Polyurethane wrapping basalt fiber wire rope and processing method thereof

A technology of basalt fiber and processing method, which is applied to auxiliary devices for rope making, textiles, papermaking, textile cables, etc., can solve the problems of easy breaking of monofilament, non-wearability of wire rope, loss of tensile strength of tensile skeleton layer, etc. , to achieve the effect of high bonding strength, long service life and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

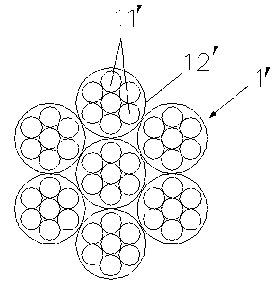

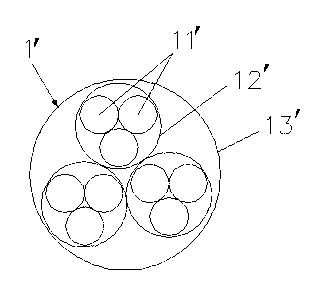

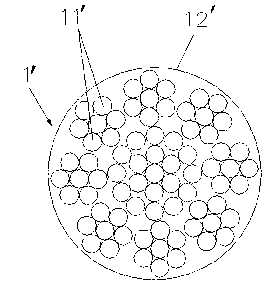

[0024] Such as Figure 1 to Figure 3 As shown, the present invention is composed of a basalt fiber core wire 11' and a cladding layer 12'. The outside of the basalt fiber core wire is provided with a thermoplastic polyurethane elastomer cladding layer 12'. The basalt fiber core wire includes It is a cord made of single-ply or multi-ply double-twisted basalt fiber roving. A single-strand basalt fiber strand is a basalt fiber roving with only one strand; a single basalt fiber core wire is composed of several to dozens of strands of double-twisted strands; a thread made of multiple basalt fiber core wires twisted Rope, when the outer surface is coated with a thermoplastic polyurethane elastomer coating layer 13', the polyurethane elastomer coated wire rope 1' is formed.

[0025] The processing method of the polyurethane-coated basalt fiber cord will be described below in conjunction with the examples.

[0026] The following thermoplastic polyurethane elastomers are represented ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com