High temperature-resistant nanosized self-adhesive optical protective film and production method thereof

A production method and self-adhesive technology, applied in chemical instruments and methods, layered products, other household appliances, etc., can solve the problems of optical film deformation, inelastic shrinkage, etc., and achieve non-decreasing viscosity, low surface energy, and transparent high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of the high temperature-resistant nano-scale self-adhesive optical protective film comprises the following steps:

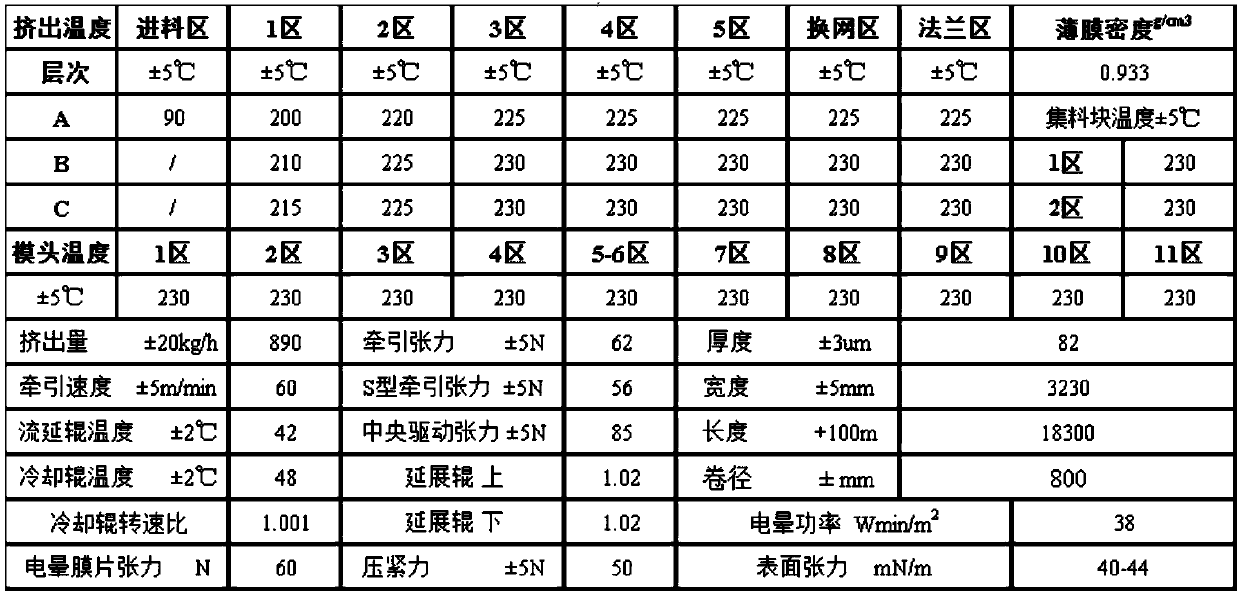

[0031] Step 1, put the materials contained in the self-adhesive layer, middle layer and unwinding layer into the corresponding suction area of the multi-layer co-extrusion casting machine according to the above-mentioned component ratio requirements, and transport them to the extruder hopper under vacuum negative pressure , is plasticized into a melt by the extruder; the cylinder where the self-adhesive layer is located includes 6 heating sections and the temperature of each heating section is 210°C, 225°C, 230°C, 230°C, 230°C, 230°C, so The cylinder where the intermediate layer is located includes 8 heating sections and the temperatures of each heating section are 90°C, 200°C, 220°C, 225°C, 225°C, 225°C, 225°C, 225°C, the unwinding layer It includes 6 heating sections and the temperature of each heating section is 215°C, 225°C, 23...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com