Preparation method of pink zirconia ceramic

A zirconia ceramic, pink technology, applied in the field of preparation of pink zirconia ceramics, can solve the problems of high energy consumption, high mold material requirements, rising production costs, etc., to achieve simple and easy-to-use preparation process and low production process cost , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0036] Weigh 20 grams of polyvinyl alcohol and dissolve it in 1000 grams of water, pour it into a 5L ball mill jar after fully dissolving, add 1000 grams of yttria-containing stabilized tetragonal zirconia powder (purity is 99%, average particle size is 0.5 μm) and 50 After 24 hours of ball milling, pour out the suspension, dry and remove the moisture, grind the ceramic powder and pass through a 500-mesh sieve, and dry press and cold isostatic press to prepare a product with a diameter of 28 mm and a thickness of 8 mm zirconia round cake. Then put it into a high-temperature sintering furnace to remove the glue and sinter it into a pink zirconia ceramic product.

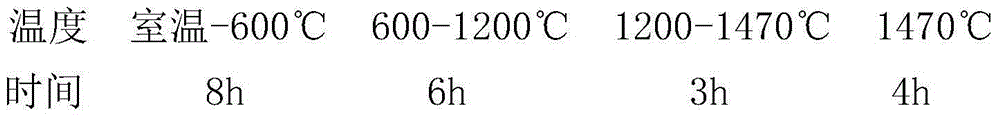

[0037] The debinding and sintering integrated process segment can be expressed as:

[0038]

[0039] The fired zirconia ceramic products are tested experimentally, among which, the Archimedes principle is used to detect the density, the microhardness tester is used to test the Vickers hardness of the material, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com