Modified graphite nanoflake heavy anti-corrosion coating and preparation method thereof

A graphene nanosheet, heavy-duty anti-corrosion technology, applied in anti-corrosion coatings, coatings, polyurea/polyurethane coatings, etc., can solve the problems of high degree of cross-linking, high cost, poor corrosion resistance, etc., and improve the degree of cross-linking. , good compactness, good resistance to electrochemical corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

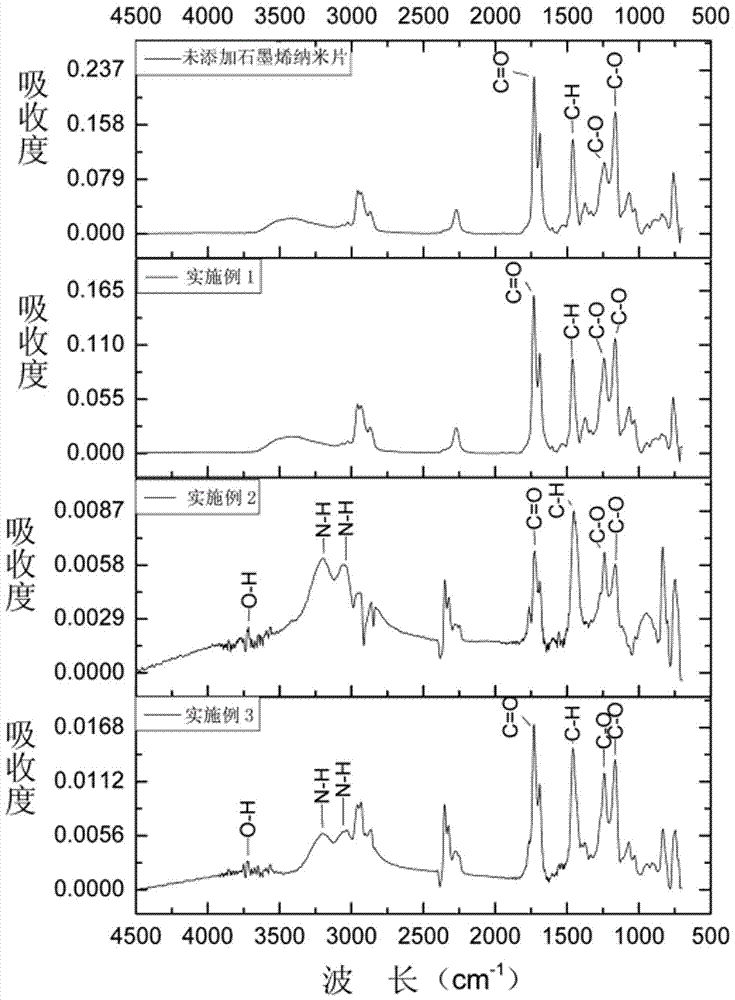

Embodiment 1

[0041] Step 1: Weigh 0.1g graphene nanosheets, and 0.2g sodium dodecylbenzenesulfonate in 10mL ultrapure water for 12 hours, filter, and dry at 70°C for 4 hours to obtain modified graphene nanosheets;

[0042] Step 2: Ultrasound the modified graphene nanosheets in 2mL of acetone for 30min, add them to 10g of acrylic polyurethane resin, add 3g of indene, add 3 drops of dibutyltin dilaurate (drying agent), mix well and let stand for 30min ~2h, after the acetone is completely volatilized, it is coated on the surface-treated metal surface, and the preparation is completed after natural drying for 24h.

Embodiment 2

[0044] Step 1: Weigh 0.2g graphene nanosheets, and 0.4g sodium dodecylbenzenesulfonate in 10mL ultrapure water for 12h, filter, wash with ethanol and water and dry to obtain modified graphene nanosheets;

[0045] Step 2: Ultrasound the modified graphene nanosheets in 3mL xylene for 30min, add them to 10g acrylic polyurethane resin, add 3g oxyindene, add 4 drops of dibutyltin dilaurate, mix well and let stand until the xylene volatilizes Finally, it is coated on the surface-treated metal surface and dried naturally for 48 hours to complete the preparation.

Embodiment 3

[0047] Step 1: Weigh 0.3g graphene nanosheets, and 0.6g sodium dodecylbenzenesulfonate in 10mL ultrapure water for 12h, filter, wash with ethanol and water and dry to obtain modified graphene nanosheets;

[0048] Step 2: Ultrasound the modified graphene nanosheets in 5mL of ethanol for 30min, add them to 10g of acrylic polyurethane resin, add 3g of indene, add 5 drops of dibutyltin dilaurate, mix well and let stand until the ethanol is completely volatilized , coated on the surface-treated metal surface, and dried naturally for 48 hours to complete the preparation.

PUM

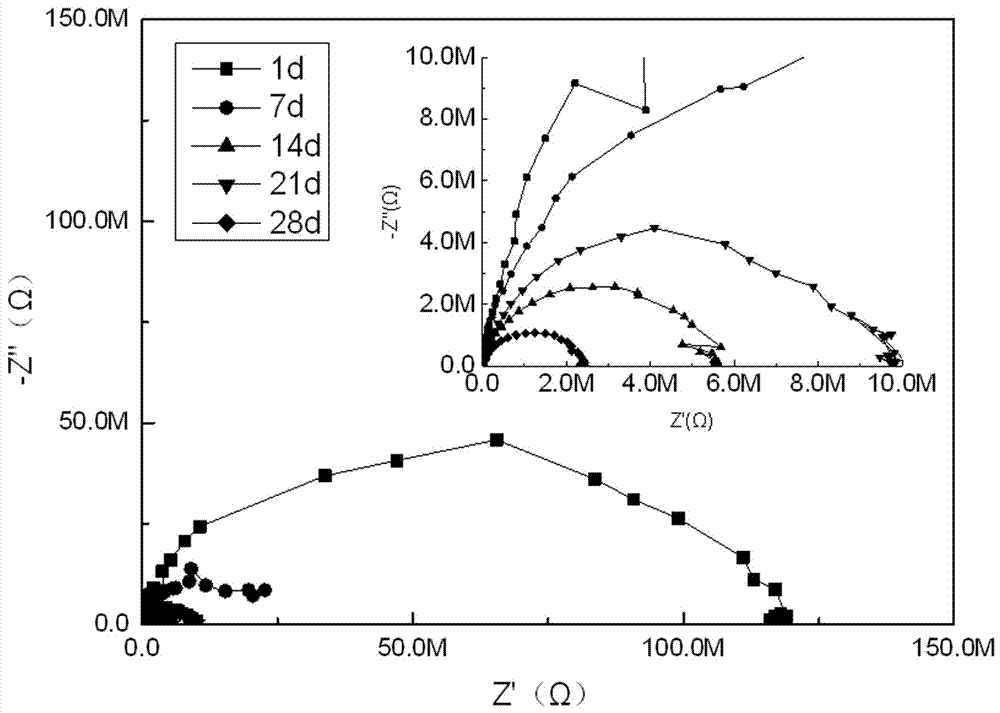

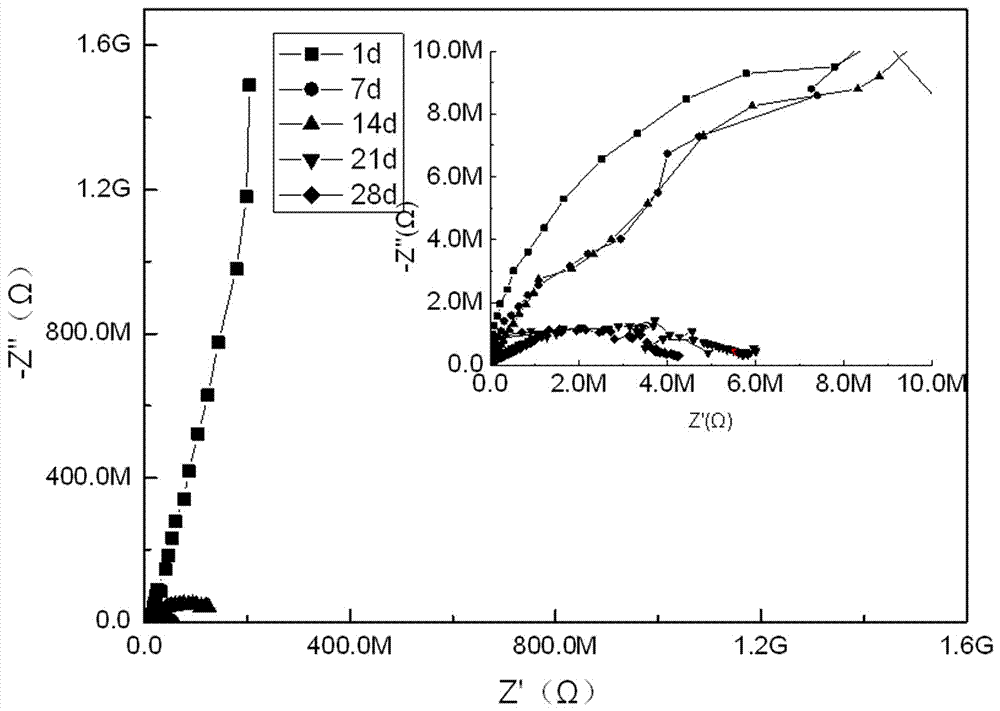

| Property | Measurement | Unit |

|---|---|---|

| Impedance value | aaaaa | aaaaa |

| Impedance value | aaaaa | aaaaa |

| Impedance value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com