UV-curing glass protecting ink with fragment stripping and preparation method thereof

A technology to protect ink and release film, applied in ink, household appliances, applications, etc., can solve the problems of not easy to fade film, consumption of production time, immature performance, etc., and achieve the effect of improving adhesion, improving water resistance and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

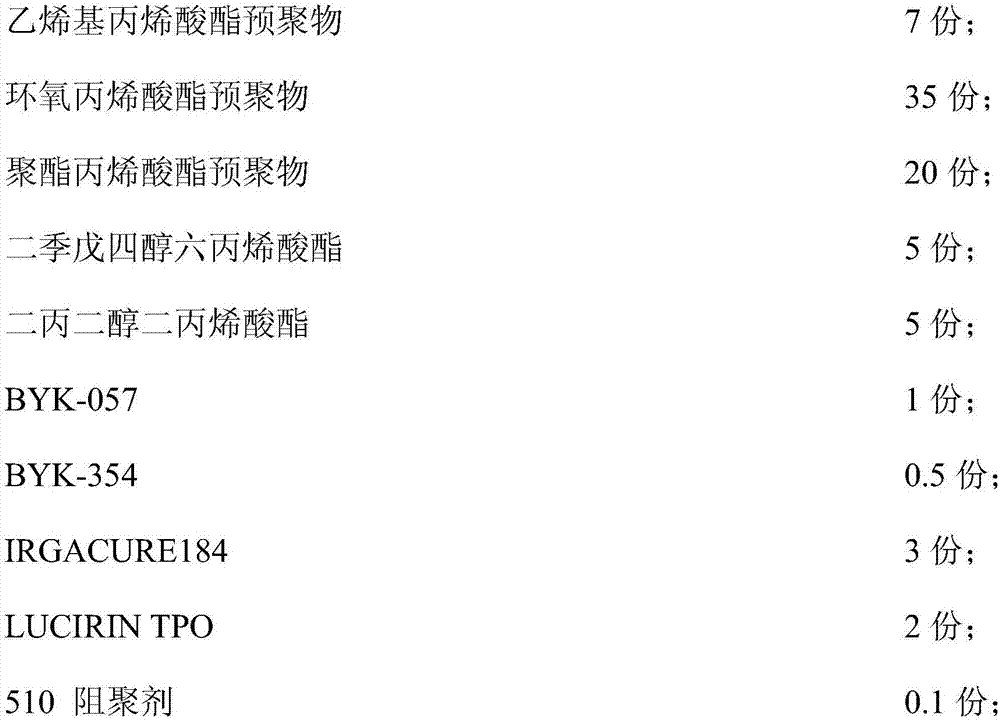

[0051] A kind of UV solidified glass protection ink that fragment releases film, the composition of described protection ink comprises according to mass parts:

[0052]

[0053]

[0054] A kind of preparation method of the UV cured glass protective ink of above-mentioned fragment release, described preparation method comprises the following steps:

[0055] (1) Disperse vinyl acrylate prepolymer, epoxy acrylate prepolymer, polyester acrylate prepolymer, dipentaerythritol hexaacrylate, dipropylene glycol diacrylate, BYK-057 and BYK-354 under stirring Mix and disperse in the machine to obtain the mixture;

[0056] (2) Mix the mixture obtained in step (1) with IRGACURE184, LUCIRIN TPO, 510 polymerization inhibitor, and talcum powder, stir and disperse, and obtain UV-cured glass protection ink for fragment release.

[0057] Wherein, the acid value of the epoxy acrylate prepolymer is 160, and the acid value of the polyester acrylate prepolymer is 35.

Embodiment 2

[0059] A kind of UV solidified glass protection ink that fragment releases film, the composition of described protection ink comprises according to mass parts:

[0060]

[0061]

[0062] A kind of preparation method of the UV cured glass protective ink of above-mentioned fragment release, described preparation method comprises the following steps:

[0063] (1) Mix and disperse vinyl acrylate prepolymer, epoxy acrylate prepolymer, polyester acrylate prepolymer, tripropylene glycol diacrylate, BYK-053 and BYK-355 in a stirring disperser, get the mixture;

[0064] (2) Mix the mixture obtained in step (1) with benzoin methyl ether, tris(N-nitroso-N-phenylhydroxylamine) aluminum salt, and talcum powder, stir and disperse, and obtain the UV-cured fragment release film Glass protection ink.

[0065] Wherein, the acid value of the epoxy acrylate prepolymer is 150, and the acid value of the polyester acrylate prepolymer is 25.

Embodiment 3

[0067] A kind of UV solidified glass protection ink that fragment releases film, the composition of described protection ink comprises according to mass parts:

[0068]

[0069]

[0070] A kind of preparation method of the UV cured glass protective ink of above-mentioned fragment release, described preparation method comprises the following steps:

[0071] (1) Put vinyl acrylate prepolymer, epoxy acrylate prepolymer, polyester acrylate prepolymer, di-trimethylolpropane tetraacrylate, BYK-053 and BYK-355 in a stirring disperser Mixing and dispersing to obtain a mixture;

[0072] (2) The mixture obtained in step (1) is mixed with 2,2-dimethoxy-2-phenylacetophenone, 2,2-diethoxy-2-phenylacetophenone, three (N- Nitroso-N-phenylhydroxylamine) aluminum salt and aluminum oxide powder are mixed, stirred and dispersed to obtain UV curing glass protection ink with fragment release.

[0073] Wherein, the acid value of the epoxy acrylate prepolymer is 180, and the acid value of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com