Production system for paper pulp moulded products and production method utilizing production system

A pulp molding and production system technology, which is applied in textiles and papermaking, can solve the problems of high production cost, long time consumption, and many production links, achieve good drying and dehydration effects, and avoid the effect of bulky equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

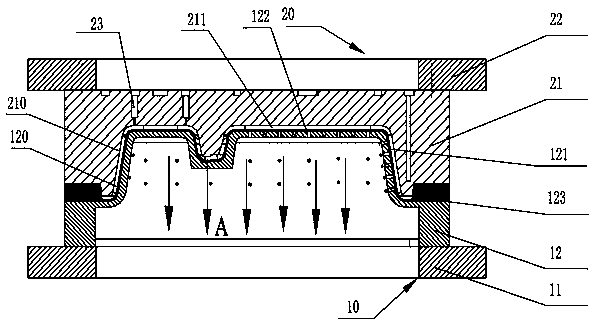

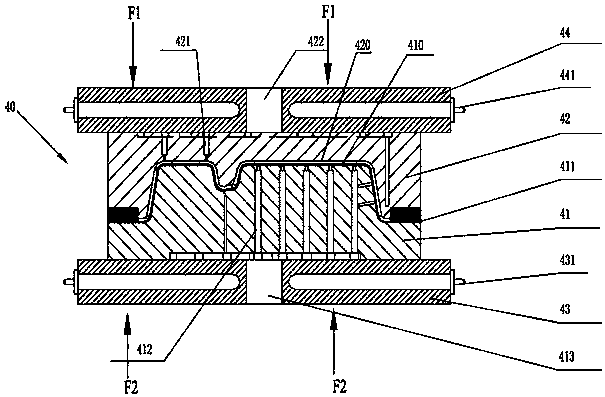

[0039] figure 1 , figure 2 The main components in the pulp molded product production system of one embodiment of the present invention are shown.

[0040] Generally, the pulp molded product production system includes a forming device for forming, a drying device for drying, and a transfer device for transferring the formed pulp molded product blank from the forming device into the drying device.

[0041] (1) Forming device, transfer device

[0042] Wherein, the forming device includes a forming die and a forming machine, and the forming machine is used to support and control the movement of the forming die. When working, the forming mold is installed on the forming machine, the forming machine is turned on, and the forming mold is clamped by the manipulator of the forming machine and immersed in the pulp suspension; when the pulp is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com