Molding method of high-density and low-porosity concrete

A molding method and concrete technology, applied in the direction of ceramic molding machines, manufacturing tools, etc., can solve the problems of uncompacted concrete, poor performance of concrete mixture, and affecting the safe use of concrete structures, so as to achieve good compactness, improve mechanical properties and The effect of durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

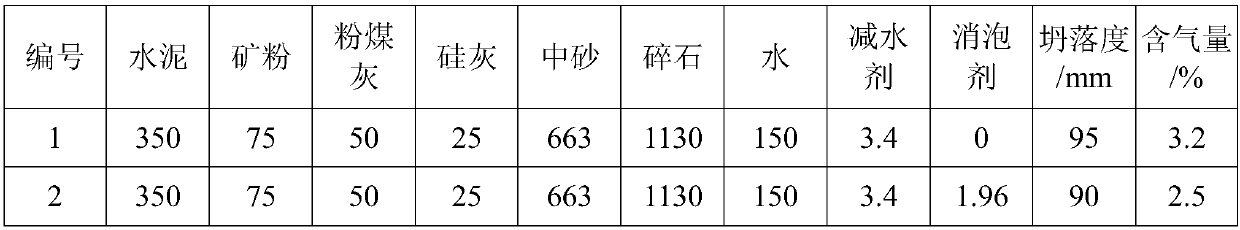

Embodiment 1

[0024] In order to achieve the nuclide transfer coefficient of concrete ≤ 1.0×10 -3 cm 2 / d, C80 high-strength and high-performance concrete material was developed by using a low water-binder ratio and a three-mixing system of fly ash, mineral powder, and silica fume mineral admixtures. The concrete with this ratio has better durability and impermeability protrude. In order to ensure that the nuclide transfer coefficient index cannot meet the specified requirements due to large defects introduced during the concrete forming process or the size of the pores is too large, the formed concrete specimen (specimen size Ф100mm×50mm) is required to be free of defects such as honeycombs and holes , the maximum pore diameter of the pores is less than or equal to 1mm, and the measured porosity is less than or equal to 7%.

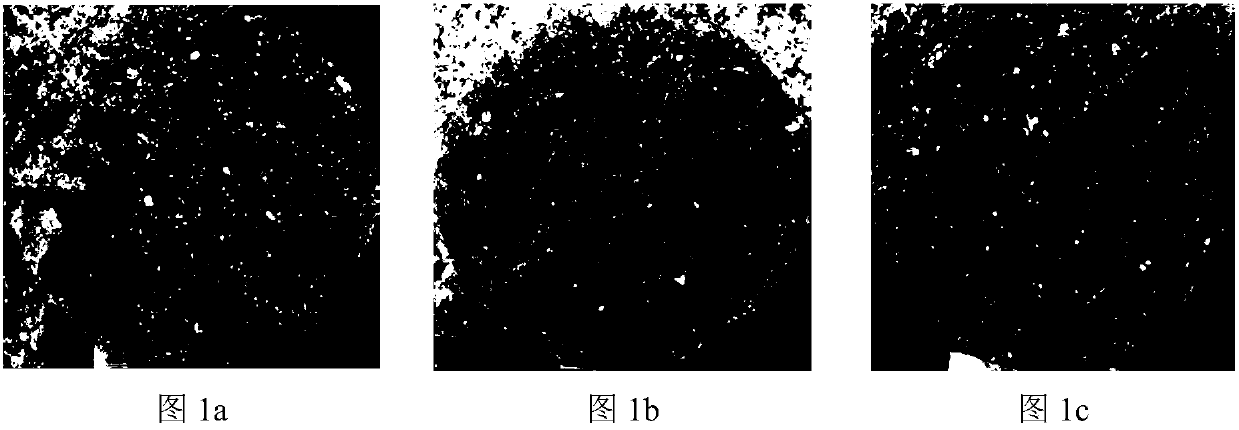

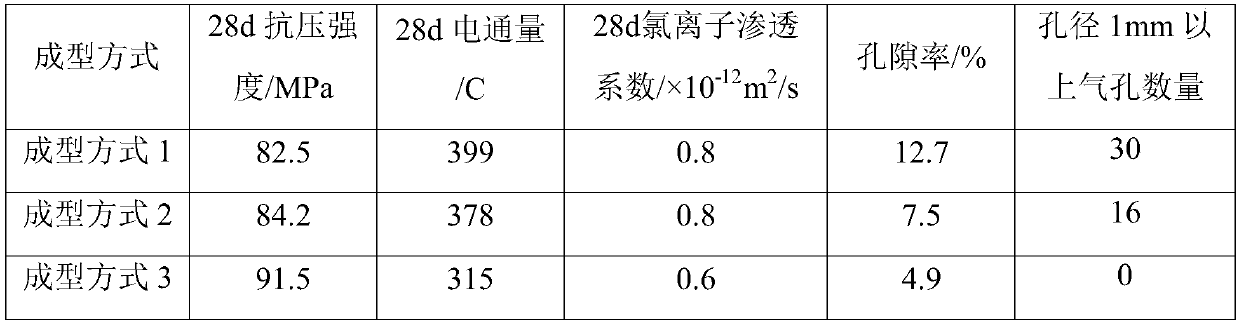

[0025] Three methods were used for compact molding, and the molding effects were compared: molding method 1 is to mix C80 high-strength and high-performance concret...

Embodiment 2

[0033] The high-performance concrete materials used for hazardous waste disposal containers require concrete to have high durability. Usually, the concrete is required to meet the service life of more than 100 years or even 300 years. Therefore, it is more important to vibrate and compact concrete containers during the pouring process and should be avoided There are more obvious honeycombs, holes and pockmarks on the surface. The surface compactness of concrete containers made by two molding methods is given here. Forming method A is to place the mold on a vibrating table to form a container by vibration; forming method B is to pour in three layers according to the high-density and low-porosity concrete forming process described in the present invention, and repeatedly vibrate, insert and tamp to form the container.

[0034] Observe the compactness of the surface of the concrete container formed by the two molding methods. From the actual production effect of the concrete cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com