Method for continuous hydrogenation preparation of 4-amino diphenylamine

A technology of aminodiphenylamine and nitrodiphenylamine, which is applied in the field of preparation of 4-aminodiphenylamine, which can solve problems such as many side reactions, increased fatigue strength of hydrogenation reactors, and "three wastes" pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

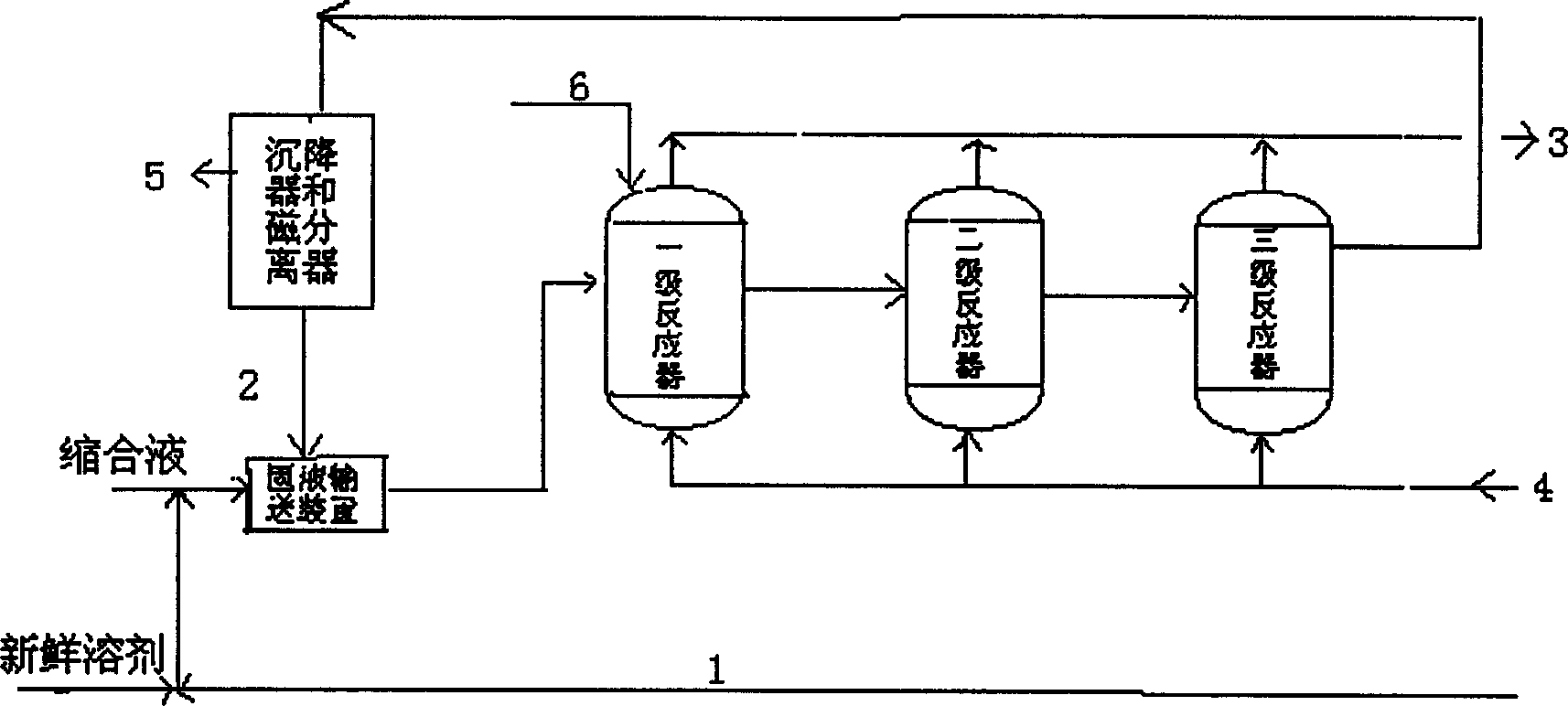

Method used

Image

Examples

Embodiment 1

[0021] First check the airtightness of the device. It is required that the leakage rate of the system should be less than 5% after the nitrogen pressure test. Then make preparations before feeding, lay the bottom material, replace the nitrogen with hydrogen, pressurize to 1.3MPa, and start the cycler to maintain The flow rate of circulating hydrogen is 6 meters 3 (standard square) / hour, hydrogen enters the hydrogenation reactor in the form of bubbling through the circulator, to increase the gas-liquid mass transfer effect during the reaction, the flow rate of the condensation liquid after the reaction of nitrobenzene and aniline is 200 kg / hour , the flow rate of methyl alcohol is 60 kilograms / hour, and 4-nitrosodiphenylamine content 15.1 (weight %) after mixing, 4-nitrosodiphenylamine content 2.5 (weight %) enters one-stage hydrogenation reactor, and reactor has magnetic Seal and stir, cool the heating system, add composite powdery catalyst simultaneously, keep the temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com