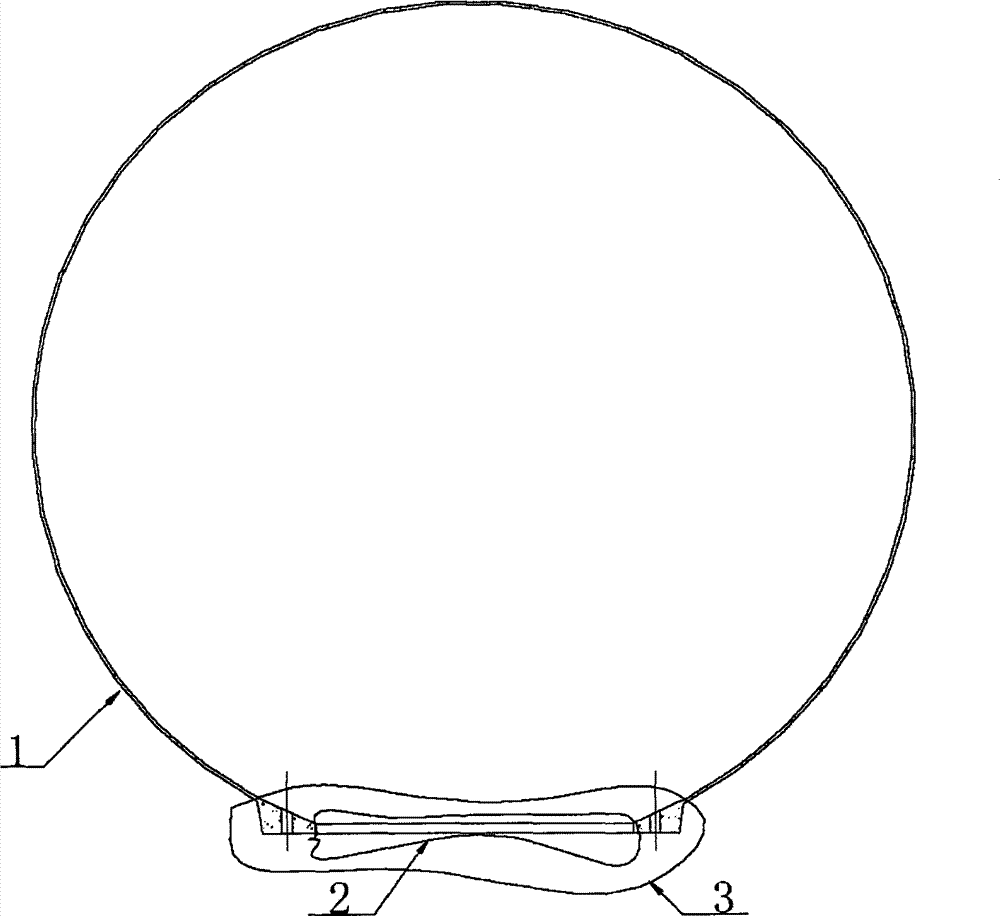

Method for manufacturing seamless spherical screen by using ball bladder

A technology of seamless spherical shells and bladders, which is applied in optics, instruments, projection devices, etc., can solve the problems of difficulty in processing seamless spherical screens, affecting projection effects, and insufficient roundness of spherical shells, etc., to achieve good transparency and improve Projection effect, fast curing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Pre-treatment: First, make a full-spherical bladder, which can be a hollow bladder, apply #8 wax evenly on all the outer surfaces of the bladder with a clean cotton cloth, and the number of times of waxing depends on the size of the bladder. Adjust the size and effect of smearing, generally smearing twice.

[0032] Preparation of resin mixture: take 1000 parts by weight of o-phthalic unsaturated polyester resin, first add 1 part by weight of accelerator (cobalt isooctanoate) and 1 part by weight of curing agent (cyclohexanone peroxide), and stir evenly.

[0033] The accelerator can also choose cobalt naphthenate or tertiary amine, and the curing agent can also choose isopropyl hydroperoxide, benzoyl peroxide or methyl ethyl ketone peroxide.

[0034] Add 5 parts by weight of UV absorber to slow down the yellowing speed of the resin system.

[0035] The proportions of the above components can be varied according to seasonal changes or room temperature changes, and can al...

Embodiment 2

[0042] The pretreatment method is the same as in Example 1.

[0043] Prepare epoxy resin mixture A:

[0044] 400 parts by weight of liquid bisphenol A type epoxy resin;

[0045] 250 parts by weight of liquid bisphenol F type epoxy resin;

[0046] 50 parts by weight of 1,4 butanediol diglycidyl ether;

[0047] Thoroughly stir and mix uniformly to obtain resin mixture A.

[0048] To prepare curing agent mixture B:

[0049] 100 parts by weight of m-xylylenediamine;

[0050] 20 parts by weight of triethylenetetramine;

[0051] 60 parts by weight of polyetheramine;

[0052] Thoroughly stir and mix uniformly to obtain curing agent mixture B.

[0053] Take 700 parts by weight of resin mixture A, add 300 parts by weight of curing agent mixture B, and add 20 parts by weight of defoamer, and stir evenly.

[0054] Add 5 parts by weight of ultraviolet absorber to the above system to obtain the target mixture, so as to delay the yellowing speed of the resin system.

[0055] Sprayi...

Embodiment 3

[0058] Operation method is identical with embodiment 1, and difference is that the formula of the resin mixture of preparation is different, as follows:

[0059] 1000 parts by weight of unsaturated resin;

[0060] 3 parts by weight of ultraviolet absorber;

[0061] Accelerator 2 parts by weight;

[0062] 2 parts by weight of curing agent.

[0063] Note: The amount of curing agent and accelerator added determines the curing speed of the resin. Add 2 parts by weight of curing agent and accelerator, suitable for operating environments with low temperature (below room temperature, higher than 10 degrees Celsius).

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com