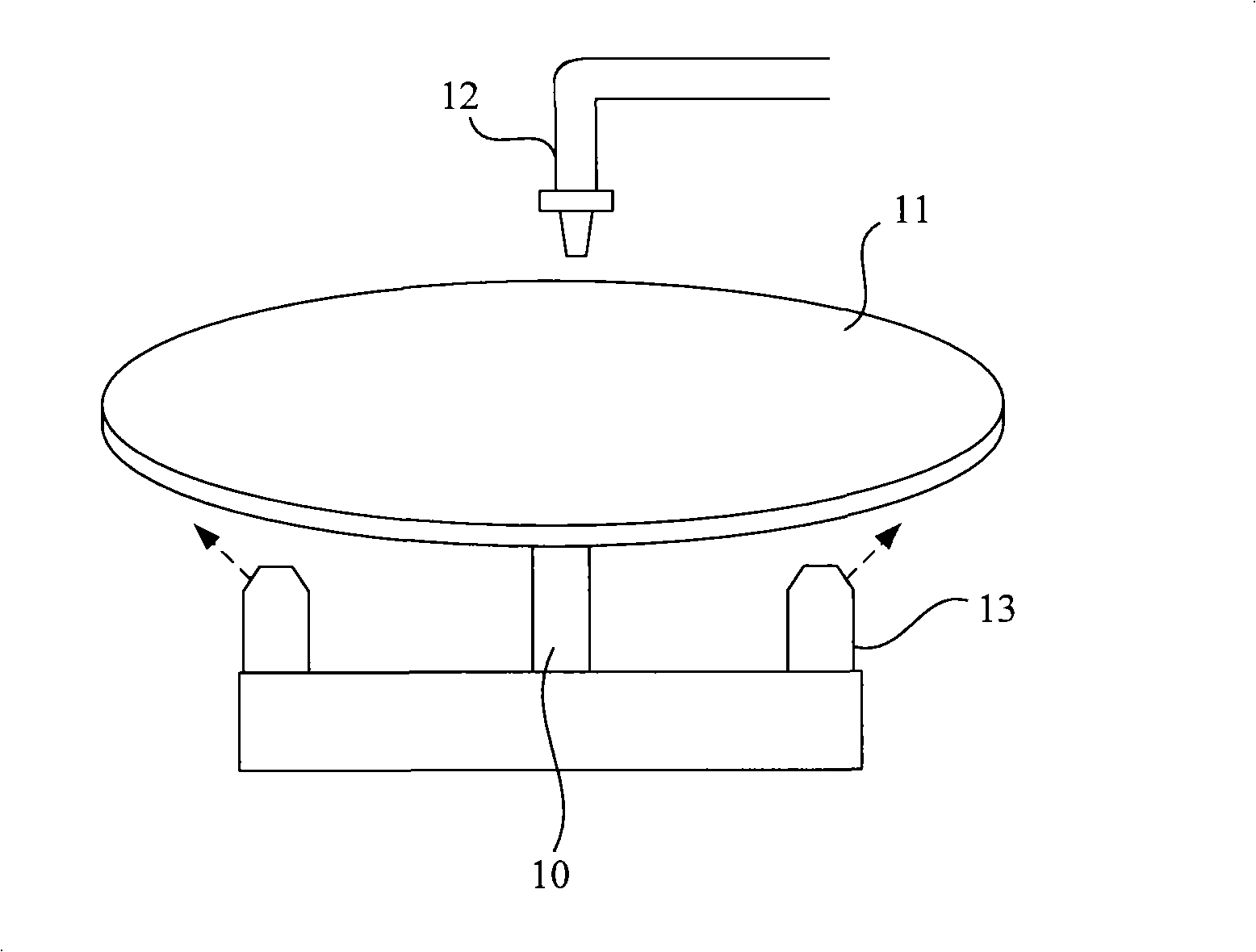

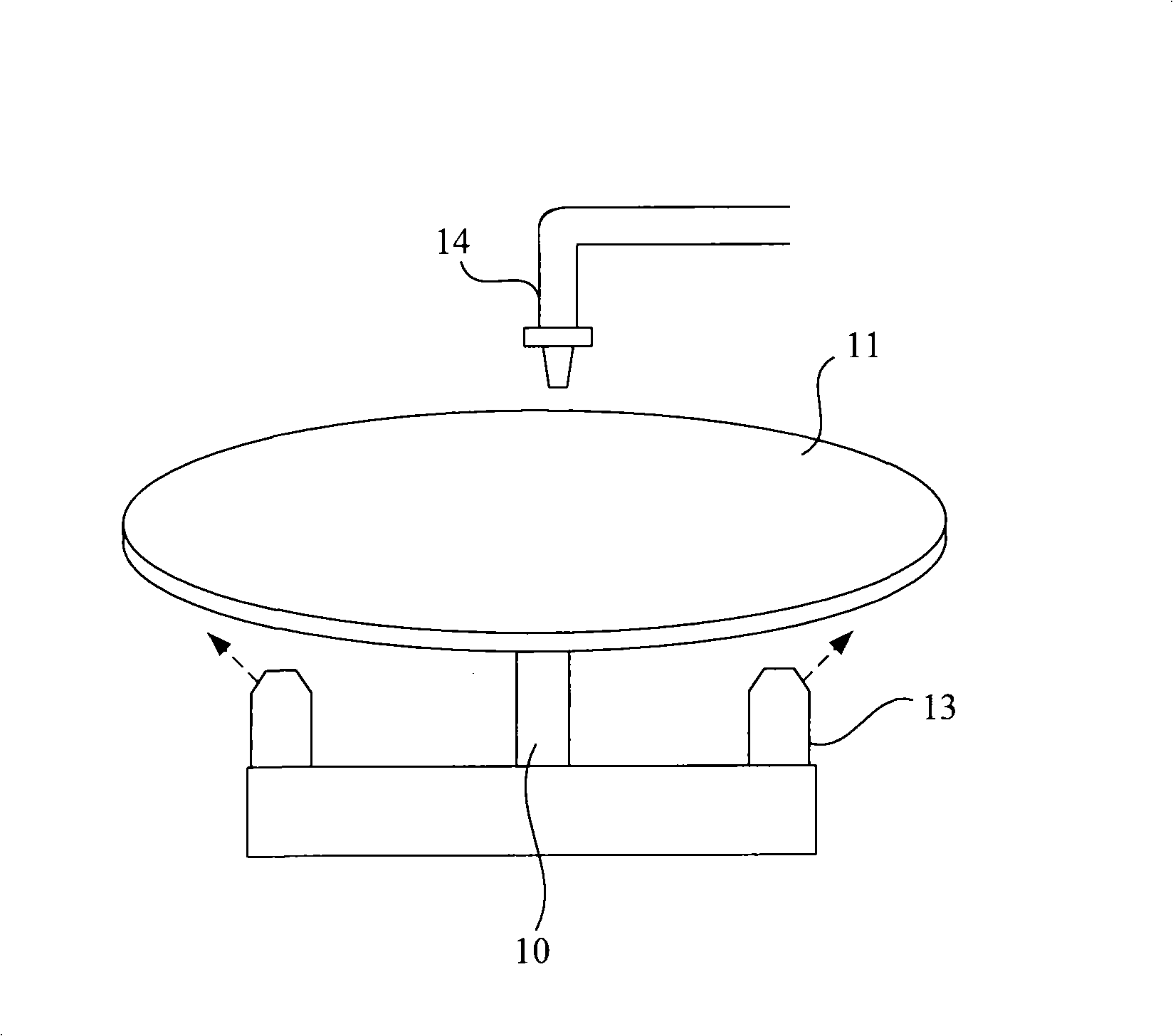

Molten aluminum refining degassing and slag-removing device

The invention relates to a molten aluminum refining degassing and slag-removing device. The molten aluminum refining degassing and slag-removing device comprises a heat insulation furnace and a bracket, wherein the heat insulation furnace is provided with a cover body which is connected with a hoisting plate by a connection rod; the hoisting plate is connected with the bracket by a hydraulic retractable rod; the lower end of the cover body is connected with an agitating shaft; a driving motor is arranged at the upper end of the cover body; the upper end of the agitating shaft vertically penetrates through the cover body and is connected with the driving motor; the lower end of the agitating shaft is arranged in the heat insulation furnace and is further connected with a graphite rotor; an air vent is formed in the surface of the graphite rotor; the agitating shaft is a hollow shaft and is internally provided with an air ventilation pipeline; one end of the air ventilation pipeline stretches out of the agitating shaft to be connected with a nitrogen generator; the other end of the air ventilation pipeline is communicated with the air vent of the graphite rotor. According to the molten aluminum refining degassing and slag-removing device, hydrogen and non-metal impurities in molten aluminum can be removed and the molten aluminum is purified; scrap caused by needle holes and the non-metal impurities after the molten aluminum is cast into a casting is reduced; the inner quality of the casting is improved greatly and the market competitiveness of products is improved.

Owner:LUOYANG ANLUN ALUMINUM PROD

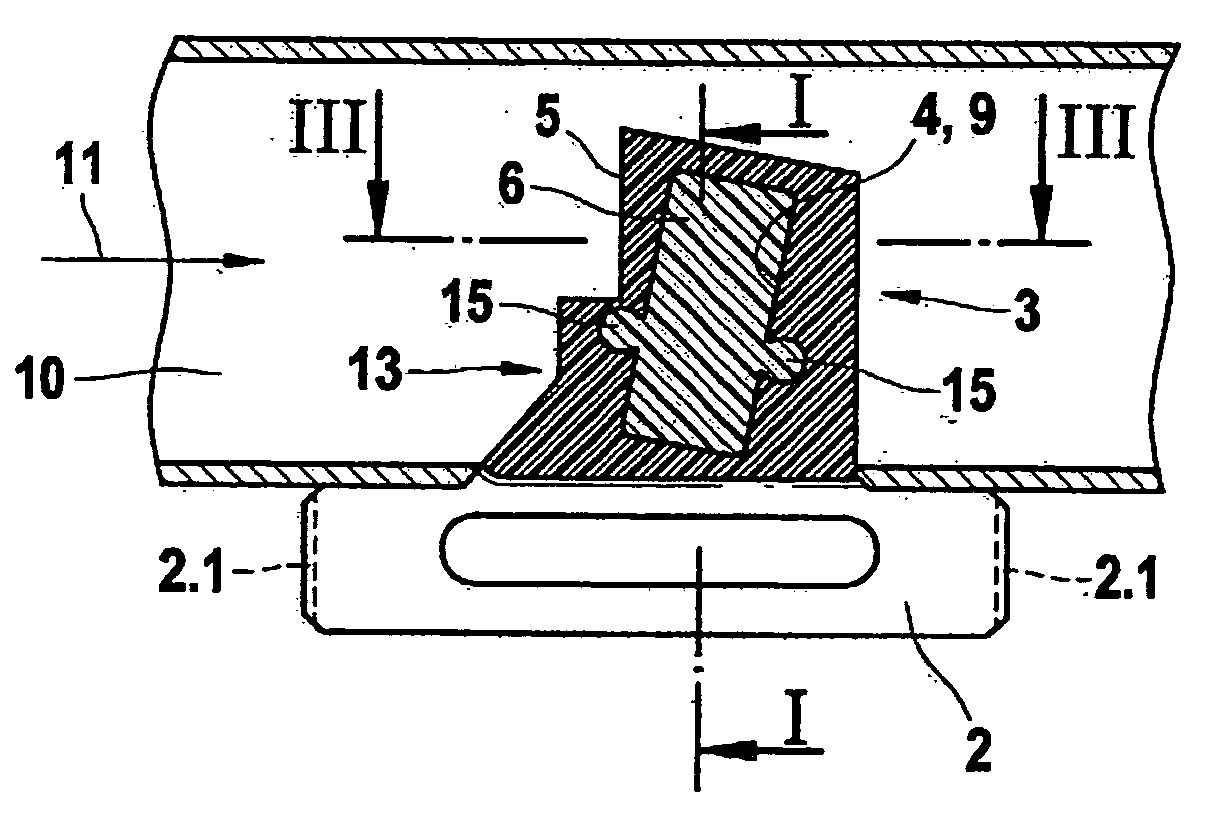

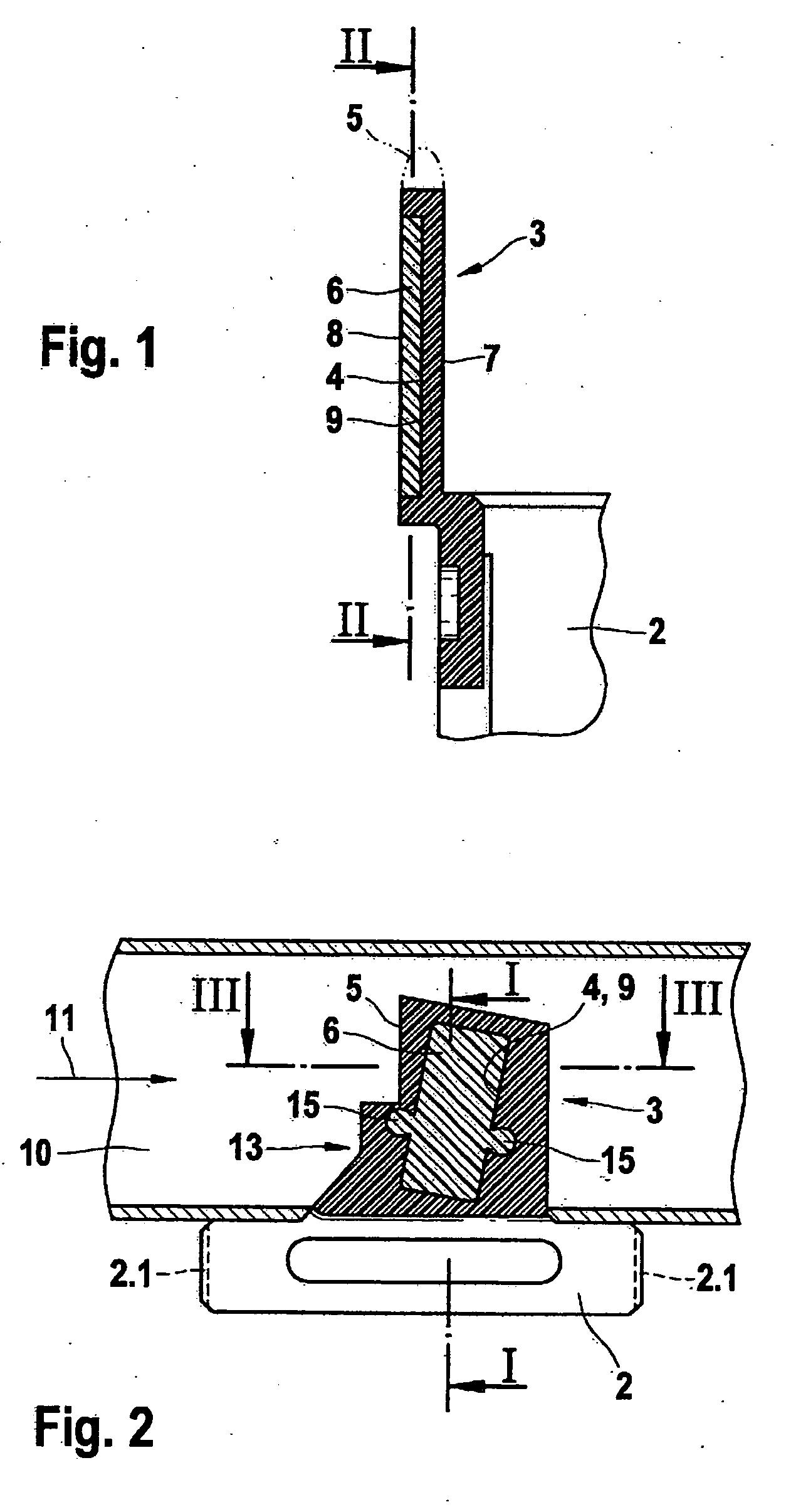

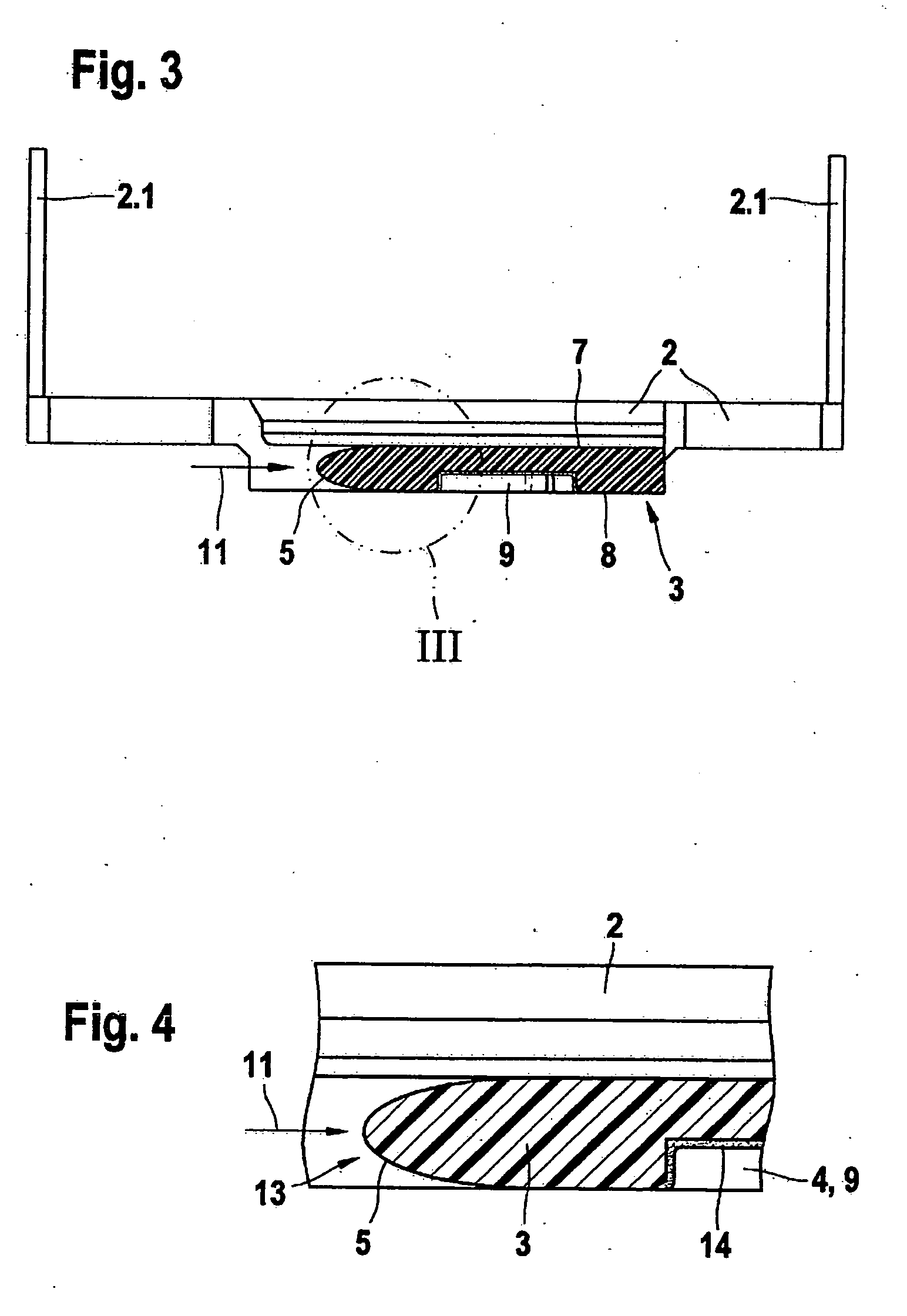

Printed-circuit board having a plastic part for accommodating a measuring device

ActiveUS20070107511A1Low production costQuality improvementVolume/mass flow by thermal effectsVolume flow proportion measurementLeading edgePlastic materials

The arrangement relates to a hot-film mass flow meter for recording the flow rate of a flowing medium in the intake tract or the charge air tract of an internal combustion engine. A substrate part is provided, that accommodates a sensor chip, which is allocated to a channel that has flowing through it at least one partial mass flow of the flowing medium. The sensor chip extends into channel that has flowing through it the partial mass flow of the flowing medium. The substrate part is formed either as a separately extruded plastic tongue or as a cavity extruded of plastic material. The sensor chip is integrated downstream with respect to a flow direction of the flowing medium, so as to lie behind a leading edge.

Owner:ROBERT BOSCH GMBH

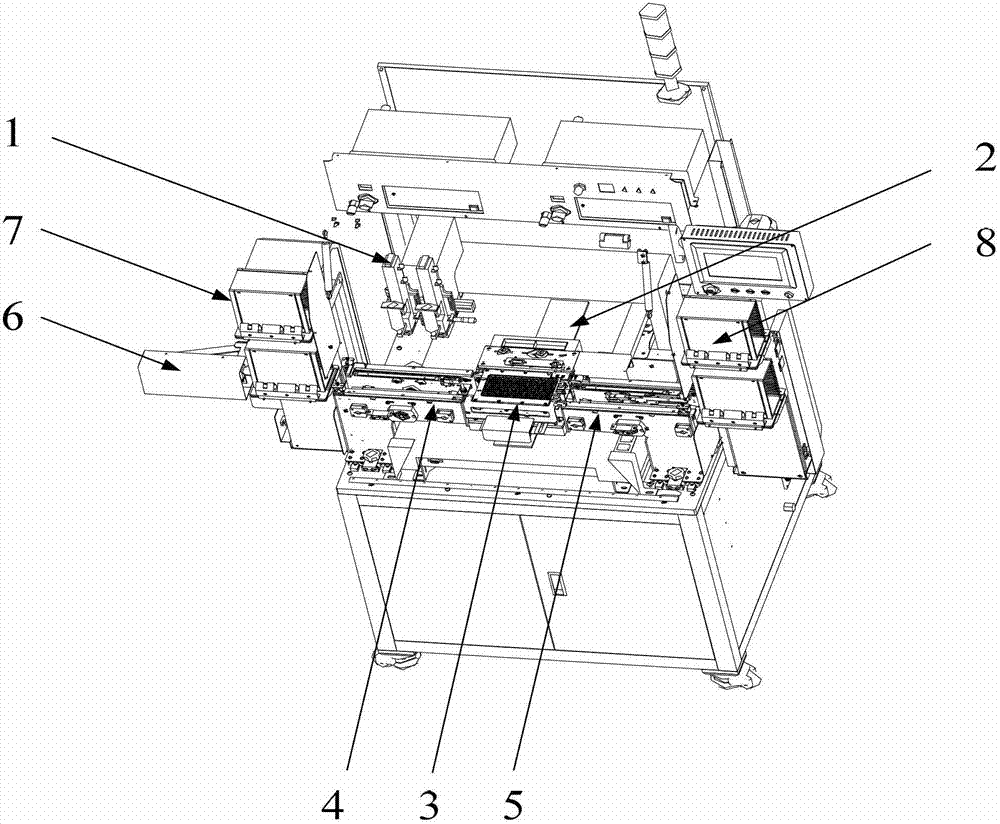

Cast-welding production device of accumulator and production process thereof

The invention provides a cast-welding production device of an accumulator and a production process thereof, belonging to accumulator industry. The technical scheme is characterized in that the production device comprises a brushing device, a steeping device and a cast-welding mainframe; the brushing device and the steeping device are connected with each other sequentially by a battery conveying line; and the brushing device comprises a brushing mainboard with an ejector cylinder and a steel wire brush with a brushing cylinder. The cast-welding production device and the production process have the following advantages that the cast-welding machine adopts a mode of closed production, has special smoke gas exhausting system and higher automation degree, only needs a worker to carry out simple transporting operation, greatly reduces the environmental pollution and the harm to human body, has regular and attractive cast-welding appearance and extremely low reject rate and welding repair rate, and leads the worker to not need technical requirements, thus greatly saving cost for manufacturers, improving output and increasing production value.

Owner:FUJIAN JIANYANG YAHENG MACHINERY MFG

Deplating liquid for NiCuNi plating on surface of sintered NdFeB and deplating process thereof

InactiveCN102787321AFast stripping speedImprove deplating efficiencySodium sulfocyanatePotassium thiocyanate

The invention discloses a deplating liquid for a NiCuNi plating on the surface of sintered NdFeB and a deplating process thereof. The deplating liquid for the NiCuNi plating on the surface of sintered NdFeB adopts deionized water or clean tap water as the liquid solvent, and all components and component contents are as follows: 60-90g / L reserve salt S, 120-150ml / L ethylene diamine, 20-40g / L anti-corrosion complexing agent and 50-100ml / L mineral acid. The solute further comprises a surface active agent of 0.5-1g / L. The anti-corrosion complexing agent is sodium citrate or triammonium citrate; the mineral acid is nitric acid or ammonium nitrate; and the surface active agent is potassium thiocyanate, or sodium sulfocyanate or ammonium thiocyanate. The deplating process comprises the following steps: preparing a deplating bath; disposing a deplating liquid; executing the deplating; and removing the deplating liquid on a product. The deplating liquid has the advantages of stable property, good deplating effect and low cost; and the deplating operation is simple and convenient, pollution is prevented, body harm of operators is relieved, waste is changed into valuable and the benefits are remarkable.

Owner:牛凯

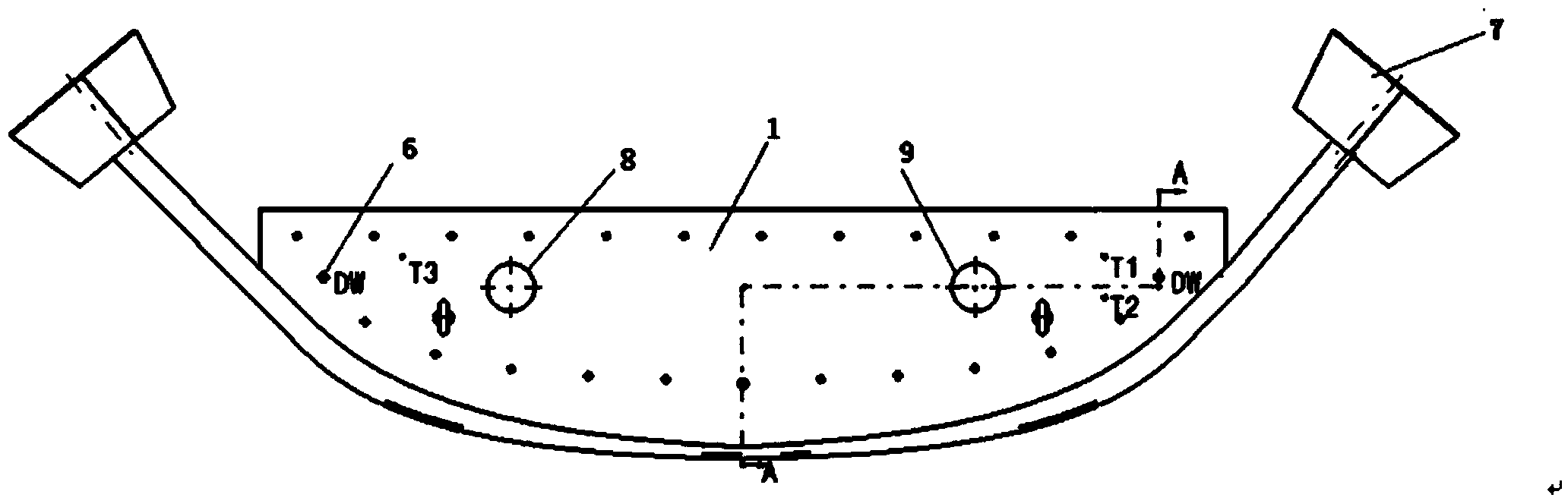

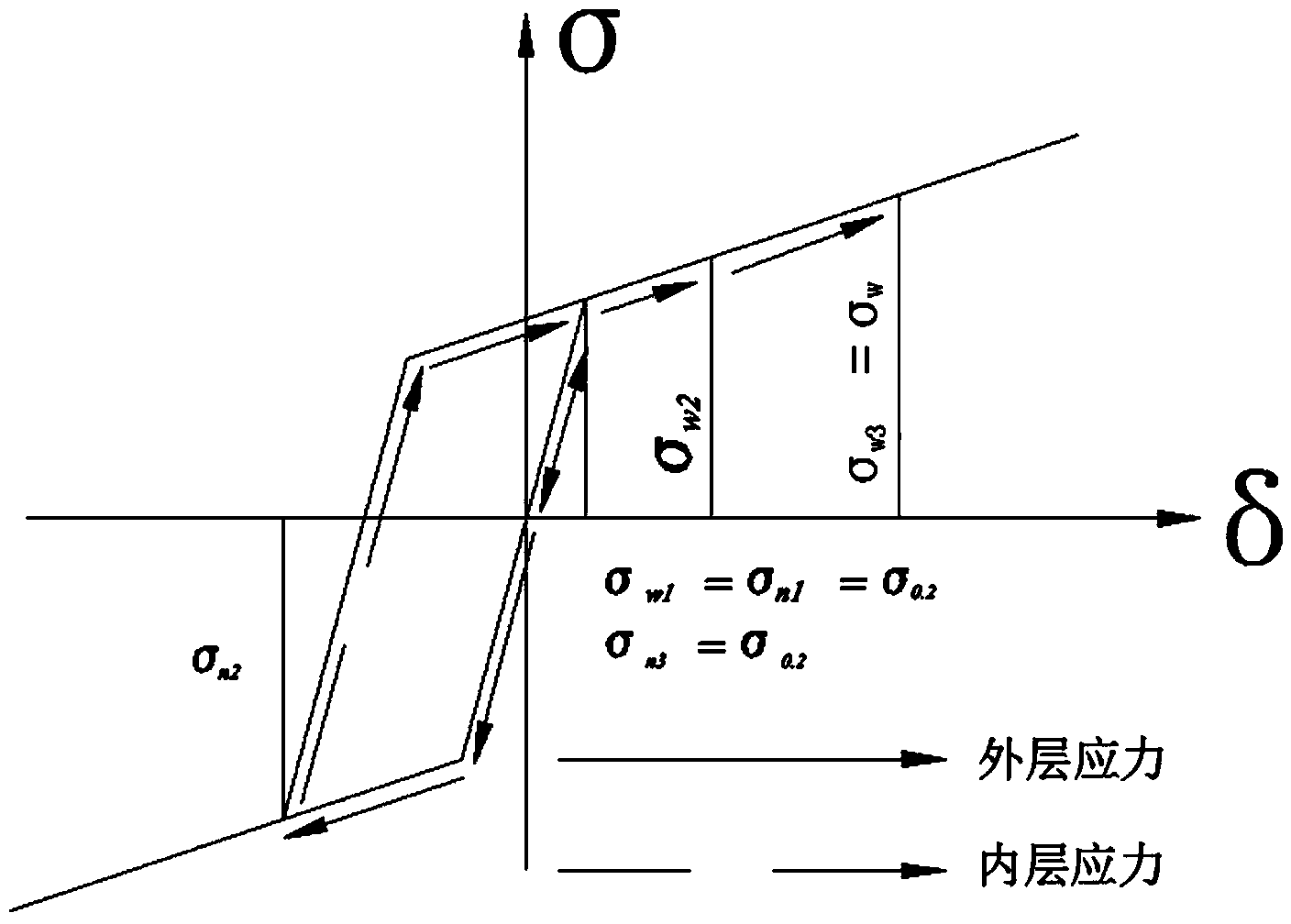

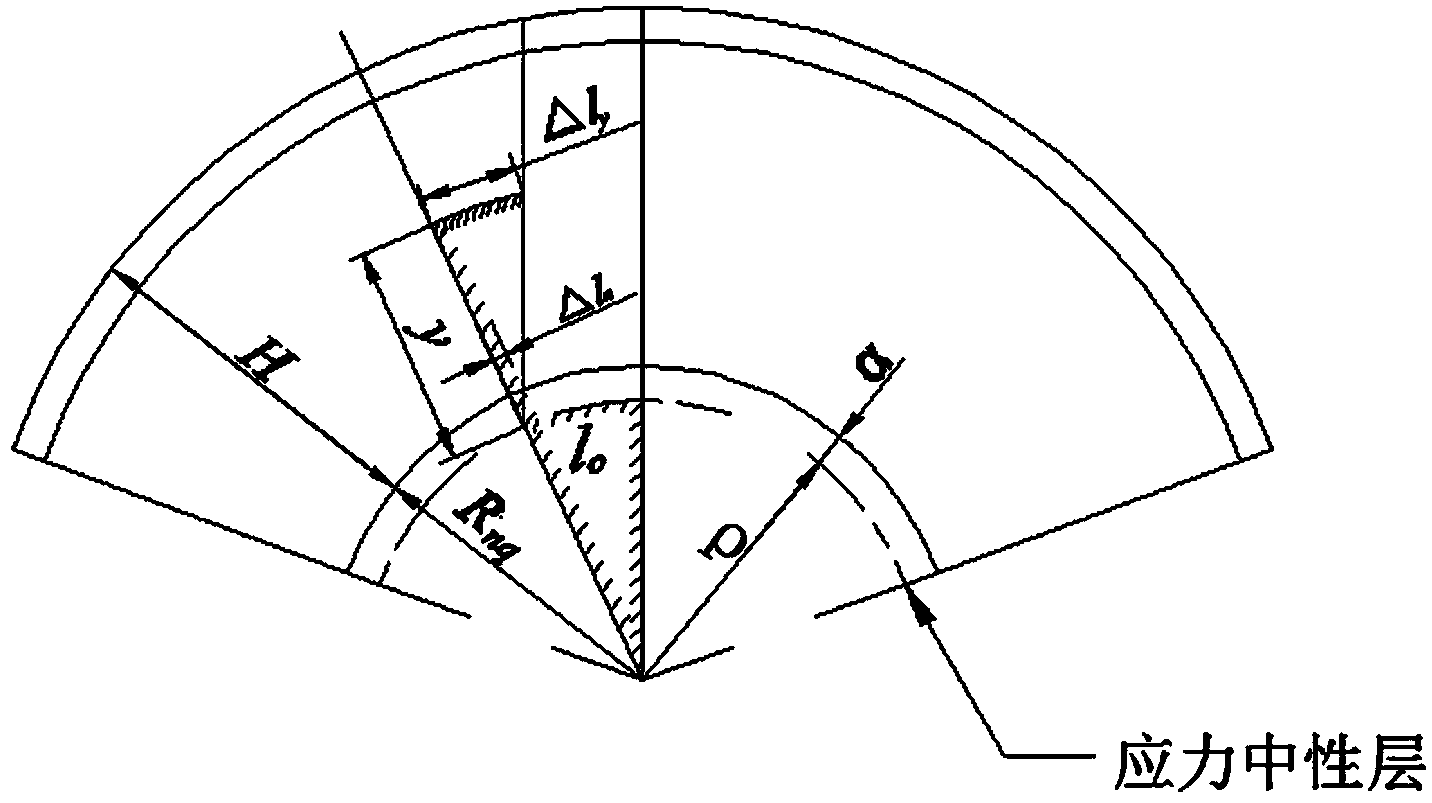

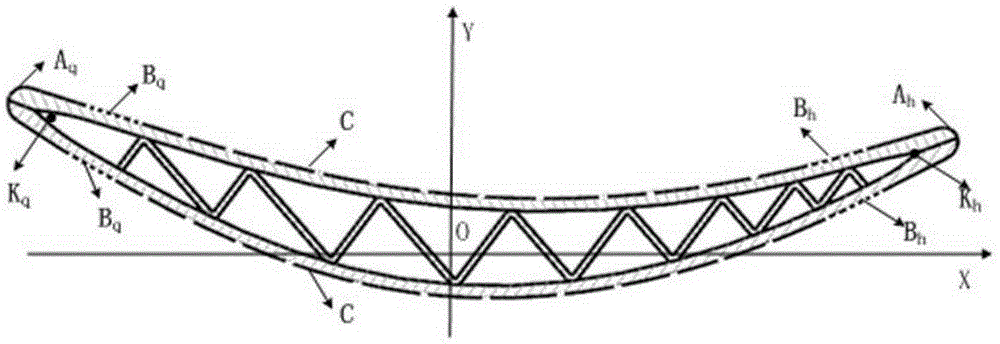

Three-dimensional multi-curvature part bending method

InactiveCN104281725ALower requirementReduce the cost of updatesSpecial data processing applications3D modellingNumerical controlComputer Aided Design

The invention discloses a three-dimensional multi-curvature part bending method. According to the method, the structural form of a section bending die and a suitable section bending machine are determined by analyzing the shape, size, bending angle and forming force of a part to be bent; a digital model of the part to be bent is subjected to curvature analysis through a computer; bending springback theoretical analysis is adopted, and a die profile springback compensation design is performed by a numerical simulation method through computer aided design. The bending of a section requires matched bending chuck, bending die and machine tool. The die is processed by a numerical control technology. A measuring machine is used for detecting and correcting the die to be processed, and an error between theory and actuality is reduced, so that the part manufacturing accuracy is improved. Dies for three-dimensional complicated parts can be formed on a two-dimensional bending machine, the bending pass is reduced, and repair or scraping of the bending dies is reduced, so that the part manufacturing cost is effectively reduced; moreover, the production efficiency is high.

Owner:XIAN JIAYE AVIATION TECH

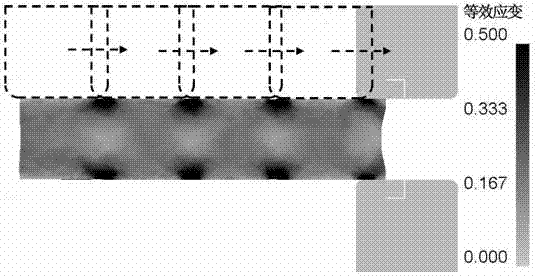

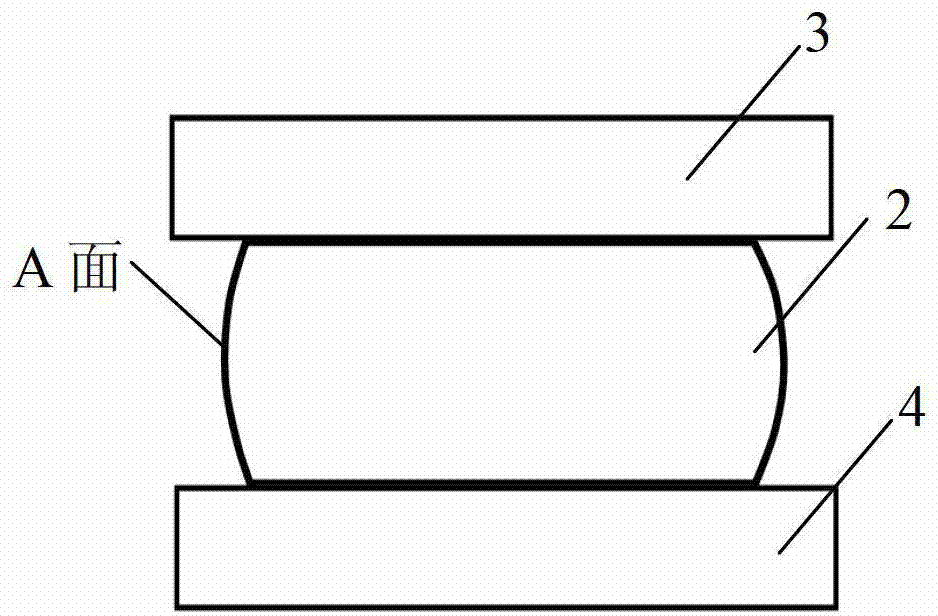

Forging method for efficiently healing hole flaws inside blank with large height-diameter ratio

ActiveCN102756062APromote healingLarge strainMetal-working apparatusThermal insulationDiameter ratio

The invention belongs to the field of forging, and specifically relates to a forging method with a small screw-down rate, which is capable of efficiently healing hole flaws inside a blank with a height-diameter ratio. The forging method adopts a numerical simulation technique to research the distribution status of strain inside the blank in the conventional forging process, thus providing a radial wide anvil compaction process which comprises the following steps of: pressing down the blank by virtue of the radial wide anvil compaction process, wherein flat plates serve as upper and lower anvil; after radial the wide anvil compaction process, returning the blank to a furnace to be re-heated and be subjected to thermal insulation; and turning over the blank by 90 degrees and drawing out the blank by the upper and lower anvil. The forging method is suitable for a free forging process for various blanks (for example continuous-casting blanks) or steel ingots with a large height-diameter ratio and the like, and particularly has good effects on the blank with the large height-diameter ratio and serious centre looseness. Forged pieces produced by the forging method can ensure the healing of the hole flaws inside the blank with the large height-diameter ratio, so that the possibility of forged piece scrapping caused by the loosened and non-forged center of the forged piece is greatly reduced; and moreover, a forged piece with a larger size can be manufactured by virtue of a small screw-down rate.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

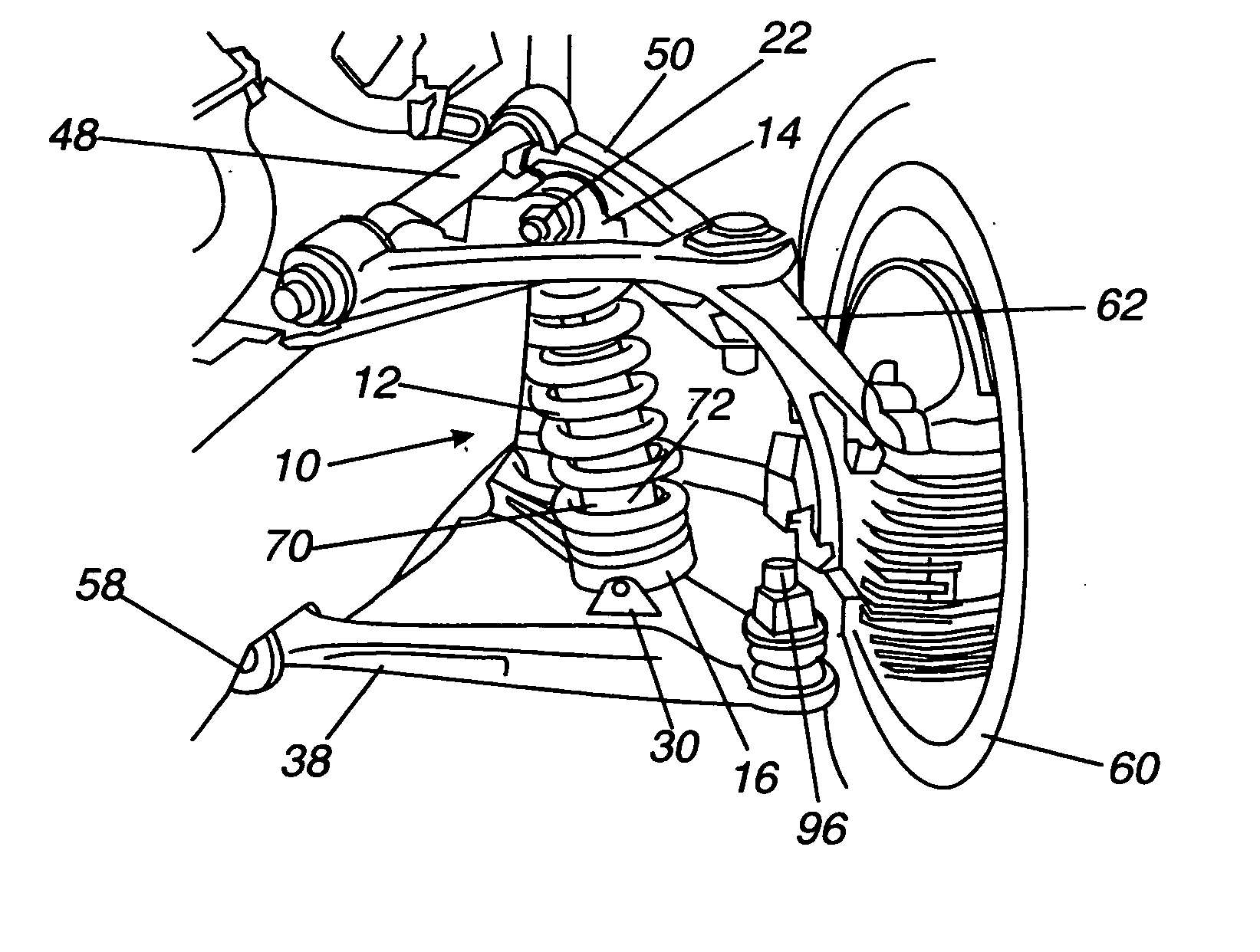

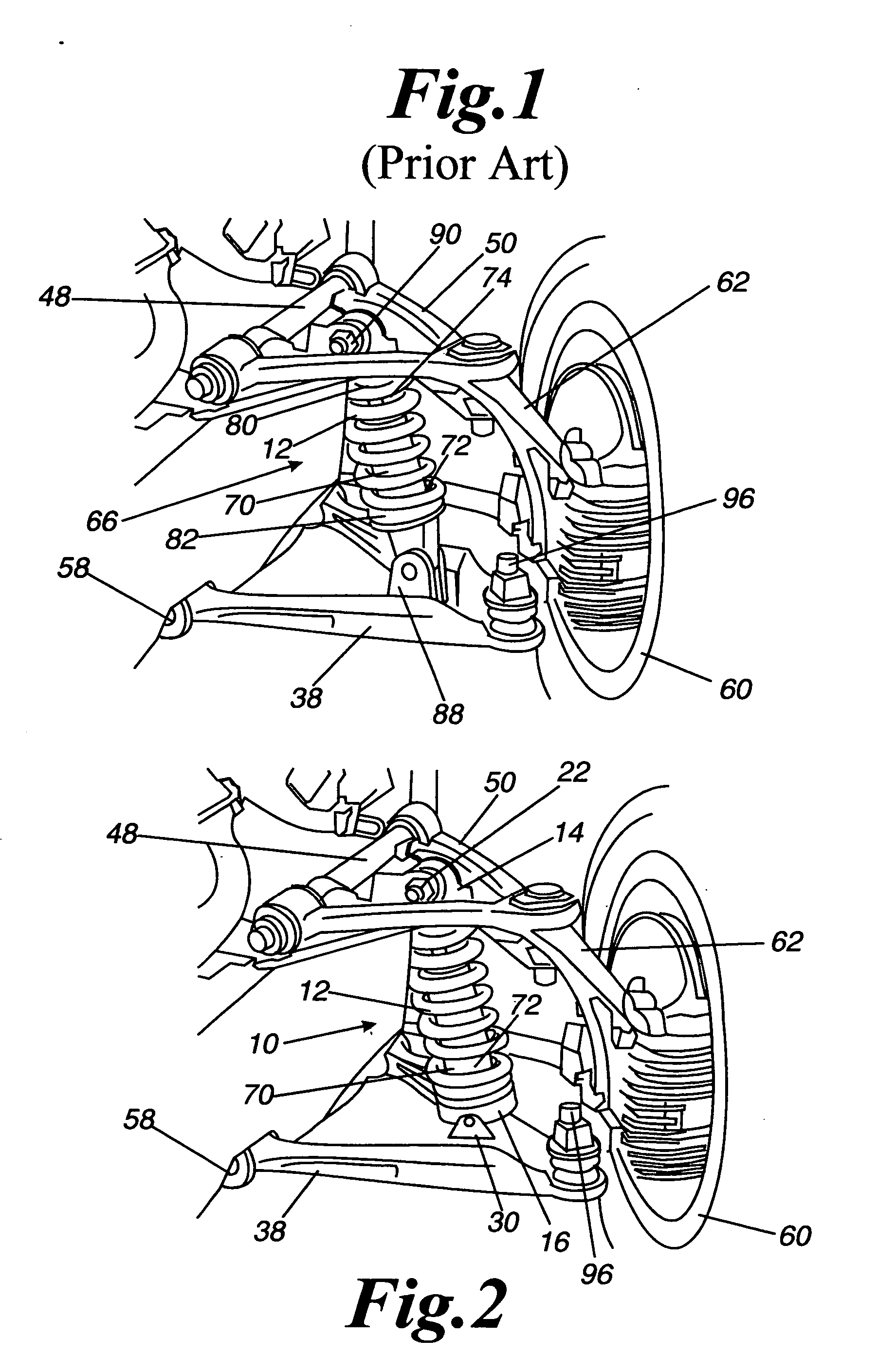

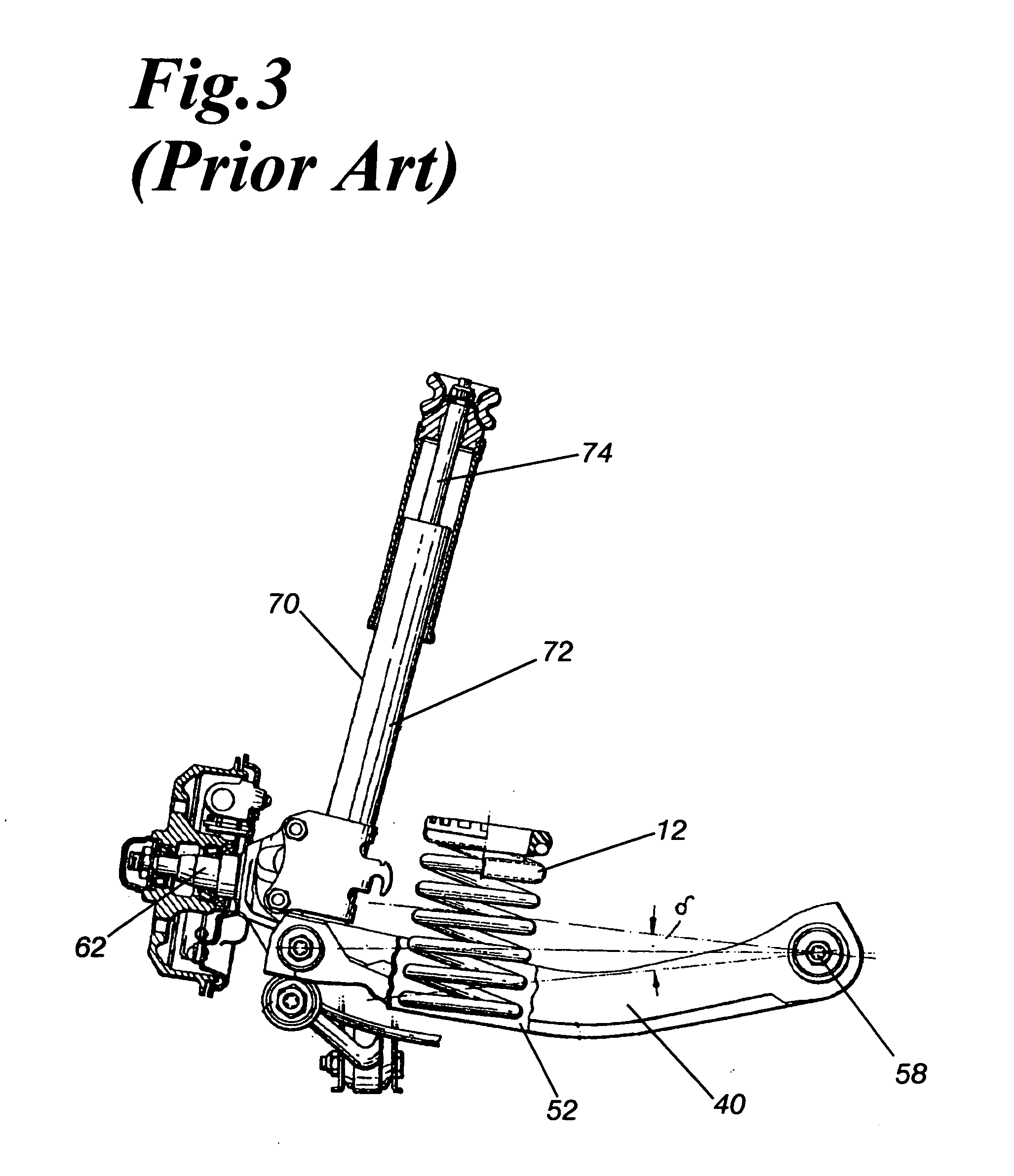

Linear suspension spring

InactiveUS20050258614A1Better dampeningSolution to short lifeResilient suspensionsPivoted suspension armsControl armEngineering

The invention is a suspension spring apparatus for a vehicle wherein the suspension spring maintains a linear alignment irrespective of the position of the articulating strut, where the articulating strut is selected from the group consisting of: control arms, axle arms, solid axles, adjustable spring tensioning devices, and longitudinal struts. The apparatus is comprised of a compression spring mounted between a pivoting lower seat and a pivoting upper seat, where the pivoting lower seat is coupled to the articulating strut and the pivoting upper seat is coupled to a support element. The support element is static, and serves to support the suspension system, and to distribute the forces generated by the suspension system. The pivoting lower seat and the pivoting upper seat can, in combination, pivot through substantially the same plane as the articulating strut, such that when there is a change in angle of the articulating strut with respect to the support element there is a commensurate change in the pivoting lower seat and the pivoting upper seat. The compensation maintains the compression spring aligned linearly between the pivoting lower seat and the pivoting upper seat. Compression and expansion occurs along the centerline of the spring, and there is no transverse curvature, or other deformation of the spring.

Owner:DOVE JASON L

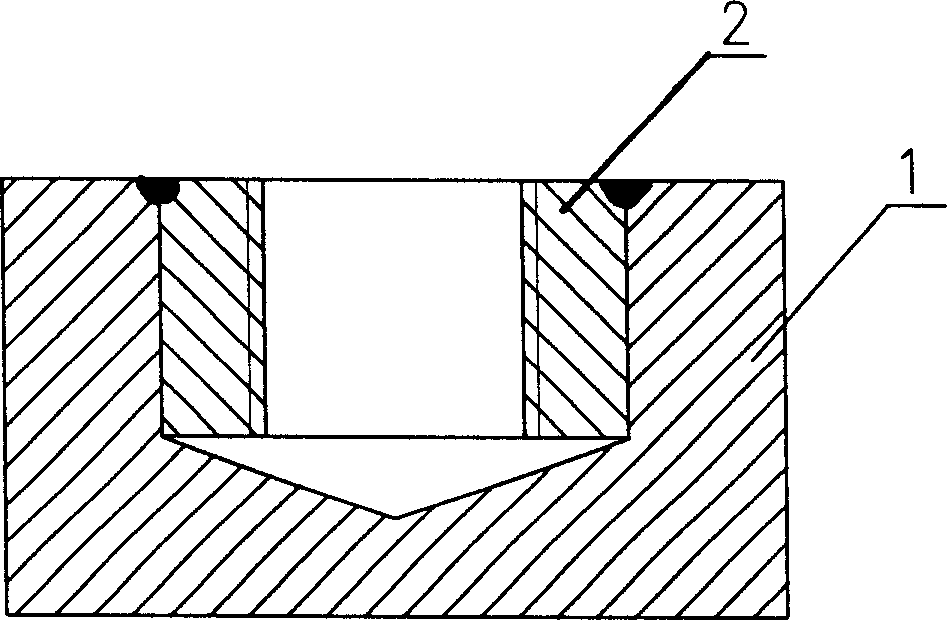

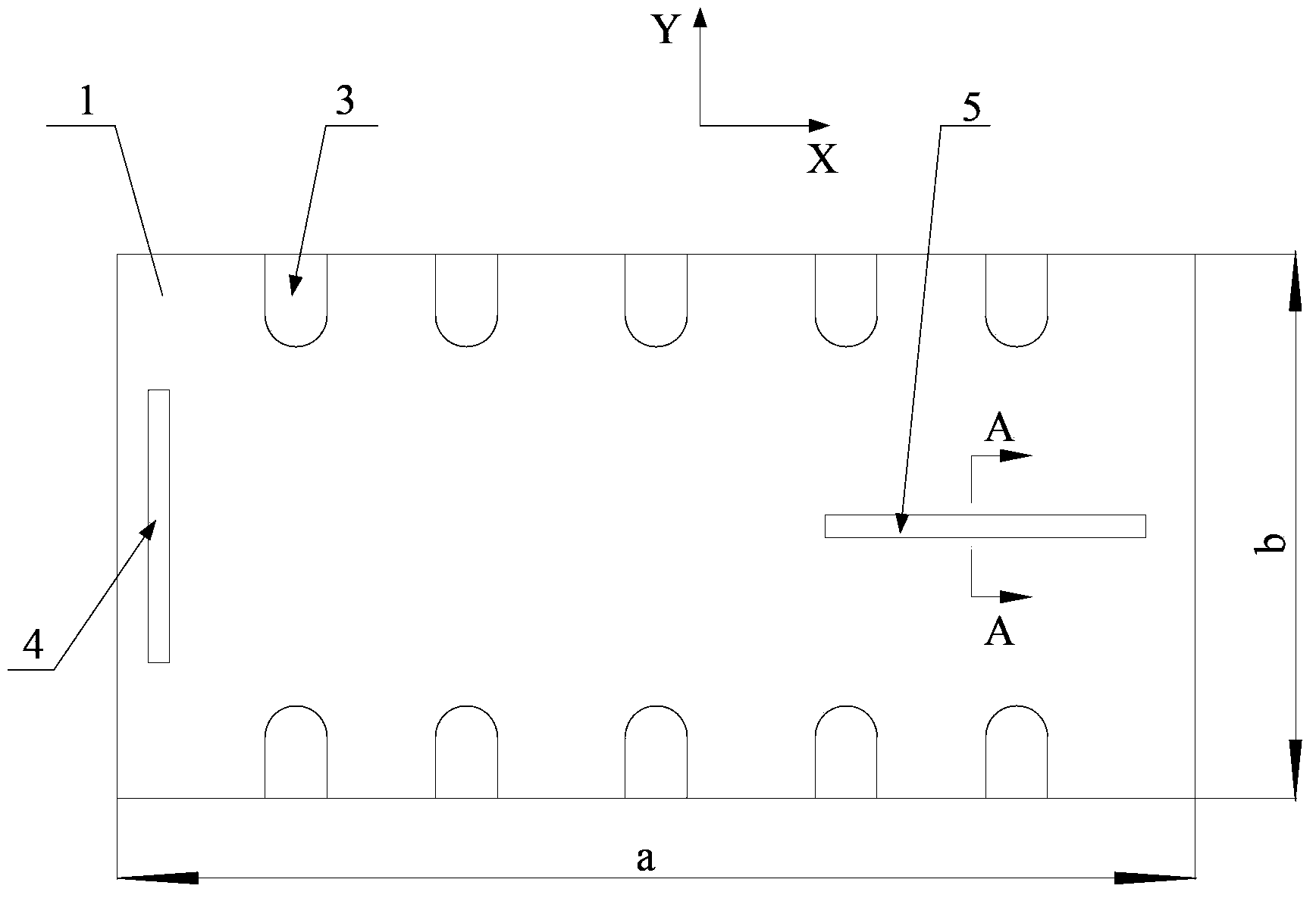

Riveting and positioning fixture, PCB riveting method, manufacturing method for PCB and PCB

InactiveCN103847097AReduce pulling forceReduce misalignmentWork holdersPrinted circuit manufacturePull forceEngineering

The invention provides a riveting and positioning fixture. The riveting and positioning fixture comprises a fixture body; two opposite sides of the fixture body are respectively provided with a plurality of rivet installation holes; one of the other two opposite sides of the fixture body is provided with a first positioning slide groove extending along a Y-axis direction, and the other of the other two opposite sides of the fixture body is provided with a second positioning slide groove extending along an X-axis direction; and a pin can slide in the first positioning slide groove and the second positioning slide groove and can be fixed at a designated position. The invention also provides a PCB riveting method, a manufacturing method for a PCB and the PCB. According to PCB riveting technology provided by the invention, riveting requirements of all standard jointed board products can be met only by manufacturing one riveting and positioning fixture, so production management is simplified; a pulling force generated in the riveting process can be effectively reduced, thereby avoiding scraping caused by dislocation and improving product yield; after pressing, rivets are drilled out through drilling, so the problems of board separation and delamination at positions where the rivets are located in later processing are overcome.

Owner:PEKING UNIV FOUNDER GRP CO LTD +1

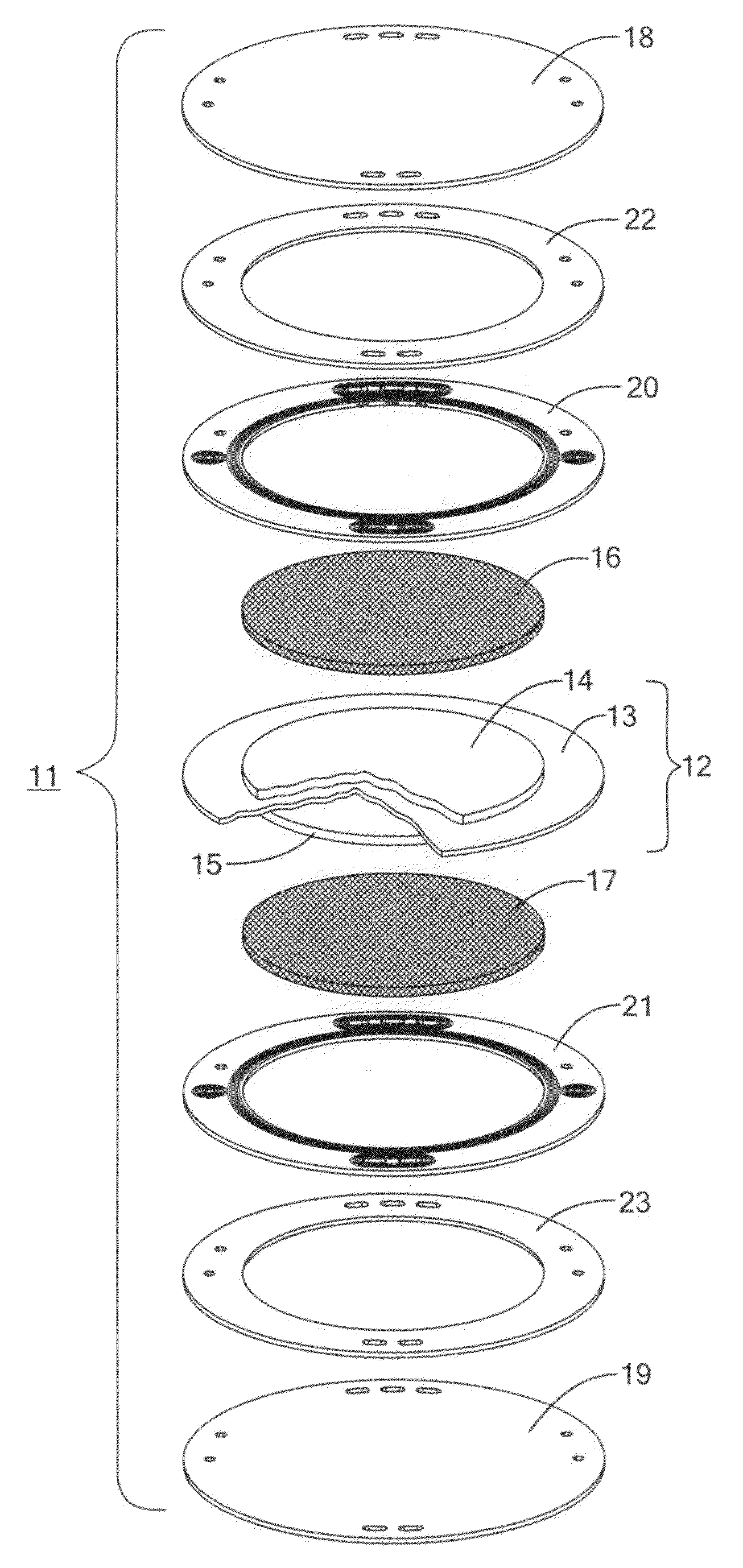

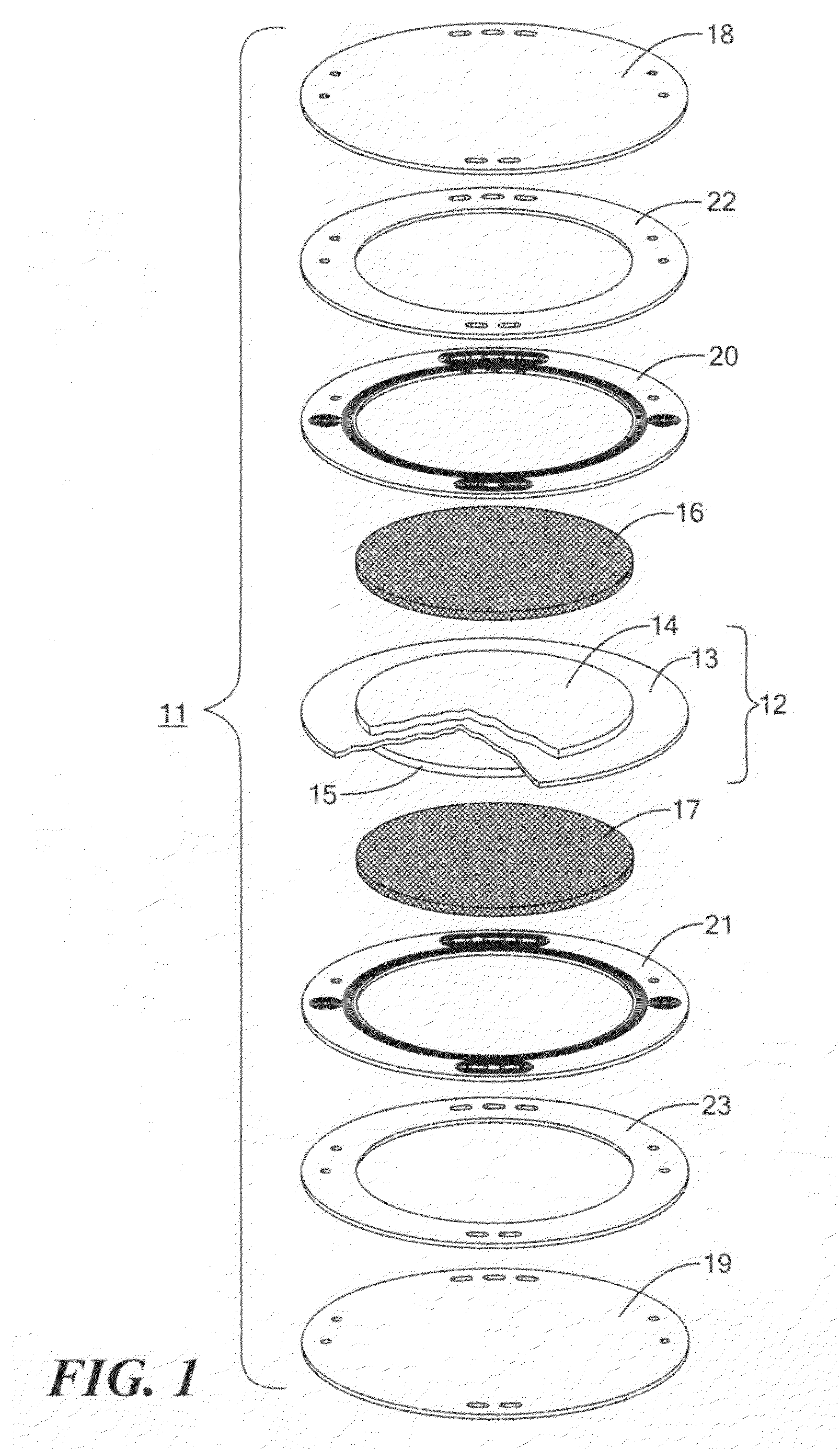

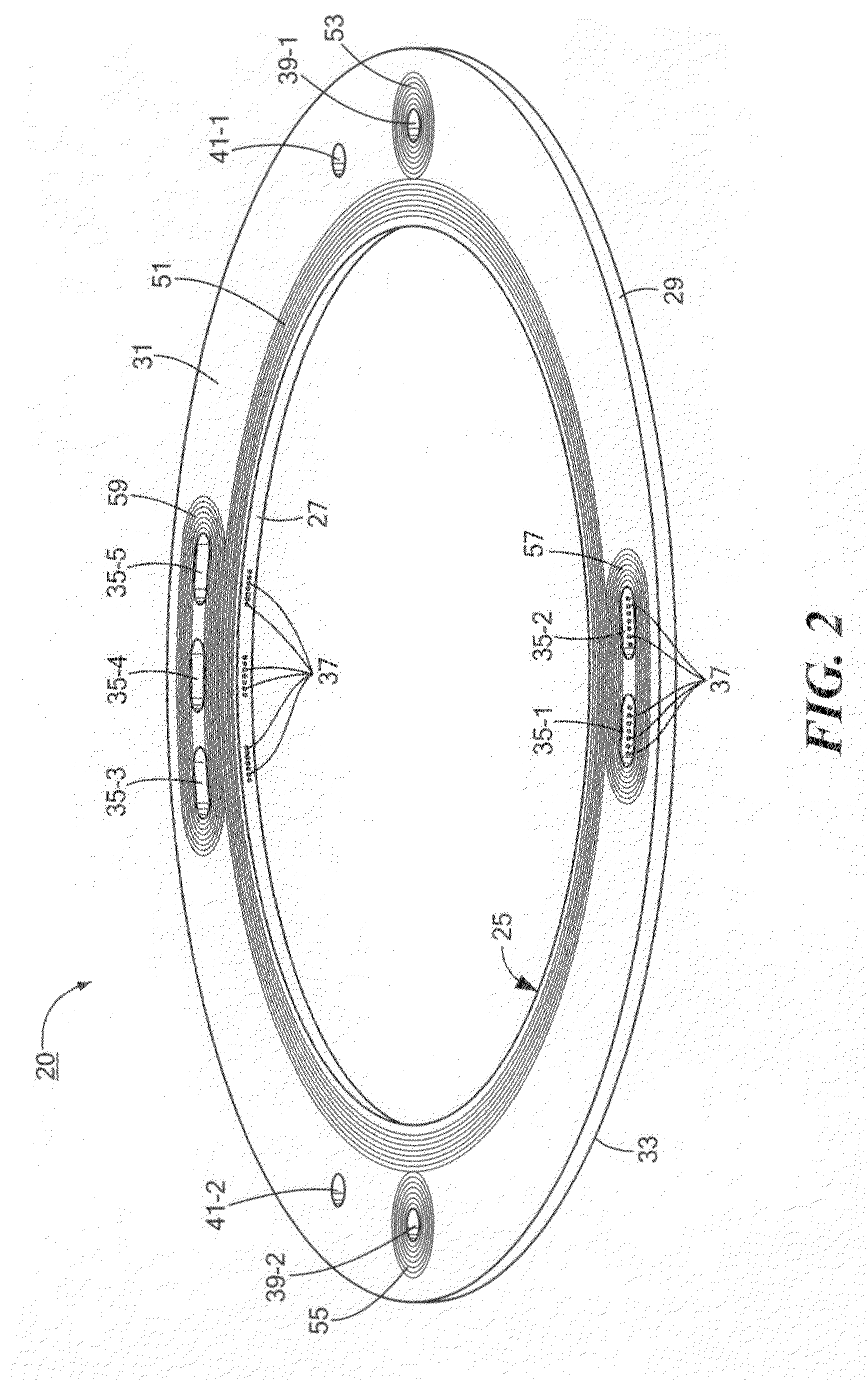

Universal cell frame for high-pressure water electrolyzer and electrolyzer including the same

ActiveUS20100187102A1Reduce scrapStack assemblyCellsElectrical-based auxillary apparatusElectrical batteryEngineering

Universal cell frame generic for use as an anode frame and as a cathode frame in a water electrolyzer. According to one embodiment, the universal cell frame includes a unitary annular member having a central opening. Four trios of transverse openings are provided in the annular member, each trio being spaced apart by about 90 degrees. A plurality of internal radial passageways fluidly interconnect the central opening and each of the transverse openings of two diametrically-opposed trios of openings, the other two trios of openings lacking corresponding radial passageways. Sealing ribs are provided on the top and bottom surfaces of the annular member. The present invention is also directed at a water electrolyzer that includes two such cell frames, one being used as the anode frame and the other being used as the cathode frame, the cathode frame being rotated 90 degrees relative to the anode frame.

Owner:PLUG POWER

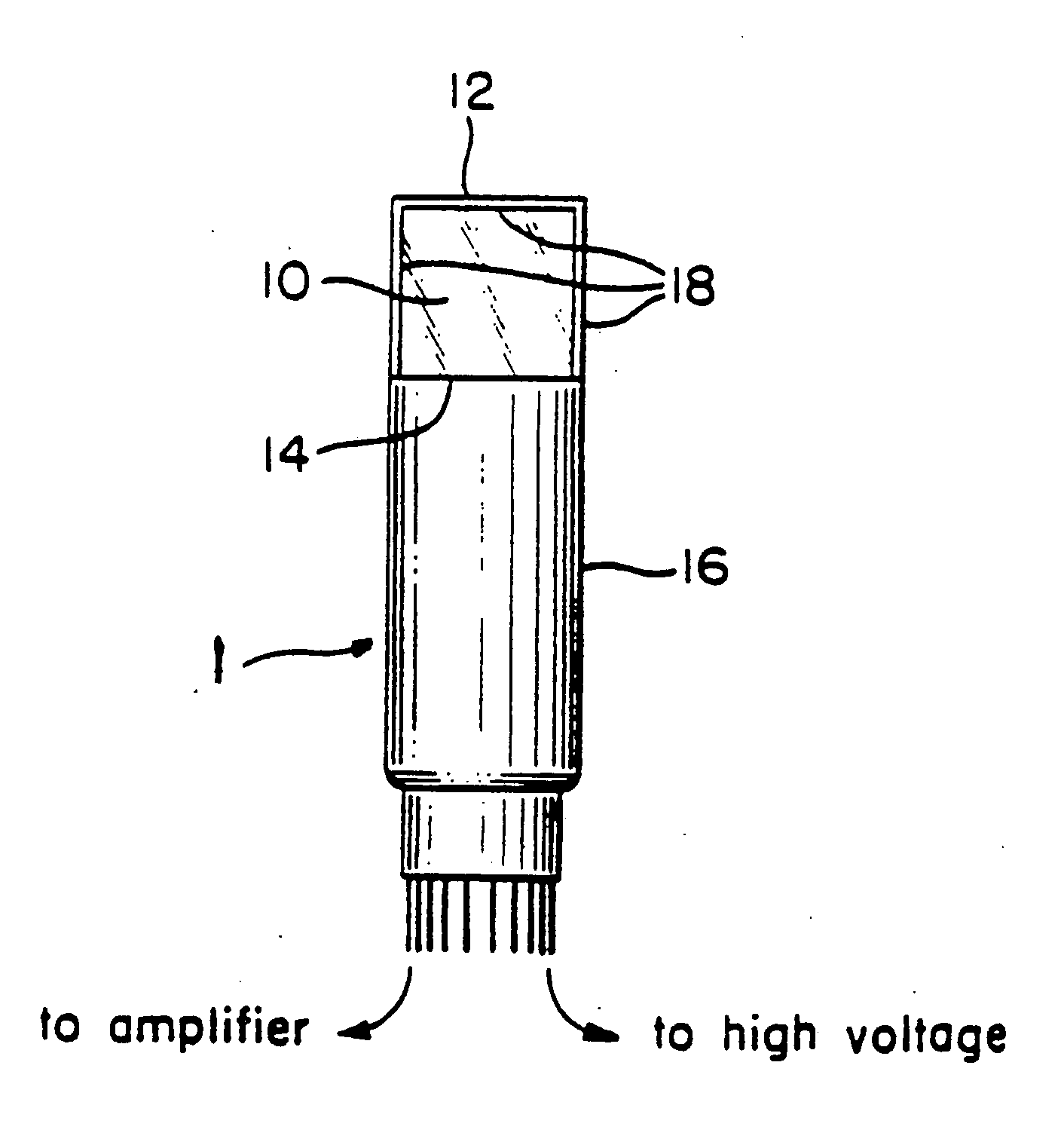

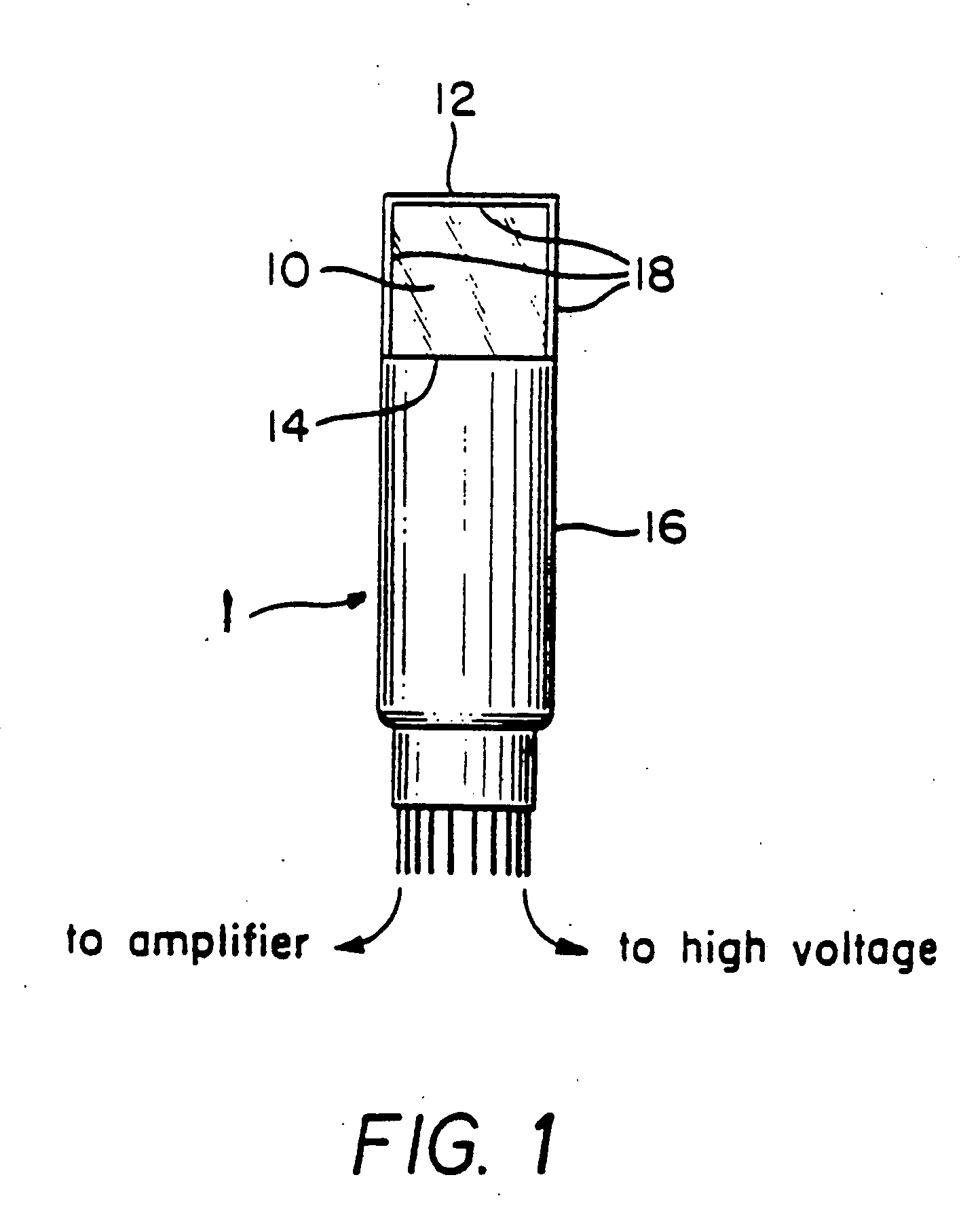

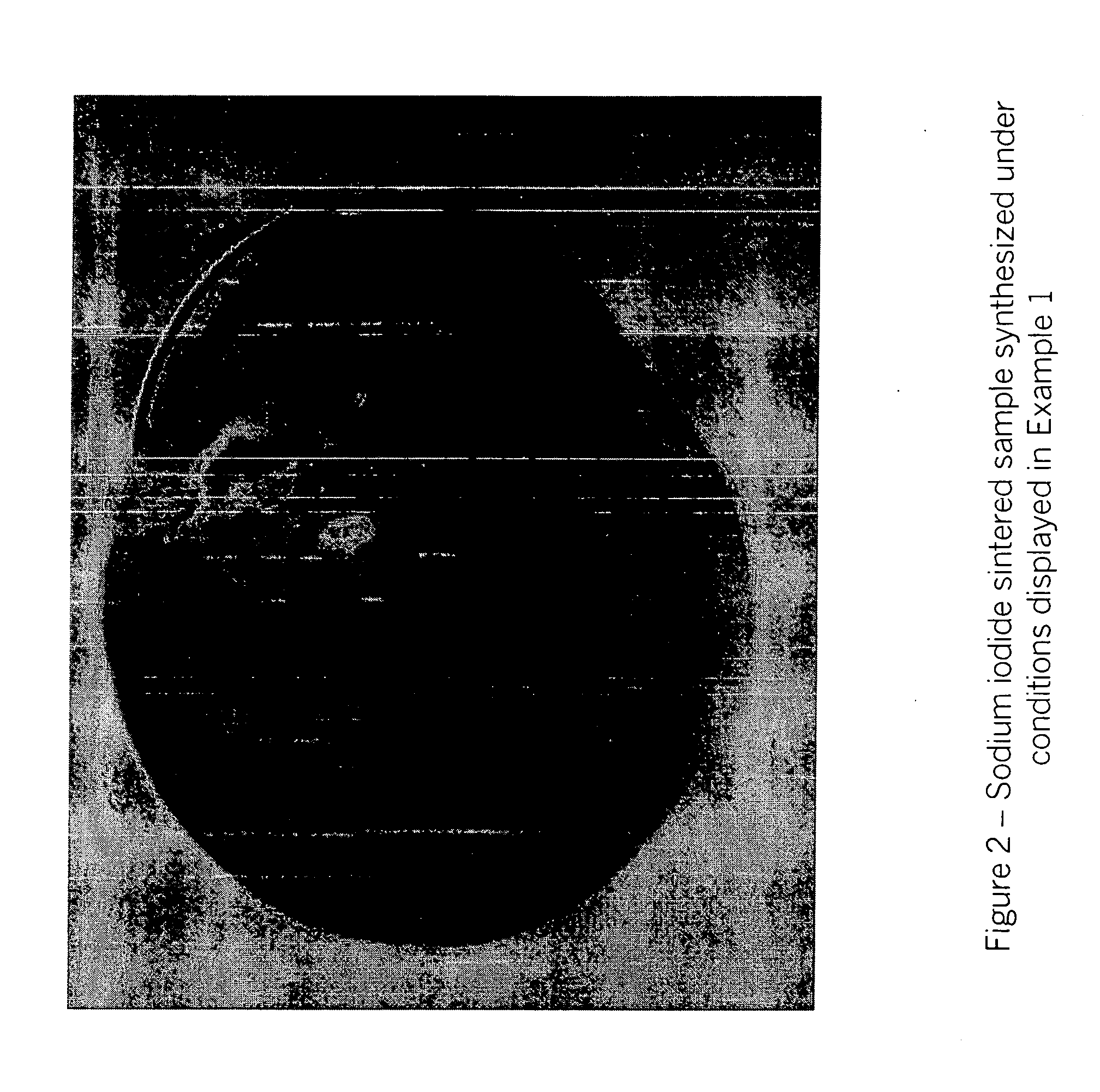

Sintered cubic halide scintillator material, and method for making same

ActiveUS20070237668A1Improve throughputHigh yieldMaterial nanotechnologyMaterial analysis by optical meansPowder mixtureMicrometer

A method of making a cubic halide scintillator material includes pressing a powder mixture of cubic halide and at least one activator under conditions of pressure, temperature, residence time and particle size effective to provide a polycrystalline sintered cubic halide scintillator having a pulse height resolution of from about 7% to about 20%. The conditions include a temperature ranging from about ambient temperature up to about 90% of the melting point of the cubic halide, a pressure of from about 30,000 psi to about 200,000 psi, a pressing residence time of from about 5 minutes to about 120 minutes and an average cubic halide particle size of from about 60 micrometers to about 275 micrometers.

Owner:MOMENTIVE PERFORMANCE MATERIALS QUARTZ INC

Front and rear edge profile redesign method for adaptive processing

The invention discloses a front and rear edge profile redesign method for adaptive processing. A blade-shaped crosshatch is divided into a front and rear edge near-end area, a transitional area and a blade body area, a tolerance area of the centroids of the front and rear edge near-end area is determined according to tolerance requirements for blade components, the tolerance area of the centroids is optimized to obtain a tolerance track which reflects the torsion deformation and position deformation, to satisfy the processing balance, coordinates of the centroids of the front and rear edge near-end area are transformed to obtain a redesign contour of the front and rear edge near-end area of the blade, a contour of the transitional area is fit under the constraint of smooth connection between the near-end area and the blade body, the front and rear edges are combined, the crosshatch is redesigned, and further the curved profile of the front and rear edges is obtained. The method has the advantages that the front and rear edges which are not arched can be processed, and the searching range is narrow during contour adjustment.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

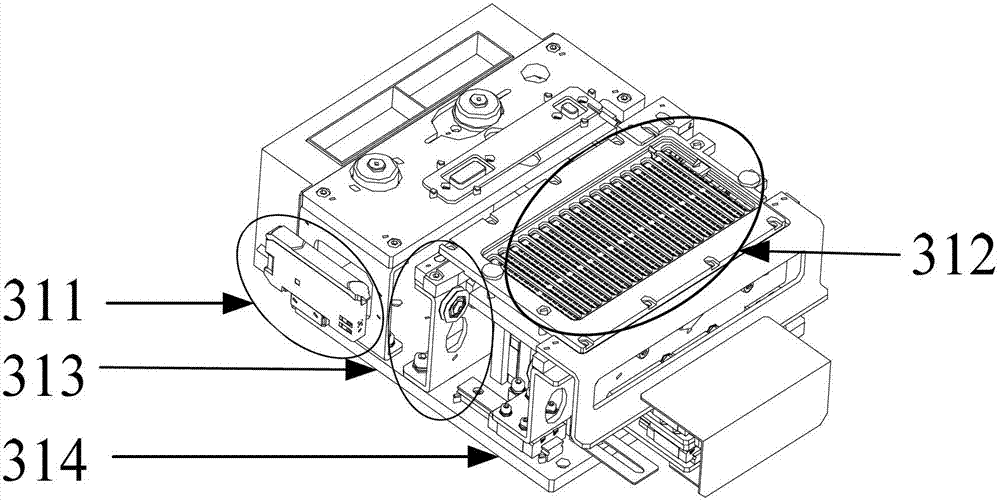

Battery gas-discharging equipment and use method thereof

ActiveCN102263206AReduce battery wasteFacilitates overall assemblyCell component detailsPneumatic pressurePower battery

The invention provides battery gas-discharging equipment and a use method thereof, which are used for reducing abandonment possibility due to battery breakage and causing power batteries to be more practical. The battery gas-discharging equipment comprises a box body, wherein the box body is movably provided with a box cover, a vacuum pumping pipeline port communicated with the inside and outsideof the box body and a scavenging air valve; the box body is connected with a vacuum pumping device by the vacuum pumping pipeline port; a box body wall or the box cover is provided with a spindle in a motive seal penetration mode; and one end stretching into the box body, of the spindle is provided with a matching part which is matched with safety valves of the batteries. The battery gas-discharging equipment can carry out vacuum air discharge on the batteries after the batteries are formed and before the batteries leave a factory, so that a great quantity of gases generated by the formed batteries can be discharged, and the batteries are sealed when the inside of each battery is in a negative pressure state, thus avoiding the battery abandonment caused by breakage of an explosion-proof valve film because the air pressures inside the batteries are too high, ensuring that the outer sizes of the batteries are not changed, and being beneficial to integrally assembling battery packs.

Owner:奇瑞新能源汽车股份有限公司

Automatic dispenser

ActiveCN103203299AReduce touchReduce pollutionLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention provides an automatic dispenser comprising a dispensing operation platform, a guide rail, a feeding convey device, a discharging convey device and a dispensing convey device. The guide rail is arranged on the dispensing operation platform. The dispensing convey device moves along the guide rail to an output end of the feeding convey device to receive to-be-dispensed products conveyed by the feeding convey device and enters the dispensing operation platform along the guide rail to complete dispensing operation; and the dispensing convey device moves from the dispensing operation platform along the guide rail to an input end of the discharging convey device to convey dispensed products carried by the dispensing convey device to the discharging convey device. By the aid of the automatic dispenser, full automatic operations of feeding and discharging are realized, and working efficiency is high; and further, the process to place the to-be-dispensed products manually is avoided, manual touch by processing personnel on the products is reduced, and declared worthless of the to-be-dispensed products caused by false operation by the processing personnel is reduced, and quality of the dispensed products is improved.

Owner:SHENZHEN DINGJING TECH CO LTD

Method for coating photoresist and method for forming photolithography pattern

InactiveCN101354534AReduce or eliminate pollutionReduce scrapPhotomechanical coating apparatusLithographic artistSemiconductor chip

The invention discloses a photoresist coating method, which comprises the following steps of providing a semiconductor chip; rotating the semiconductor chip and spraying the photoresist on the area of the center or close to the center of the surface of the semiconductor chip, wherein, in the process of rotating the semiconductor chip, spraying gas to the nearly marginal area of the back of the semiconductor chip to prevent the photoresist from being coated on the back along the margin of the semiconductor chip. The invention also provides a formation method of lithography patterns, which can reduce or eliminate the defects caused by back washing.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com