Preparation method of high-speed steel tool protective coating

A technology of protective coating and high-speed steel, applied in coating, metal material coating process, gaseous chemical plating, etc., can solve the problems of high production cost and high defect density of tool protective coating, and improve the utilization rate of raw materials , good compactness, the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

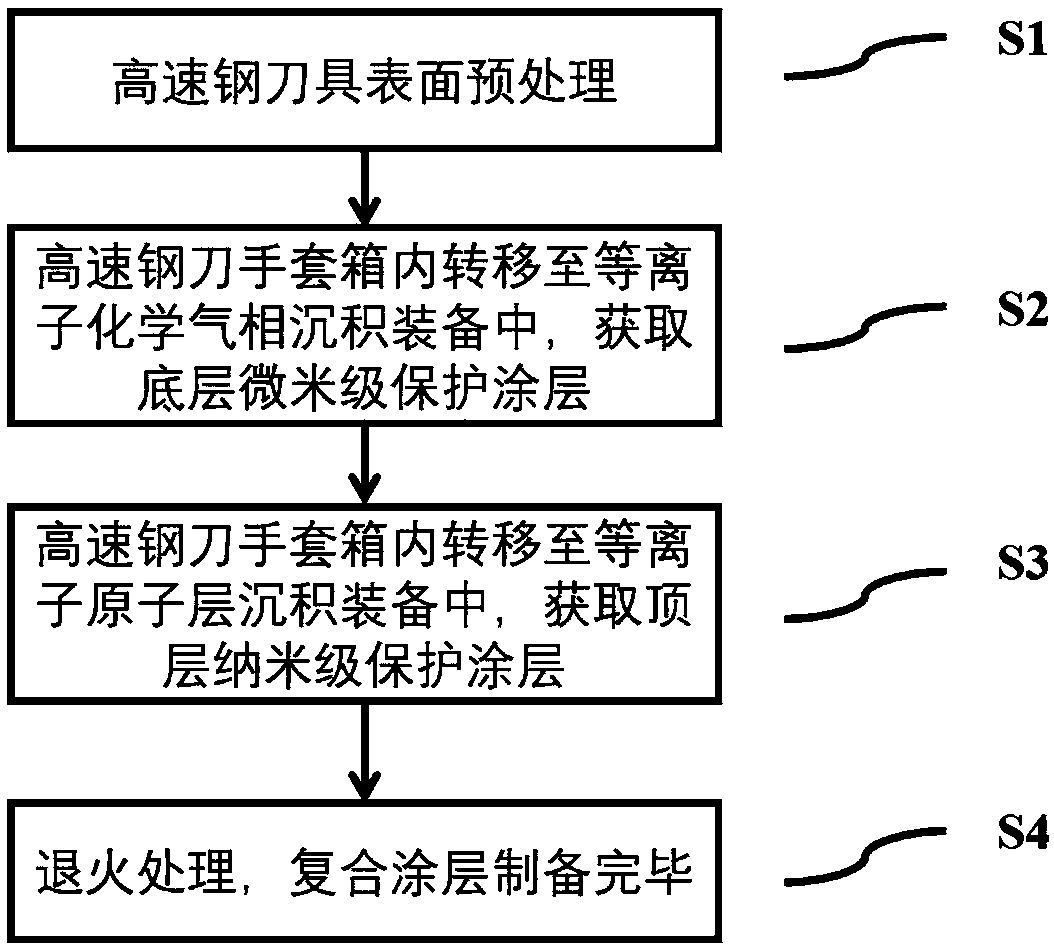

[0041] like figure 1 As shown, the preparation method of a high-speed steel tool protective coating provided by the embodiment of the present invention is used to deposit a dense composite film on the surface of the high-speed steel tool to protect it. The method includes the following steps:

[0042] S1 Pretreatment of cleaning and drying the surface of the high-speed steel tool to be protected

[0043] In the above cleaning steps, the high-speed steel tool is soaked in absolute ethanol, cleaned with a plasma cleaner, then wiped and dried with a dust-free cloth or paper, and blown dry with a nitrogen air gun.

[0044] S2 is deposited on the surface of high-speed steel cutting tools to obtain a micron-sized bottom film

[0045] The high-speed steel cutters processed by the above pretreatment steps are stored in a glove box to keep the surface clean and dry, and then transferred to a plasma-enhanced chemical vapor deposition (PECVD) chamber for plasma-enhanced chemical vapor d...

Embodiment 1

[0077] In this embodiment, a protective coating is prepared on the surface of a typical high-speed steel cutting tool, and a silicon wafer is used for a comparative experiment.

[0078] First, a silicon nitride film with a thickness of 5 μm was deposited by plasma chemical vapor deposition at a deposition temperature of 80 °C, and the two precursors introduced were SiH 4 , NH 3 , the chemical reaction equation for preparing silicon nitride film is:

[0079]

[0080]

[0081] And the overall reaction equation is:

[0082]

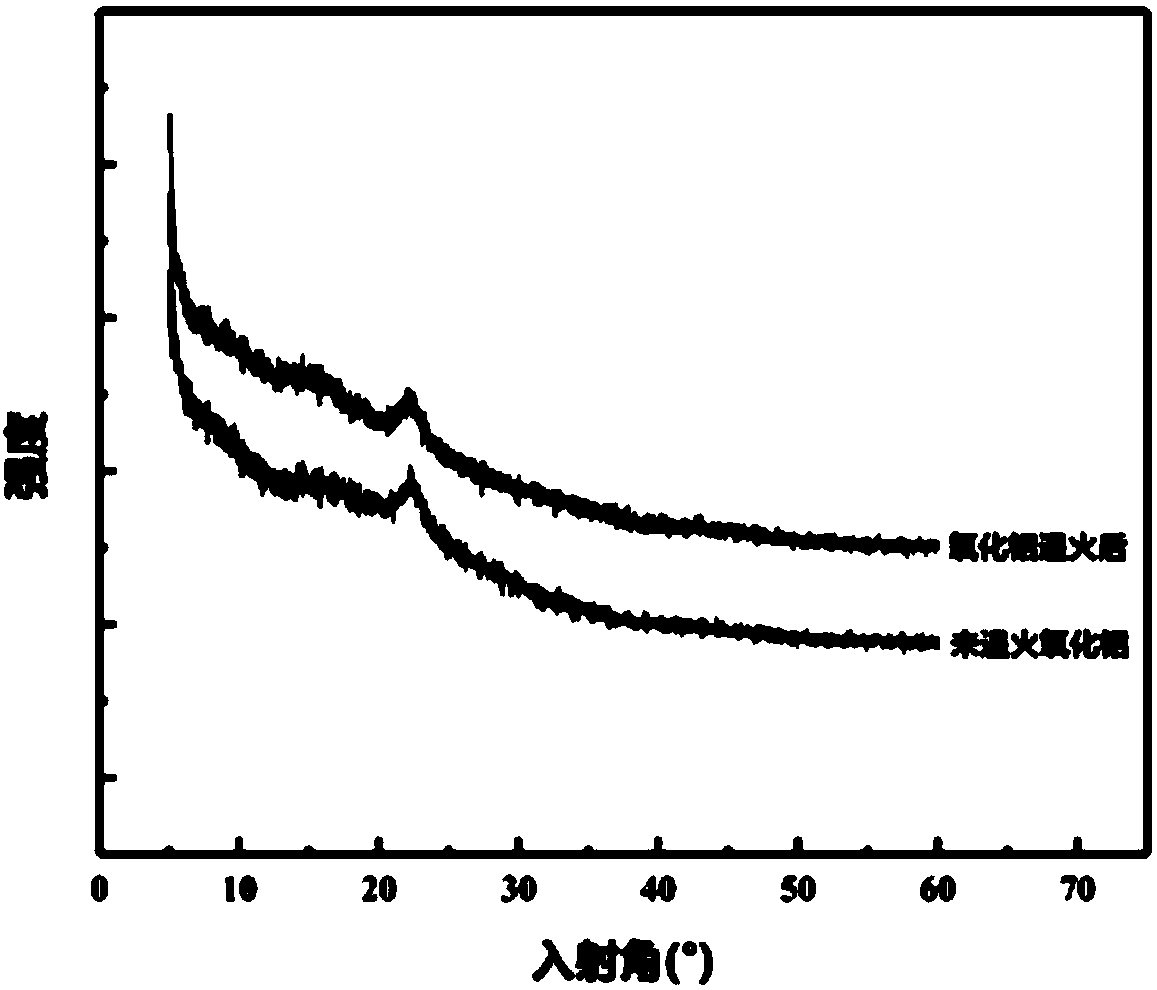

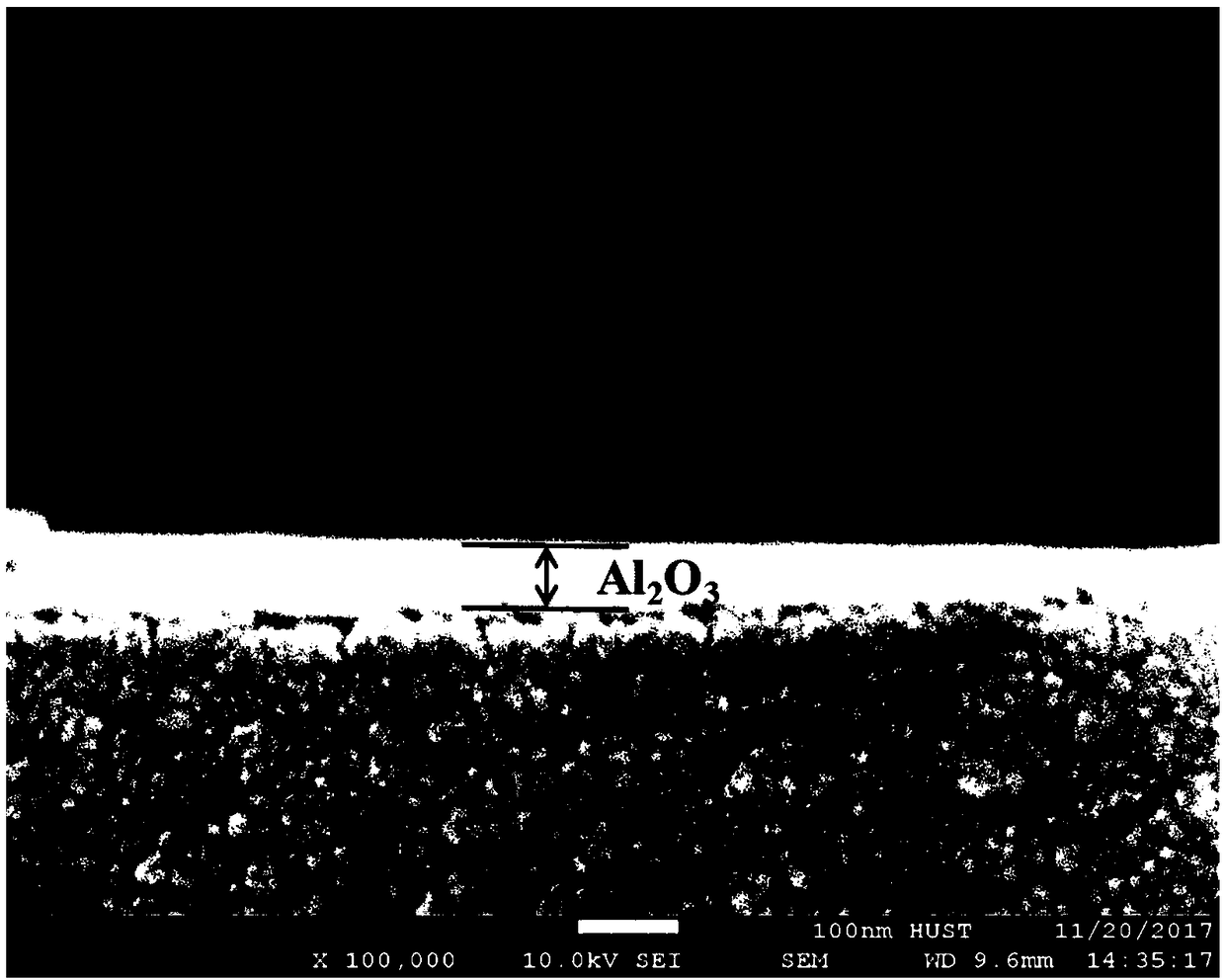

[0083] Then, after the silicon nitride film was prepared, a layer of aluminum oxide film with a thickness of 20nm was deposited on the silicon nitride film by plasma-enhanced atomic layer deposition, the deposition temperature was 80°C, and the three precursors introduced were Al( CH 3 ) 3 , O 2 and H 2 O.

[0084] The chemical reaction equation for preparing aluminum oxide film is:

[0085] AlOH * +Al(CH 3 ) 3 →Al-O-(CH 3 ) 2 +CH 4

...

Embodiment 2

[0097] The knives are easily eroded by various gases during storage, such as water vapor in the air. The invention uses a composite film layer to protect the OLED device with an area of 5cm×5cm. The lighting state of the OLED device can be used to observe the knife more intuitively. The barrier effect of the encapsulation layer and the defect failure site can prove that the encapsulation film has good water vapor barrier ability.

[0098] A silicon nitride layer with a thickness of 1 μm + an aluminum oxide film with a thickness of 50 nm was prepared on the surface of an OLED device by using the preparation method of the present invention, and the reaction equation was the same as that in Example 1. After the reaction is completed, the device is placed in an environment of 60°C and 90% relative humidity for aging test. The test comparison diagram is as follows Figure 4 shown. in, Figure 4 a) is the lighting state diagram of the initial state of the OLED device, Figure 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com