Composite coating piston ring inlaid with wear-resistant particles, and processing method thereof

A technology of composite coating and processing method, used in piston rings, coatings, electrolytic coatings, etc., can solve the problems of high working temperature, frequent friction, and large thermal shock of piston rings, saving oil energy, prolonging service life, improving The effect of power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with embodiment and accompanying drawing, the present invention is described in further detail:

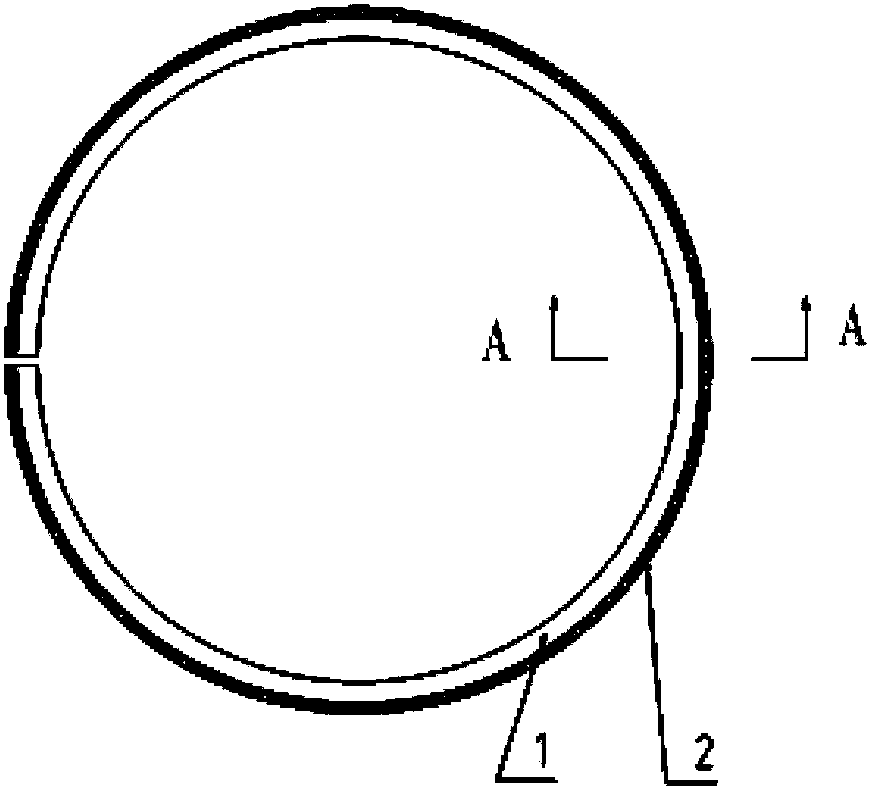

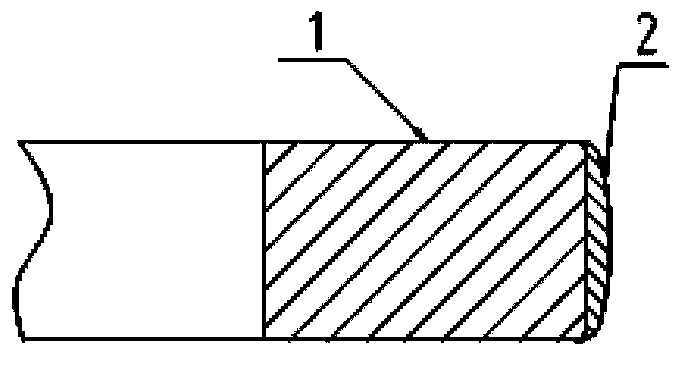

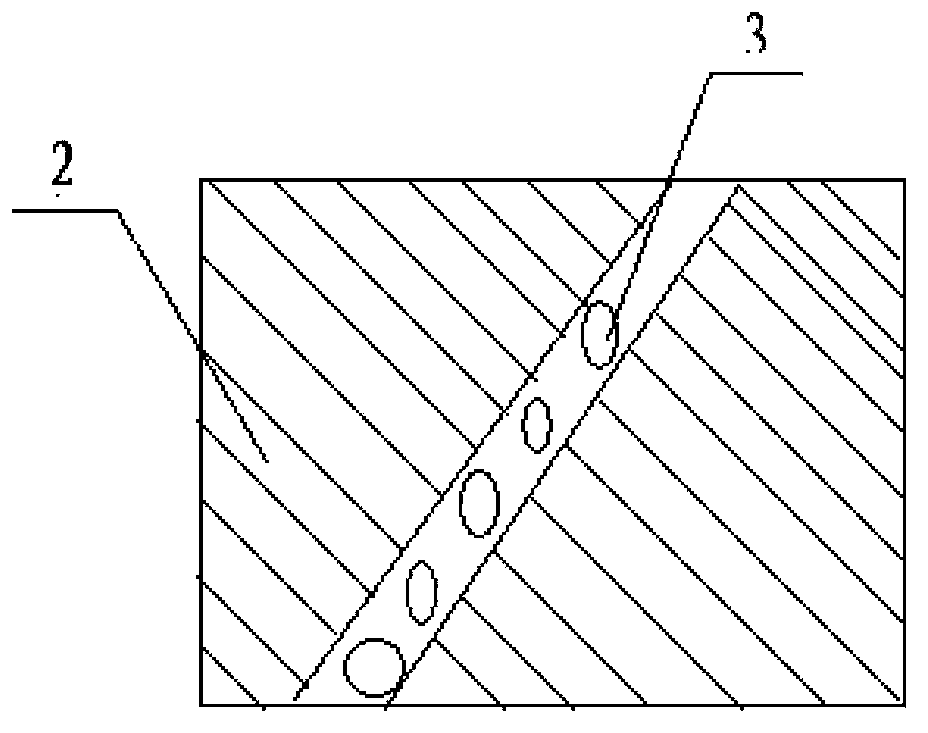

[0029] Composite coating piston ring inlaid with wear-resistant particles, its structure is shown as figure 1 , figure 2 and image 3 As shown, it includes the body 1 and the composite coating 2, the composite coating 2 is covered on the outer circle of the body 1; the body 1 is made of cast iron, and the composite coating 2 is a coating inlaid with wear-resistant particles 3. Abrasive particles are embedded in the texture of the composite coating; the wear-resistant particles 3 are one or more of silicon carbide, silicon dioxide, alumina, and diamond, and the particle size of the wear-resistant particles 3 is 0.5-5 μm. The mass percentage in the composite coating 2 is 2-6%.

[0030] The texture density of the composite coating 2 is 40-100 texture / mm, the texture width is 1-5 μm, the texture depth is 2-20 μm, the hardness of the composite coating is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com