Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

108 results about "Thin-film diode" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thin film diode (TFD) generally refers to any diode produced using thin-film technology. Within the flat panel display industry TFD more often refers to thin film bi-directional diodes, also known as metal-insulator-metal (MIM) TFDs or nonlinear resistors. Bi-directional MIM TFDs have very low current flow at low applied voltages, but then begin to conduct electricity above a threshold voltage, of either positive or negative polarity. Owing to this behavior these two terminal devices may be used as a switch. The exact threshold voltage at which a MIM TFD switches on and begins to conduct electricity depends on its physical dimensions, such as thickness of the insulating layer, as well as the physical properties of the materials from which it is made, such as the work function of each metal layer.

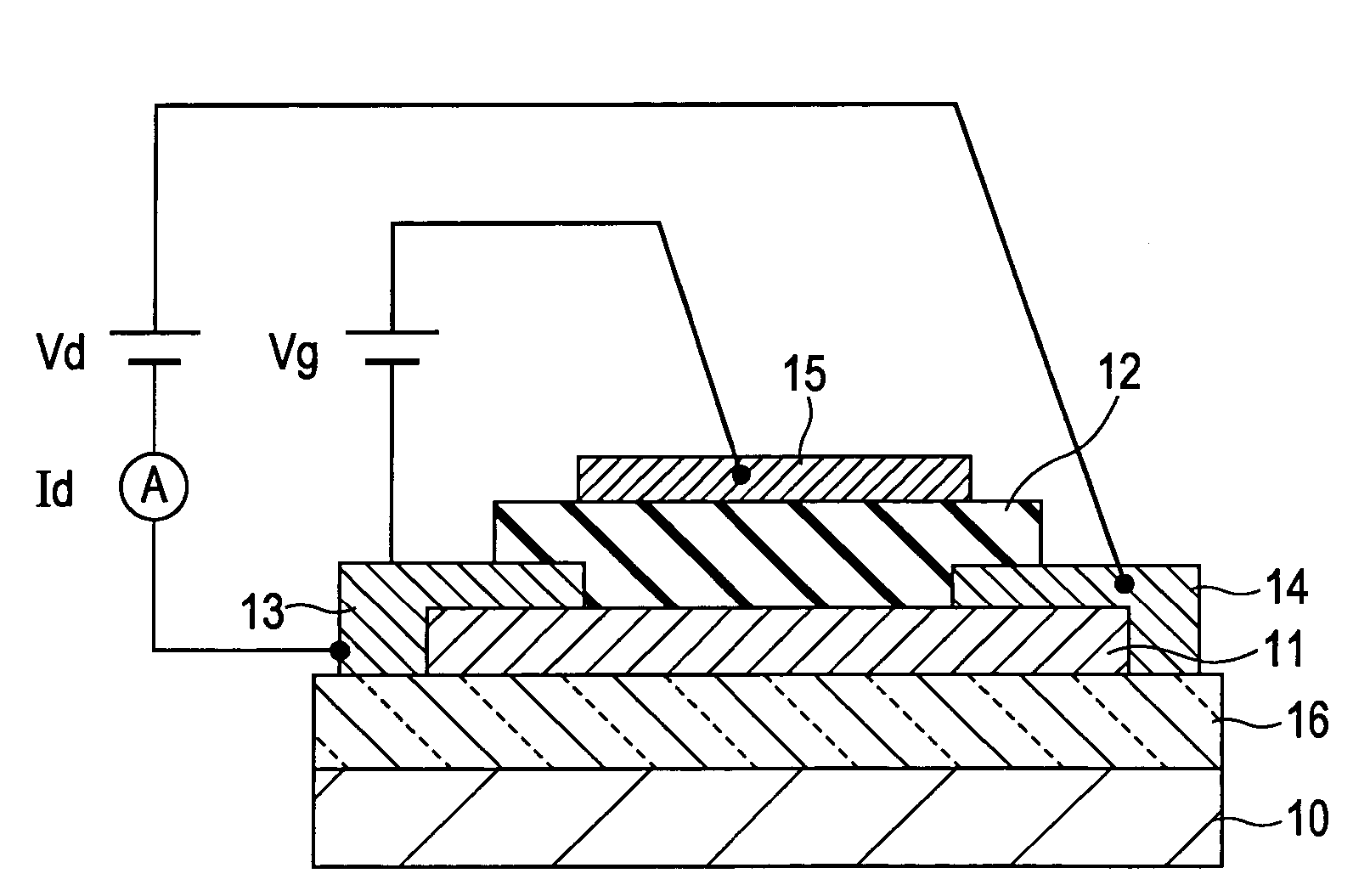

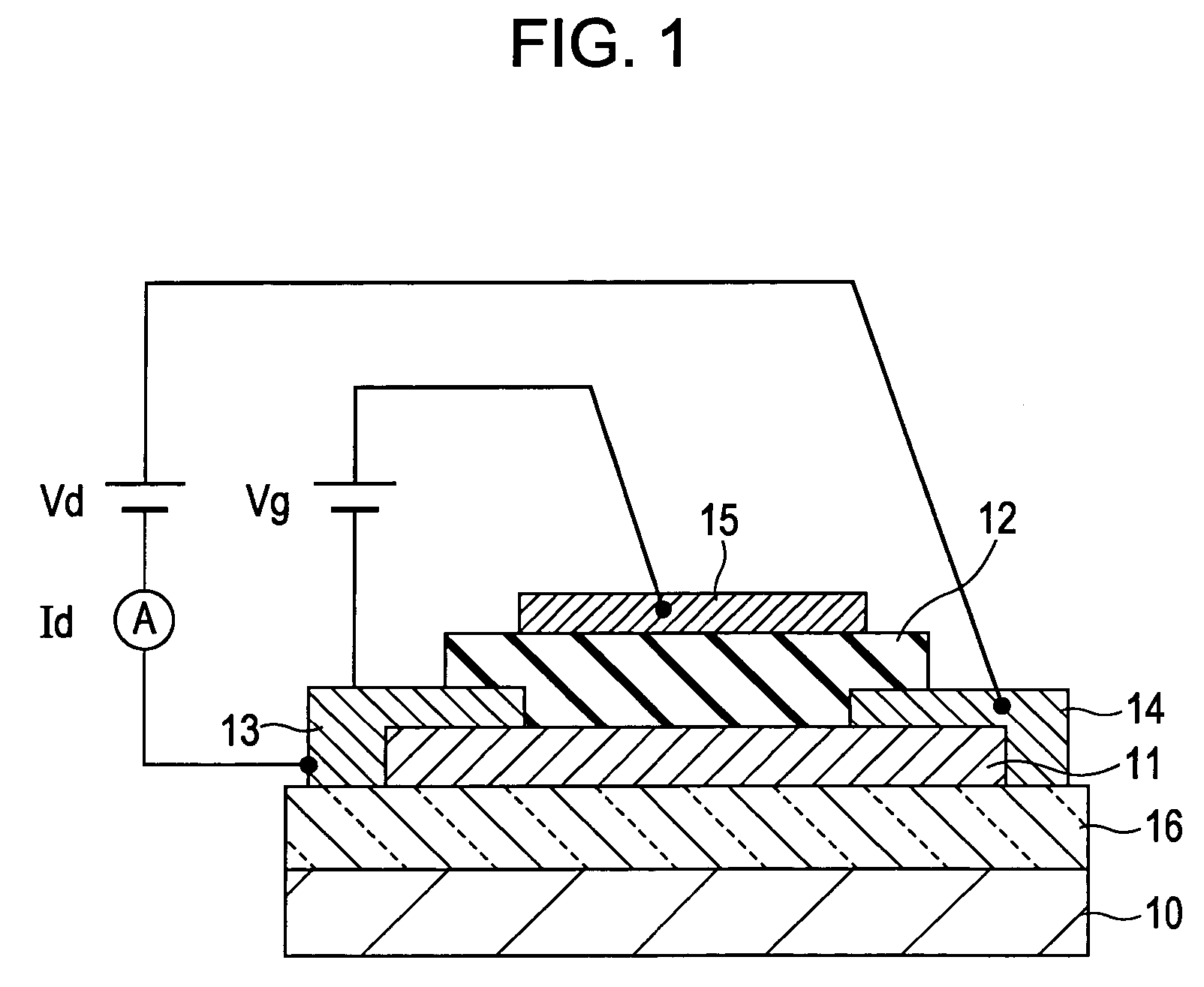

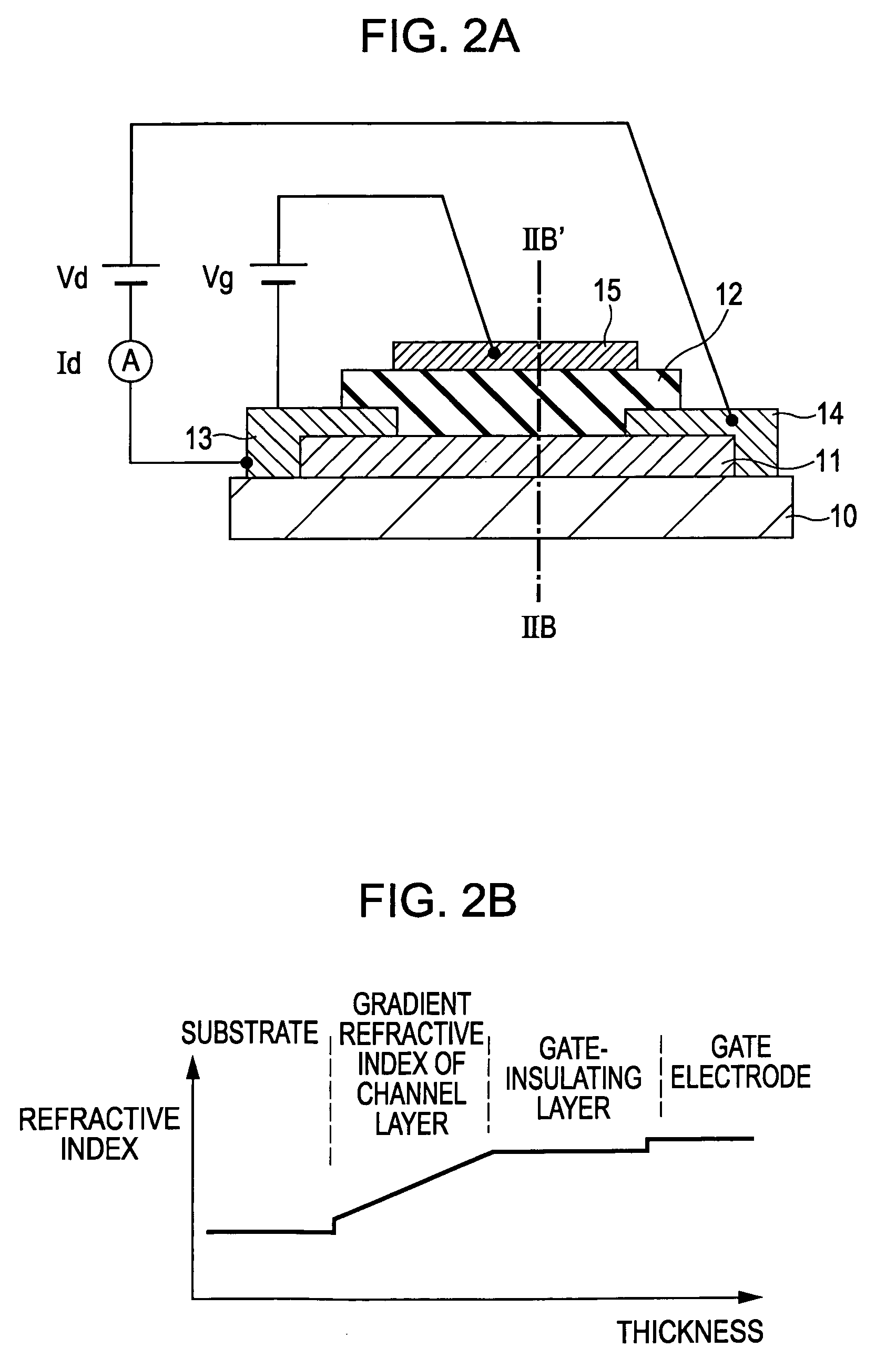

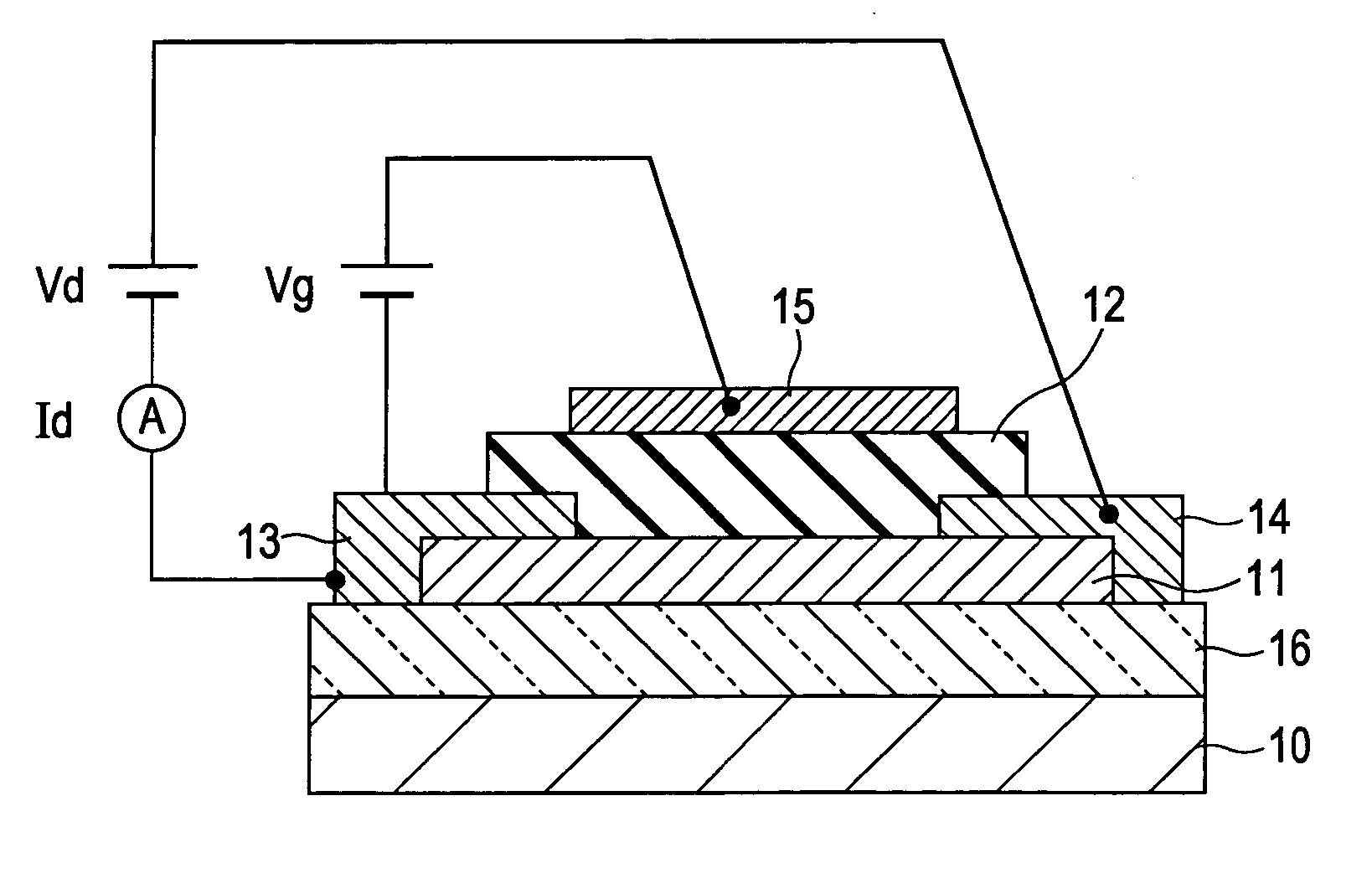

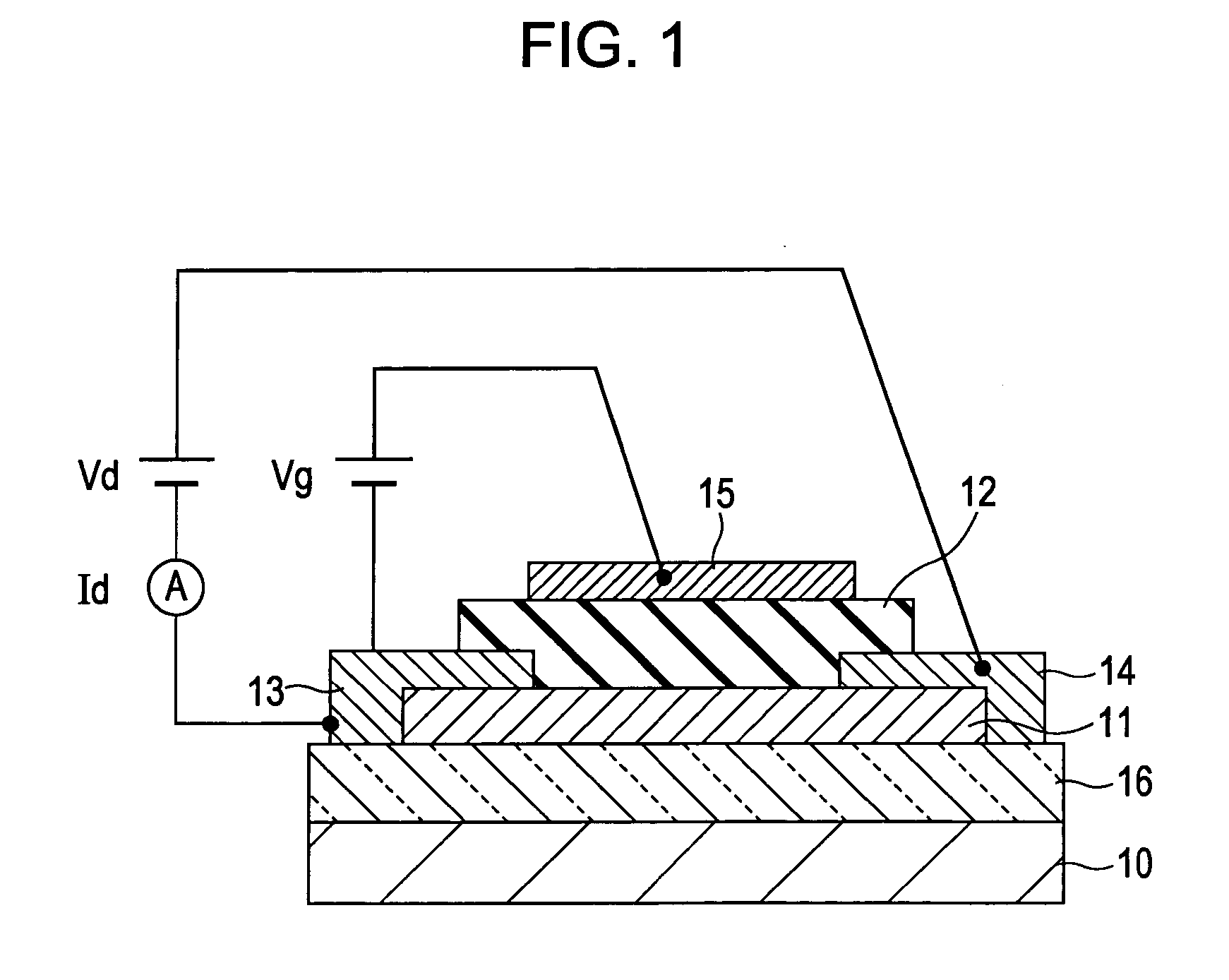

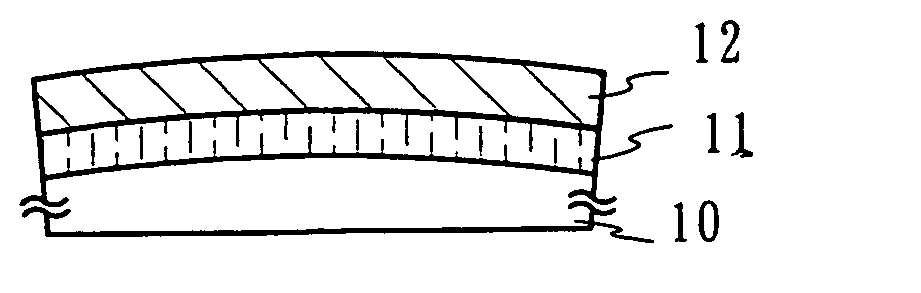

Thin-film transistor and thin-film diode having amorphous-oxide semiconductor layer

ActiveUS7453087B2High light transmittanceHigh transparencyTransistorSemiconductor/solid-state device manufacturingThin-film diodeRefractive index

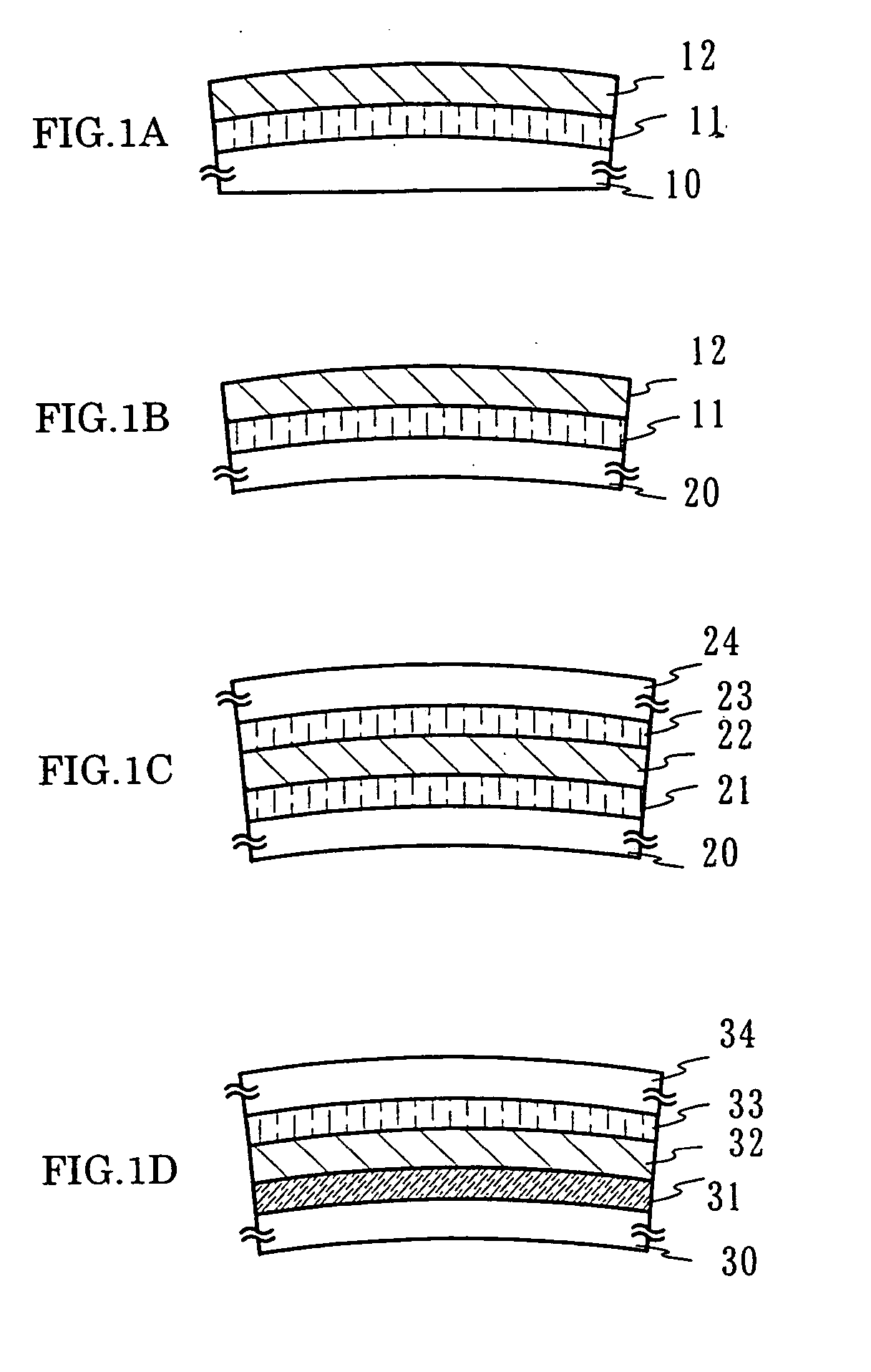

A thin-film transistor including a channel layer being formed of an oxide semiconductor transparent to visible light and having a refractive index of nx, a gate-insulating layer disposed on one face of the channel layer, and a transparent layer disposed on the other face of the channel layer and having a refractive index of nt, where there is a relationship of nx>nt. A thin-film transistor including a substrate having a refractive index of no, a transparent layer disposed on the substrate and having a refractive index of nt, and a channel layer disposed on the transparent layer and having a refractive index of nx, where there is a relationship of nx>nt>no.

Owner:CANON KK

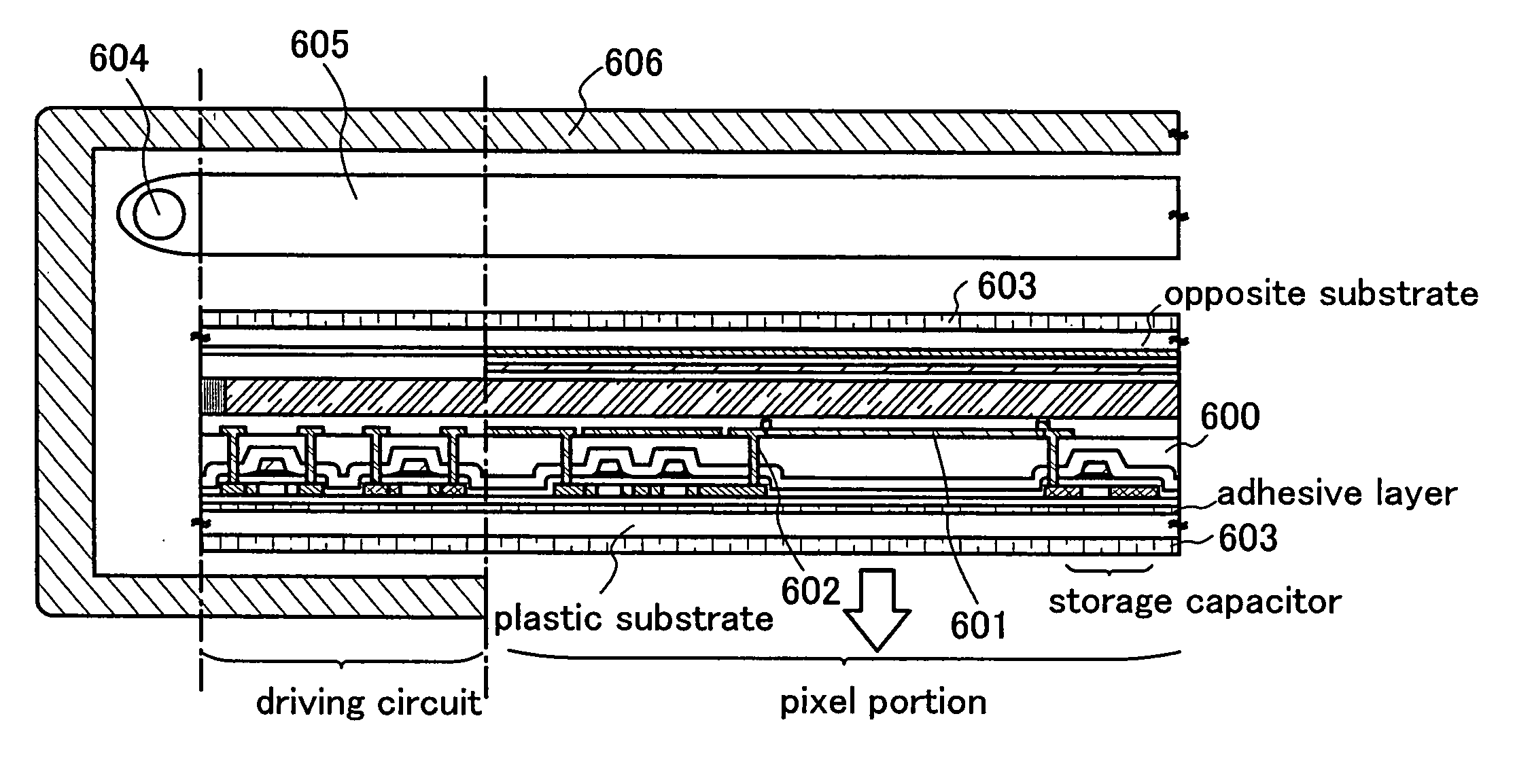

Semiconductor device and method of manufacturing the same

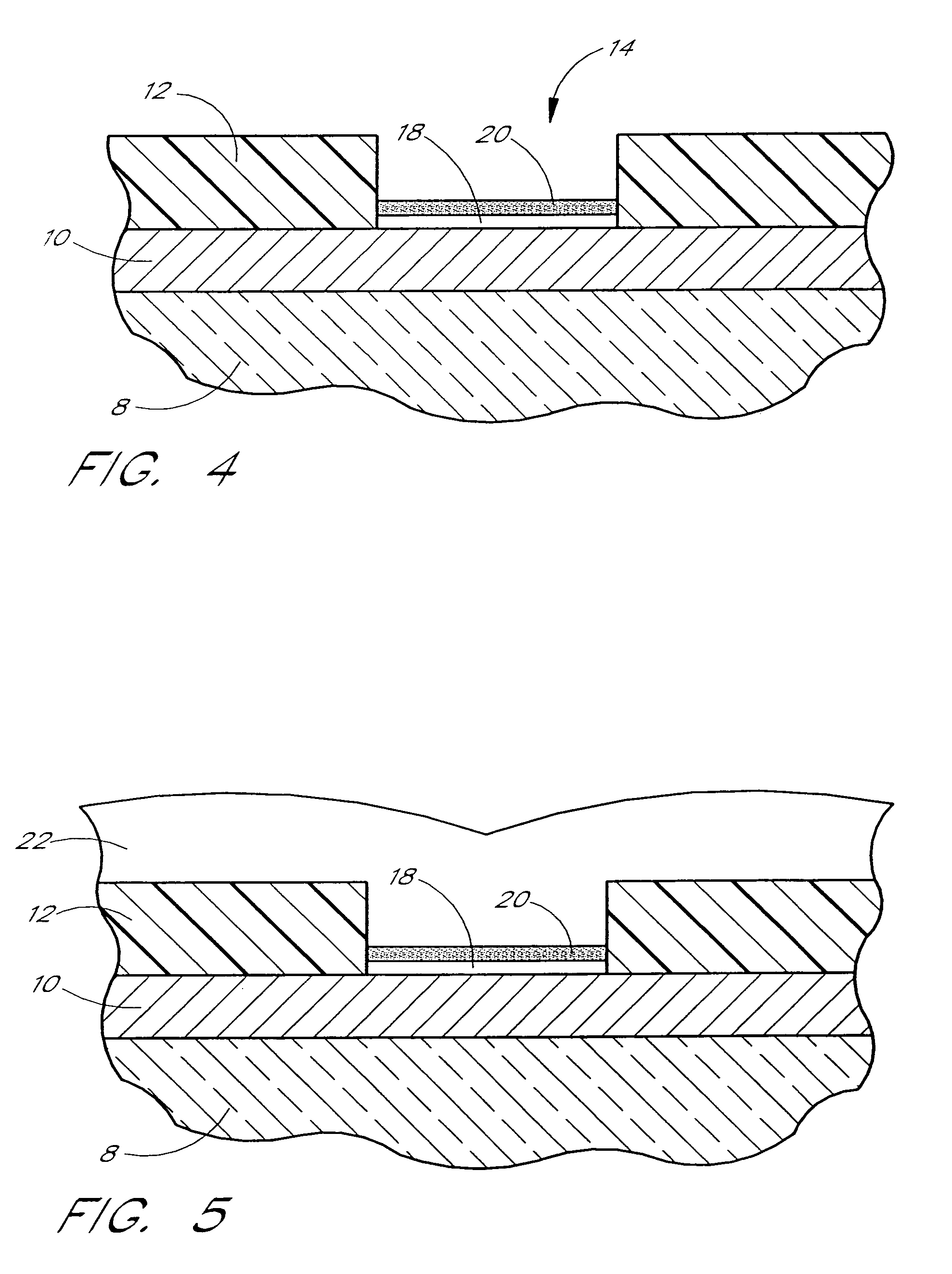

InactiveUS7332381B2More light-weightMore flexibleTransistorElectroluminescent light sourcesAdhesiveThin-film diode

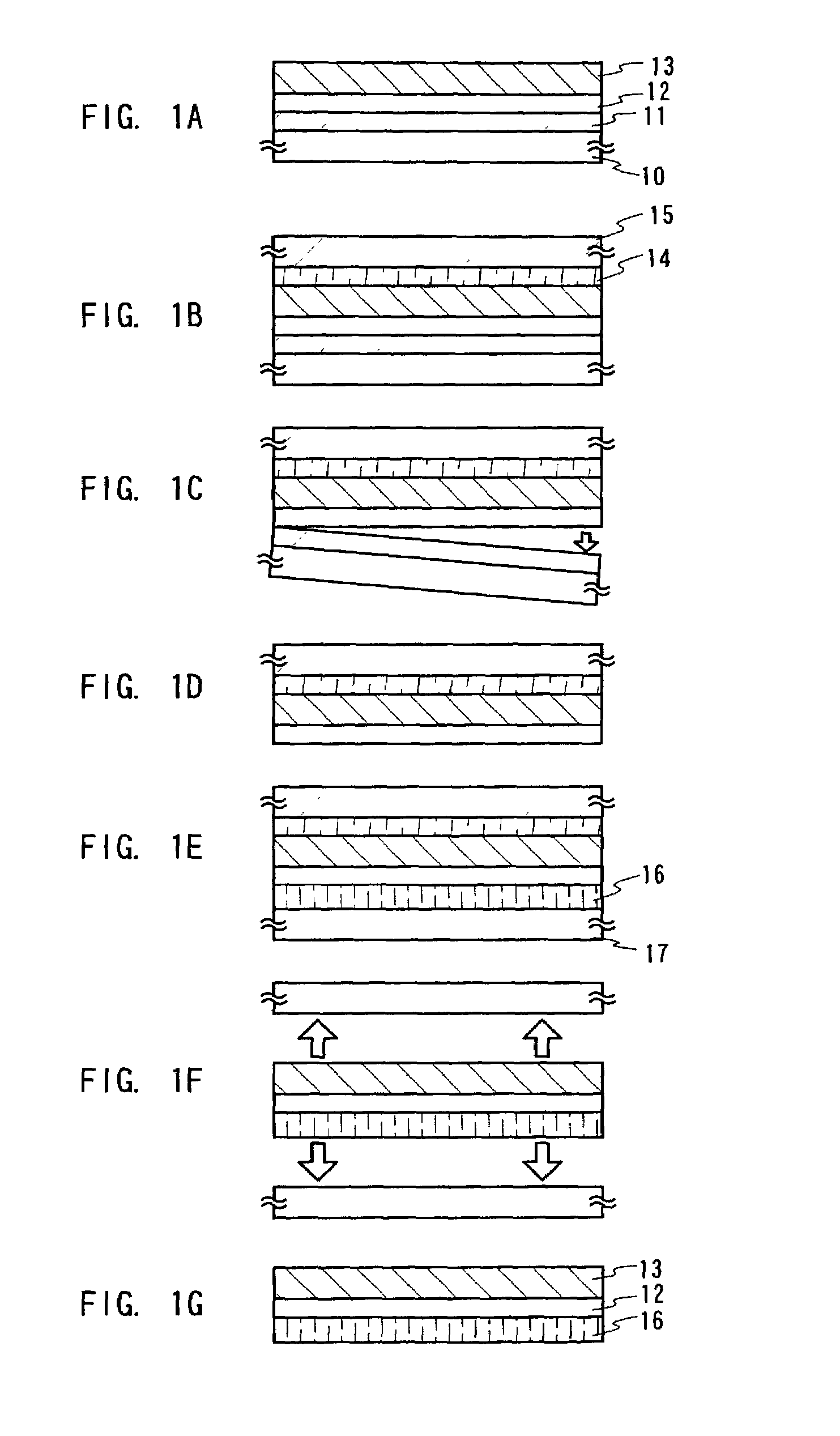

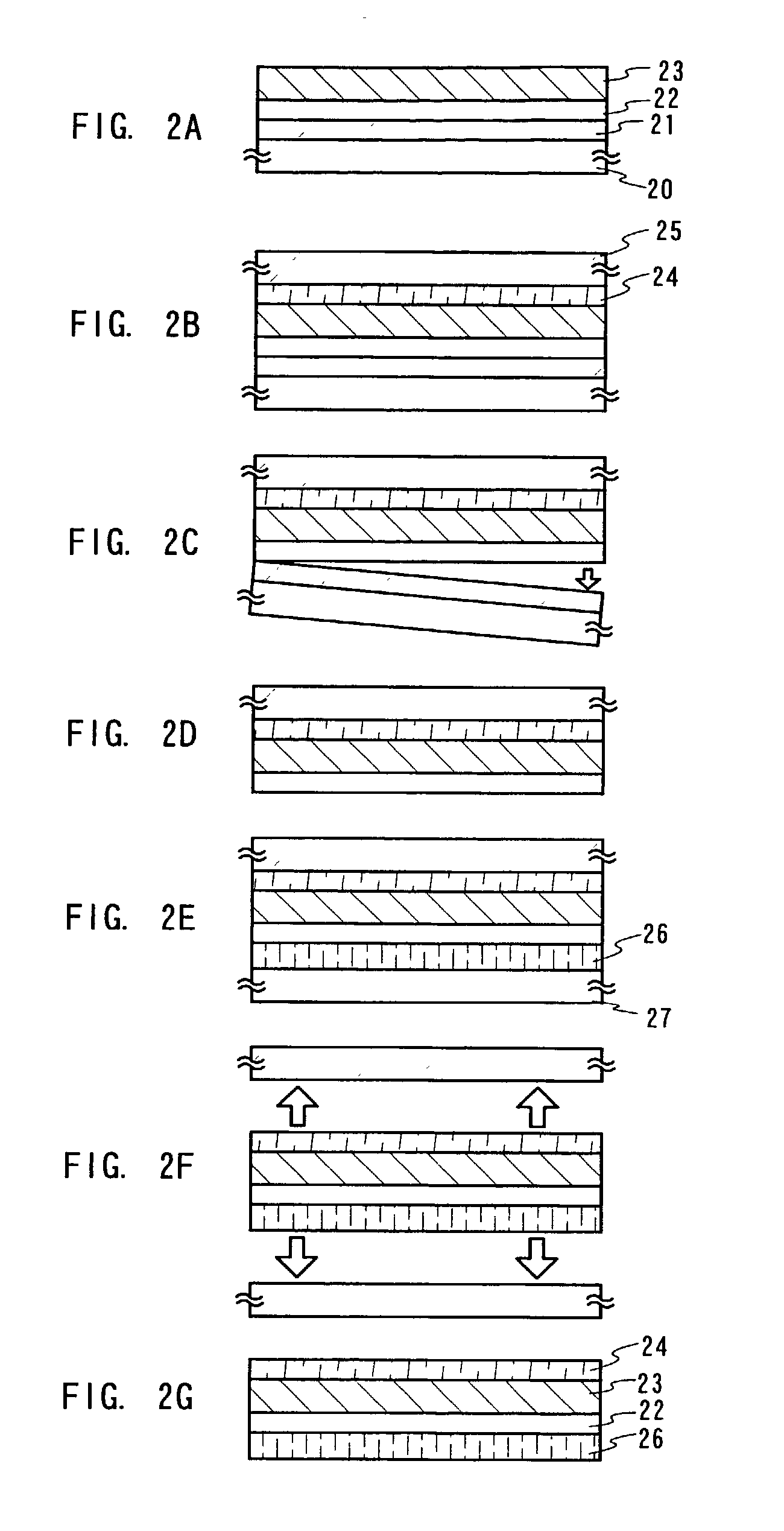

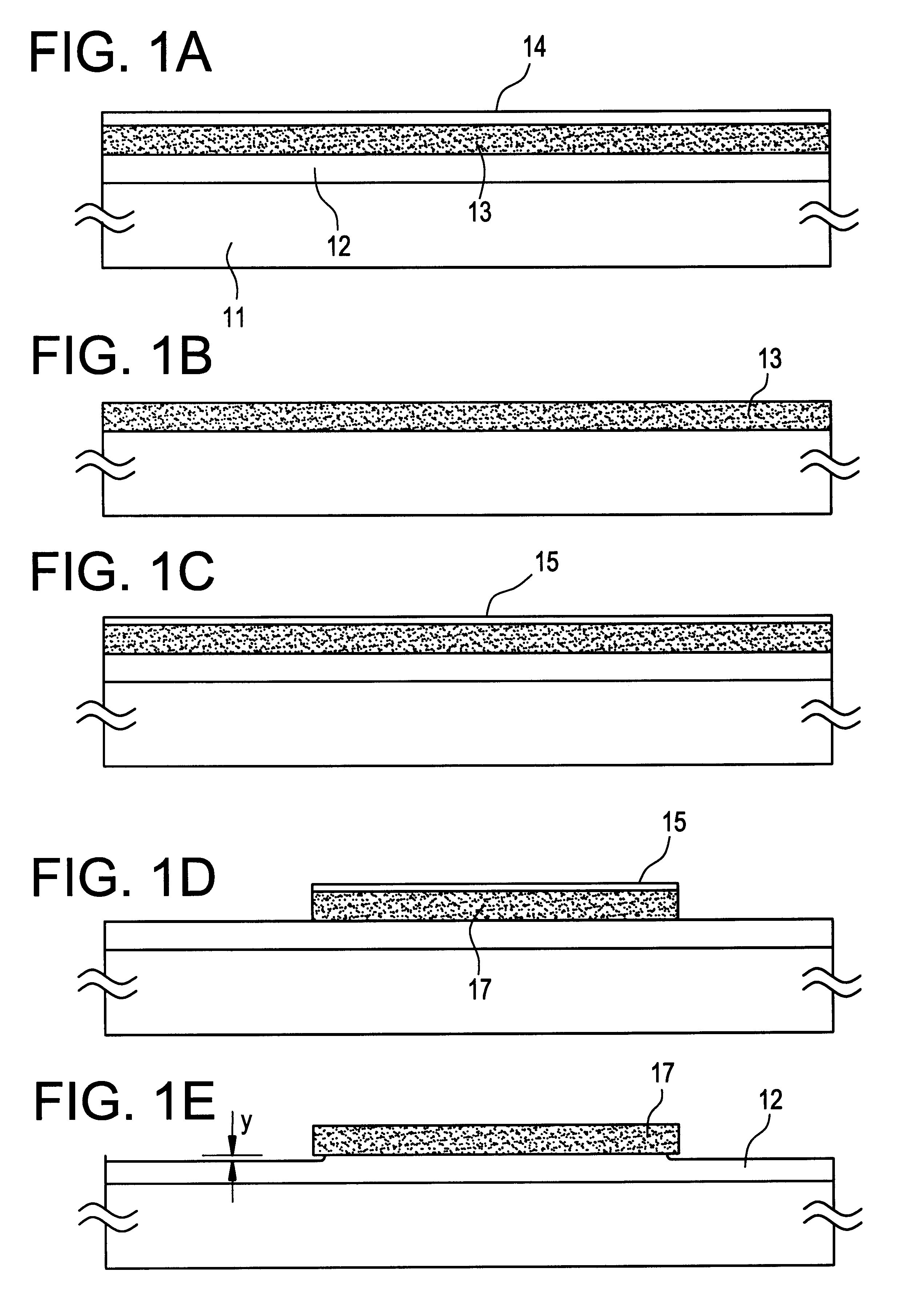

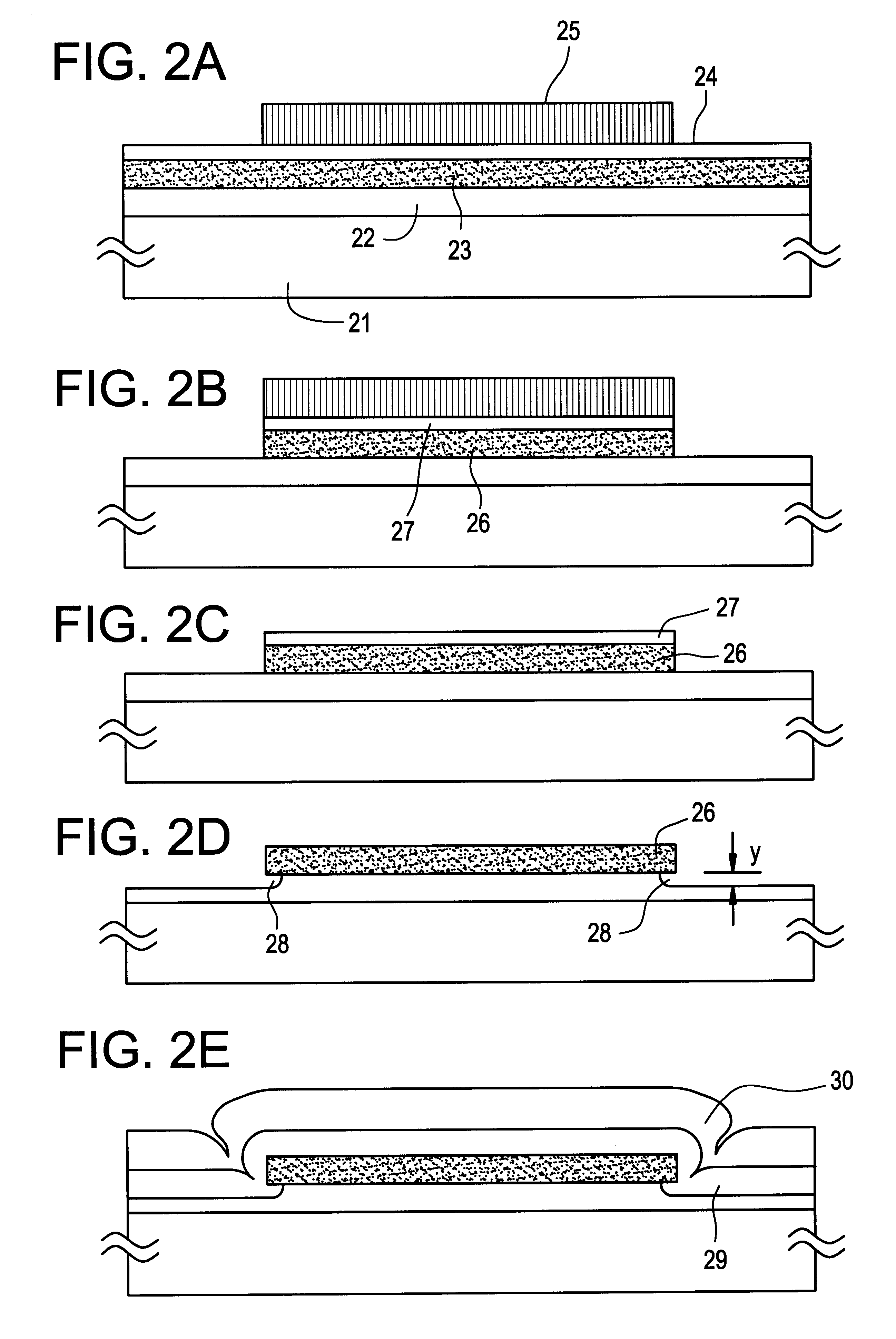

A semiconductor device having a semiconductor element (a thin film transistor, a thin film diode, a photoelectric conversion element of silicon PIN junction, or a silicon resistor element) which is light-weight, flexible (bendable), and thin as a whole is provided as well as a method of manufacturing the semiconductor device. In the present invention, the element is not formed on a plastic film. Instead, a flat board such as a substrate is used as a form, the space between the substrate (third substrate (17)) and a layer including the element (peeled layer (13)) is filled with coagulant (typically an adhesive) that serves as a second bonding member (16), and the substrate used as a form (third substrate (17)) is peeled off after the adhesive is coagulated to hold the layer including the element (peeled layer (13)) by the coagulated adhesive (second bonding member (16)) alone. In this way, the present invention achieves thinning of the film and reduction in weight.

Owner:SEMICON ENERGY LAB CO LTD

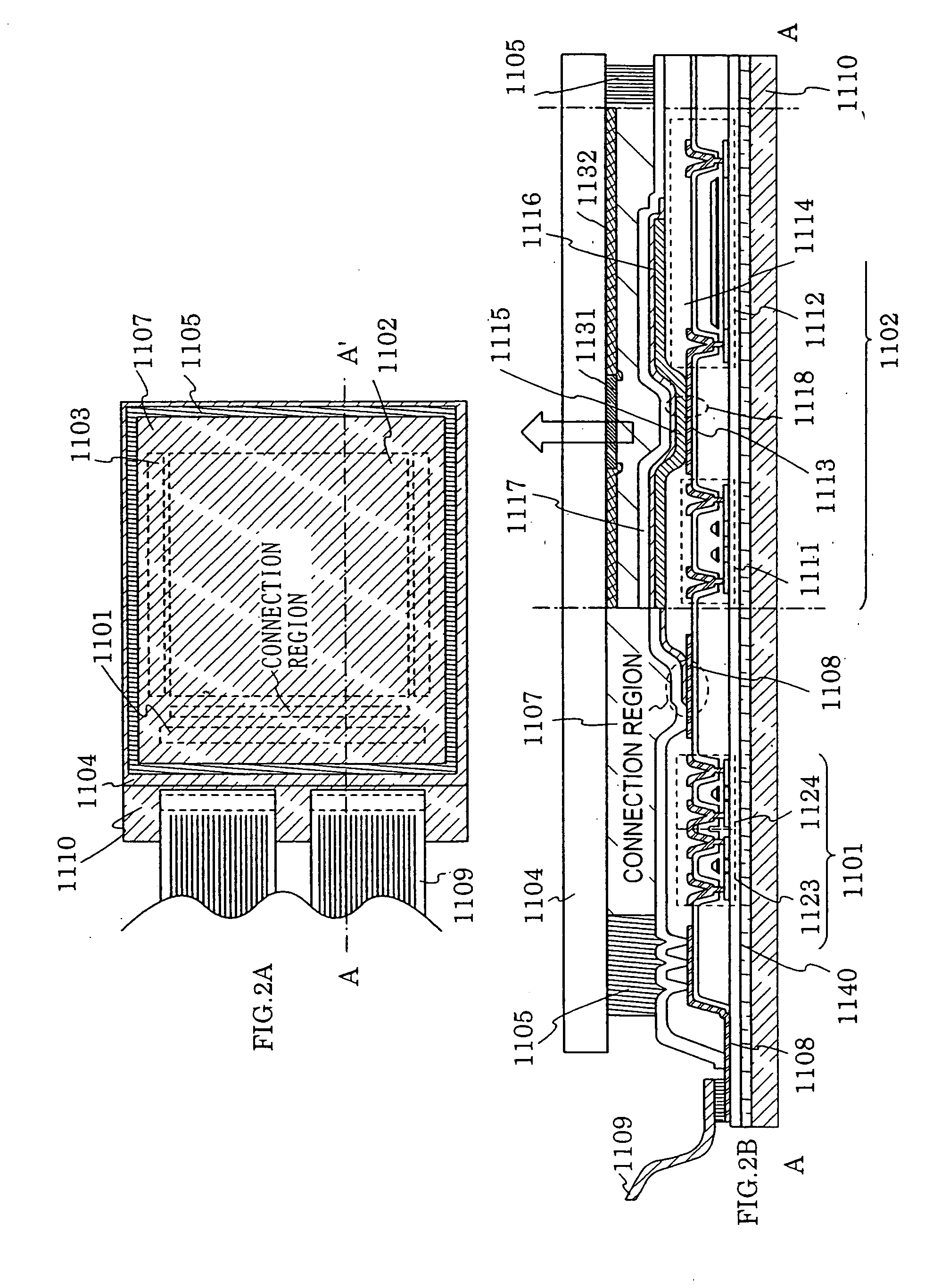

Semiconductor apparatus and fabrication method of the same

InactiveUS7067392B2Inhibit deteriorationImprove thermal conductivityTransistorFinal product manufactureDevice formThin-film diode

It is an object of the present invention to provide a semiconductor device capable of preventing deterioration due to penetration of moisture or oxygen, for example, a light-emitting apparatus having an organic light-emitting device that is formed over a plastic substrate, and a liquid crystal display apparatus using a plastic substrate. According to the present invention, devices formed on a glass substrate or a quartz substrate (a TFT, a light-emitting device having an organic compound, a liquid crystal device, a memory device, a thin-film diode, a pin-junction silicon photoelectric converter, a silicon resistance element, or the like) are separated from the substrate, and transferred to a plastic substrate having high thermal conductivity.

Owner:SEMICON ENERGY LAB CO LTD

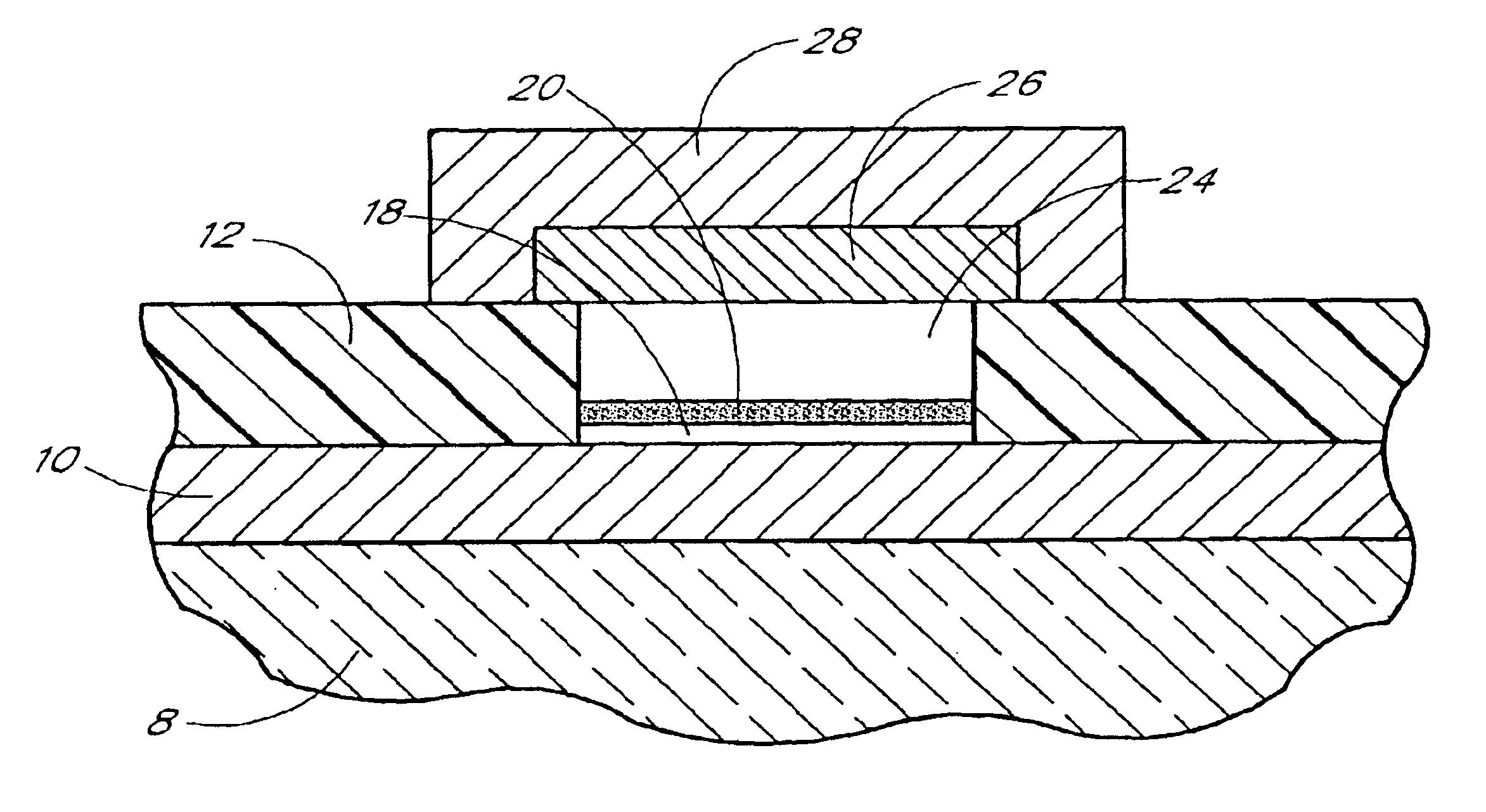

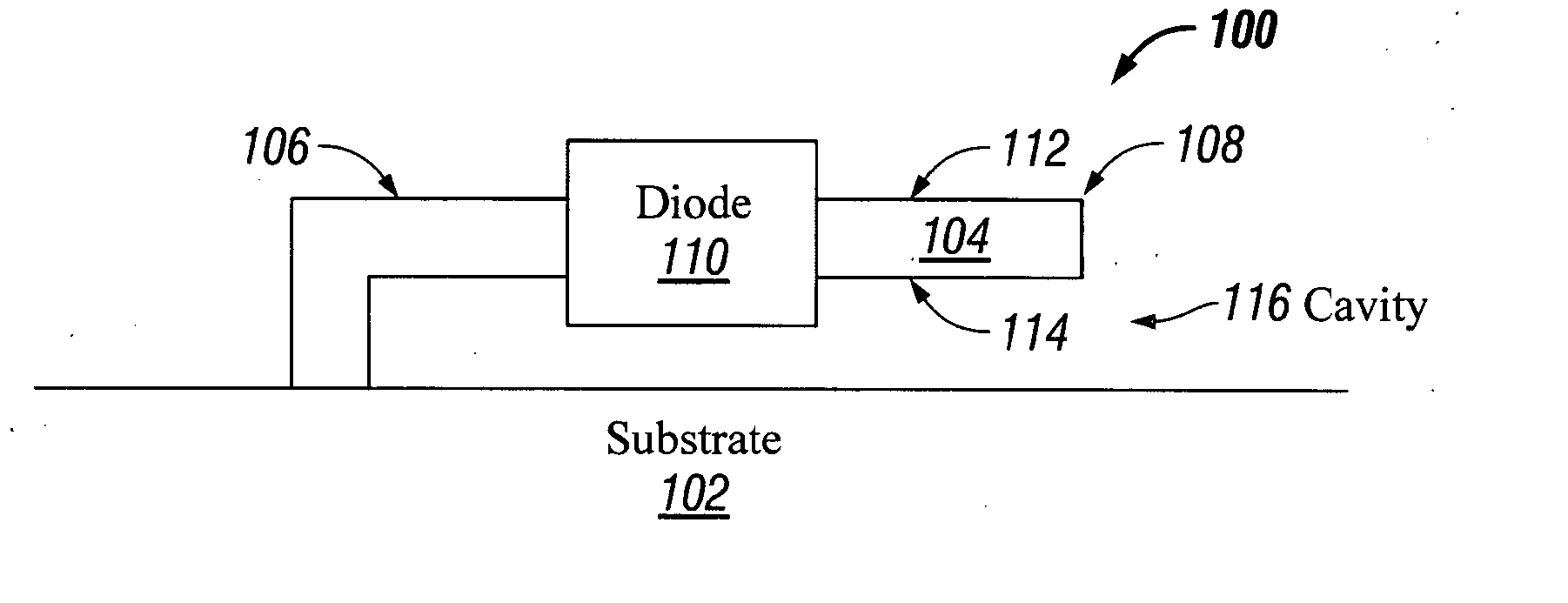

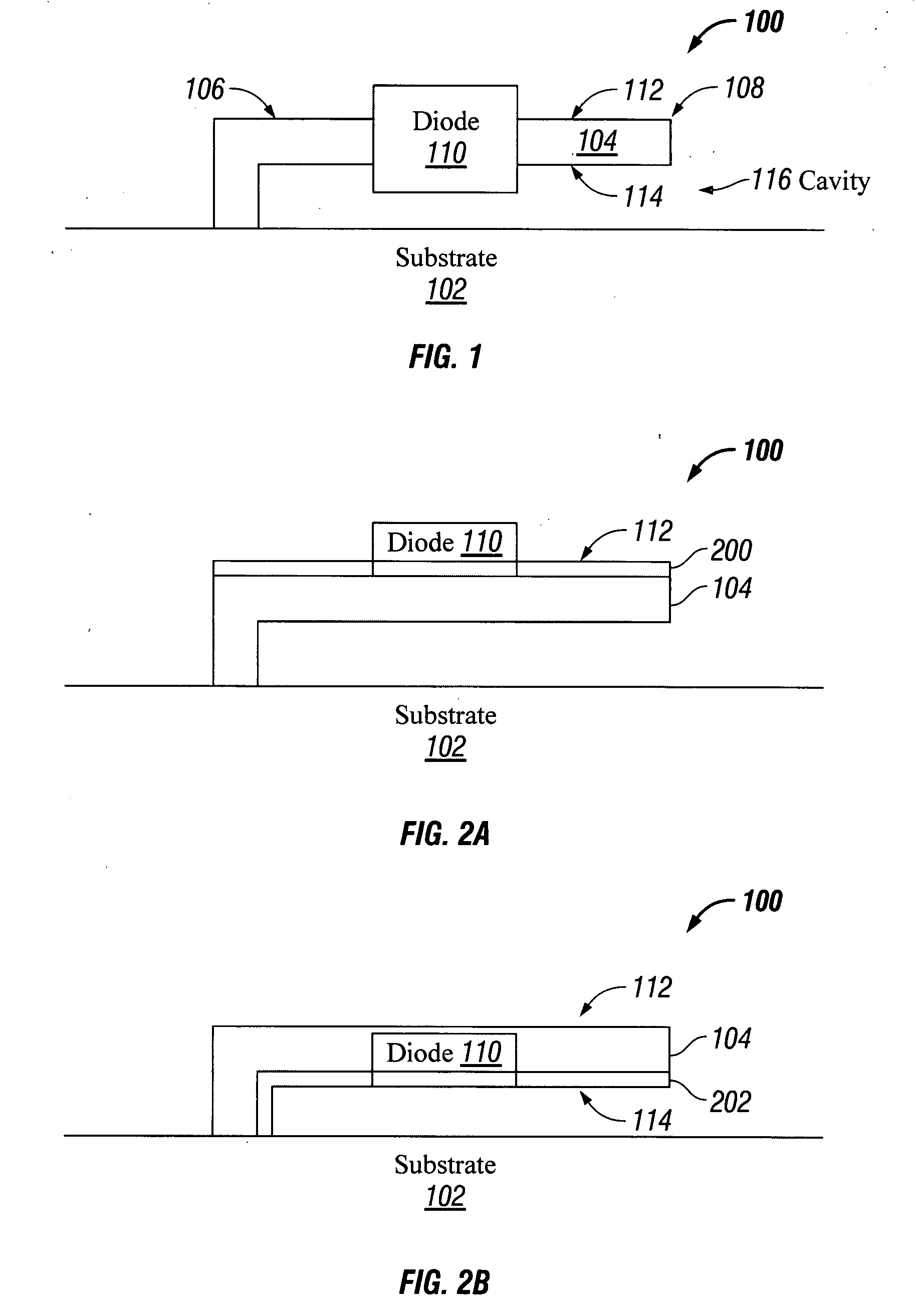

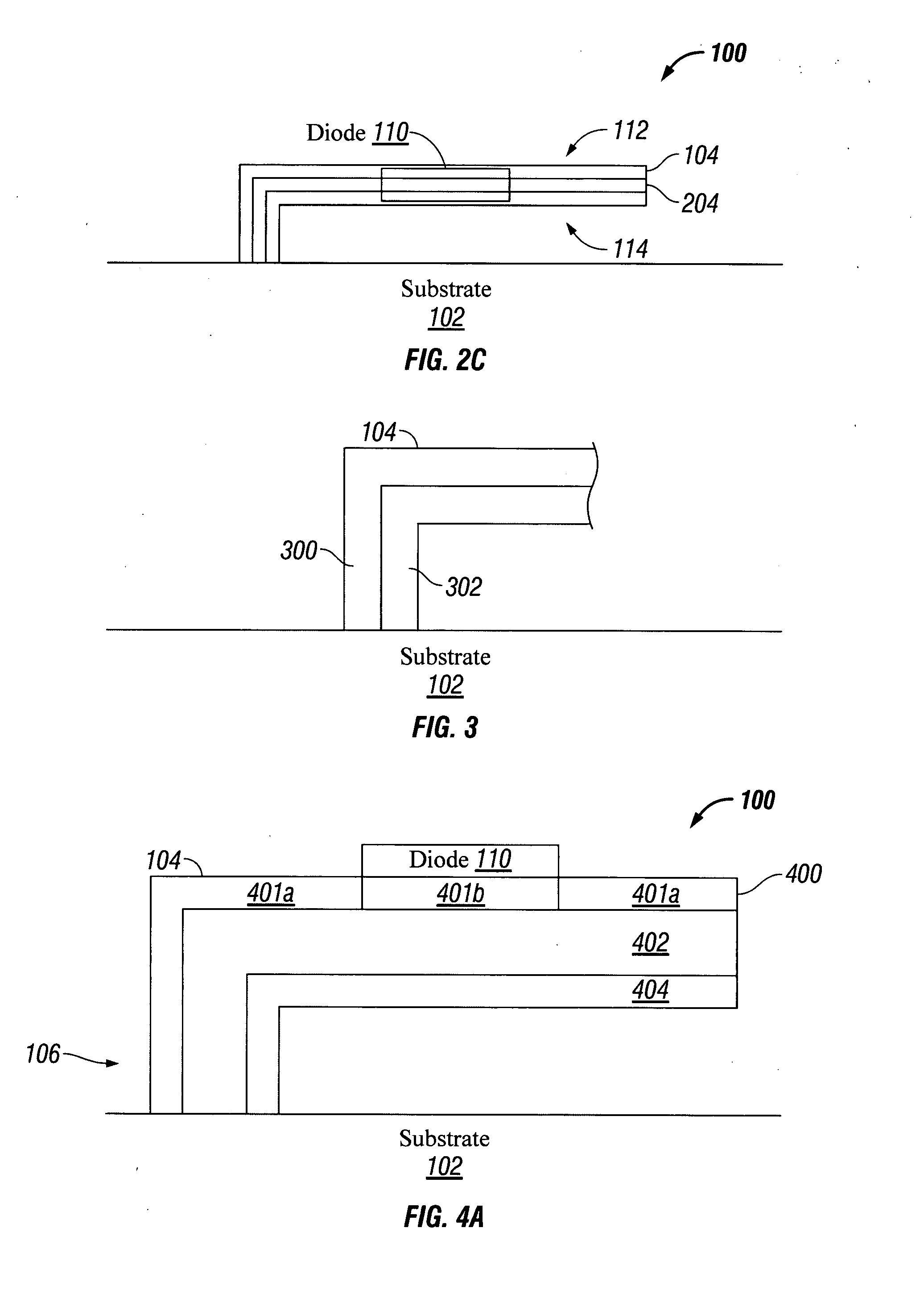

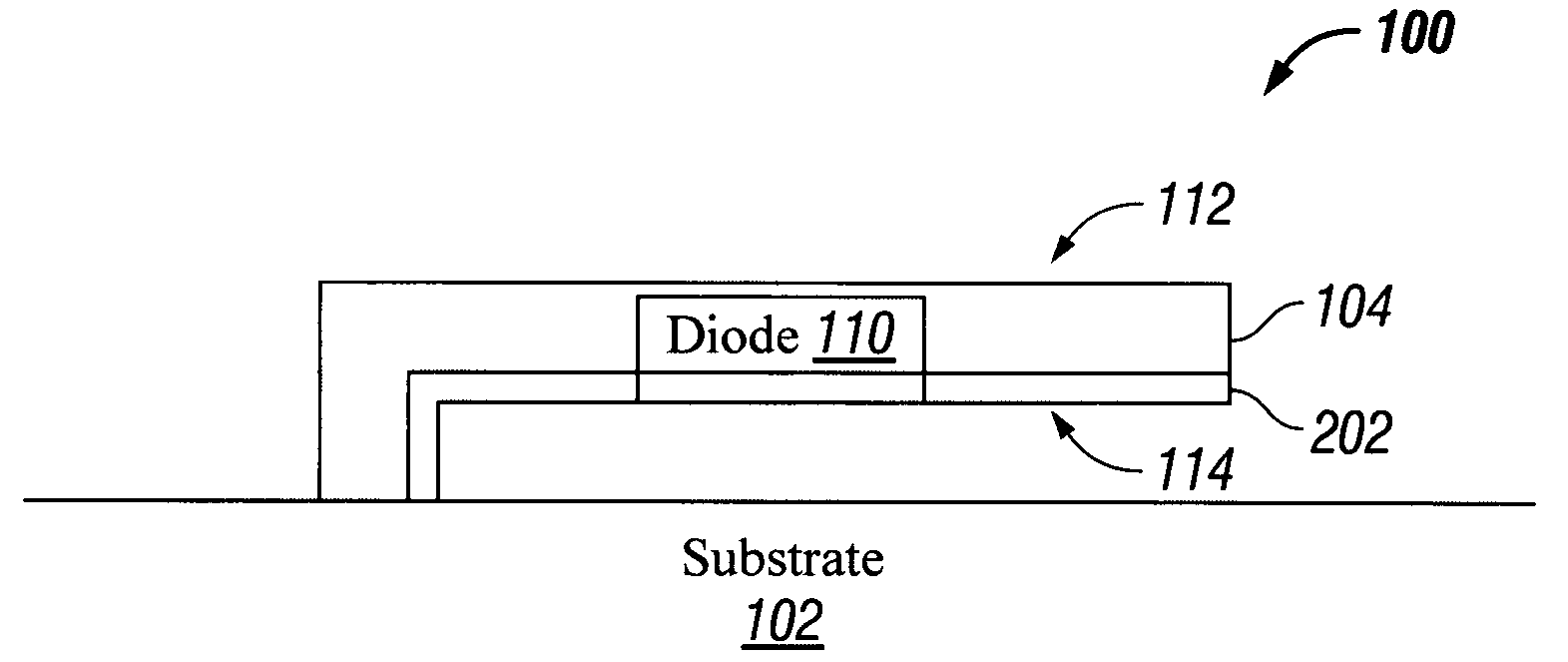

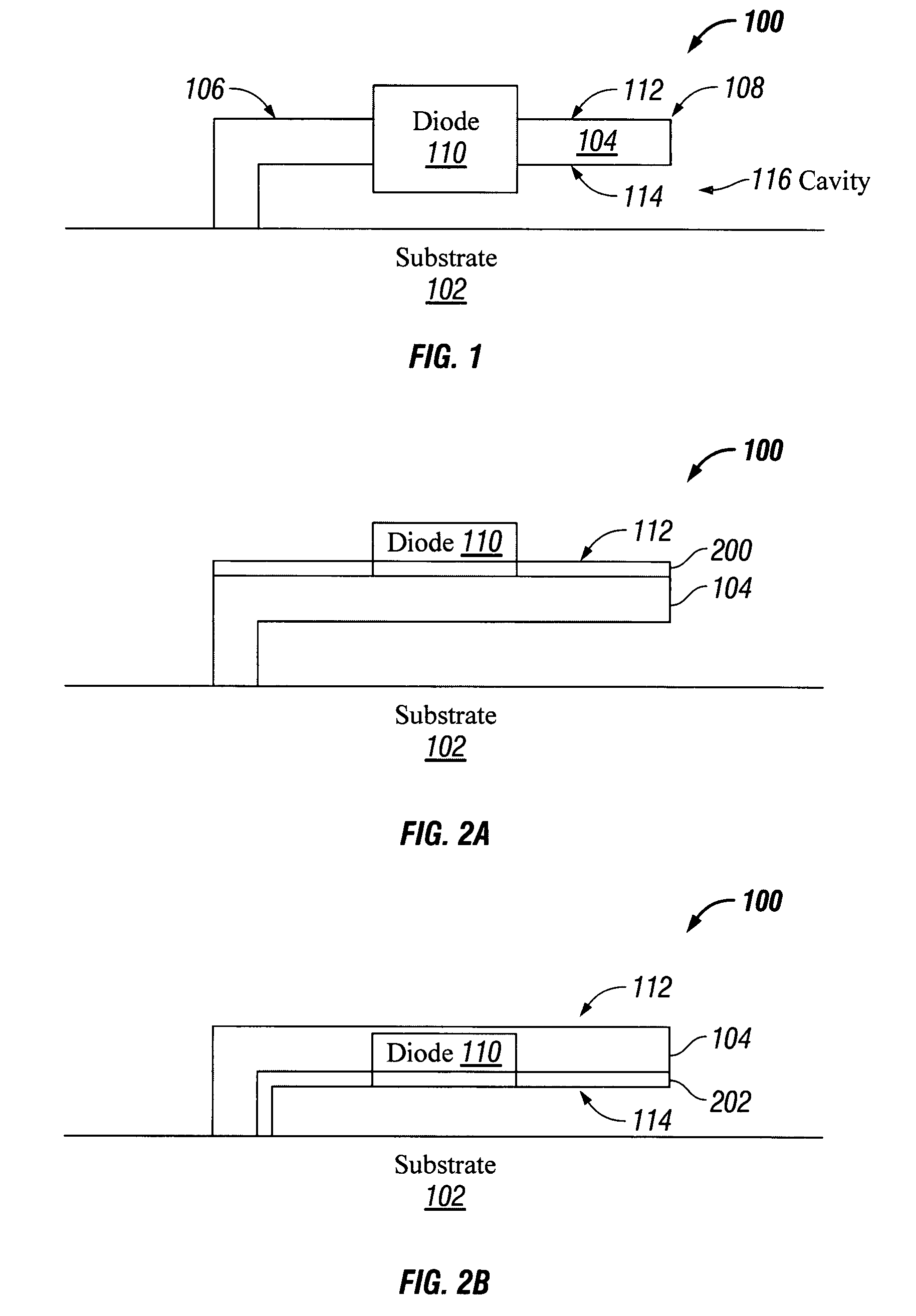

Thin film diode integrated with chalcogenide memory cell

InactiveUS6855975B2TransistorSemiconductor/solid-state device detailsThin-film diodeChalcogenide glass

An integrated programmable conductor memory cell and diode device in an integrated circuit comprises a diode and a glass electrolyte element, the glass electrolyte element having metal ions mixed or dissolved therein and being able to selectively form a conductive pathway under the influence of an applied voltage. In one embodiment, both the diode and the memory cell comprise a chalcogenide glass, such as germanium selenide (e.g., Ge2Se8 or Ge25Se75). The first diode element comprises a chalcogenide glass layer having a first conductivity type, the second diode element comprises a chalcogenide glass layer doped with an element such as bismuth and having a second conductivity type opposite to the first conductivity type and the memory cell comprises a chalcogenide glass element with silver ions therein. In another embodiment, the diode comprises silicon and there is a diffusion barrier layer between the diode and the chalcogenide glass memory element. Methods of fabricating integrated programmable conductor memory cell and diode devices are also disclosed.

Owner:OVONYX MEMORY TECH LLC

Thin-film transistor and thin-film diode having amorphous-oxide semiconductor layer

ActiveUS20070063211A1High light transmittanceHigh transparencyTransistorSemiconductor/solid-state device manufacturingRefractive indexThin-film diode

A thin-film transistor including a channel layer being formed of an oxide semiconductor transparent to visible light and having a refractive index of nx, a gate-insulating layer disposed on one face of the channel layer, and a transparent layer disposed on the other face of the channel layer and having a refractive index of nt, where there is a relationship of nx>nt. A thin-film transistor including a substrate having a refractive index of no, a transparent layer disposed on the substrate and having a refractive index of nt, and a channel layer disposed on the transparent layer and having a refractive index of nx, where there is a relationship of nx>nt>no.

Owner:CANON KK

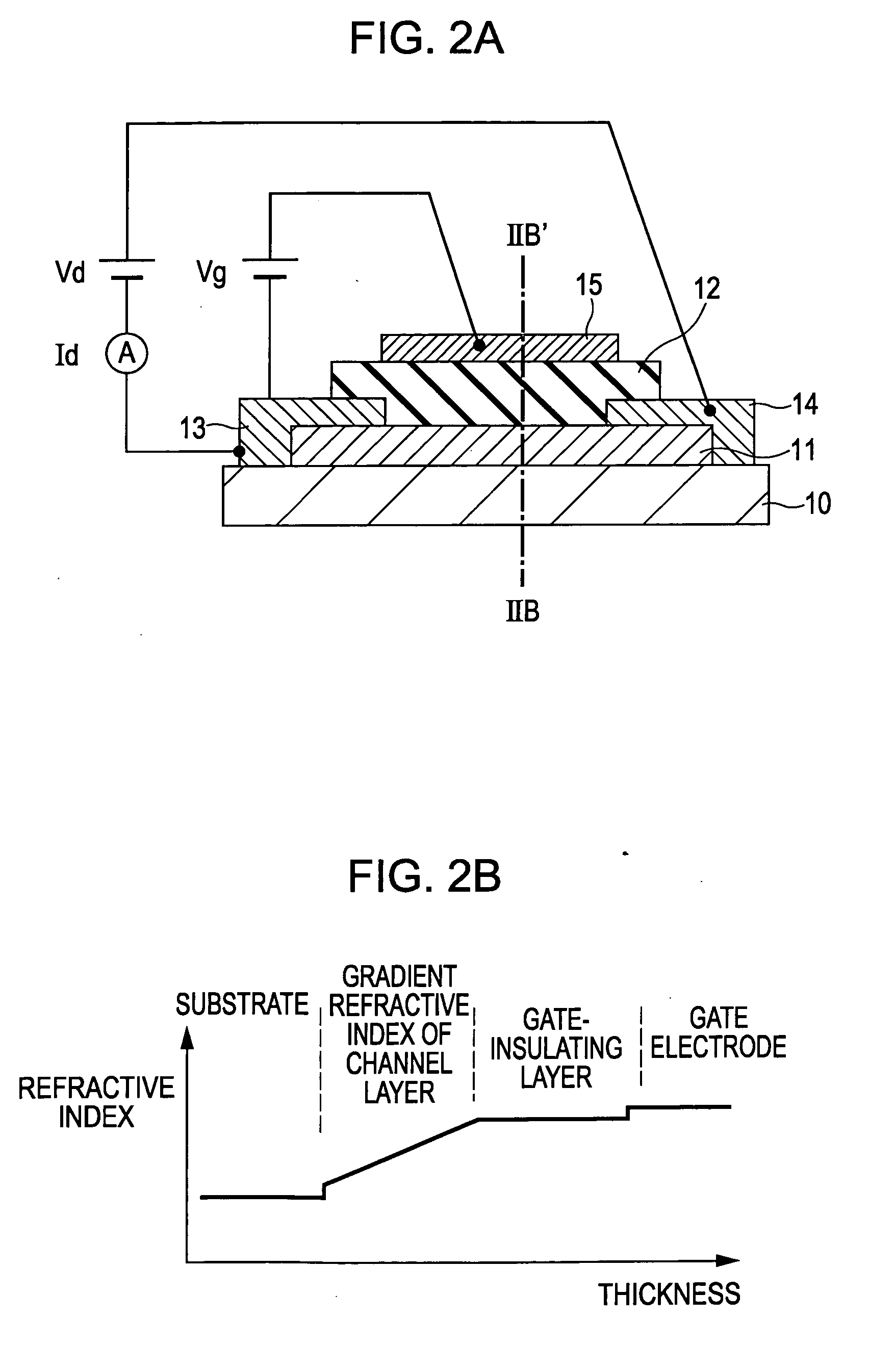

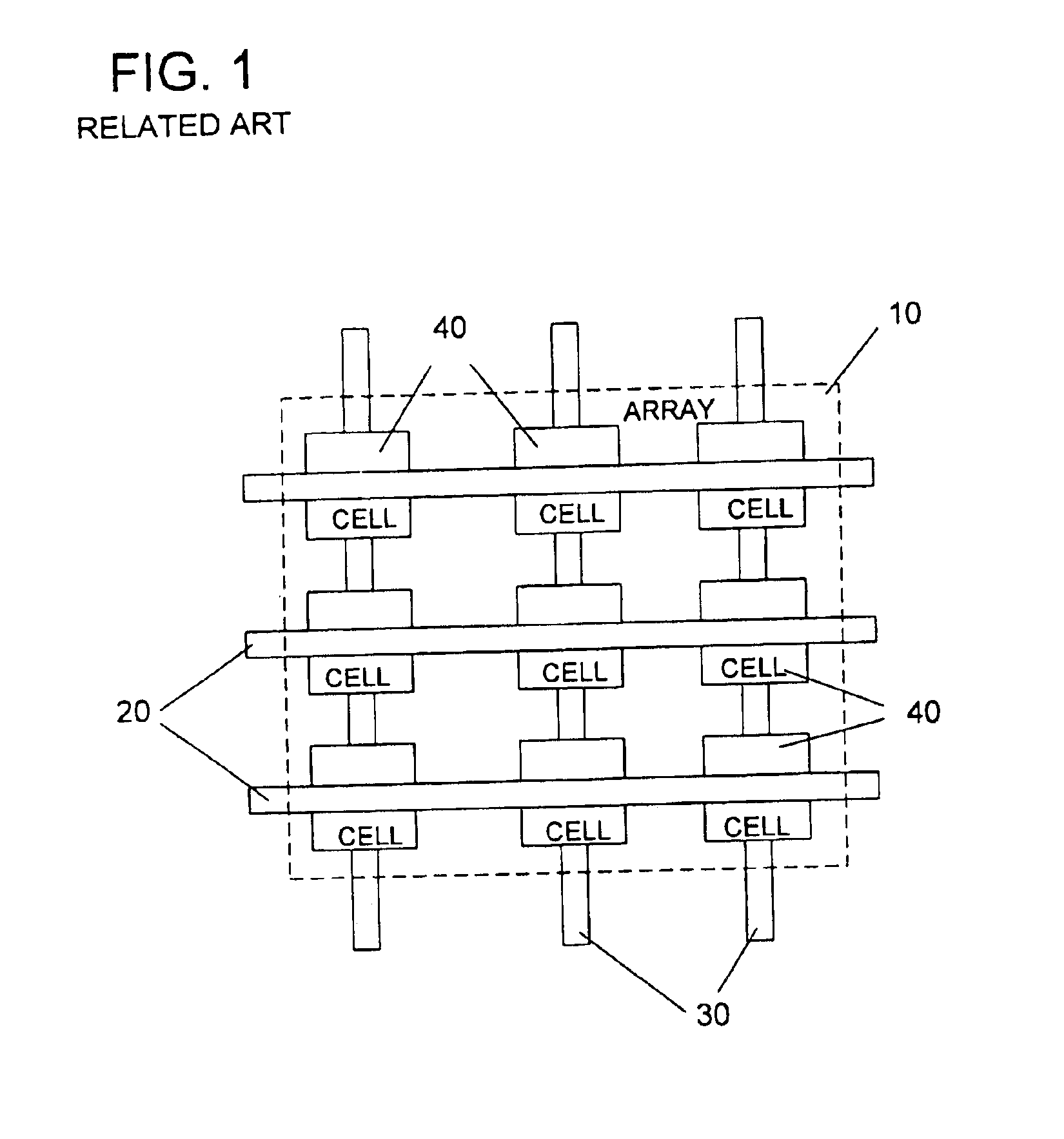

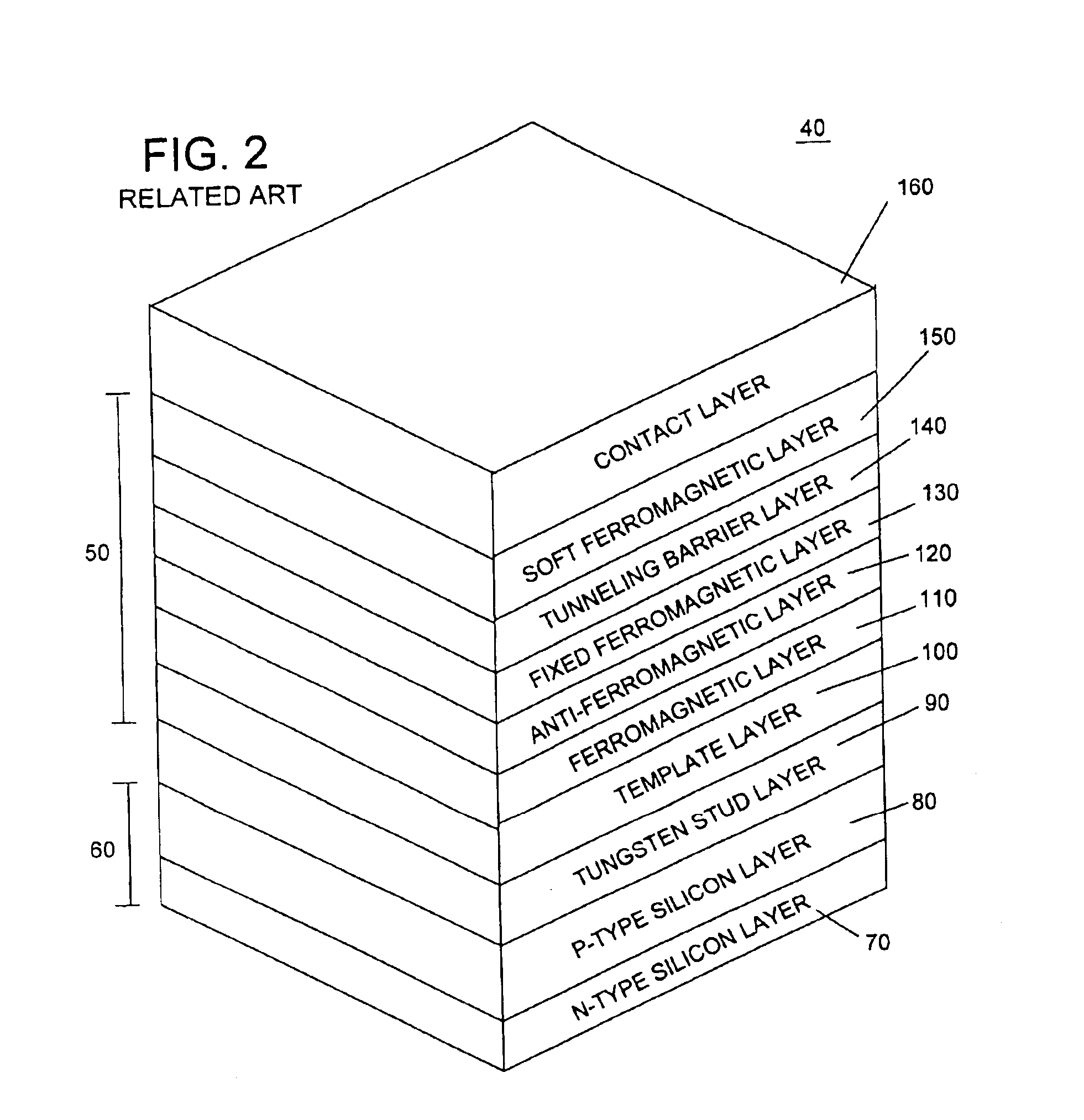

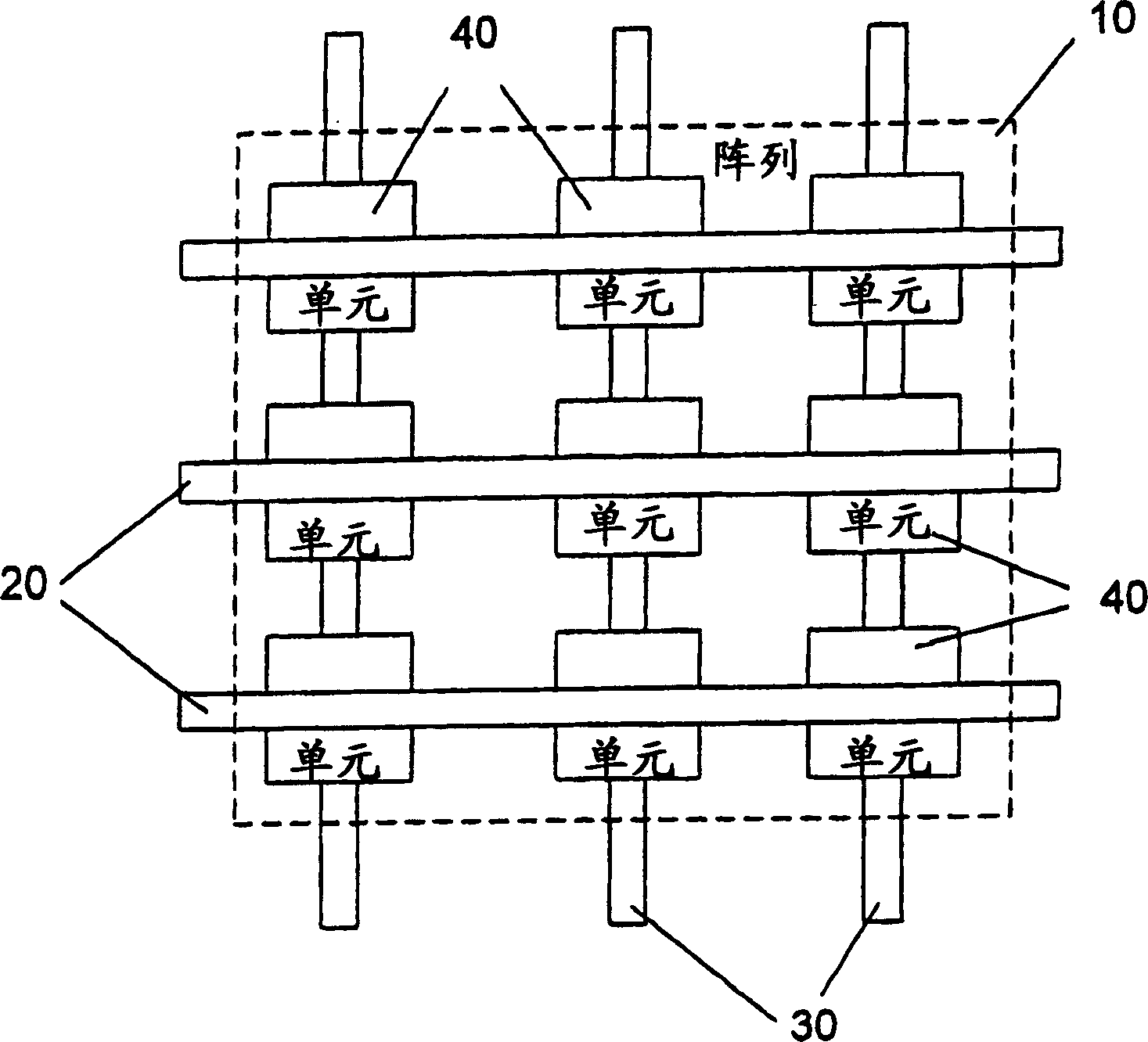

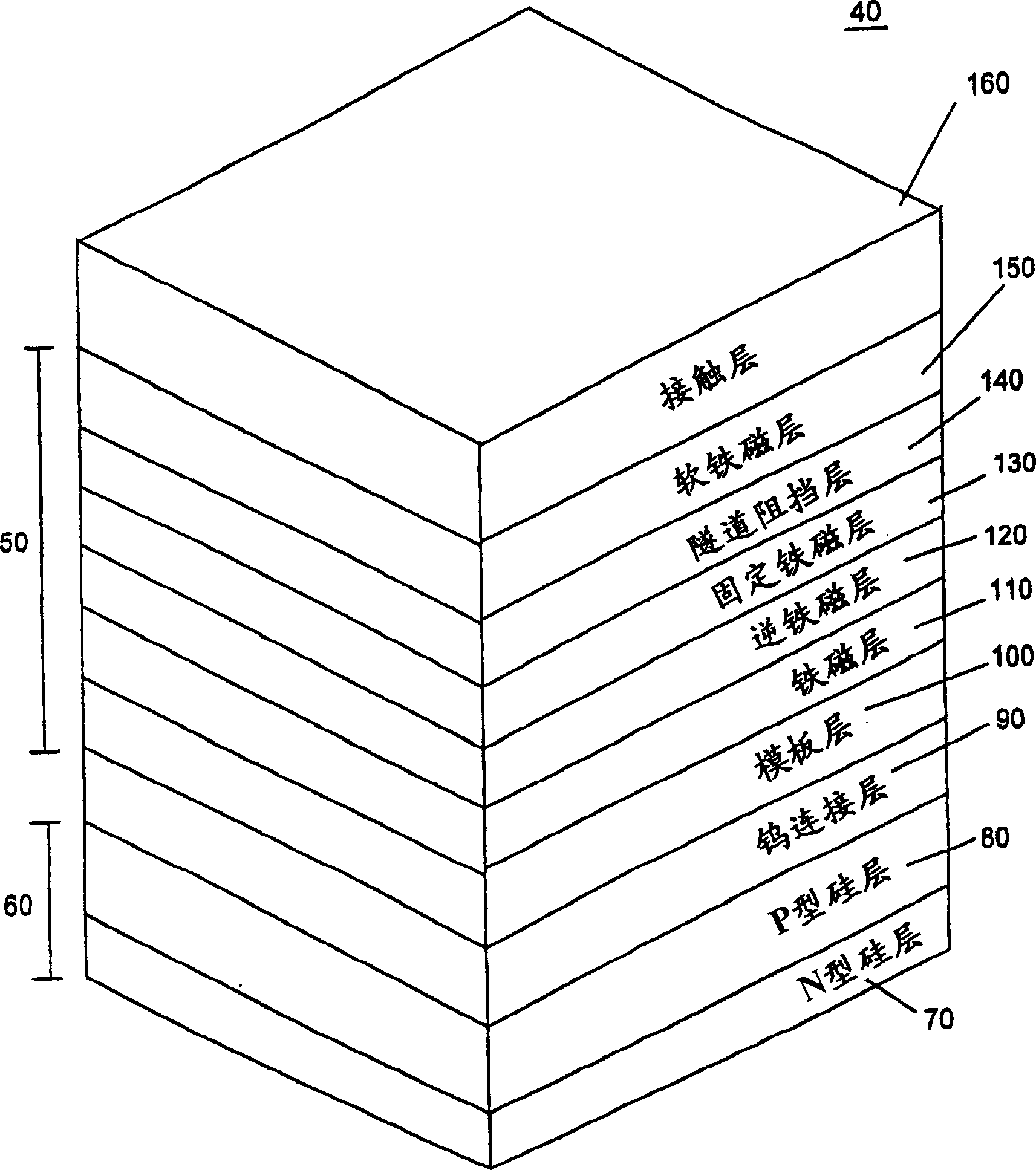

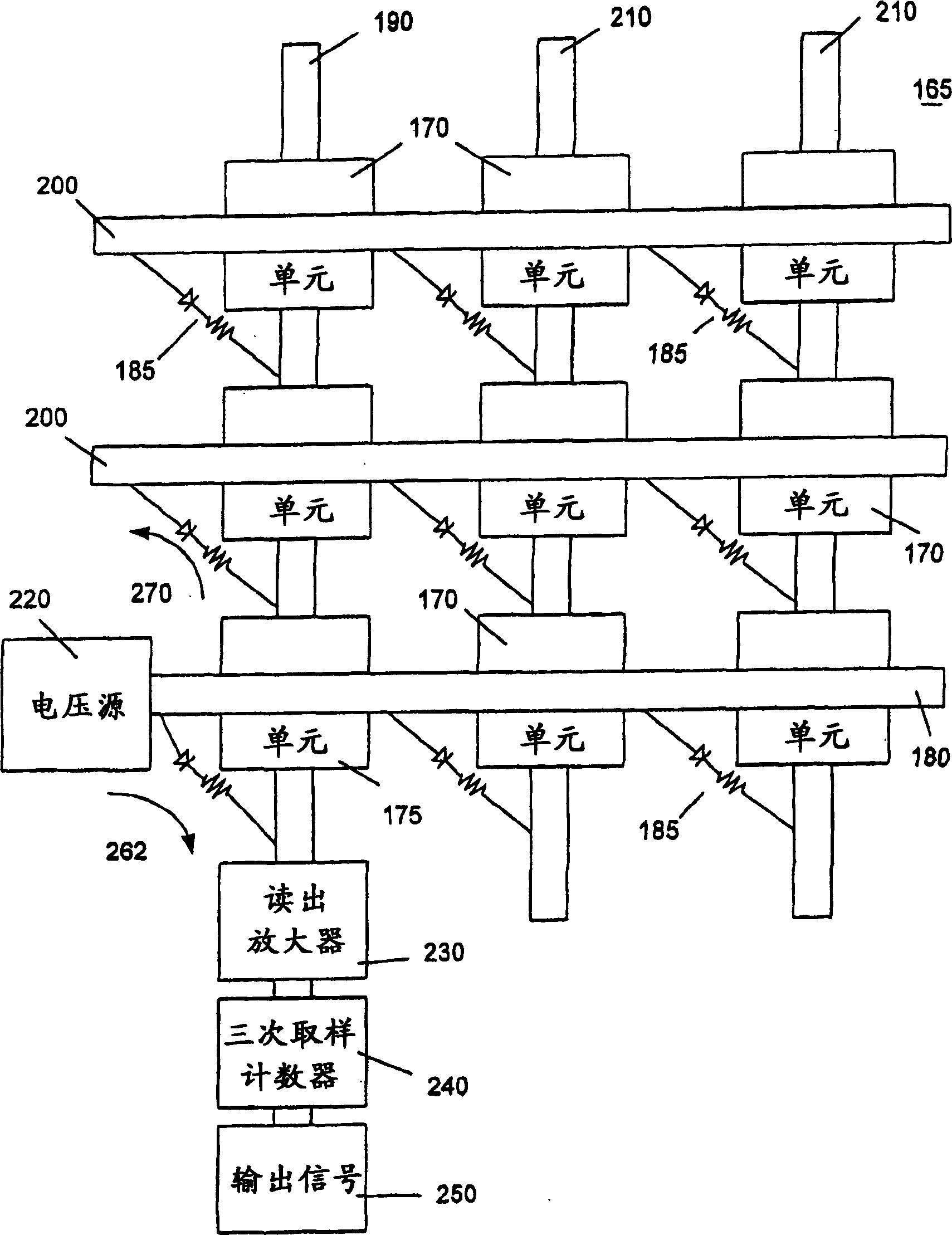

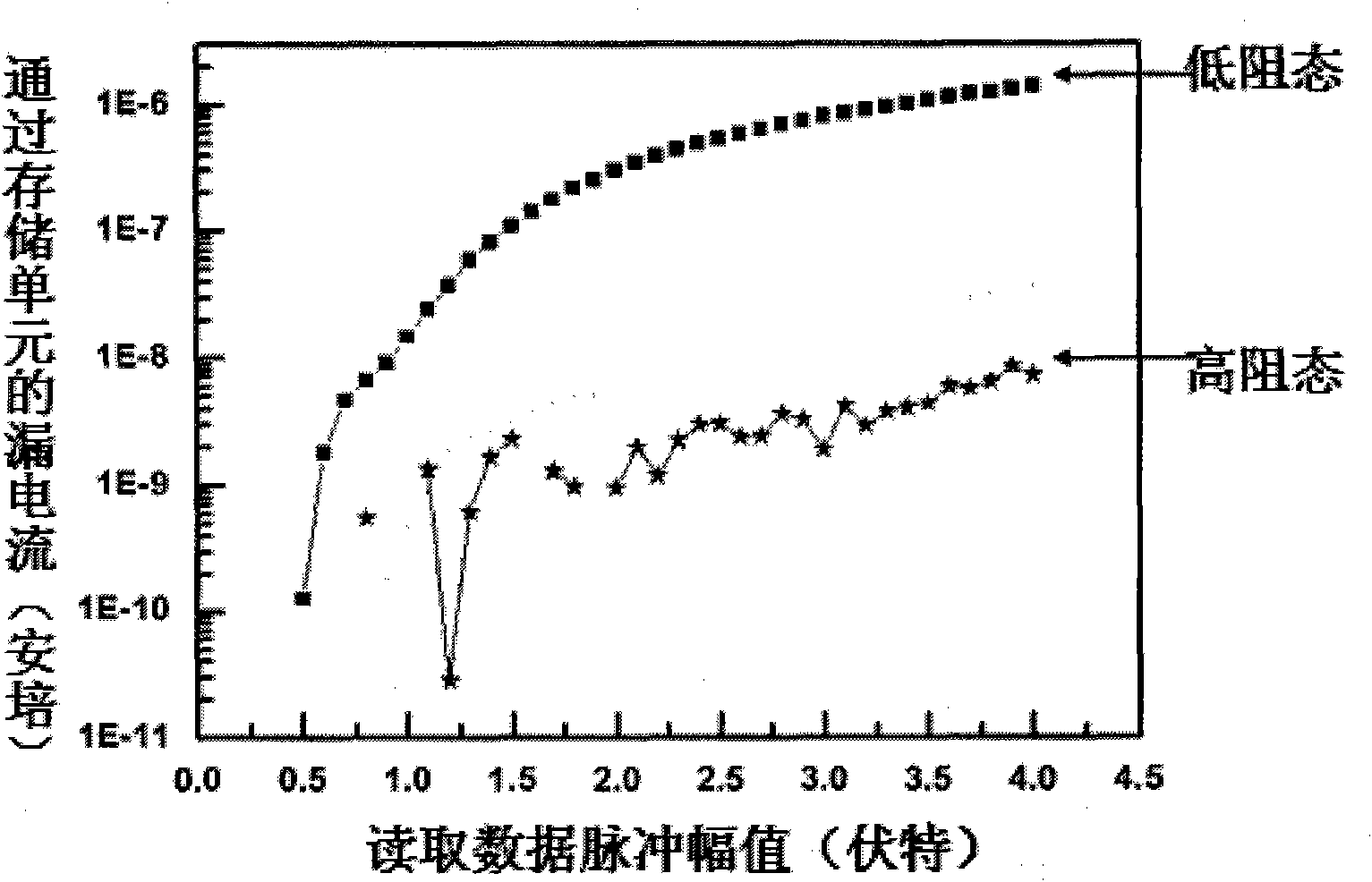

Triple sample sensing for magnetic random access memory (MRAM) with series diodes

InactiveUS6873544B2Magnetic-field-controlled resistorsElectric analogue storesElectricityReference current

A data storage device that includes an array of resistive memory cells. The resistive memory cells may include a magnetic tunnel junction (MTJ) and a thin-film diode. The device may include a circuit that is electrically connected to the array and that is also capable of monitoring a signal current flowing through a selected memory cell. Once the signal current has been monitored, the circuit is capable of comparing the signal current to an average reference current in order to determine which of a first resistance state and a second resistance state the selected memory cell is in. Also, a method for operating the data storage device.

Owner:SAMSUNG ELECTRONICS CO LTD

Triple sampling readout of magnetic RAM having series diode

InactiveCN1459792AMagnetic-field-controlled resistorsSolid-state devicesElectrical resistance and conductanceElectricity

Owner:SAMSUNG ELECTRONICS CO LTD

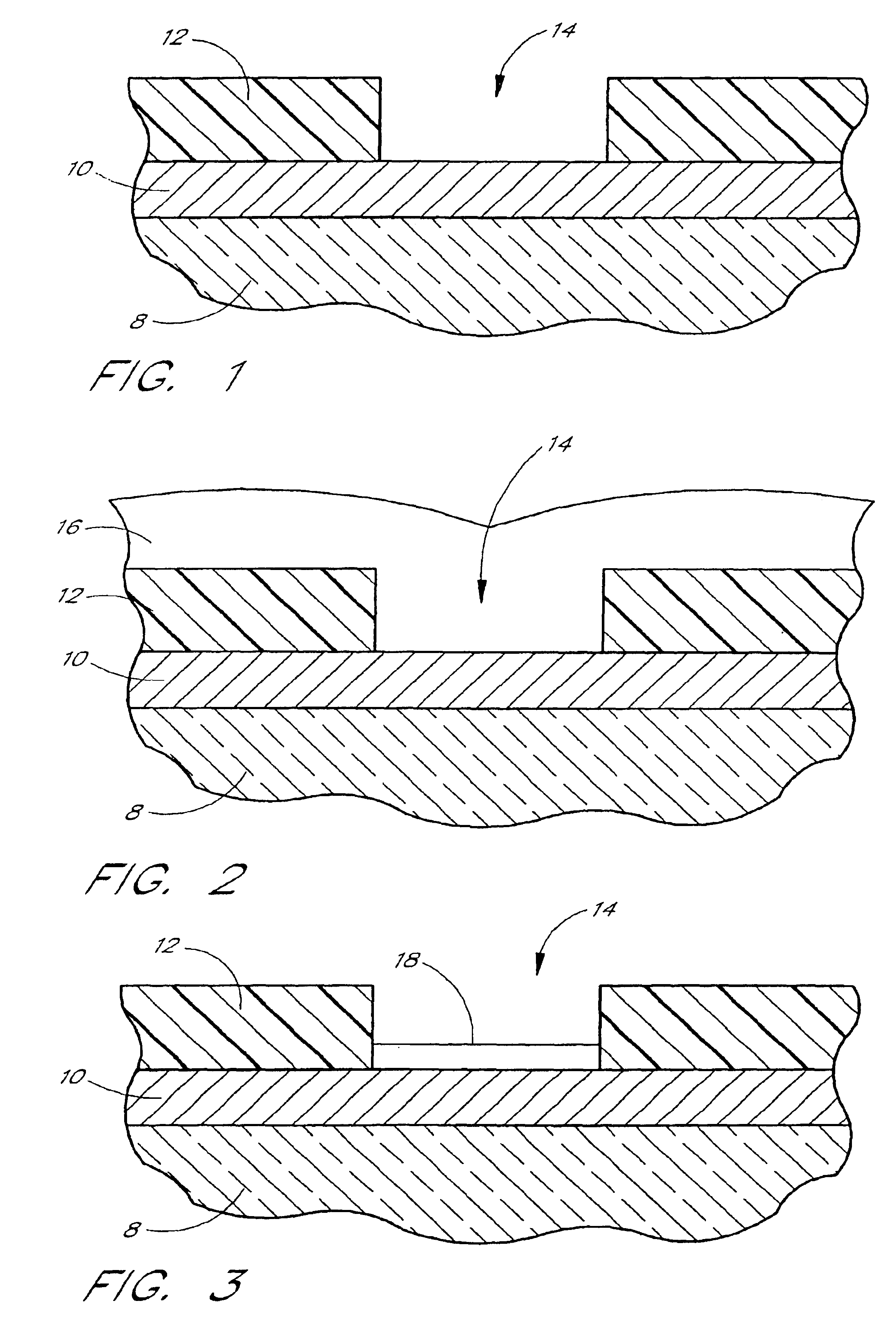

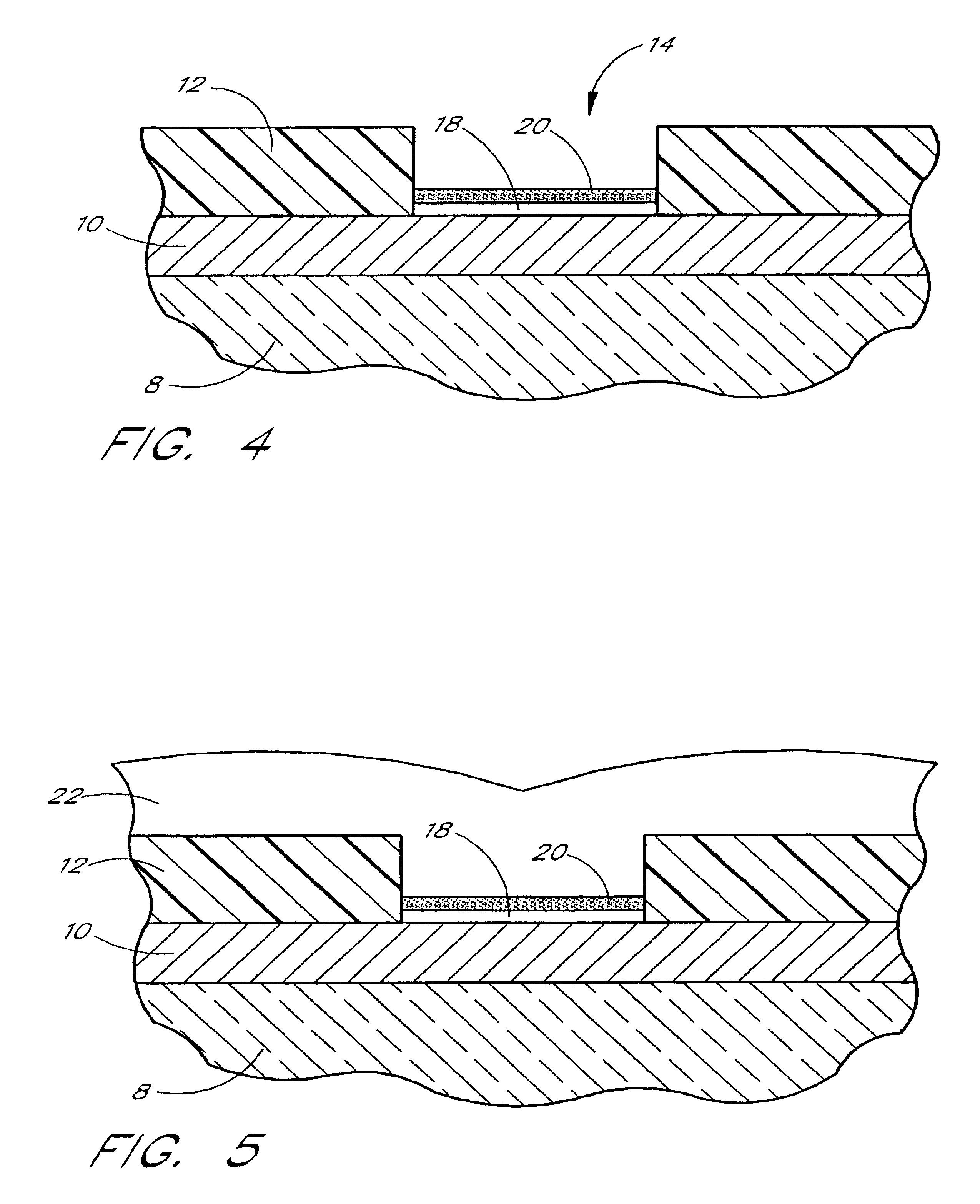

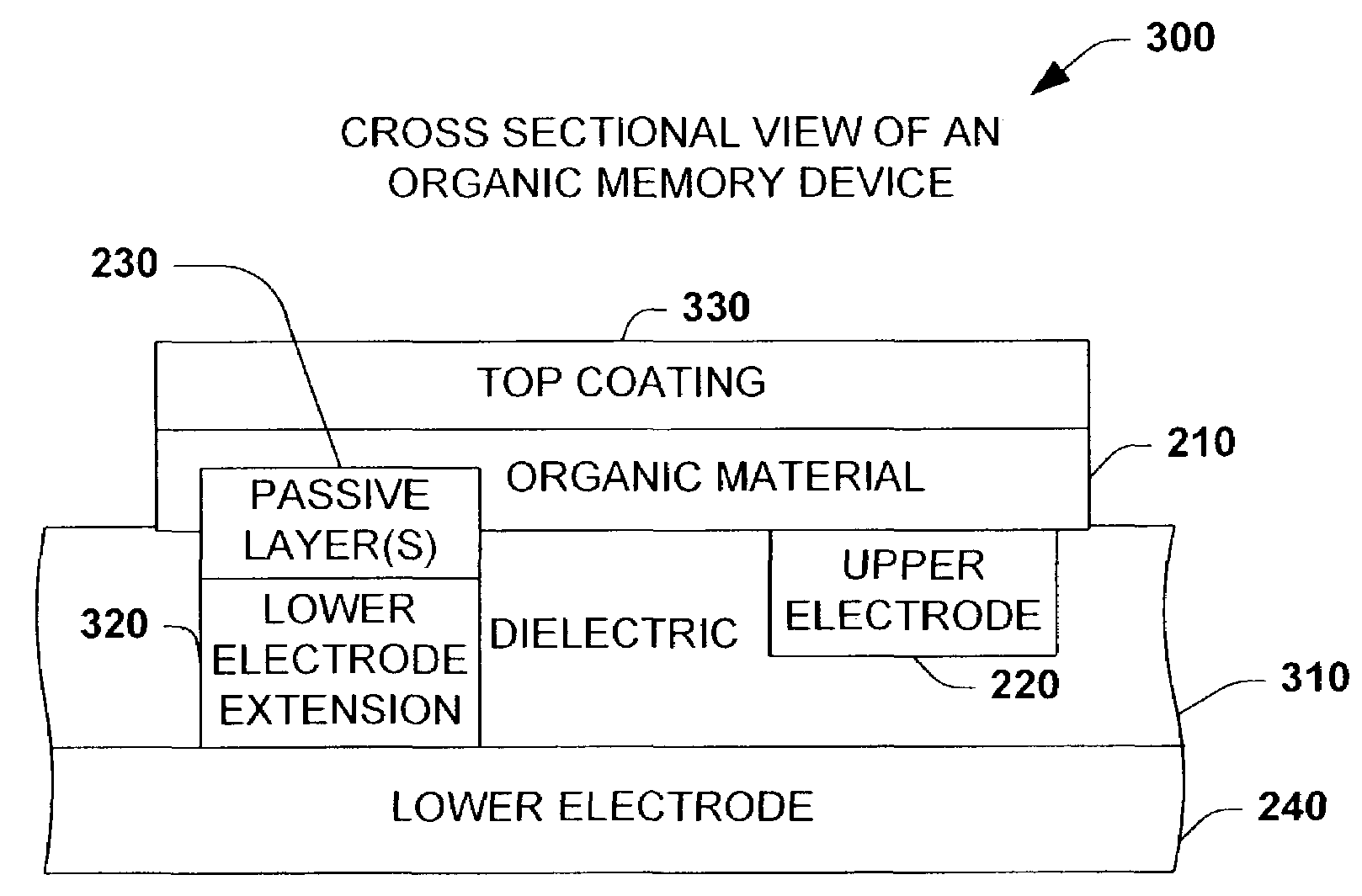

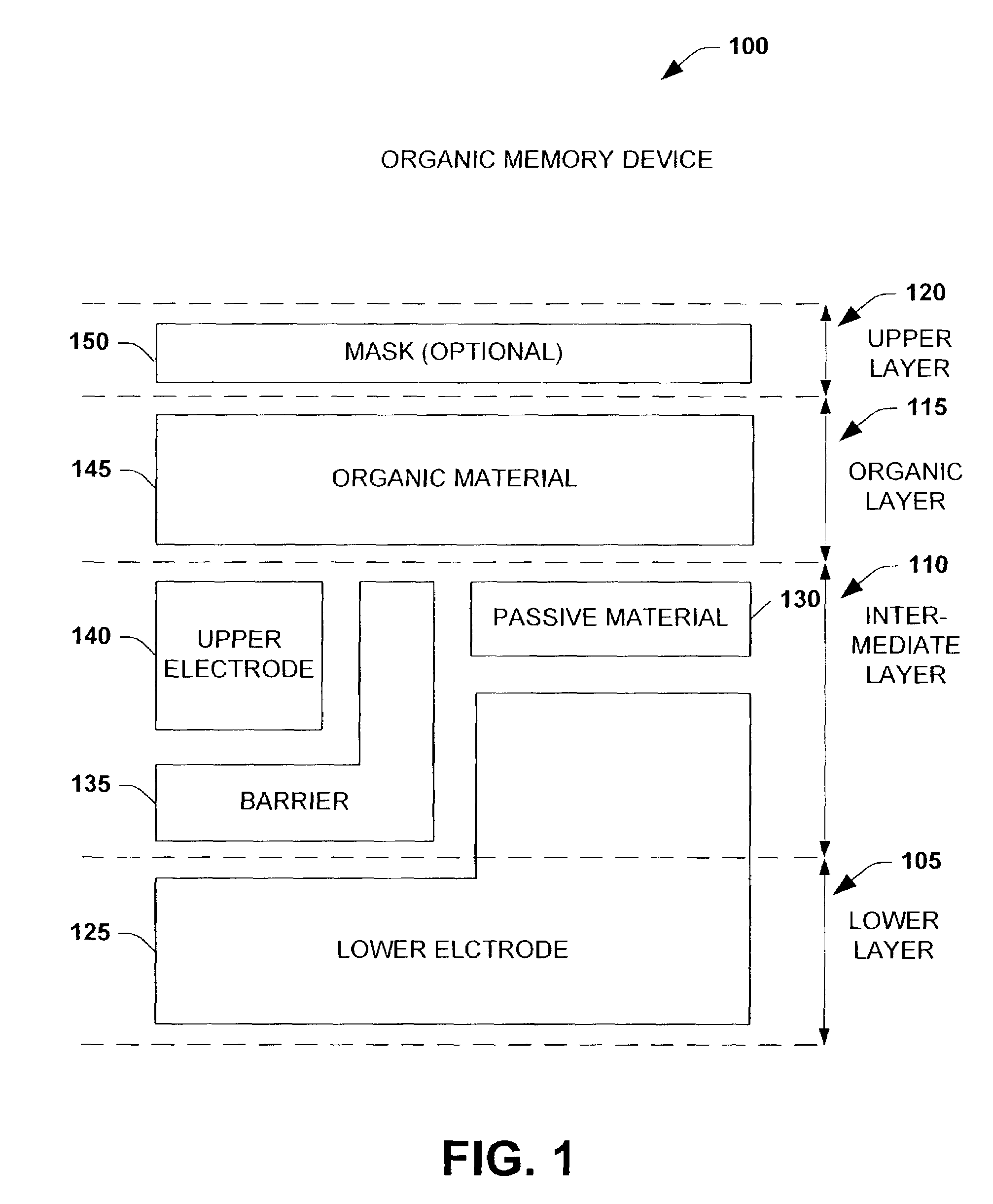

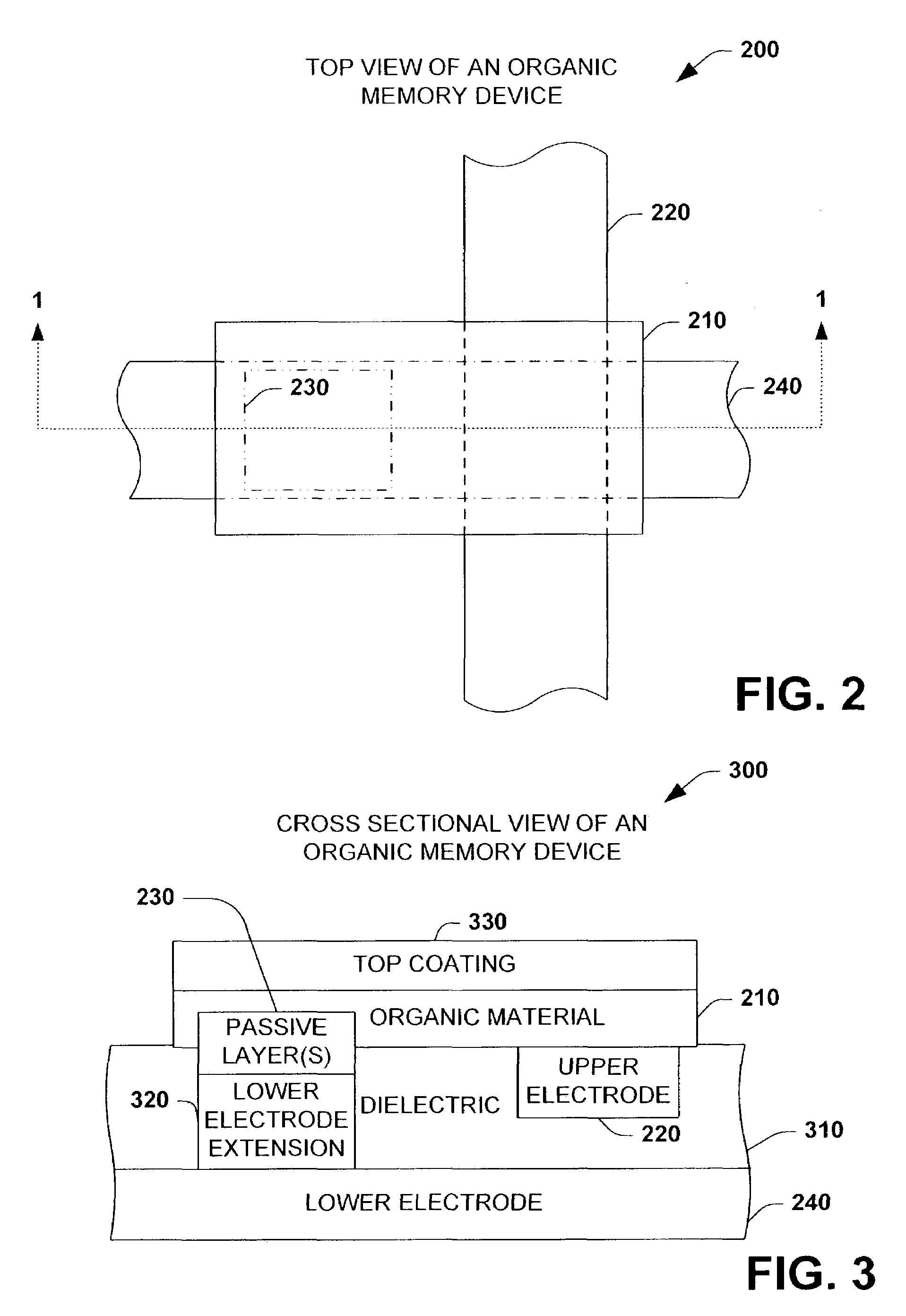

Planar polymer memory device

InactiveUS6977389B2Easy constructionHigh speed accessTransistorNanoinformaticsDielectricThin-film diode

The present invention provides a planar polymer memory device that can operate as a non-volatile memory device. A planar polymer memory device can be formed with two or more electrodes and an electrode extension associated with one electrode, wherein a selectively conductive medium and dielectric separate the electrodes. The method for forming a planar polymer memory device comprises at least one of forming a first electrode with an associated plug, forming a second electrode, forming a passive layer over the extension, depositing an organic polymer and patterning the organic polymer. The method affords integration of a planar polymer memory device into a semiconductor fabrication process. A thin film diode (TFD) can further be employed with a planar polymer memory device to facilitate programming. The TFD can be formed between the first electrode and the selectively conductive medium or the second electrode and the selectively conductive medium.

Owner:MONTEREY RES LLC

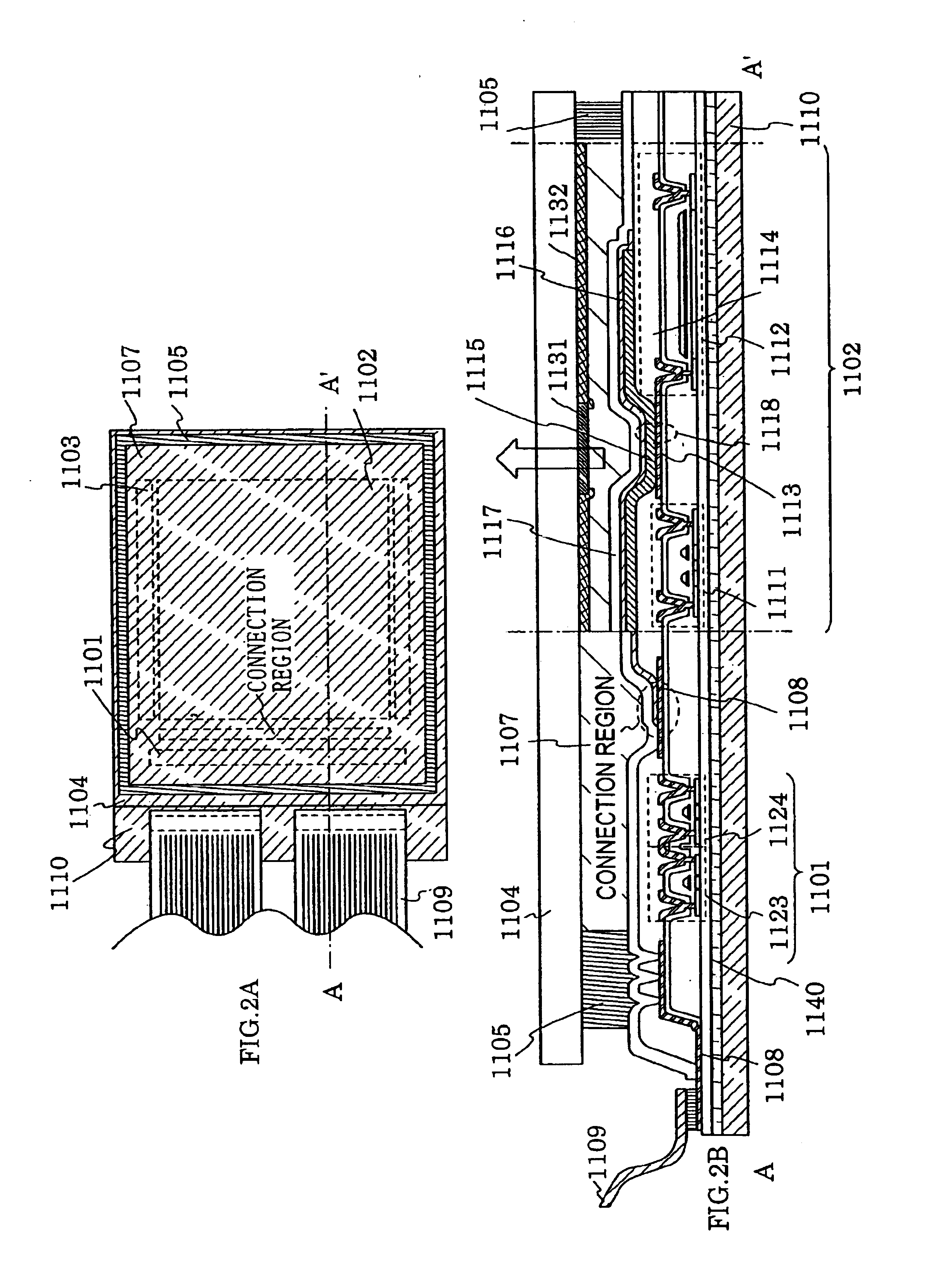

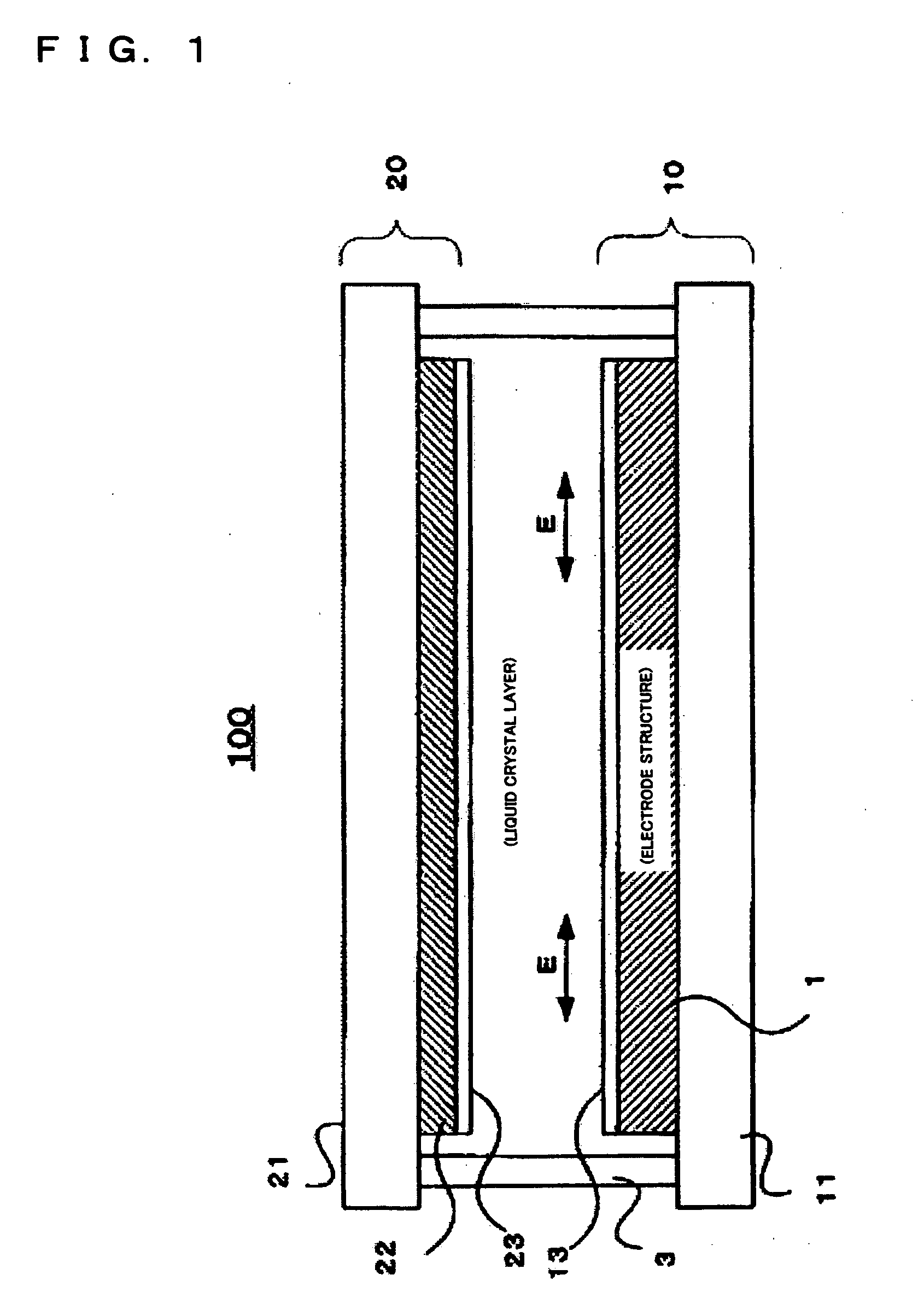

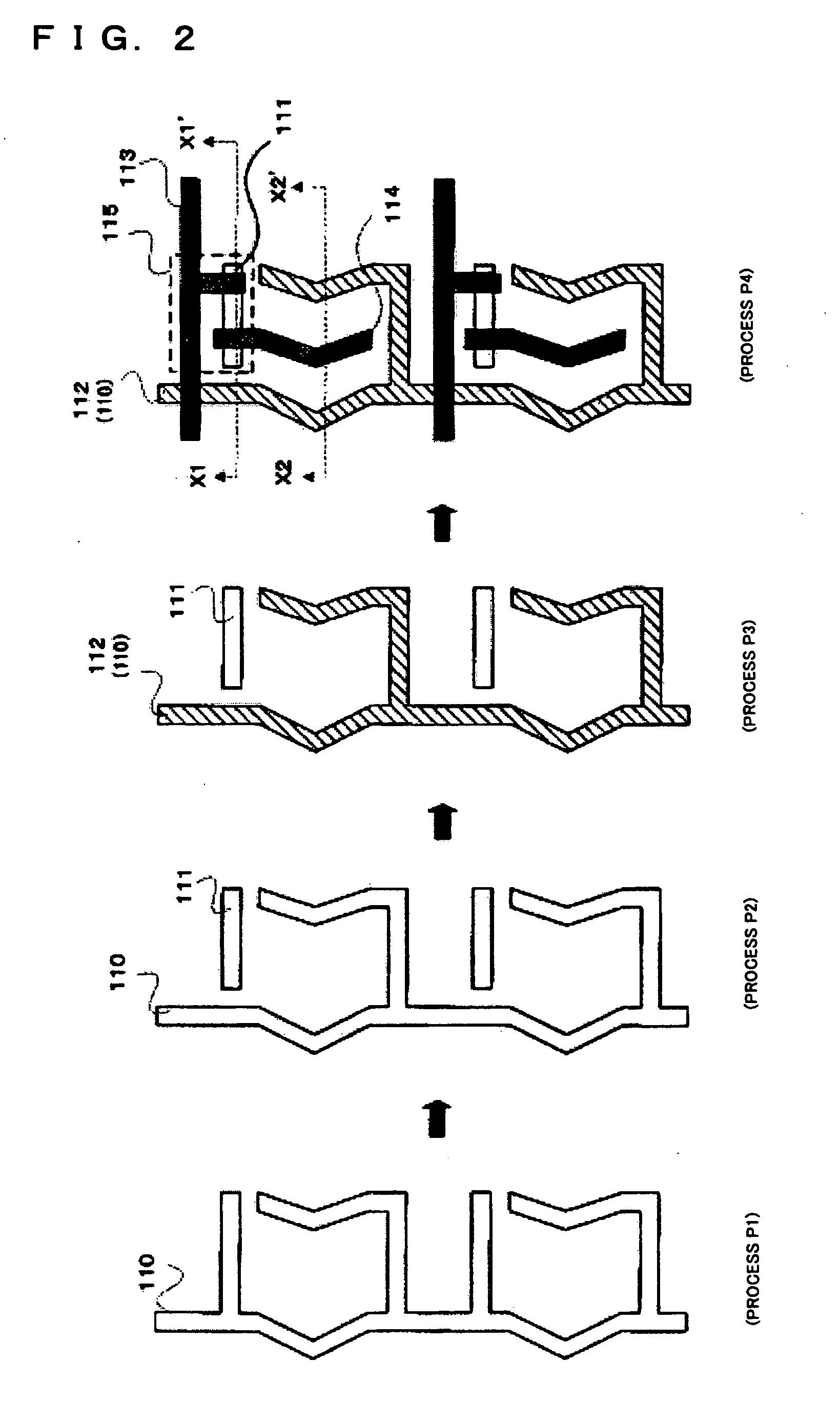

Electro-optical device and method of manufacturing the same

InactiveUS20050231673A1Simple manufacturing processLow costStatic indicating devicesSolid-state devicesNonlinear resistorThin-film diode

To simplify a manufacturing process of a transverse electric field mode liquid crystal display device by using a non-linear resistance element such as a TFD (Thin Film Diode) as a switching element. In a liquid crystal display device having a pair of substrates with liquid crystal interposed therebetween, one of the substrates consists of an electrode substrate. On the electrode substrate, there are provided a first group of electrodes, a second group of electrodes crossing the first group of electrodes with an insulating layer interposed therebetween, non-linear resistance elements, one end of each of the non-linear resistance elements being connected to the respective one of the second group of electrodes, and pixel electrodes opposing the first group of electrodes, each pixel electrode being connected to the other end of each of the non-linear resistance elements. Since the non-linear resistance elements have a so-called TFD (MIM) structure made of metal-insulating layer-metal, the manufacturing process is simple. Therefore, it is possible to manufacture the transverse electric field mode display device at low cost.

Owner:SEIKO EPSON CORP

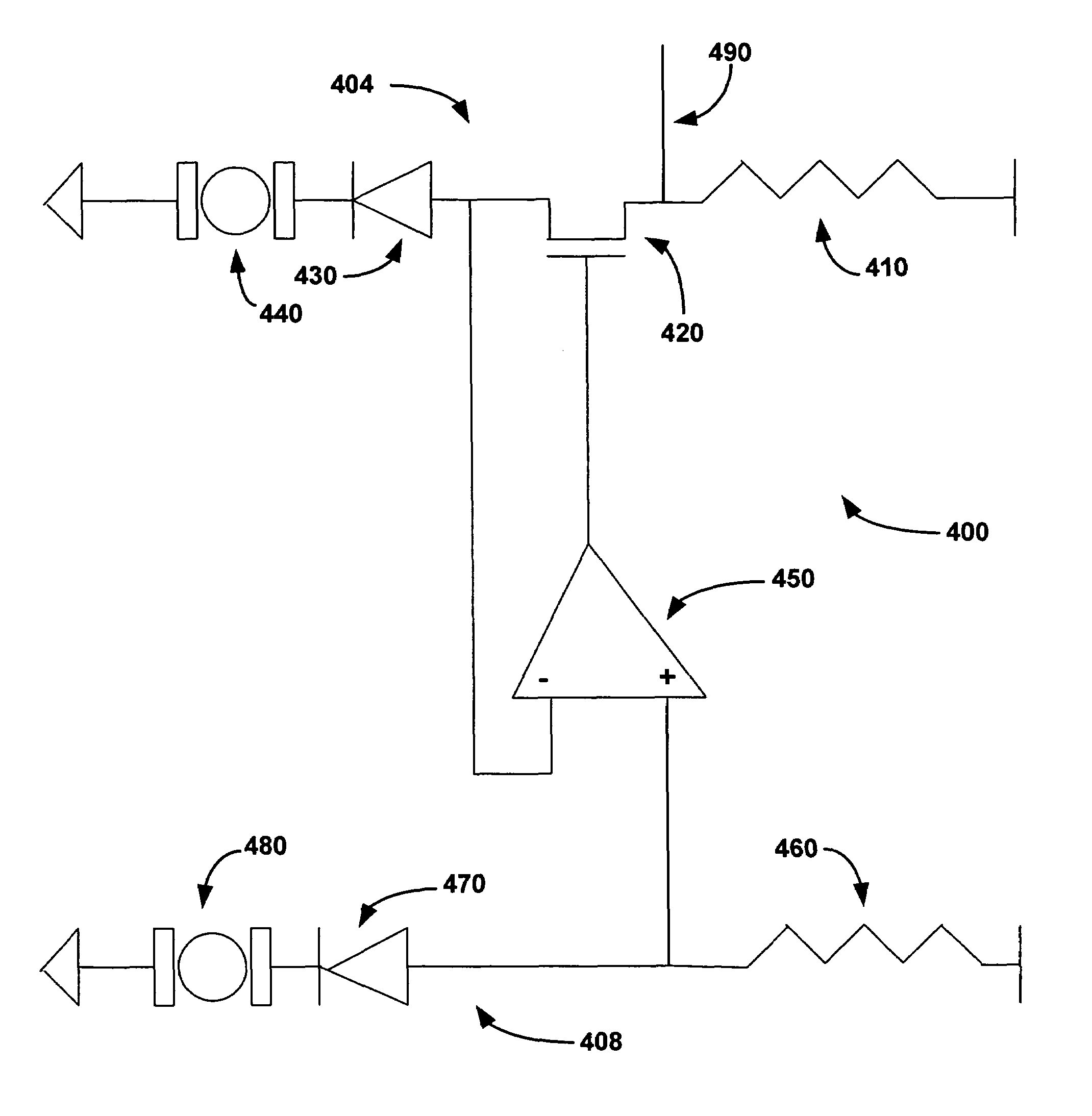

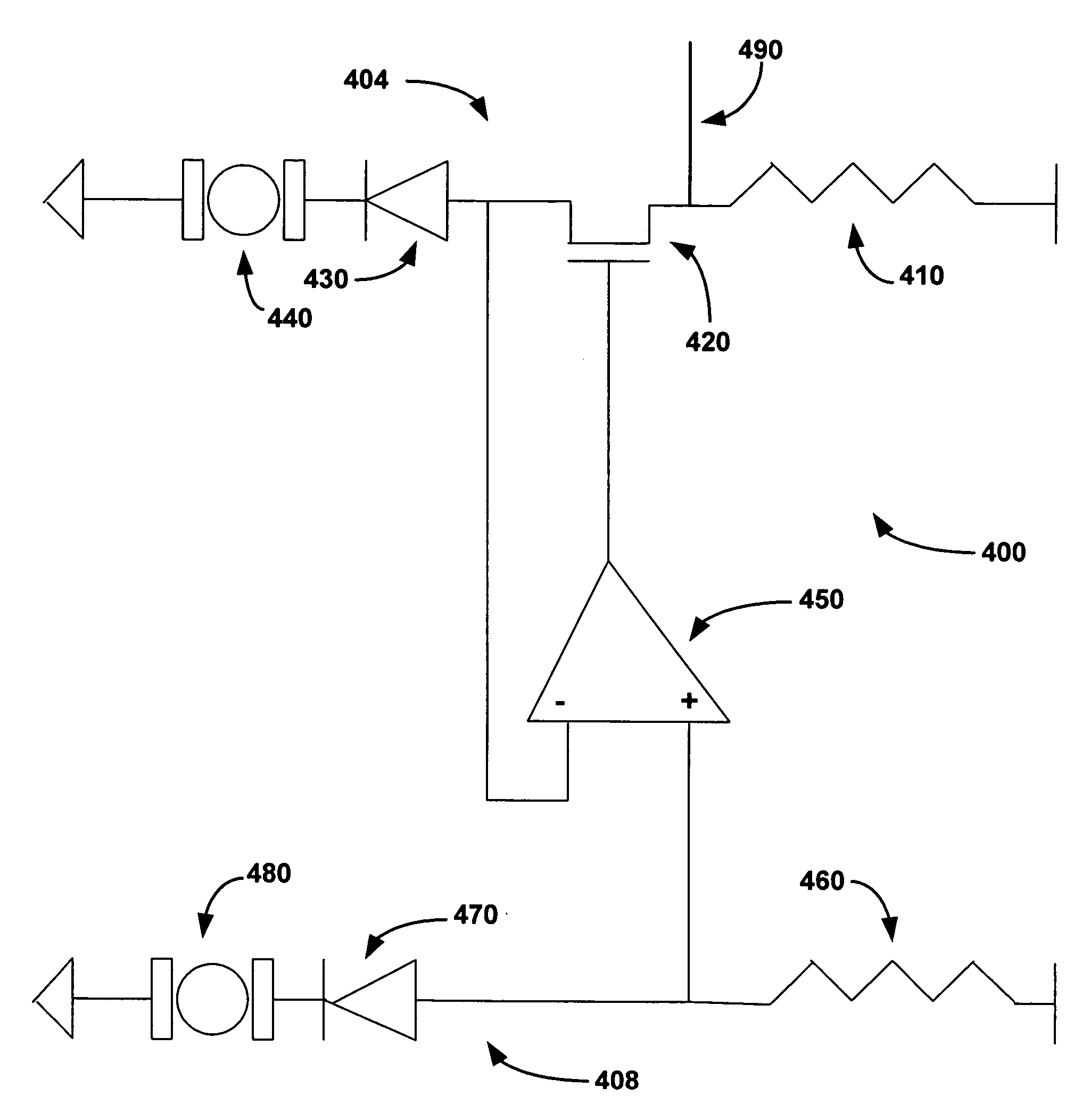

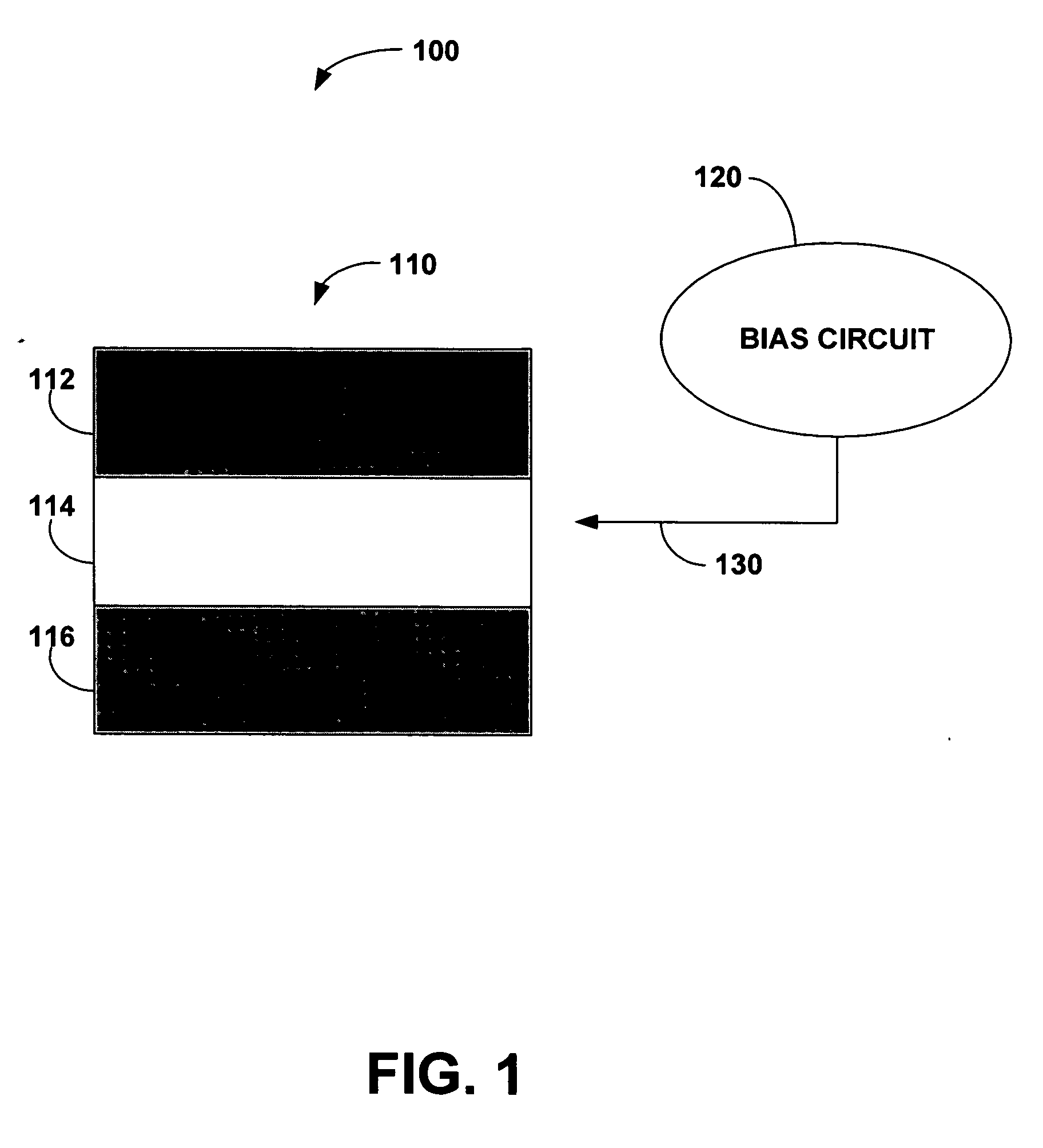

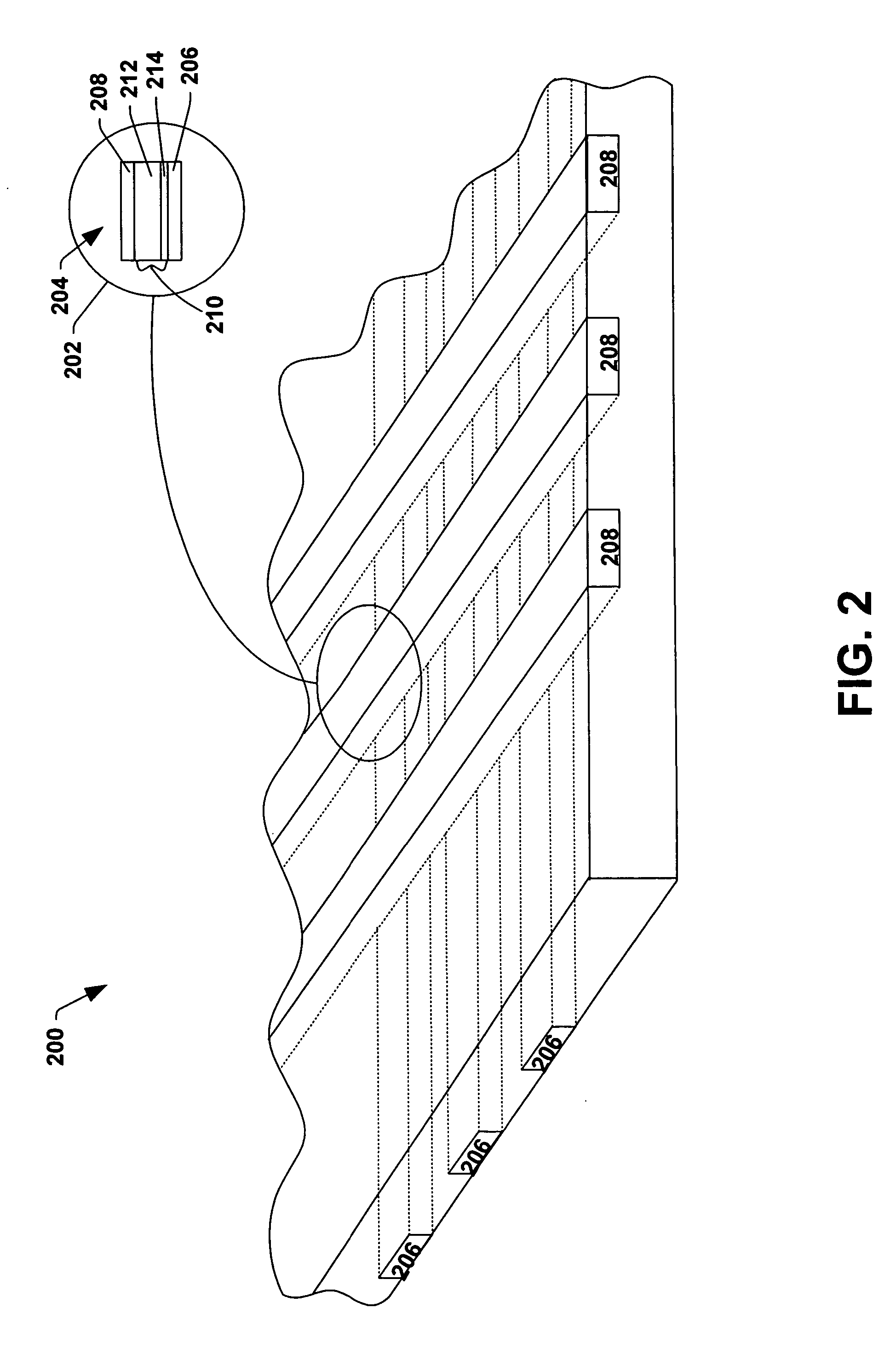

Temperature compensation of thin film diode voltage threshold in memory sensing circuit

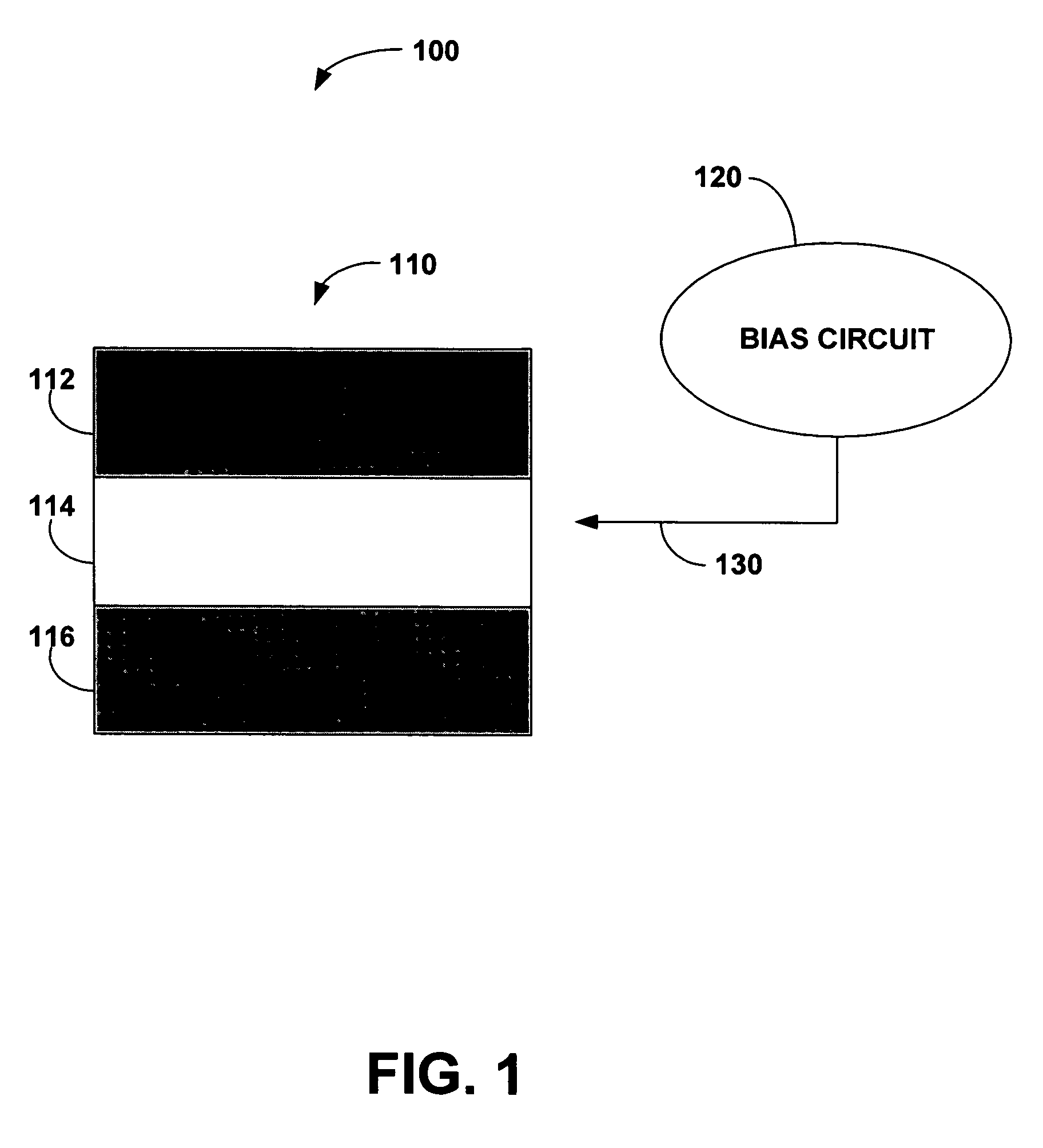

Systems and methodologies are provided for temperature compensation of thin film diode voltage levels in memory sensing circuits. The subject invention includes a temperature sensitive bias circuit and an array core with a temperature variable select device. The array core can consist of a thin film diode in series with a nanoscale resistive memory cell. The temperature sensitive bias circuit can include a thin film diode in series with two resistors, and provides a temperature compensating bias voltage to the array core. The thin film diode of the temperature sensitive bias circuit tracks the diode of the array core, while the two resistors create a resistive ratio to mimic the effect of temperature and / or process variation(s) on the array core. The compensating bias reference voltage is generated by the temperature sensitive bias circuit, duplicated by a differential amplifier, and utilized to maintain a constant operation voltage level on the nanoscale resistive memory cell.

Owner:CYPRESS SEMICON CORP

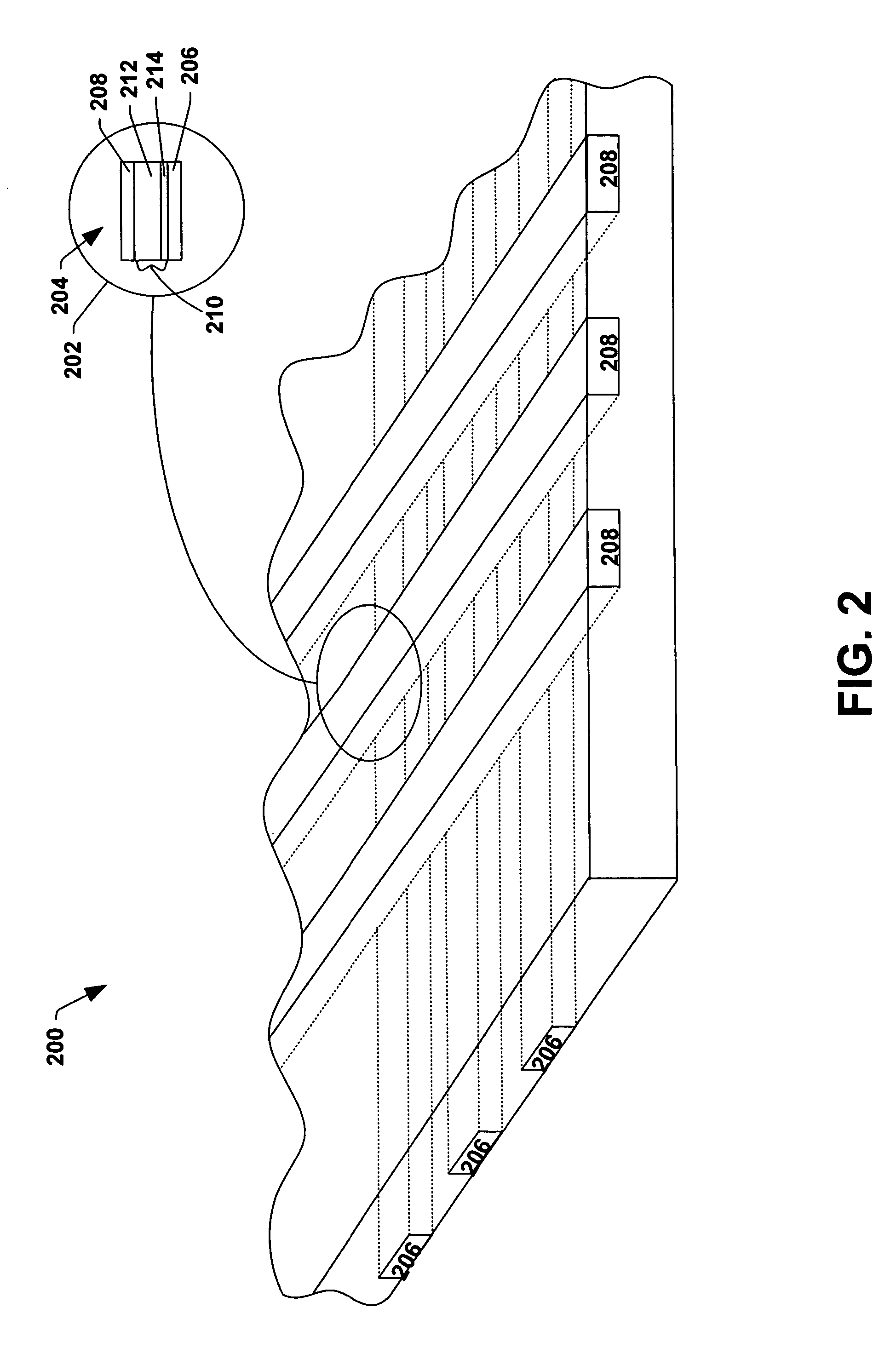

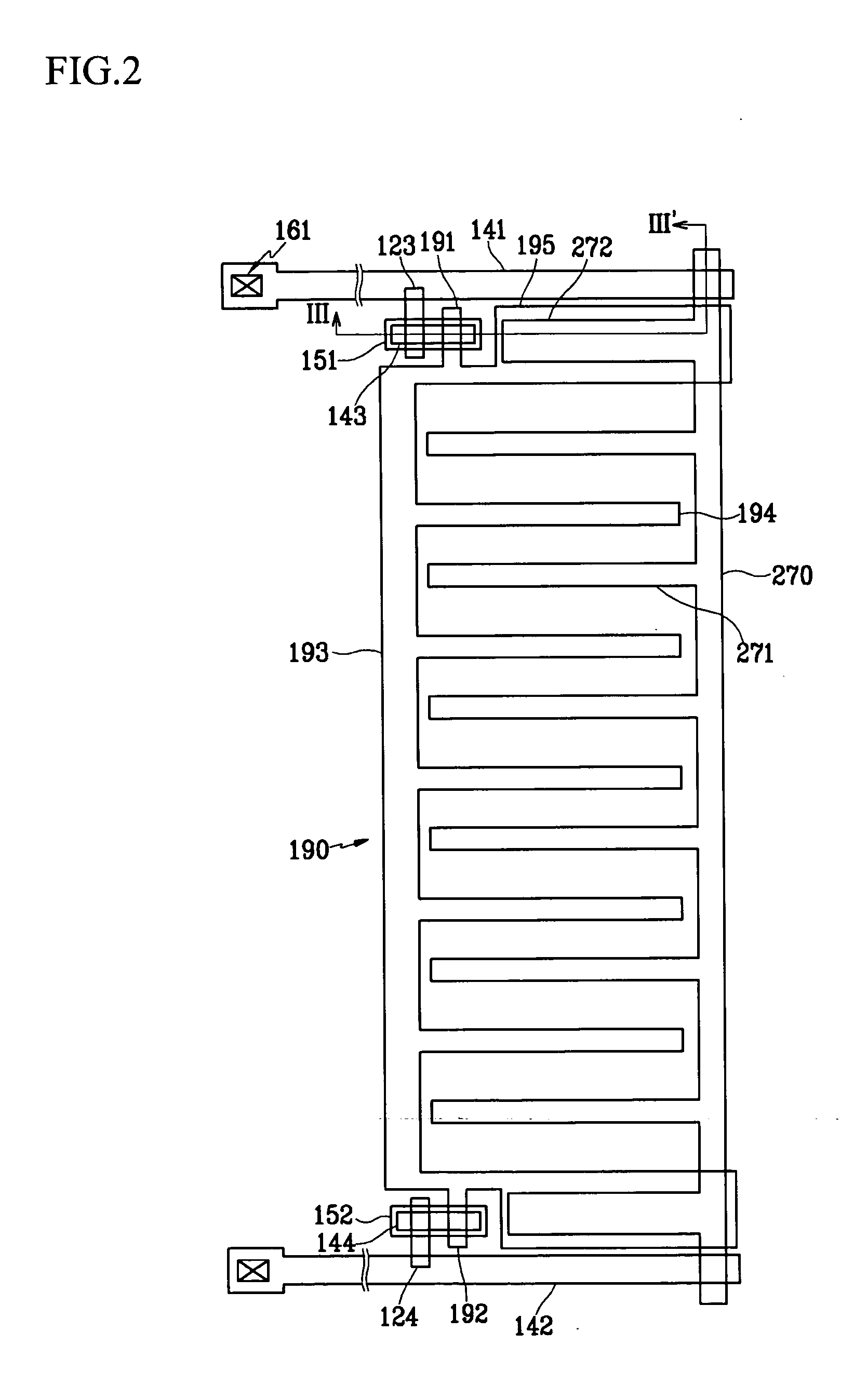

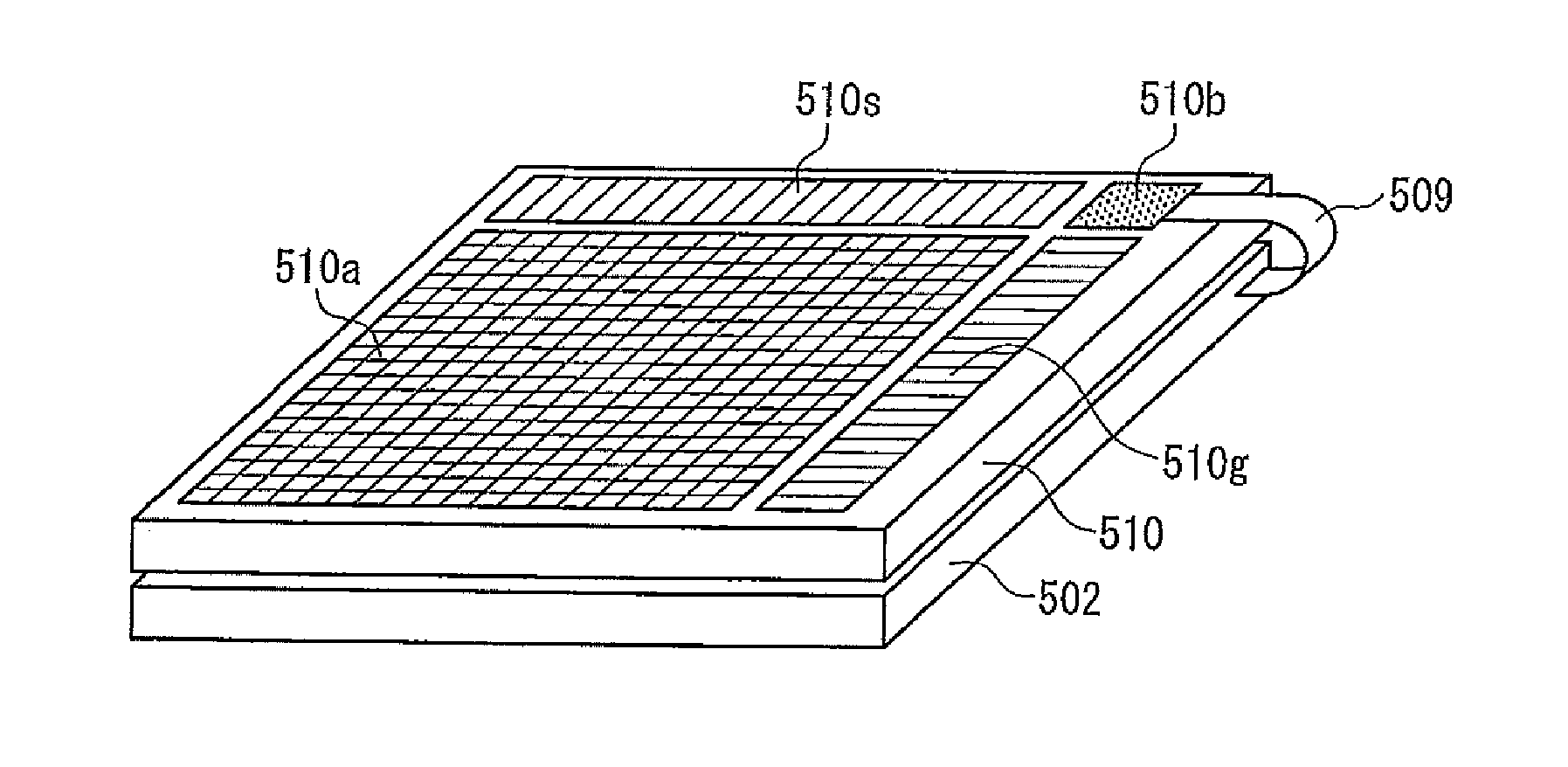

Liquid crystal display, thin film diode panel, and manufacturing method of the same

ActiveUS20050105010A1Reduce widthIncrease widthTransistorStatic indicating devicesThin-film diodeEngineering

A thin film diode panel comprises a pixel electrode formed on a substrate, the pixel electrode including a stem portion and a plurality of branch portions extended from the stem portion, and a data electrode line formed on the substrate, the data electrode line including a plurality of branch electrodes formed parallel to the plurality of branch portions. The plurality of branch portions may extend in a direction perpendicular to the stem portion and the plurality of branch electrodes may extend in a direction perpendicular to the data electrode line.

Owner:SAMSUNG DISPLAY CO LTD

Temperature compensation of thin film diode voltage threshold in memory sensing circuit

ActiveUS20060215439A1Constant operation voltageAvoid it happening againNanoinformaticsDigital storageThin-film diodeHemt circuits

Systems and methodologies are provided for temperature compensation of thin film diode voltage levels in memory sensing circuits. The subject invention includes a temperature sensitive bias circuit and an array core with a temperature variable select device. The array core can consist of a thin film diode in series with a nanoscale resistive memory cell. The temperature sensitive bias circuit can include a thin film diode in series with two resistors, and provides a temperature compensating bias voltage to the array core. The thin film diode of the temperature sensitive bias circuit tracks the diode of the array core, while the two resistors create a resistive ratio to mimic the effect of temperature and / or process variation(s) on the array core. The compensating bias reference voltage is generated by the temperature sensitive bias circuit, duplicated by a differential amplifier, and utilized to maintain a constant operation voltage level on the nanoscale resistive memory cell.

Owner:CYPRESS SEMICON CORP

Method for manufacturing a semiconductor device

A method for forming a silicon island used for forming a TFT or thin film diode comprises the step of pattering a silicon film with a photoresist mask. In order to prevent the contamination of the semiconductor film due to the photoresist material, a protective film such as silicon oxide is interposed between the semiconductor film and the photoresist film. Also, the protective film is preferably formed by thermal annealing or light annealing in an oxidizing atmosphere.

Owner:SEMICON ENERGY LAB CO LTD

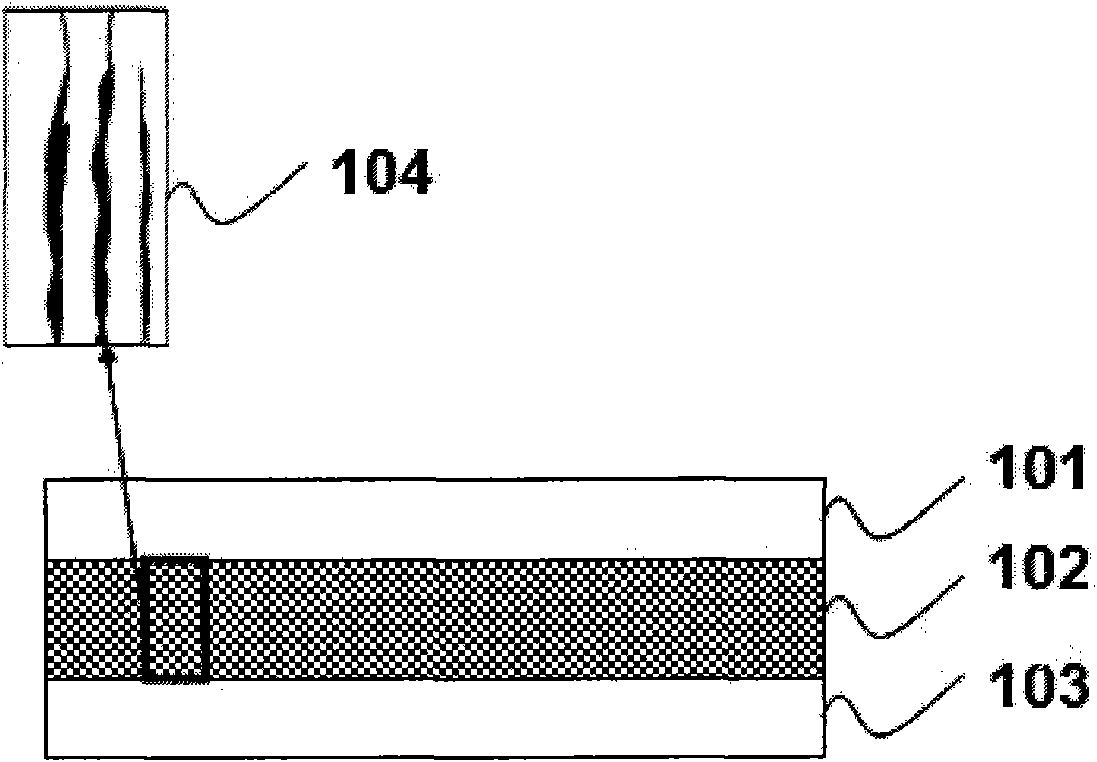

Ferroelectric oxide/semiconductor composite film diode resistance change memory

ActiveCN101789490ARealize rewritable functionIncrease program/erase speedElectrical apparatusDigital storageStrontium titanateComposite film

The invention belongs to the technical field of the information memory and particularly relates to a ferroelectric oxide / semiconductor sequentially composite film diode resistance change memory. The resistance change memory comprises a substrate, a bottom electrode, a ferroelectric oxide / semiconductor composite memory function layer and a top electrode, and is prepared by the following method which comprises the following steps: developing compound electrodes, such as strontium ruthenium, lanthanum nickel and the like, or metal on the monocrystal strontium titanate or SiO2 / Si substrate to serve as the bottom electrode; then developing the ferroelectric oxide / semiconductor composite film function layer by a pulsed laser deposition or radio frequency magnetron sputtering method; and developing the metal top electrode to form a single diode memory unit structure. The polarity of the diode changes with the orientation of the electric domain. The ferroelectric oxide / semiconductor composite film diode resistance change memory has the advantages of high memory density, good information retentivity and low power consumption.

Owner:FUDAN UNIV

Thin film diode integrated with chalcogenide memory cell

InactiveUS20050101084A1Solid-state devicesSemiconductor/solid-state device manufacturingThin-film diodeChalcogenide glass

An integrated programmable conductor memory cell and diode device in an integrated circuit comprises a diode and a glass electrolyte element, the glass electrolyte element having metal ions mixed or dissolved therein and being able to selectively form a conductive pathway under the influence of an applied voltage. In one embodiment, both the diode and the memory cell comprise a chalcogenide glass, such as germanium selenide (e.g., Ge2Se8 or Ge25Se75). The first diode element comprises a chalcogenide glass layer having a first conductivity type, the second diode element comprises a chalcogenide glass layer doped with an element such as bismuth and having a second conductivity type opposite to the first conductivity type and the memory cell comprises a chalcogenide glass element with silver ions therein. In another embodiment, the diode comprises silicon and there is a diffusion barrier layer between the diode and the chalcogenide glass memory element. Methods of fabricating integrated programmable conductor memory cell and diode devices are also disclosed.

Owner:OVONYX MEMORY TECH LLC

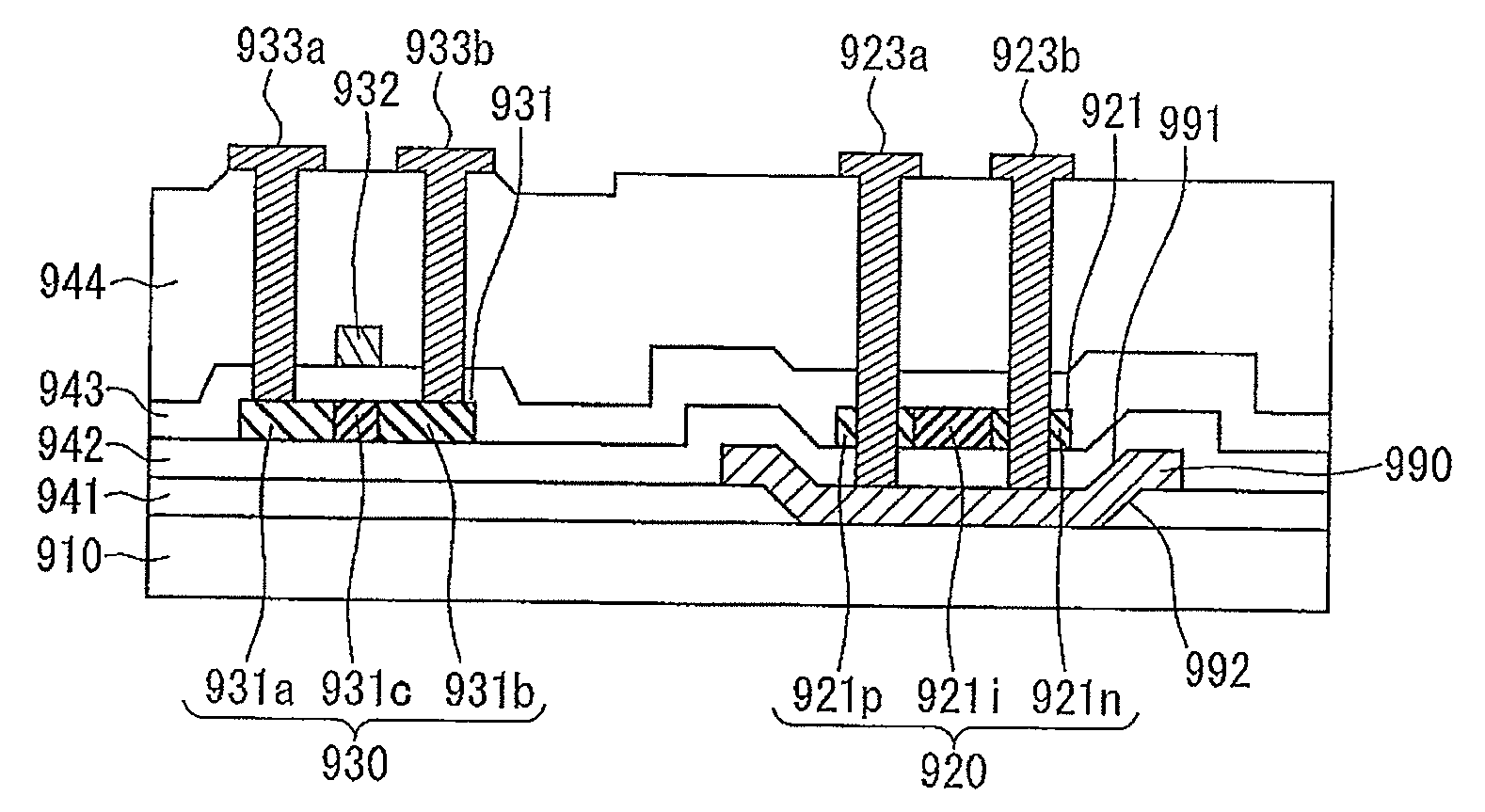

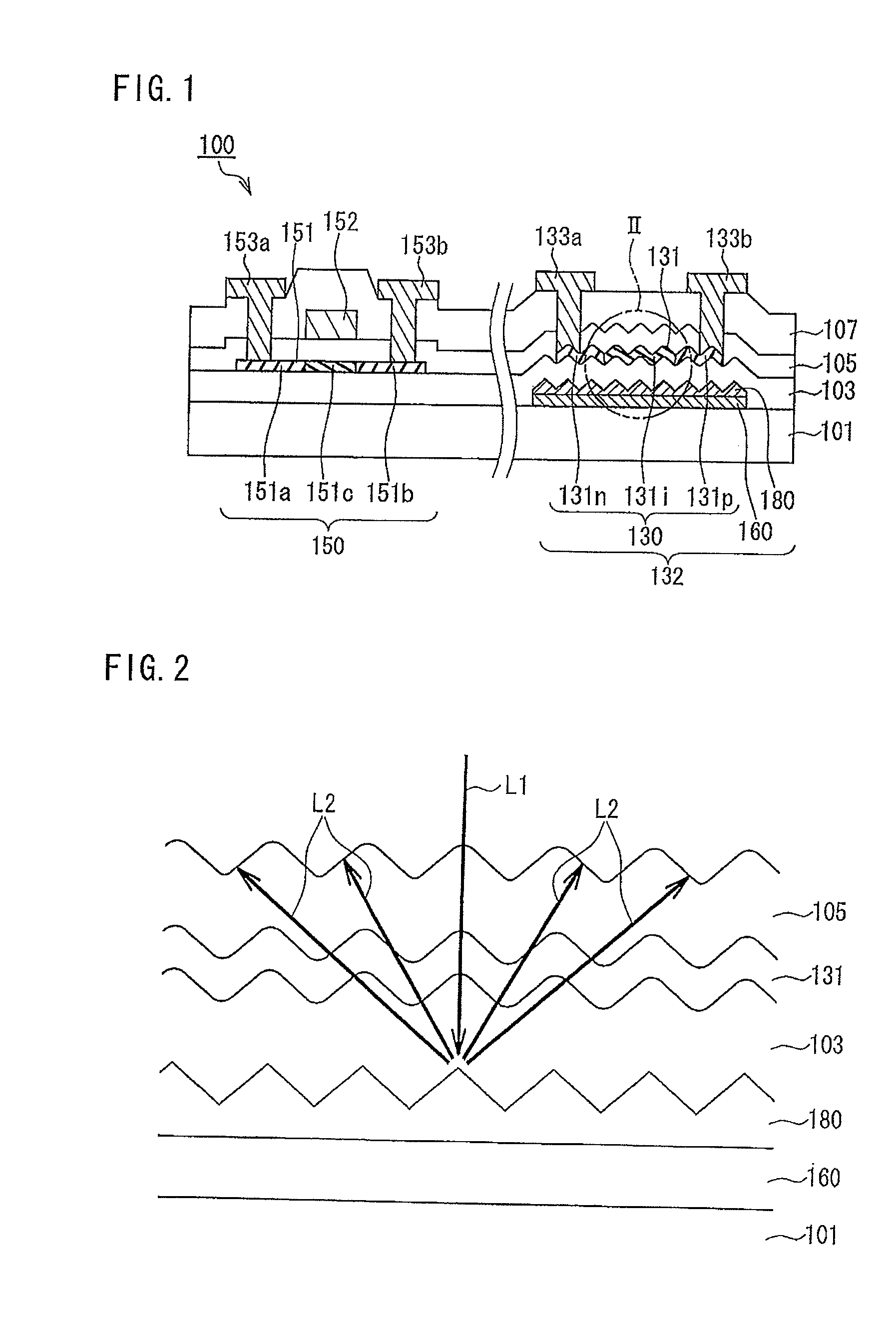

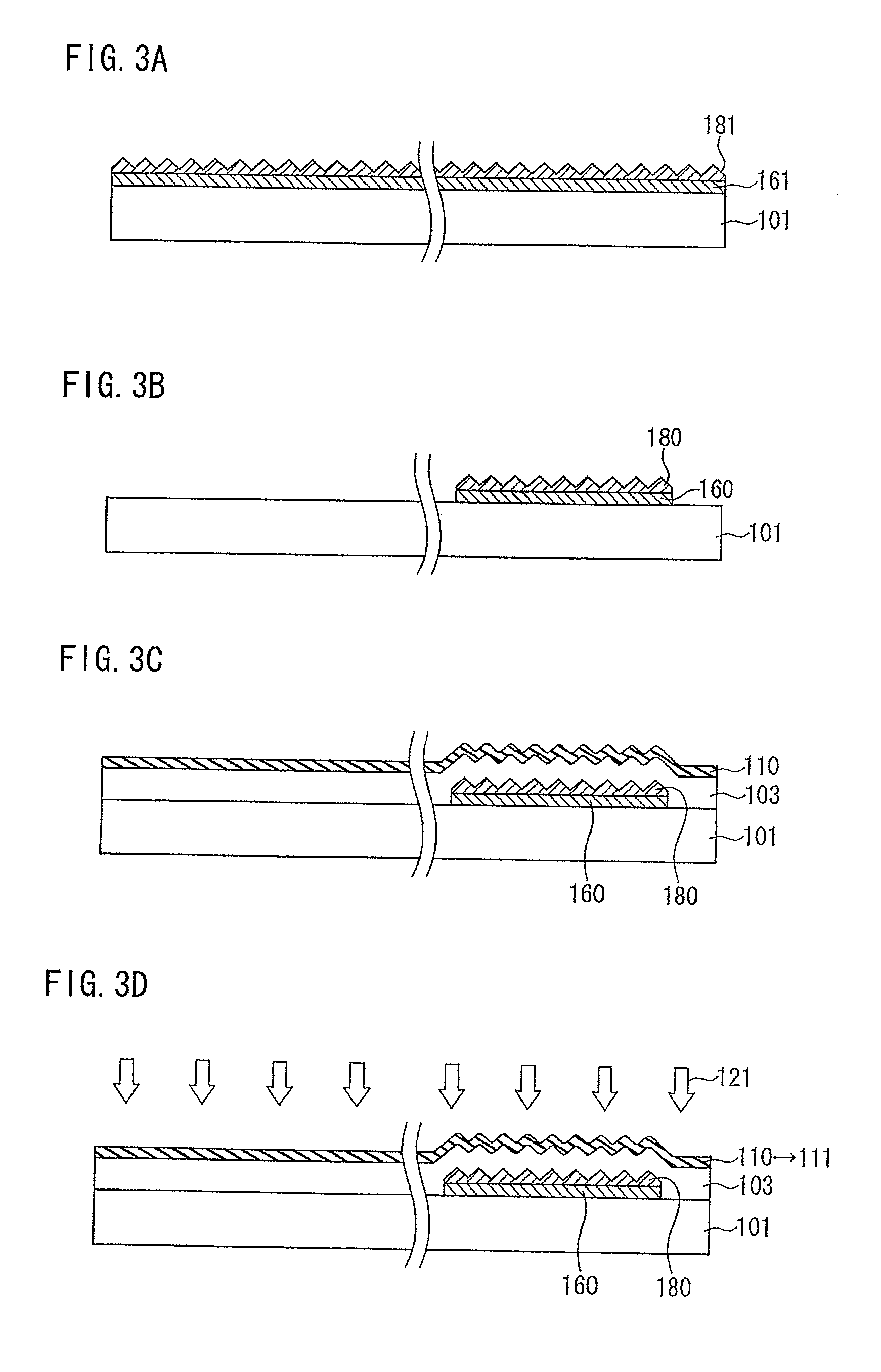

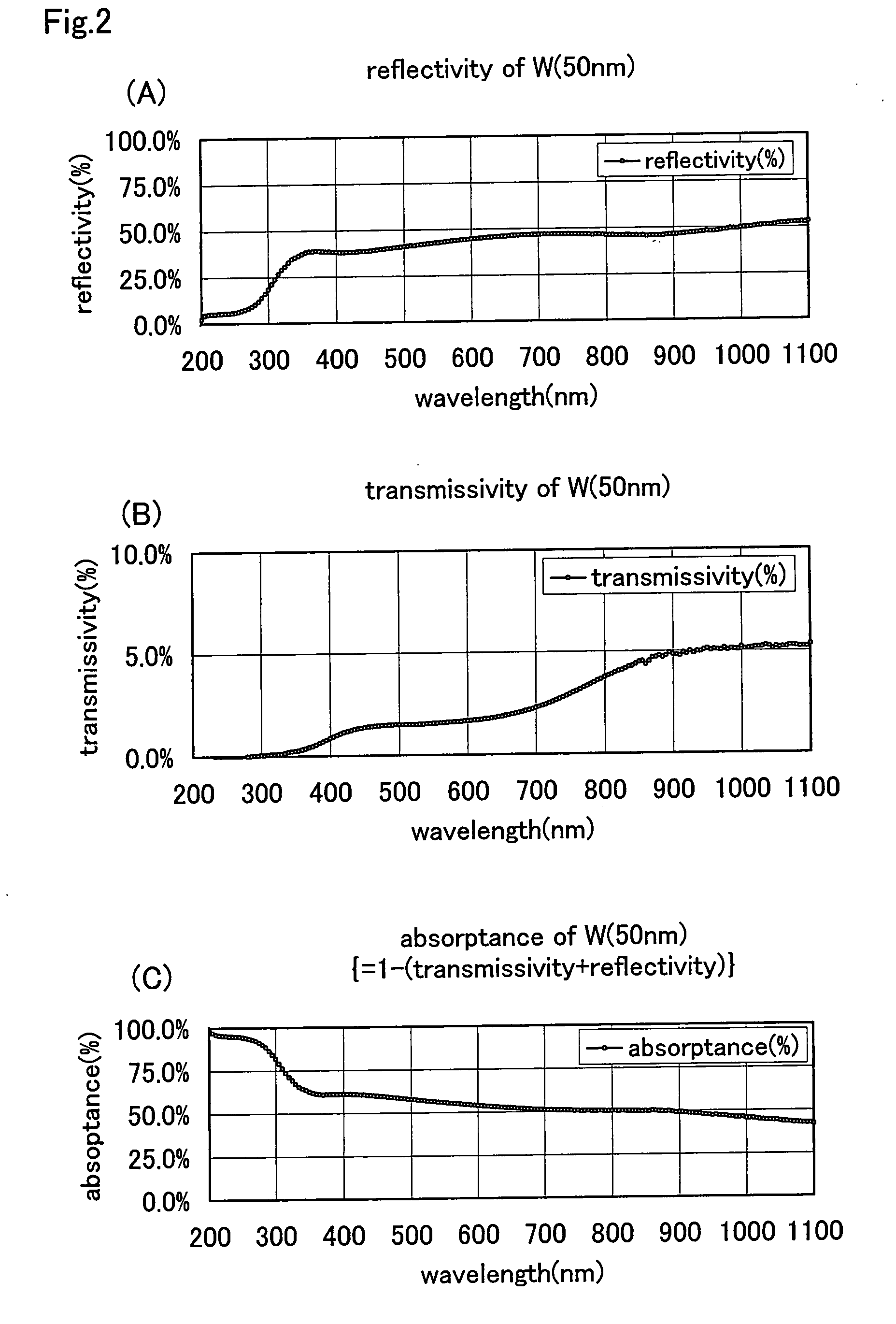

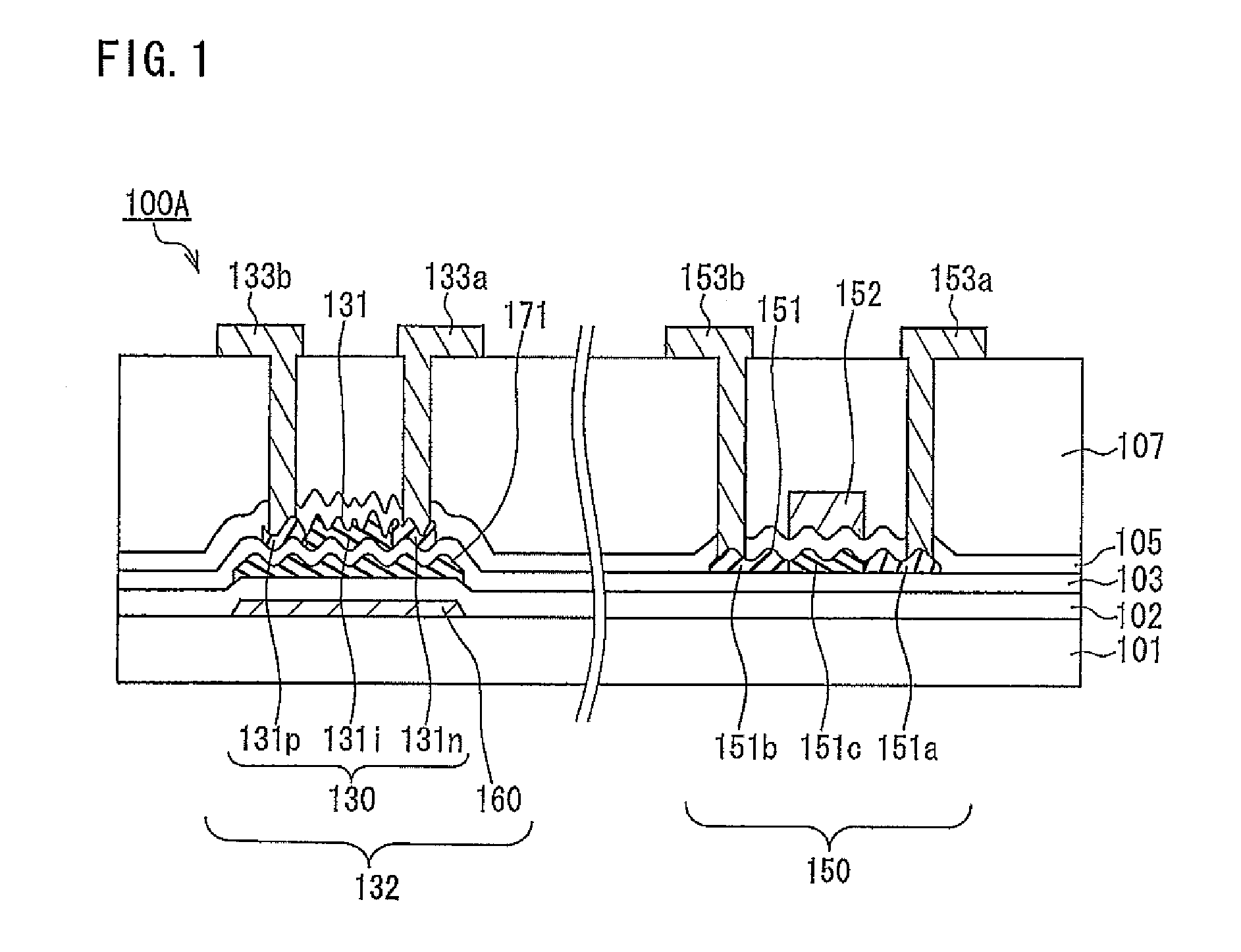

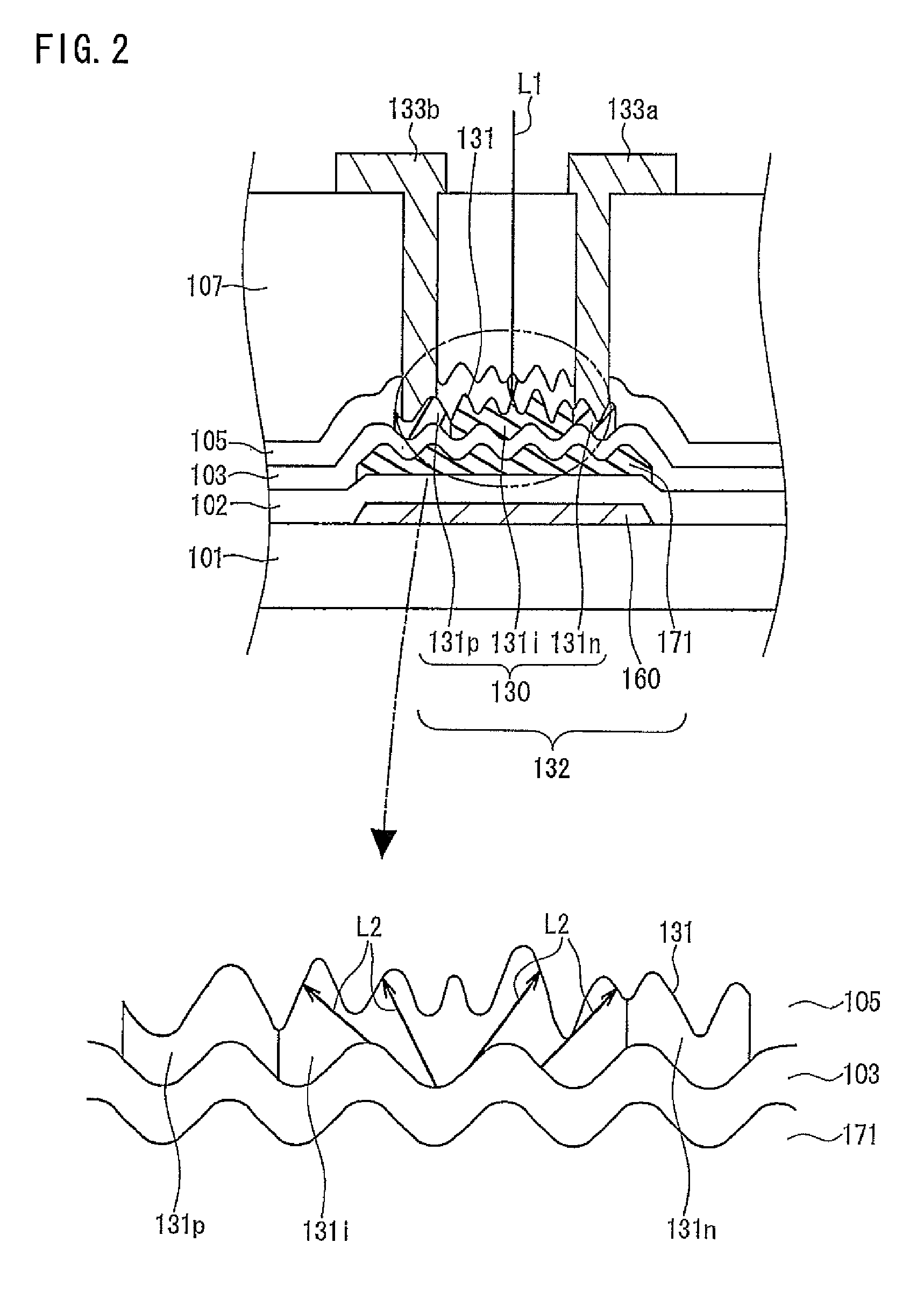

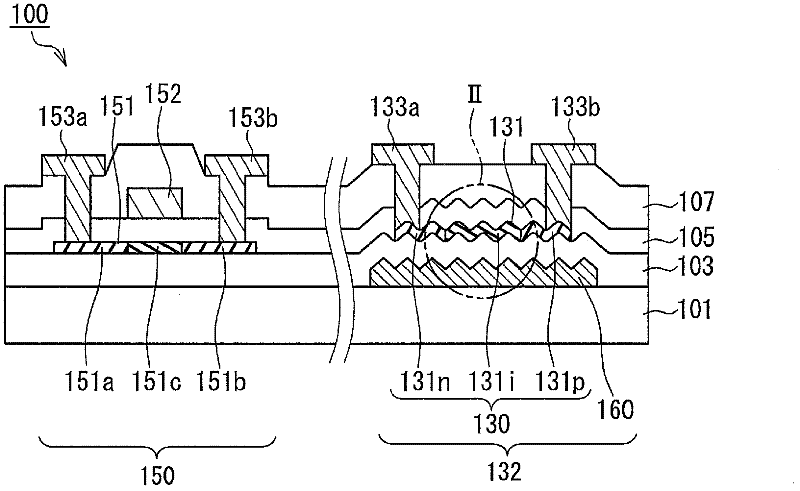

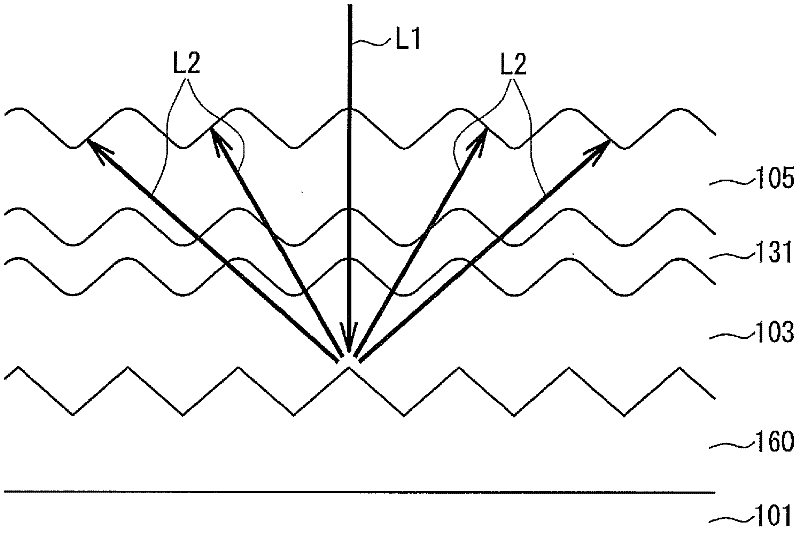

Photosensor, semiconductor device, and liquid crystal panel

InactiveUS20120146028A1Improve light detection sensitivityImprove light utilization efficiencyTransistorSolid-state devicesThin-film diodeBlocking layer

The light use efficiency of a thin film diode is improved even when the semiconductor layer of the diode has a small thickness, thereby improving the light detection sensitivity of the diode. Further, a short circuit between the electrodes of the thin film diode via the light-blocking layer is prevented. A thin film diode (130) having a first semiconductor layer (131) including, at least, an n-type region (131n) and a p-type region (131p) is provided on one side of a substrate (101), and a light-blocking layer (160) is provided between the substrate and the first semiconductor layer. A metal oxide layer (180) is provided on the side of the light-blocking layer facing the first semiconductor layer. Asperities are provided on the side of the metal oxide layer facing the first semiconductor layer, and the first semiconductor layer has a geometry of asperities conforming with the asperities on the metal oxide layer.

Owner:SHARP KK

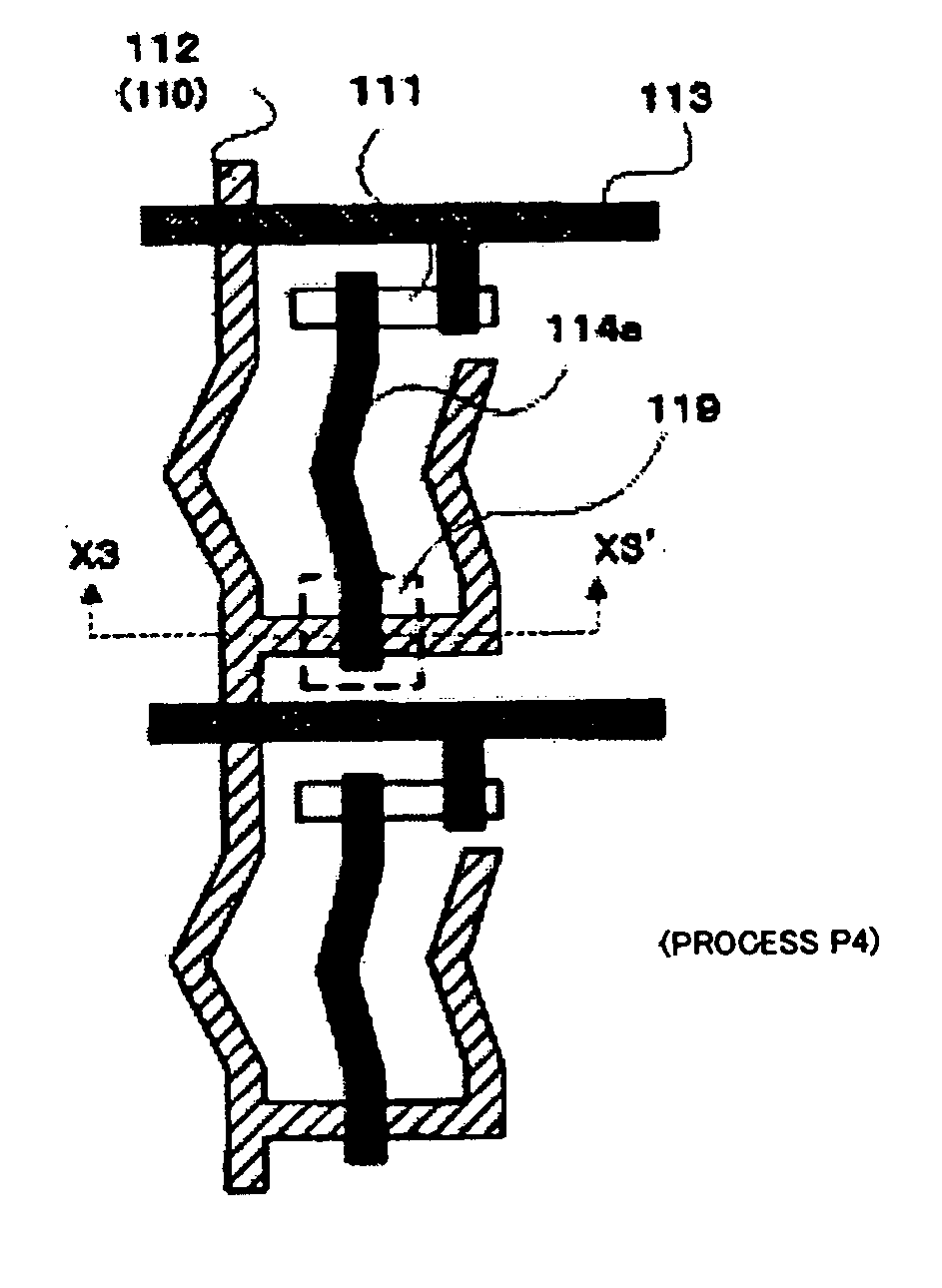

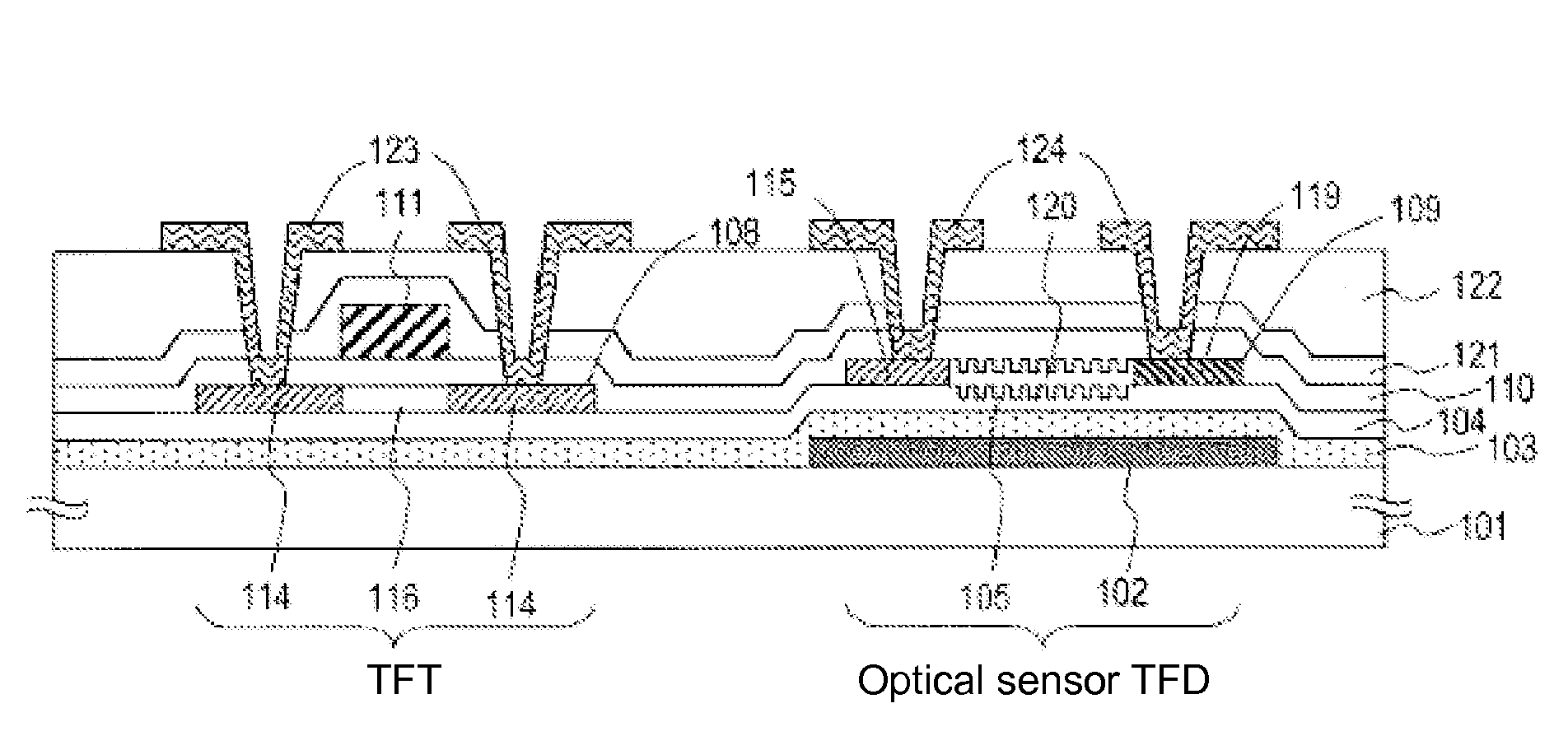

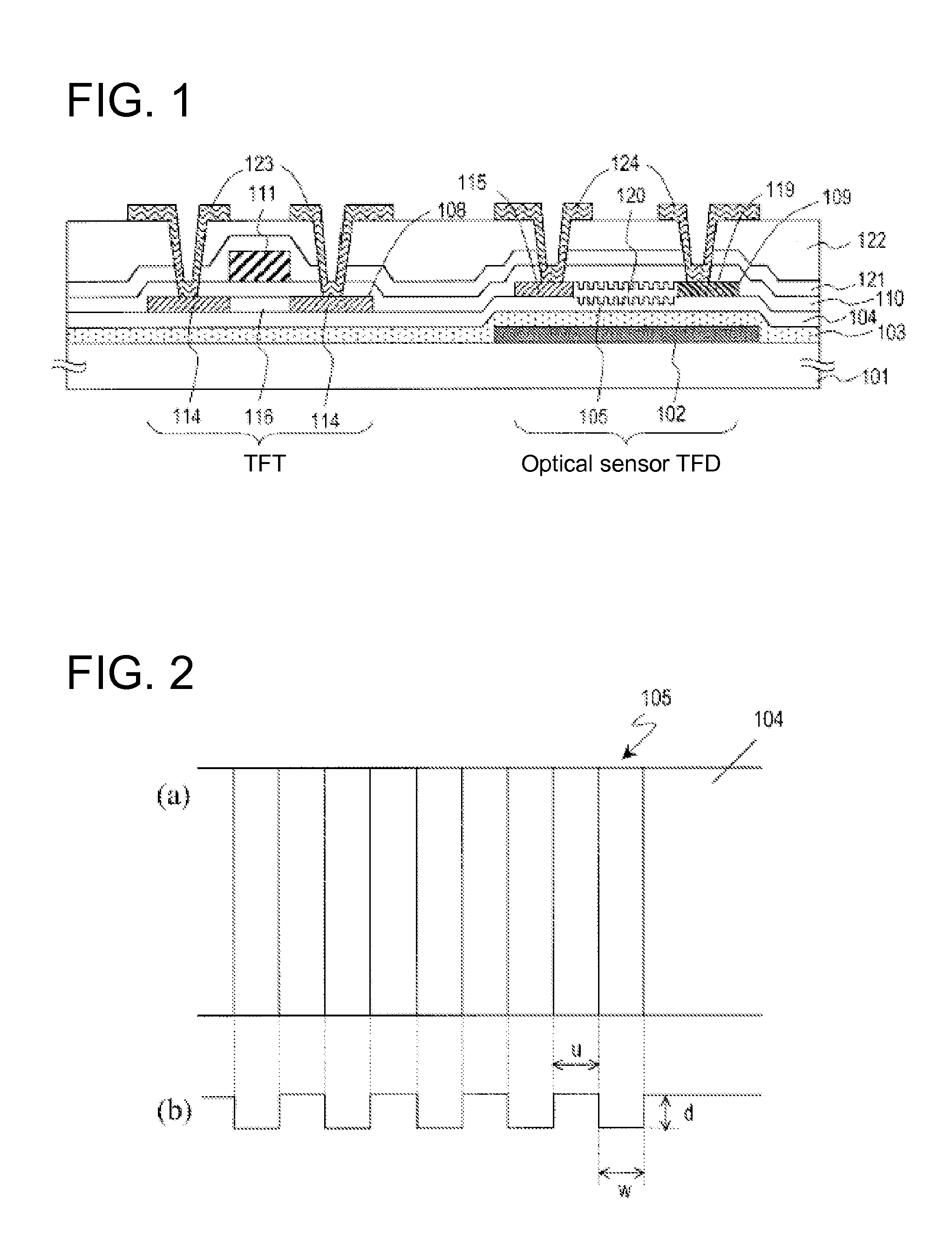

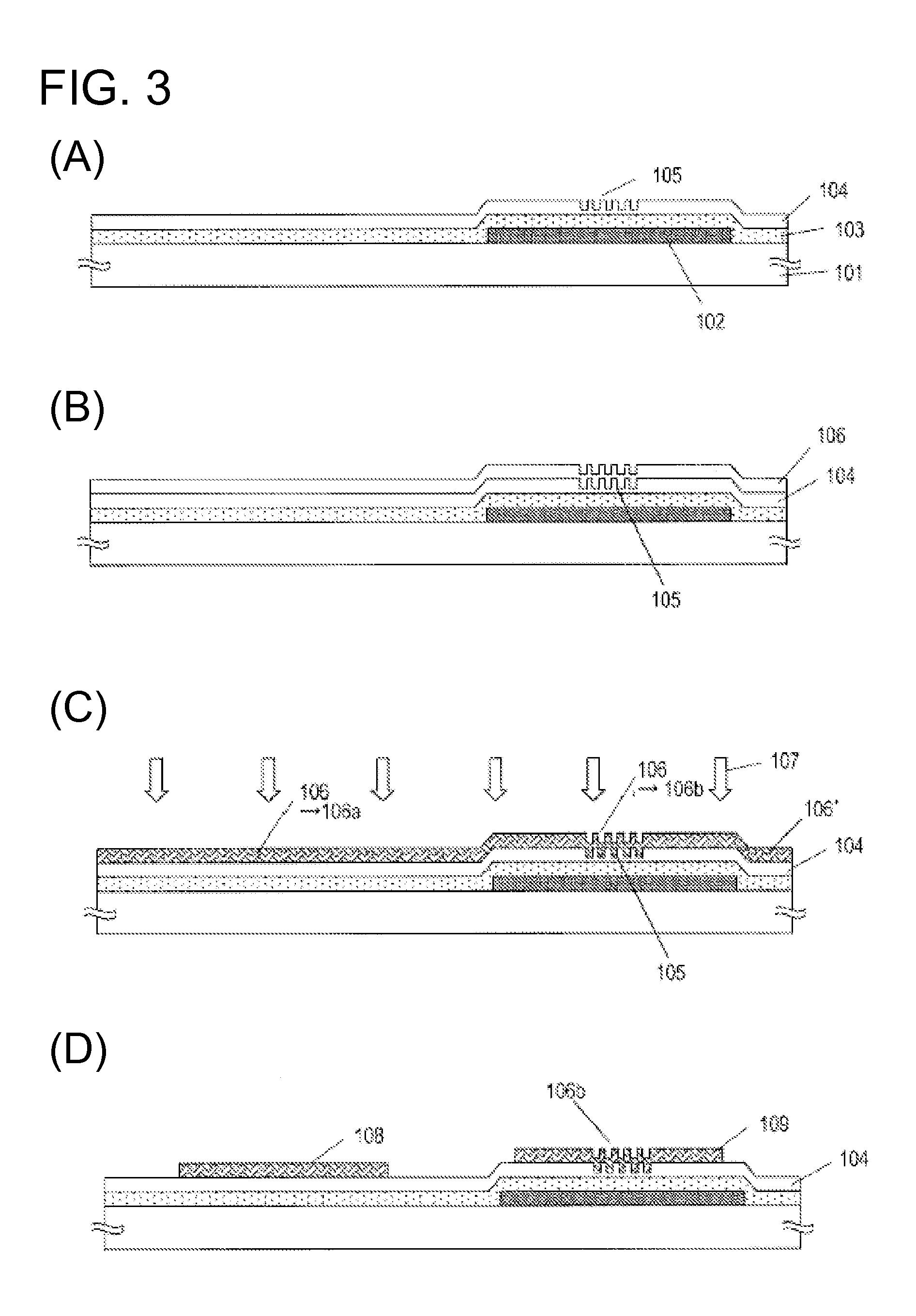

Semiconductor device, method for manufacturing same, and display device

InactiveUS20110273390A1Layer is optimizedIncrease surface recessTransistorSolid-state devicesDisplay deviceThin-film diode

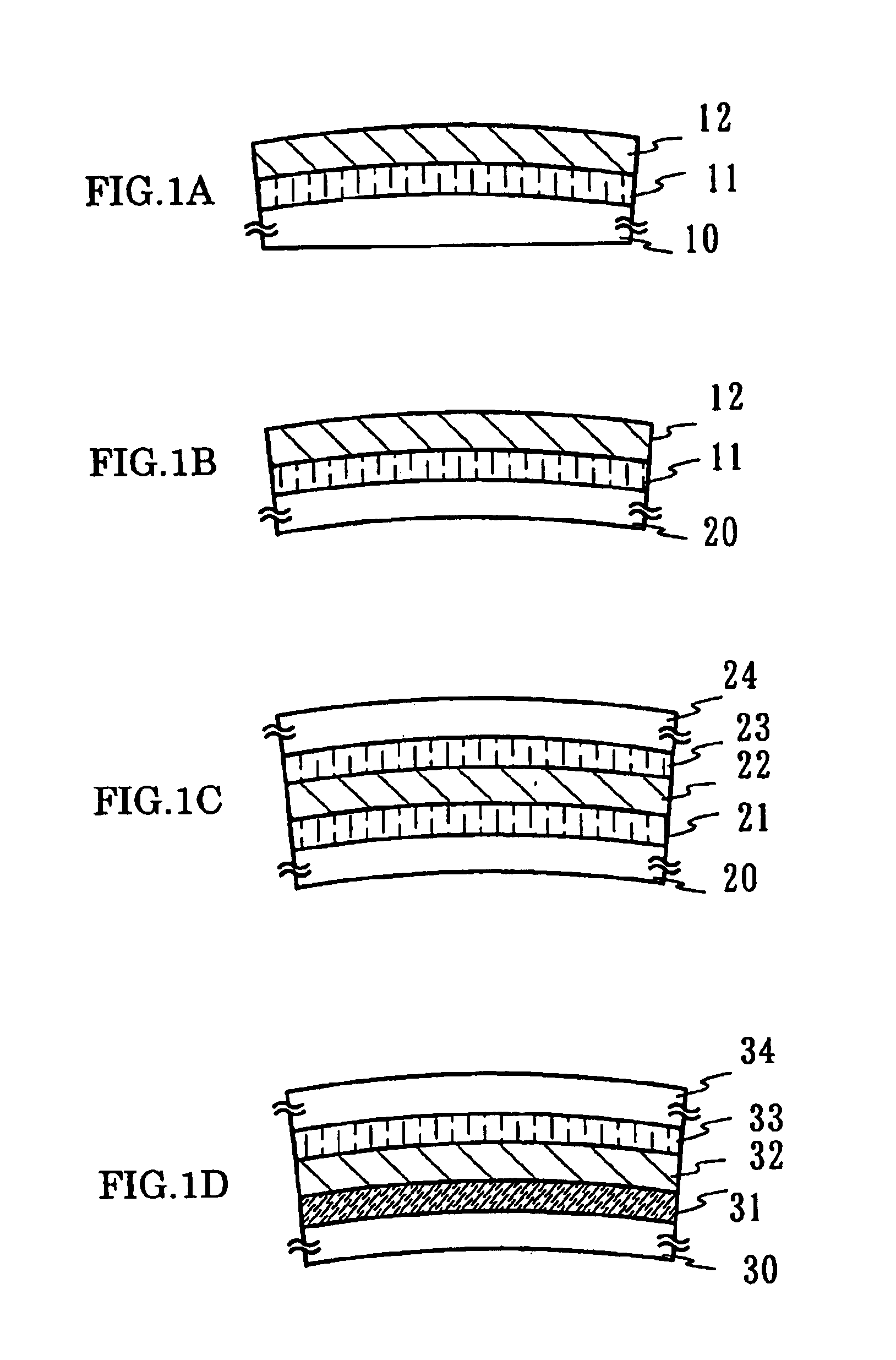

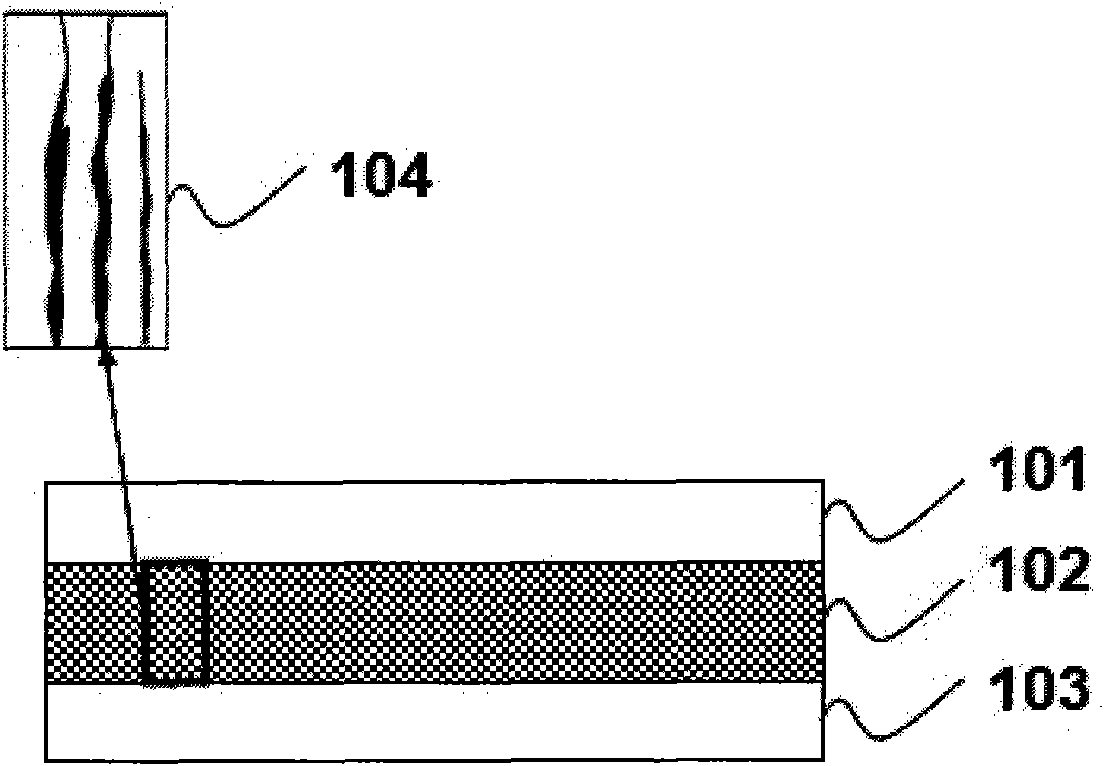

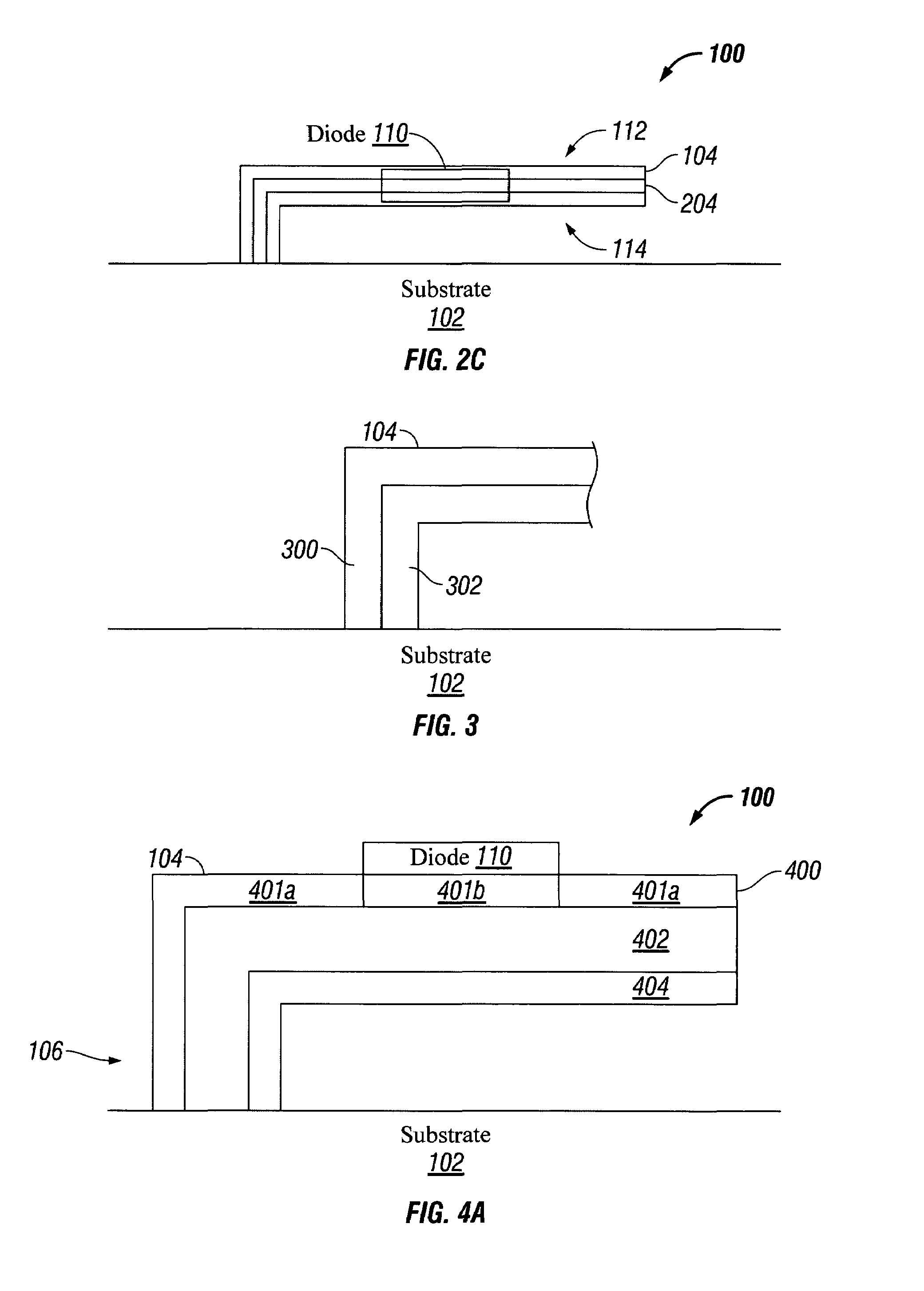

Disclosed is a semiconductor device in which a thin film transistor and a thin film diode are provided on one same substrate, and the characteristics respectively required for the thin film transistor and the thin film diode are achieved. Specifically disclosed is a semiconductor device that includes an insulating layer (104) formed on the surface of a substrate (101), and a thin film transistor and a thin film diode that are formed on the insulating layer (104). A portion of the surface of the insulating layer (104), which is positioned below a semiconductor layer (109) for the thin film diode, is provided with a first recessed and projected pattern (105). Meanwhile, a portion of the surface of the insulating layer (104), which is positioned below a semiconductor layer (108) for the thin film transistor, is not provided with the first recessed and projected pattern (105). The surface of the semiconductor layer (109) for the thin film diode has a second recessed and projected pattern that reflects the shape of the first recessed and projected pattern (105).

Owner:SHARP KK

Piezo-diode cantilever MEMS

InactiveUS20070278600A1Increase mechanical strainLow costAcceleration measurement using interia forcesSemiconductor/solid-state device manufacturingMetal foilThin-film diode

A piezo thin-film diode (piezo-diode) cantilever microelectromechanical system (MEMS) and associated fabrication processes are provided. The method deposits thin-films overlying a substrate. The substrate can be made of glass, polymer, quartz, metal foil, Si, sapphire, ceramic, or compound semiconductor materials. Amorphous silicon (a-Si), polycrystalline Si (poly-Si), oxides, a-SiGe, poly-SiGe, metals, metal-containing compounds, nitrides, polymers, ceramic films, magnetic films, and compound semiconductor materials are some examples of thin-film materials. A cantilever beam is formed from the thin-films, and a diode is embedded with the cantilever beam. The diode is made from a thin-film shared in common with the cantilever beam. The shared thin-film may a film overlying a cantilever beam top surface, a thin-film overlying a cantilever beam bottom surface, or a thin-film embedded within the cantilever beam.

Owner:SHARP KK

Piezo-diode cantilever MEMS

InactiveUS7763947B2Low costReducing MEMSAcceleration measurement using interia forcesPiezoelectric/electrostrictive/magnetostrictive devicesMetal foilThin-film diode

A piezo thin-film diode (piezo-diode) cantilever microelectromechanical system (MEMS) and associated fabrication processes are provided. The method deposits thin-films overlying a substrate. The substrate can be made of glass, polymer, quartz, metal foil, Si, sapphire, ceramic, or compound semiconductor materials. Amorphous silicon (a-Si), polycrystalline Si (poly-Si), oxides, a-SiGe, poly-SiGe, metals, metal-containing compounds, nitrides, polymers, ceramic films, magnetic films, and compound semiconductor materials are some examples of thin-film materials. A cantilever beam is formed from the thin-films, and a diode is embedded with the cantilever beam. The diode is made from a thin-film shared in common with the cantilever beam. The shared thin-film may a film overlying a cantilever beam top surface, a thin-film overlying a cantilever beam bottom surface, or a thin-film embedded within the cantilever beam.

Owner:SHARP KK

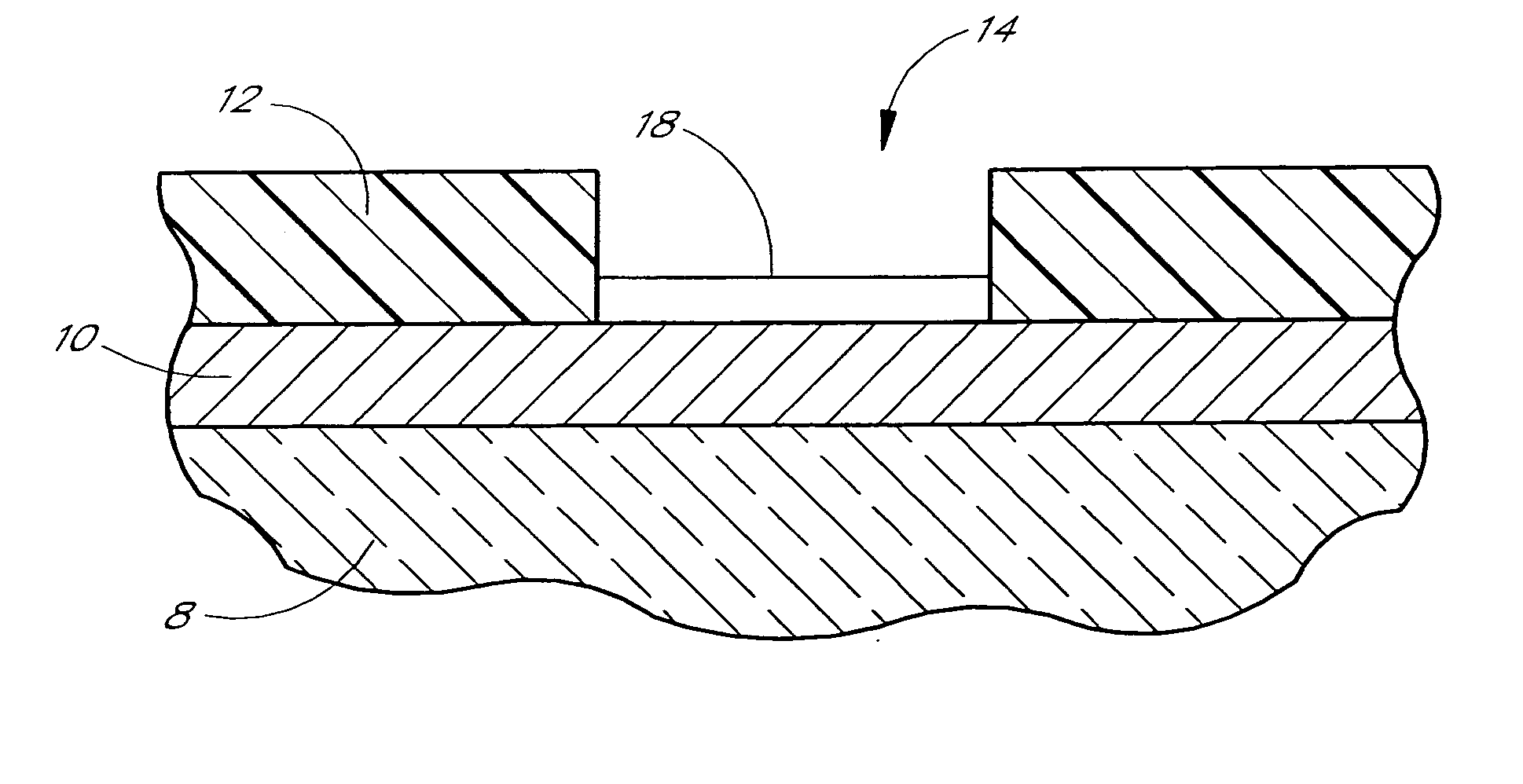

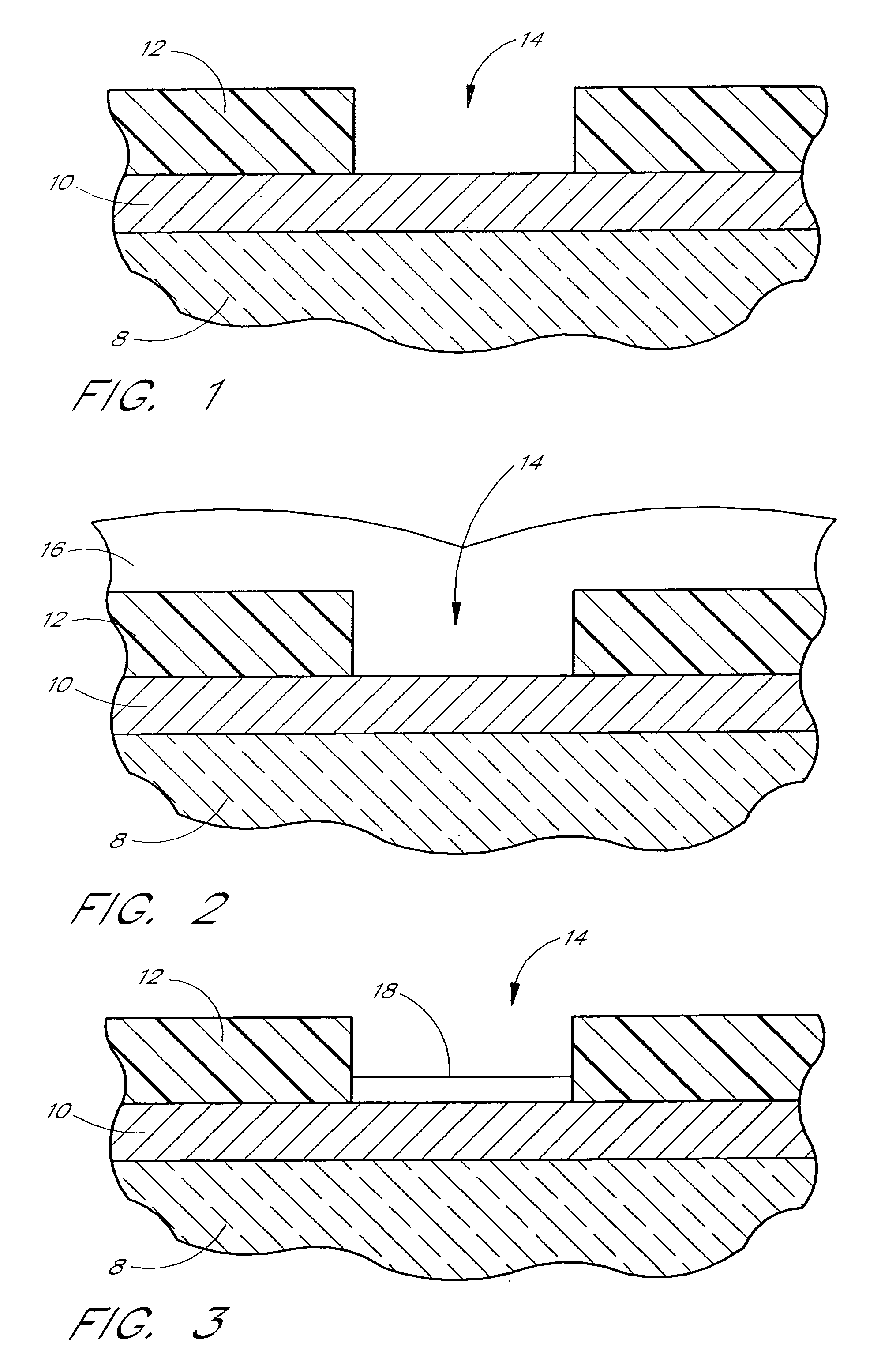

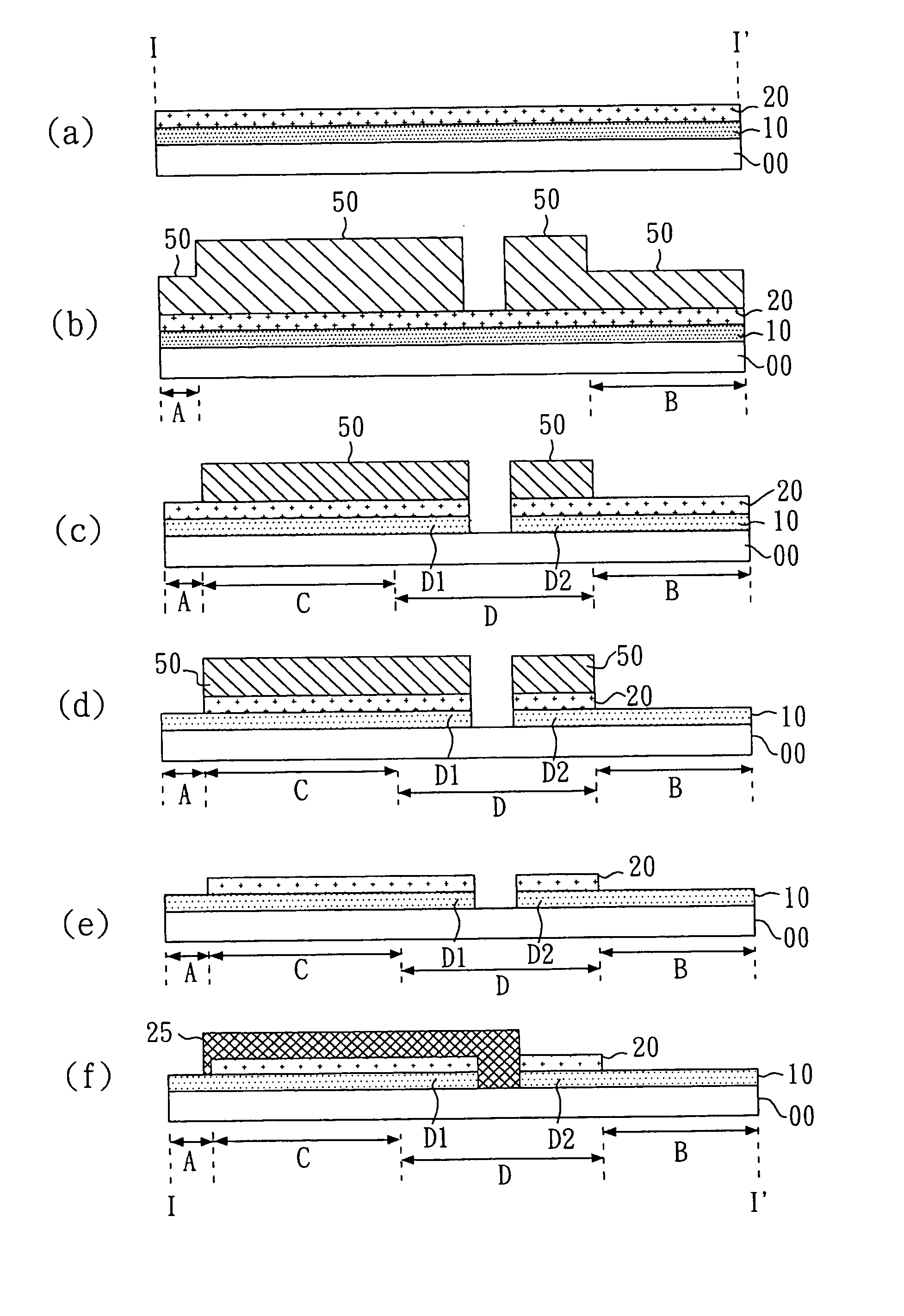

Semiconductor device and method for manufacturing the same

InactiveUS20120241825A1Efficiently incidentImprove sensor sensitivitySolid-state devicesSemiconductor/solid-state device manufacturingPower semiconductor deviceElectrical conductor

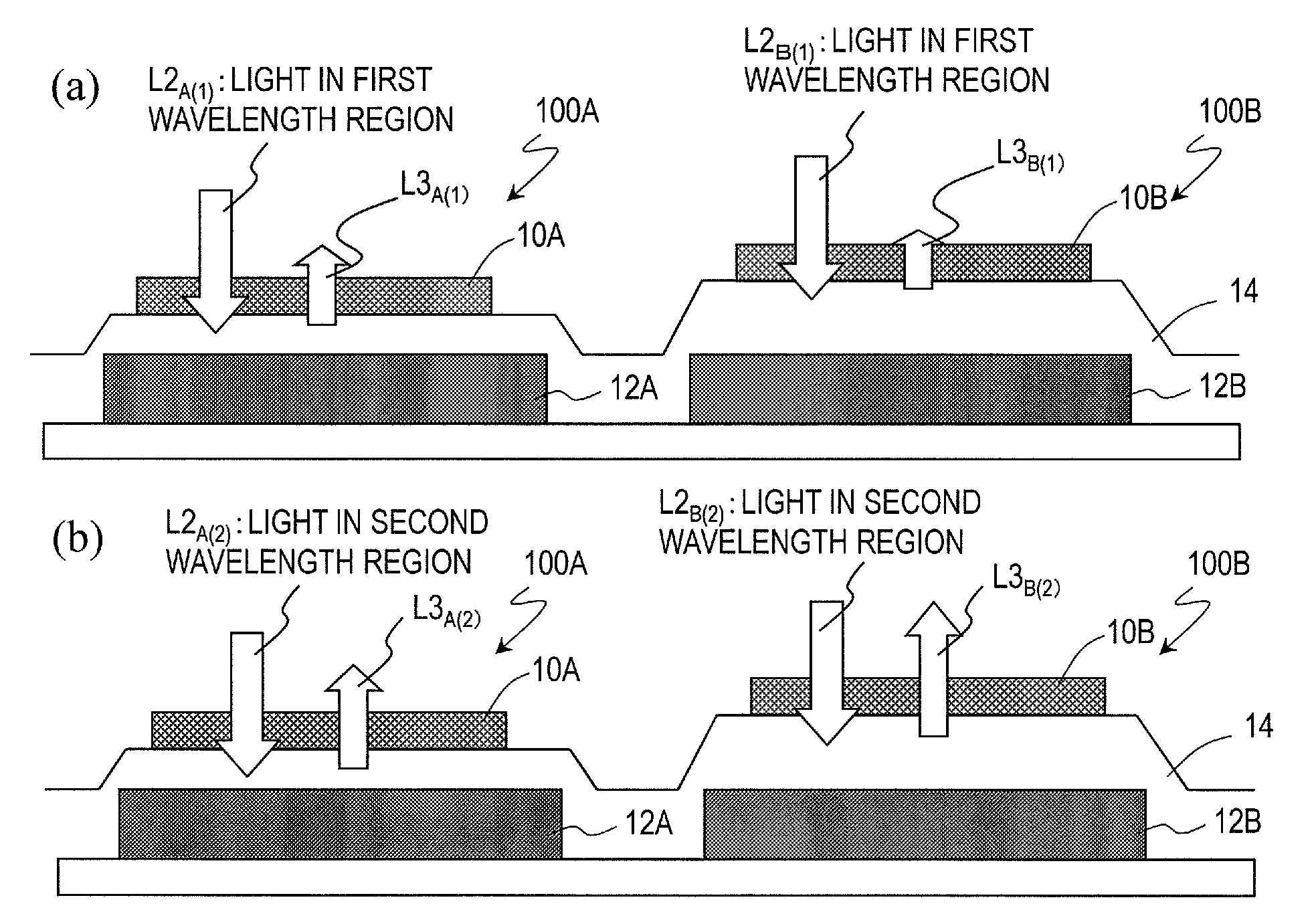

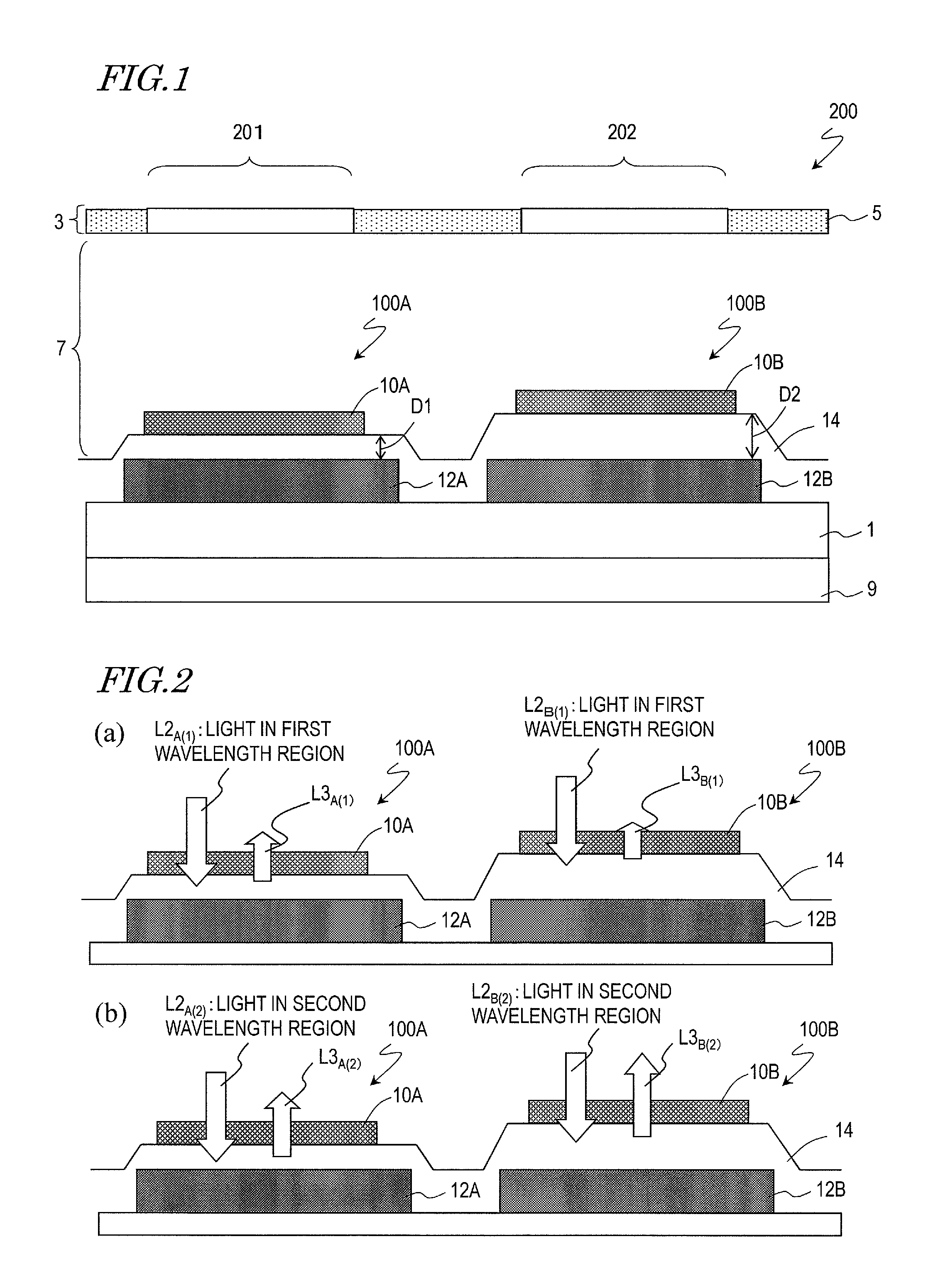

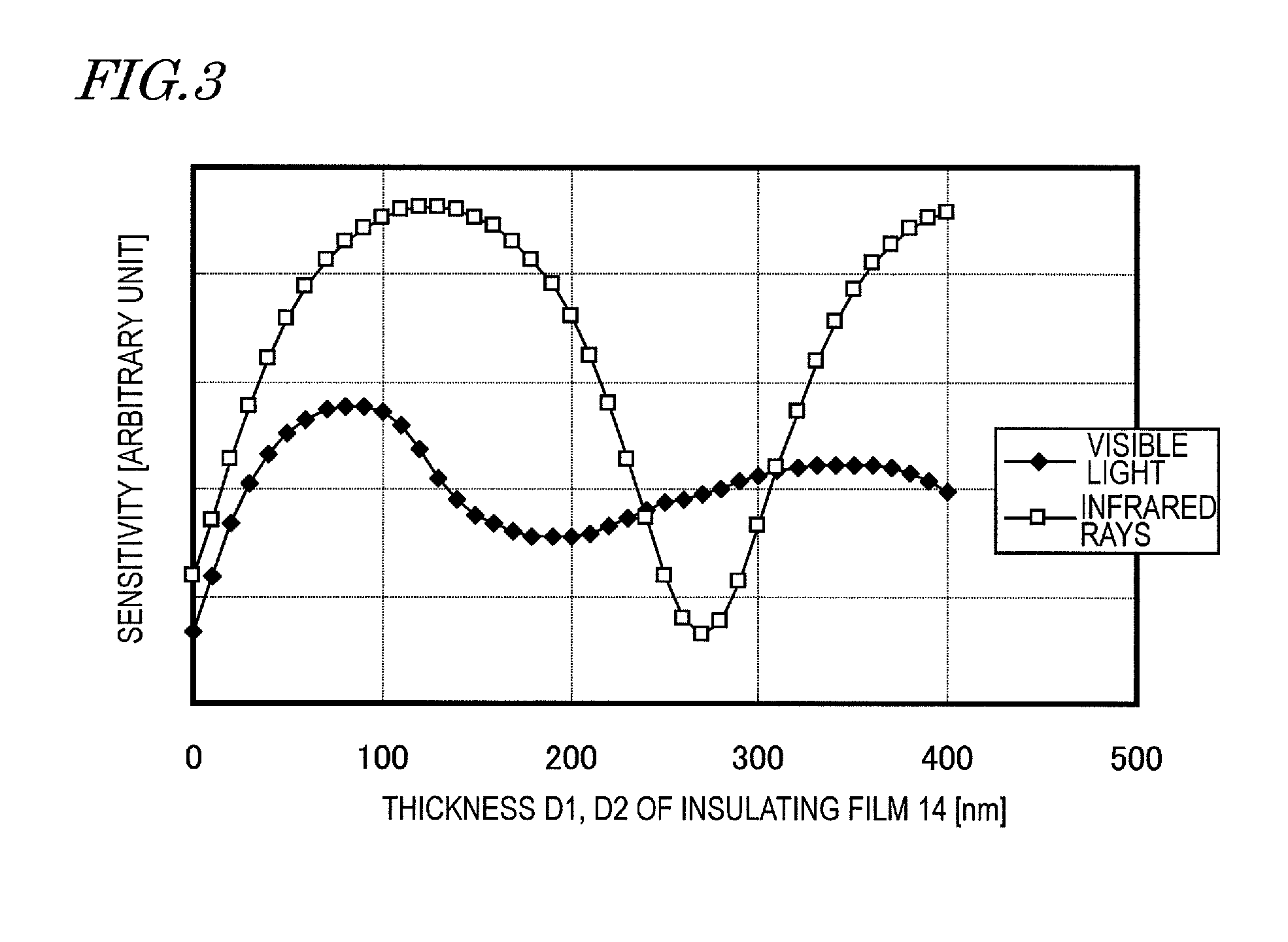

A first thin film diode (100A) has a first semiconductor layer (10A) and a first light blocking layer (12A) disposed on the substrate side of the first semiconductor layer. A second thin film diode (100B) has a second semiconductor layer (10B) and a second light blocking layer (12B) disposed on the substrate side of the second semiconductor layer. An insulating film (14) is formed between the first semiconductor layer (10A) and the first light blocking layer (12A) and between the second semiconductor layer (10B) and the second light blocking layer (12B). A thickness D1 of a portion of the insulating film (14) positioned between the first semiconductor layer (10A) and the first light blocking layer (12A) is different from a thickness D2 of a portion of the insulating film (14) positioned between the second semiconductor layer (10B) and the second light blocking layer (12B). The intensity of light in a first wavelength region incident on the first semiconductor layer (10A) is higher than the intensity of light in the first wavelength region incident on the second semiconductor layer (10B). The intensity of light in a second wavelength region including a wavelength longer than the maximum wavelength of the first wavelength region incident on the second semiconductor layer (10B) is higher than the intensity of light in the second wavelength region incident on the first semiconductor layer (10A).

Owner:SHARP KK

Method for manufacturing bottom substrate of liquid crystal display device

ActiveUS20070020822A1Increase productionSemiconductor/solid-state device manufacturingNon-linear opticsManufacturing cost reductionLithographic artist

A method for manufacturing liquid crystal display substrates comprises the steps of: (a) providing a substrate having a transparent electrode layer and a metal layer; (b) forming a patterned photoresist layer through half-tone or diffraction; (c) defining signal line area and thin film diode area, or pixel area and conductive electrode-lines by etching; and (d) forming an oxidized layer on partial surface of the metal layer. The disclosure here provides a patterning process of lithography and etching with one photolithography of one single mask in the manufacturing of liquid crystal display substrates. Furthermore, the method disclosed here can effectively increase the yield of manufacturing, and reduce the cost of manufacturing.

Owner:AU OPTRONICS CORP

Semiconductor apparatus and fabrication method of the same

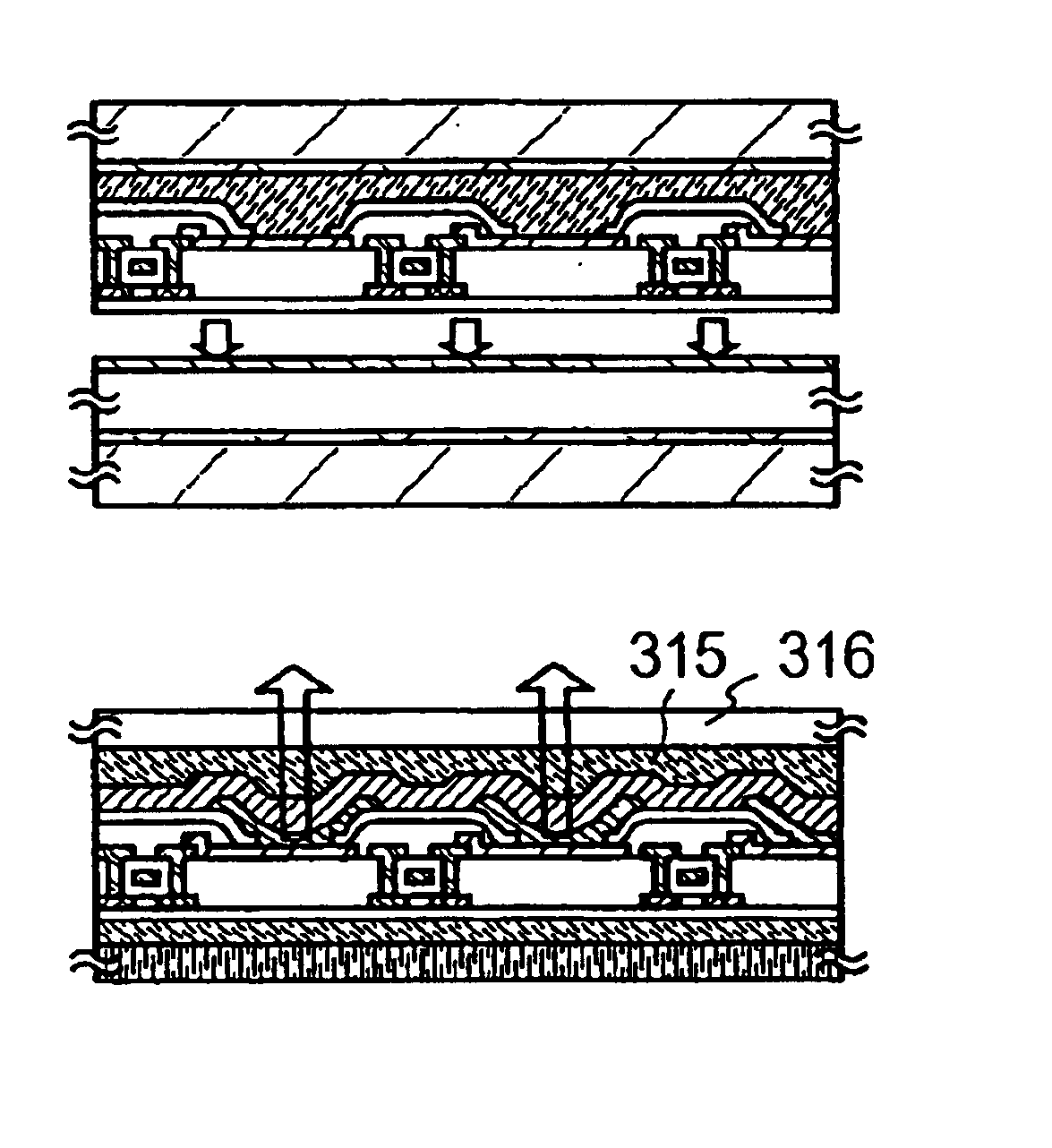

ActiveUS20060186399A1Inhibit deteriorationImprove thermal conductivityTransistorFinal product manufactureDevice formThin-film diode

It is an object of the present invention to provide a semiconductor device capable of preventing deterioration due to penetration of moisture or oxygen, for example, a light-emitting apparatus having an organic light-emitting device that is formed over a plastic substrate, and a liquid crystal display apparatus using a plastic substrate. According to the present invention, devices formed on a glass substrate or a quartz substrate (a TFT, a light-emitting device having an organic compound, a liquid crystal device, a memory device, a thin-film diode, a pin-junction silicon photoelectric converter, a silicon resistance element, or the like) are separated from the substrate, and transferred to a plastic substrate having high thermal conductivity.

Owner:SEMICON ENERGY LAB CO LTD

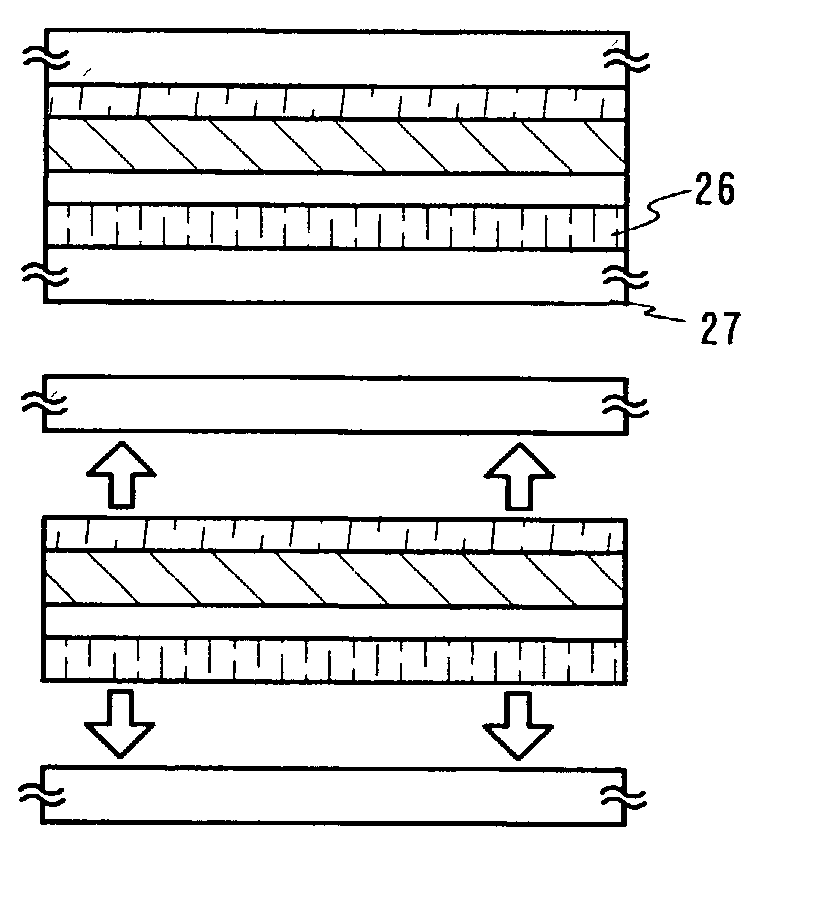

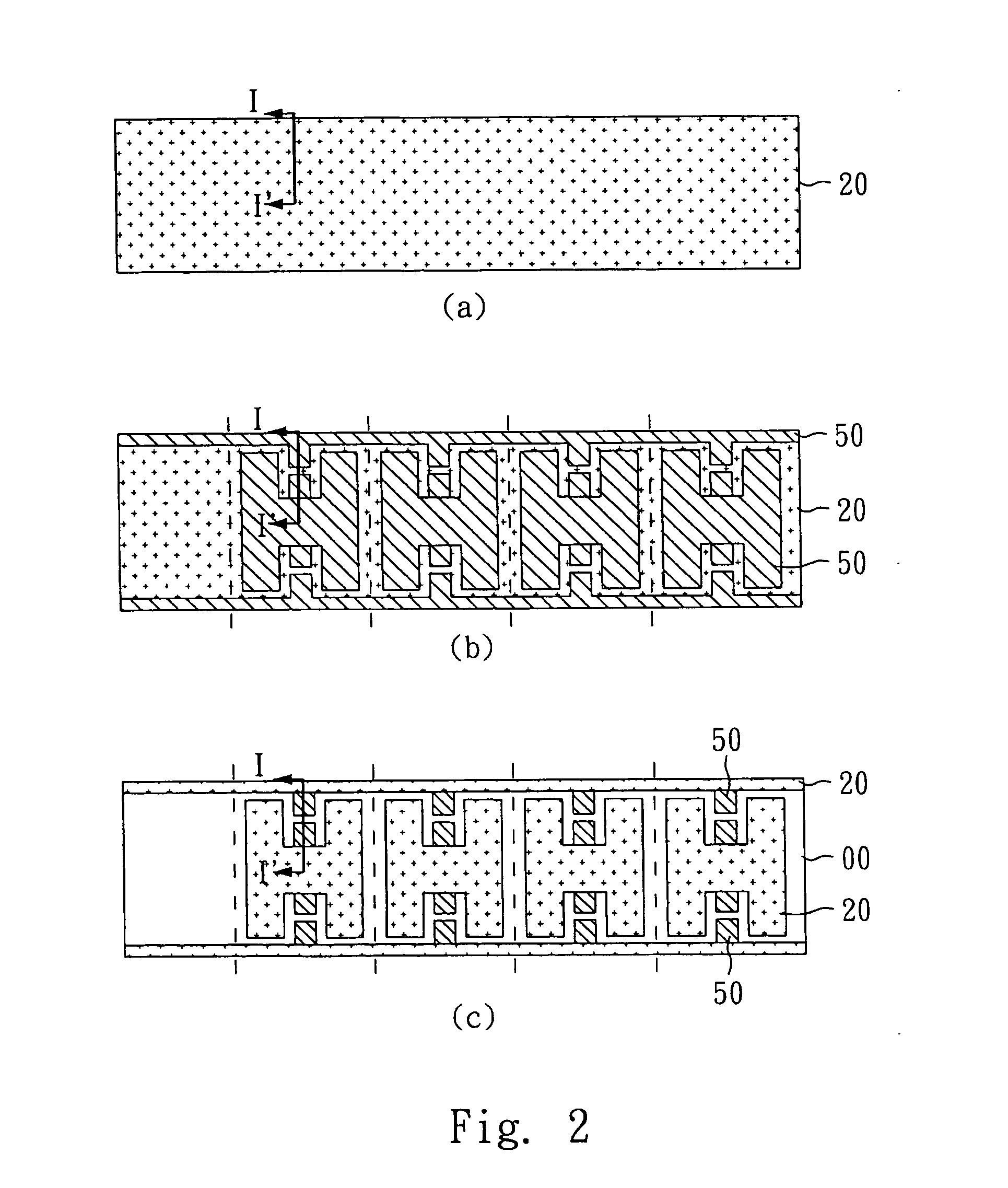

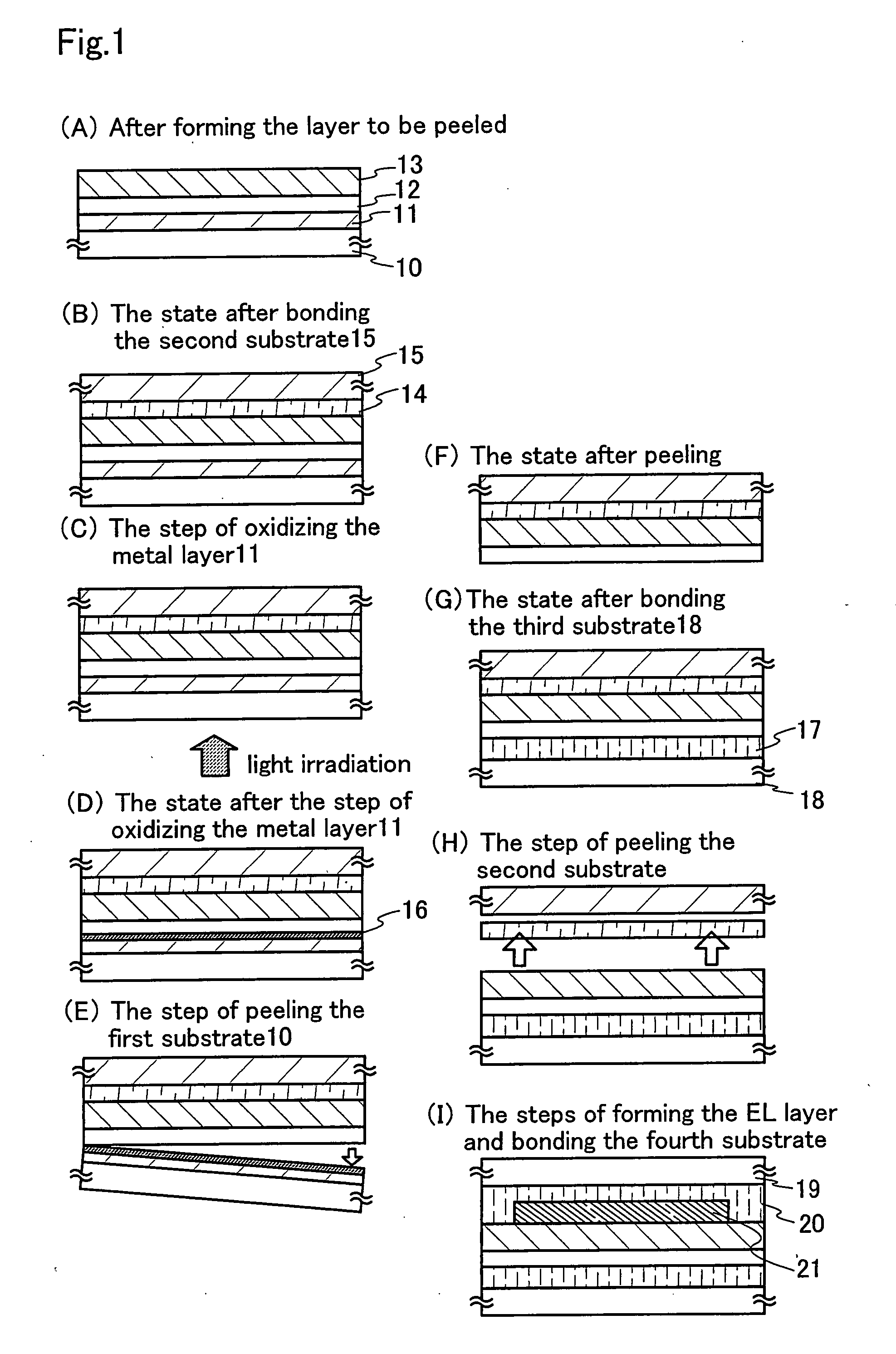

Semiconductor device and manufacturing method thereof

InactiveUS20070158745A1Easy to peelHigh yieldTransistorSemiconductor/solid-state device detailsThin-film diodePhotoelectric conversion

(Object) It is an object of the present invention to provide a peeling method that causes no damage to a layer to be peeled and to allow not only a layer to be peeled with a small surface area but also a layer to be peeled with a large surface area to be peeled entirely. Further, it is also an object of the present invention to bond a layer to be peeled to various base materials to provide a lighter semiconductor device and a manufacturing method thereof. Particularly, it is an object to bond various elements typified by a TFT, (a thin film diode, a photoelectric conversion element comprising a PIN junction of silicon, or a silicon resistance element) to a flexible film to provide a lighter semiconductor device and a manufacturing method thereof. (Solving Means) When a metal layer 11 is provided over a substrate, an oxide layer 12 is provided in contact with the metal layer 11, a layer to be peeled 13 is formed, and the metal layer 11 is irradiated with a laser beam to perform oxidization and form a metal oxide layer 16, a clear separation is possible with a physical means within the metal oxide layer 12 or at an interface between the metal oxide layer 16 and the oxide layer 12.

Owner:SEMICON ENERGY LAB CO LTD

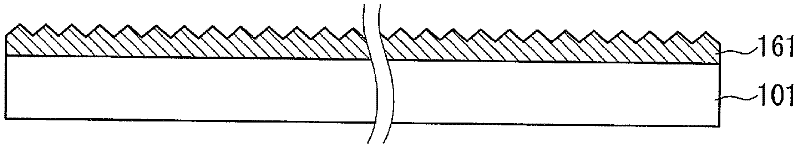

Photosensor, semiconductor device, and liquid crystal panel

InactiveUS20120154704A1Improve light utilization efficiencyConvenient lightingSolid-state devicesRadiation controlled devicesThin-film diodeSilicon

The light use efficiency of a thin film diode is improved even when the semiconductor layer of the diode has a small thickness, thereby improving the light detection sensitivity of the diode. A thin film diode (130) having a first semiconductor layer (131) including, at least, an n-type region (131n) and a p-type region (131p) is provided on one side of a substrate (101), and a silicon layer (171) is provided between the substrate and the first semiconductor layer, facing the first semiconductor layer. Asperities are formed on the side of the silicon layer facing the first semiconductor layer, and asperities are provided on the side of the first semiconductor layer facing the silicon layer and the side thereof opposite the side facing the silicon layer.

Owner:SHARP KK

High thermal conductive and high air-tightness packaging material of film and preparation method

InactiveCN1563243AHigh hardnessIncrease stiffnessOther chemical processesSynthetic resin layered productsComposite filmGas phase

A film material is prepared by using polymer as backing material and forming multilayer composite film for packaging film of diamoundloid film through vapour hase surface deposition. the thickness of diamoundloid film is 50-500 nm as its structure can be two layers structure or three layers structure or composite structure of the two but nine layers is the maximum. The vapour phase surface diposition can be chemical and physical vapour phase diposition.

Owner:FUDAN UNIV

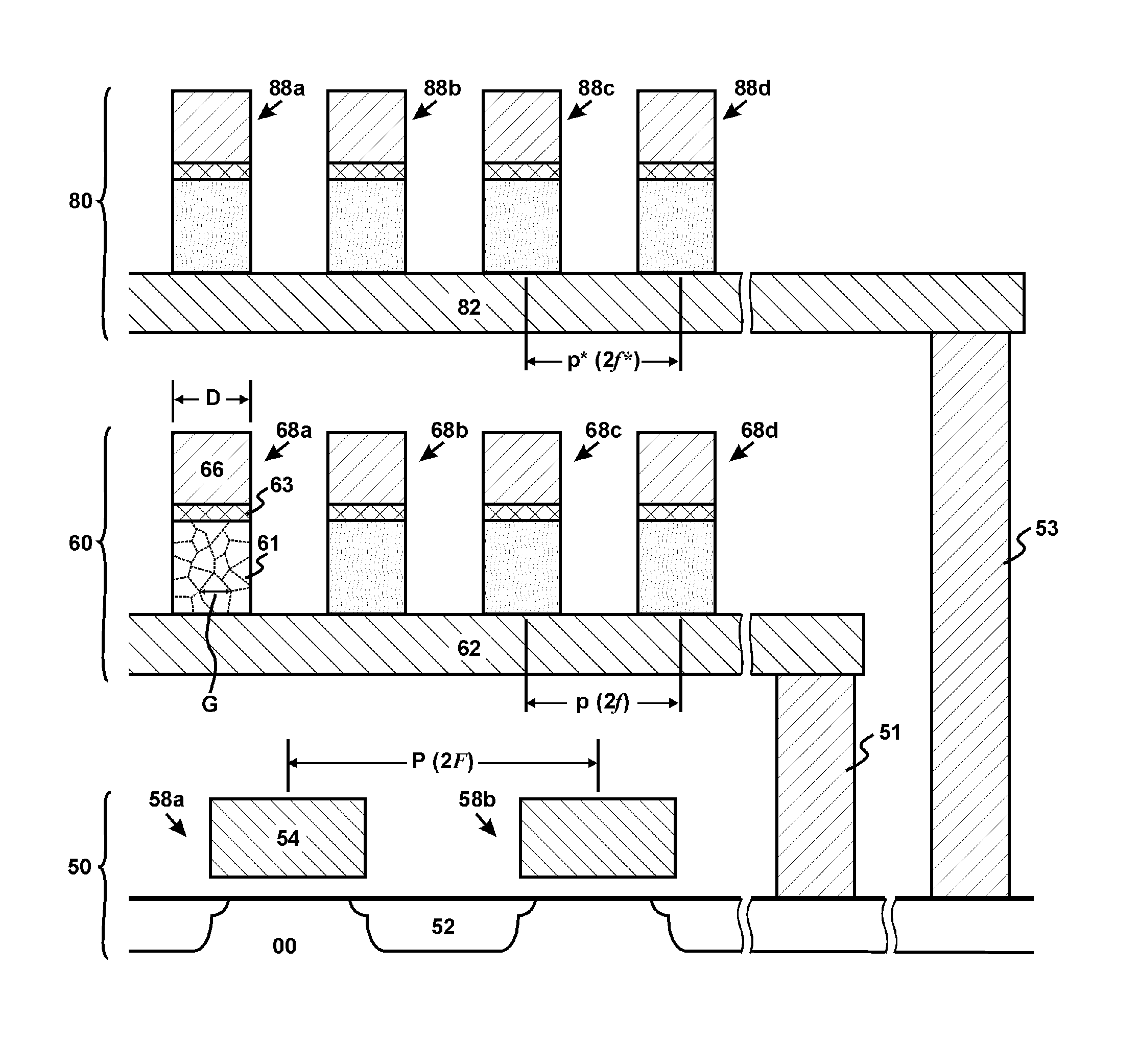

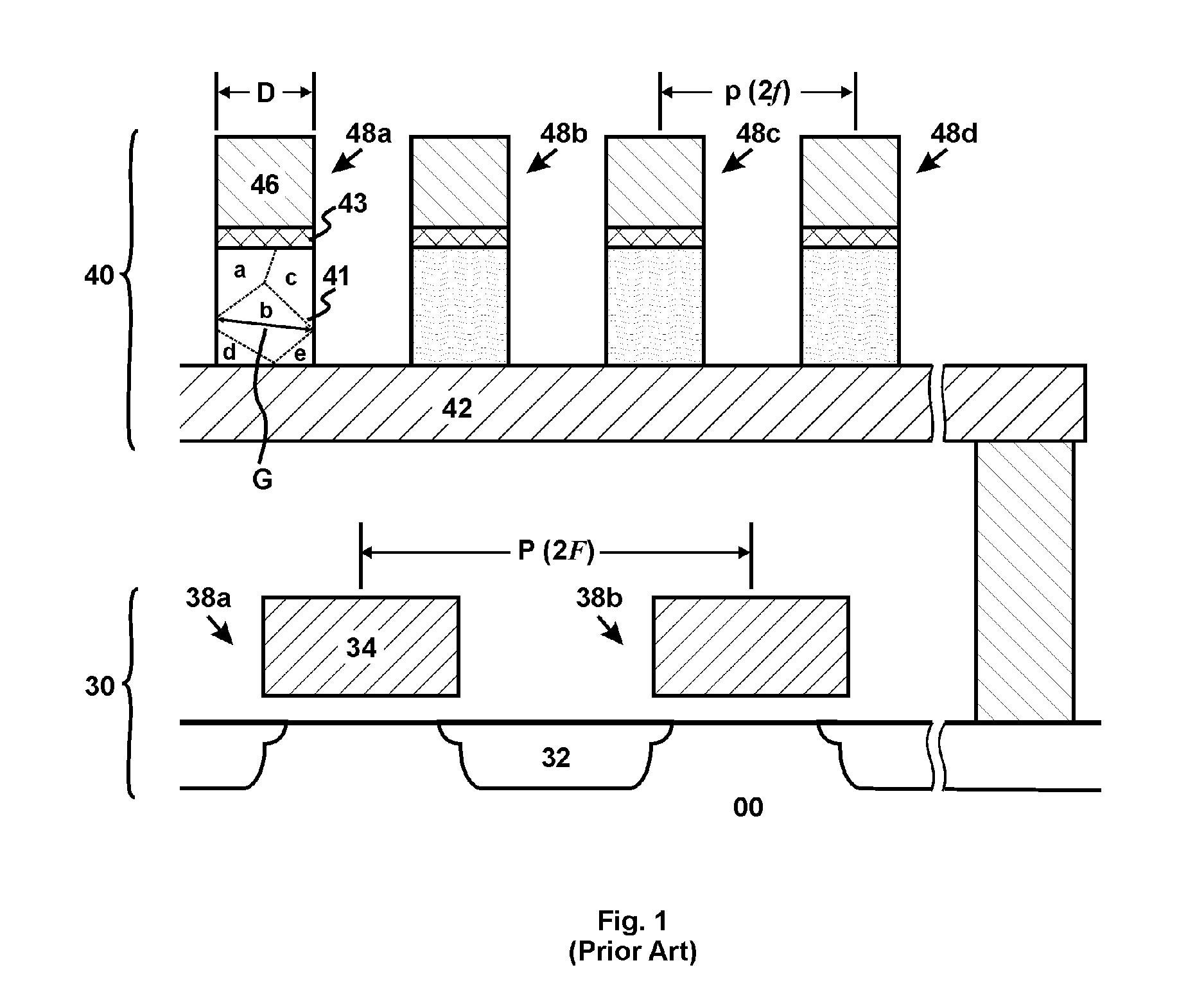

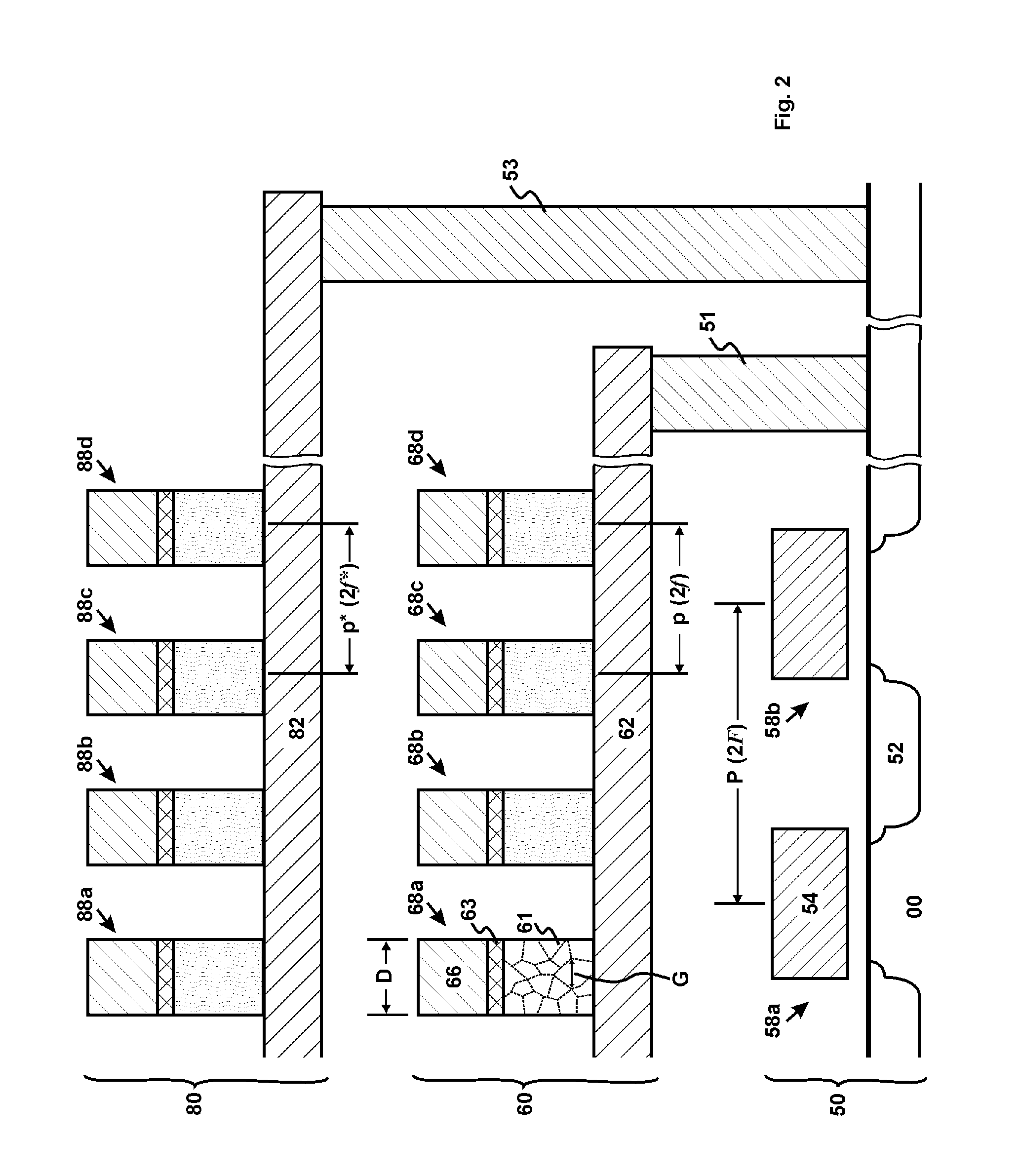

Small-Grain Three-Dimensional Memory

ActiveUS20130258740A1Improve performanceImprove storage densityRead-only memoriesDigital storageThin-film diodeSingle crystal

The present invention discloses a small-grain three-dimensional memory (3D-MSG). Each of its memory cells comprises a thin-film diode with critical dimension no larger than 40 nm. The thin-film diode comprises at least a small-grain material, whose grain size G is substantially smaller than the diode size D. The small-grain material is preferably a nano-crystalline material or an amorphous material. The critical dimension f of the small-grain diode is smaller than the critical dimension F of the single-crystalline transistor.

Owner:CHENGDU HAICUN IP TECH +1

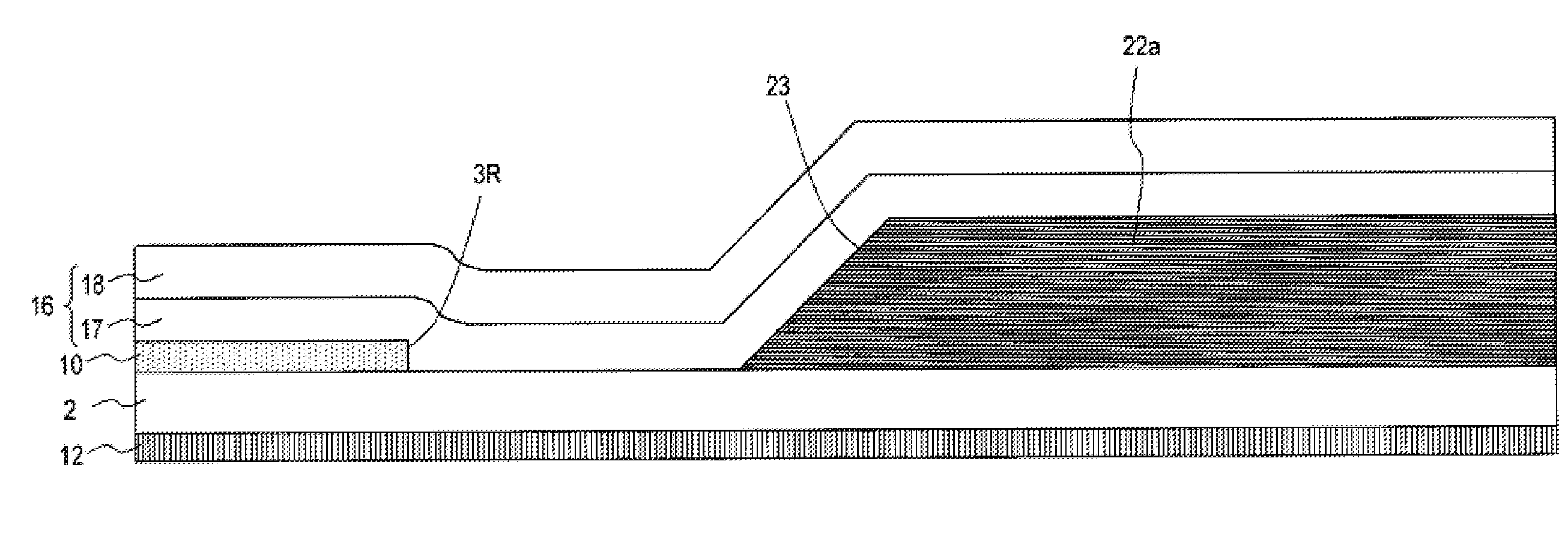

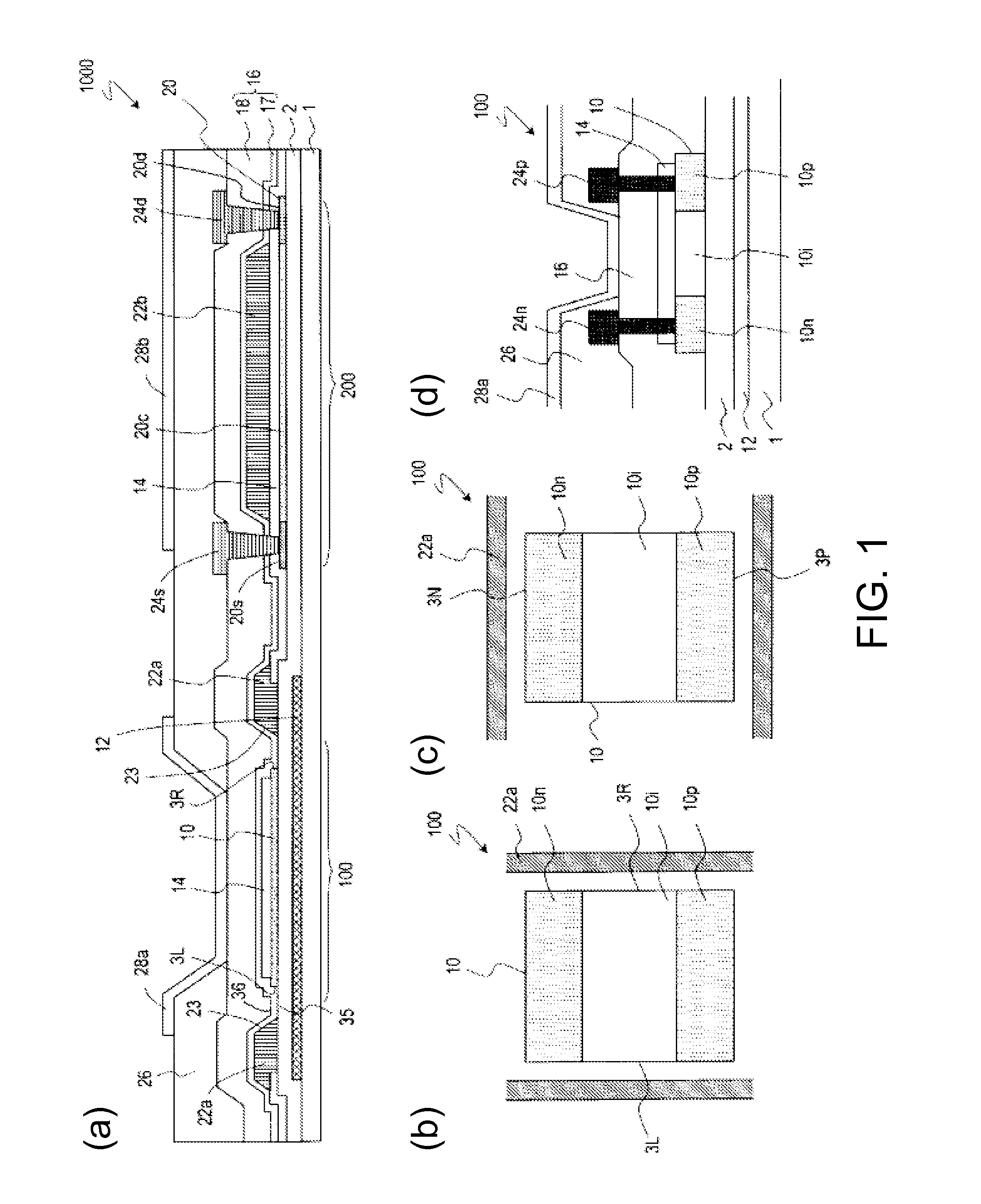

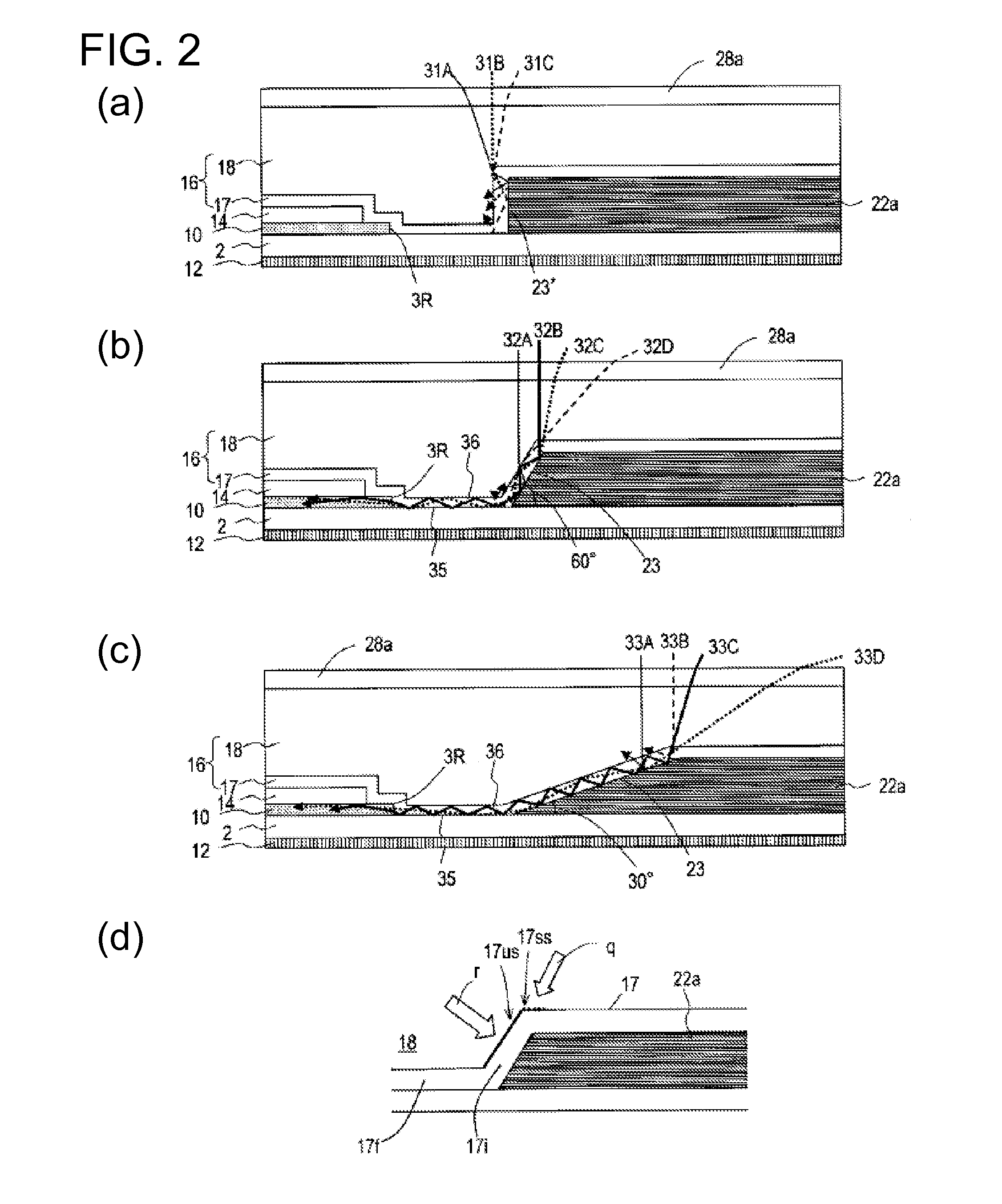

Semiconductor device and display device equipped with same

InactiveUS20130082267A1Increase light intensityIncrease the amount of lightTransistorSolid-state devicesElectrical conductorDisplay device

Disclosed is a semiconductor device 1000 including a substrate 1, a thin film diode 100 that is supported by the substrate 1 and has a first semiconductor layer 10 having a light-receiving region 10i, a thin film transistor 200 that is supported by the substrate 1 and has a second semiconductor layer 20, and a metal layer 22a that has an inclined surface 23 that is inclined to the surface of the substrate 1, in which the thin film diode 100 can detect light that enters the light-receiving region 10i and has a prescribed wavelength, in which both the first semiconductor layer 10 and the second semiconductor layer 20 are composed of the same semiconductor film, and in which the inclined surface 23 of the metal layer 22a faces at least a part of the side faces 3R and 3L of the first semiconductor layer 10. This constitution enables an increase in the amount of light absorbed by the thin film diode and an improvement in the effective light reception sensitivity of an optical sensor part.

Owner:SHARP KK

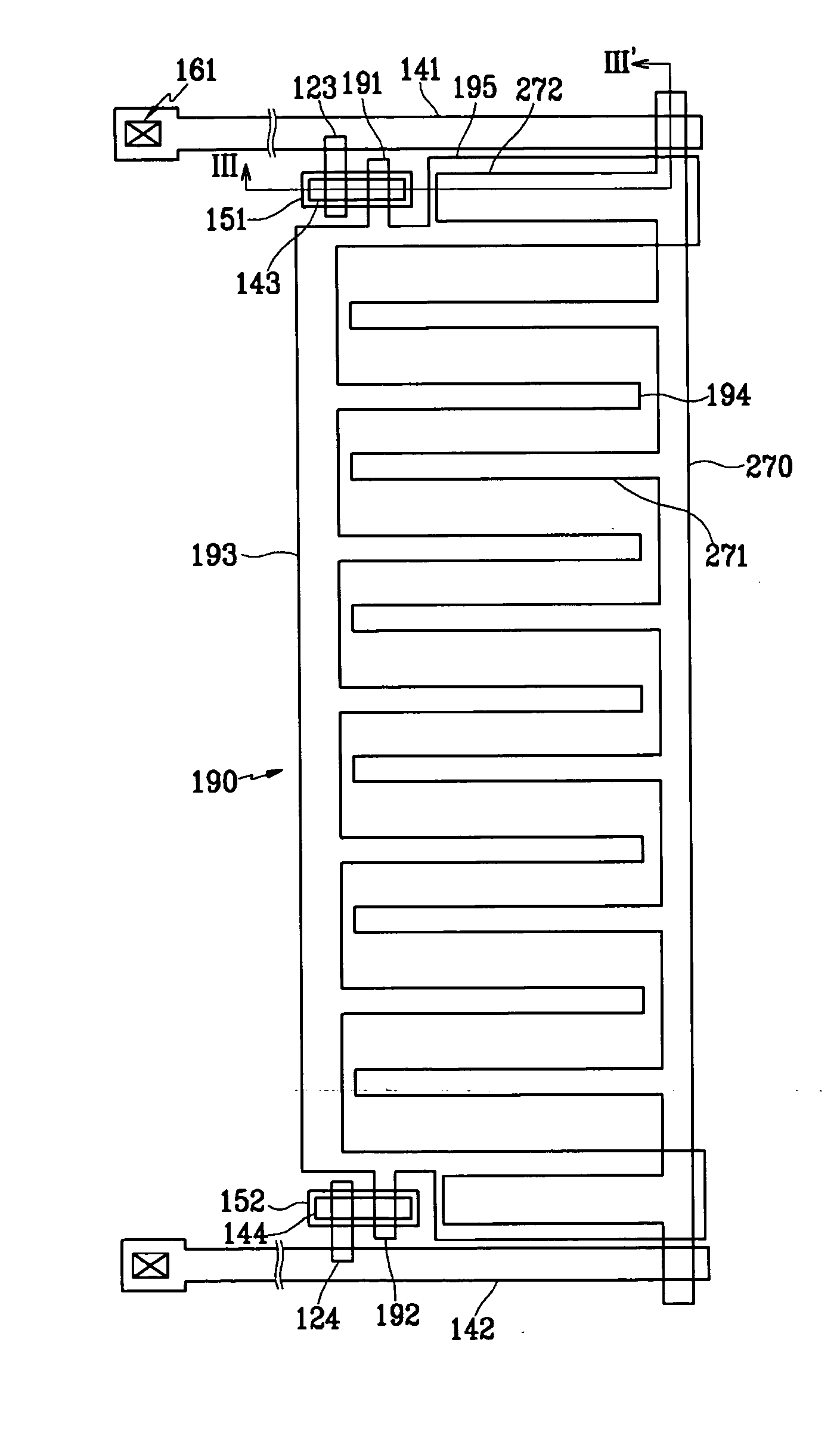

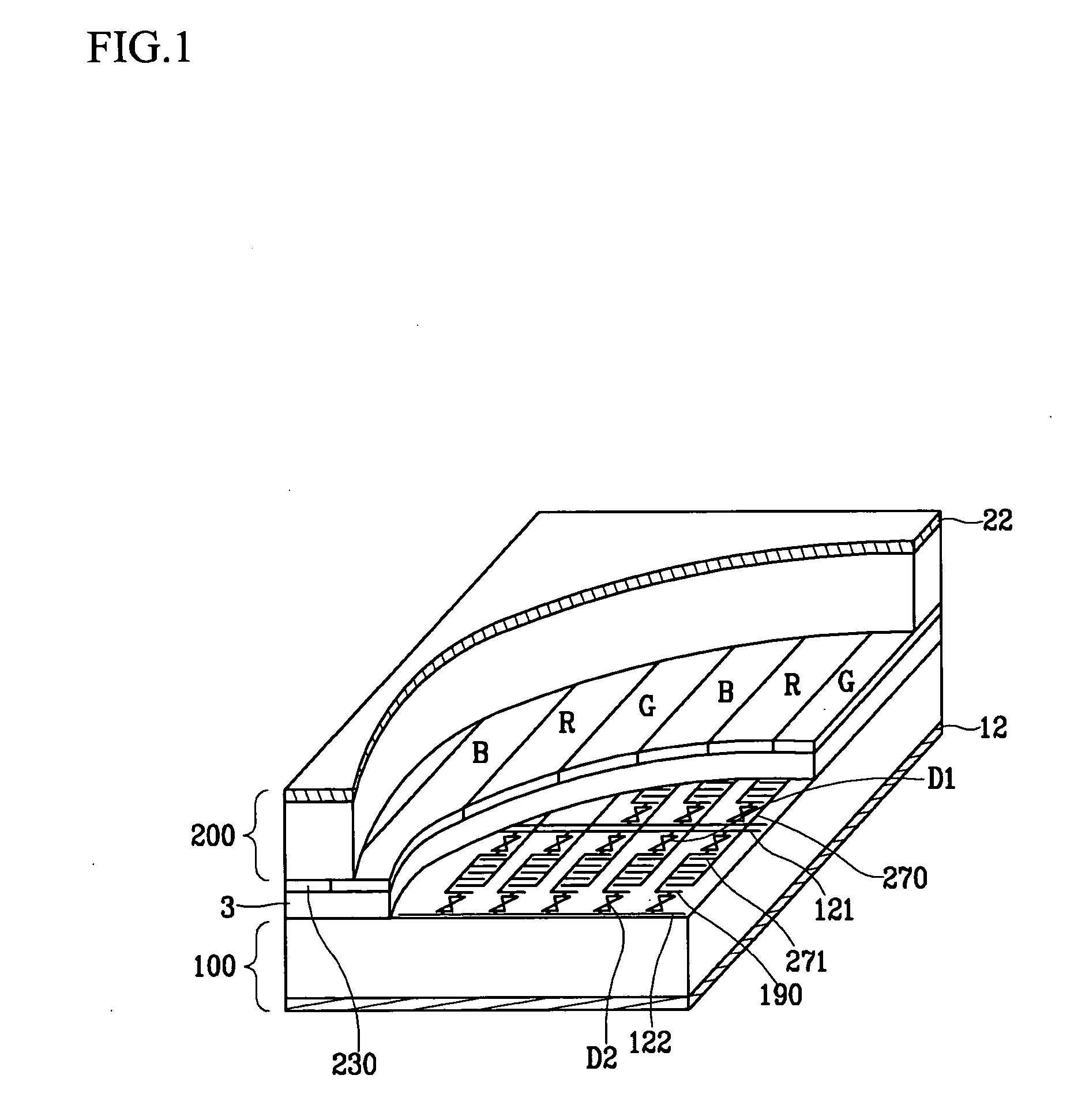

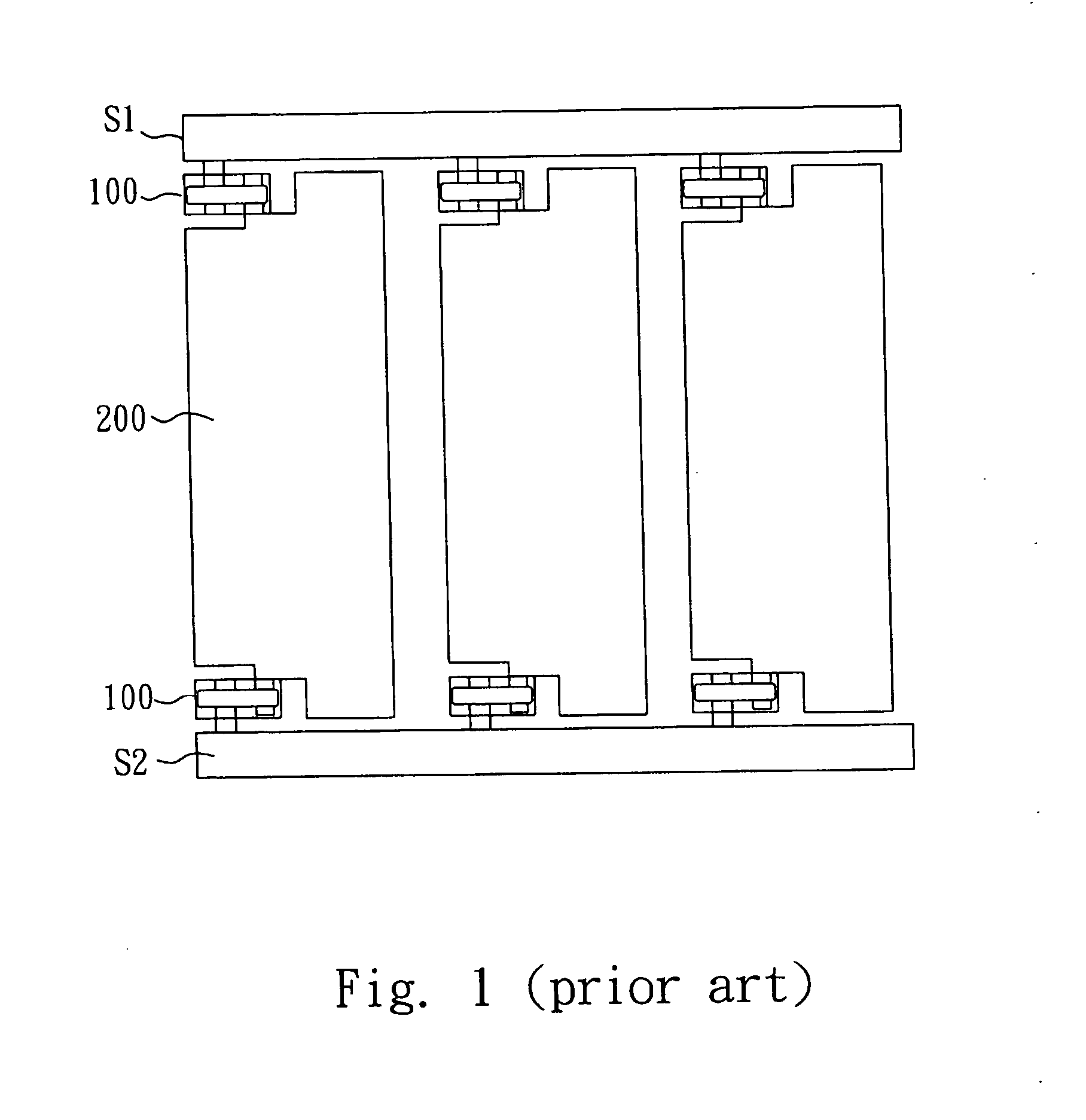

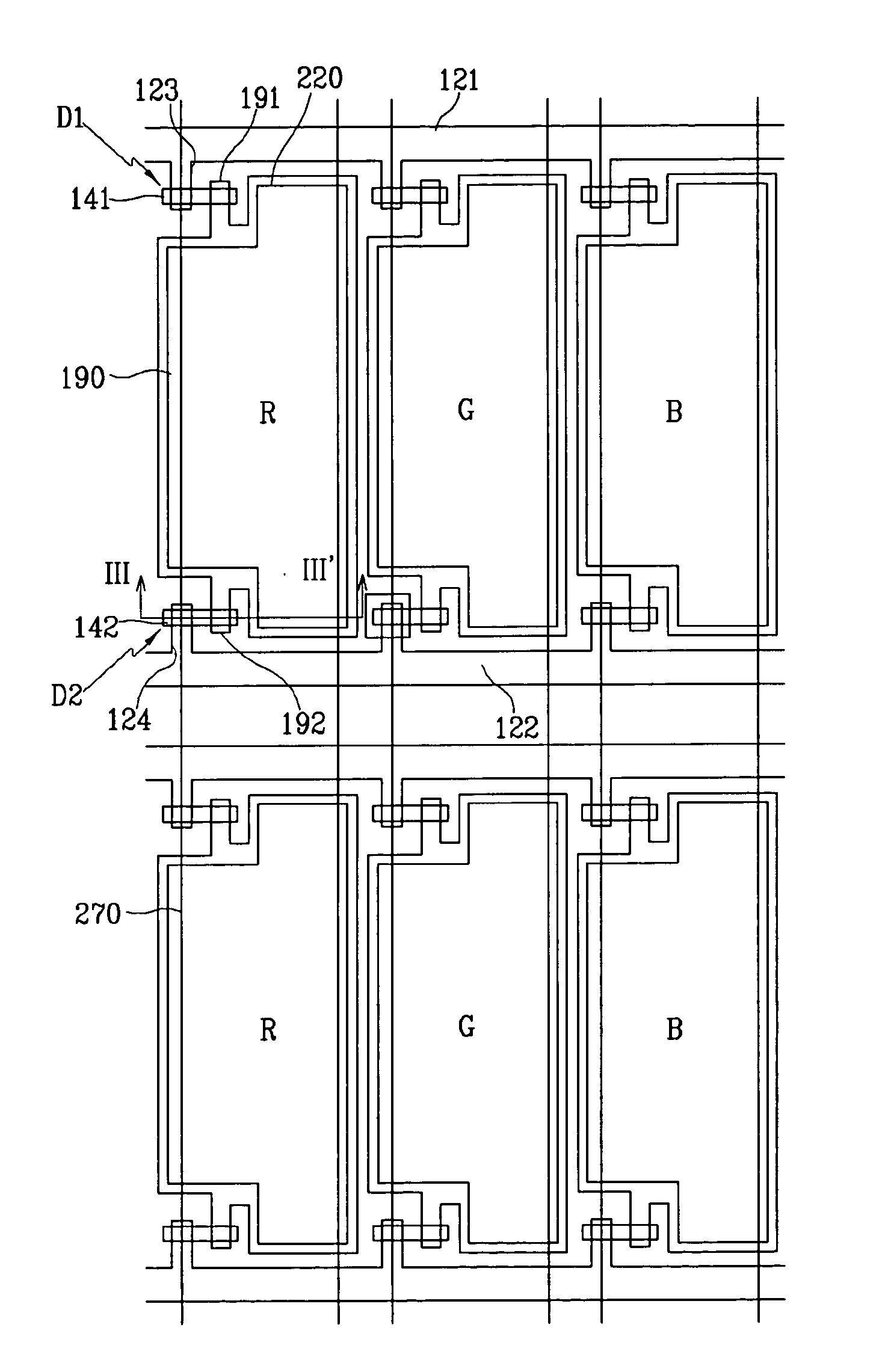

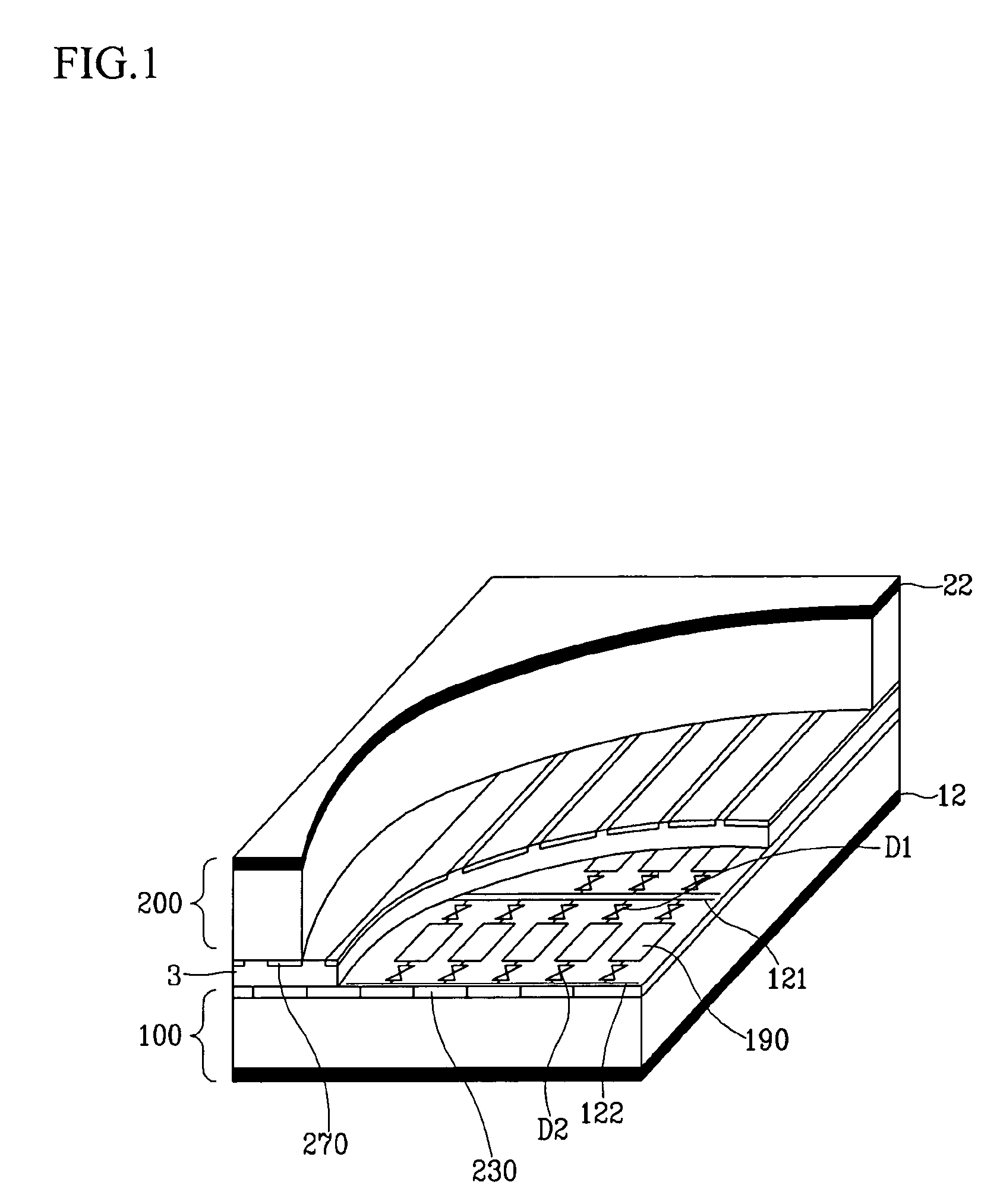

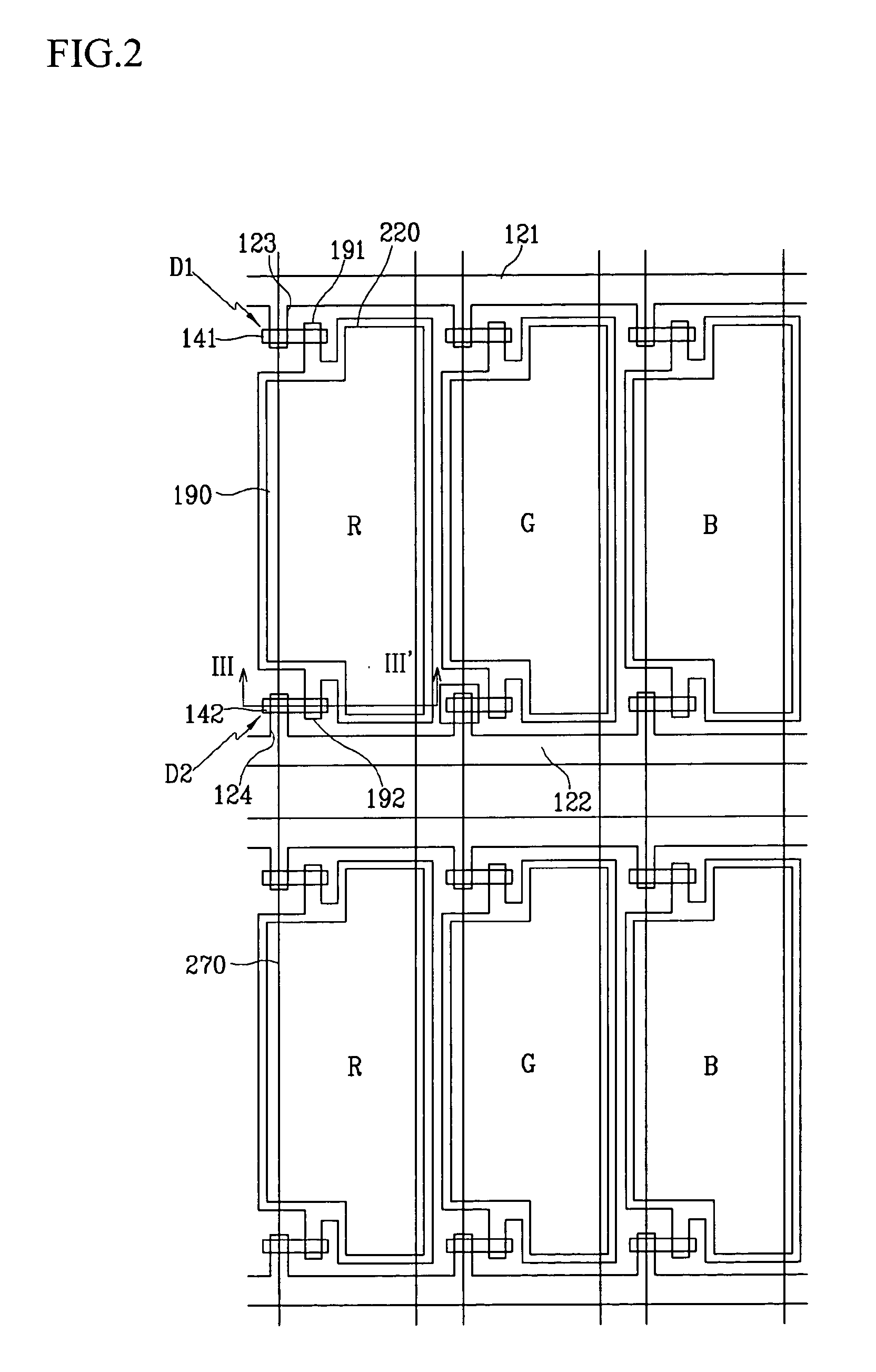

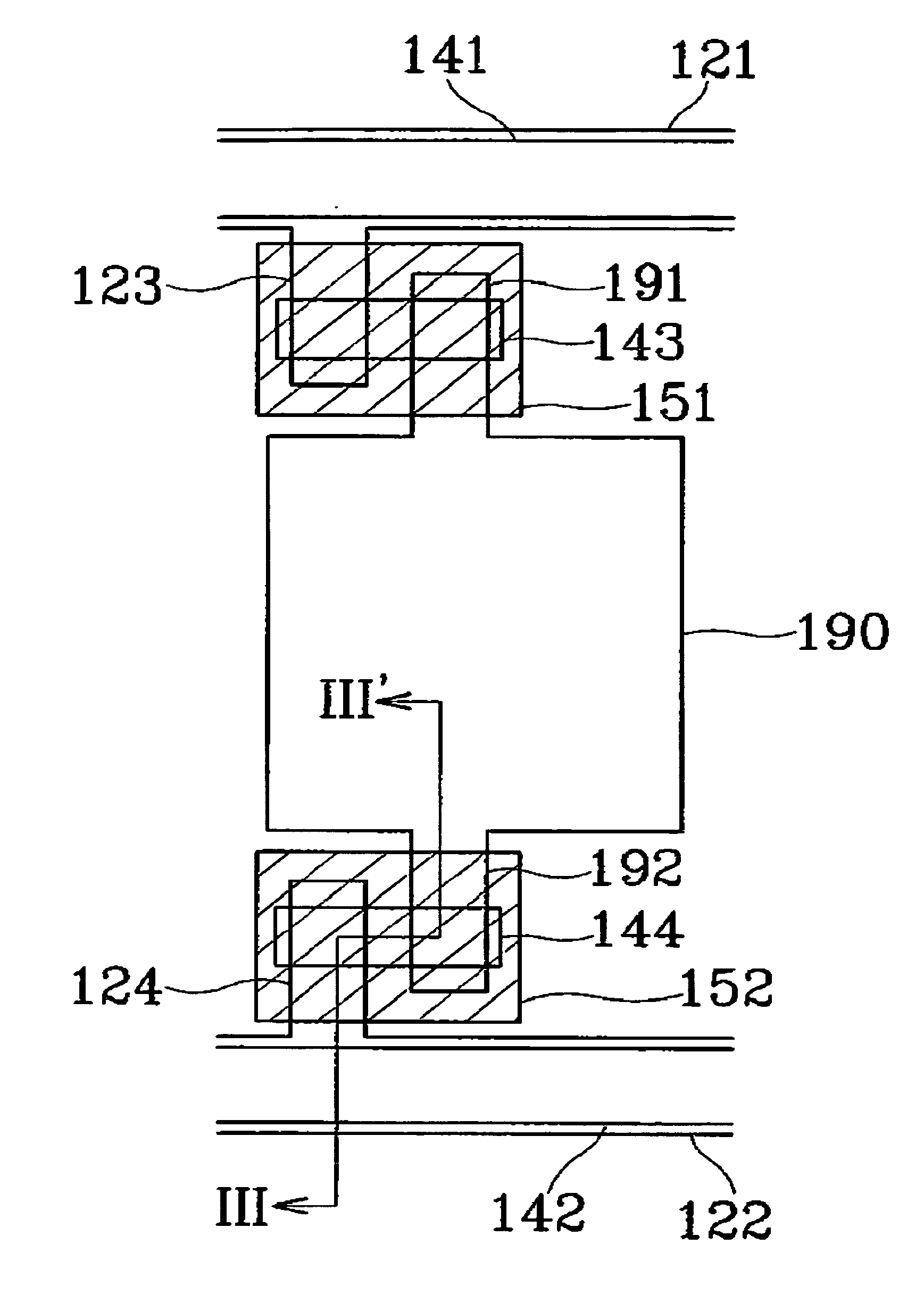

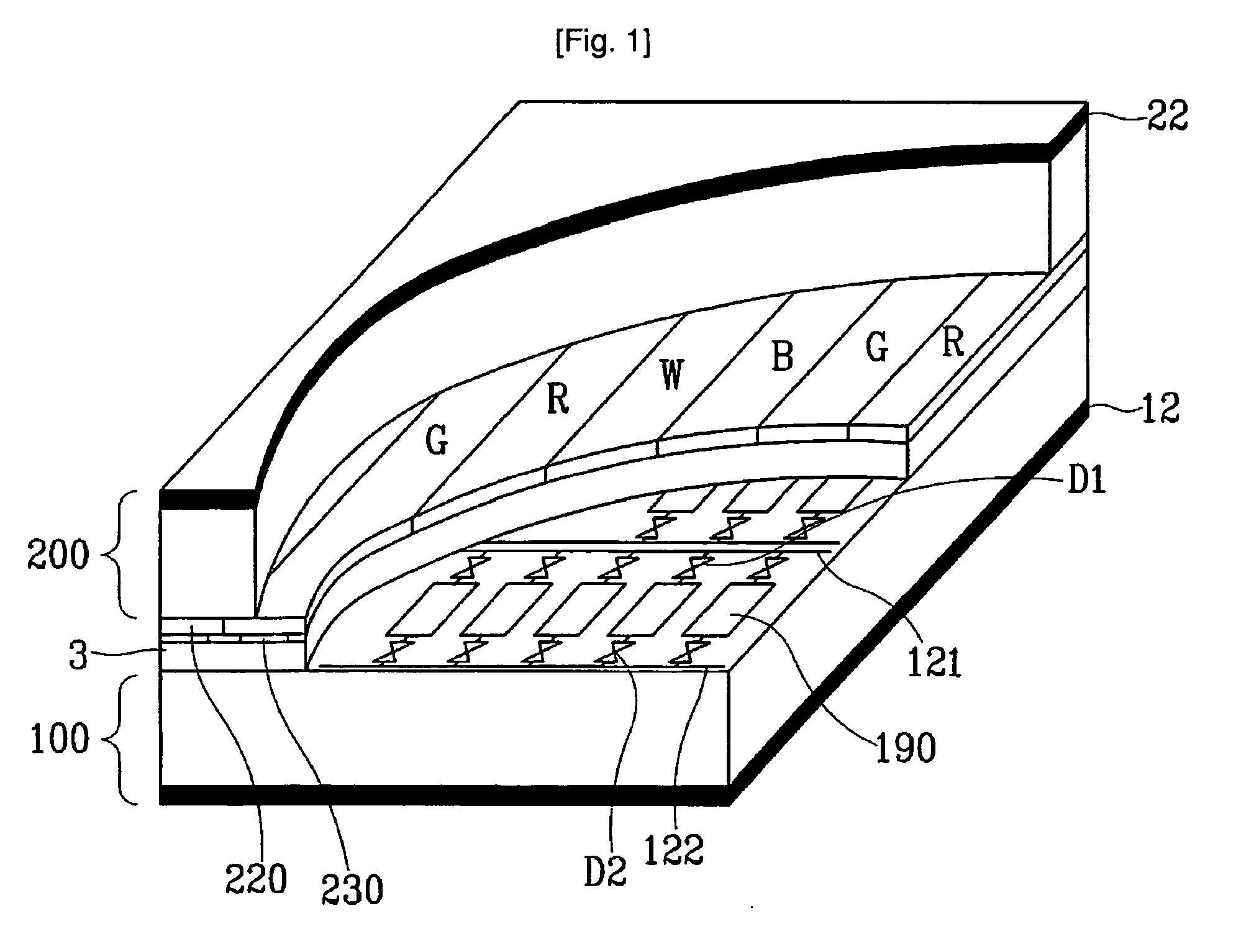

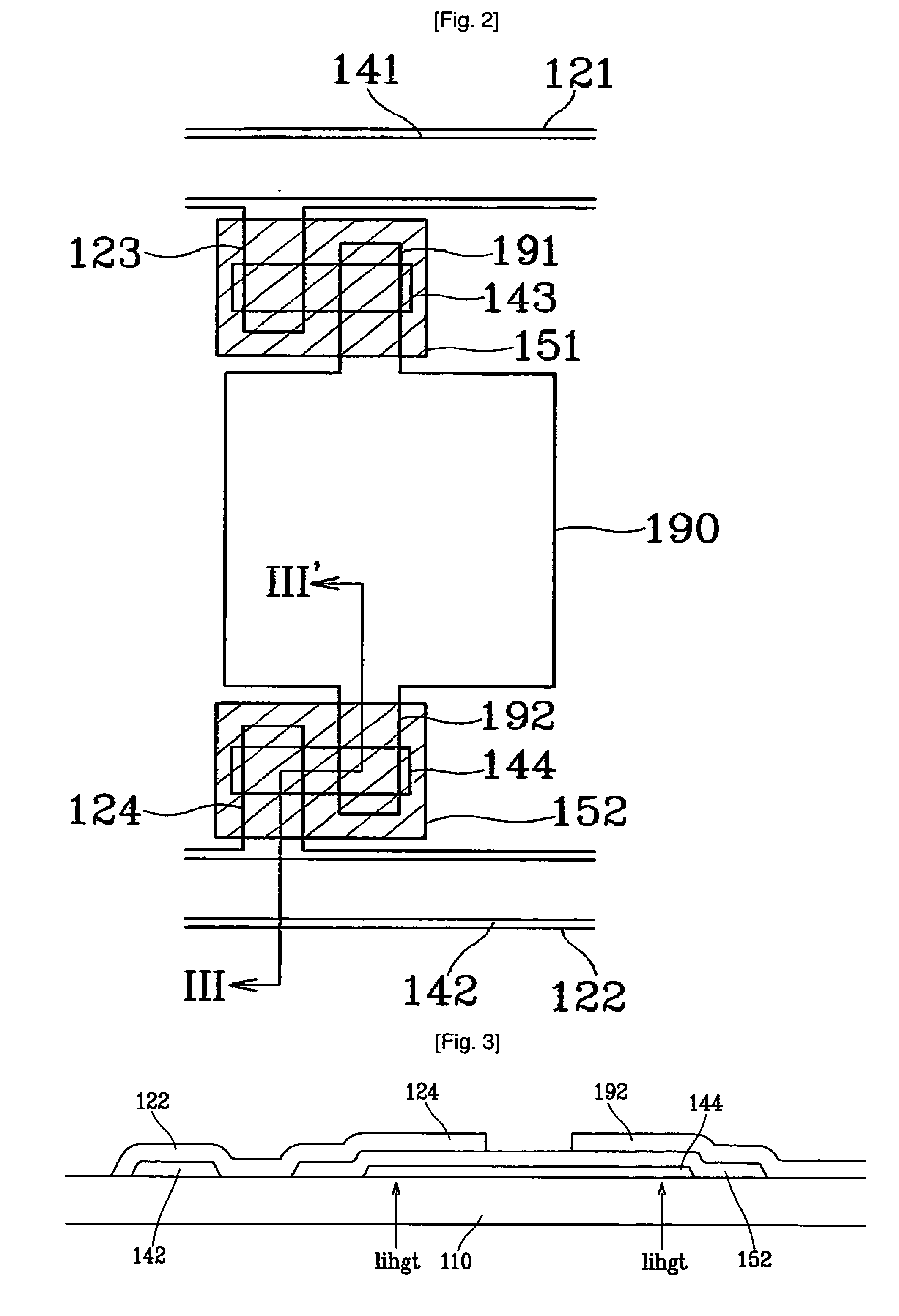

Thin film diode panel and manufacturing method of the same

The present invention provides a liquid crystal display comprising: an insulating substrate; a plurality of color filters formed on the insulating substrate; a plurality of first and second gate lines formed on the color filters; a plurality of pixel electrodes formed on the color filters; a plurality of first MIM diodes formed on the color filters and connecting the first gate line and the pixel electrodes; and a plurality of second MIM diodes formed on the color filters and connecting the second gate line and the pixel electrodes.

Owner:SAMSUNG ELECTRONICS CO LTD

Thin film diode panel and manufacturing method of the same

InactiveUS20070040956A1Reduce the possibilityTotal current dropNon-linear opticsElectrical conductorThin-film diode

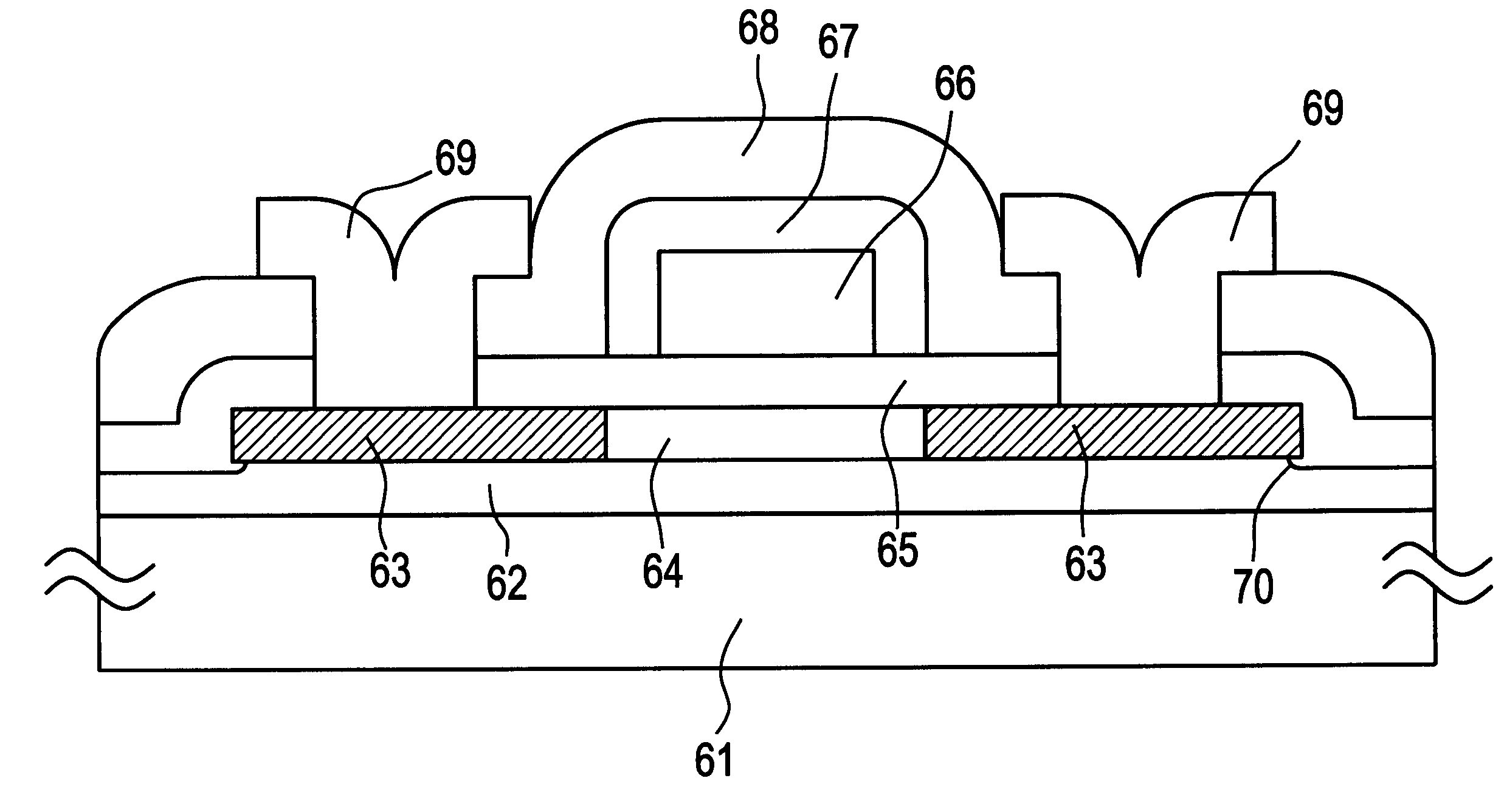

A thin film diode array panel comprising: an insulating substrate (110); first and second redundant gate lines (141, 142) made of an opaque conductor and formed on the insulating substrate; first and second floating electrodes (143, 144) made of an opaque conductor, formed on the insulating substrate, and disposed between the first and second redundant gate lines (141, 142); an insulating layer (151, 152) formed on the first and second floating electrodes (143, 144); a first gate line (121) formed on the first redundant gate line (141) and including a first input electrode (123) overlapping the first floating electrode (143) where the insulating layer (151) is interposed between the first input electrode and the first floating electrode; a second gate line (122) formed on the second redundant gate line (142) and including a second input electrode (124) overlapping the second floating electrode (144) where the insulating layer (152) is interposed between the second input electrode (124) and the second floating electrode (144); and a pixel electrode (190) including a first contact electrode (191) overlapping the first floating electrode (143) where the insulating layer (151) is interposed between the first contact electrode (191) and the first floating electrode (143), a second contact electrode (192) overlapping the second floating electrode (144) where the insulating layer (152) is interposed between the second contact electrode (192) and the second floating electrode (144), and a main body is provided.

Owner:SAMSUNG DISPLAY CO LTD

Optical sensor, semiconductor device, and liquid crystal panel

InactiveCN102473792AImprove utilization efficiencyHigh detection sensitivityTransistorSolid-state devicesThin-film diodeBlocking layer

Disclosed are an optical sensor, a semiconductor device, and a liquid crystal panel wherein a thin-film diode has improved optical detection sensitivity and a semiconductor layer thereof has improved light-use efficiency, even if the semiconductor layer is thin. One side of a substrate (101) is provided with a thin-film diode (130) having a first semiconductor layer (131) containing an n-type region (131n) and a p-type region (131p), at least. A light-blocking layer (160) is provided between the substrate and the first semiconductor layer. Surface asperities are formed on the side of the light-blocking layer that faces the first semiconductor layer, and the first semiconductor layer has a texture that matches the surface asperities of the light-blocking layer. Light incident on the light-blocking layer is diffusely reflected into the first semiconductor layer. Since the first semiconductor layer has a texture that matches the surface asperities of the light-blocking layer, the distance the diffusely-reflected light travels in the first semiconductor layer is increased. As a result, the amount of light absorbed by the first semiconductor layer increases and the optical detection sensitivity improves.

Owner:SHARP KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com