Preparation method of conductive copolymer film

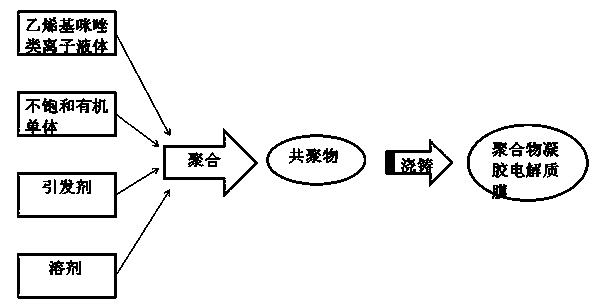

A technology of copolymer membrane and ionic liquid, applied in non-metallic conductors, organic material conductors, etc., can solve the problems of poor membrane flexibility, poor film-forming properties of copolymers, and low electrical conductivity, and achieve good film-forming properties and good electrical conductivity. , good film flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1: 12 g of N-vinyl-N-ethylimidazole bromide and 13.71 mL of ethylene were dissolved in 60 mL of chloroform; a mixture of 0.183 g of azobisisobutyronitrile and potassium persulfate was added to the solution In the medium, quickly install the condenser tube, feed nitrogen gas, stir and react at 65 °C for 5 h, then filter to obtain a polymer gel electrolyte, wash it with chloroform several times, and dry it in vacuum at 80 °C for later use; The gel electrolyte is dissolved in methanol, stirred until uniform, cast on a polytetrafluoroethylene plate, and dried to obtain a polymer gel electrolyte membrane 1 .

Embodiment 2

[0019] Example 2: Dissolve 12 g of N-vinyl-N-ethylimidazole bromide and 3.26 mL of methyl methacrylate and 1.37 mL of ethylene in 60 mL of chloroform; then add 0.0789 g of azobisisoheptanonitrile to In this solution, a condenser tube was quickly installed, and argon gas was introduced, stirred and reacted at 70 °C for 5 h, and then filtered to obtain a polymer gel electrolyte, which was washed several times with chloroform, and vacuum-dried at 80 °C for later use; then the obtained The polymer gel electrolyte is dissolved in methanol, stirred until uniform, cast on a polytetrafluoroethylene plate, and dried to obtain the polymer gel electrolyte membrane 2 .

Embodiment 3

[0020] Example 3: 12 g of N-vinyl-N-propylimidazolium boron tetrafluoride and 1.68 mL of vinylidene fluoride were dissolved in 60 mL of carbon tetrachloride; 0.0651 g of benzoyl peroxide was added to the solution In the medium, quickly install the condenser tube, pass in argon, stir and react at 80 °C for 3 h, then filter to obtain a polymer gel electrolyte, wash it with carbon tetrachloride several times, and dry it in vacuum at 80 °C for later use; The polymer gel electrolyte was dissolved in DMF, stirred until uniform, cast on a polytetrafluoroethylene plate, and dried to obtain the polymer gel electrolyte membrane 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com