Asymmetrical light diffusion element and manufacturing method thereof

A manufacturing method and light diffusion technology, applied in the direction of optical elements, optical elements, diffusion elements, etc., to achieve the effect of simplifying development and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

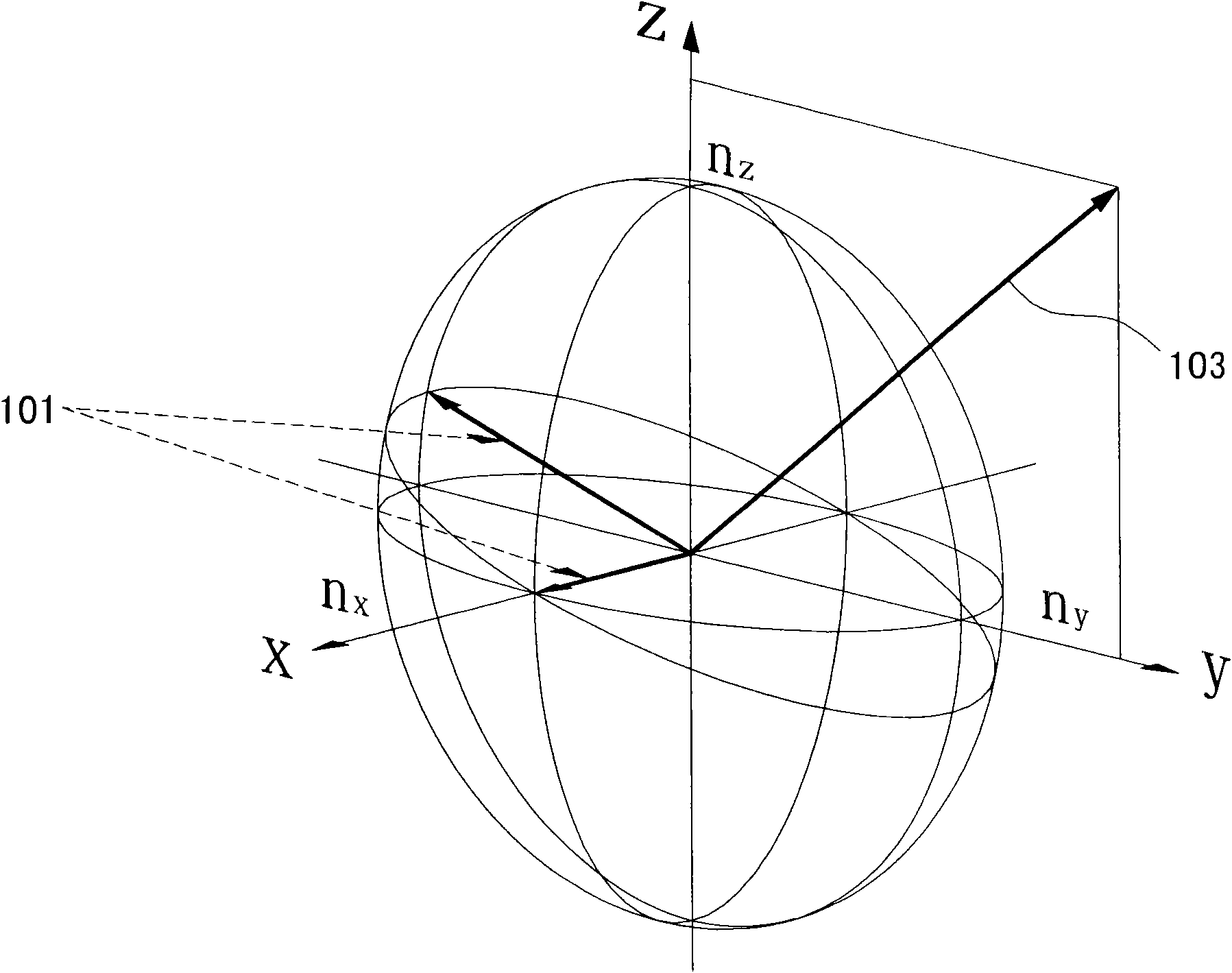

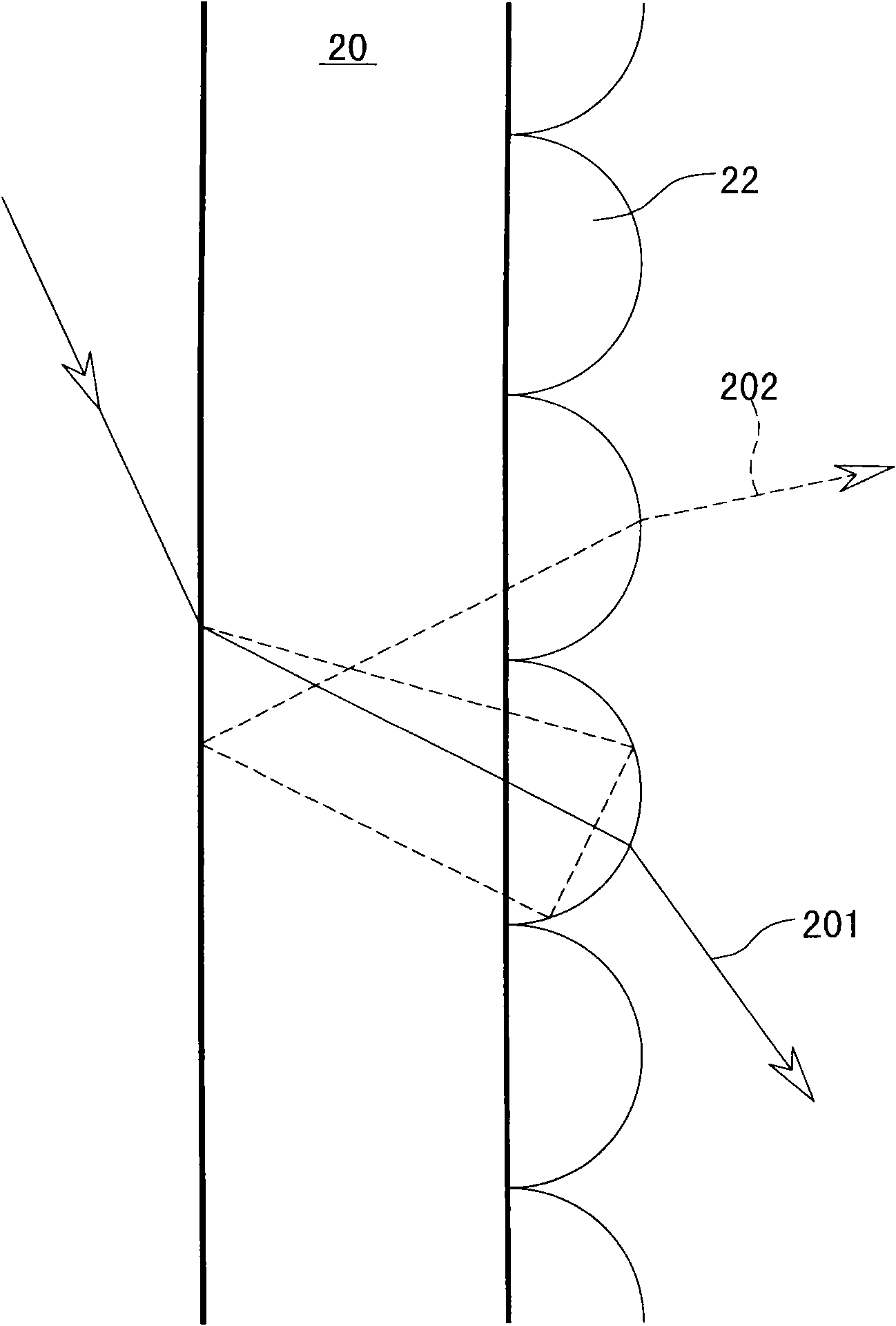

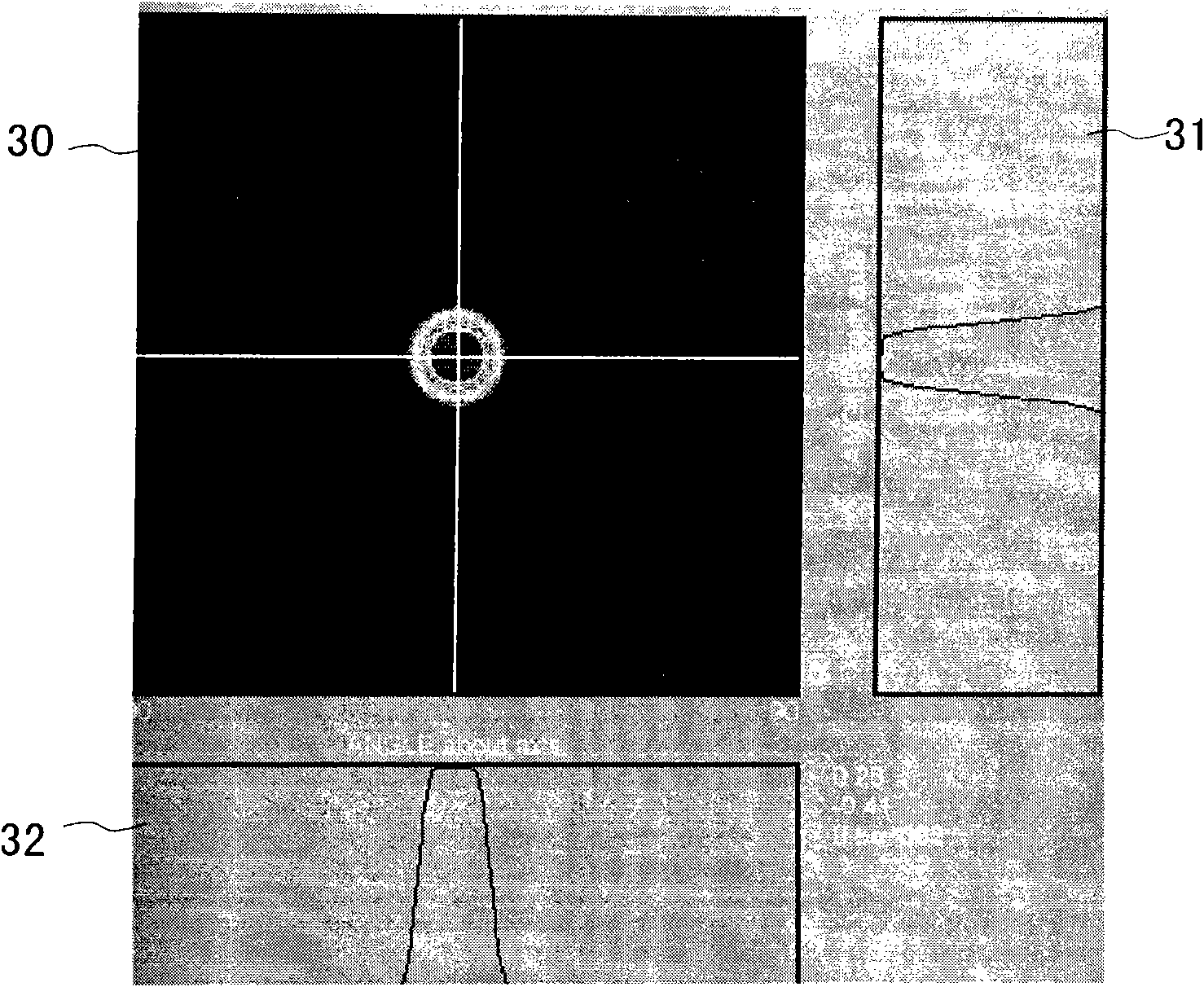

[0043] The present invention relates to an asymmetric light diffusion element and its manufacturing method. The diffusion element is a diffusion element with better diffusion characteristics, which can be mainly used for the backlight source of a display panel, such as a diffusion plate or a diffusion film. The process of the diffusion element is to use The stress extension and the surface structure of the component cause the birefringent diffusion characteristic of the transparent substrate with the diffusing particles. In addition, an asymmetric and undulating surface microstructure can be formed on the surface of the substrate, so that the light passing through the diffusion element can be uniformly scattered by the substrate and the surface structure of anisotropic material.

[0044] In particular, the refractive index selection of the above-mentioned scattering particles in the substrate and the substrate itself and the refractive index matching and thickness of the stretc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com