Manufacturing method for LED chip

A technology for light-emitting diodes and a manufacturing method, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of high cost, cumbersome process, unfavorable reflective layer formation, etc., so as to reduce manufacturing cost, increase reflective area, and reduce instability phenomenon Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for manufacturing a gallium nitride-based light-emitting diode chip, the manufacturing steps comprising:

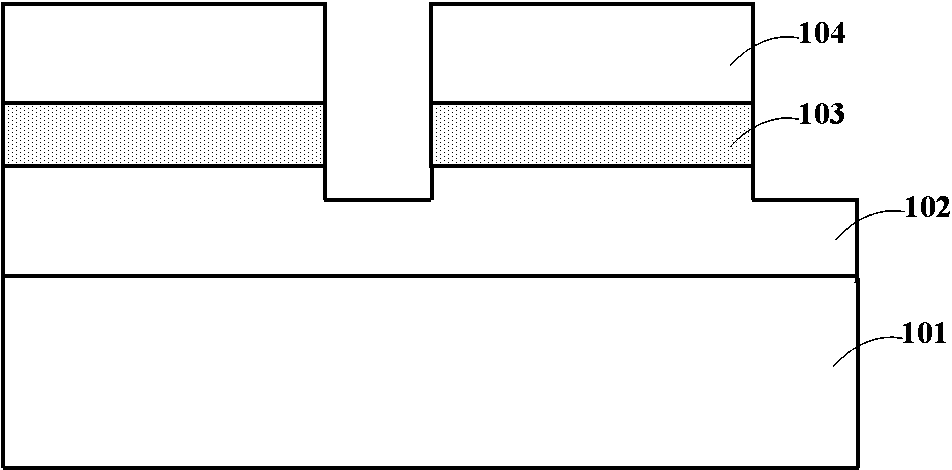

[0035] like figure 1 As shown, an N-type layer 102 , a light-emitting layer 103 and a P-type layer 104 are epitaxially grown sequentially on a sapphire substrate 101 by metal organic chemical vapor deposition (MOCVD).

[0036] like figure 2 As shown, the N-type layer 102 is partially exposed by photolithography and etching techniques.

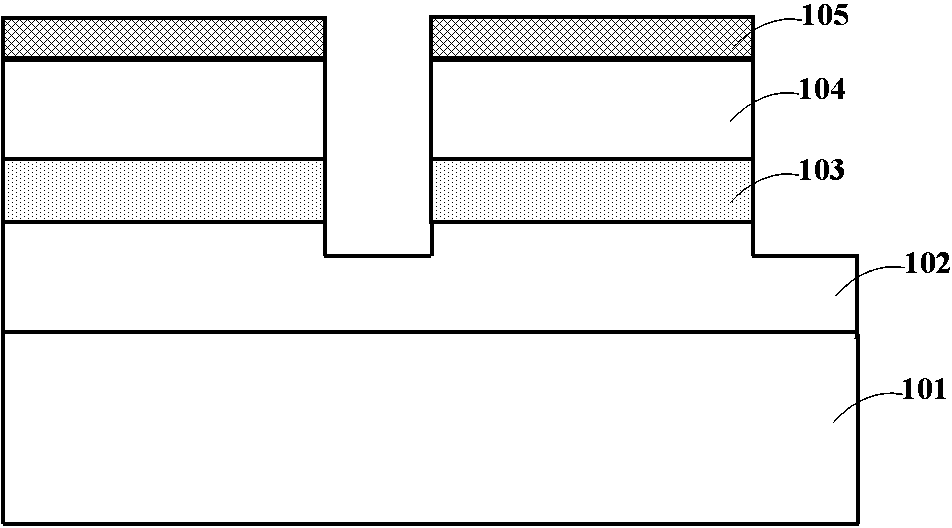

[0037] like image 3 As shown, an ITO transparent conductive layer 105 is formed on the surface of the epitaxial layer, that is, on the surface of the P-type layer 104 .

[0038] like Figure 4 As shown, a P electrode 106 and an N electrode 107 are respectively formed on the ITO transparent conductive layer 105 and the exposed N-type layer 102 by photolithography and etching techniques.

[0039] like Figure 5 As shown, the sapphire substrate 101 is thinned, and the thickness of the thinned sapphire substrate 101 ...

Embodiment 2

[0046]Different from Embodiment 1, in this embodiment, after the distributed Bragg reflection layer is vapor-deposited on the backside of the sapphire substrate and the U-shaped notch, the Al metal reflection layer is then sputtered to form an omnidirectional reflection layer. High thermal conductivity and high reflectivity, which is conducive to the further improvement of the light extraction efficiency of the LED chip and the improvement of the heat dissipation performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com