Coating material for high anticorrosive pack, and preparation method

A kind of coating and strong technology, applied in the direction of anti-corrosion coatings, rosin coatings, polyurea/polyurethane coatings, etc., can solve the problems of non-recyclable, non-reusable, non-stripping, etc., and achieve strong adhesion, large cohesion, molecular The effect of compact structure

Inactive Publication Date: 2007-10-10

郑州博庆环保科技有限公司 +2

View PDF0 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, the common anti-rust materials on the market are not peelable after film formation, and most of them need to be coated with outer packaging materials (such as anti-rust paper, plastic bags, etc.) and cannot be recycled or reused.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

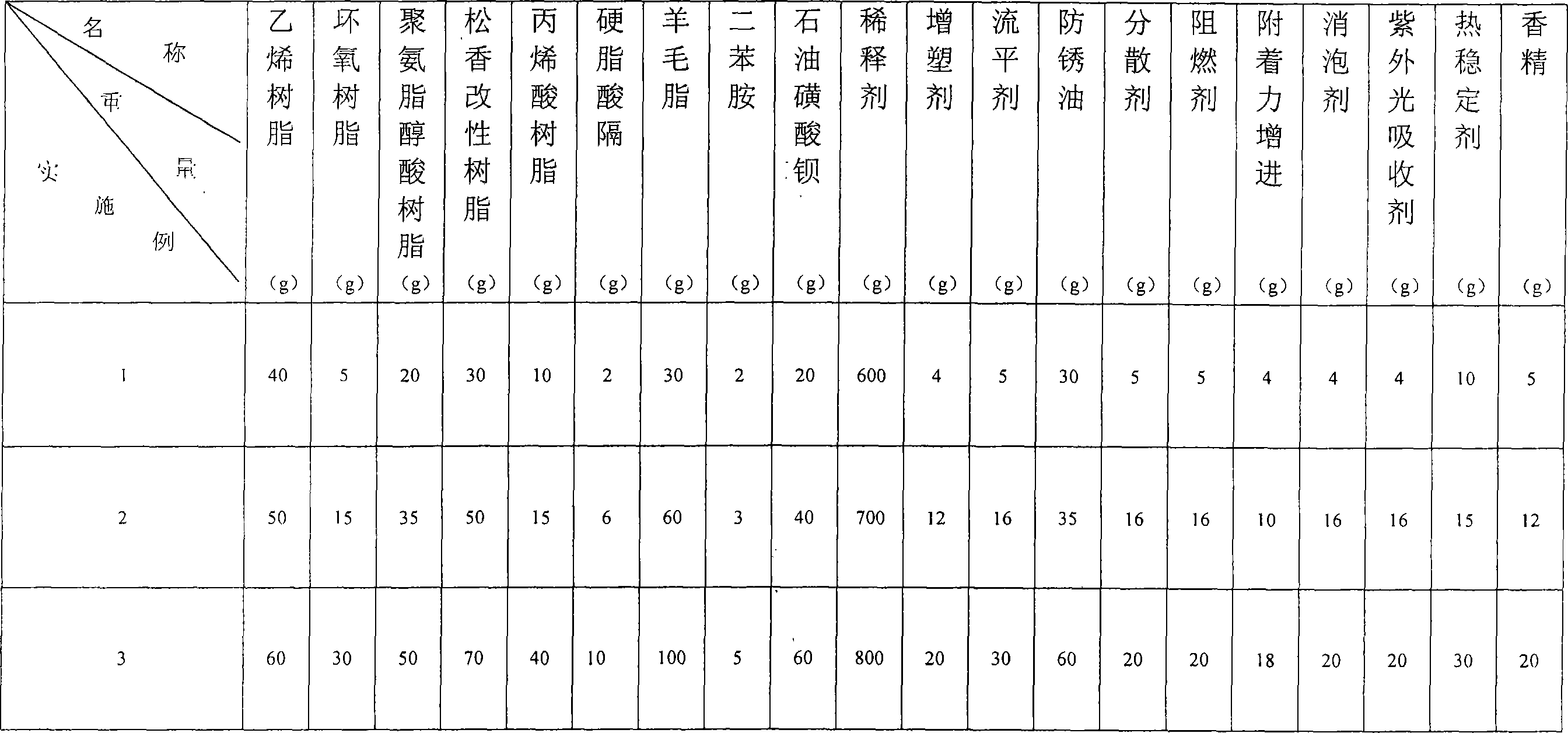

[0015]

[0016] The above-mentioned three embodiments all put the materials in a container, mix and dissolve, stir at room temperature for 30 minutes, filter with 360 mesh, pour them into containers of different capacities, and finally seal them into products.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

This invention discloses a high-strength antirust packaging paint, which is composed of: ethylene resin, epoxy resin, polyurethane alkyd resin, rosin-modified resin, acrylate resin, cadmium stearate, lanoline, diphenyl amine, barium petroleum sulfonate, essence, antirust oil, plasticizer, heat stabilizer, antirust agent, diluting agent, adhesion promoter, leveling agent, UV absorbent, dispersant, defoamer and flame retardant. The packaging paint can be directly sprayed, soak-coated or brush-coated onto objects with any shape or appearance. A bright and smooth protective film is formed several minutes later. The protective film has high antirust performance, and can be stripped off for recycling.

Description

Technical field: [0001] The invention relates to a paint composition, in particular to an antirust paint. It is a strong anti-rust packaging material synthesized with a variety of high-molecular polymer resins as the main film-forming substance, together with plasticizers, stabilizers, anti-rust agents, flame retardants, etc. Background technique: [0002] At present, the common anti-rust materials on the market are not peelable after film formation, and most of them need to be coated with outer packaging materials (such as anti-rust paper, plastic bags, etc.) and cannot be recycled or reused. Invention content: [0003] In view of the above-mentioned situation, the object of the present invention is: regardless of the shape and appearance of the object, a kind of coating can be directly sprayed, dipped or brushed, and after a few minutes, a bright and smooth protective film can be formed. It not only has a strong anti-rust effect, but also serves as an outer packaging ma...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09D123/06C09D175/04C09D193/04C09D5/08C09D133/02

Inventor 吴伟农

Owner 郑州博庆环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com