Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

140results about How to "Improve light extraction rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

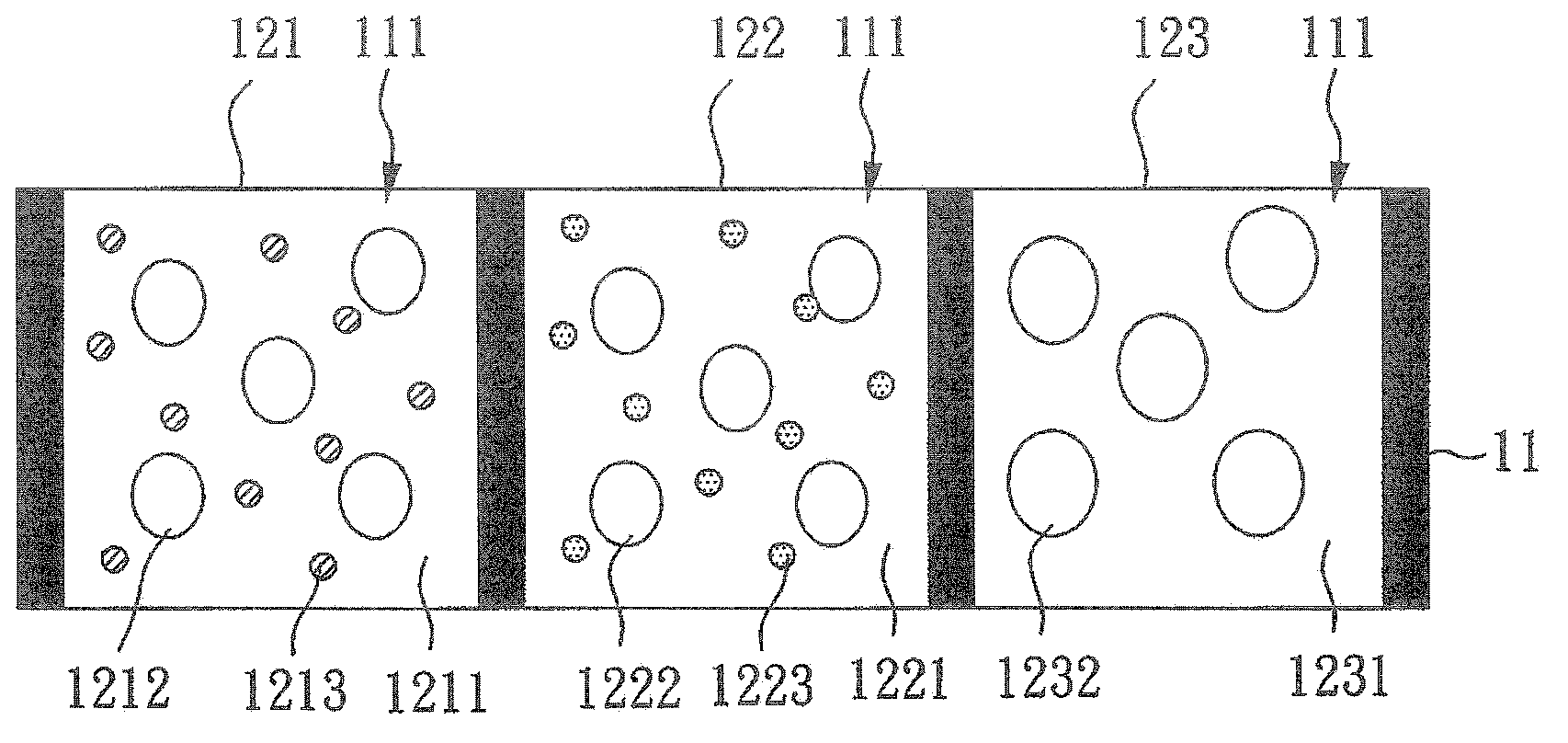

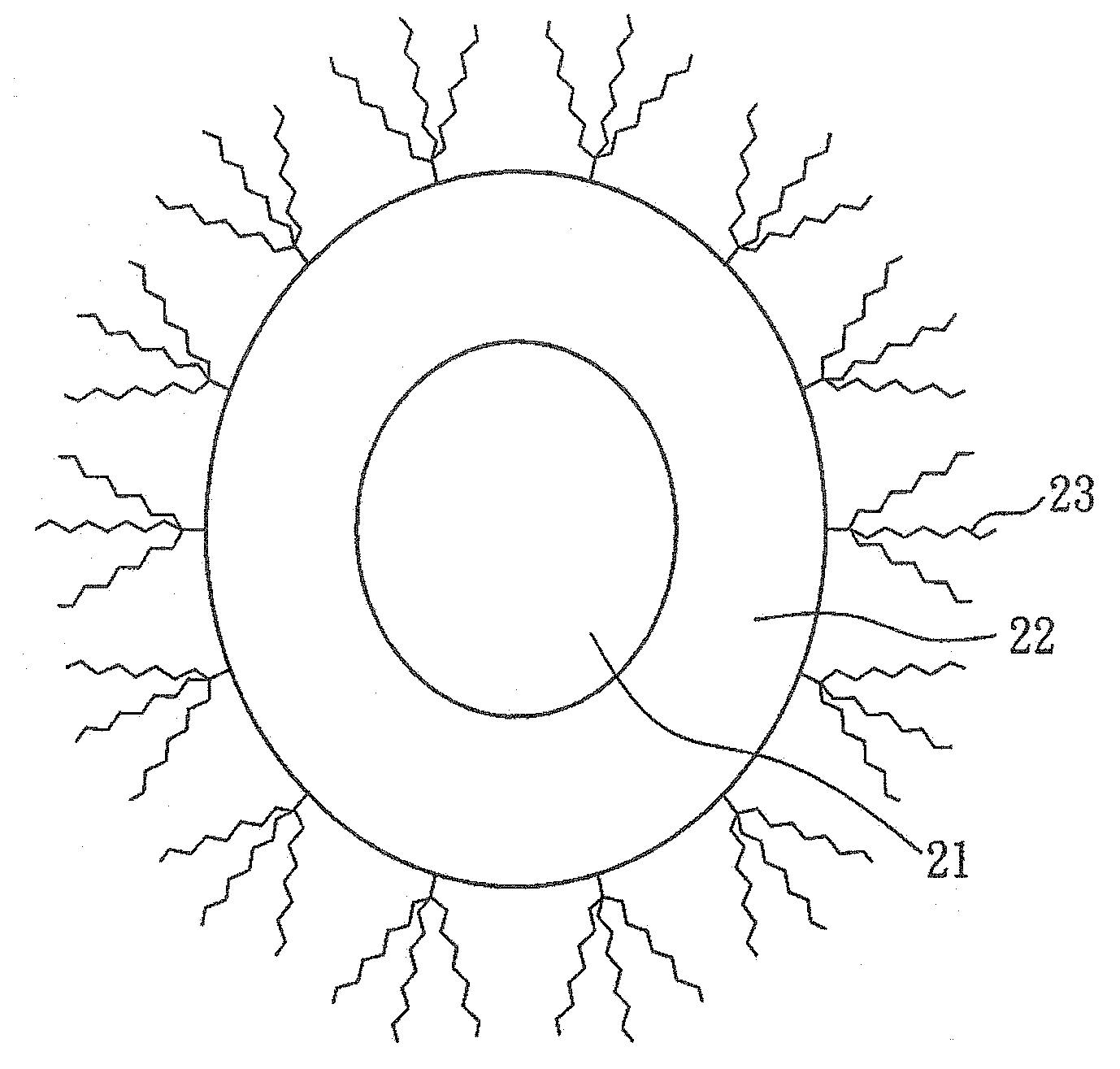

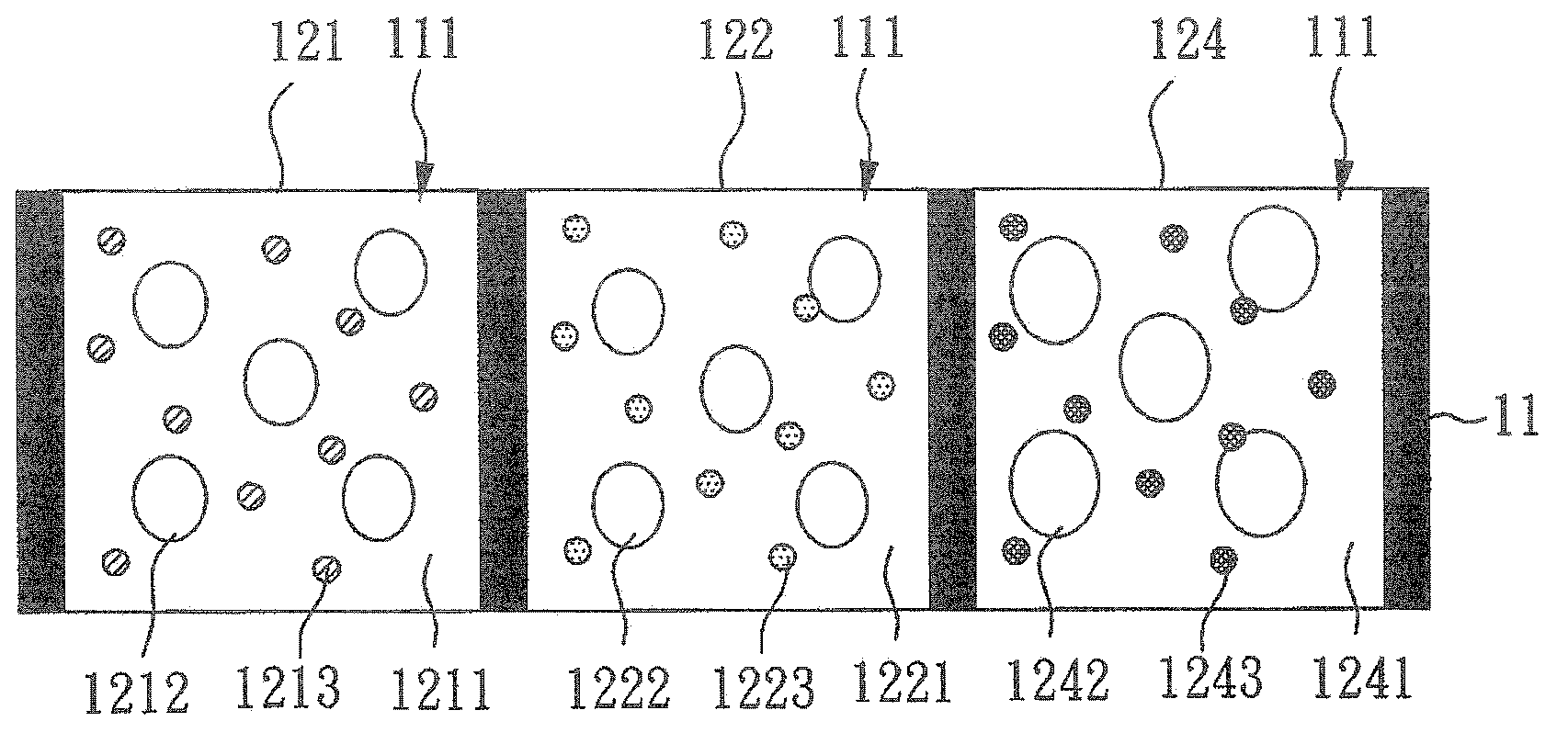

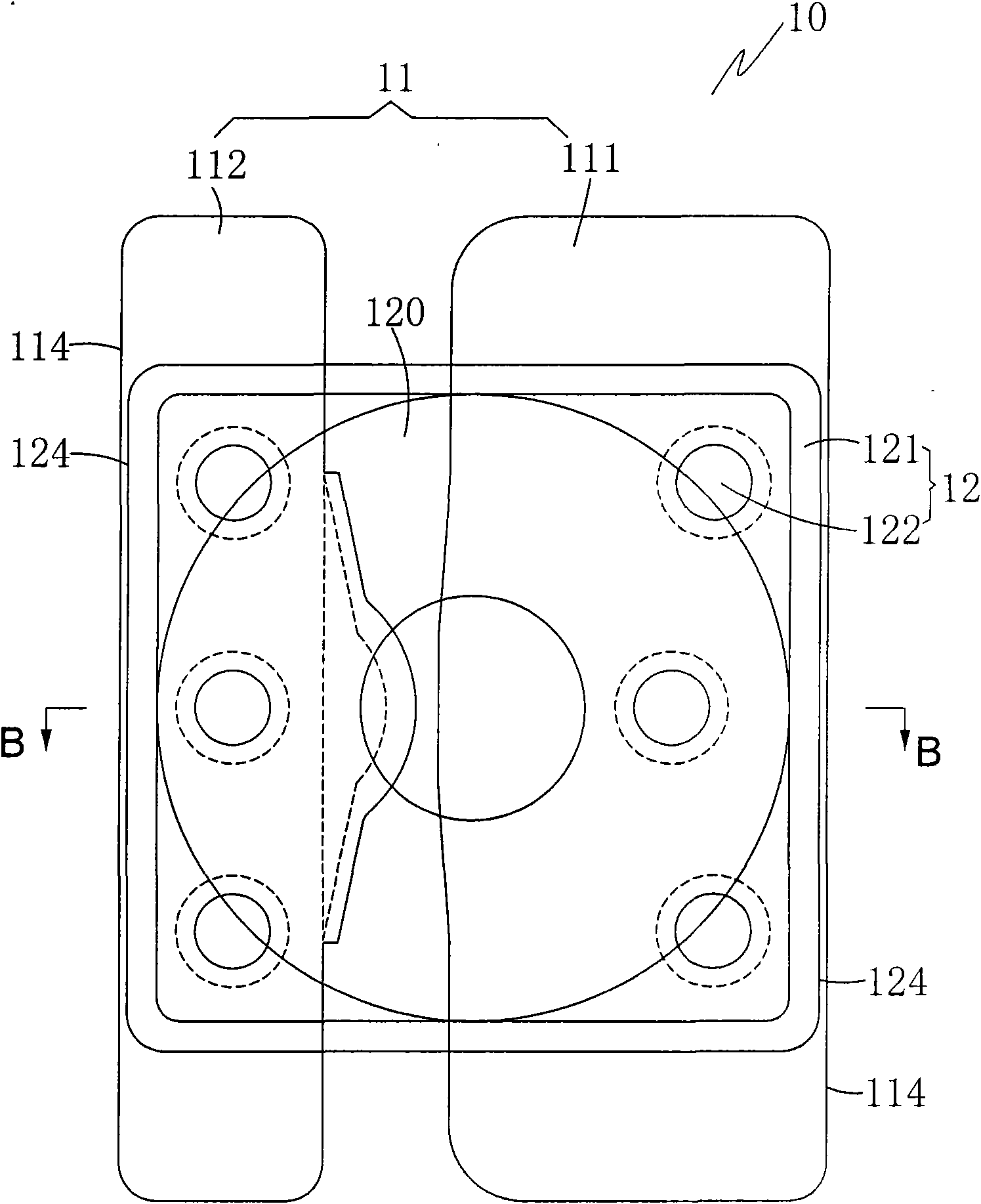

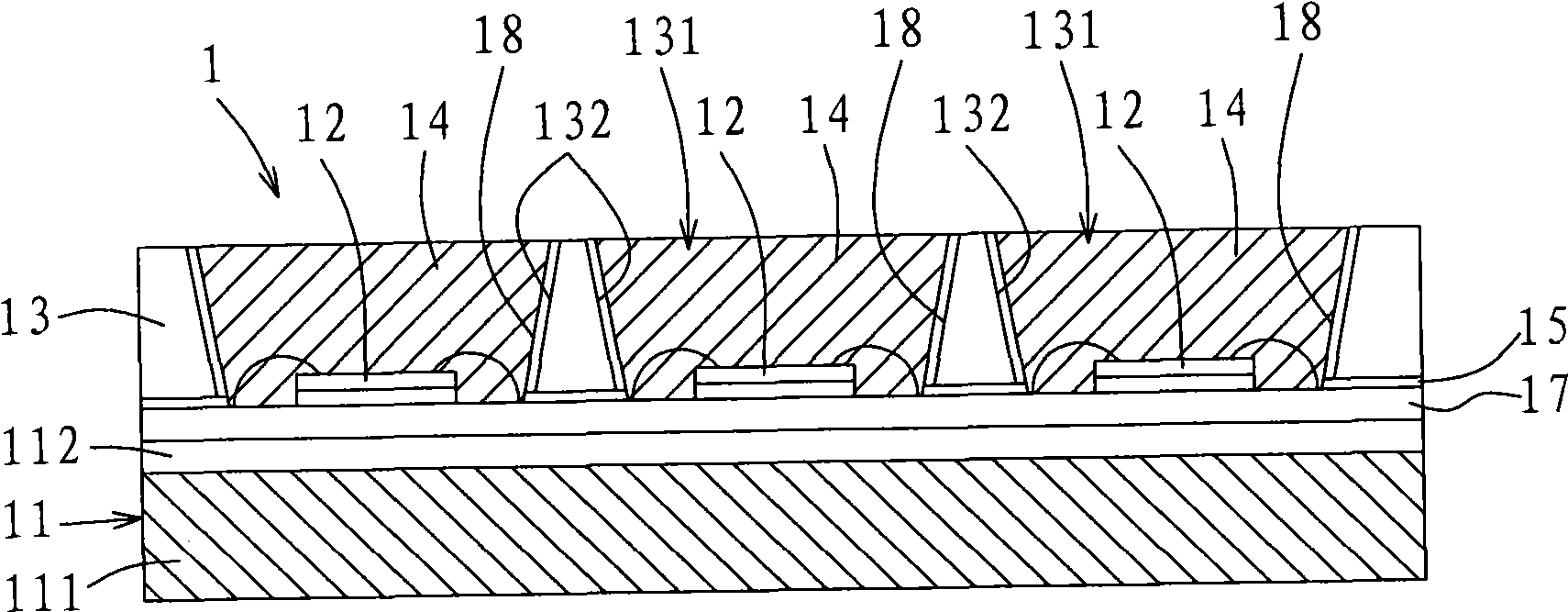

Patterned color conversion film and display device using the same

ActiveUS20140192294A1Increase utilization ratePoor view angleSpectral modifiersNon-linear opticsQuantum dotQuantum

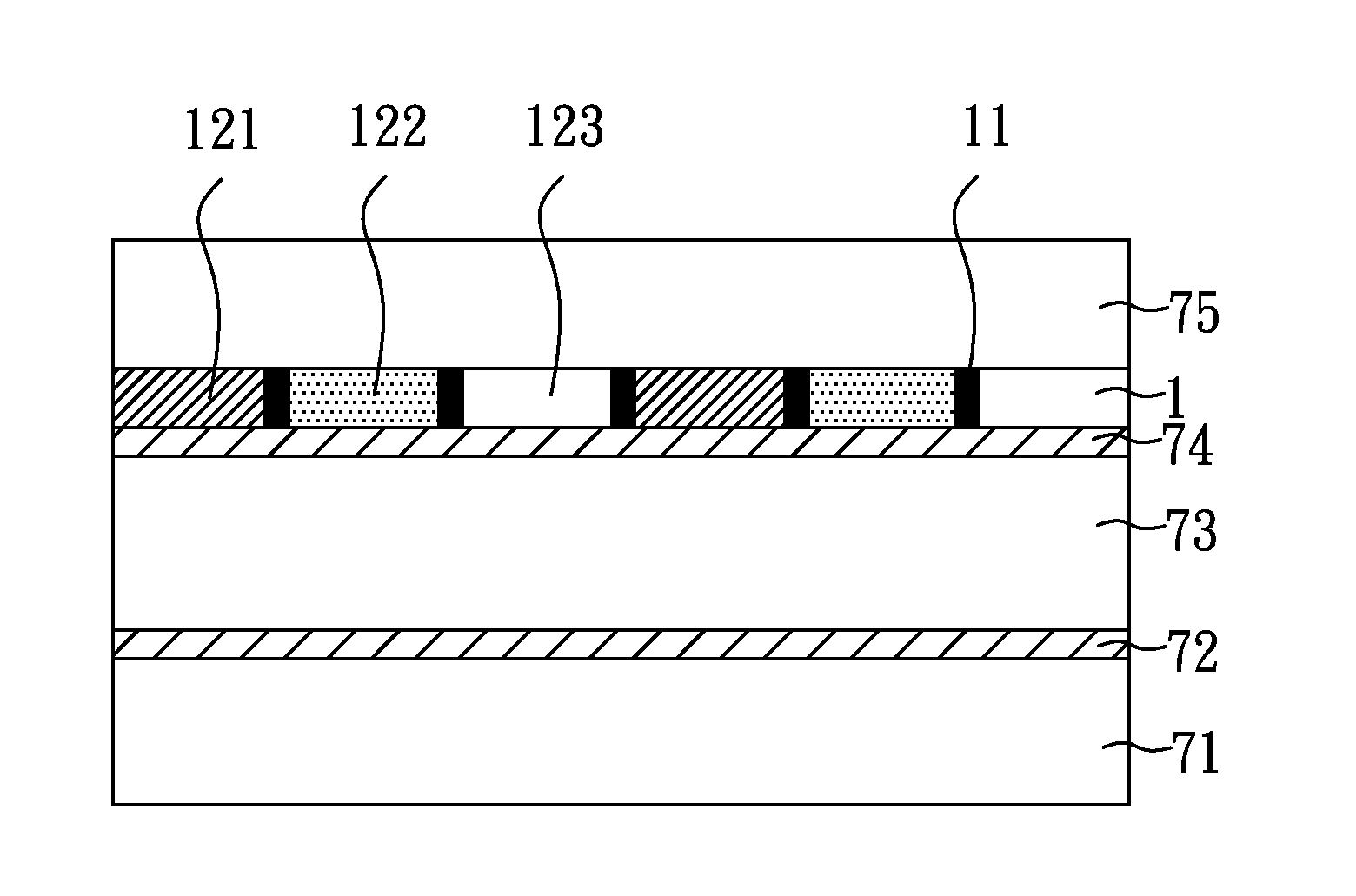

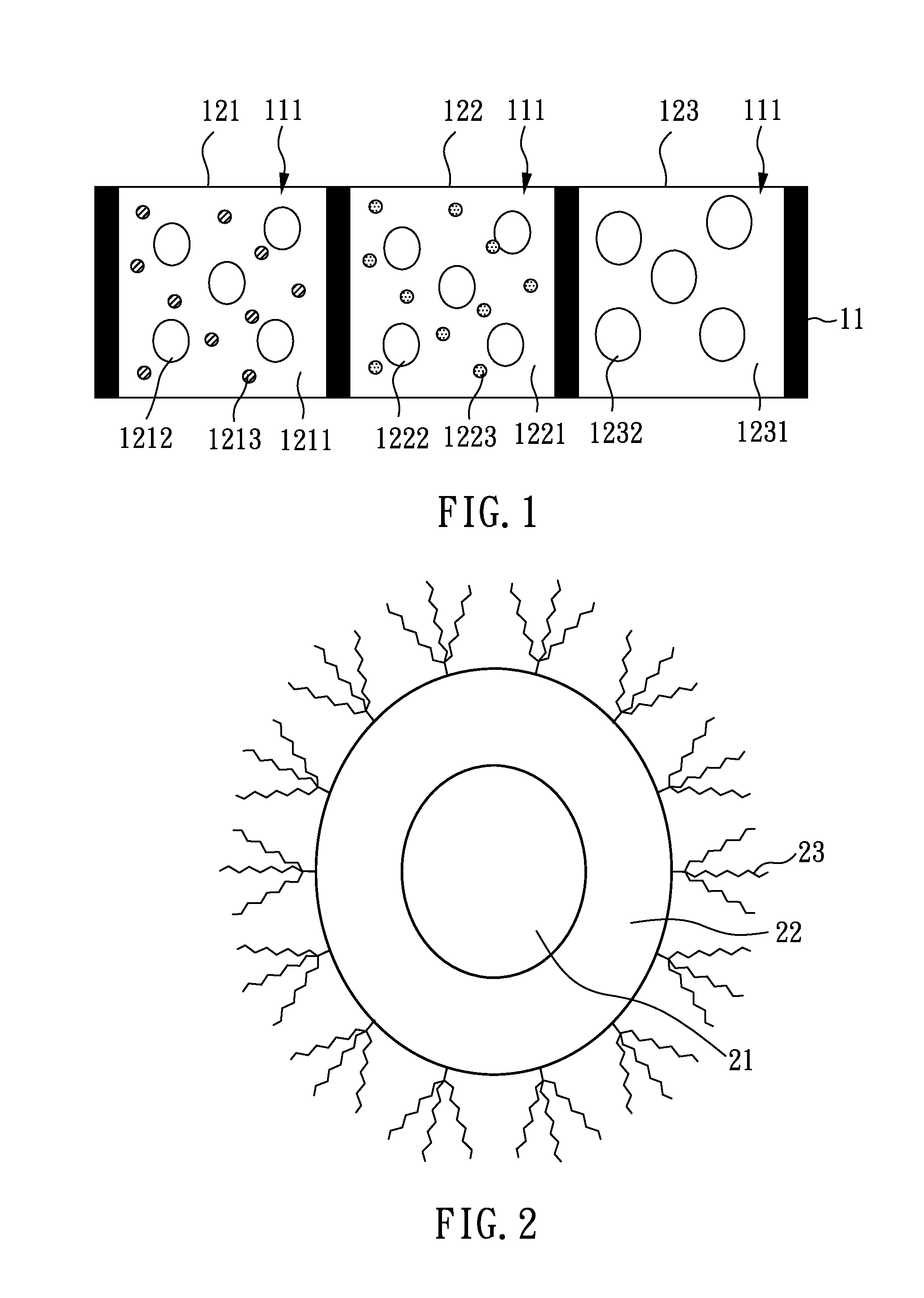

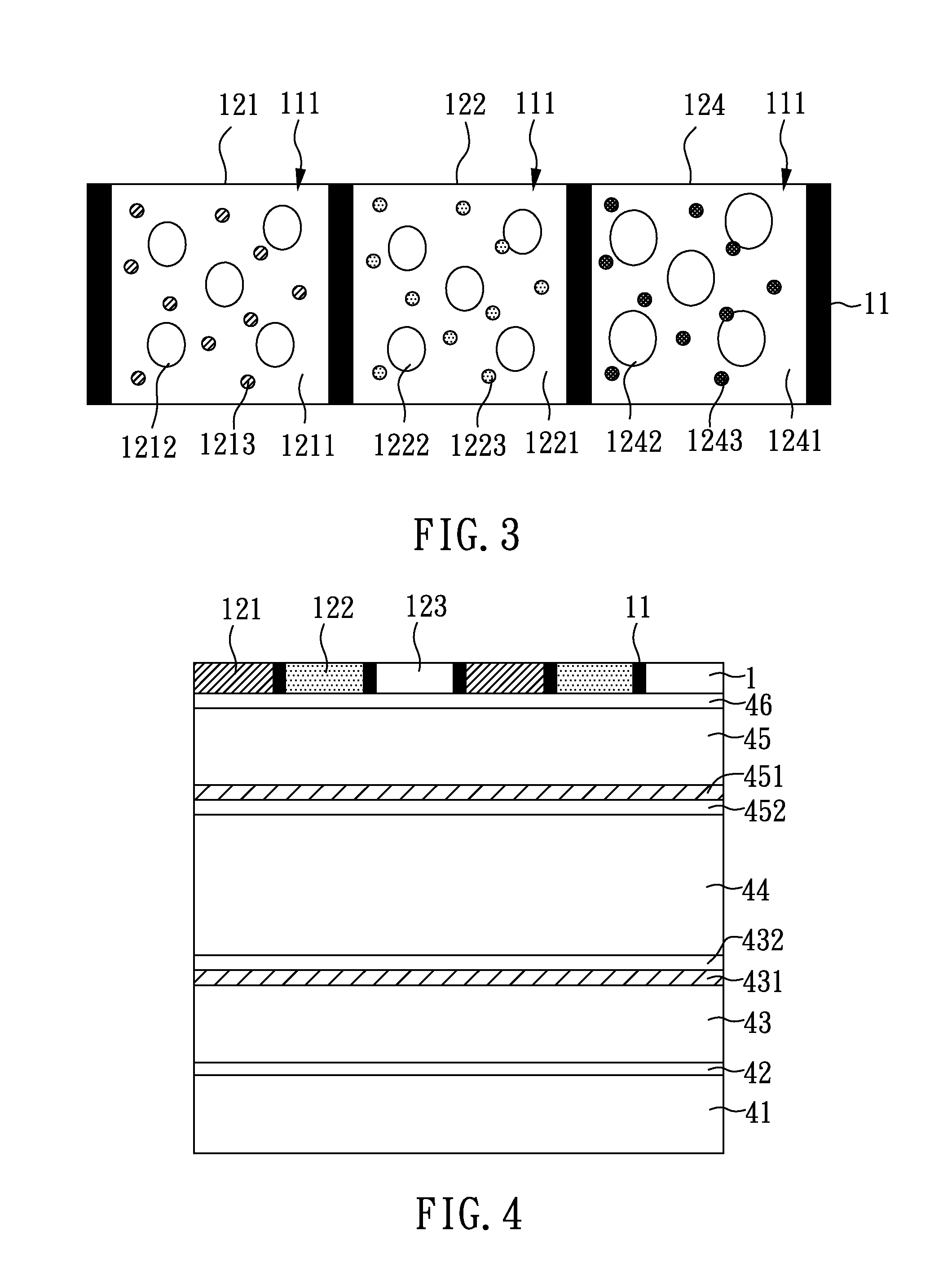

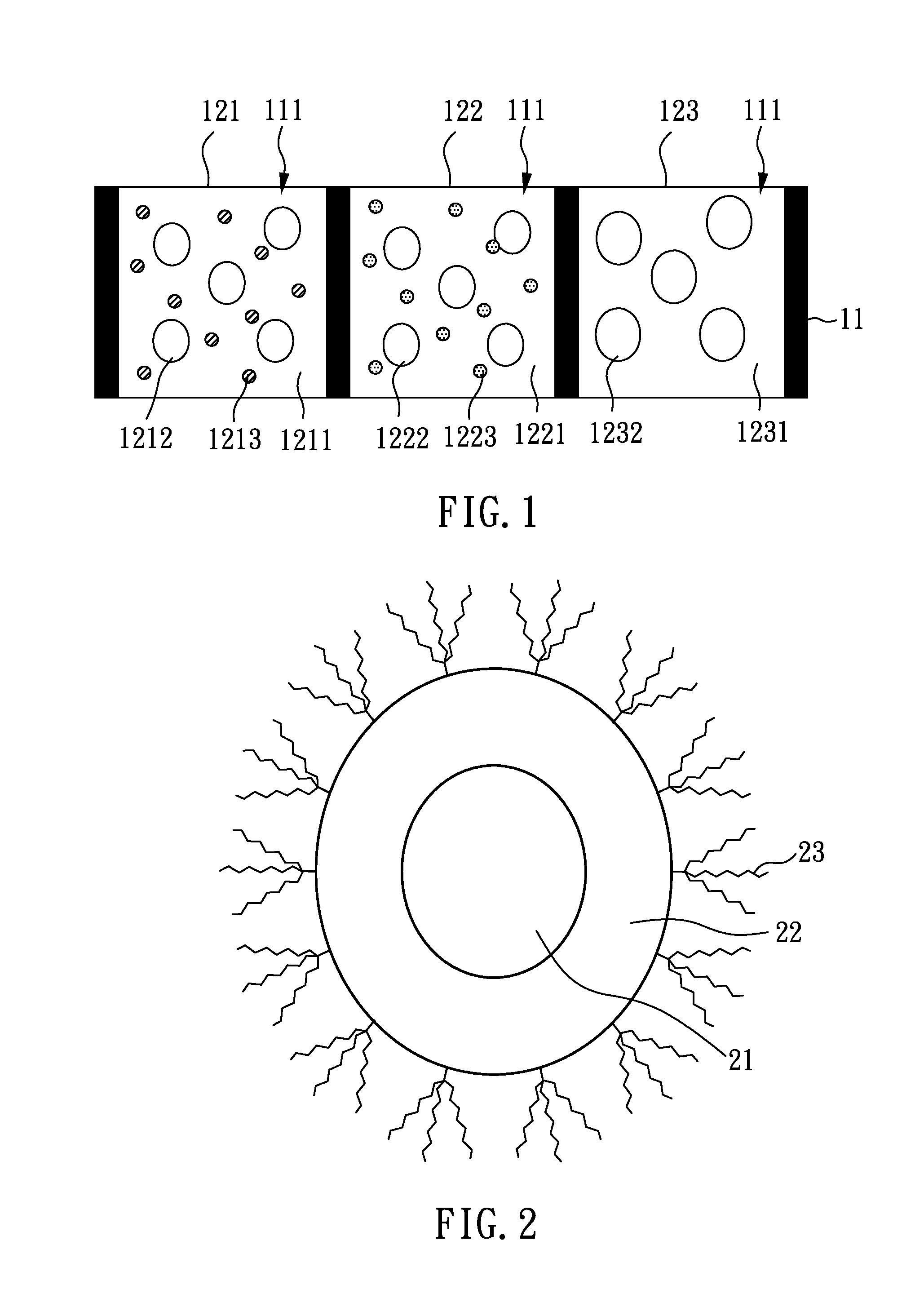

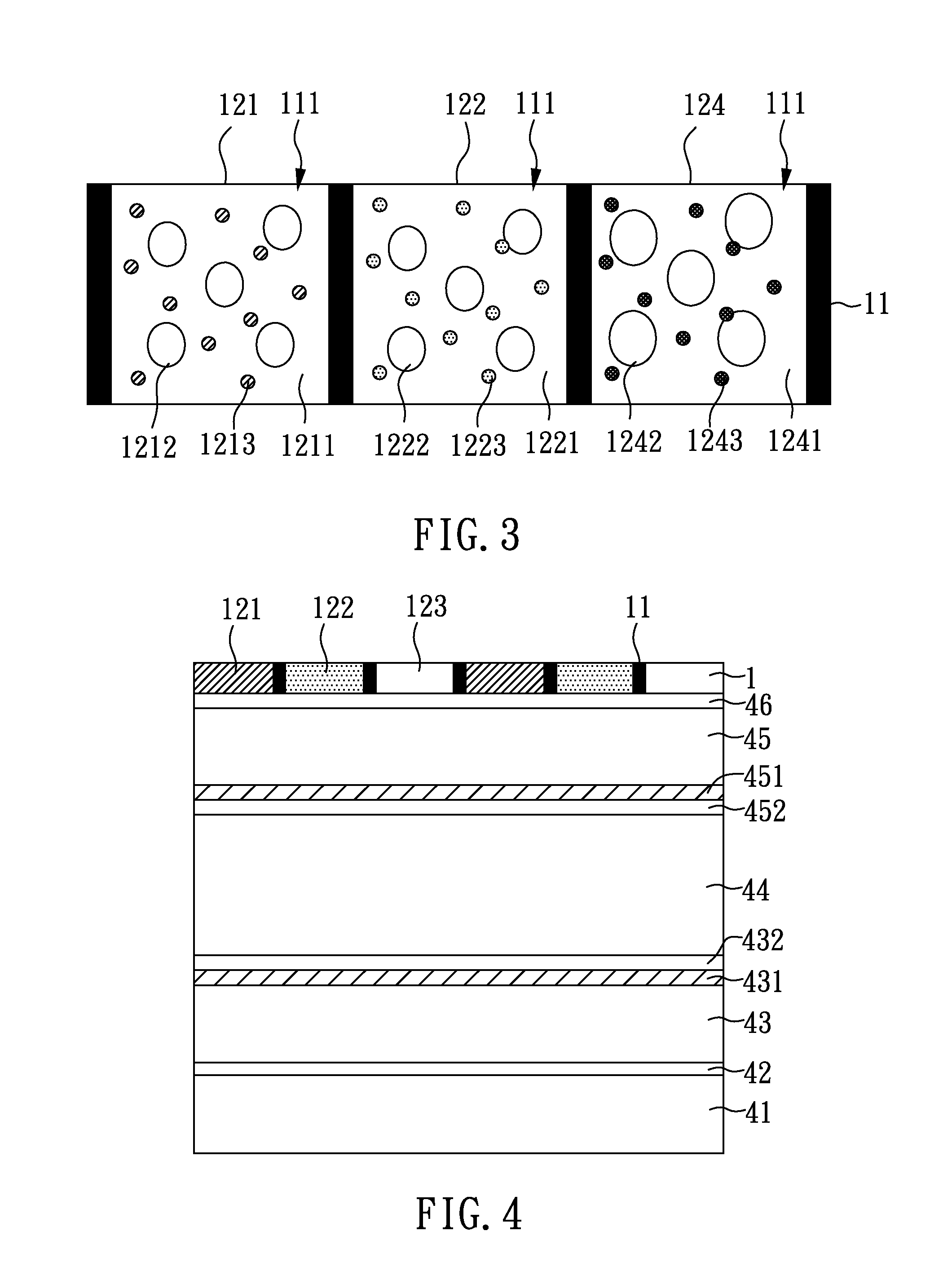

A patterned color conversion film and a display device using the same are disclosed. The patterned color conversion film of the present invention comprises: a separator with plural openings; and plural pixel units disposed in the openings respectively, each pixel unit respectively comprising: a medium and scattering particles dispersed therein. Herein, at least one of the plural pixel units comprises quantum dots having the scattering particles sized of between 0.05 and 1 μm when a volume concentration of the quantum dots is in a range more than or equal to 5% and less than or equal to 80%, or having the scattering particles sized of between 0.2 and 2 μm when the volume concentration of the quantum dots is in a range less than 5% and more than or equal to 0%.

Owner:INNOLUX CORP

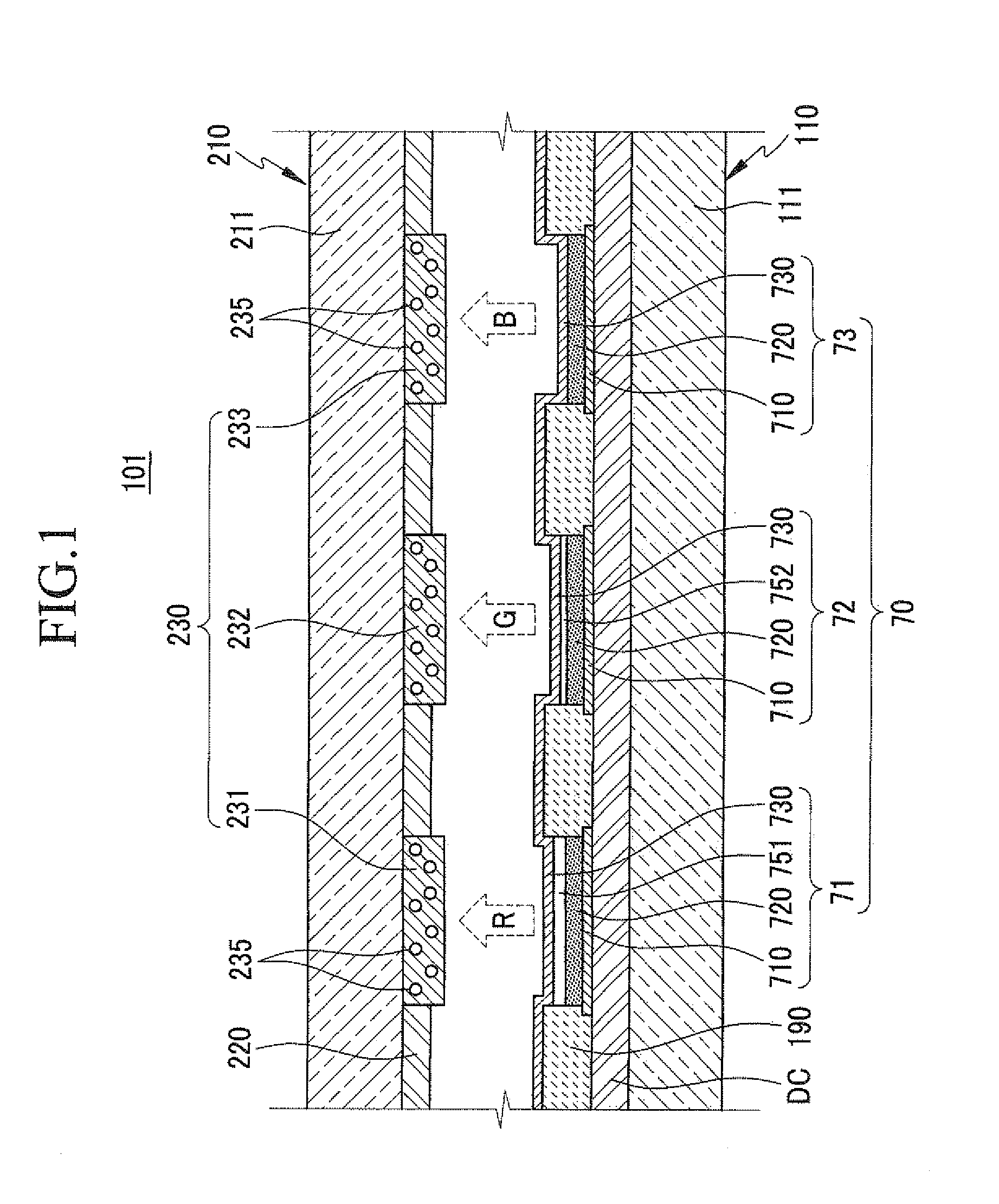

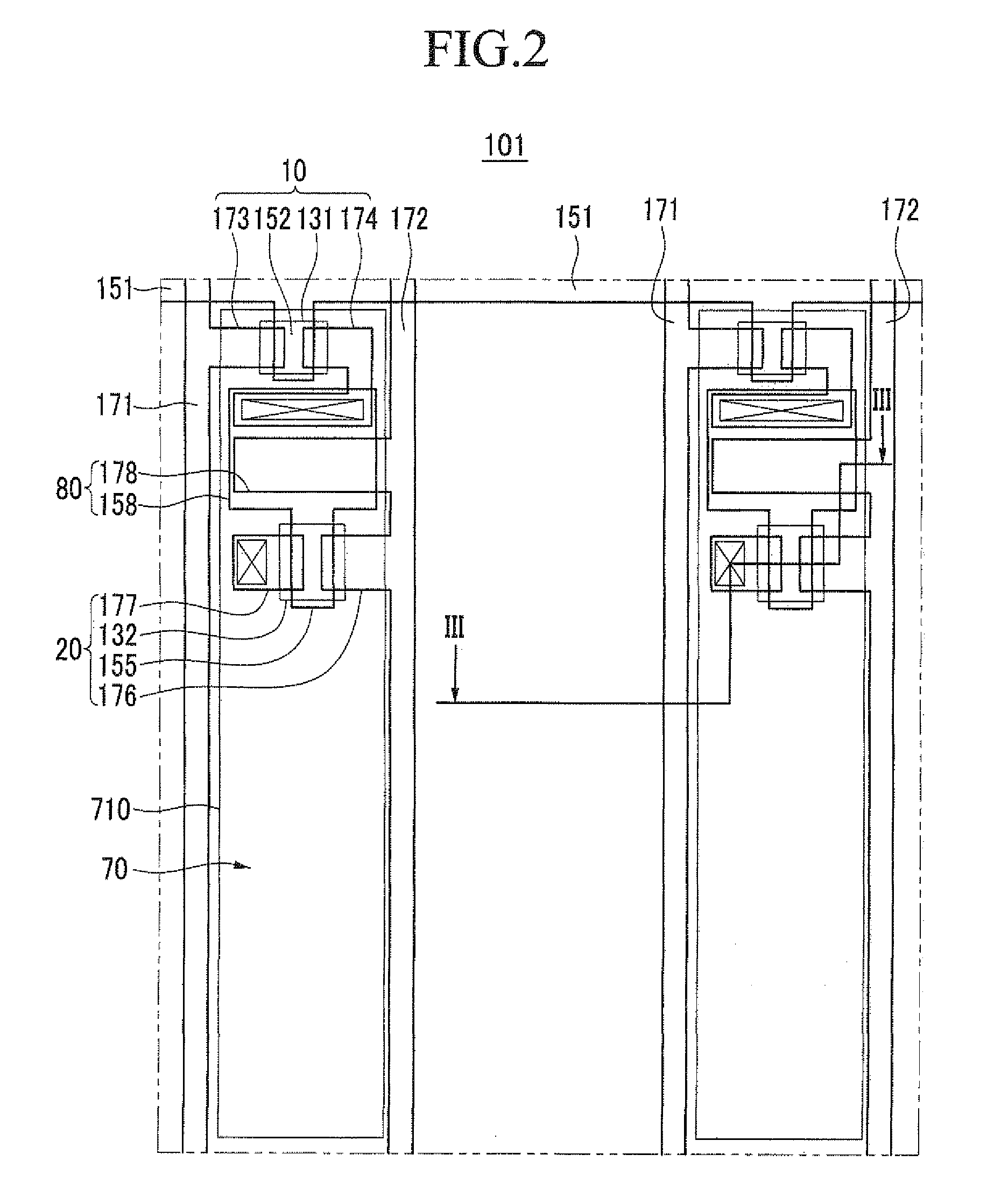

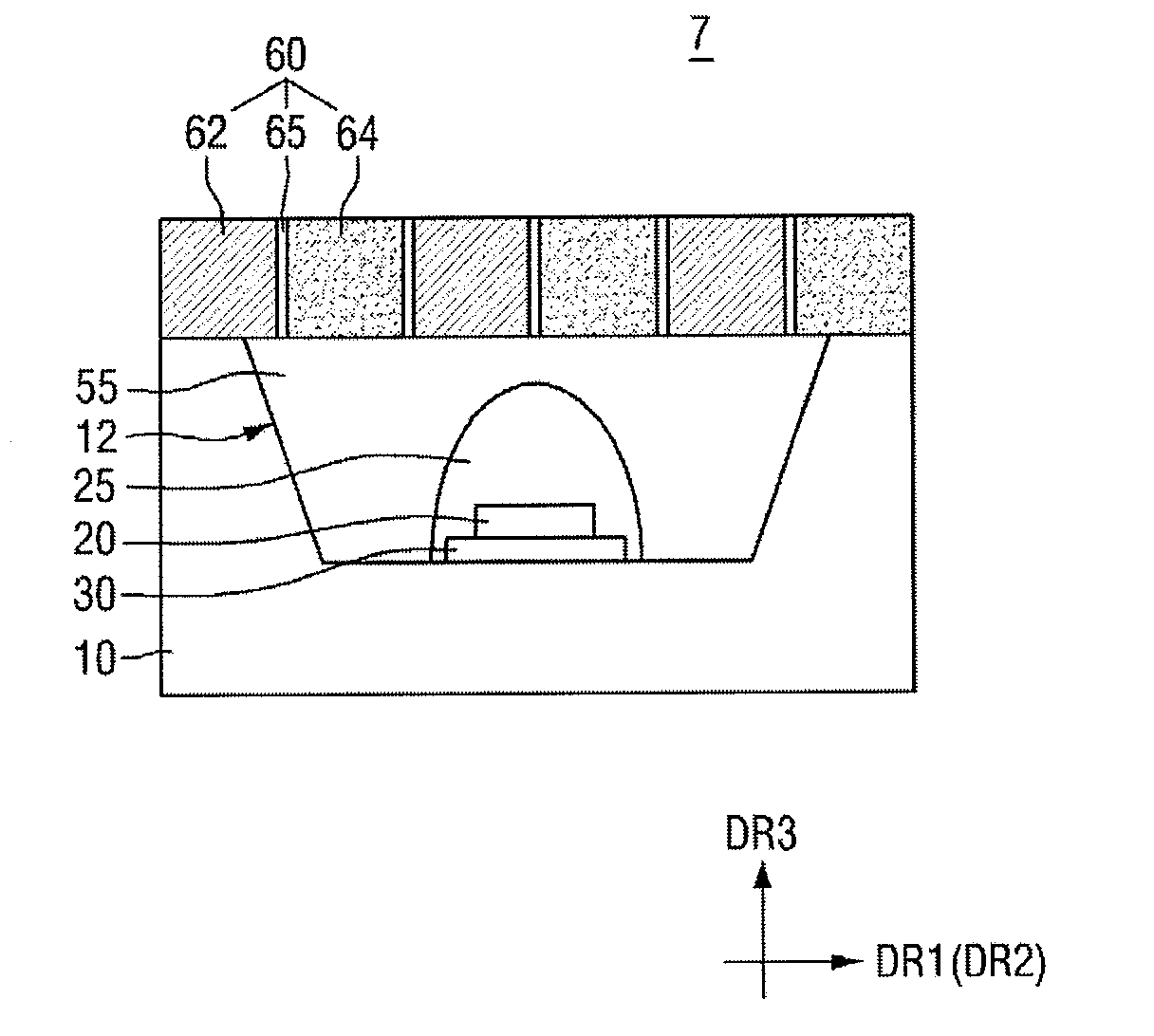

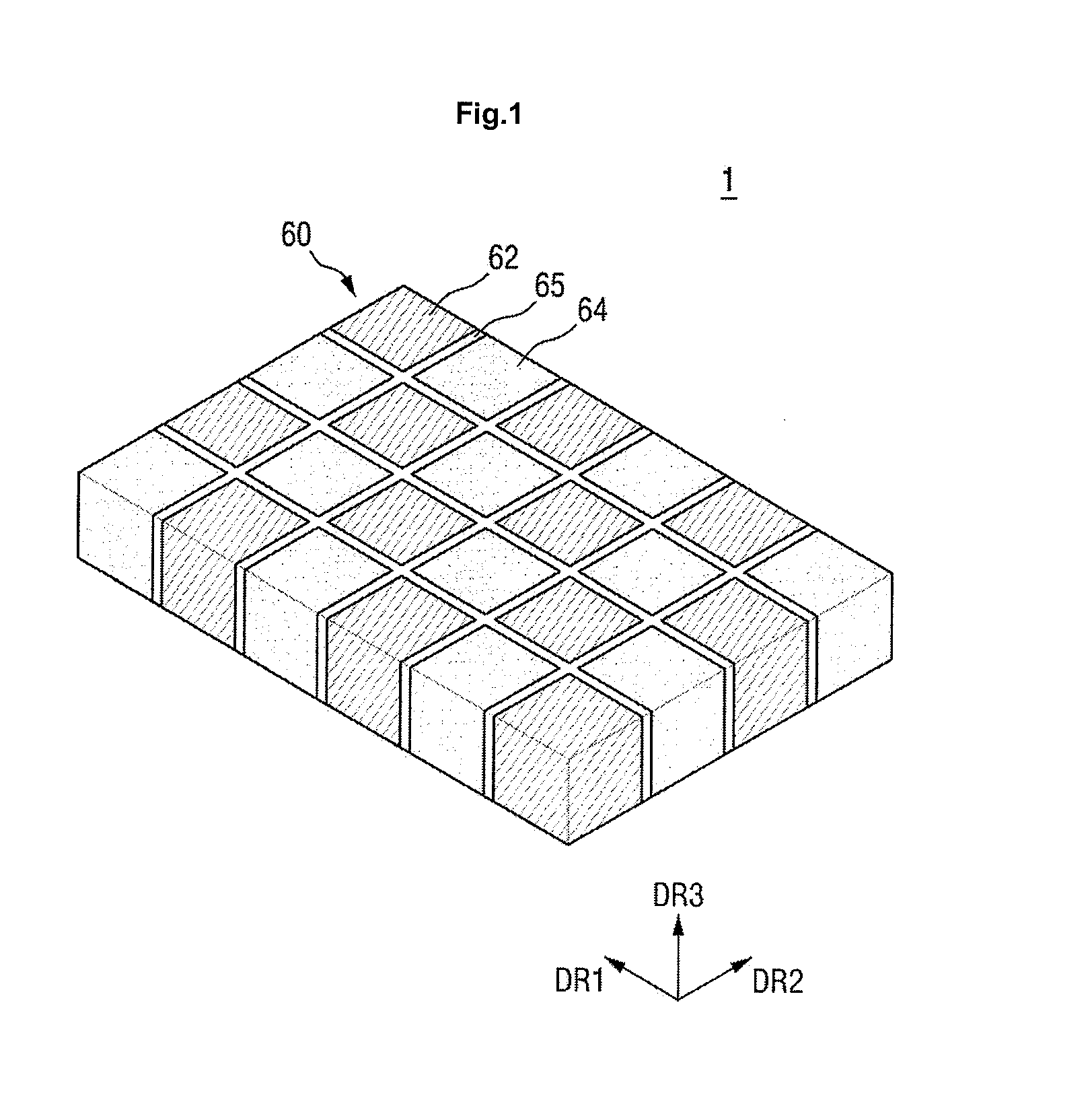

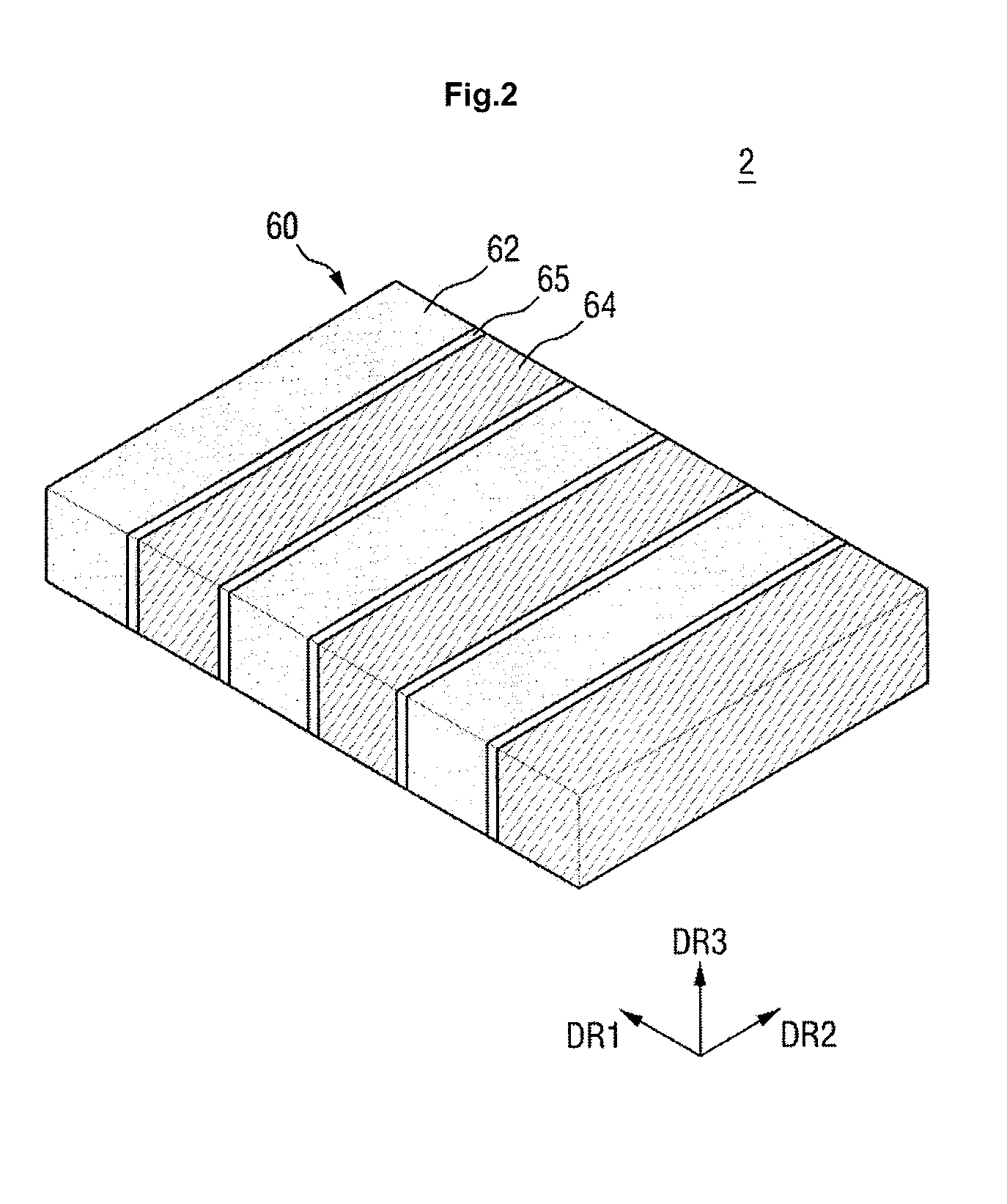

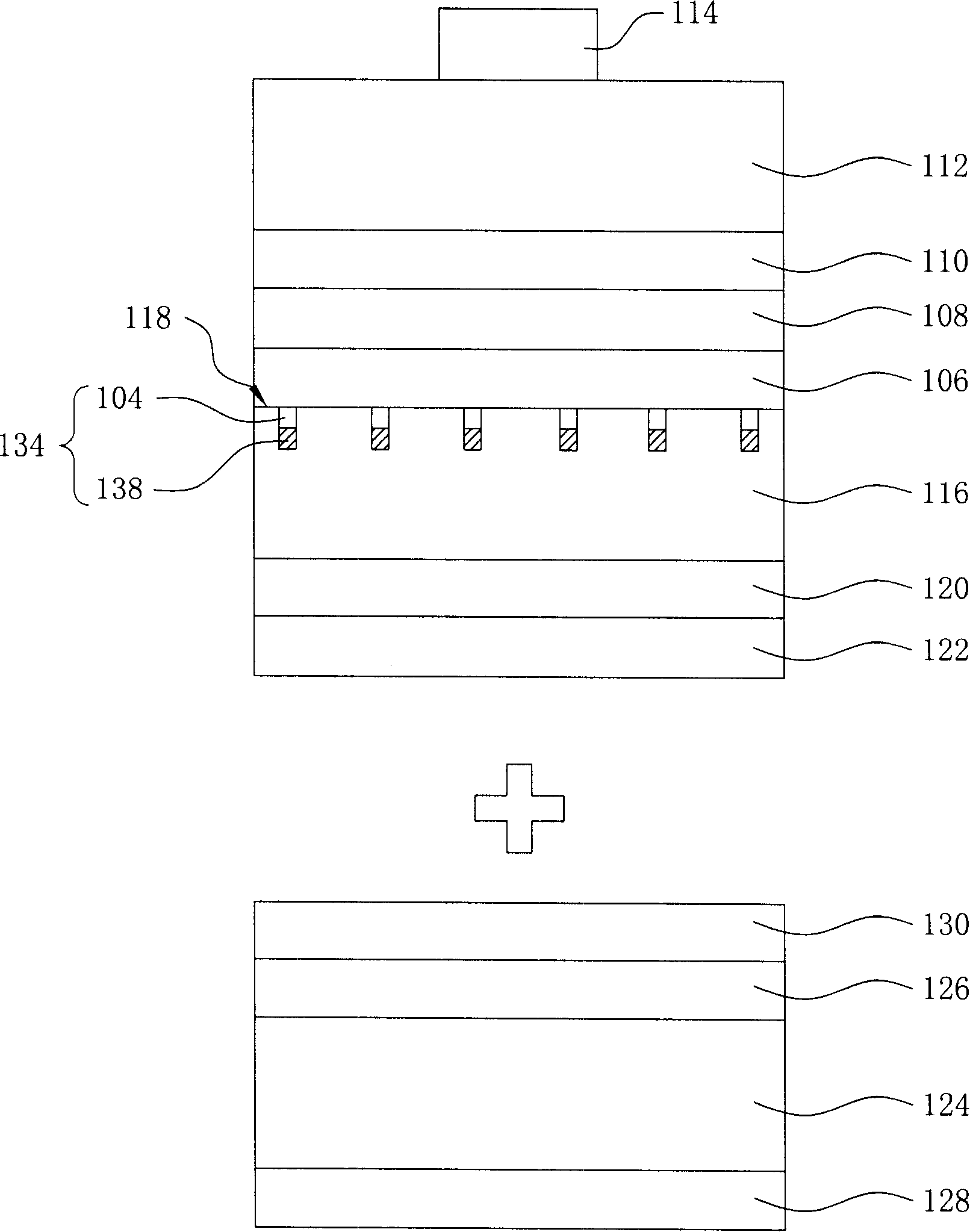

Organic Light Emitting Diode Display

ActiveUS20110042697A1Suppress reflection of external lightImprove light extraction rateOptical filtersSolid-state devicesDisplay deviceLight-emitting diode

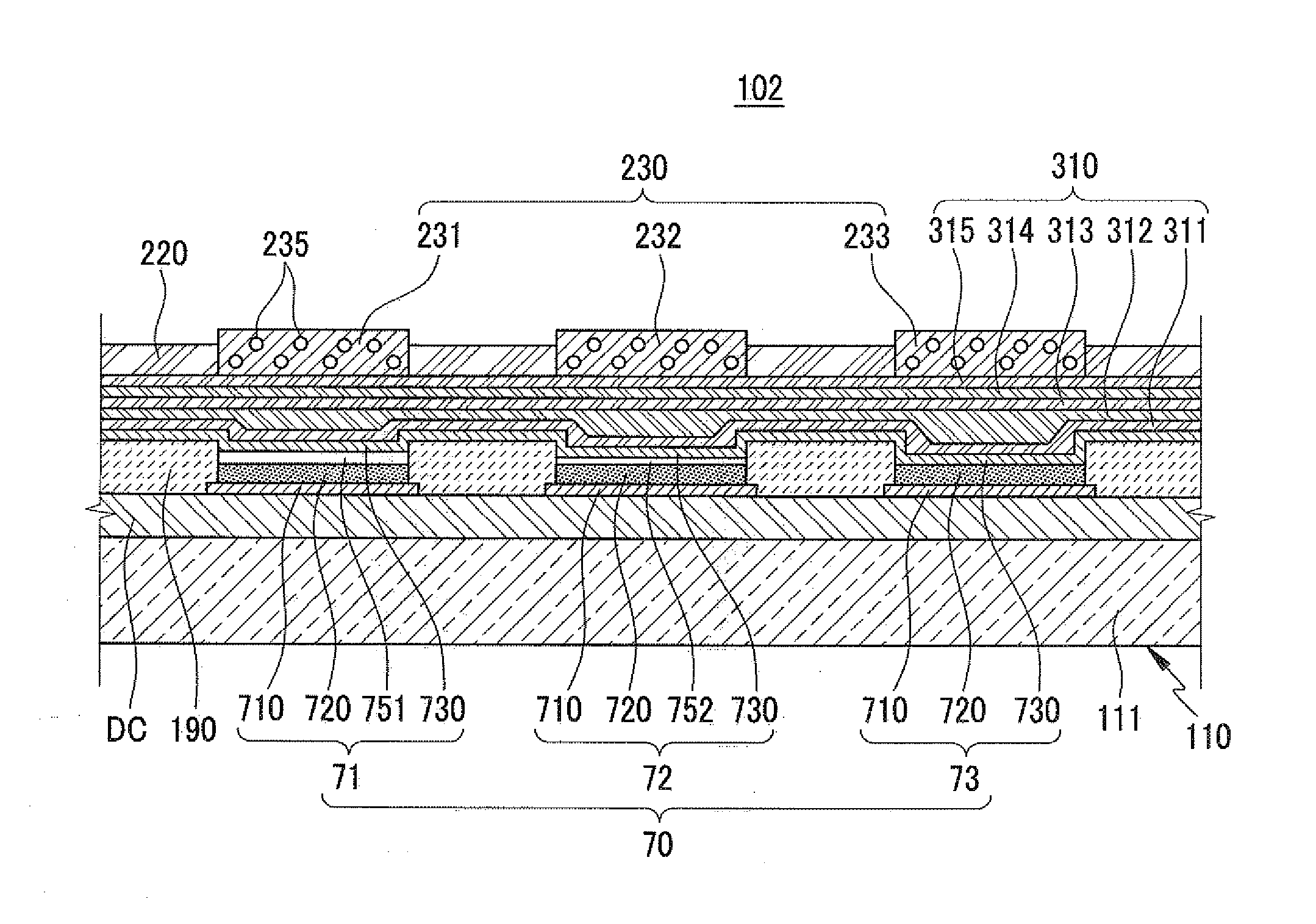

An organic light emitting diode display includes a display substrate including a plurality of organic light emitting diodes, a plurality of color filters on the plurality of organic light emitting diodes respectively corresponding thereto, and a plurality of light scattering particles dispersed in the plurality of color filters.

Owner:SAMSUNG DISPLAY CO LTD

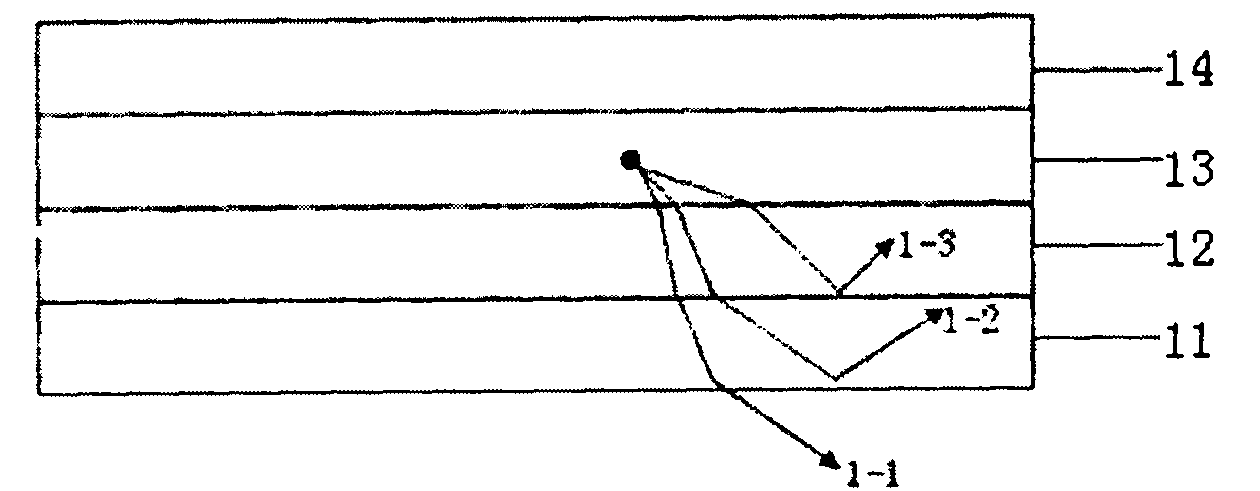

Patterning color conversion film and display device applying same

ActiveCN103917000AImprove light extraction rateImprove backlight utilizationElectrical apparatusElectroluminescent light sourcesMicrometerQuantum dot

The invention relates to a patterning color conversion film and a display device applying the same. The patterning color conversion film comprises a separator and a plurality of pixel units. The separator is provided with a plurality of openings in a separating mode, the pixel units are arranged in the openings respectively. Each pixel unit comprises a substrate and a plurality of scattering particles which are scattered in the substrate, at least one pixel unit comprises a plurality of quantum dots, wherein the volume percentage concentration of the pixel unit which comprises the quantum dots is larger than or equal to 5V% and smaller than or equal to 80V%, and the particle diameters of the scattering particles are 0.05-1 micrometer; or when the volume percentage concentration is smaller than 5V% and larger than or equal to 0V%, the particle diameters of the scattering particles are 0.2-2 micrometers.

Owner:INNOCOM TECH SHENZHEN +1

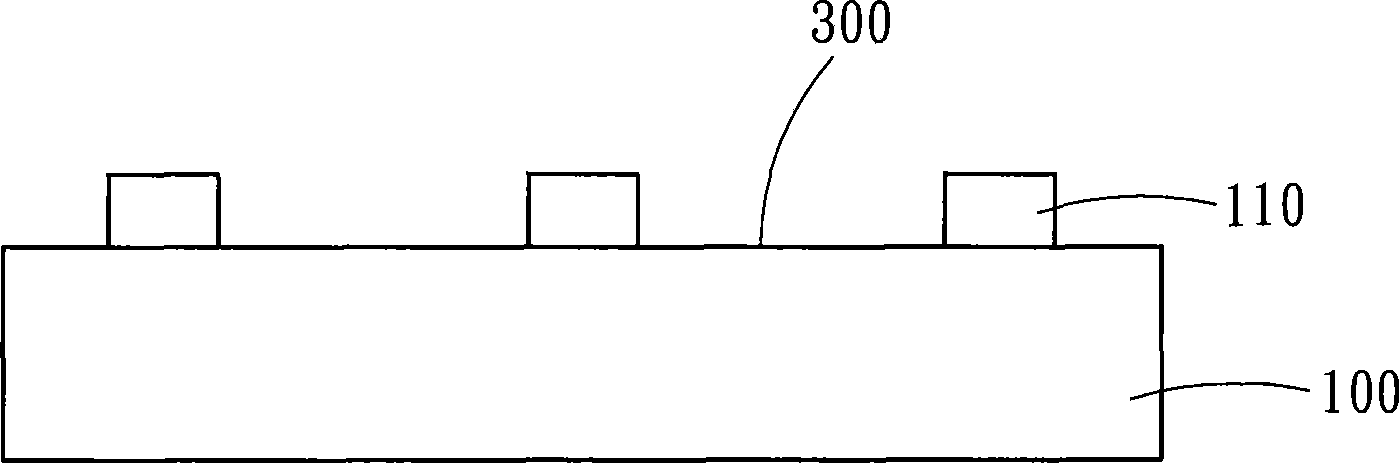

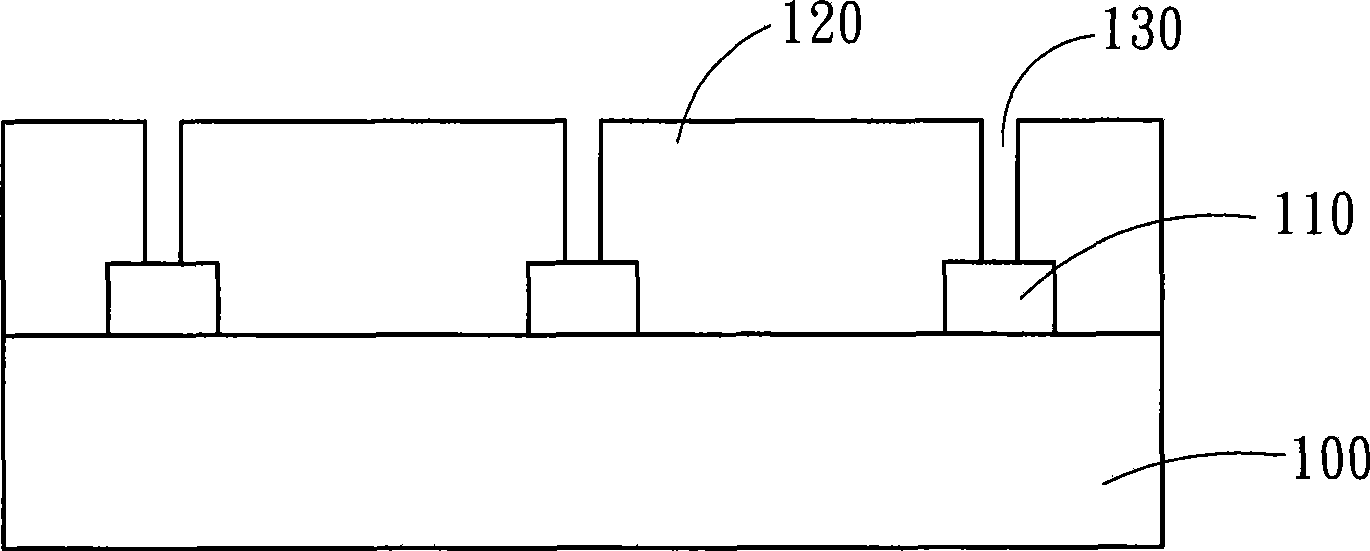

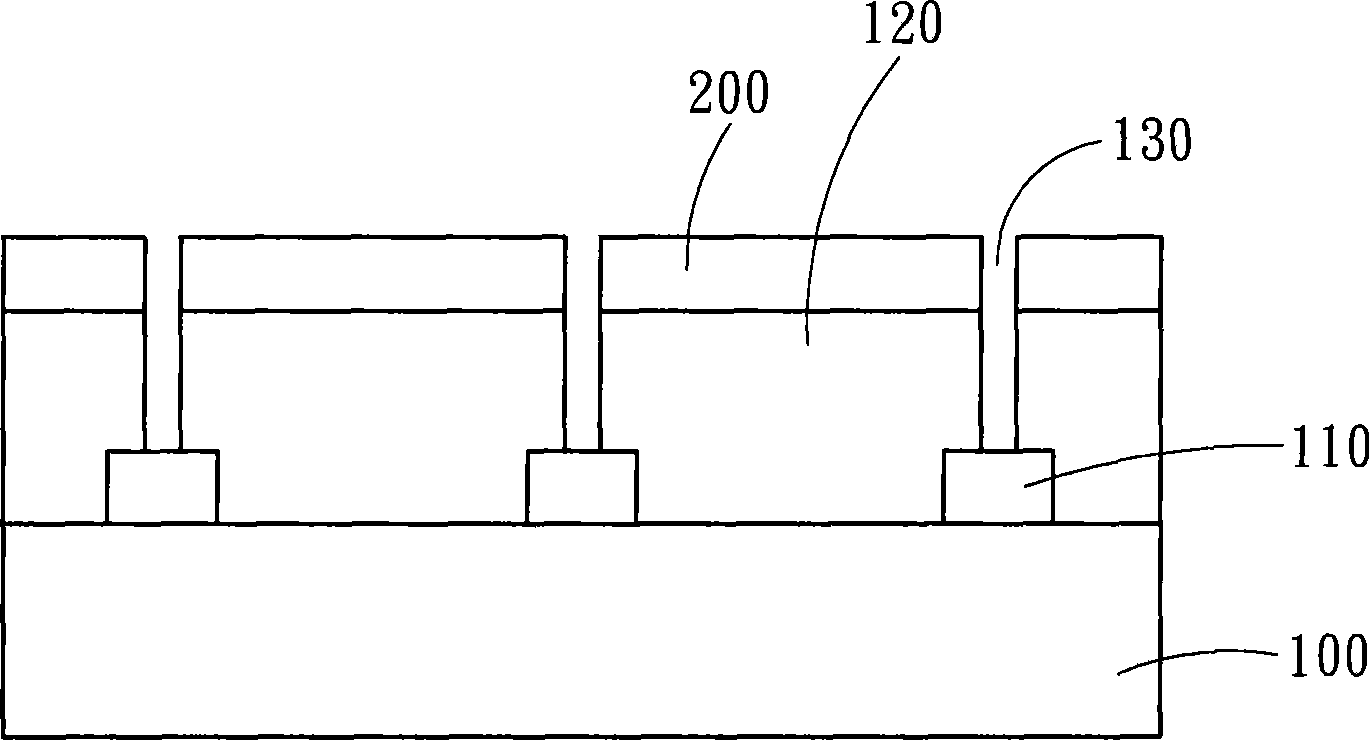

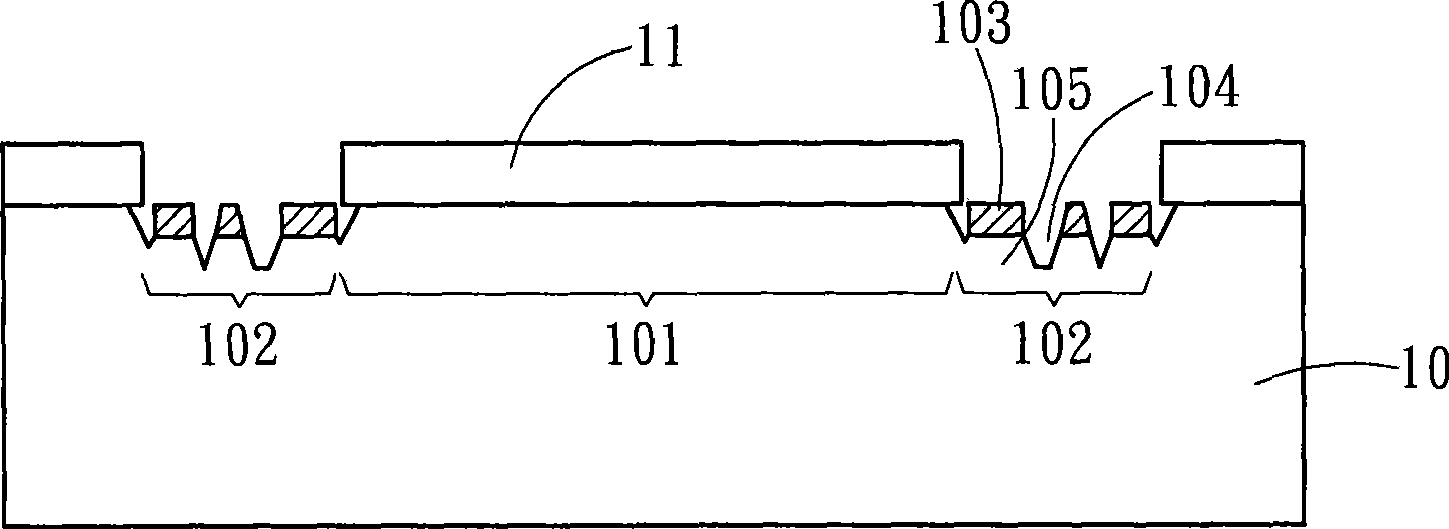

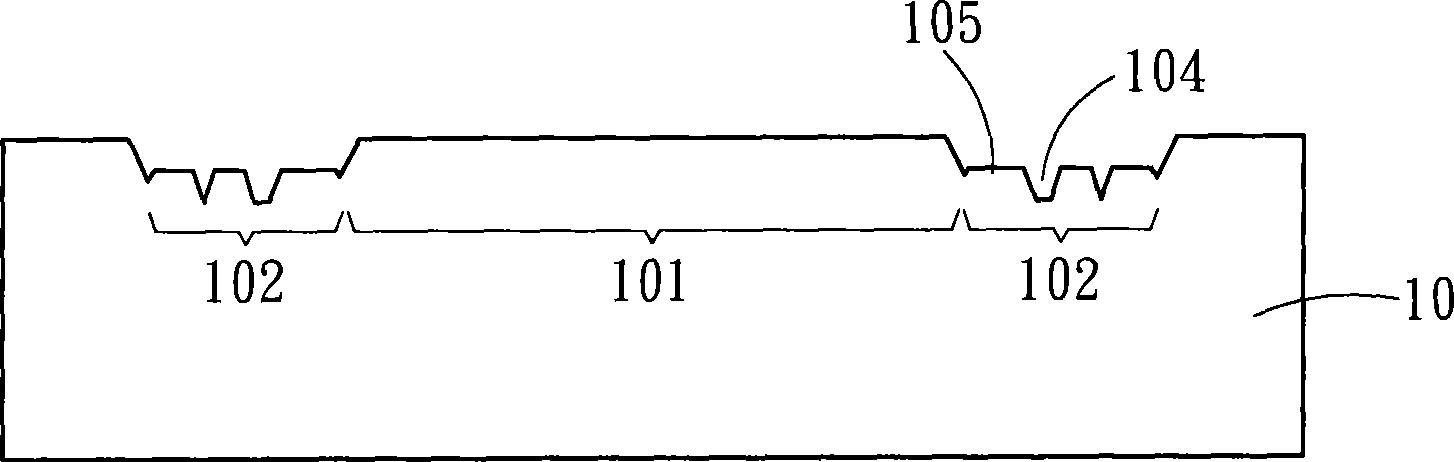

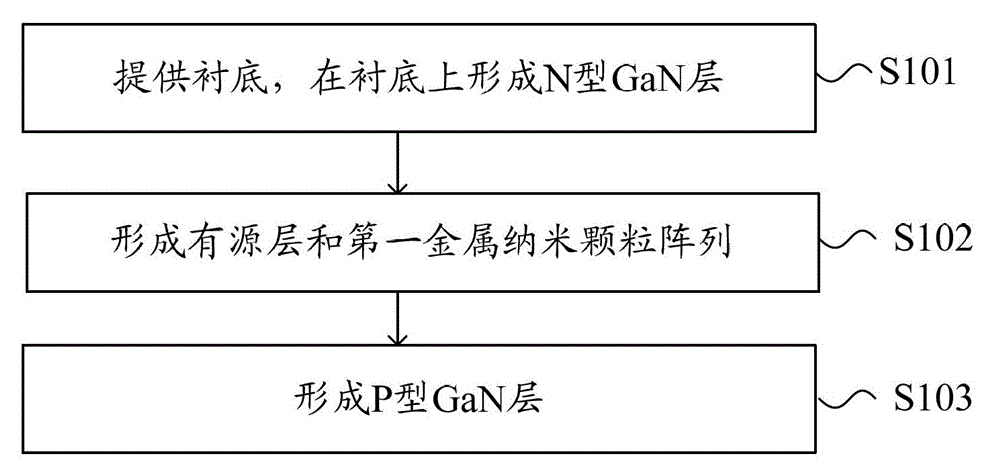

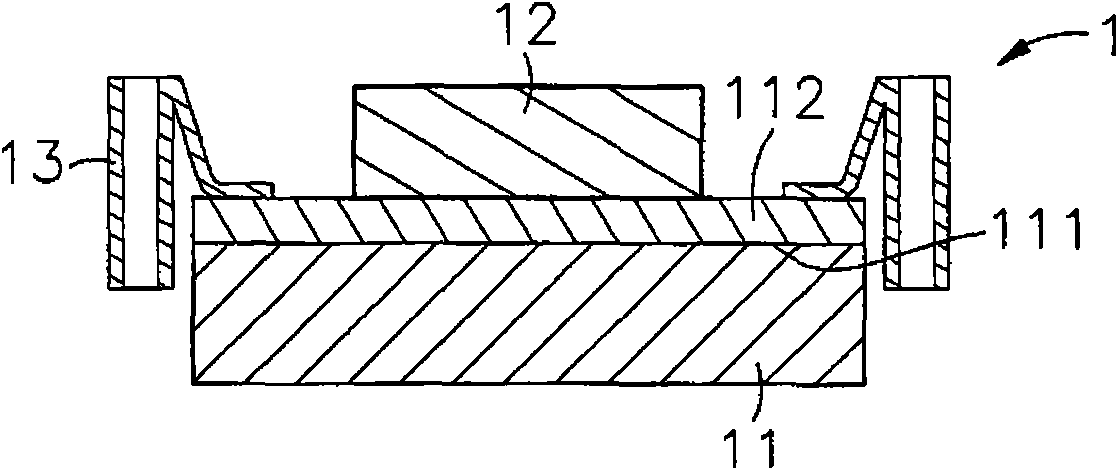

Manufacturing method of LED element

InactiveCN101388427AImprove light extraction rateImprove the phenomenon of total reflectionSemiconductor devicesLight-emitting diodeStructural shapes

The invention relates to a production method of a light-emitting diode, which comprises facilitating the epitaxial layer of the light-emitting diode to start etching from the bottom to form a structural shape whose side is overhung and projected through combining the epitaxial way and the etching way, and leading the epitaxial layer of the light-emitting diode to change into a non-rectangular inclined plane, thereby improving the phenomenon of interface total reflection of the light-emitting diode, and increasing the light sending rate of the light-emitting diode. The invention can reduce production cost owing to simple manufacture, and is suitable to be produced in industrialization.

Owner:TEKCORE CO LTD

Electroluminescence device based on boron-containing organic compound

ActiveCN110492006AImprove efficiencyExtend your lifeSolid-state devicesSemiconductor/solid-state device manufacturingOrganic light emitting deviceCharge carrier

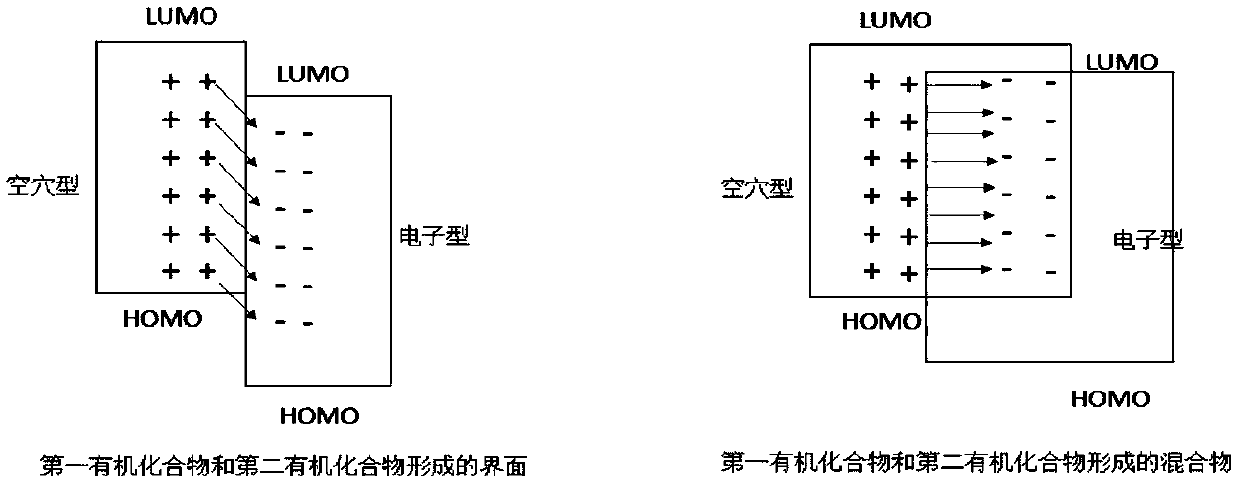

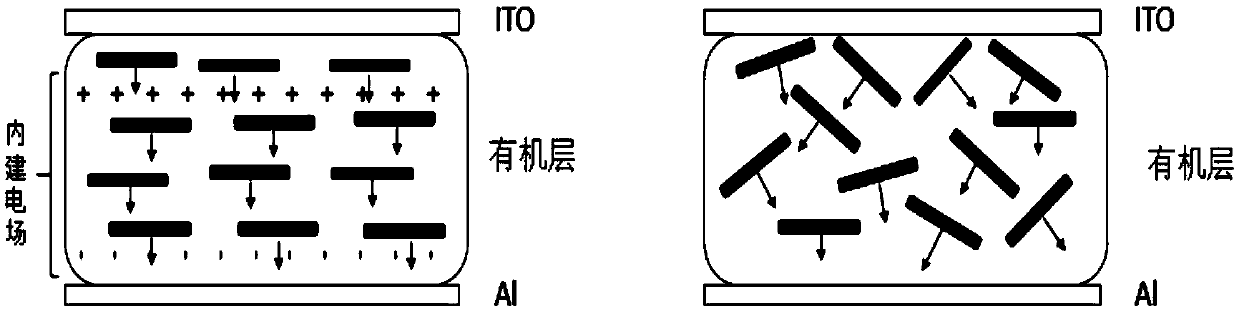

The present invention relates to an electroluminescence device based on a boron-containing organic compound, wherein a main body material comprises a first organic compound and a second organic compound, the difference between a singlet state energy level and a triplet state energy level of the first organic compound is not greater than 0.2 eV, the singlet energy level of the second organic compound is greater than the singlet energy level of the first organic compound by more than 0.1 eV, and the triplet energy level of the second organic compound is greater than the triplet energy level of the first organic compound by more than 0.1 eV; the first organic compound and the second organic compound have the different carrier transport characteristics, wherein an object material is the boron-containing organic compound, the singlet energy level of the object material is lower than that of the first organic compound, and the triplet energy level of the object material is lower than that ofthe first organic compound. An organic light-emitting device prepared by the method has the characteristics of high efficiency and long service life.

Owner:JIANGSU SUNERA TECH CO LTD

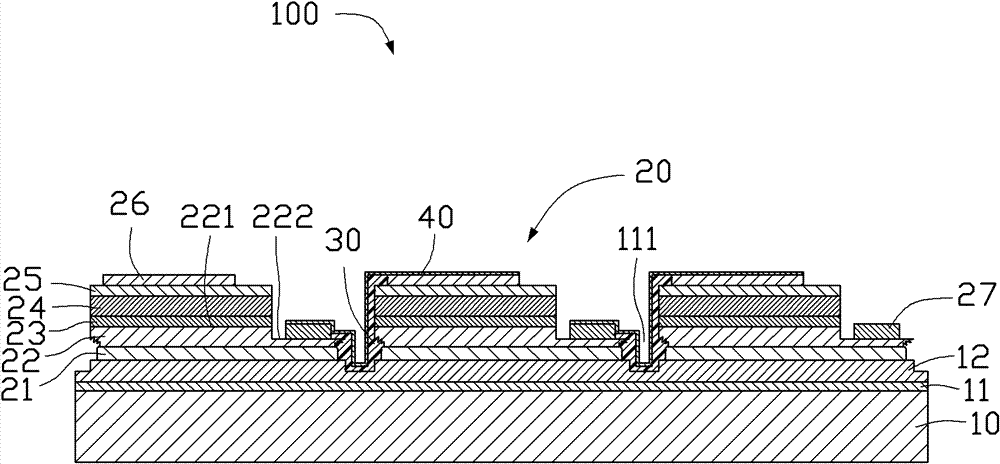

Active organic light-emitting diode (OLED) display device and manufacturing method thereof

ActiveCN103258968AImprove flatnessReduce contact resistanceSolid-state devicesSemiconductor/solid-state device manufacturingElectrical resistance and conductanceDisplay device

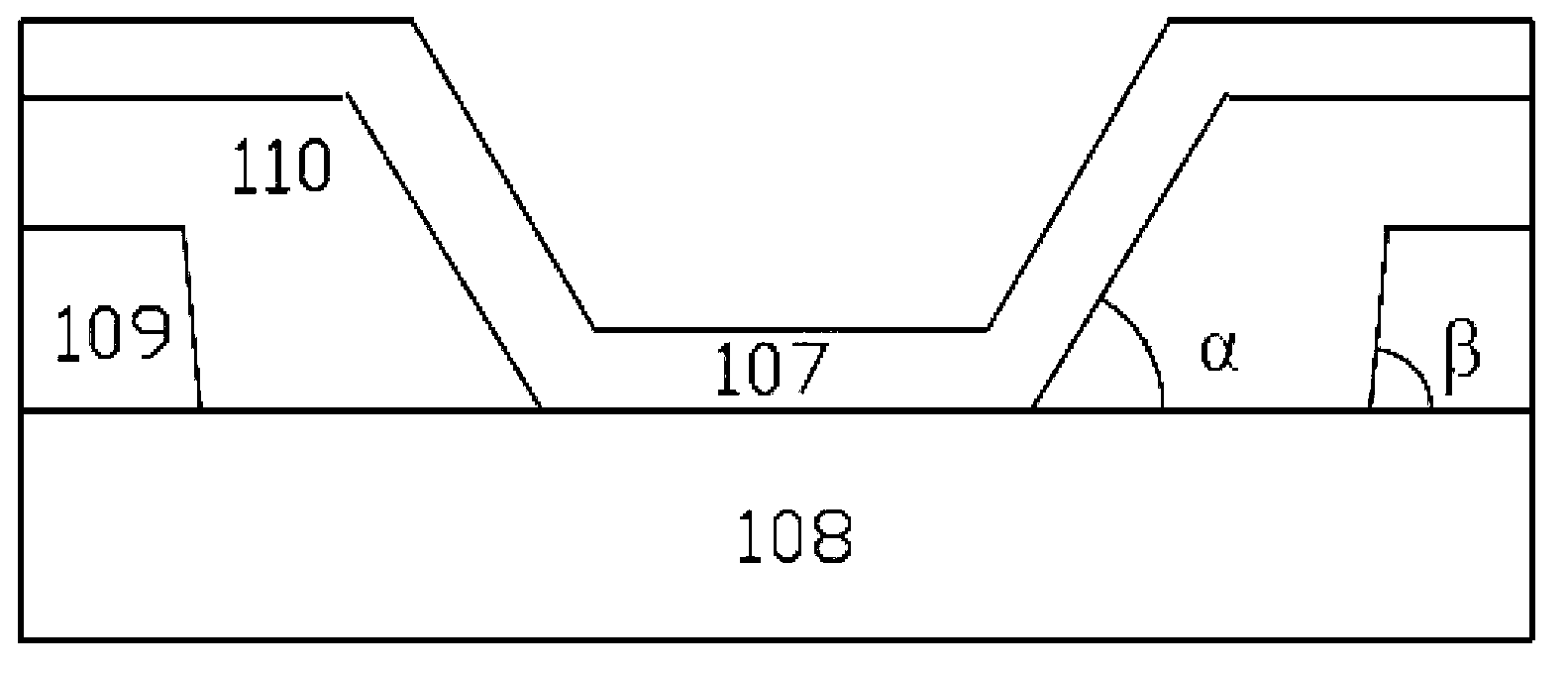

The invention provides an active organic light-emitting diode (OLED) display device and a manufacturing method thereof. The active OLED display device comprises a display area and a non-display area. The non-display area comprises a negative electrode power line, wherein an insulating layer is arranged on the negative electrode power line, a planarization layer further covers the insulating layer and extends to and covers the negative electrode power line, and a gradient included angle alpha formed by the planarization layer and the contact surface of the negative electrode power line is smaller than a gradient included angle beta formed by the insulating layer and the contact surface of the negative electrode power line, so transition is flatly and slowly formed from a negative electrode to the negative electrode power line, smoothness from the negative electrode to the contact area of the negative electrode power line is increased, and contact resistance is effectively reduced. The planarization layer covers a non-pixel area of a positive electrode, and the thickness of the planarization layer is larger than or equal to the sum of the thickness of the positive electrode, the thickness of an organic functional layer and the thickness of the negative electrode, so a pixel area can be protected against scratching, the rate of finished products of the display device is effectively guaranteed, a manufacturing process is simple, and the process is easy to achieve.

Owner:KUNSHAN NEW FLAT PANEL DISPLAY TECH CENT

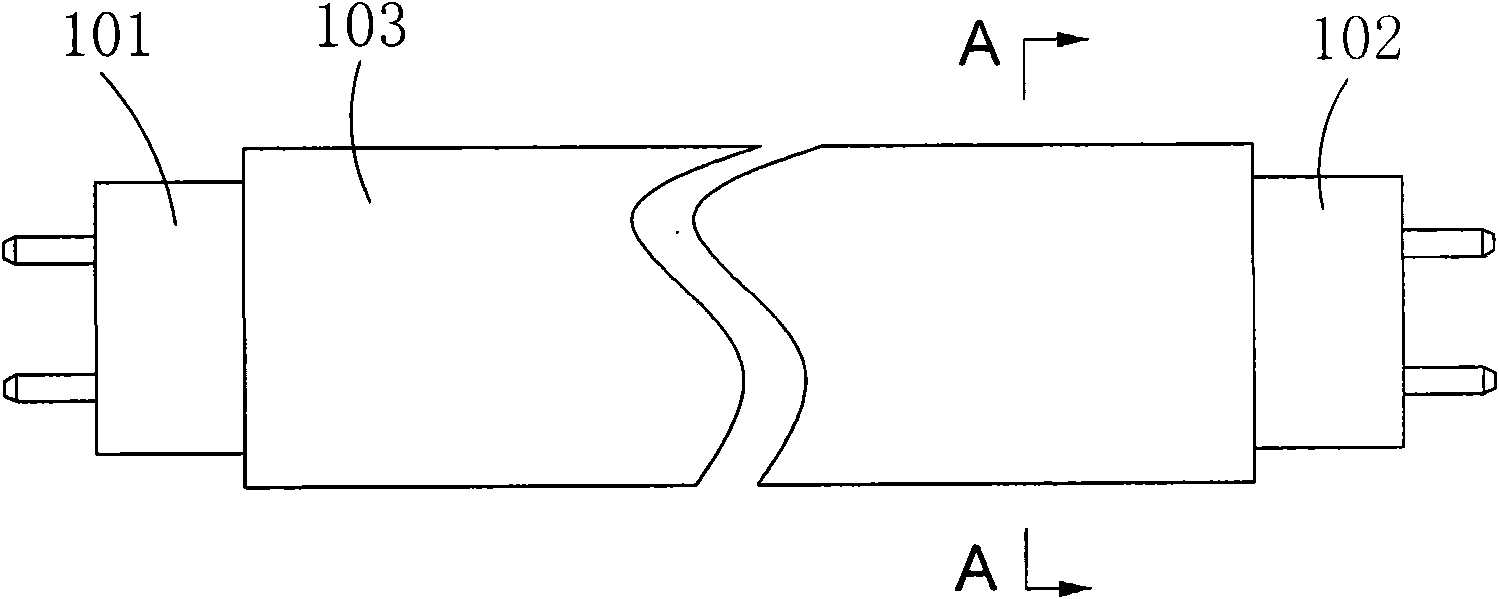

Phosphor film, and light emitting device and system using the same

InactiveUS20140264419A1Improve light extraction rateSolid-state devicesNatural mineral layered productsPhosphorQuantum dot

Phosphor film, and light emitting device and system using the same are provided. The light emitting device comprises a package body, a light emitting element disposed on the package body to generate first light, one or more first quantum dot phosphor layers formed above the light emitting element to perform wavelength conversion of the first light and generate second light, and one or more second quantum dot phosphor layers formed above the light emitting element so as not to overlap with the first quantum dot phosphor layers to perform wavelength conversion of the first light and generate third light different from the second light.

Owner:UNIV IND FOUND UIF

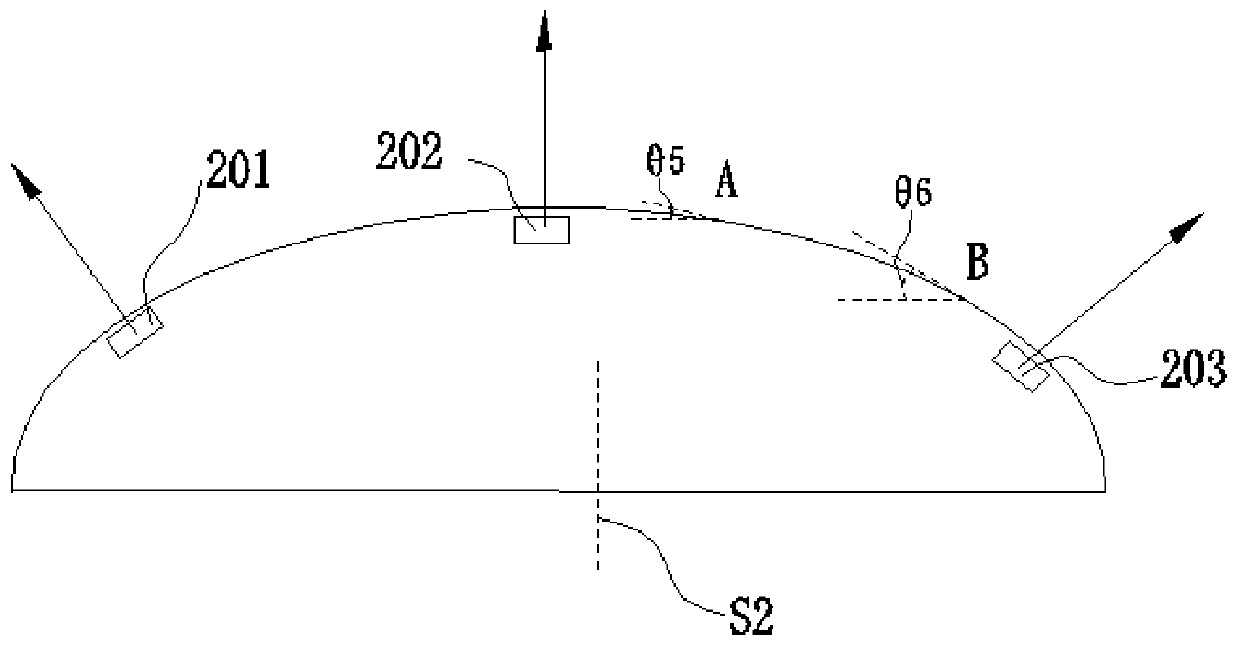

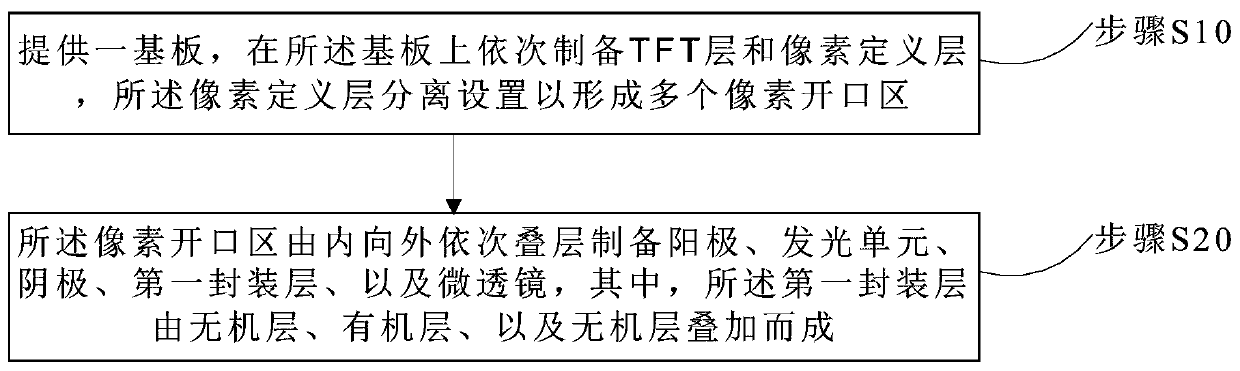

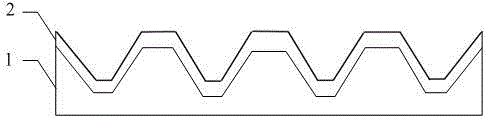

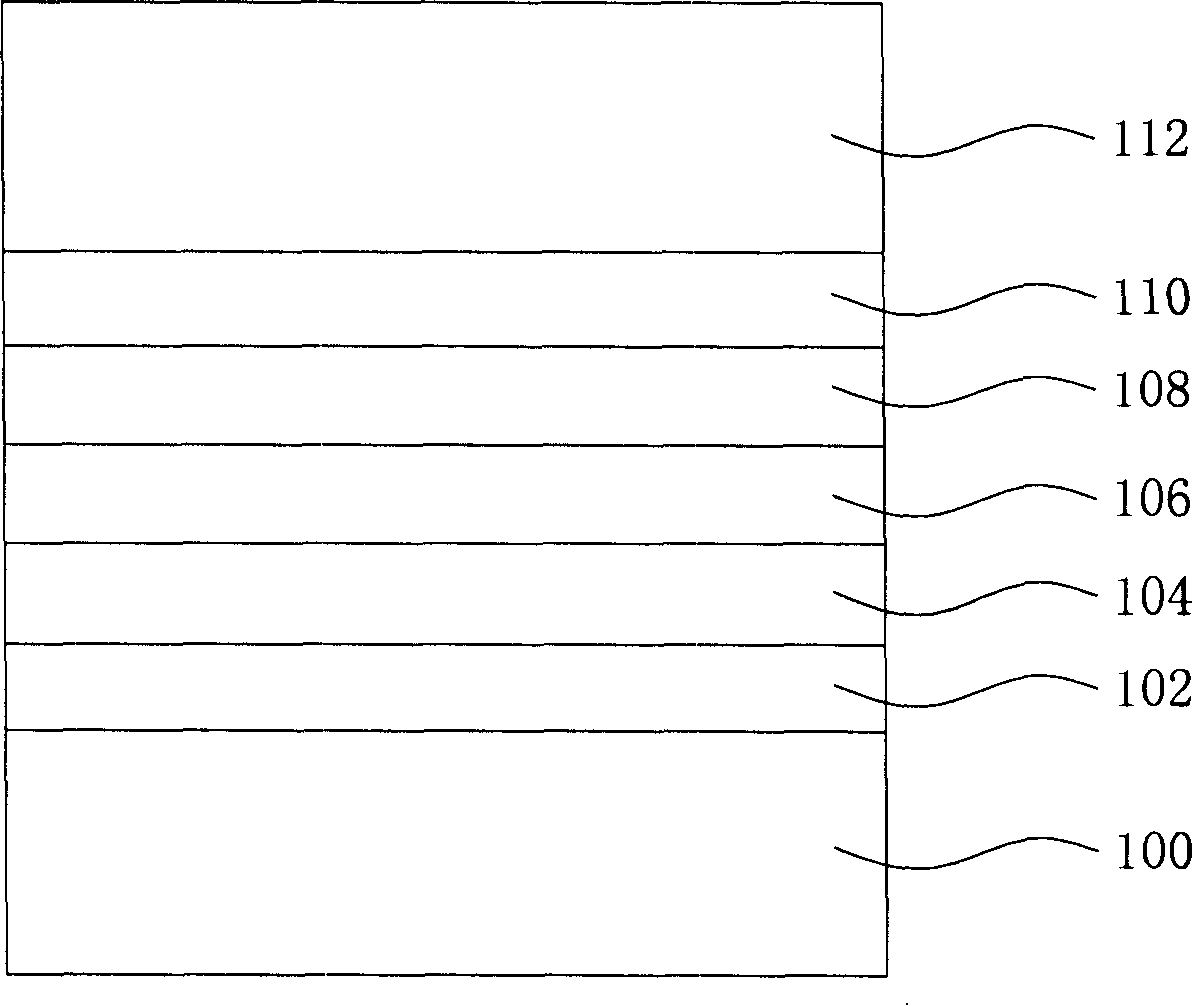

OLED display panel and preparation method thereof

ActiveCN111276515AImprove light extraction rateImprove the viewing angle problemSolid-state devicesSemiconductor/solid-state device manufacturingRefractive indexMaterials science

The invention provides an OLED display panel and a preparation method thereof. Each pixel opening area is provided with a first micro lens and a second micro lens; the first micro lens is positioned in the pixel opening area, is exposed of and seals the pixel opening area; the second micro lens and the first micro lens are arranged in an aligned manner; the second micro lens covers the first microlens and the pixel opening area; wherein a first planarization layer is arranged between the first micro lens and the second micro lens, a second planarization layer is arranged on the surface of thesecond micro lens, and the refractive index of the first micro lens is smaller than that of the first planarization layer, so that the first micro lens enables the visual angle of emergent light to be narrowed, and more light is emitted to the second micro lens; the refractive index of the second micro lens is greater than that of the second planarization layer, and the emission angle of the emergent light of the second micro lens is increased, so that the display visual angle of the OLED is enlarged, and the double-layer micro lens can improve the light extraction rate of the OLED display panel and improve the display visual angle.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

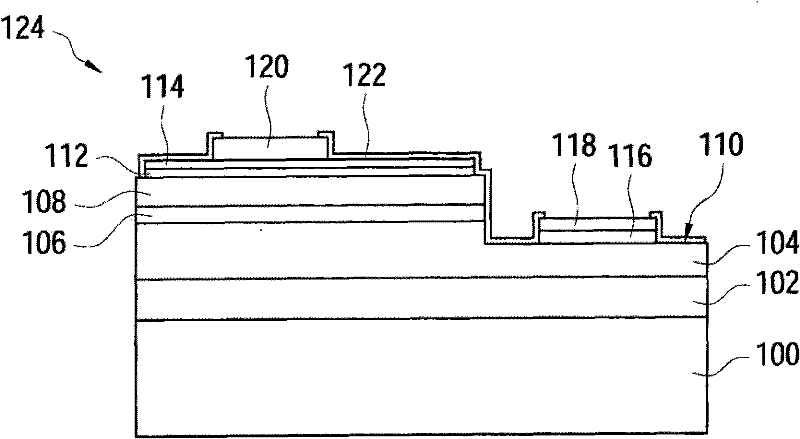

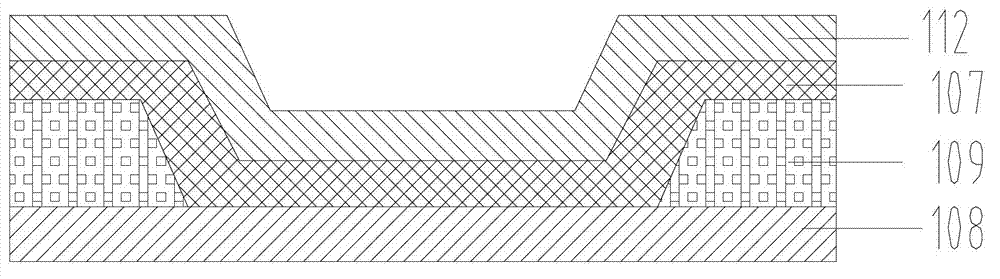

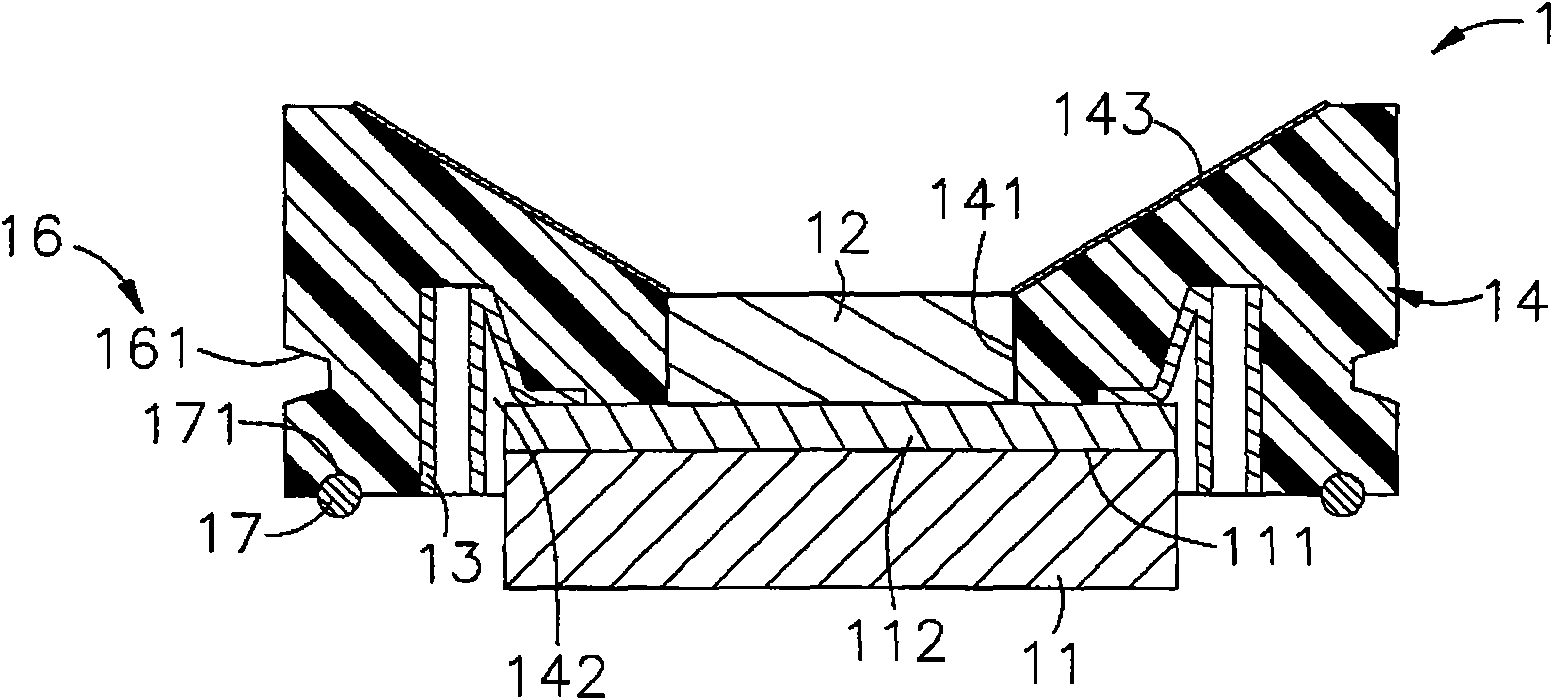

LED (Light Emitting Diode) structure and manufacturing method thereof

InactiveCN102447016AReduce difficultyImprove light extraction rateSemiconductor devicesEngineeringReflective layer

The invention discloses an LED (Light Emitting Diode) structure and a manufacturing method thereof. The LED structure comprises a base plate, a light emitting epitaxy structure, a first electric contact layer, a second electric contact layer, a transparent insulating layer, a first reflection layer, a second reflection layer, a first barrier layer, a second barrier layer, a first electric electrode and a second electric electrode. The first electric contract layer and the second electric contact layer are respectively arranged on a first electric semiconductor layer and a second electric semiconductor layer which are in a light emitting epitaxy structure. The transparent insulating layer covers the light emitting epitaxy structure, the first electric contact layer and the second electric contact layer and comprises a first contact window and a second contact window which respectively expose the first electric contact layer and the second electric contact layer. The first reflection layer and the second reflection layer respectively cover the first contact window and the second contact window and extend on the transparent insulating layer. The first barrier layer and the second barrier layer respectively cover the first reflection layer and the second reflection layer. The first electric electrode and the second electric electrode are respectively arranged on the first barrier layer and the second barrier layer and fully fill the first contact window and the second contact window.

Owner:佛山市奇明光电有限公司 +1

LED structure and manufacturing method thereof

InactiveCN101414653AImprove light extraction rateReduced instances of lateral spreadSemiconductor devicesChemical reactionLithography process

The invention discloses an LED structure and a fabrication method. The method comprises the following steps: placing a substrate in a solution for reaction; naturally forming a chemical reaction layer on the surface of a cutting street region of the substrate; forming a plurality of concave parts and convex parts on the surface of the cutting street region by selective etching; growing a semiconductor layer structure on a component region and the cutting street region on the surface of the substrate by an epitaxial growth technology; and then forming the LED by the semiconductor layer structure on the component region using yellow light lithography process.

Owner:TEKCORE CO LTD

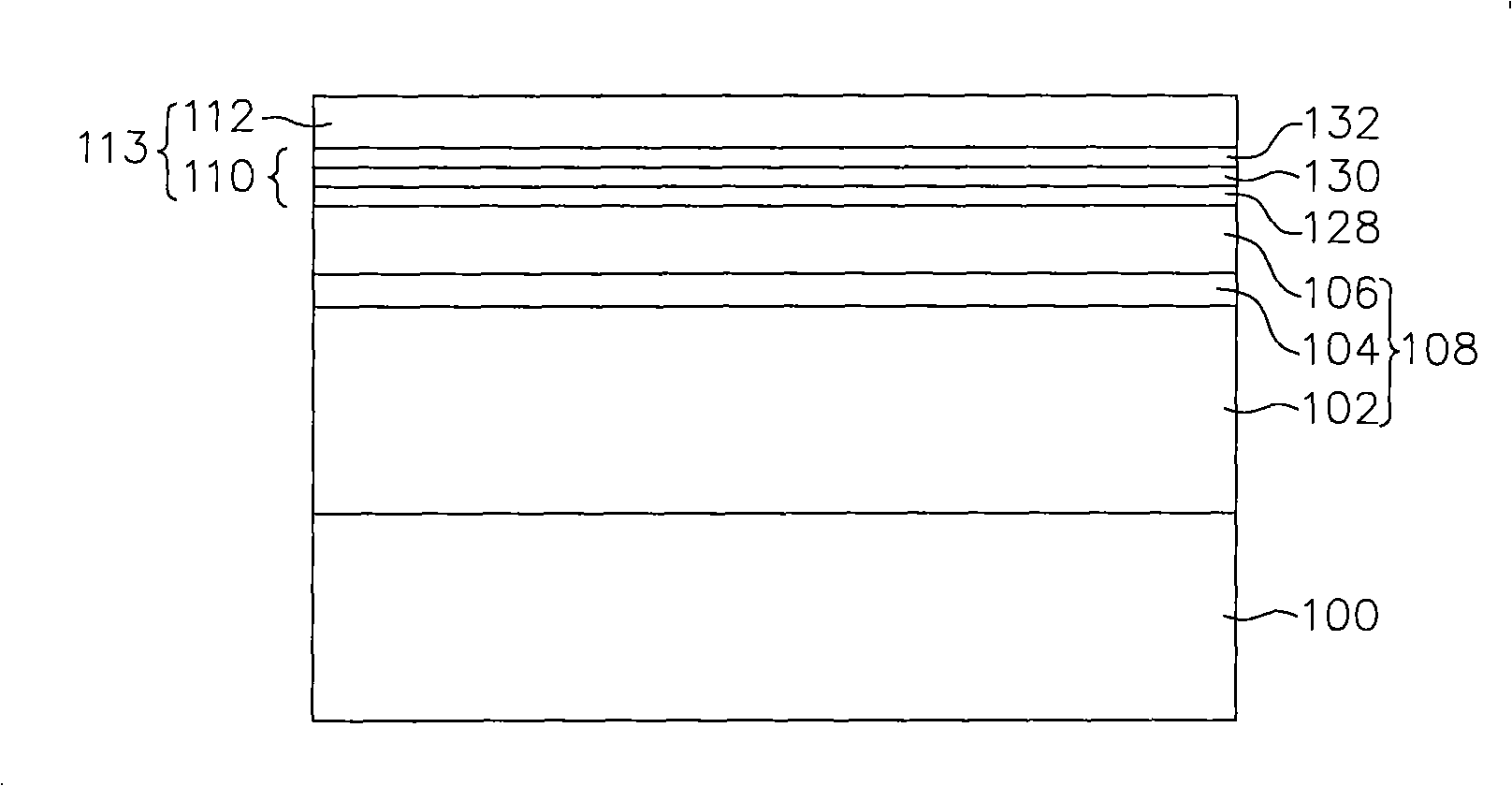

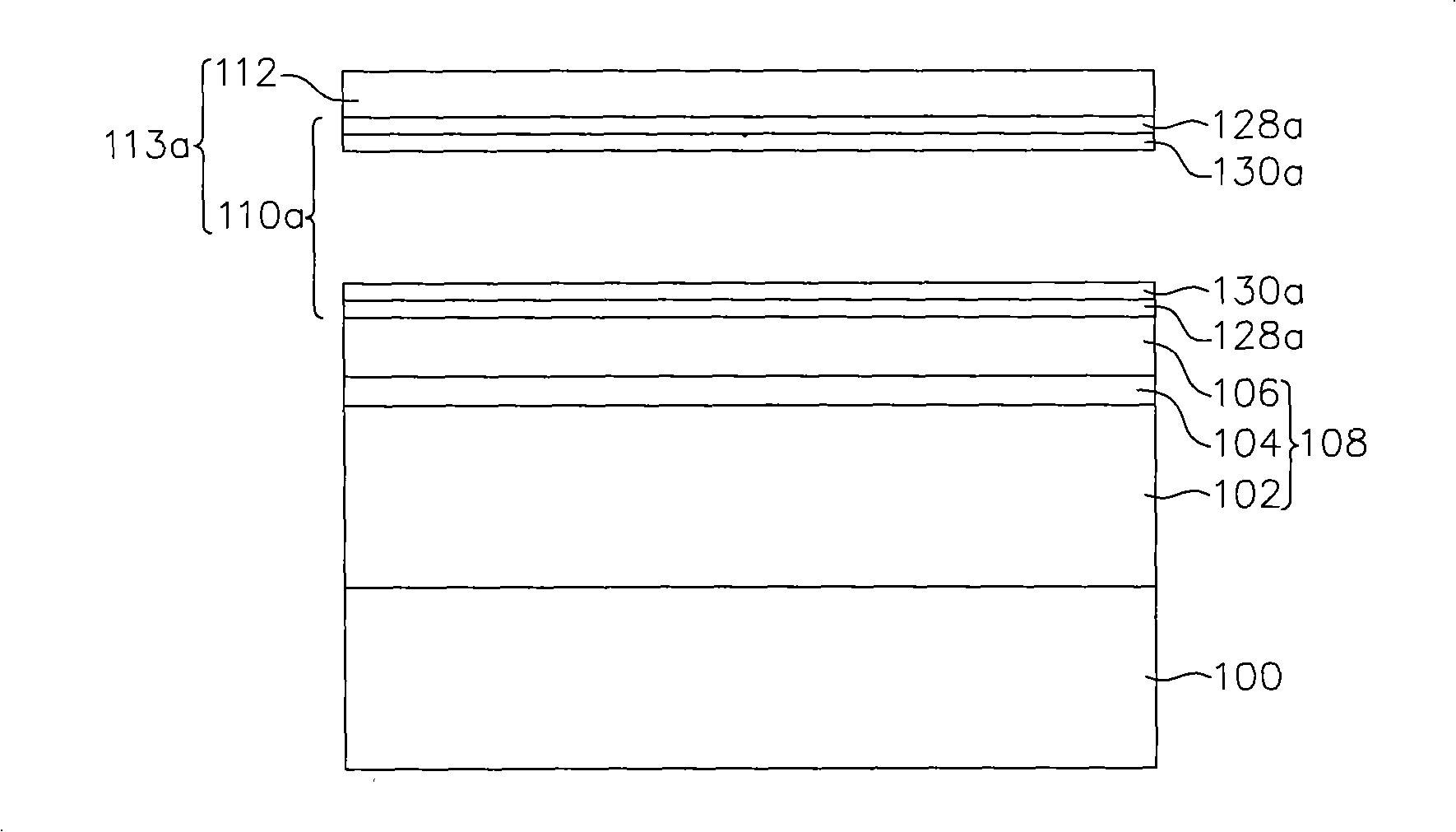

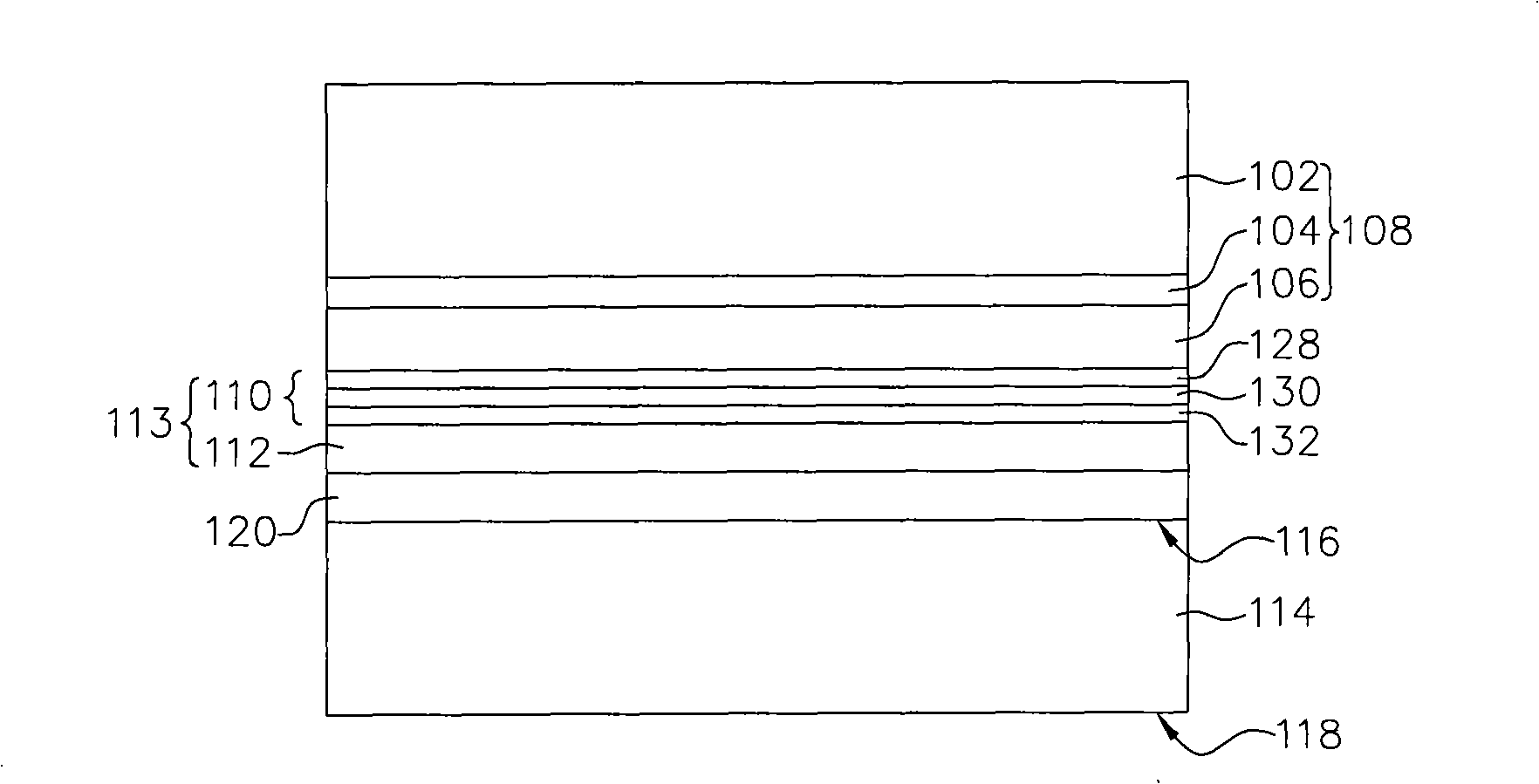

LED and manufacturing method thereof

ActiveCN101276862AImprove light extraction rateConductiveSemiconductor devicesLight-emitting diodeElectrode

The invention discloses a LED and a manufacturing method thereof. The LED at least comprises: a conductive substrate with oppositely a first and a second surfaces; a reflection structure at least comprising a conductive reflection layer jointed on the conductive substrate, and a conductive dispersed Bragg reflection structure overlapped on the conductive reflection layer; a light emitting epitaxial structure arranged on the reflection structure; a first electrode arranged on part of the light emitting epitaxial structure; and a second electrode jointed with the second surface of the conductive substrate.

Owner:EPISTAR CORP

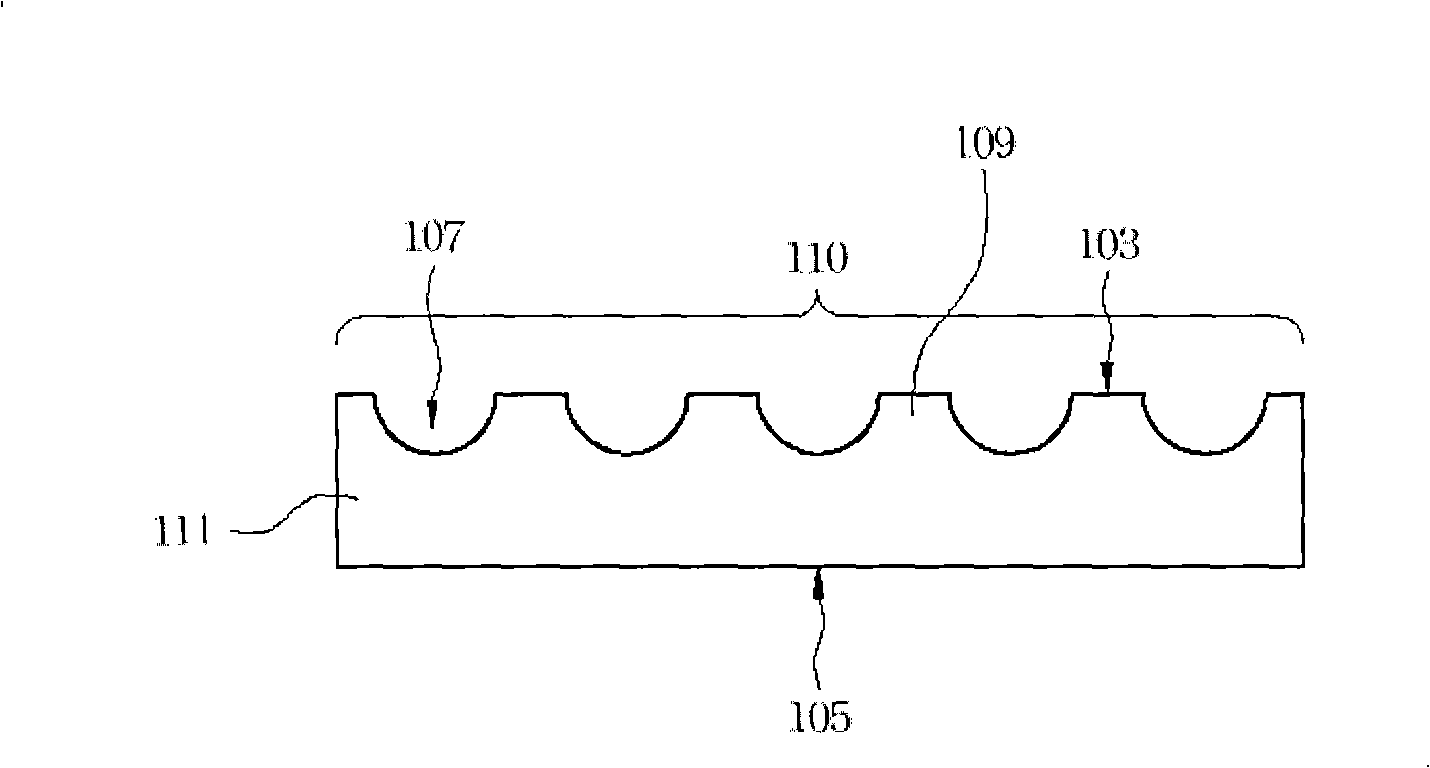

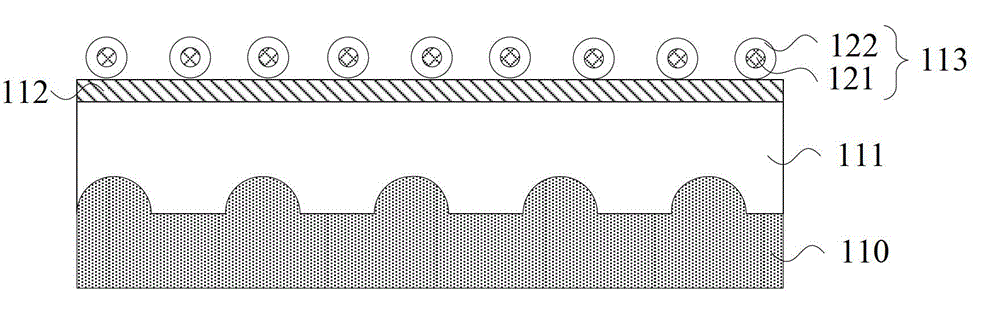

Light emitting diode element and manufacture method thereof

InactiveCN101308890AImprove light extraction rateImprove processing yieldSemiconductor devicesCushioningLight-emitting diode

Disclosed is a light-emitting diode which comprises a microlens baseplate, a reflecting layer, a cushioning layer, a first electric semiconductor layer, a source bed, a second electric semiconductor layer, a first electrode and a second electrode. A plurality of microlenses are arranged on the upper surface of the microlens baseplate; the cushioning layer is arranged on the upper surface of the microlens baseplate, and the first electric semiconductor layer is arranged on the cushioning layer; the source bed is partially arranged on the first electric semiconductor layer; the second electric semiconductor layer is arranged on the source bed; the first electrode is arranged on the other part of the source bed, which is uncovered by the first electric semiconductor layer; the second electrode is arranged on the second electric semiconductor layer; the reflecting layer is arranged on the lower surface of the microlens baseplate.

Owner:EPISTAR CORP

LED chip and manufacturing method thereof

InactiveCN102983236AImprove internal quantum efficiencyImprove luminous efficiencySemiconductor devicesQuantum wellActive layer

The invention discloses an LED (light-emitting diode) chip and a manufacturing method of the LED chip. The LED chip is characterized in that a first metal nanoparticle array is formed on an interface between an active layer and an adjacent layer of the active layer. Metal nanoparticles of the first metal nanoparticle array are excited by the light emitted from the active layer and provides an additional quantum well localized state for the active layer, so that the probability that electrons conduct radiationless recombination with voids by a defect level is reduced; an inner quantum effect is improved, and the luminous efficiency of the LED chip is improved.

Owner:ENRAYTEK OPTOELECTRONICS

Active type OLED (organic light-emitting diode) display device and manufacturing method thereof

InactiveCN103247762ADoes not affect light extraction efficiencyReduce contact resistanceSolid-state devicesSemiconductor/solid-state device manufacturingElectrical resistance and conductanceDisplay device

The invention provides an active type OLED display device and a manufacturing method thereof. The active type OLED display device comprises an OLED pixel unit, wherein the OLED pixel unit comprises at least two TFTs (thin film transistors) as well as anodes, cathodes and organic functional layers which are arranged on the TFTs; the active type OLED display device further comprises a cathode power line and an insulating layer which is arranged between the cathodes and the cathode power line; contact holes used for communicating the cathodes and the cathode power line are formed in the insulating layer; cathode thickening layers are arranged on the cathodes; and the cathode thickening layers are only flatly arranged in orthographic projection areas of the contact holes on the cathodes. The thickness of the cathodes in cathode power supply contact areas is larger than that of the cathodes in other areas; the cathodes are thickened after the cathodes are prepared through an open type shade, so that the contact resistance between the OLED cathodes and the cathode power line is effectively reduced, and at the same time, the cathodes in an OLED open area are not thickened, so that the luminous efficiency of an OLED is not affected; and the preparation technology is simple and the technology can be easily implemented.

Owner:KUNSHAN NEW FLAT PANEL DISPLAY TECH CENT

Organic light emitting display panel and display device

ActiveCN107195799AReduce reflectionImprove luminous efficiencySolid-state devicesSemiconductor/solid-state device manufacturingMicro structureOrganic light emitting device

The invention discloses an organic light emitting display panel and a display device. The organic light emitting display panel comprises a substrate, an organic light emitting device and a cap layer, wherein the organic light emitting device is arranged on the substrate; the cap layer is arranged at the side far away from the substrate of the organic light emitting device; the cap layer comprises scattering particles; and a scattering micro-structure is arranged on the surface far away from the organic light emitting device of the cap layer. According to the organic light emitting display panel and the display device which are provided by the invention, the scattering particles and the scattering micro-structure are simultaneously arranged on the cap layer, and the light is emergent to each direction on the surface of the organic light emitting display panel through the combined action of two structures, so that the scattered light can be seen from all angles of the organic light emitting display panel, the view color cast phenomenon is improved, and meanwhile, the total reflection of the light can be reduced through the scattered particles, the optical loss is reduced and the light output rate is improved, and thus the luminous efficiency of the OLED device is improved.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

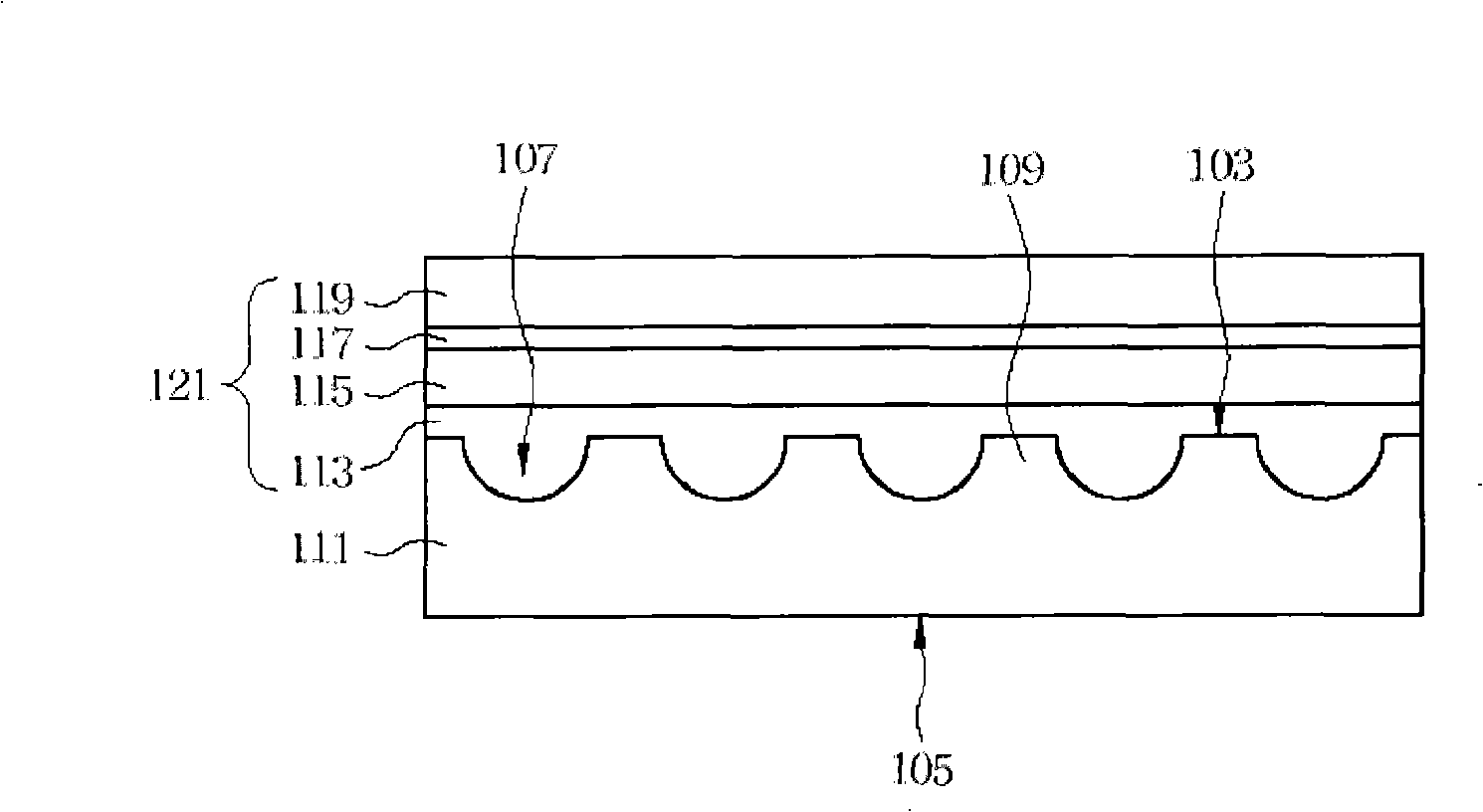

Organic electrogenic light-emitting component

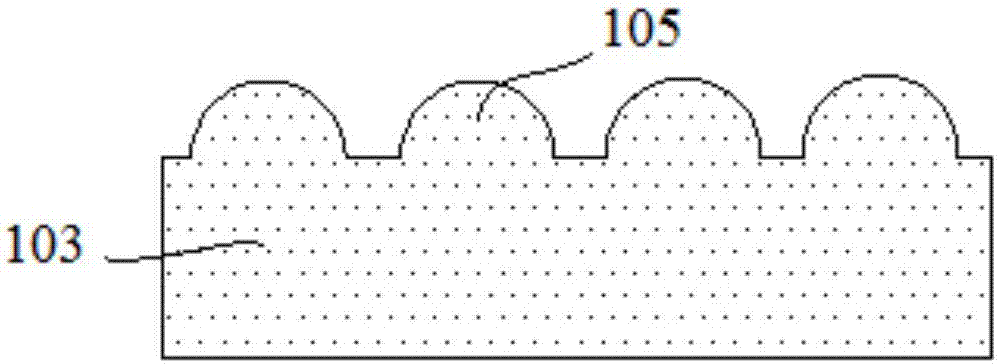

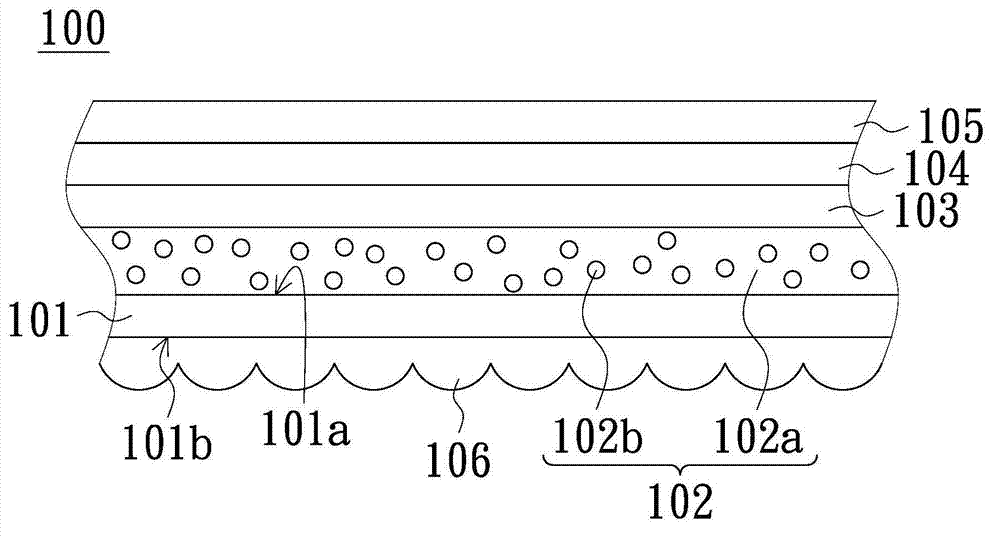

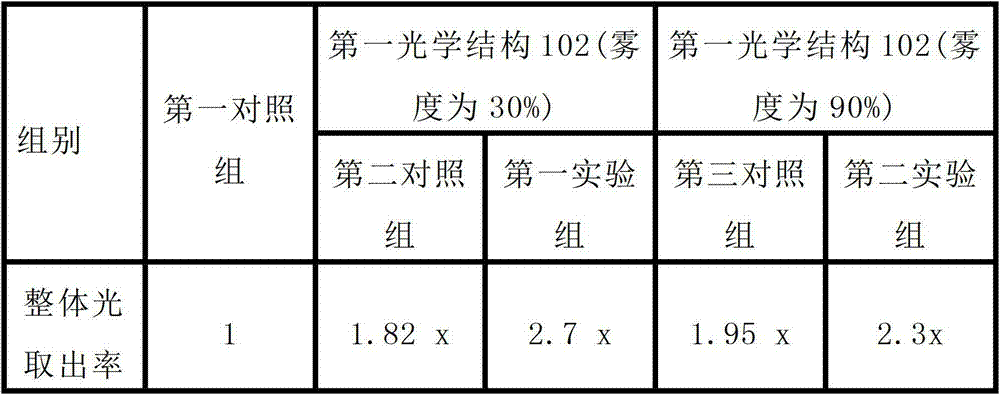

ActiveCN103050639AThe first haze is smallImprove light extraction rateSolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsOrganic electroluminescence

The invention discloses an organic electrogenic light-emitting component, comprising a base material, a first optical structure, a transparent electrode, an organic light-emitting structure, a reflective layer and a second optical structure. The base material possesses a first surface and a second surface. The first optical structure is located on the first surface of the base material and possesses a first haze. The transparent electrode is located on the first optical structure. Theorganic light-emitting structure is located on the transparent electrode; the reflective layer is located on the organic light-emitting structure. The second optical structure is located on the second surface of the base material, wherein the first haze is smaller than a second haze. The organic electrogenic light-emitting component can substantially raise light out rate of the organic electrogenic light-emitting component.

Owner:AU OPTRONICS CORP

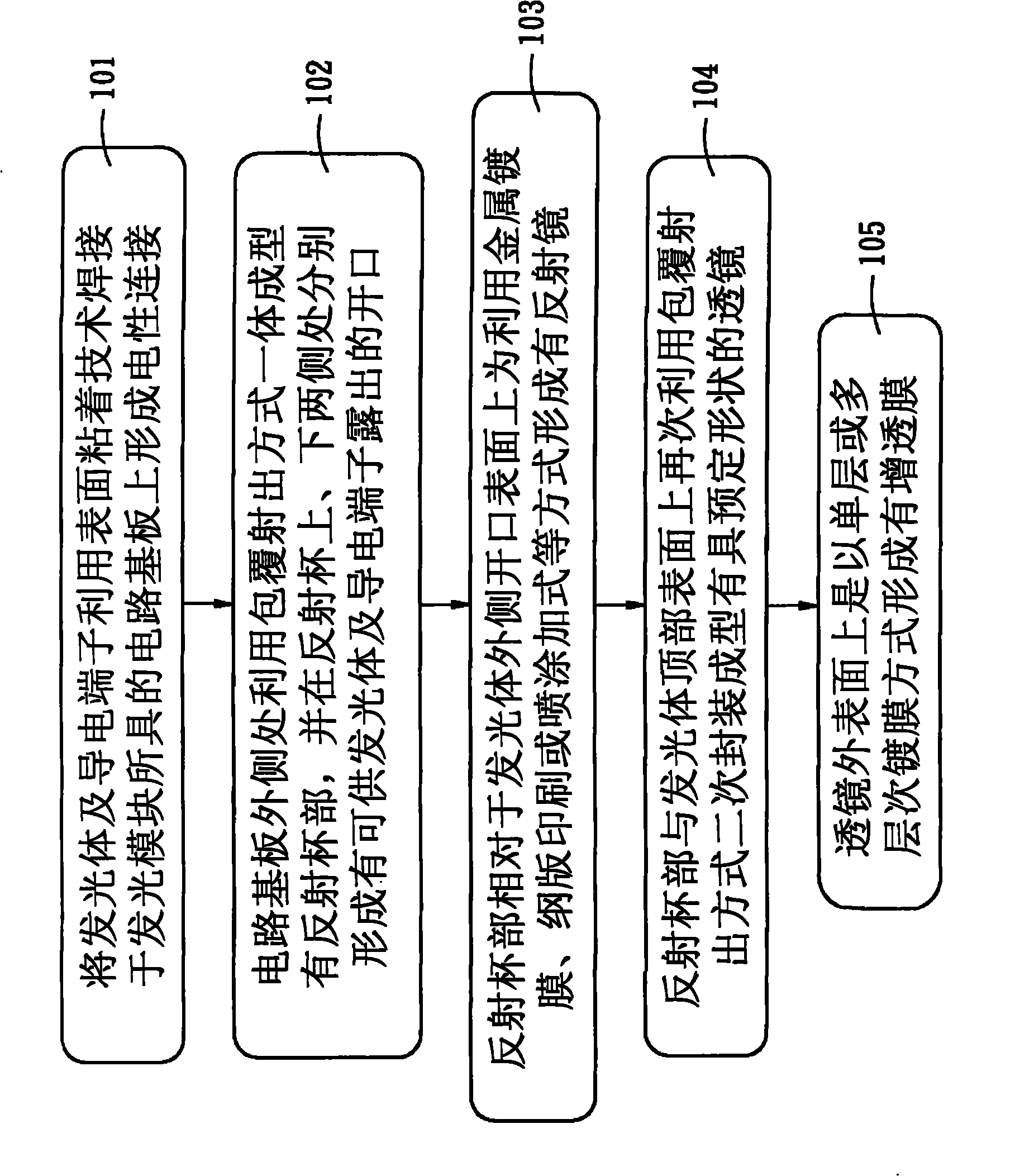

LED light-emitting module processing method

InactiveCN101930932AIncrease luminous fluxReduce refractionSemiconductor/solid-state device manufacturingSemiconductor devicesElectrical connectionEngineering

The invention relates to an LED light-emitting module processing method which comprises the steps of: respectively welding at least one LED and two or more conductive terminals on a circuit substrate of a light source module to form electrical connection, integrally forming an accommodating cup part outside the circuit substrate in a covering and ejecting mode and respectively forming openings for exposing the LEDs and the conductive terminals in the upper side and the lower side of the accommodating cup part; and carrying out secondary package on the surfaces of the tops of the accommodating cup part and the LEDs in a covering and ejecting mode to form a lens with preset shape, wherein the lens can be directly secondarily packaged and formed on the accommodating cup part and the LEDs to ensure that the inside of the lens does not have clearance so that the phenomena of refraction and light attenuation because lights passes through different media can be decreased for improving the intensity of illumination of the LEDs through projecting bright lights towards the lens and then being capable of ensuring that the light source module generates a planar light source uniformly and outwards emitting lights.

Owner:KWO GER METAL TECH +1

Manufacturing method for LED chip

ActiveCN103904174AImprove light extraction efficiencyFlat surfaceSemiconductor devicesEtchingEngineering

The invention provides a manufacturing method for an LED chip by utilizing the laser scribing technology, the etching technology and the reflective layer back-plating technology. Two times of laser light are adopted for deflecting back scribing, so that scribing width and scribing depth are increased, and a U-shaped gap is formed; due to etching, scraps caused by laser scribing can be removed, and the surface of the U-shaped gap is more flat; a locally tilted side face is formed on a sapphire substrate through the U-shaped gap, after the side face and the obverse side of the substrate form a high-reflectance layer, rays emitted from a light-emitting layer can be reflected upward to a greater degree, and therefore the light-emitting efficiency of the LED chip is enhanced.

Owner:ANHUI SANAN OPTOELECTRONICS CO LTD

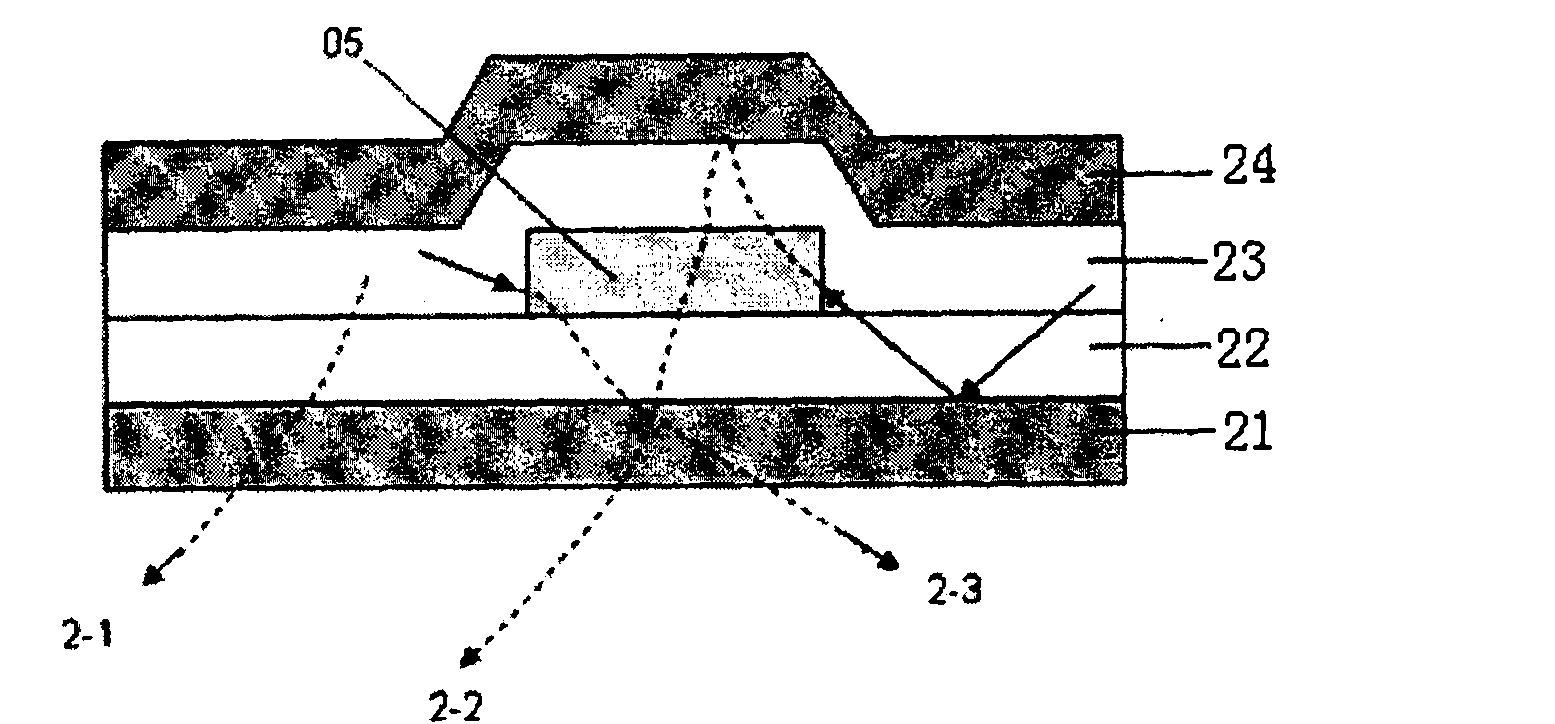

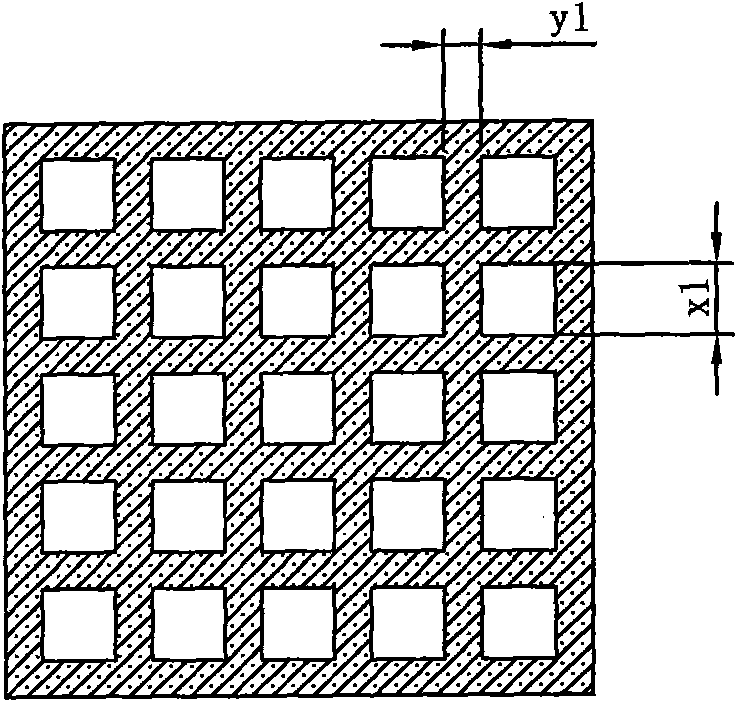

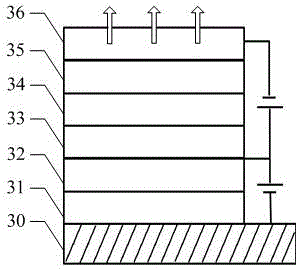

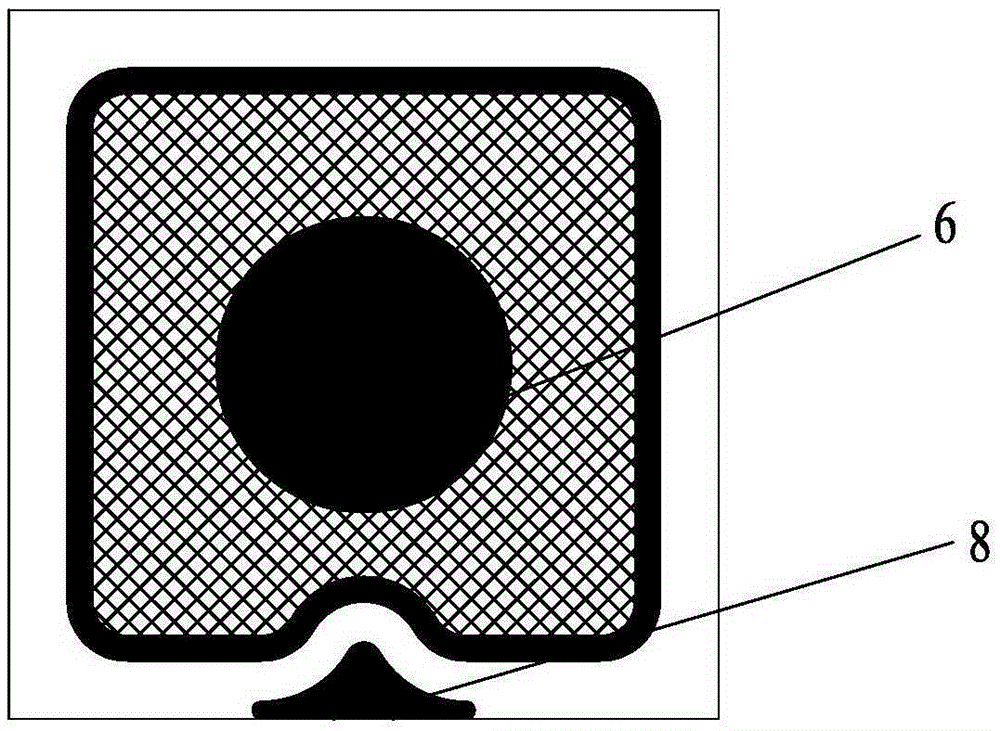

Organic electroluminescence device

ActiveCN102110778ANo change in color coordinatesImprove light extraction rateSolid-state devicesSemiconductor/solid-state device manufacturingOrganic electroluminescencePhotoresist

The invention relates to an organic electroluminescence device, in particular to a device structure for improving light extraction efficiency of the organic electroluminescence device. A reticular light extraction layer made of photoresist is additionally arranged in the device, and the grids of the reticular shape can be rectangles, regular triangles, regular hexagons, etc., through photoetchingprocessing. Owning to the reticular light extraction layer, light incapable of being emitted from the surface of the device due to total reflection is less, and the light extraction efficiency is improved.

Owner:GUAN YEOLIGHT TECH CO LTD +1

LED lamp for eliminating glare

InactiveCN101943329AReduce lossImprove light extraction ratePoint-like light sourceElectric lightingFluorescenceOptoelectronics

The invention relates to a LED lamp for eliminating glare, which comprises a base, wherein a plurality of light reflecting cups are arranged on the base; a LED chip is arranged at the bottom of each light reflecting cup, and a fluorescent powder layer is coated above each LED chip; a light reflecting sheet is arranged on the surface of each fluorescent powder layer; and the surface of either light reflecting sheets is parallel and level with that of the corresponding fluorescent powder layer. In the LED lamp, a reversal light reflecting layer is formed on the upper part of the fluorescent powder layer additionally through a plurality of light reflecting sheets, so that a high light-emitting part of each LED chip can diffuse well towards periphery and is reflected finally, light rays are soft and are not dazzling, and the loss of light can be ensured to be minimum.

Owner:FUJIAN WANBAN OPTOELECTRONICS TECH

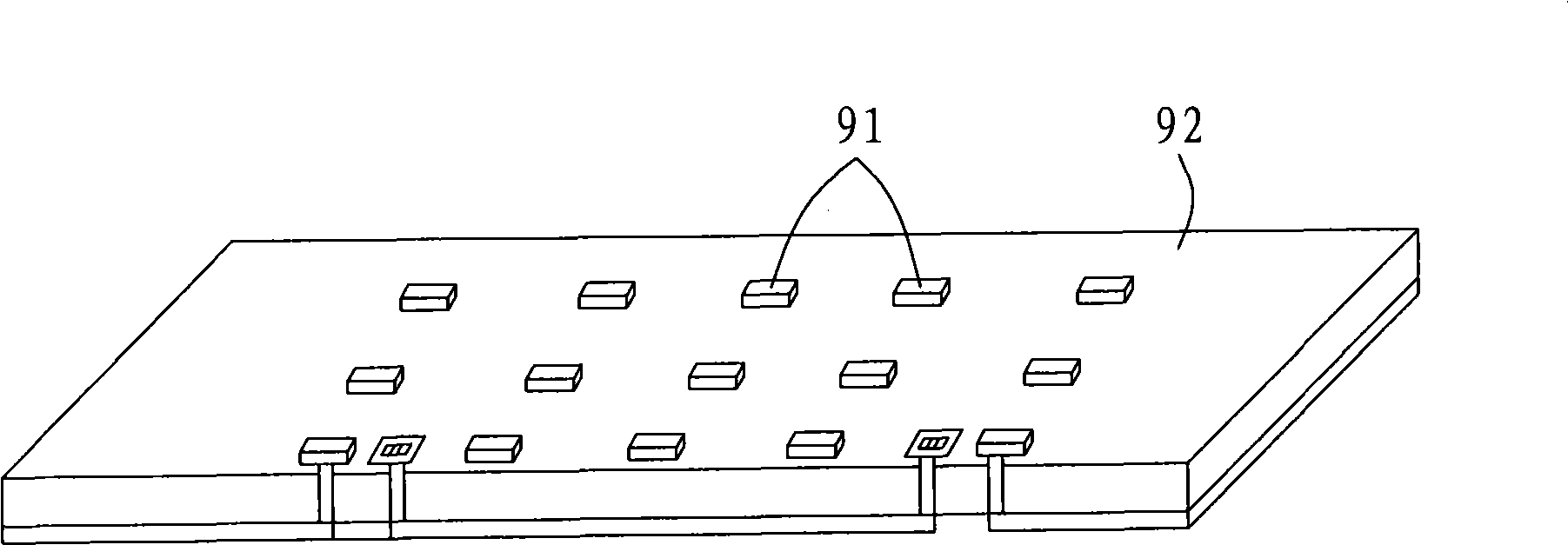

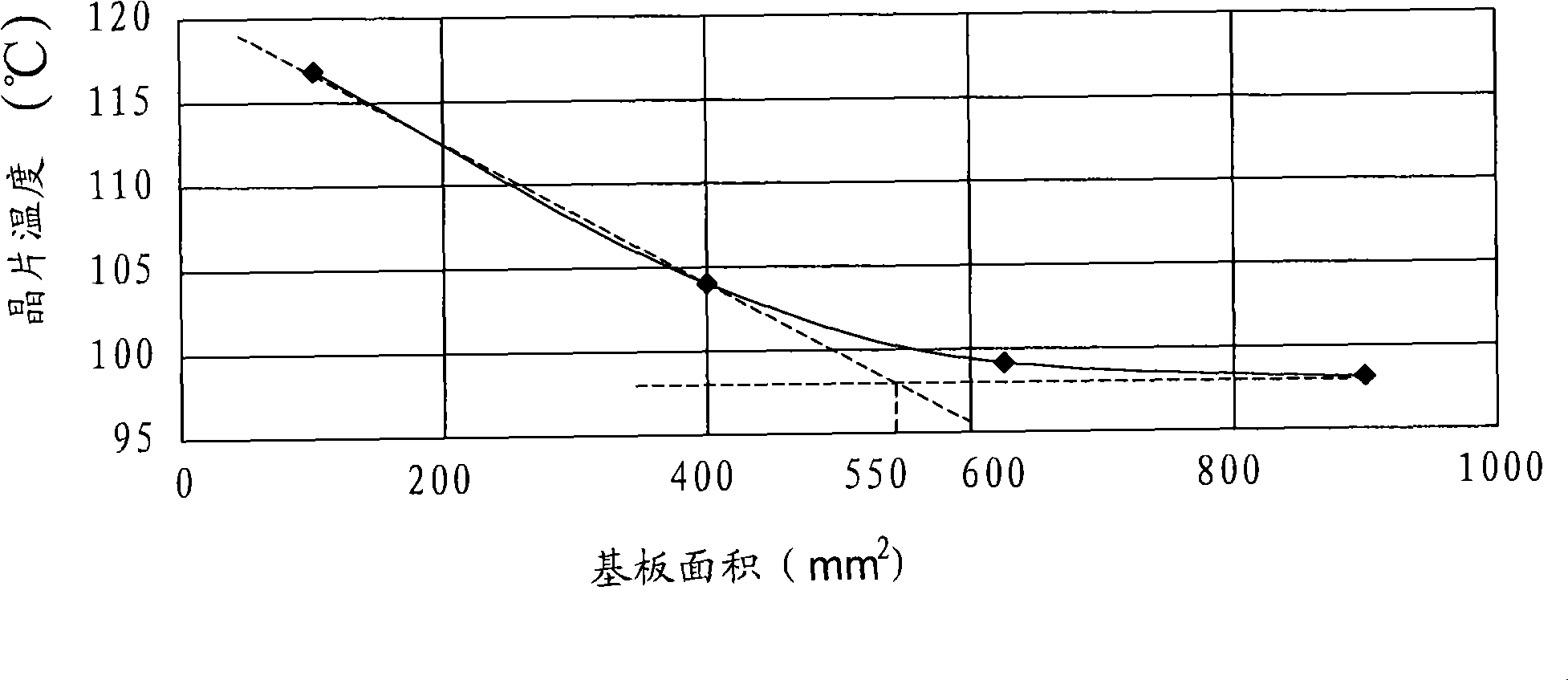

Light emitting diode surface light source device

ActiveCN101545615ABlock out lightOptimize thermal designPlanar light sourcesLighting support devicesLight-emitting diodeLight source

The invention relates to a light emitting diode surface light source device, which comprises a substrate and a plurality of light emitting diode chips arranged on the substrate in array type arrangement. The thickness of the substrate is more than 1 mm. The area of the light emitting diode chip is between 0.08 and 0.25 mm <2>; and the distance between every two light emitting diode chips is more than twice of the dimension of the chip. The light emitting diode surface light source device uses the chip with small dimension and controls the distance between the chips and the thickness of the substrate, can achieve the promotion of luminous efficiency of the whole surface light source device through utilization of the chip with the small dimension, can maintain the temperature of the chip in a lower state, reduce the amplitude needed for radiation and is further favorable for the following radiation design of the whole light emitting diode surface light source device.

Owner:BRIGHT LED ELECTRONICS CORP

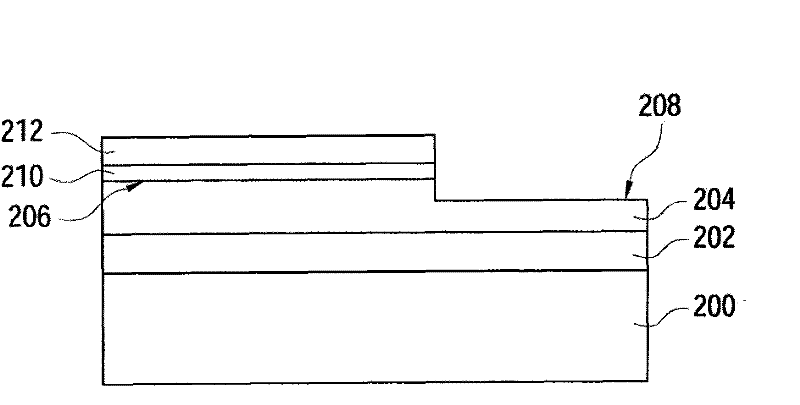

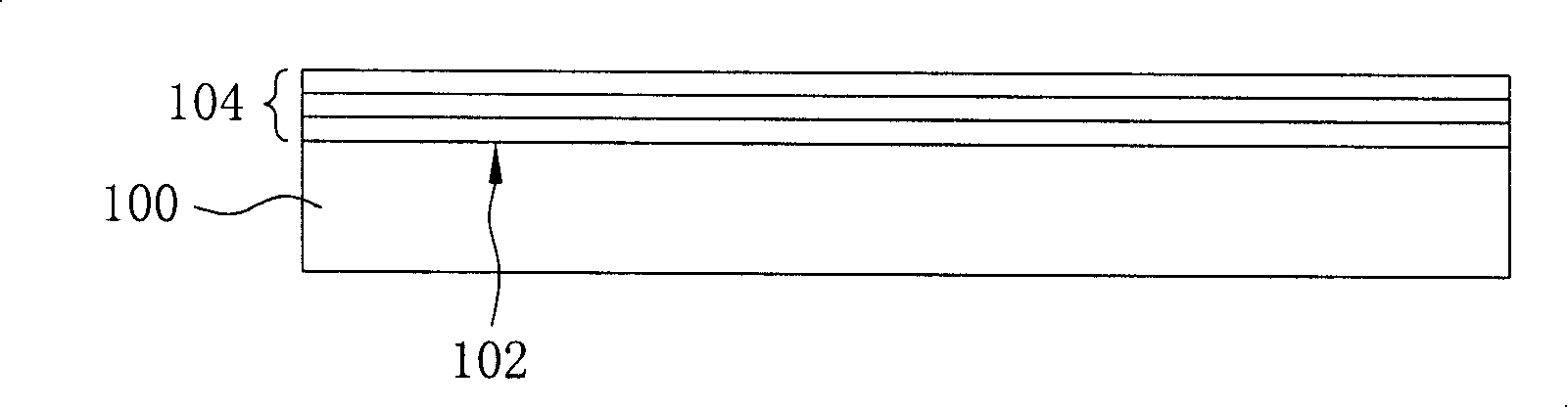

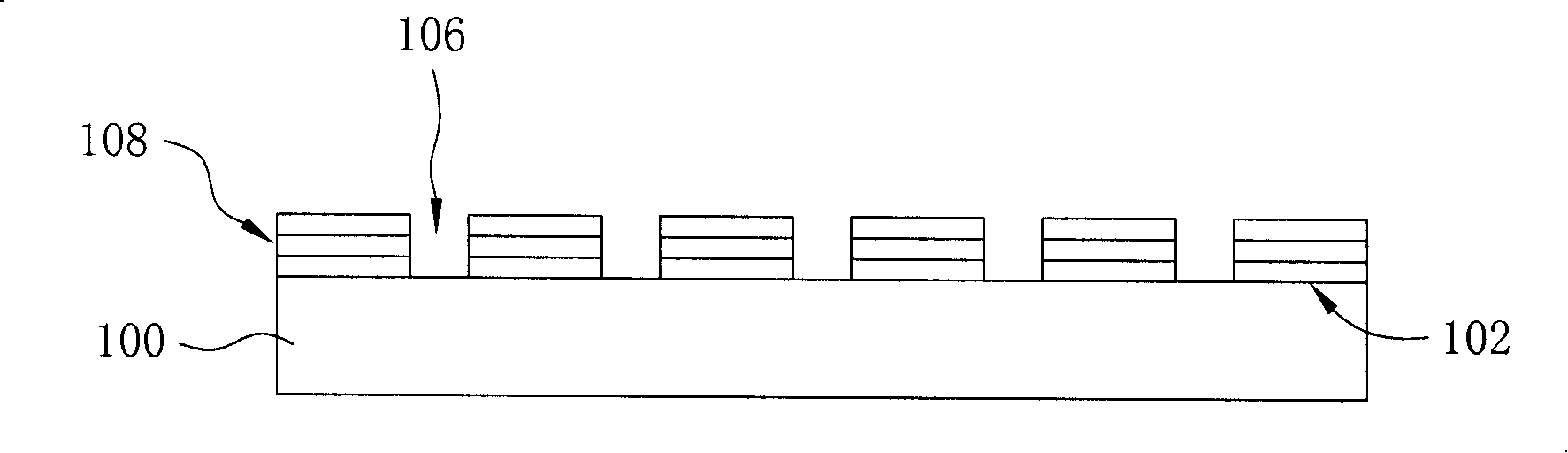

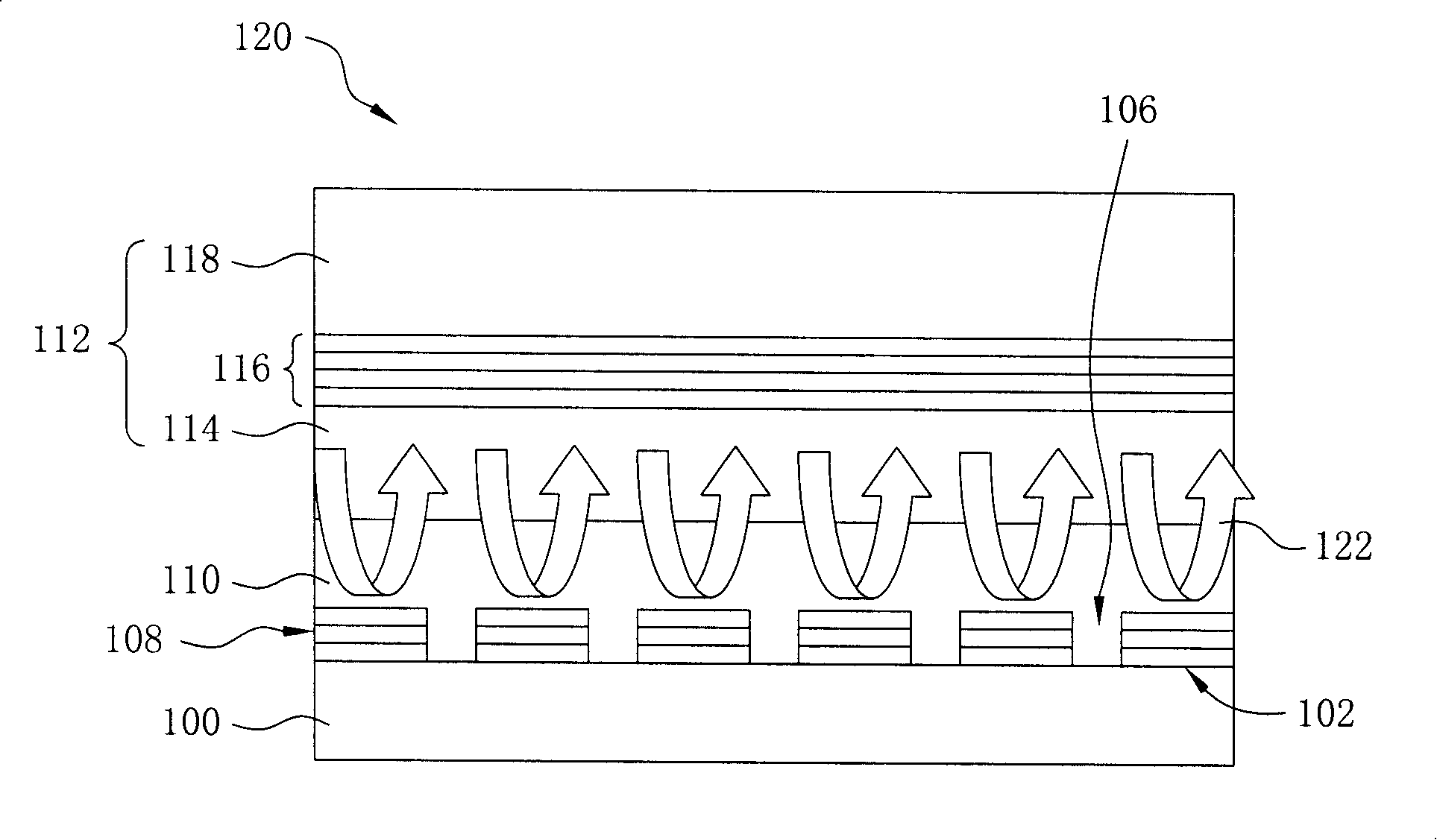

LED and its making method

InactiveCN101222008AIncreased axial light extraction rateImprove luminous efficiencySemiconductor devicesRegular patternLight-emitting diode

The invention discloses a light-emitting diode (LED) and the manufacturing method thereof. The light-emitting diode at least comprises a substrate, a reflection structure, a buffer layer and a light-emitting epitaxy structure. The reflection structure is arranged on one surface of the substrate, wherein, a plurality of openings are arranged in the reflection structure to make the reflection structure formed into a structure in a regular pattern, and further, one part of the surface of the substrate is exposed. The buffer layer is arranged on the exposed part of the surface of the reflection structure and the substrate and fills the openings. The light-emitting epitaxy structure is arranged on the buffer layer.

Owner:EPISTAR CORP

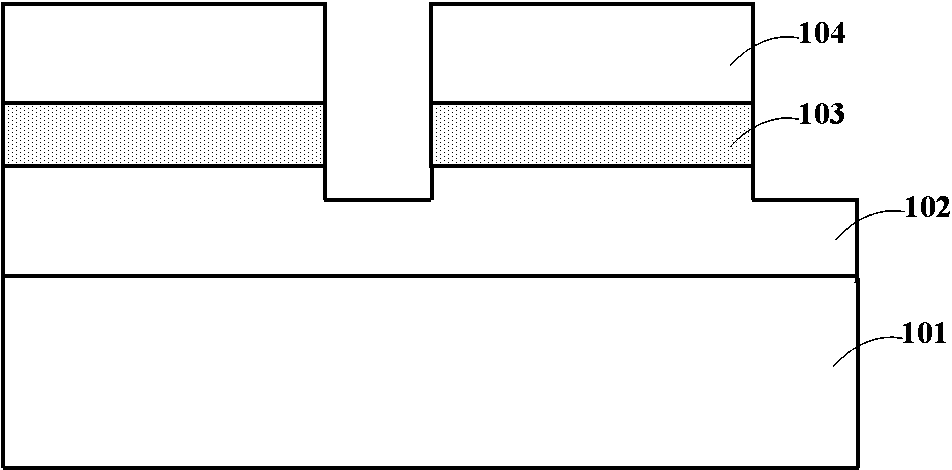

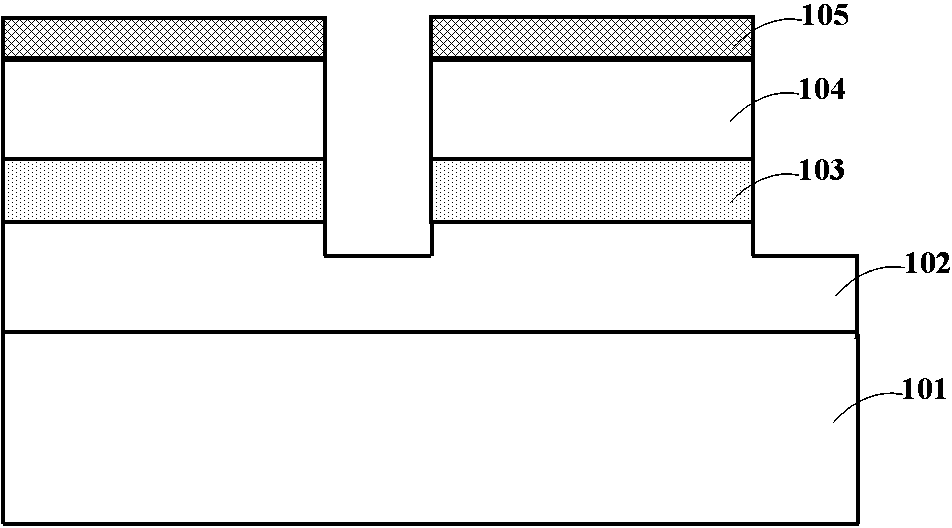

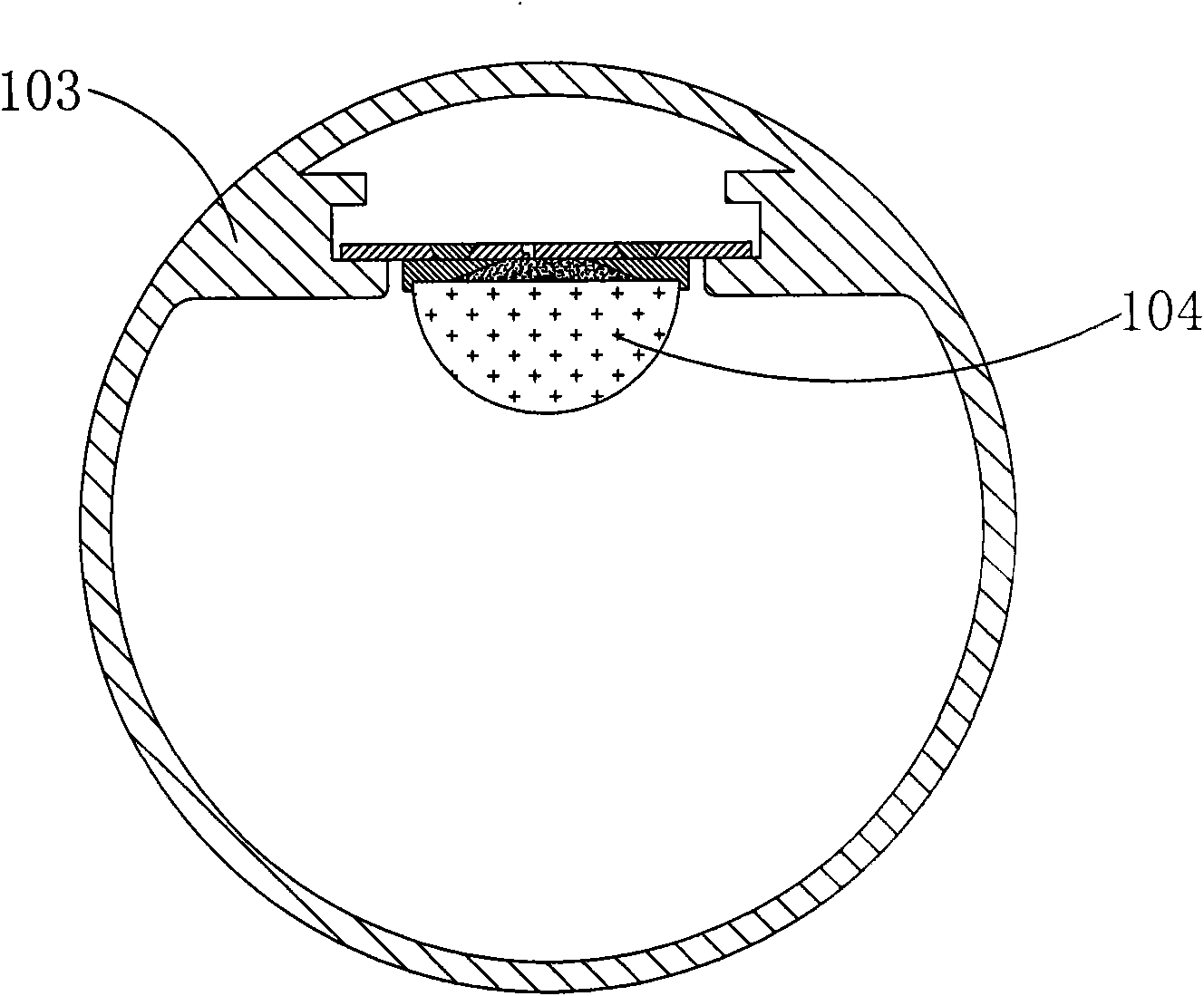

QLED field effect transistor with improved light extraction ratio, and preparation method for QLED field effect transistor

InactiveCN106711177AImprove light extraction efficiencyImprove light extraction rateFinal product manufactureSolid-state devicesPhysicsField-effect transistor

The invention discloses a QLED field effect transistor with the improved light extraction ratio, and a preparation method for the QLED field effect transistor. The QLED field effect transistor sequentially comprises an SOI substrate with the surface being provided with a plurality of nano-pits, and an OLED device located on the surface of the SOI substrate. The SOI substrate comprises a first silicon layer, an insulating layer and a second silicon layer, wherein the first silicon layer, the insulating layer and the second silicon layer are sequentially arranged. According to the invention, the surface of the SOI substrate is provided with the plurality of nano-pits, thereby enabling the surface of the SOI substrate to be in an uneven structure, and enabling the QLED device to form an uneven structure. Compared with a conventional plane structure, the QLED field effect transistor can improve the light extraction ratio, and improve the luminous efficiency of the device.

Owner:TCL CORPORATION

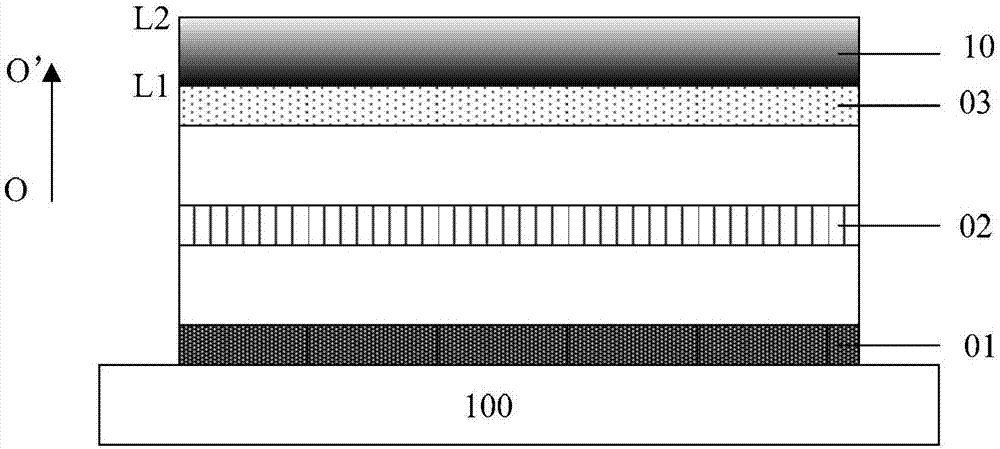

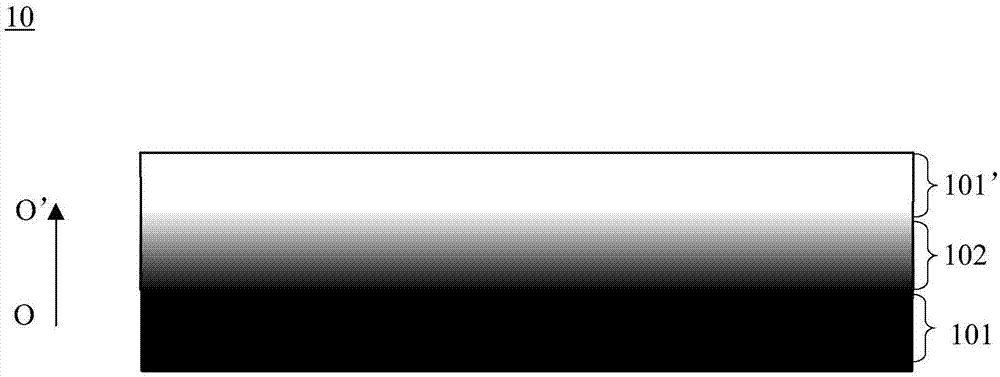

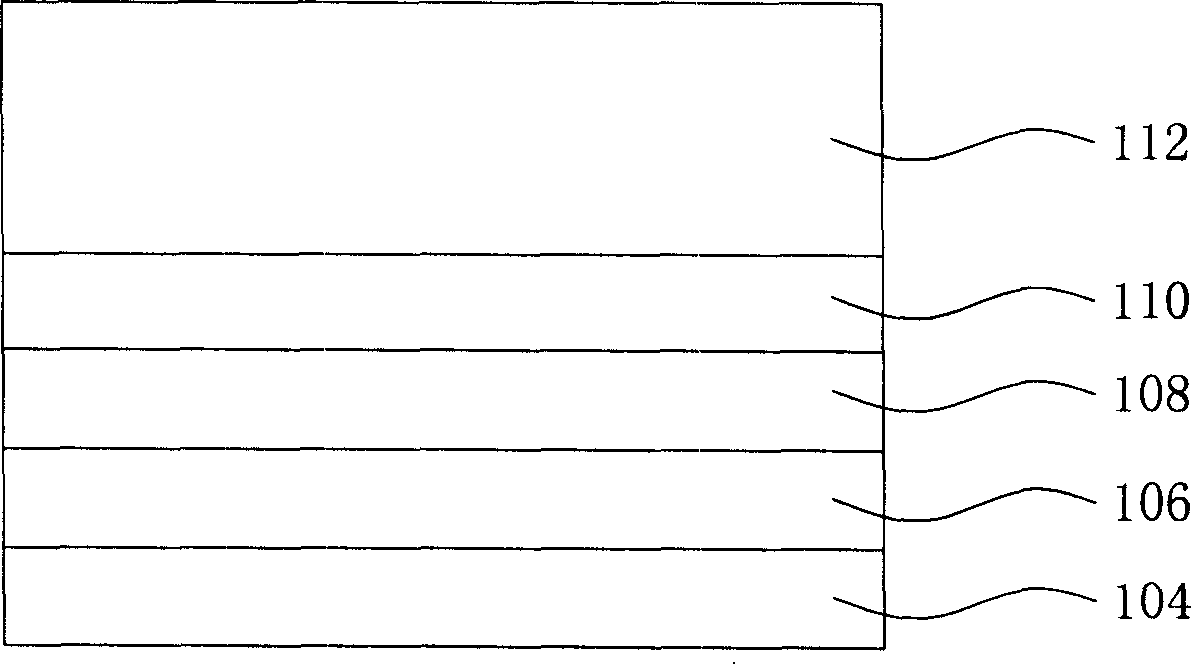

OLED light emitting device, preparation method, display substrate and display device

PendingCN107516713AImprove light extraction rateAvoid lostSolid-state devicesSemiconductor/solid-state device manufacturingLight extraction in LEDsRefractive index

The embodiment of the invention provides an OLED light emitting device, a preparation method, a display substrate and a display device, and relates to the technical field of display. According to the technical purposes, the light extraction efficiency of the OLED light emitting device can be improved, and the visual angle can be increased. The OLED light emitting device comprises a reflecting electrode, an organic light-emitting layer and a semitransparent electrode, wherein the reflecting electrode, the organic light-emitting layer and the semitransparent electrode are arranged in sequence; the OLED light emitting device further comprises a light extraction layer which is located on the side, away from the organic light-emitting layer, of the semitransparent electrode and makes contact with the semitransparent electrode, the light extraction layer is of a single-layer structure in which the refractive index is decreased progressively in the light-emitting direction, and the light-emitting direction is the direction, away from the organic light-emitting layer, of the light extraction layer, wherein the refractive index of the side, making contact with the semitransparent electrode, of the light extraction layer is larger than the refractive index of the semitransparent electrode.

Owner:BOE TECH GRP CO LTD

LED and its making method

ActiveCN101212011AIncrease brightnessAid in diffusionSemiconductor devicesConductive materialsReflective layer

The invention relates to a luminescent diode (LED) and a manufacturing method thereof. The LED at least comprises the following processes: a conductive base plate is provided with a first surface relative with a second surface; a metal joint layer is arranged on the first surface of the conductive base plate; a metal reflecting layer is jointed with the metal joint layer; an N type semiconductor layer is arranged on the metal reflecting layer; an active layer is arranged on the N type semiconductor layer; a P type semiconductor layer is arranged on the active layer; a window layer is arranged on the P type semiconductor layer, wherein the thickness of the window layer is above 50Mum and the window layer is composed of transparent conductive material; a P type electrode is arranged on the window layer.

Owner:EPISTAR CORP

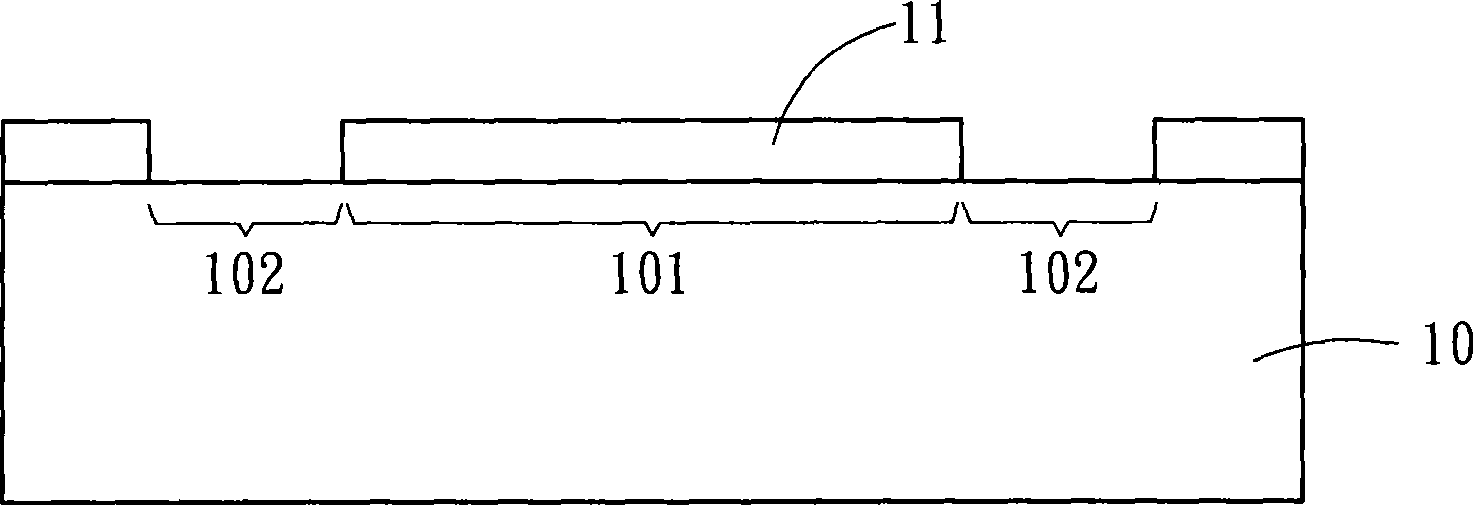

Sapphire-substrate single-electrode LED chip structure and preparation method thereof

InactiveCN105355747AReduce area ratioImprove light extraction rateSemiconductor devicesOptoelectronicsSingle electrode

The invention relates to a sapphire-substrate single-electrode LED chip structure and a preparation method thereof. The sapphire-substrate single-electrode LED chip structure comprises a sapphire substrate. Epitaxial structural layers are grown on the sapphire substrate. The epitaxial structural layers include a U-GaN layer, an N-GaN layer, an MQW layer and a P-GaN layer. The MQW layer and a P-GaN layer are partially etched, and the N-GaN layer is exposed. An ITO layer is arranged on the P-GaN layer. A positive electrode is arranged on the ITO layer. The sapphire-substrate single-electrode LED chip structure is characterized in that negative electrodes are arranged on the side surfaces of the sapphire substrate, the negative electrodes are arranged in a skewed slot of one side surface or skewed slots of a plurality of side surfaces or side edges, and metal 1-5 [mu]m in thickness covers side walls of the skewed slots to form the negative electrodes. According to the invention, the area ratio of the electrodes is greatly lowered, and the light extraction rate of the chip is effectively improved.

Owner:JIANGSU XINGUANGLIAN SEMICON

Light emitting diode array and manufacturing method thereof

InactiveCN102790045AImprove light extraction rateEasy to coarsenSolid-state devicesSemiconductor devicesGallium nitrideLight-emitting diode

The invention relates to a light emitting diode array which comprises a substrate and a plurality of light emitting diodes formed at one side of the substrate, wherein the plurality of light emitting diodes are electrically connected; each light emitting diode comprises a connection layer, an n-type gallium nitride layer, a light emitting layer and a p-type gallium nitride layer, which are orderly formed on the substrate; the connection layer can be etched by alkaline solution; the bottom surface of the n-type gallium nitride layer facing to the connection layer is oppositely polarized gallium nitride, and a bared roughened surface is arranged on the bottom surface. The invention also relates to a manufacturing method of the light emitting diode array.

Owner:ZHANJING TECH SHENZHEN +1

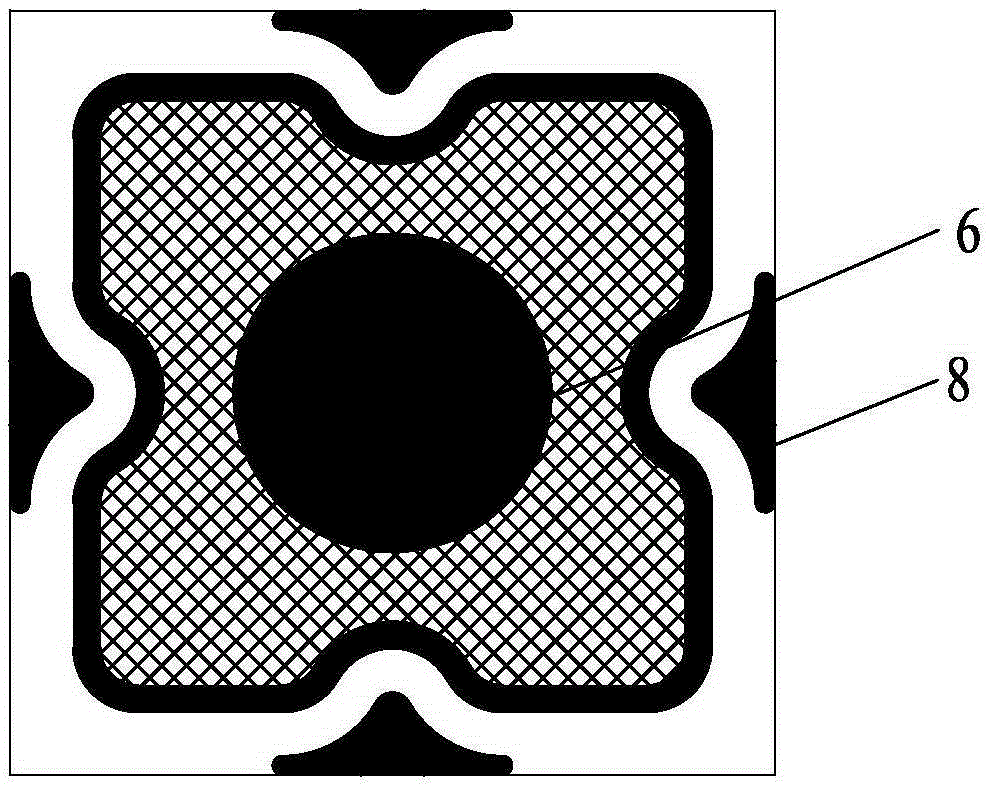

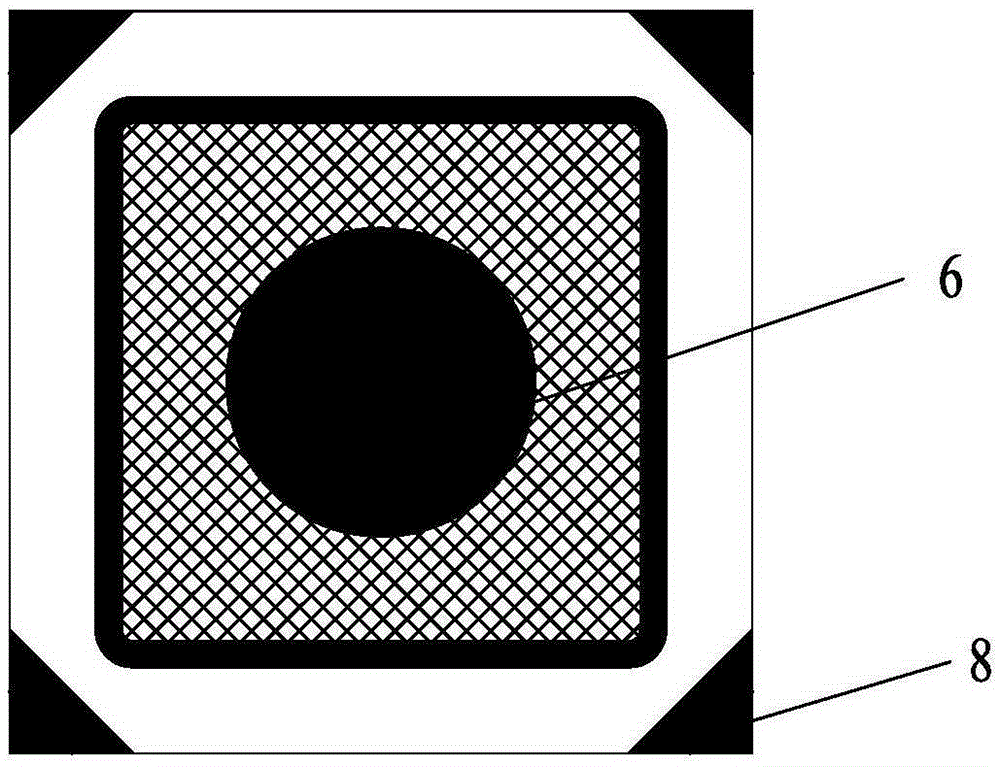

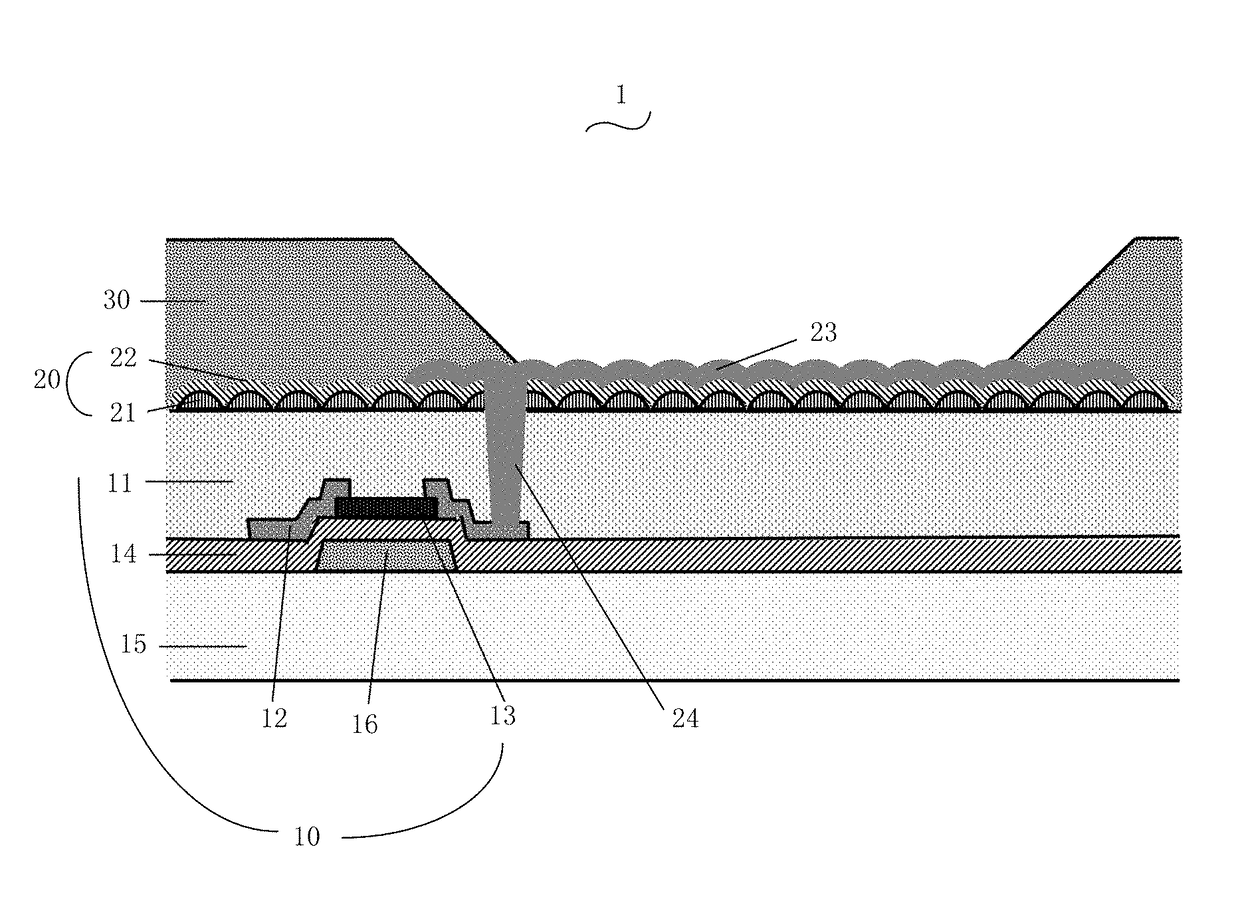

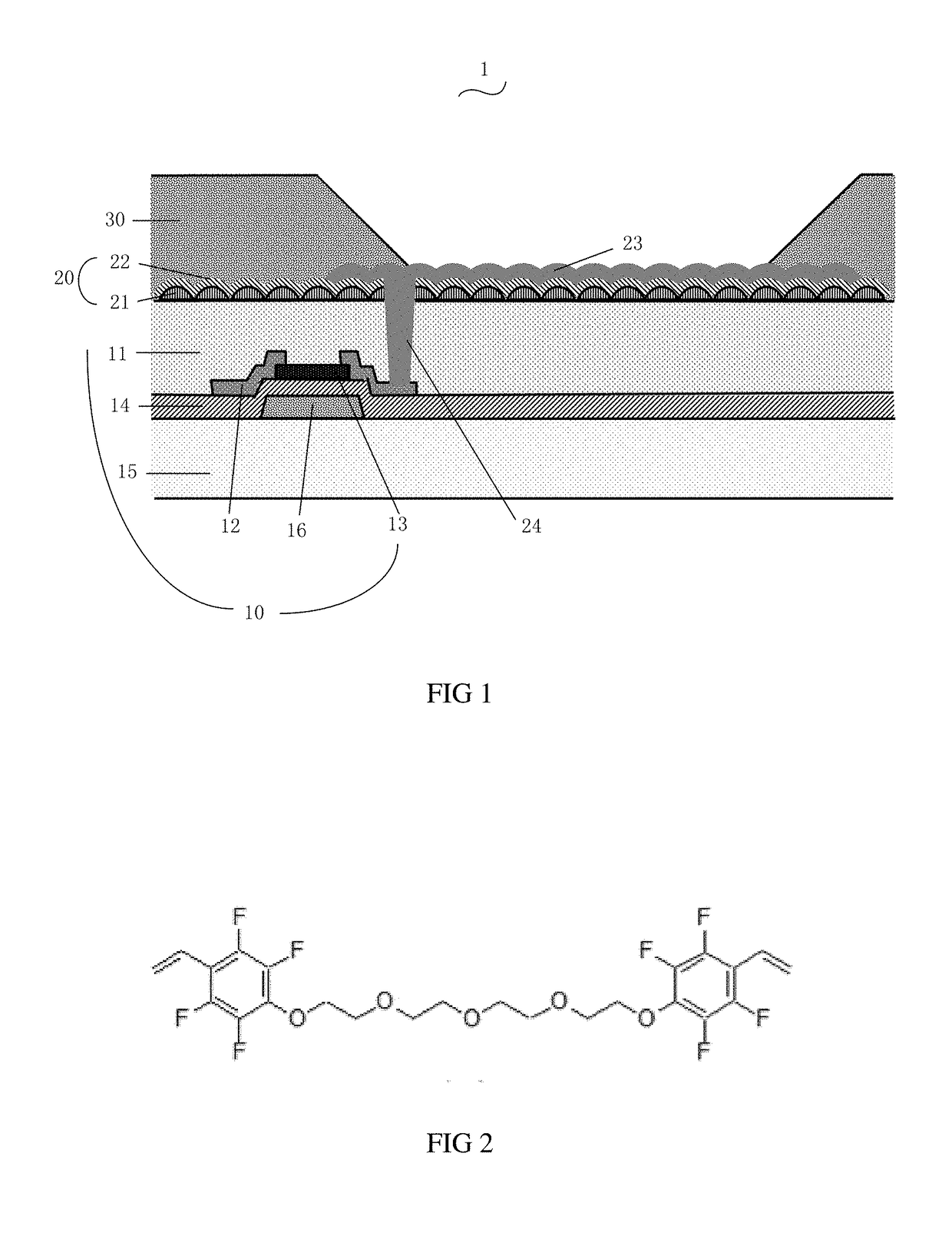

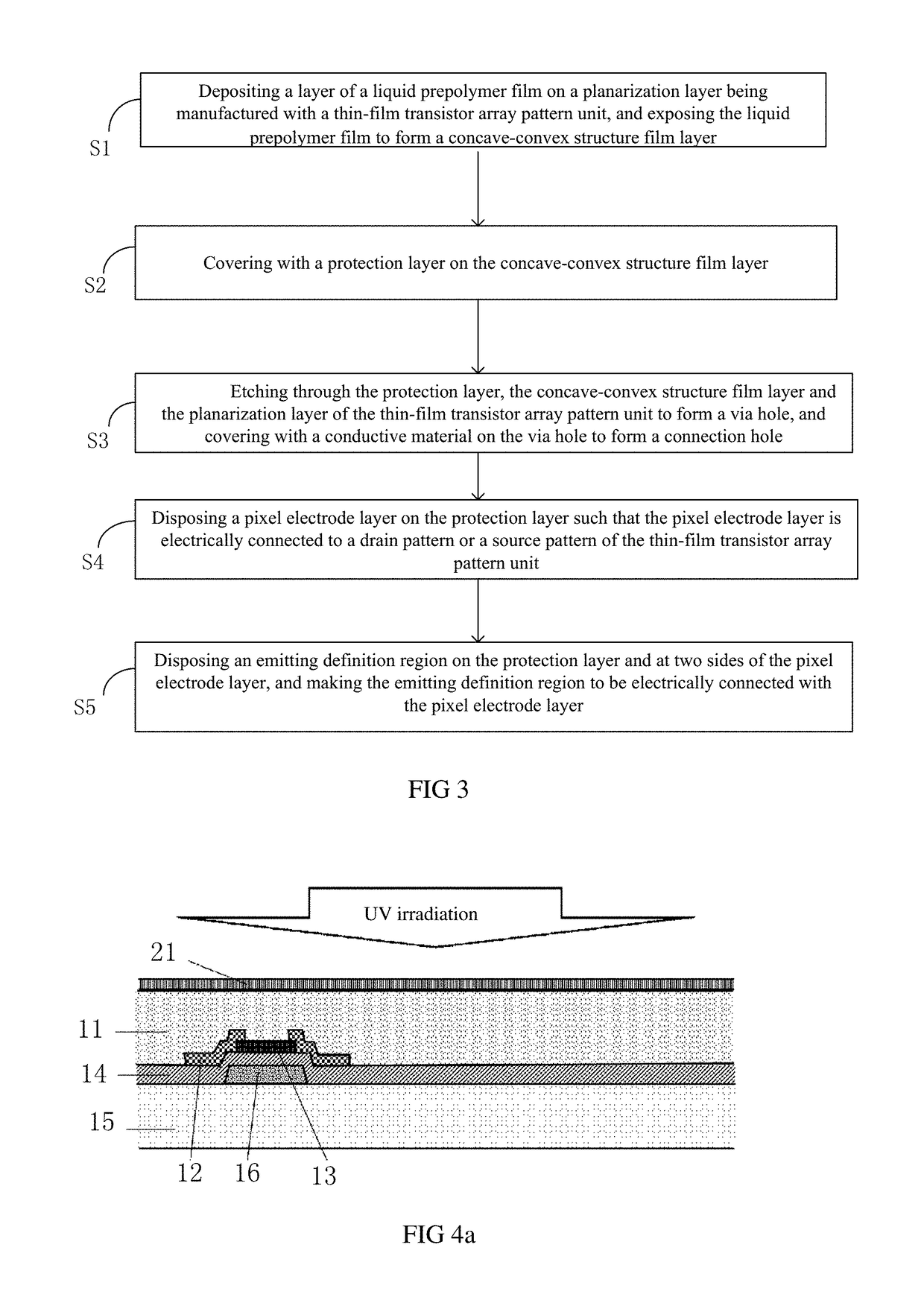

Pixel structure, manufacturing method and display panel

InactiveUS20180197894A1Improve light extraction rateReduce power consumptionTransistorSemiconductor/solid-state device detailsConvex structureDisplay device

A pixel structure, a manufacturing method and a display panel are provided. The pixel structure comprises a thin-film transistor array pattern unit and a pixel pattern unit which are disposed stacked; the pixel pattern unit includes a concave-convex structure film layer disposed on the thin-film transistor array pattern unit, a protection layer covered on the concave-convex structure film layer, a pixel electrode layer located on the protection layer, and electrically connected to the thin-film transistor array pattern unit and an emitting definition region so as to increase a light extraction rate of the light emitting device, decrease the power consumption of the display device and extend the life.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

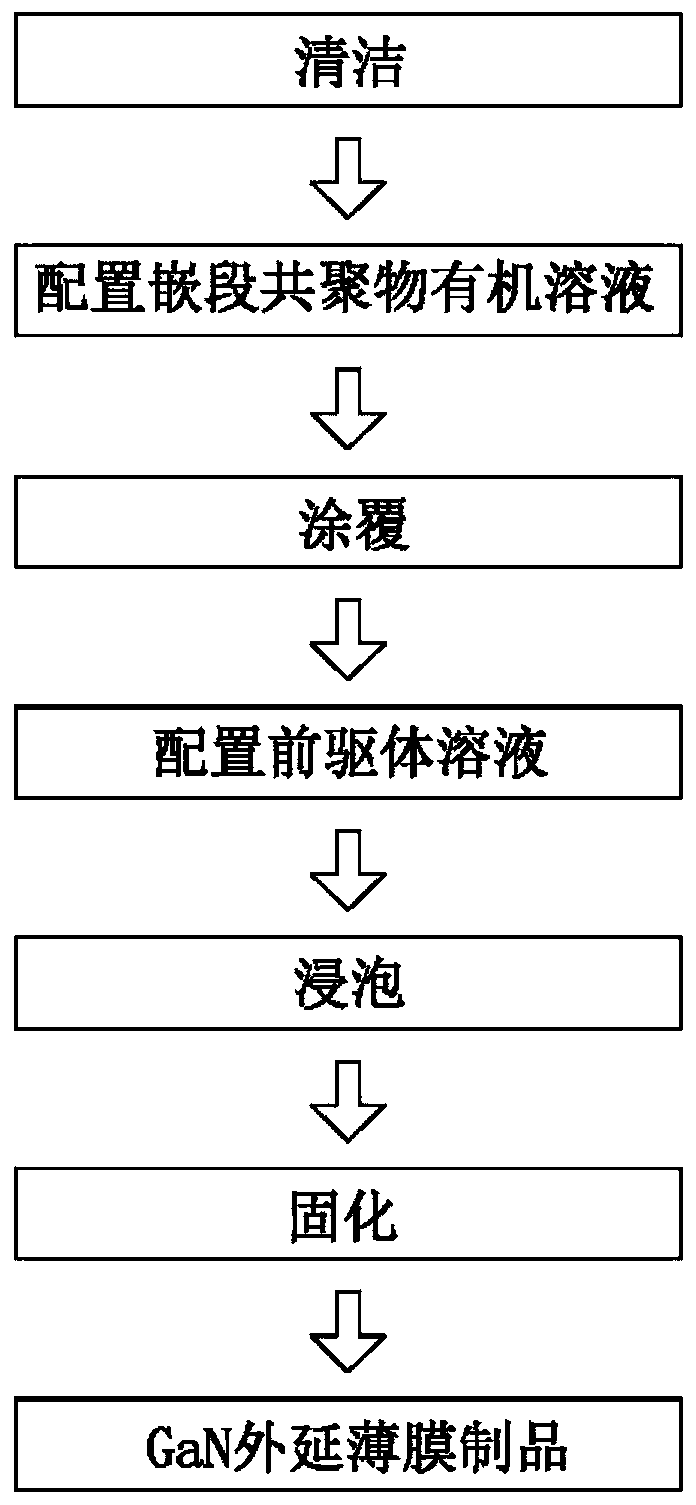

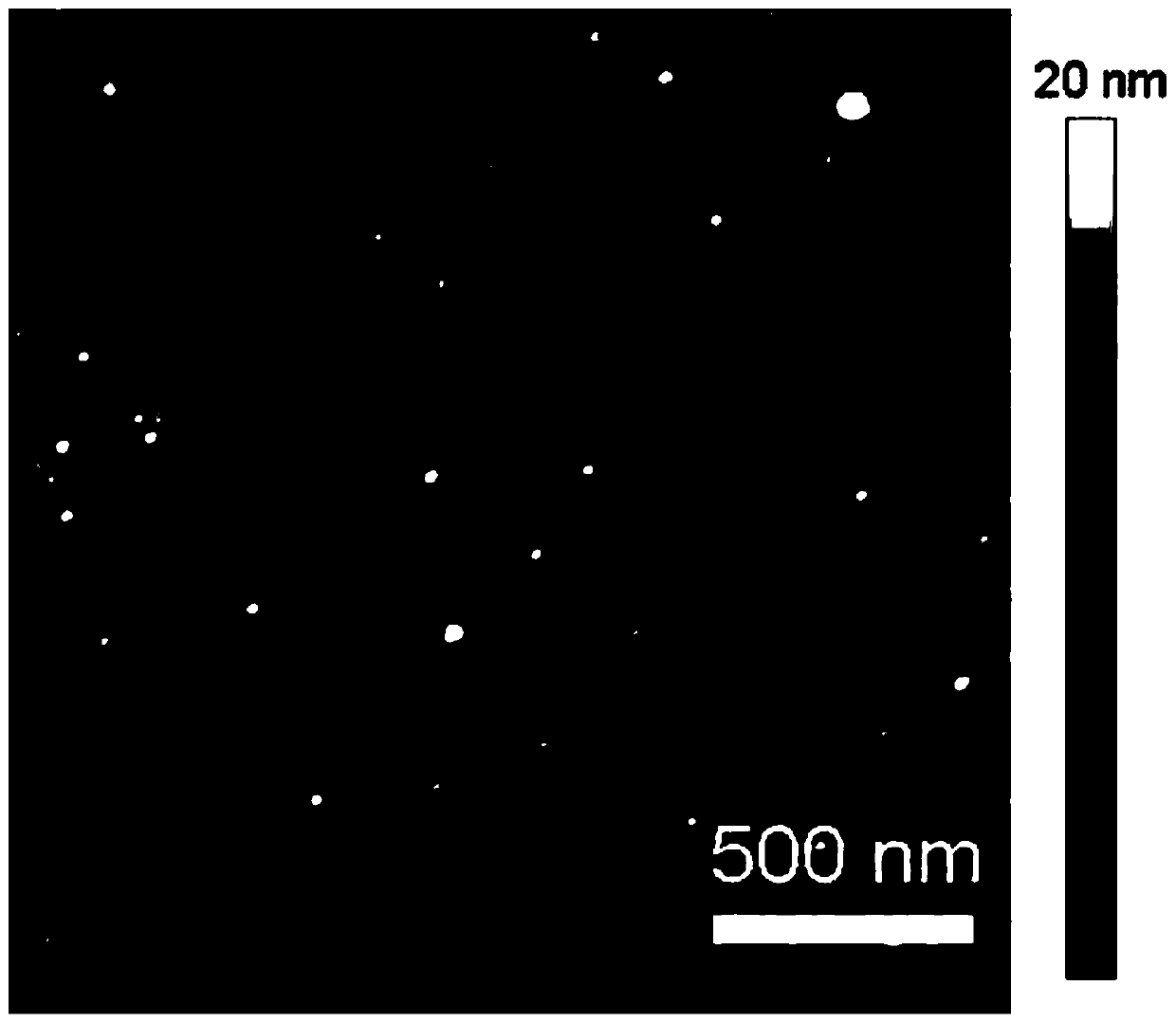

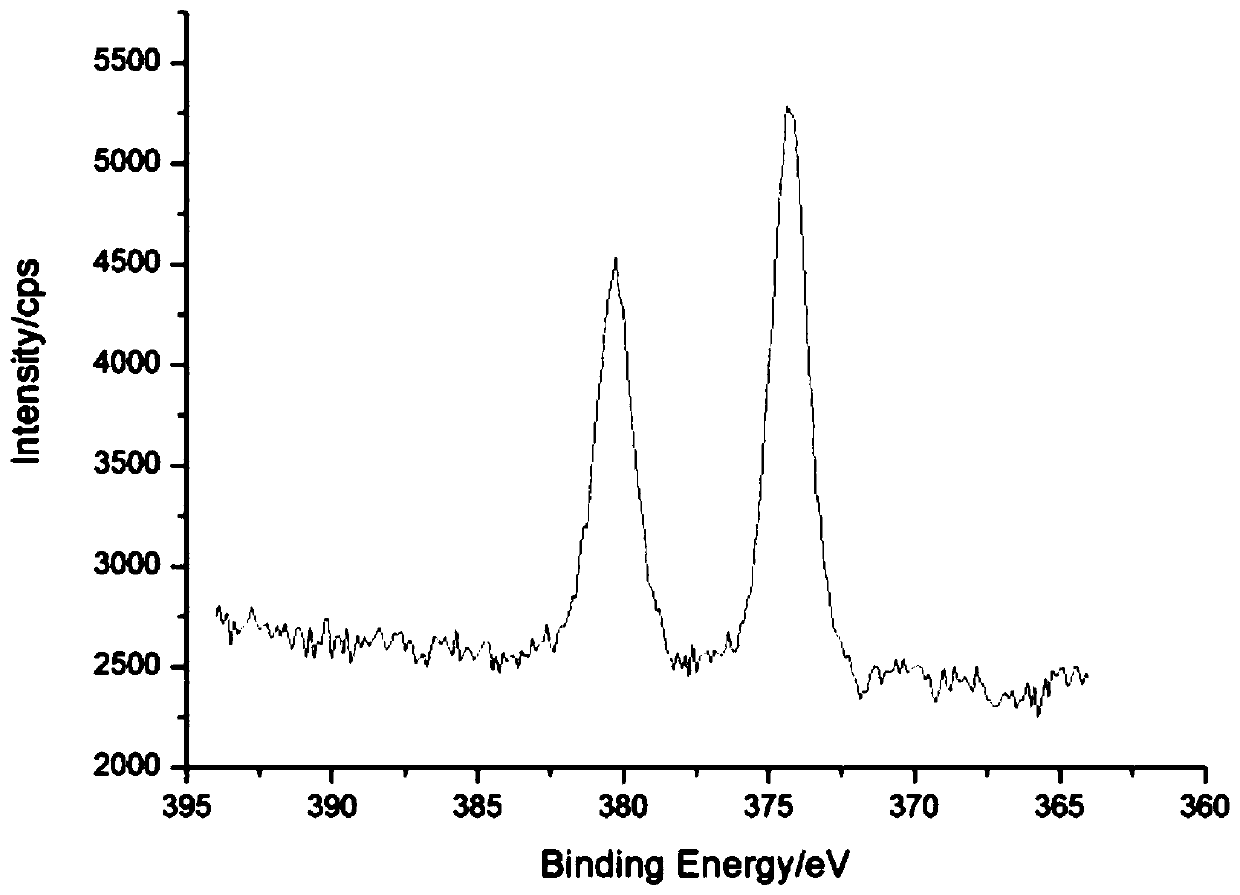

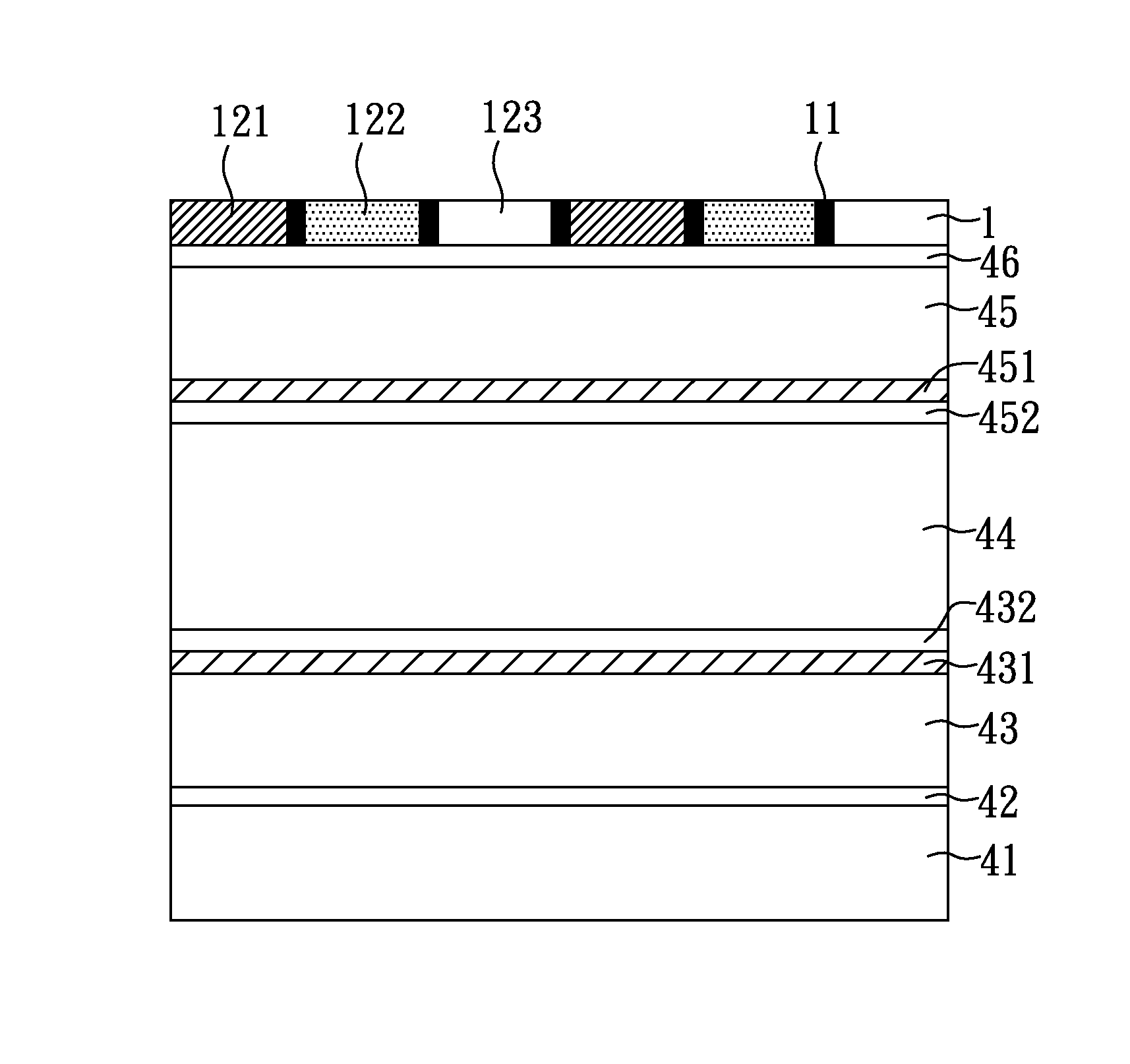

Method for enhancing luminous efficiency of nitride-based LED by using metal nanoparticles

ActiveCN111029443AImprove luminous efficiencySimple processSemiconductor devicesThin membraneMetallic nanostructures

The invention discloses a method for enhancing the luminous efficiency of a nitride-based LED by using metal nanoparticles. The method comprises the following steps: (1) cleaning; (2) preparing a block copolymer organic solution; (3) coating; (4) preparing a precursor solution; (5) soaking; (6) curing. According to the method provided by the invention, the highly ordered metal nanoparticles are self-assembled on the surface of the GaN-based epitaxial thin film by utilizing a PS-b-P4VP block copolymer template method, the self-assembled metal nanoparticles are uniform in size and highly orderedin the arrangement, the plasma elements are generated through the surface ordered metal nanostructures to improve the light extraction rate, the whole enhancement method is simple and feasible in process, high in repeatability and suitable for large-scale industrial operation, subsequent special environments such as acid, alkali and high temperature do not exist, adverse effects on the GaN-basedepitaxial film structure are avoided and the product quality is guaranteed.

Owner:SONGSHAN LAKE MATERIALS LAB

Patterned color conversion film and display device using the same

ActiveUS9267664B2Increase profitImprove the problemSolid-state devicesSpectral modifiersDisplay deviceQuantum dot

A patterned color conversion film and a display device using the same are disclosed. The patterned color conversion film of the present invention comprises: a separator with plural openings; and plural pixel units disposed in the openings respectively, each pixel unit respectively comprising: a medium and scattering particles dispersed therein. Herein, at least one of the plural pixel units comprises quantum dots having the scattering particles sized of between 0.05 and 1 μm when a volume concentration of the quantum dots is in a range more than or equal to 5% and less than or equal to 80%, or having the scattering particles sized of between 0.2 and 2 μm when the volume concentration of the quantum dots is in a range less than 5% and more than or equal to 0%.

Owner:INNOLUX CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com