Method and device suitable for laminating film for ultrathin wafer

A film sticking device and wafer technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of easy damage, and achieve the effects of avoiding cracks, improving capabilities, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

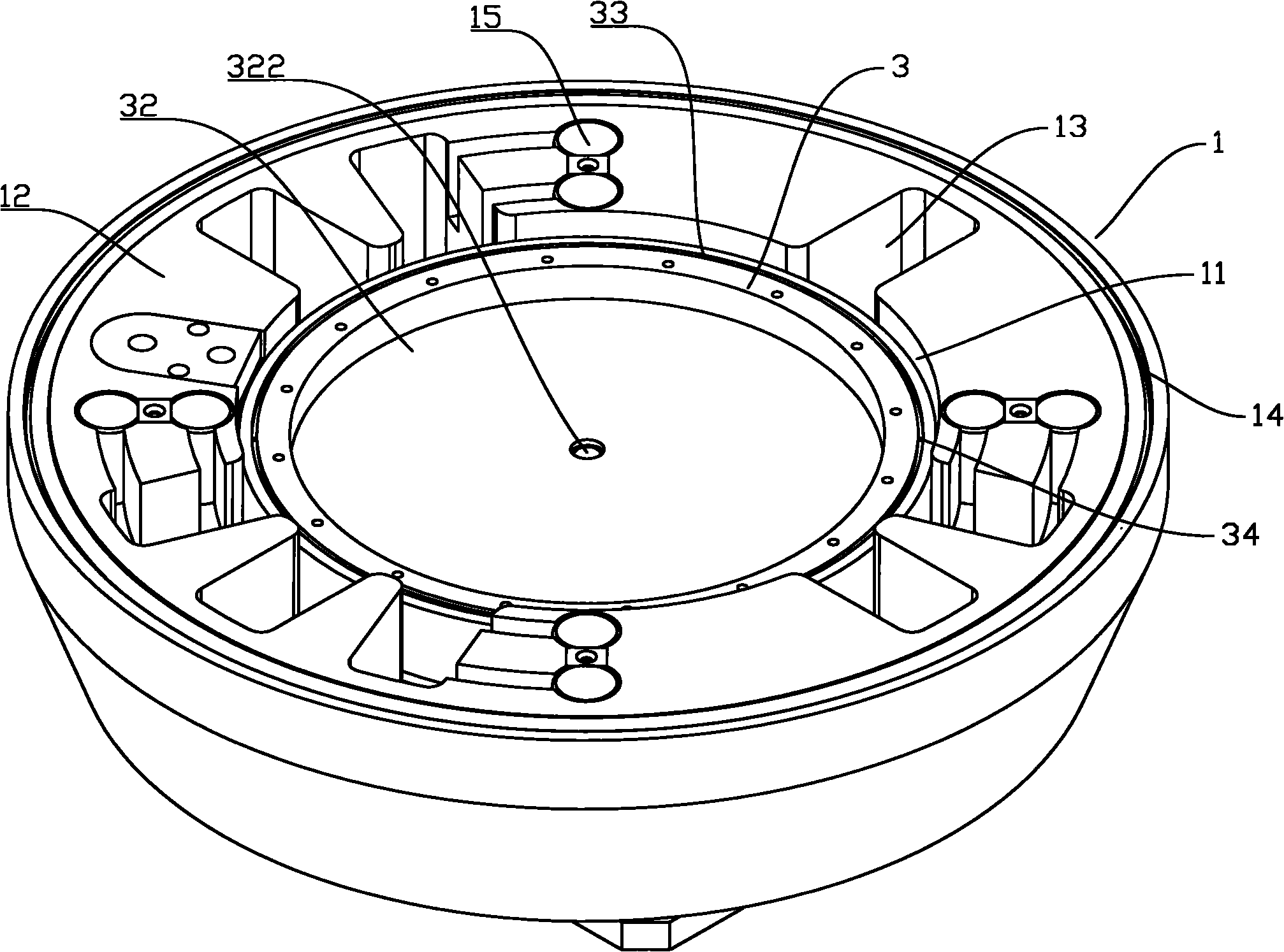

[0069]Replace the second vacuum device in Example 1 with a second gas compressor, the second gas compressor communicates with the second groove, and omit the third groove 13, the first air hole 21, the first vacuum device, the second Three air holes 23 and the third vacuum device. The second gas compressor can blow compressed gas into the second groove 32 through the second air hole, and when the wafer is placed on the upper surface of the platform 3, the second gas compressor can adjust the gas pressure in the second groove 32 . Because the gas pressure between the wafer and the film is constant, as long as the gas pressure in the second groove 32 is increased, the wafer can be pressed against the film, and because the edge of the wafer is fixed by adsorption, the wafer arches from the center and is first aligned with the film. The film is in contact, and gradually contacts the film from the center to the edge until the suction force on the edge of the wafer is released, and...

Embodiment 3

[0071] Replace the second vacuum device in Example 1 with a second gas compressor, the second gas compressor communicates with the second groove, omit the third groove 13 and the first air hole 21, and replace the third vacuum device with The third gas compressor communicates with the third air hole 23 . The gas compressor can blow compressed gas into the second groove 32 through the second air hole, and when the wafer is placed on the upper surface of the platform 3 , the second gas compressor can adjust the gas pressure in the second groove 32 . Since the gas pressure between the wafer and the film remains constant, as long as the gas pressure in the second groove 32 is increased, the wafer can be pressed against the film, and since the edge of the wafer is adsorbed and fixed, the wafer starts to arch from the center Contact the film, and gradually contact the film from the center to the edge, until the vacuum suction force that adsorbs the edge of the wafer disappears, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com