3D printing method of metal dental crown

A 3D printing and metal technology, applied in the field of 3D printing, can solve the problems of reducing user experience, rough inner and outer surfaces of crowns, and easy to wear gums, etc., to achieve the effect of improving experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

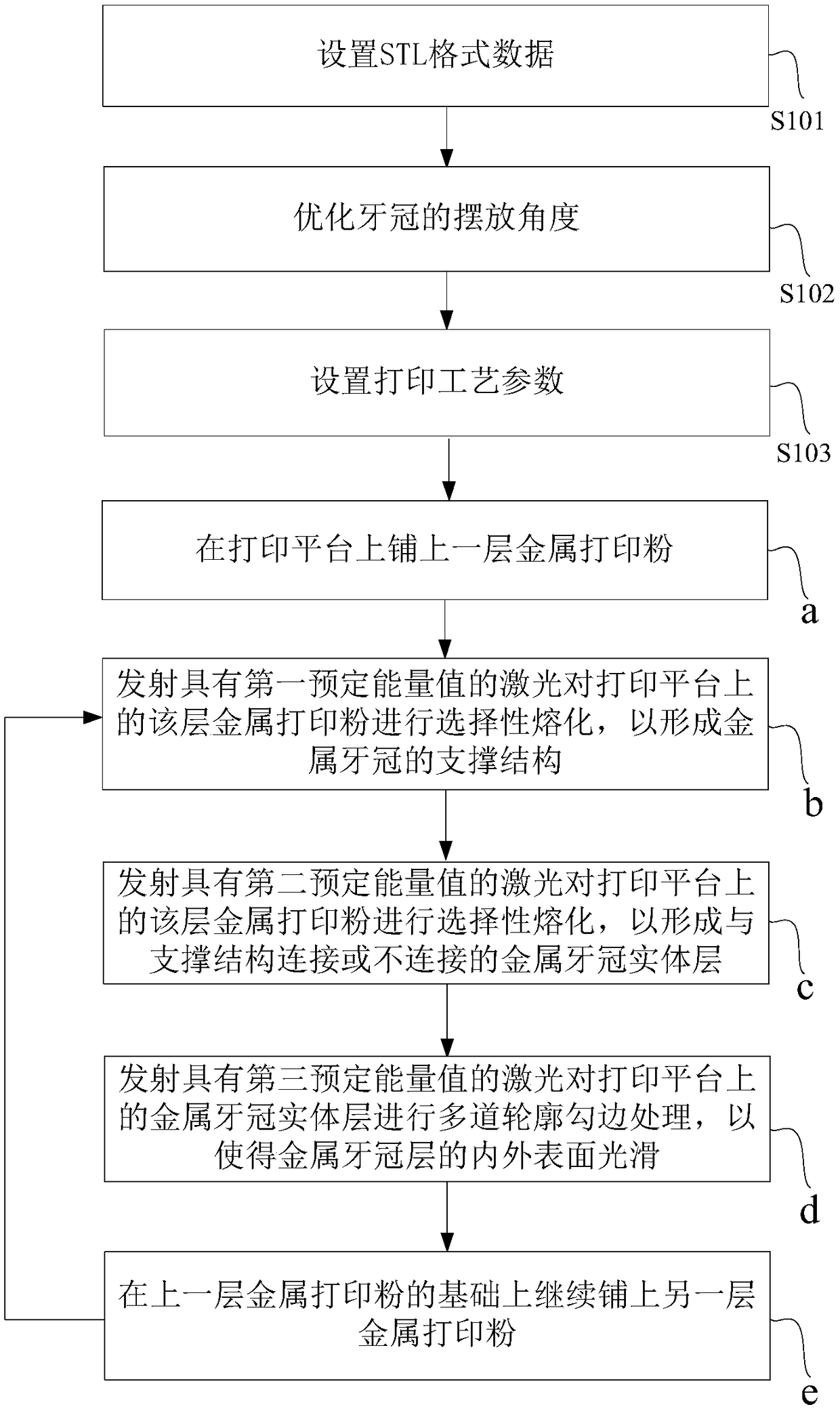

[0017] Such as figure 1 as shown, figure 1 It is a schematic flow chart of the 3D printing method of the metal dental crown of the present invention. The 3D printing method comprises the following steps:

[0018] Step 101: Set STL format data.

[0019] It should be understood that STL is a specific 3D printing data format, and the three-dimensional data of the part to be printed can be converted into the STL format.

[0020] Step 102: Optimizing the placement angle of the dental crown.

[0021] It should be understood that since the inner surface of the fixed bridge of the crown will be in direct contact with the patient’s abutment teeth, it is an important molding surface, and in order to ensure the suitability of the crown edge and the interior of the crown, grinding has to be carried out in the subsequent processing, so in order to To ensure the molding quality of the inner surface, that is, to make the inner surface convenient for grinding, it is necessary to optimize ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com