Oxidative desulfurization process for continuous regeneration of desulfurizing agent

A technology for oxidative desulfurization and desulfurization agent, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of air, water environment and water source pollution, human and environmental hazards, difficulty in waste solvent treatment, etc., to avoid Large fluctuations, no secondary pollution, and the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Properties of desulfurizer: commercially available W701 type iron oxide desulfurizer, Φ3~5×(3~15)mm round bar shape, bulk density 0.8~0.9g / ml, average radial crushing strength / N cm -1 ≥50.

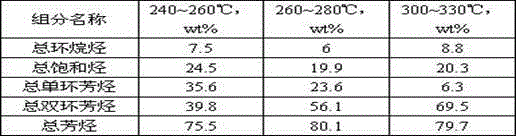

[0040] The distillation range of catalytic cracking diesel oil is 240~260°C; in the solid-liquid separator: the temperature for cooling and separating sulfur is 10°C.

Embodiment 2

[0044] Properties of desulfurizer: Prepare amorphous iron oxyhydroxide desulfurizer according to CN101898108A, containing 97wt% amorphous iron oxyhydroxide, spherical shape of Φ8~10mm, bulk density of 0.9~1.0g / ml, average crush resistance of particle points / N· Pieces ≥ 30.

[0045] The distillation range of catalytic cracking diesel oil is 260~280°C; in the solid-liquid separator: the temperature for cooling and separating sulfur is 8°C.

Embodiment 3

[0049] Desulfurizer properties: commercially available TC-22 zinc oxide desulfurizer, Φ4×(4~10)mm round bar shape, bulk density 0.9~1.1g / ml, average radial crushing strength / N cm -1 ≥40. The distillation range of catalytic cracking diesel oil is 300~330°C; in the solid-liquid separator: the temperature for cooling and separating sulfur is 10°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com