Optical sensor, semiconductor device, and liquid crystal panel

A light sensor and semiconductor technology, applied in the field of light sensors, can solve the problems of not being able to detect changes in light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

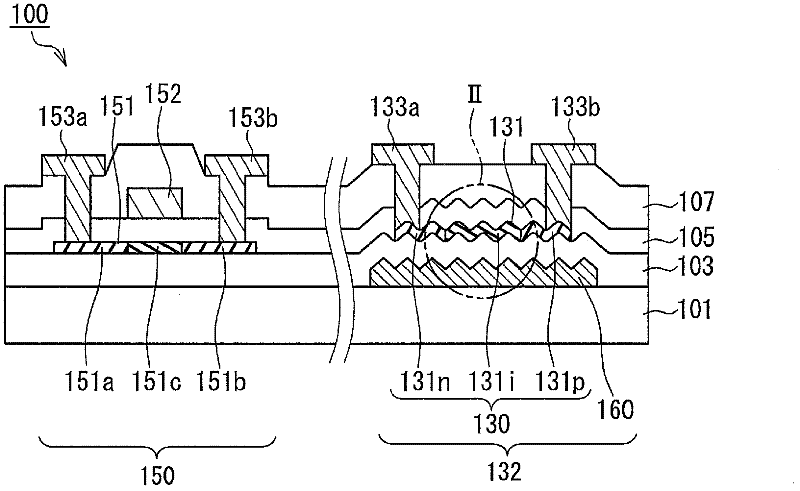

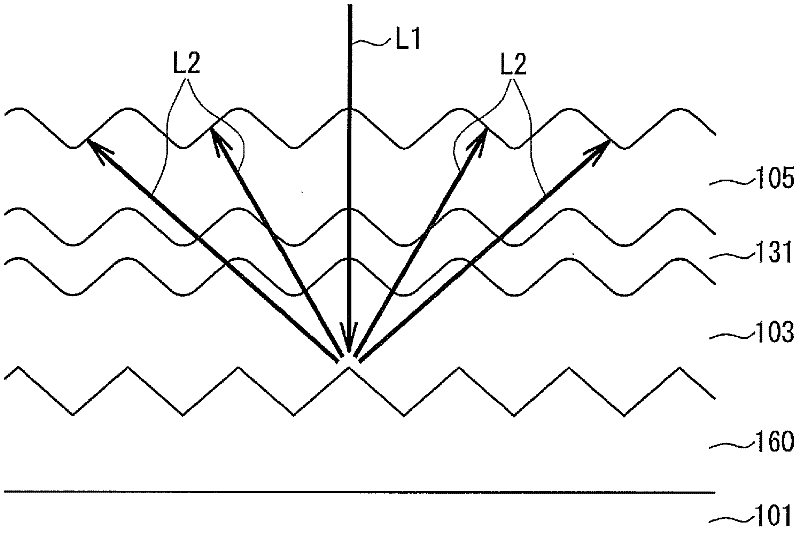

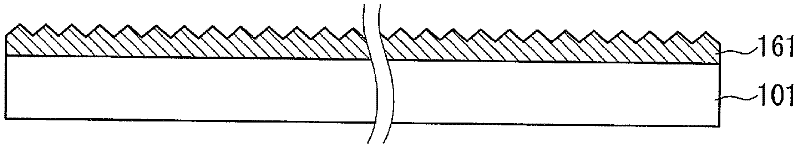

[0044] figure 1 is a cross-sectional view showing a schematic configuration of the semiconductor device 100 according to Embodiment 1 of the present invention. The semiconductor device 100 includes: a substrate 101, a thin film diode 130 formed on the substrate 101 with a base layer 103 as an insulating layer interposed therebetween, a light sensor 132 having a light shielding layer 160 provided between the substrate 101 and the thin film diode 130, and a thin film Transistor 150. The substrate 101 is preferably light-transmitting. exist figure 1 In order to simplify the drawing, only a single photosensor 132 and a single thin film transistor 150 are shown, but a plurality of photosensors 132 and a plurality of thin film transistors 150 can be formed on a common substrate 101 . In addition, in figure 1 In the figure, for easy understanding, a cross-sectional view of the photosensor 132 and a cross-sectional view of the thin film transistor 150 are shown in the same draw...

Embodiment approach 2

[0081] In Embodiment 2, a liquid crystal panel including a semiconductor device having the photodetection function described in Embodiment 1 will be described.

[0082] Figure 4 It is a cross-sectional view showing a schematic configuration of a liquid crystal display device 500 including a liquid crystal panel 501 according to the second embodiment.

[0083] The liquid crystal display device 500 includes: a liquid crystal panel 501 ; an illuminating device 502 for illuminating the backside of the liquid crystal panel 501 ;

[0084] The liquid crystal panel 501 includes: a TFT array substrate 510 and an opposing substrate 520 , both of which are light-transmitting plate-like members; and a liquid crystal layer 519 sealed between the TFT array substrate 510 and the opposing substrate 520 . Materials for forming the TFT array substrate 510 and the counter substrate 520 are not particularly limited. For example, the same materials as those used in conventional liquid crystal p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com