Production method of crossed multi-barrier-layer co-extruded film

A production method and technology of barrier layer, applied in the field of preparation of co-extruded film, can solve the problems of uneven thickness of pipe wall, low production efficiency, uneven thickness, etc., and achieve the effect of avoiding wire drawing, improving product performance and optimizing barrier performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

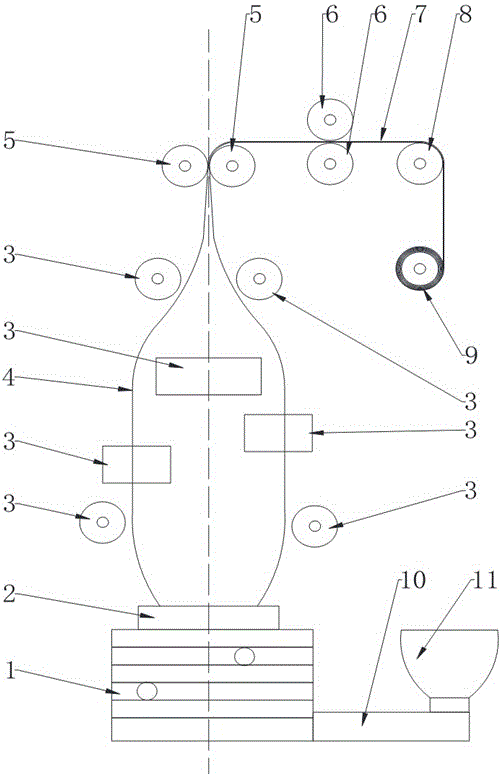

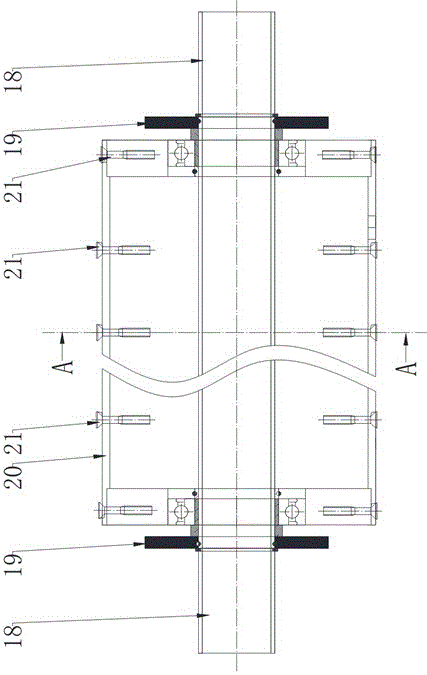

[0035] The production method of cross multi-barrier layer co-extruded film adopts figure 1 Production equipment shown, image 3 with Figure 4 For the structure of the air roller used in this embodiment, the concrete production steps of this embodiment are:

[0036] (1) The extruder and the die head extrude the film bubble of the multi-layer co-extrusion film, and the airflow ejected from the 10 air cushion rollers outside the film bubble above the die head supports the floating film bubble; the air cushion roller cools the film bubble, so that The bubble has a certain structural strength, which determines its fixed diameter and bubble thickness; at the same time, the bubble is supported and floated by the air cushion roller, which will not cause friction with the bubble, avoiding the phenomenon of wire drawing on the surface of the bubble, and ensuring the smoothness of the bubble. The best quality; the distance between the two air cushion rollers at the top becomes smaller...

Embodiment 2

[0047] On the basis of Example 1, the preferred embodiment of the present invention is the production method of cross multi-barrier layer co-extruded film, the temperature of the heating nip roll in step (2) is 45°C; the temperature of the heating roll in step (3) is 95°C; the temperature of the cooling roll in step (4) is 20°C.

[0048] The bubble has an 11-layer structure with a barrier layer, and the prepared sheet has a 22-layer structure with doubled layers. The self-adhesive material of the innermost self-adhesive material layer of the bubble is PP. The film thickness of the bubble is 250 μm; the thickness of the intersecting multi-barrier co-extruded film is 500 μm.

[0049] All the other parts are identical to Example 1.

Embodiment 3

[0051] On the basis of Example 1, the preferred embodiment of the present invention is the production method of cross multi-barrier layer co-extruded film, the temperature of the heating nip roll in step (2) is 60°C; the temperature of the heating roll in step (3) is 75°C; the temperature of the cooling roll in step (4) is 5°C.

[0052] The bubble has a 6-layer structure with a barrier layer, and the prepared sheet has a 12-layer structure with doubled layers. The self-adhesive material of the innermost self-adhesive material layer of the bubble is EVA. The film thickness of the bubble is 200 μm; the thickness of the intersecting multi-barrier co-extruded film is 400 μm.

[0053] All the other parts are identical to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com