Negative pole active material for silicon-based lithium ion battery and preparation and application thereof

A negative electrode active material, lithium-ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low conductivity, low lithium intercalation potential, consumption of electrolyte, etc., achieve more cycles and increase conductivity , the effect of not easy pulverization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

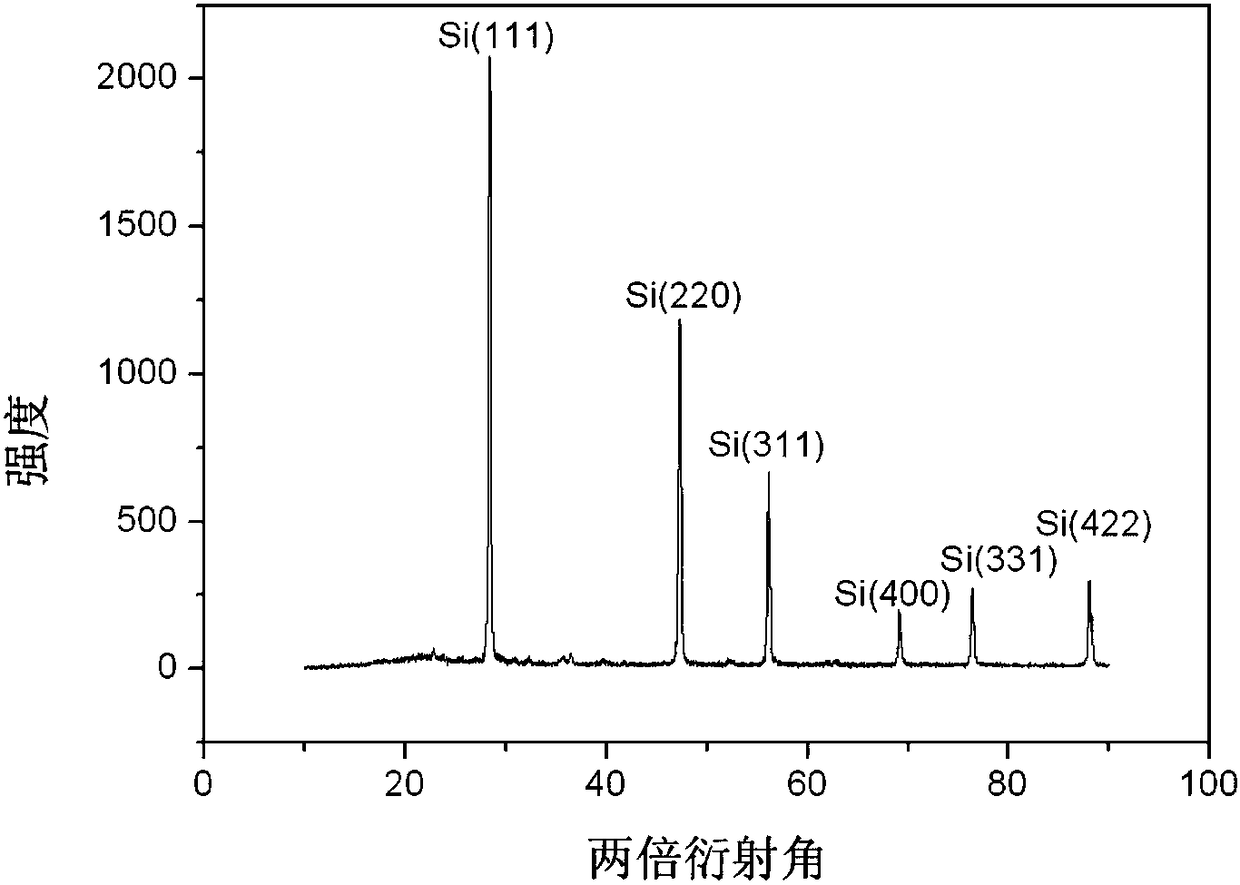

[0023] The porous silicon prepared by the above method has a pore diameter of 100nm to 300nm and a pore volume of 0.5 to 1cm 3 / g, the thickness of the conductive polymer coating layer is 50nm~200nm, the pore diameter of the porous reduced graphite oxide is 50nm~2μm, and the pore volume is 1~2cm 3 / g.

Embodiment 2

[0025] The above-mentioned final product is used as the negative electrode active material to assemble a lithium-ion battery, and it is charged and discharged at a voltage range of 0.01-1.5V and a current density of 200mA / g. The first discharge capacity of the battery reaches 2000-3000mAh / g, and the capacity is maintained after 200 cycles. The rate reaches 85-90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com