Phenyl vinyl silicon resin for adhering base as well as preparation method and application thereof

A technology based on phenylvinyl silicon and vinyl, applied in the direction of adhesives, etc., can solve the problems of light transmittance decrease, mechanical strength decrease, surface stickiness and other problems of LED packaging composition, and achieve good impurity ion content and adhesive strength The effect of improving the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

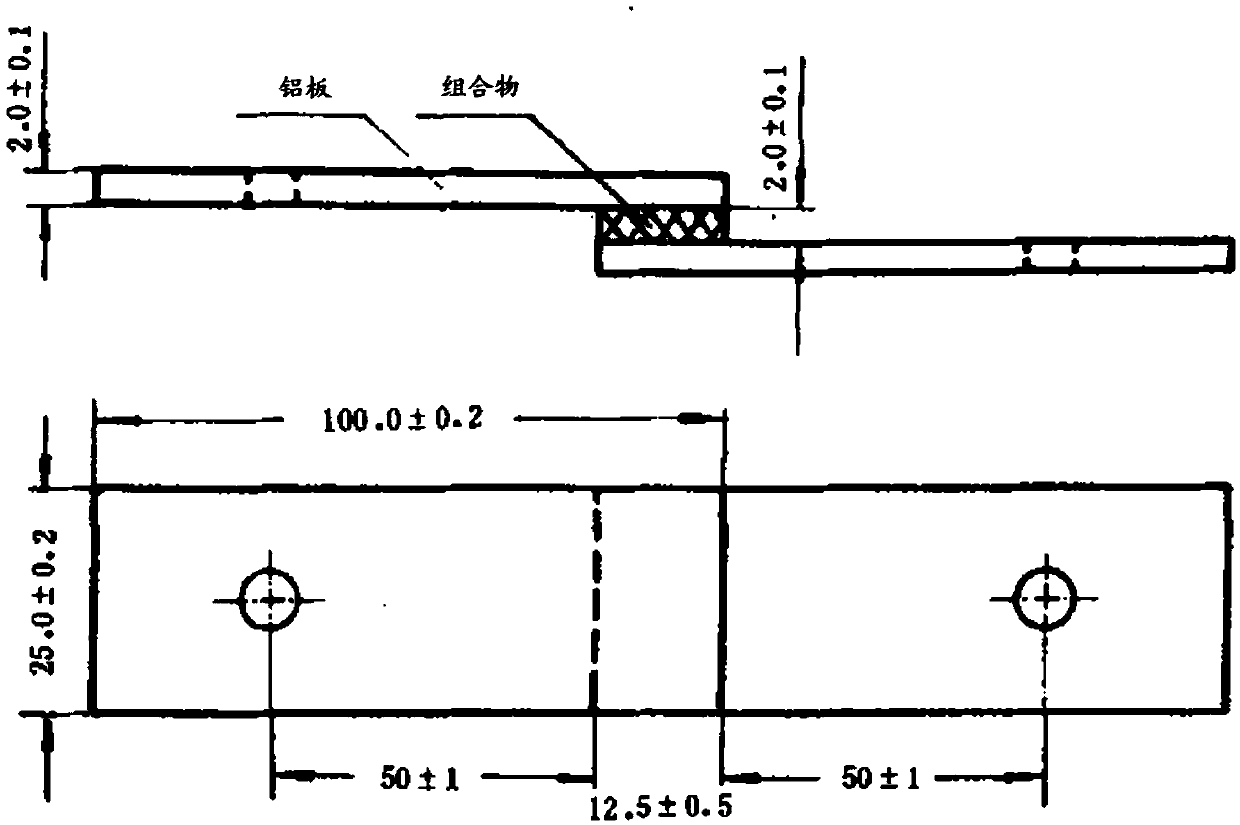

Method used

Image

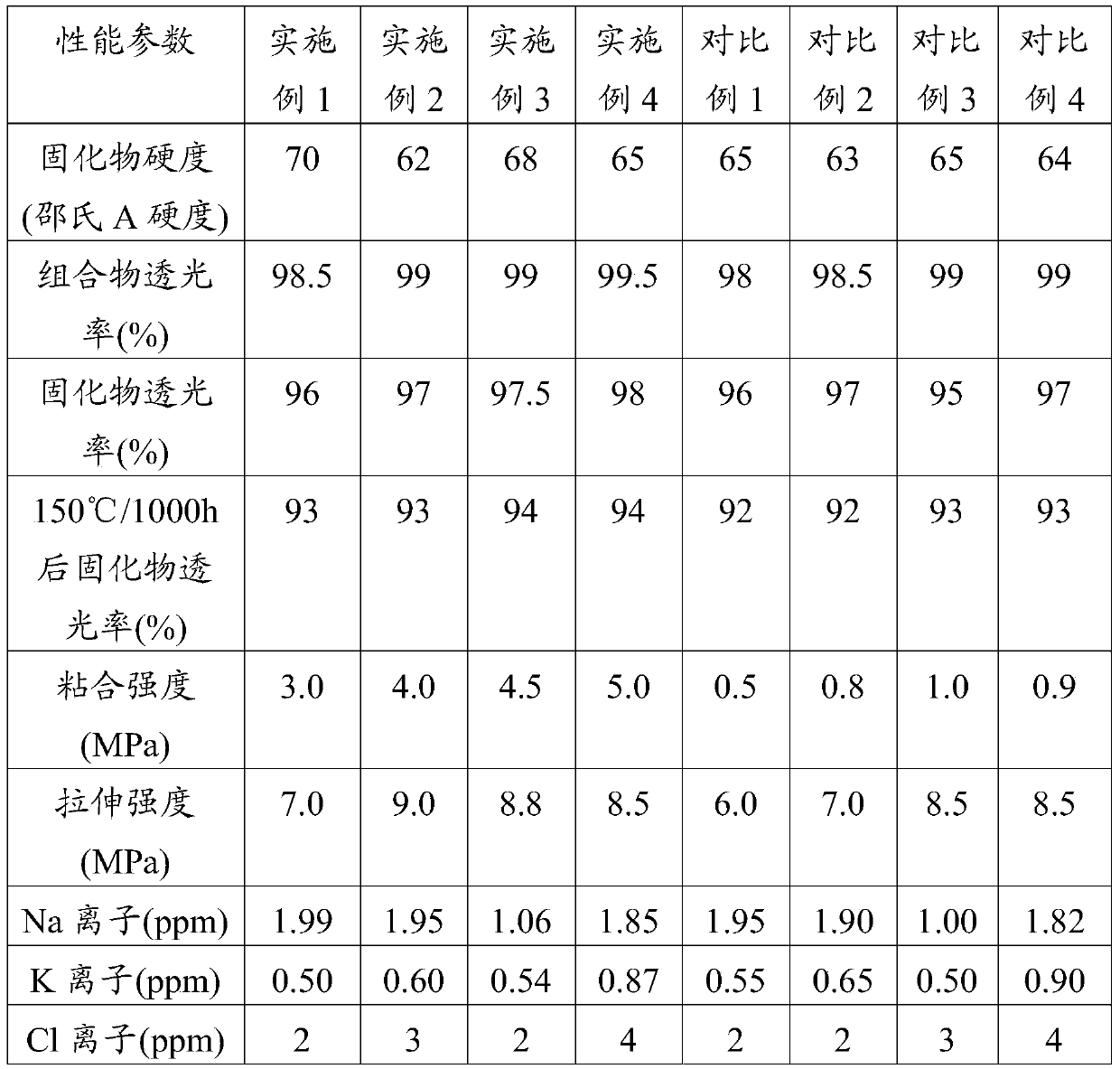

Examples

Embodiment 1

[0135] 3.3583g tetramethyldisiloxane (molecular weight 134.33), 6.7658g hexamethyldisiloxane (molecular weight 162.38), 13.98g divinyl tetramethyldisiloxane (molecular weight 186.4), 60g ethanol, 50g Deionized water and 3g of sulfuric acid were added to the reactor, and at 40°C, 128.7g of phenyltrimethoxysilane (molecular weight 198) was added dropwise to the reactor, and after the addition was completed, the temperature was raised to 80°C to continue the reaction for 6 hours; An equal volume of toluene was added to the finished mixed solution for extraction, and washed 5 times with deionized water until the pH value was close to neutral, and then anhydrous CaCl 2 Put it into the toluene solution of silicone resin to remove the moisture in the solution; add 5.5g of cation exchange resin Amberlyst15Dry to the toluene solution of the obtained silicone resin, react at 90°C for 8h, filter to remove the cation exchange resin, and then Remove the solvent and low boilers under reduce...

Embodiment 2

[0138] 2.6866g tetramethyldisiloxane (molecular weight 134.33), 9.4721g hexamethyldisiloxane (molecular weight 162.38), 5.592g divinyl tetramethyldisiloxane (molecular weight 186.4), 60g ethanol, 50g Deionized water and 20g of acetic acid were added to the reactor, and at 40°C, 108.9g of phenyltrimethoxysilane (molecular weight 198) was added dropwise to the reactor, and after the addition was completed, the temperature was raised to 50°C to continue the reaction for 8 hours; An equal volume of toluene was added to the finished mixed solution for extraction, and washed 4 times with deionized water until the pH value was close to neutral, and then anhydrous CaCl 2 Put it into the toluene solution of silicone resin to remove the moisture in the solution; add 5.5g phosphazene chloride to the toluene solution of the obtained silicone resin, react at 80°C for 1h, and then remove the solvent under reduced pressure at 170°C and low boilers to obtain a solid silicone resin containing ...

Embodiment 3

[0141] 4.0299g tetramethyldisiloxane (molecular weight 134.33), 12.9904g hexamethyldisiloxane (molecular weight 162.38), 12.42g dimethyldivinyldiphenyldisiloxane (molecular weight 310.54), 60g Add ethanol, 50g of deionized water, and 3g of trifluoromethanesulfonic acid into the reactor, and add 99g of phenyltrimethoxysilane (molecular weight: 198) dropwise to the reactor at 40°C, and raise the temperature to 70°C after the addition is completed The reaction was continued for 10 h; an equal volume of p-xylene was added to the mixed solution after the reaction for extraction, and deionized water was used to wash 3 times until the pH value was close to neutral, and then anhydrous CaCl 2 Put it into the toluene solution of silicone resin to remove the moisture in the solution; add 5.5HZSM-5 molecular sieve to the obtained p-xylene solution of silicone resin, react at 70°C for 6h, filter to remove the molecular sieve, and then in 170°C Remove the solvent and low boilers under reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com