Non-mobility graphene oxide grafted anti-aging agent and preparation method thereof

An oxide stone, non-migration technology, applied in the field of rubber anti-aging, can solve problems such as affecting the performance of rubber products, reducing the anti-aging efficiency of antioxidants, endangering health and other problems, achieving good thermal oxidation resistance and anti-extraction performance. , the effect of high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

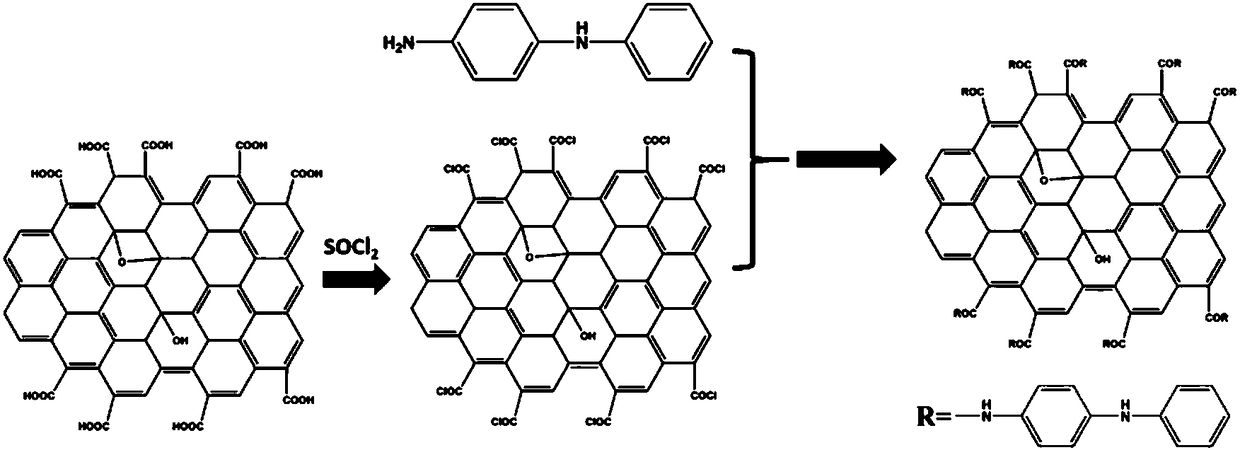

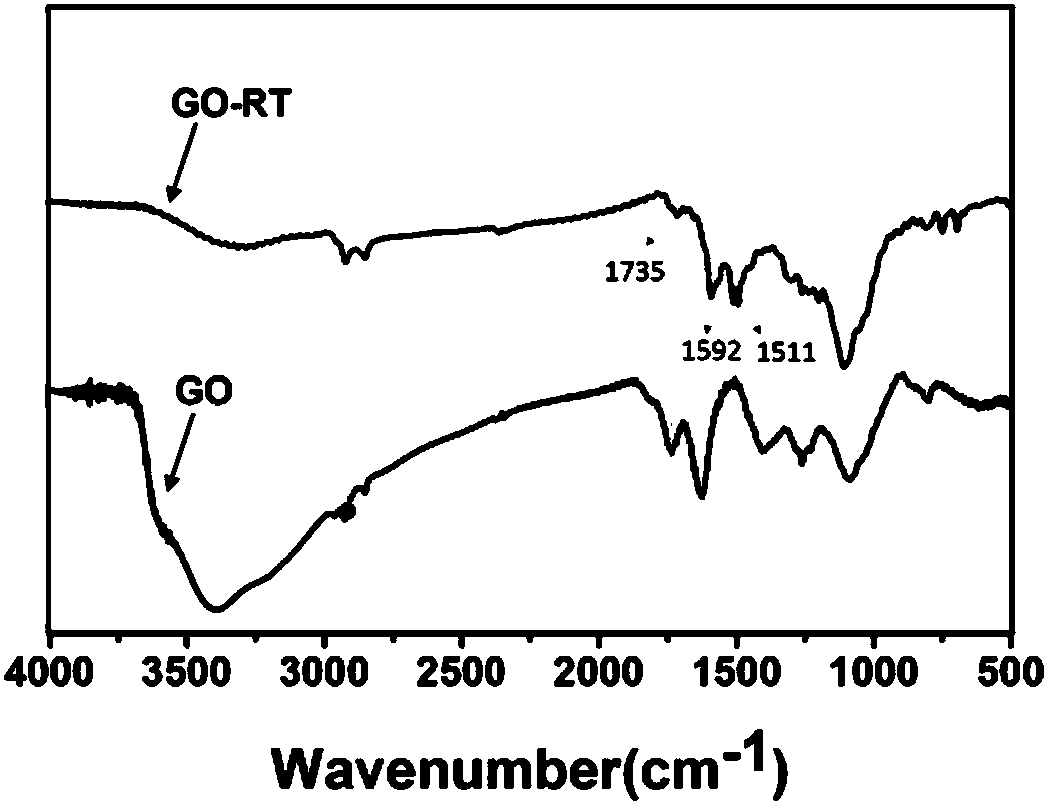

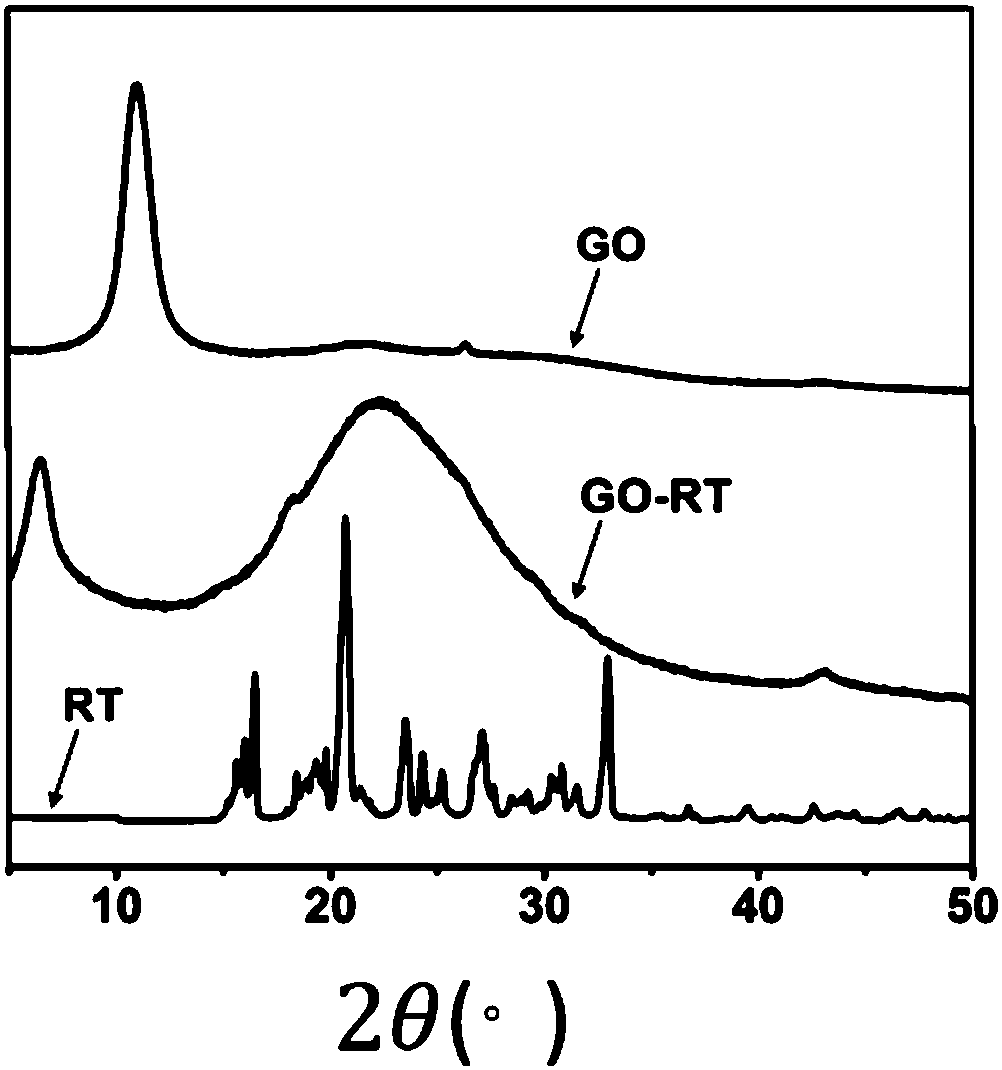

[0026] In this example, the schematic diagram of the synthesis of non-migrating graphene oxide grafted antioxidant is shown in figure 1 The preparation method of the non-migrating graphene oxide graft antioxidant is as follows:

[0027] (1) Dissolve graphene oxide (GO) in thionyl chloride, sonicate it for 1h, and then reflux for 2h at 85°C, then spin steam, wash and filter to remove thionyl chloride to obtain thionyl chloride modified Graphene oxide.

[0028] (2) Add 0.2g of thionyl chloride modified graphene oxide to 200mL of dimethylformamide (DMF), and ultrasonically dissolve thionyl chloride modified graphene oxide to obtain thionyl chloride modified Graphene oxide solution. Dissolve 4 g of 4-aminodiphenylamine (anti-aging agent intermediate RT Peis, RT for short) in DMF to form an RT solution. The amount of DMF should be such that RT can just dissolve. Mix the aforementioned two solutions, control the mass ratio of thionyl chloride modified graphene oxide to RT in the mixed ...

Embodiment 2

[0033] In this embodiment, the preparation method of the non-migrating graphene oxide grafted antioxidant is as follows:

[0034] (1) Dissolve GO in thionyl chloride, sonicate for 1.5h, and then reflux for 1h at 85°C, then spin steam, wash and filter to remove thionyl chloride to obtain thionyl chloride modified graphene oxide.

[0035] (2) Add 0.1 g of thionyl chloride-modified graphene oxide to 200 mL of DMF, and ultrasonically dissolve the thionyl chloride-modified graphene oxide to obtain a thionyl chloride-modified graphene oxide solution. Dissolve 3g of RT in DMF to form an RT solution. The amount of DMF should be such that RT just dissolves. Mix the aforementioned two solutions, control the mass ratio of thionyl chloride modified graphene oxide to RT in the mixed solution to be 1:30, reflux for 60 hours, and filter the reaction solution obtained by the reflux reaction to remove Part of the solvent DMF and RT that has not completed the grafting reaction, the solid product ob...

Embodiment 3

[0037] In this embodiment, the preparation method of the non-migrating graphene oxide grafted antioxidant is as follows:

[0038] (1) Dissolve GO in thionyl chloride, sonicate for 2h, and then reflux for 3h at 85°C, then spin steam, wash and filter to remove thionyl chloride to obtain thionyl chloride modified graphene oxide.

[0039] (2) Add 0.16 g of thionyl chloride-modified graphene oxide to 200 mL of DMF, and ultrasonically dissolve the thionyl chloride-modified graphene oxide to obtain a thionyl chloride-modified graphene oxide solution. Dissolve 2.4 g of RT in DMF to form an RT solution. The amount of DMF should be such that RT just dissolves. Mix the aforementioned two solutions, control the mass ratio of thionyl chloride modified graphene oxide to RT in the mixed solution to be 1:15, reflux for 50 hours, and filter the reaction solution obtained by the reflux reaction to remove Part of the solvent DMF and RT that did not complete the grafting reaction, the solid product o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Oxidation induction time | aaaaa | aaaaa |

| Oxidation induction time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com