Preparation method for hose sheet by multilayer co-extrusion

A multi-layer co-extrusion and hose technology, applied in the direction of chemical instruments and methods, lamination, layered products, etc., can solve the problems that cannot meet the requirements of hose production, and achieve the effect of avoiding wire drawing and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

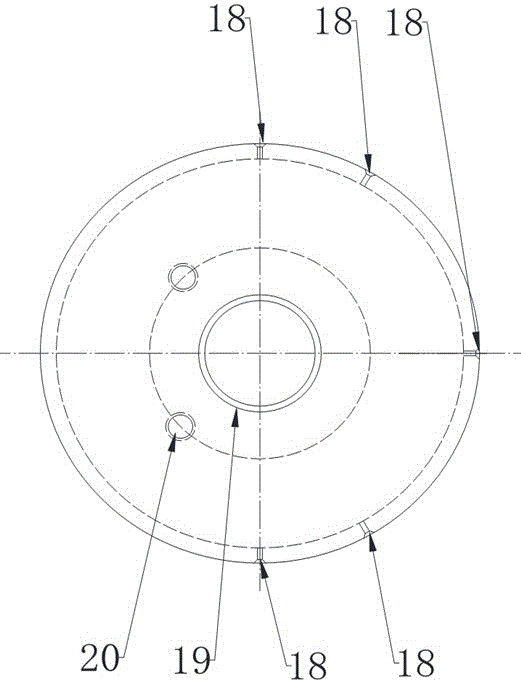

[0034] The method for preparing hose sheet by multi-layer co-extrusion adopts figure 1 Production equipment shown, image 3 For the structure of the air cushion roller that this embodiment adopts, the concrete steps of this embodiment are:

[0035] (1) The extruder and the die mouth extrude the bubble of the multi-layer co-extrusion film, the sizing cage outside the bubble above the die mouth is cooled by the air ring to determine the diameter of the bubble, and the 2 air cushion rollers above the sizing cage spray out The airflow supports the floating film bubble; the film thickness of the film bubble is 240 μm; the sizing cage and the air cushion roller cool the film bubble, so that the film bubble has a certain structural strength, and determine its fixed diameter and film thickness; at the same time, The film bubble is floated by the air support of the air cushion roller and the sizing cage, which will not cause friction with the film bubble, avoid the phenomenon of wire ...

Embodiment 2

[0046] On the basis of embodiment 1, the preferred embodiment of the present invention is the method for preparing hose sheet by multi-layer coextrusion, and its specific steps are:

[0047] The film thickness of the film bubble in step (1) is 100 μm;

[0048] The temperature of the heating roller in step (3) is 40°C;

[0049] The temperature of the cooling roll in step (4) is 15°C.

[0050] The bubble has an 11-layer structure, and the innermost layer of the bubble is provided with 2 self-adhesive material layers, and the self-adhesive material layers are EVA and Surlyn resin respectively. The thickness of the tube sheet was 200 μm.

[0051] All the other parts are identical to Example 1.

Embodiment 3

[0053] On the basis of embodiment 1, the preferred embodiment of the present invention is the method for preparing hose sheet by multi-layer coextrusion, and its specific steps are:

[0054] The film thickness of the film bubble in step (1) is 200 μm;

[0055] The temperature of the heating roller in step (3) is 78°C;

[0056] The temperature of the cooling roll in step (4) is 6°C.

[0057] The bubble has a 9-layer structure, and a layer of self-adhesive material is provided on the inner side of the bubble, and the self-adhesive material layer is Surlyn resin. The thickness of the tube sheet was 400 μm.

[0058] All the other parts are identical to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com