Structure of integral boron carbide bulletproof plugboard and ceramic pretreatment process

A bullet-proof insert plate and boron carbide technology, which is applied to the structure of the armor plate and other directions, can solve the problem of insufficient resistance to multiple bullets of the bullet-proof ceramic insert plate, and achieve the effects of shortening the production cycle, high bonding strength, and improving the problem of falling off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further explained below in conjunction with specific examples.

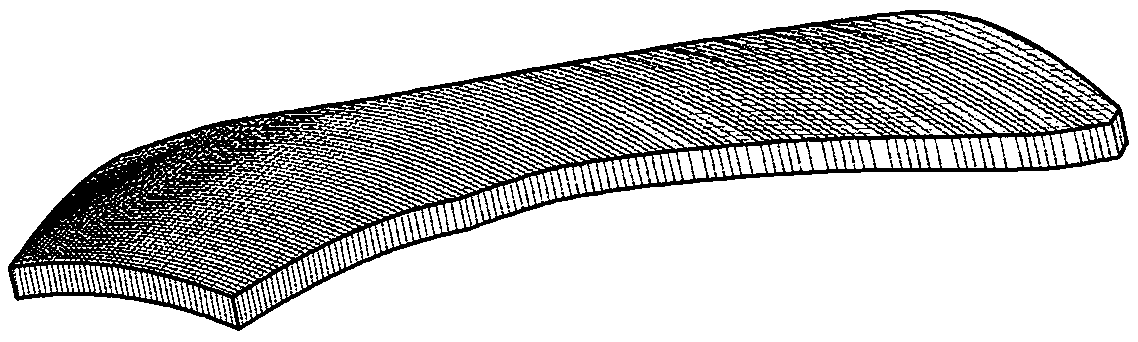

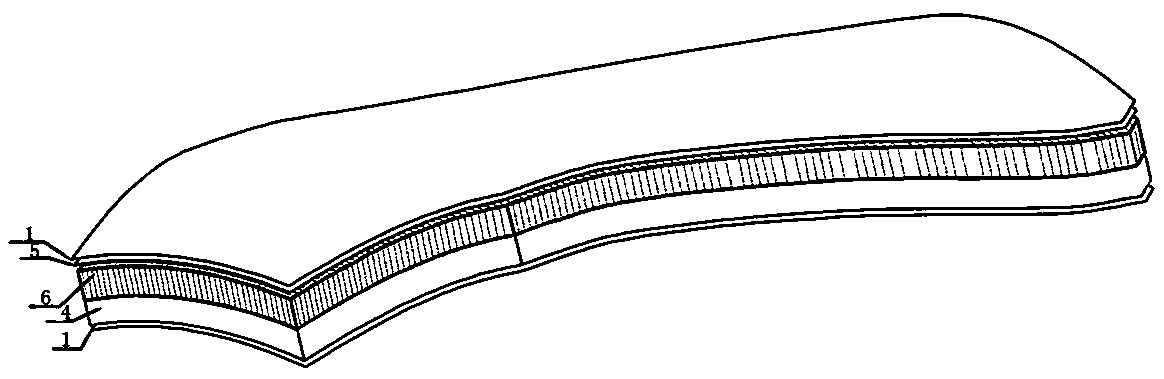

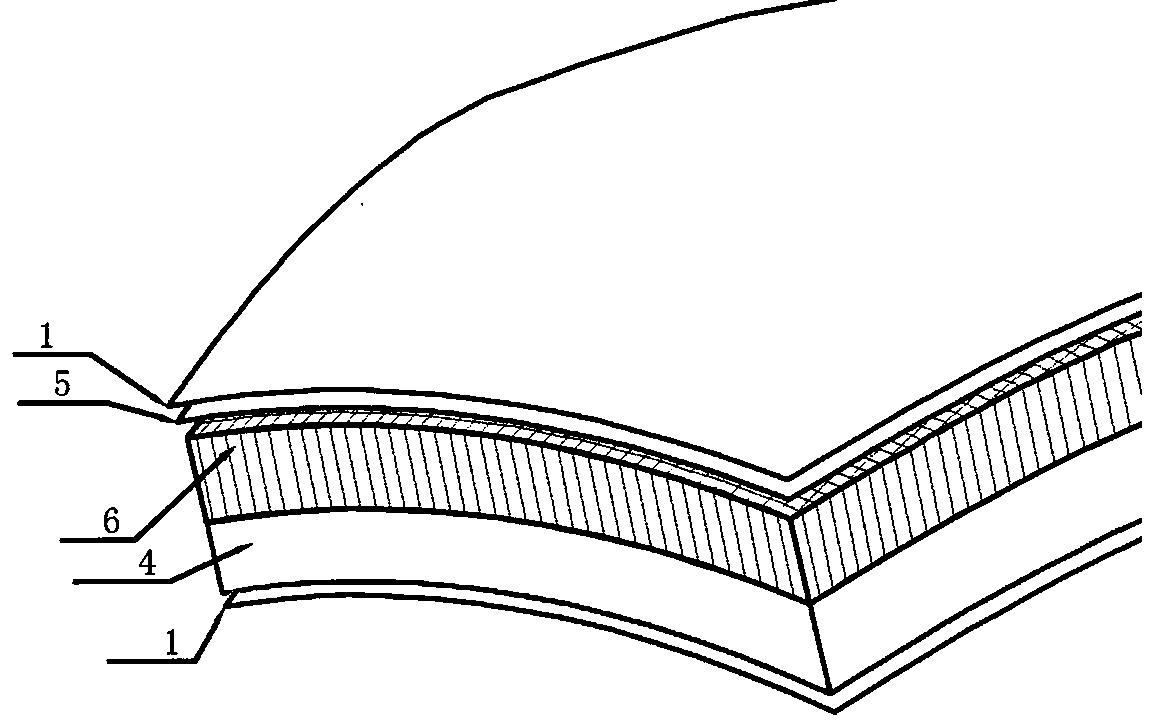

[0038] Such as Figure 1-3 As shown, the boron carbide overall bulletproof board structure mainly includes: conventional packaging material 1; JM05 super shock-absorbing layer 5; bulletproof ceramic super-strong restraint body 6, and bulletproof fiber laminate 4;

[0039] Wherein the bulletproof ceramic super-strong restraint body 6 adopts bulletproof fiber filaments to carry out full-circle restraint winding, and forms the bulletproof ceramic super-strong restraint body 6; the convex side of the bulletproof fiber laminate 4 is placed upwards, and the bulletproof ceramic super-strong restraint body 6 Bond the convex surface of the bulletproof fiber laminated board 4 to form a bulletproof whole board; the super shock absorbing layer 5 is attached to the convex surface of the side whole board by a laminating process; , each layer is bonded with thermoplastic modified silicon-po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com