Device and method for repairing friction stir welding weld defect of storage tank for carrier rocket

A friction stir welding and launch vehicle technology, which is applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems affecting the weld strength and air tightness, so as to improve the success rate, reduce holes, and ensure the welding process is stable controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

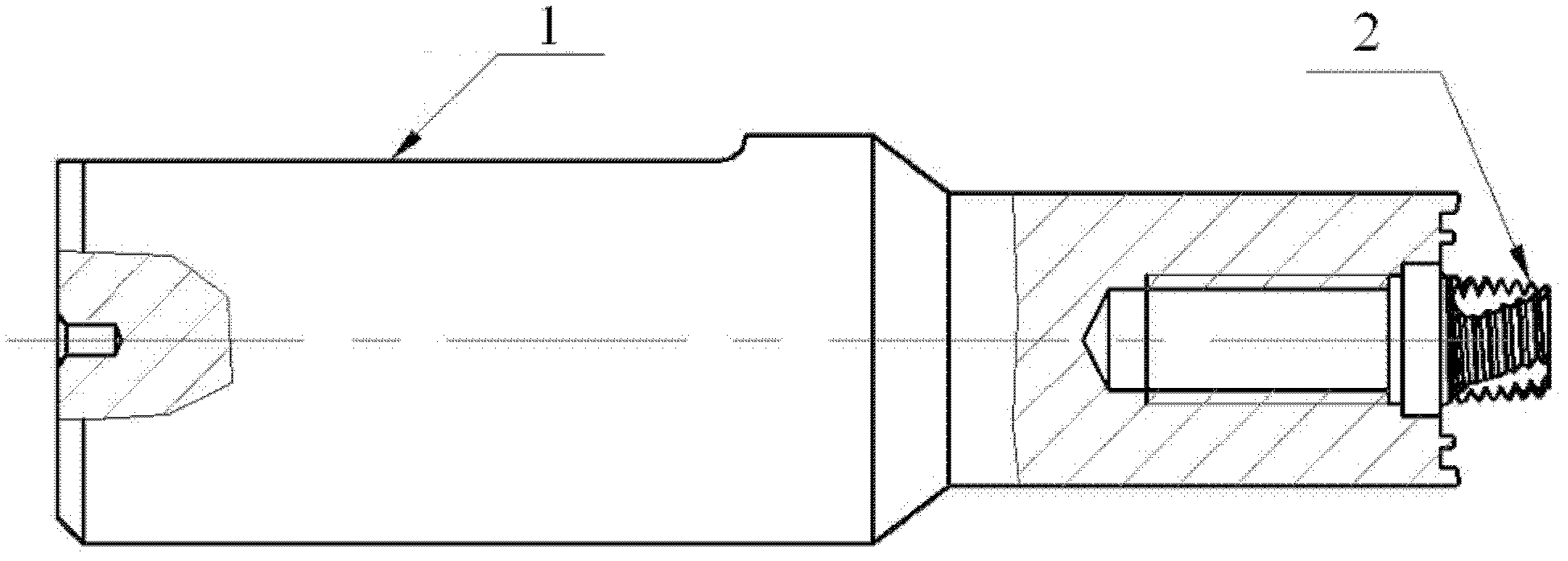

[0034] like figure 2 As shown, the repair welding stirring head used includes a stirring pin holding structure 1 and a stirring pin 2 threadedly connected to the end of the stirring pin holding structure 1 .

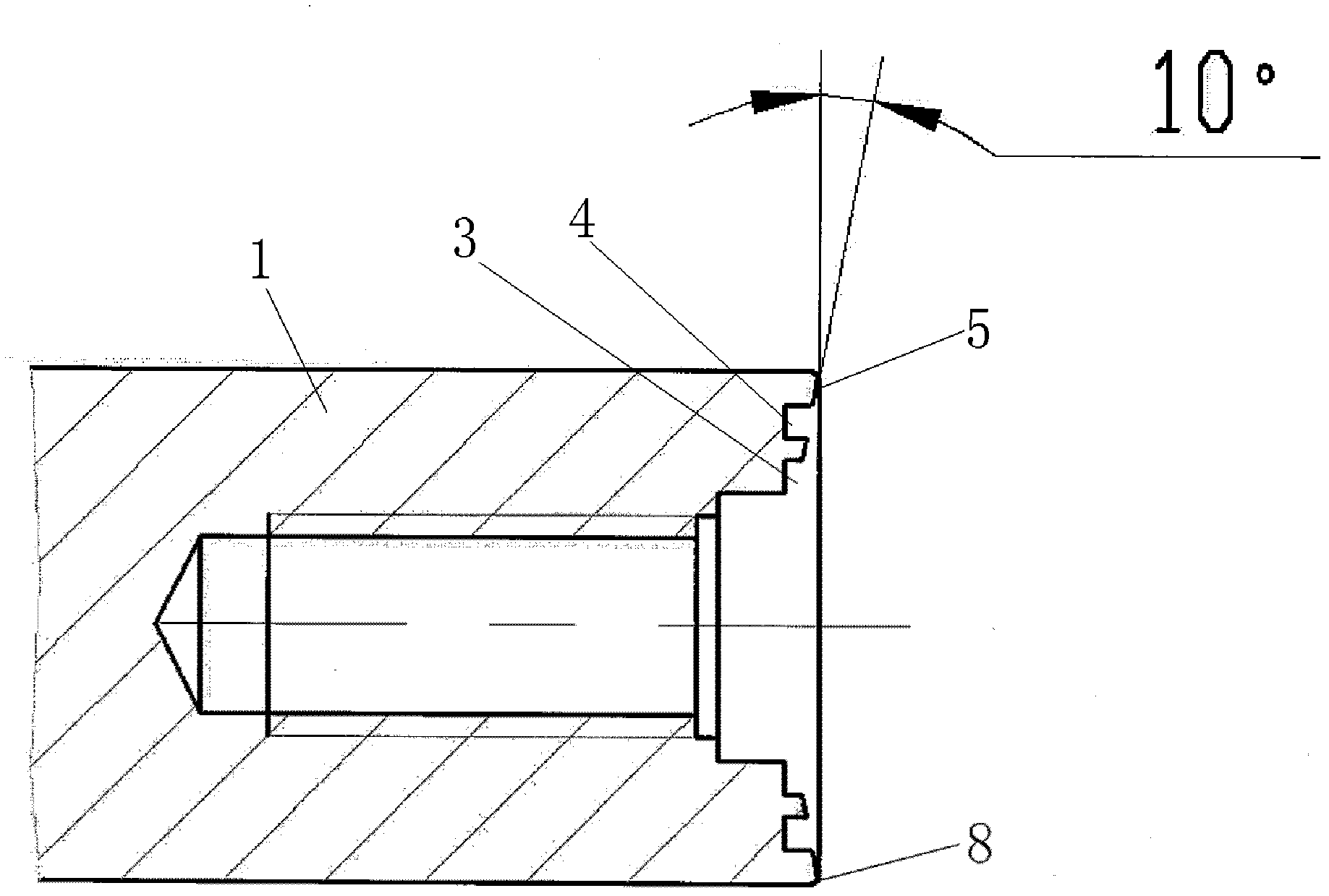

[0035] like image 3 As shown, the end surface of the shoulder portion of the stirring needle holding structure 1 is a concave slope 5 with an inclination angle of 10°. Two concentric annular grooves are provided on the slope 5, the depth of groove one 3 and groove two 4 is 1.3mm, and the width is 1.7mm. The radial interval between groove one 3 and groove two 4 is 1.5 mm. The outer edge structure of the end surface of the shaft shoulder part of the stirring needle clamping mechanism 1 is a rounded structure 8, and the radius R is 0.8 mm.

[0036] like Figure 4 and Figure 5 As shown, the front part of the stirring needle 2 is a conical thread structure, and the conical angle is 18°; three spiral grooves 7 are provided at the circumferential intervals of the conica...

Embodiment 2

[0039] The invention relates to a method for repairing defects of the friction stir welding seam of a carrier rocket storage tank, wherein the storage tank is welded by friction stir welding, and the storage tank is made of an 8mm thick aluminum alloy.

[0040] like Figure 6 As shown, the welding start point of the weld seam is set as point A, and the welding end point of the weld seam is point C; The weld has produced a "keyhole" defect and needs to be repaired.

[0041] The structural design parameters of the formal welding stirring head are shown in Table 1. It is welded from point A to point B and the stirring pin breaks off.

[0042]Table 1 Structural parameters of the mixing head for the formal welding of the longitudinal seam of the cylinder section

[0043]

[0044] The repair weld method includes the following steps:

[0045] (a) First, manually excavate the stirring pin broken at point B of the friction stir welding seam;

[0046] Firstly, X-ray flaw detecti...

Embodiment 3

[0057] The invention relates to a method for repairing defects of the friction stir welding seam of a carrier rocket storage tank, wherein the storage tank welding adopts friction stir welding, and the storage tank is made of aluminum alloy with a thickness of 10 mm.

[0058] Such as Figure 6 As shown, the welding start point of the weld seam is set as point A, and the welding end point of the weld seam is point C; The weld has produced a "keyhole" defect and needs to be repaired.

[0059] The structural design parameters of the formal welding stirring head used are shown in Table 3. It is welded from point A to point B and the stirring pin breaks off.

[0060] Table 3 Structural parameters of the mixing head for the formal welding of the longitudinal seam of the cylinder section

[0061]

[0062] The repair weld method includes the following steps:

[0063] (a) First, manually excavate the stirring pin broken at point B of the friction stir welding seam;

[0064] Fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com