Blue-light-proof film and preparation method thereof

An anti-blue light, film technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of falling and cracking, the edge of the film is prone to warping, and the curved display screen is lost, and achieves good flexibility and is not easy to interlayer. Separation, good recoat adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0077] The present invention also provides a method for preparing the aforementioned anti-blue light film, including:

[0078] Coating the anti-blue light coating liquid on a thermoplastic substrate, and after curing, obtain a thermoplastic substrate coated with an anti-blue light coating; the anti-blue light coating liquid has an acrylic coating liquid with an anti-blue light function;

[0079] Coating the functionalized coating liquid on the anti-blue light coating to obtain a thermoplastic substrate coated with the functional coating after curing; the functionalized coating liquid is a UV-cured acrylic coating liquid;

[0080] Hot-press forming the thermoplastic substrate coated with the functional coating to obtain an anti-blue light film;

[0081] Or coating the anti-blue light coating liquid on the thermoplastic substrate, and after curing, obtain the thermoplastic substrate coated with the anti-blue light coating, the anti-blue light coating liquid is an acrylic coating liquid w...

Embodiment 1

[0100] The anti-blue light coating is formed by the following components by weight: 60 parts of urethane acrylate (a reaction product of dipentaerythritol pentaacrylate and hexamethylene diisocyanate, with a functionality of 10) naphthalenediimides 1 part of compound, 5 parts of hydroxyethyl acrylate and 1 part of a-hydroxyketone photoinitiator.

[0101] The functional coating is formed by the following parts by mass: 50 parts of urethane acrylate oligomer (a reaction product of dipentaerythritol pentaacrylate and hexamethylene diisocyanate, with a functionality of 10), 1,6 -10 parts of hexanediol diacrylate (HDDA) and 1 part of a-hydroxyketone photoinitiator.

[0102] The substrate is a polycarbonate (PC) film with a thickness of 50 μm, a light transmittance of 95%, and a haze of 0.5%.

[0103] The anti-blue light coating and the functional coating are located on the same side of the substrate in turn. The anti-blue light film for curved display screens is prepared by the following...

Embodiment 2

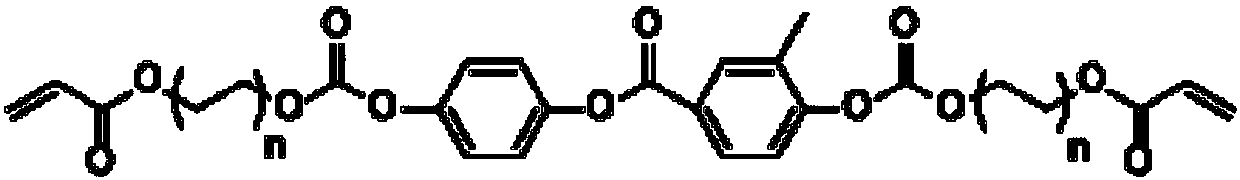

[0109] The anti-blue light coating is composed of the following parts by weight: 40 parts of urethane acrylate (a reaction product of pentaerythritol triacrylate and isophorone diisocyanate, with a functionality of 6), hydroxypropyl methacrylate (HPMA) 2 parts, nematic liquid crystal compound (formula 1, n=4) 30 parts, chiral compound 2 parts (formula 2 below), a-hydroxyketone photoinitiator 0.1 part, leveling agent 1 part .

[0110]

[0111] The functional coating is composed of the following parts by weight: 50 parts of urethane acrylate (a reaction product of pentaerythritol triacrylate and isophorone diisocyanate, with a functionality of 6), dipentaerythritol hexaacrylate (DPHA) 10 parts, 10 parts of propoxytrimethylolpropane trimethylol ester (POTMPTA), 0.3 parts of a-hydroxyketone photoinitiator, 2 parts of nano silica particles, and 1 part of leveling agent.

[0112] The substrate is a polymethacrylate (PMMA) film with a thickness of 50 μm, a light transmittance of 95%, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com