Cross-linked hyaluronan sponge and preparation method for same

A technology of cross-linking hyaluronic acid and hyaluronic acid, which is applied in the medical field, can solve the problems of unsatisfactory hemostatic effect and uneven cross-linking degree of the product, and achieve the benefits of wound healing, prolonging the retention time, and preventing the formation of adhesions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

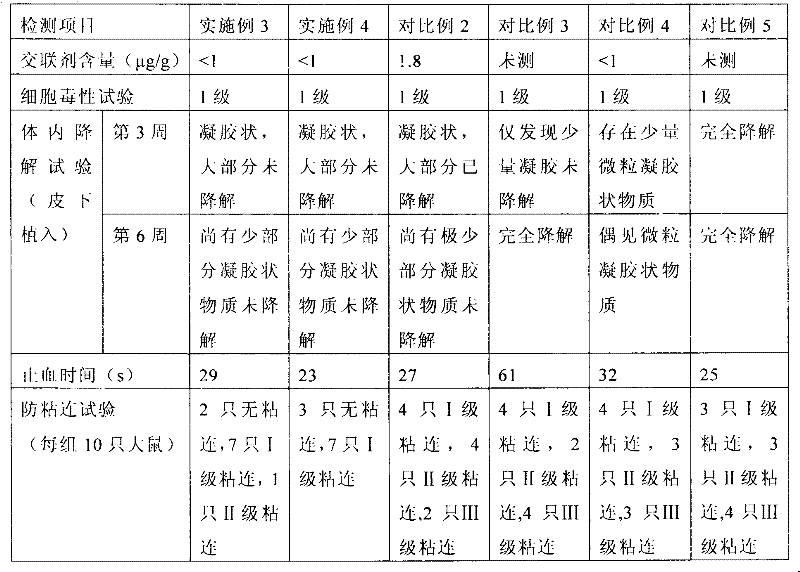

[0035] The preparation method prepared by the present invention or the obtained cross-linked hyaluronic acid sponge has the following advantages:

[0036] (1) When preparing cross-linked hyaluronic acid, the present invention first swells (dissolves) the hyaluronic acid with water, and then adjusts the pH value to be alkaline, which prevents the hyaluronic acid molecular chain from being degraded by alkali in an alkaline environment for a long time. This means that only a small amount of cross-linking agent needs to be added to obtain a product with a higher degree of cross-linking.

[0037] Hyaluronic acid molecules are degraded into hemiacetals and aldehydes at the reducing end of N-acetylglucosamine under alkaline conditions above pH 10. The α-hydrogen atom on the aldehyde group is very unstable under strong alkaline conditions. , The glycosidic bond is easily broken and further degrades to form glucuronic acid with a reducing end. Therefore, hyaluronic acid molecules are easil...

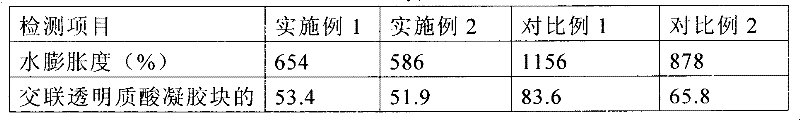

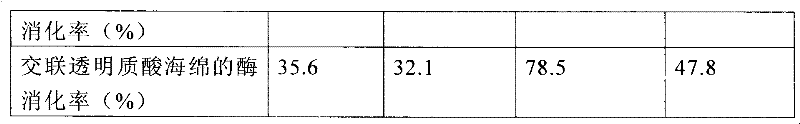

Embodiment 1

[0070] Weigh 2g of hyaluronic acid raw material dry powder into a beaker, add 35ml of distilled water, stir well with a glass rod, seal, store in a refrigerator at 4℃ for 5 days, after hyaluronic acid is fully swelled in distilled water, add 5ml of 2M sodium carbonate solution, Stir uniformly, place at room temperature for 0.5h, and measure the pH of the solution to be 11.5. Add 0.05ml of divinyl sulfone and stir evenly, then pour them into glass dishes with a thickness of about 2mm, and place them in a constant temperature oven at 40°C for 2 hours. , You can get water-insoluble cross-linked hyaluronic acid gel block. Wash the gel in distilled water. When the pH of the cleaning solution is 6.8, drain the water, transfer the cross-linked gel block to the freezer, put it in the freezer at -60℃ for 48h, and then freeze it with a freeze dryer After drying for 48 hours, the cross-linked hyaluronic acid sponge can be obtained, packaged and sealed with aluminum foil, and sterilized by...

Embodiment 2

[0072] Weigh 2g of hyaluronic acid raw material dry powder in a beaker, add 35ml of distilled water, stir well with a glass rod, seal, store in a refrigerator at 4℃ for 1 day, after hyaluronic acid is fully swelled in distilled water, add 5ml of 2M sodium carbonate solution, Stir evenly and place at room temperature for 0.5h. The measured pH value of the solution is 11.2. Add 0.05ml of divinyl sulfone and stir evenly, then pour them into glass plates with a thickness of about 2mm. Place them in a 37℃ thermostat for 4 hours. , You can get water-insoluble cross-linked hyaluronic acid gel block. Put the gel in distilled water for washing. When the pH of the washing solution is 7.1, drain the water, transfer the cross-linked gel block to the freezer, put it in the freezer at -60℃ for 48h, and then freeze it with a freeze dryer After drying for 48 hours, the cross-linked hyaluronic acid sponge can be obtained, packaged and sealed with aluminum foil, and sterilized by gamma rays.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com