Preparation method and pressing device for radiation-oriented magnet ring or multipolar magnet ring

A radiation-oriented, multi-pole magnetic ring technology, applied in the direction of inductance/transformer/magnet manufacturing, inorganic material magnetism, electrical components, etc., can solve the problem of uneven shrinkage of magnetic rings, etc. The effect of improving the magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] According to the present invention, the preparation method of radiation orientation magnetic ring and multi-pole magnetic ring comprises:

[0017] (1) Preparation of alloy ingots: the raw materials are conventionally smelted into alloy ingots in vacuum or inert gas;

[0018] (2) Alloy ingot crushing: coarsely crushing and hydrogen crushing the alloy ingot in an inert atmosphere to obtain a powder with a particle size of several hundred microns; add 0.01 to 1 wt% of an antioxidant to the hydrogen crushed powder to mix 2 Hours; use jet mill to pulverize the coarse powder after hydrogen crushing under nitrogen environment to obtain alloy powder with average particle size of about 4m and uniform particle size distribution;

[0019] (3) Powder pre-orientation: Fill the powder into the mold cavity of the molding press, and perform pre-orientation operation on the powder; change the yoke to four movable parts along the circumferential direction, and move them separately during...

Embodiment 1

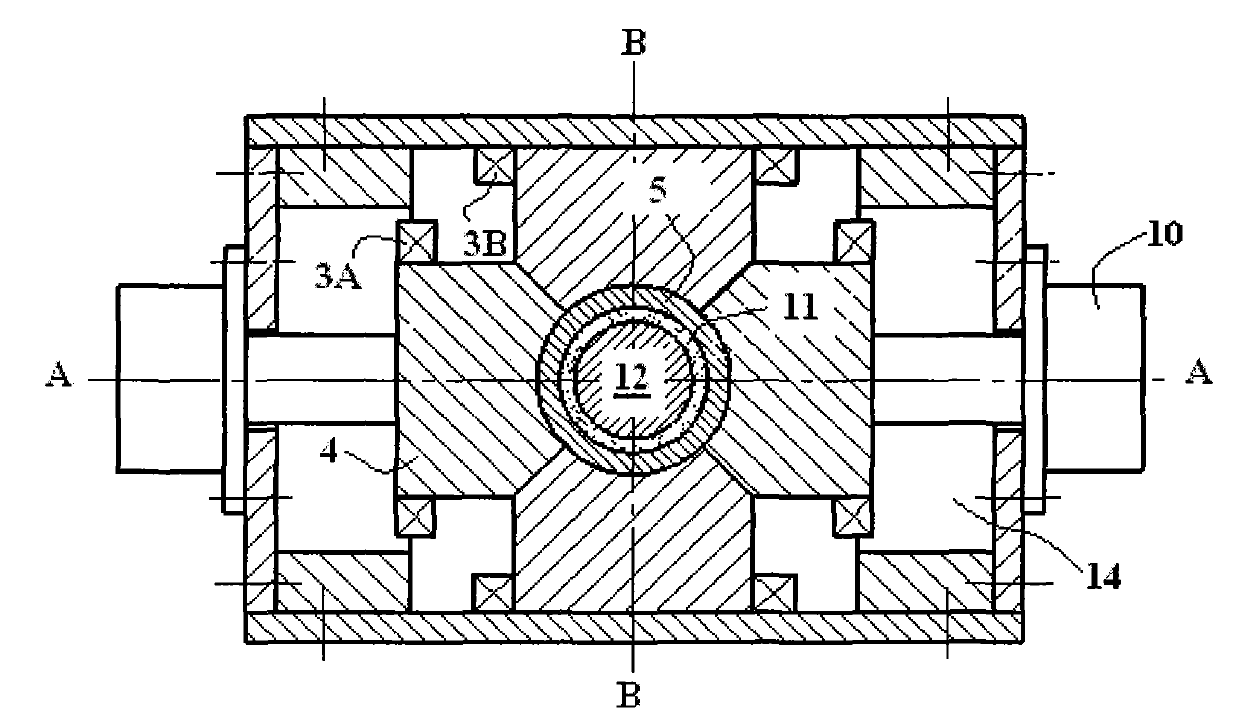

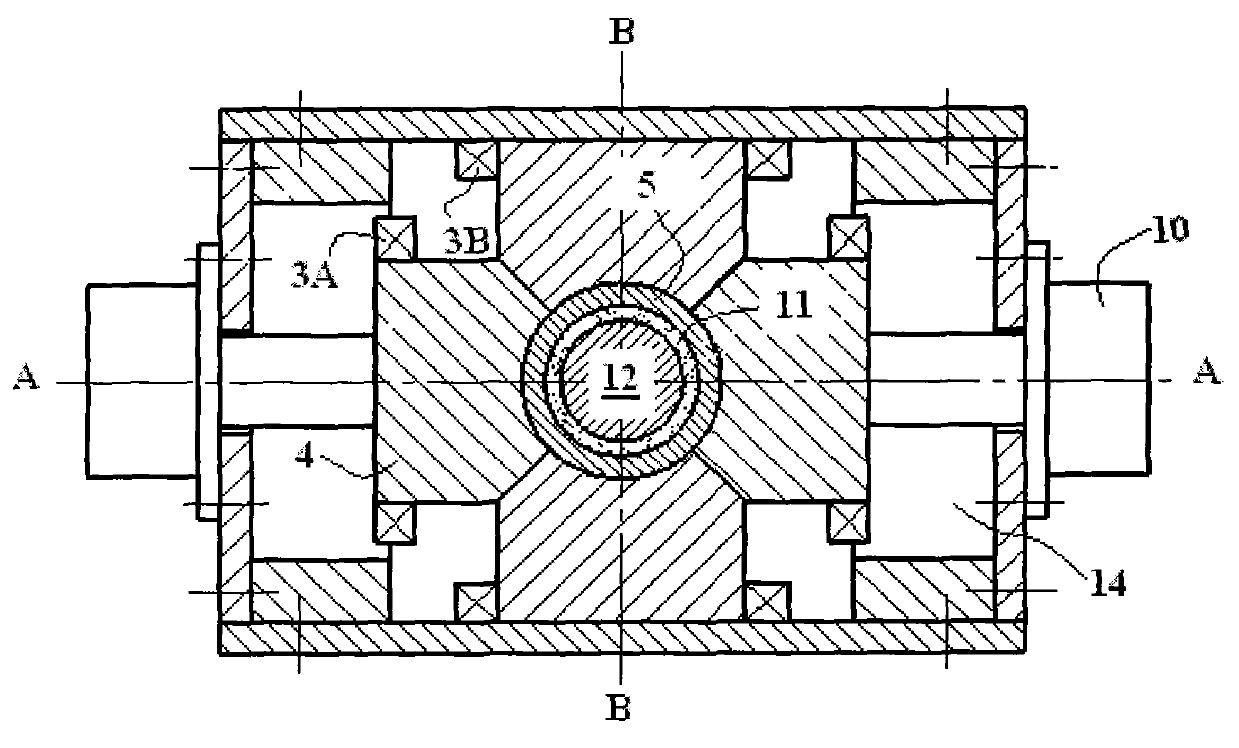

[0029] When powder is loaded, the two yokes 4 in the direction of length A-A and the two yokes 4 in the direction of width B-B form a complete ring. After the powder is loaded, the upper pressure head drops and the iron core closes. Move the two yokes 4 along the A-A direction for 50-150mm, and then, the excitation coil 3B generates a magnetic field with the same polarity along the B-B direction to pre-orient the powder for the first time, and the magnetic field in the mold cavity is 0.8-2.0T After the orientation is completed, push back the two yokes 4 in the direction of length A-A to their original positions; then move the two yokes 4 in the direction of width B-B for 50-150mm along the direction of B-B, and the excitation coil 3A generates a magnetic field with the same polarity , the direction is along the A-A direction, and the magnetic field in the mold cavity is 0.8-2.0T. After the orientation is completed, the yoke 4 in the width B-B direction is pushed back to the ori...

Embodiment 2

[0032] When powder is loaded, the two yokes 4 in the direction of length A-A and the two yokes 4 in the direction of width B-B form a complete ring. After the powder is loaded, the upper pressure head drops and the iron core closes. Pre-magnetize the pulsed magnetic field along the C-C direction (that is, the height direction), and then press the magnetic ring under the radiation orientation magnetic field.

[0033] In order to solve the cracking problem in the sintering process of the magnetic ring, after the radiation-oriented magnetic ring is pressed and isostatically pressed, it is placed in a protective gas atmosphere (such as an inert gas Ar 2 or N 2 ) or in a vacuum state, the inner wall of the magnetic ring is ground as a whole, and after the inner diameter is ground to 0.1-1 mm, the sintering aging heat treatment is performed.

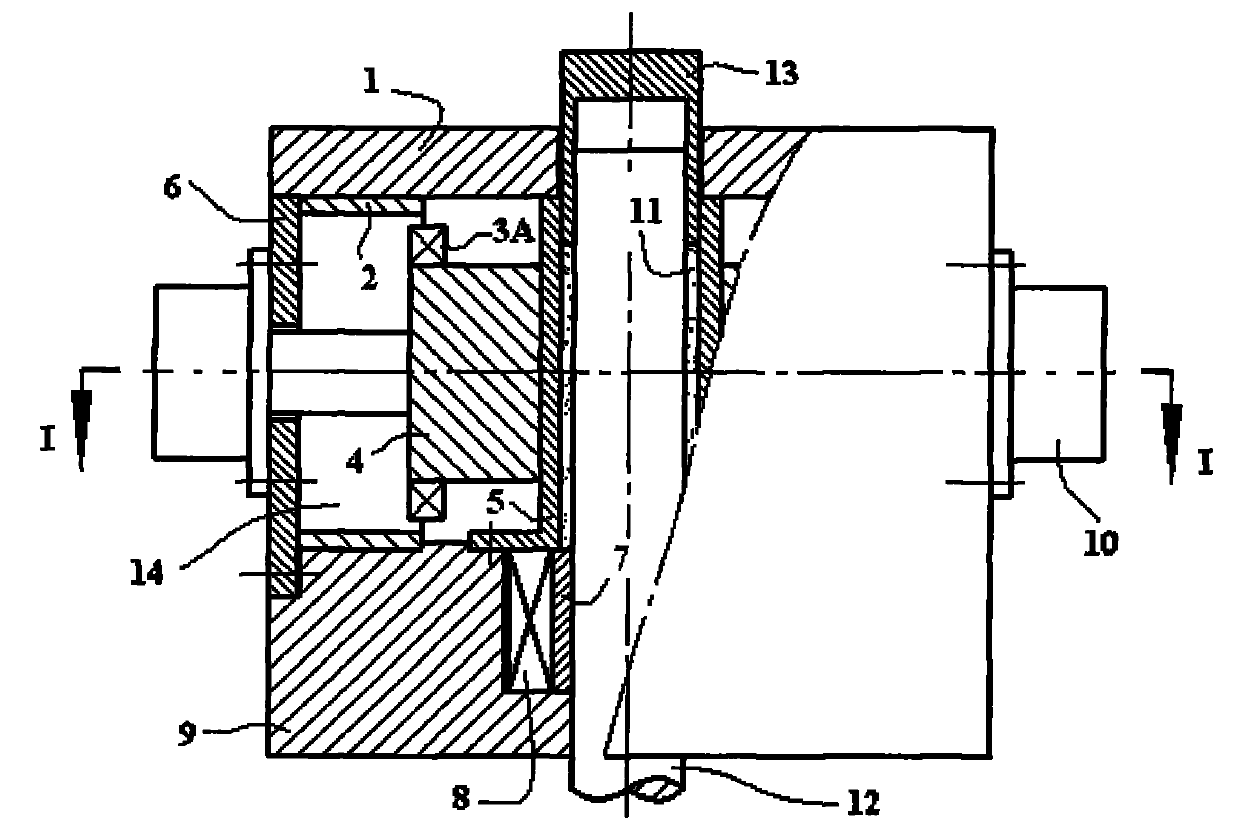

[0034] The present invention also provides a pressing device for preparing radiation-oriented magnetic rings and multi-pole magnetic rings. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com