Resin composition and cosmetic containing said resin composition

A technology of resin composition and cosmetics, applied in the direction of cosmetics, cosmetics, cosmetic preparations, etc., can solve problems such as inability to absorb smoothly all the time, damage to the uniformity of the coating film, poor skin adhesion, etc., and achieve makeup durability and gloss Excellent skin feel, excellent makeup effect, excellent long-lasting makeup effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture Embodiment 1

[0229] Preparation of resin composition (1):

[0230] After melting and stirring 100g of carnauba wax, it is solidified and formed into flakes with a size of about 5-10mm. 100 g of this flaky carnauba wax was poured into 300 ml of isopropanol preheated to 40° C. while stirring, and the temperature was kept at 40° C., and it was left to stand for 6 hours to carry out extraction treatment. It was then filtered, and isopropanol was removed from the filtrate by distillation under reduced pressure to obtain a resin composition.

[0231] According to the aforementioned measurement method, the resin concentration, softening point, etc. of the obtained resin composition were measured. The results showed that the resin concentration was 30%, the softening point was 70.4°C, the iodine value was 40, the acid value was 17, and the saponification value was 82.

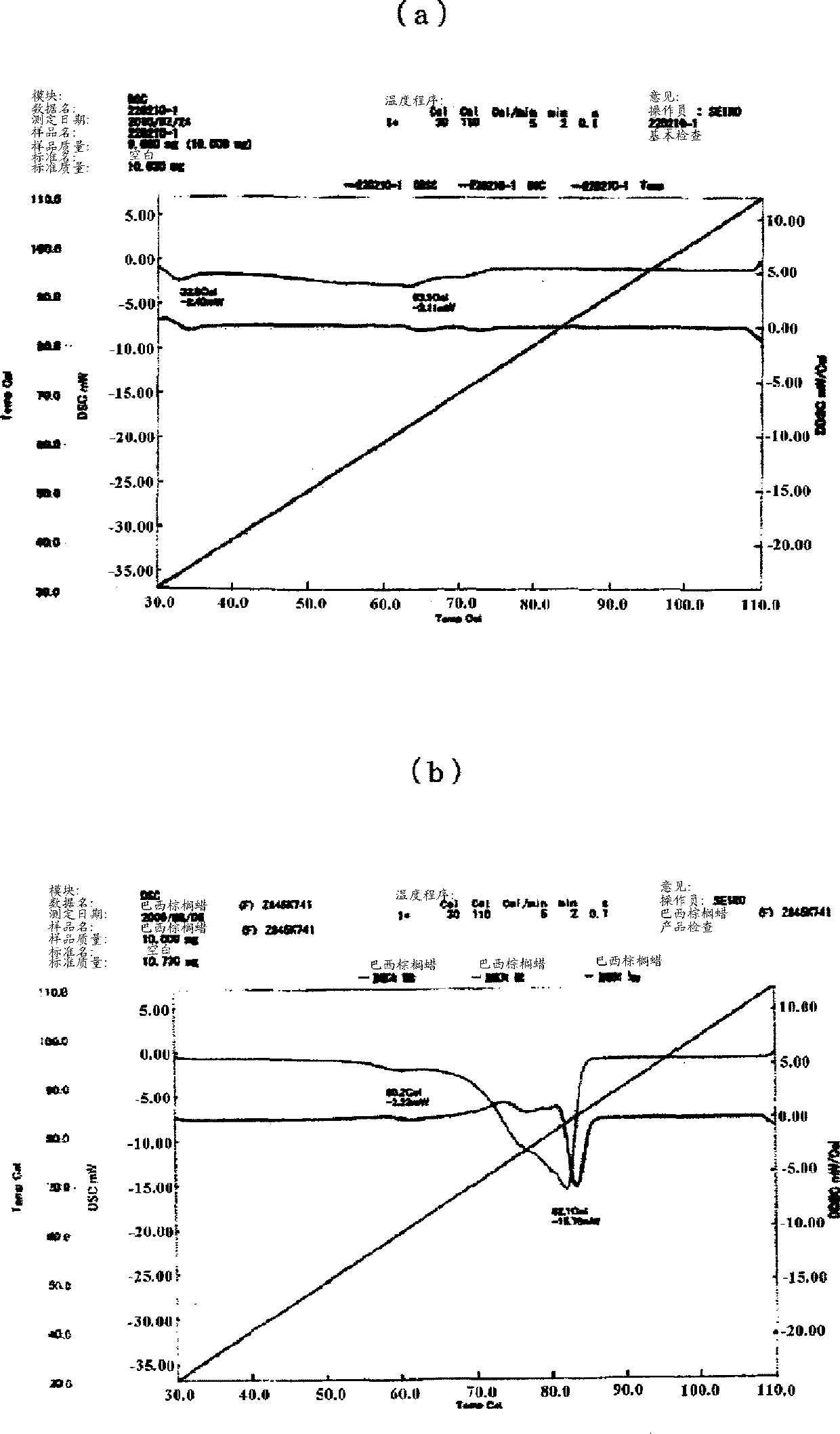

[0232] In addition, the DSC chart obtained by measuring the resin composition and carnauba wax with a differential scanning calo...

manufacture Embodiment 2

[0257] Preparation of resin composition (2):

[0258] After melting and stirring 100g of carnauba wax, it is solidified and formed into flakes with a size of about 5-10mm. 100 g of the flaky carnauba wax was thrown into 300 ml of a mixed solvent of ethanol and n-hexane 80:20 previously warmed to 40° C. while stirring, and the temperature was kept at 40° C., and it was left to stand for 4 hours and extracted. Then, it was filtered, and the mixed solvent was removed from the filtrate by distillation under reduced pressure to obtain a resin composition. The resin concentration is 25%, the softening point is 72.5°C, and the iodine value is 35.

manufacture Embodiment 3

[0260] Preparation of resin composition (3):

[0261]After melting and stirring 100g of carnauba wax, it is solidified and formed into flakes with a size of about 5-10mm. 100 g of this flaky carnauba wax was poured into 400 ml of isopropanol preheated to 40° C. while stirring, and the temperature was kept at 40° C., and it was left to stand for 8 hours for extraction treatment. It was then filtered, and isopropanol was removed from the filtrate by distillation under reduced pressure to obtain a resin composition. The resin concentration is 33%, the softening point is 69.5°C, and the iodine value is 43.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com