Cobalt disulfide/carbon nanofiber composite material and preparation method thereof

A carbon nanofiber, cobalt disulfide technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of complex preparation process, poor long-term battery cycle performance, etc. The effect of enhancing electrochemical performance and releasing internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

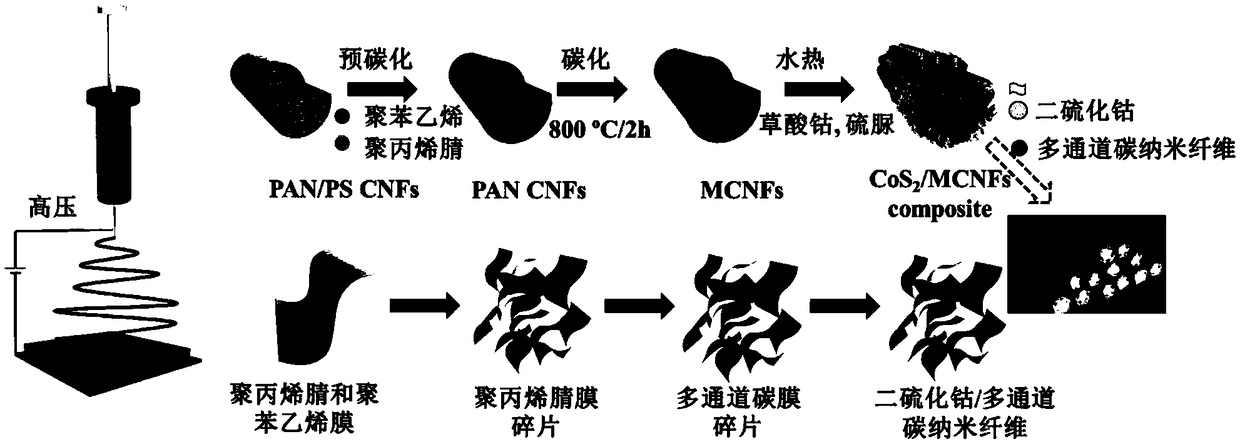

[0033] The invention provides a preparation method of a cobalt disulfide / carbon nanofiber composite material, comprising: S1A) carbonizing a polyacrylonitrile / polystyrene composite nanofiber film to obtain a carbon nanofiber film; S1B) making an organic acid cobalt salt 1. The organic sulfur source is mixed with a glycol solvent to obtain a mixed solution; the organic sulfur source contains amino groups; S2) the carbon nanofiber film is mixed with the mixed solution, and after hydrothermal reaction, cobalt disulfide / carbon nanofibers are obtained Composite material; wherein the steps S1A) and S1B) are in no particular order.

[0034] see figure 1 , figure 1 Schematic diagram of the synthesis of the cobalt disulfide / carbon nanofiber composite material provided by the present invention.

[0035] Among them, the present invention has no special limitation on the sources of all raw materials, which can be commercially available.

[0036] The polyacrylonitrile / polystyrene compos...

Embodiment 1

[0054] Take 5.3g of N,N-dimethylformamide and slowly pour it into the conical flask, then add 4.2g of polyacrylonitrile into the conical flask, mix and fully stir for 7 hours, then slowly add 0.68g of polystyrene Ethylene, and then the three were continuously stirred for 8 hours, and the temperature of the stirring was 45°C; after stirring evenly, the solution was introduced into the injection syringe of the electrospinning instrument, and the working voltage of the electrospinning was set to 13kV, and the sample delivery rate was 3μL / min, the distance between the needle and the conductive roller is 14cm, the working time is 12h, and the humidity in the cabin of the electrospinning instrument is controlled between 10% and 25%, to obtain polyacrylonitrile / polystyrene composite nanofiber membrane.

[0055] The polyacrylonitrile / polystyrene composite nanofiber membrane was cut into pieces with scissors, and then placed in a muffle furnace for pre-carbonization in air; the pre-car...

Embodiment 2

[0059] Take 5.3g of N,N-dimethylformamide and slowly pour it into the conical flask, then add 4.2g of polyacrylonitrile into the conical flask, mix and fully stir for 7 hours, then slowly add 0.68g of polystyrene Ethylene, and then the three were continuously stirred for 8h, and the temperature condition of the stirring was 45°C.

[0060] After stirring evenly, introduce the solution into the injection syringe of the electrospinning instrument, set the working voltage of the electrospinning to 17kV, the sample feeding rate to 3μL / min, the distance between the needle and the conductive roller to 10cm, the working time to 12h, and control The humidity in the cabin of the electrostatic spinning apparatus is between 10% and 25%, and a polyacrylonitrile / polystyrene composite nanofiber membrane is obtained.

[0061] The polyacrylonitrile / polystyrene composite nanofiber membrane was cut into pieces with scissors, and then placed in a muffle furnace for pre-carbonization in air; the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com