Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1807results about "Amino compound purification/separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stable liquid paracetamol compositions, and method for preparing same

PCT No. PCT / FR97 / 01452 Sec. 371 Date Jun. 5, 1998 Sec. 102(e) Date Jun. 5, 1998 PCT Filed Aug. 5, 1997 PCT Pub. No. WO98 / 05314 PCT Pub. Date Feb. 12, 1998Novel stable paracetamol compositions for use in therapeutic chemistry and specifically galenic pharmacy are disclosed. The compositions contain a solution of paracetamol in an aqueous solvent combined with a buffer having a pH of 4 to 8, and a free radical capturing agent. A water-insoluble inert gas is carefully bubbled through the aqueous solvent to remove oxygen from the medium. Said compositions may also be combined with a centrally or peripherally acting analgesic agent, and are provided as injectable compositions for relieving pain.

Owner:SCR PHARMATOP

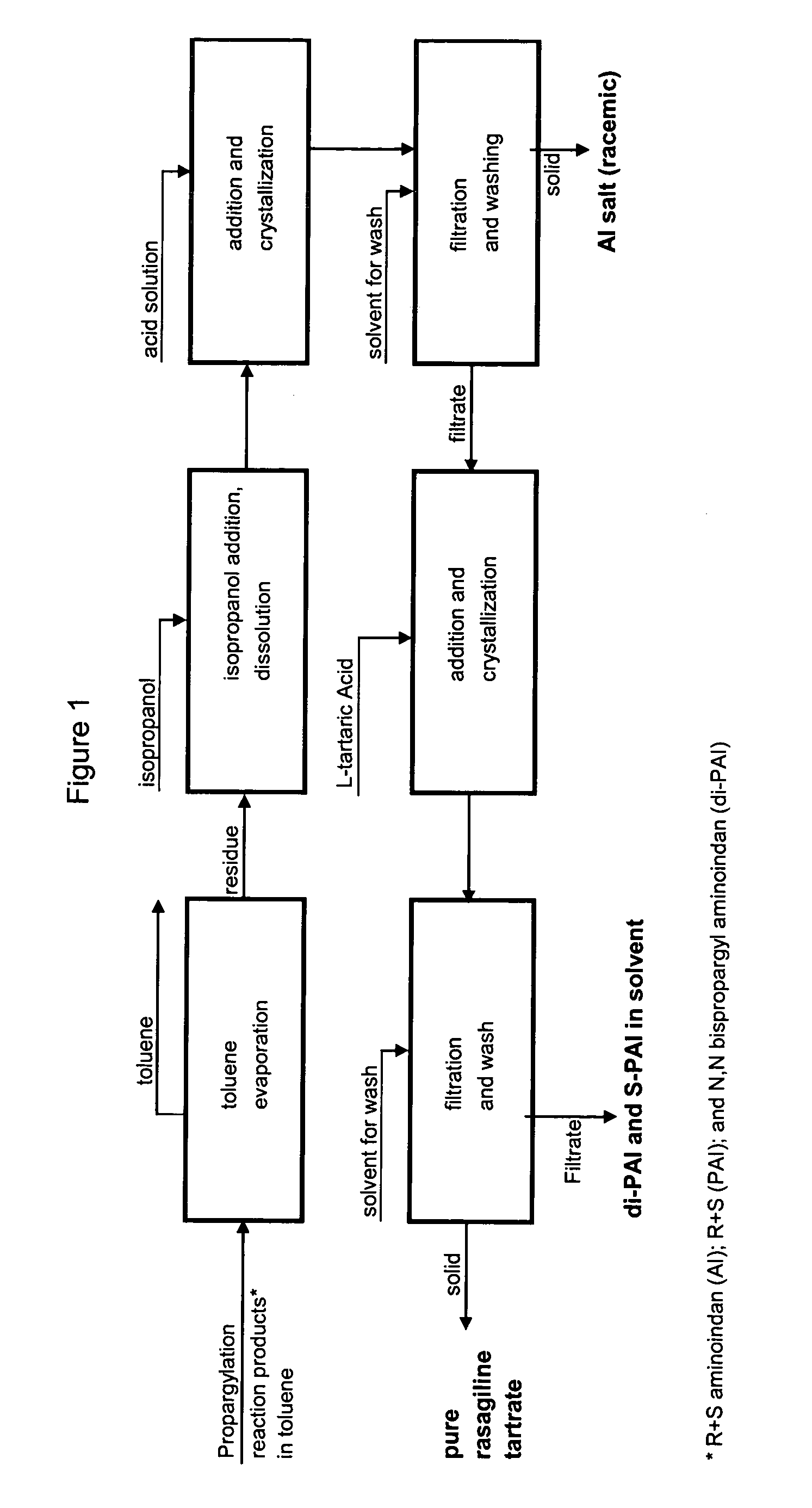

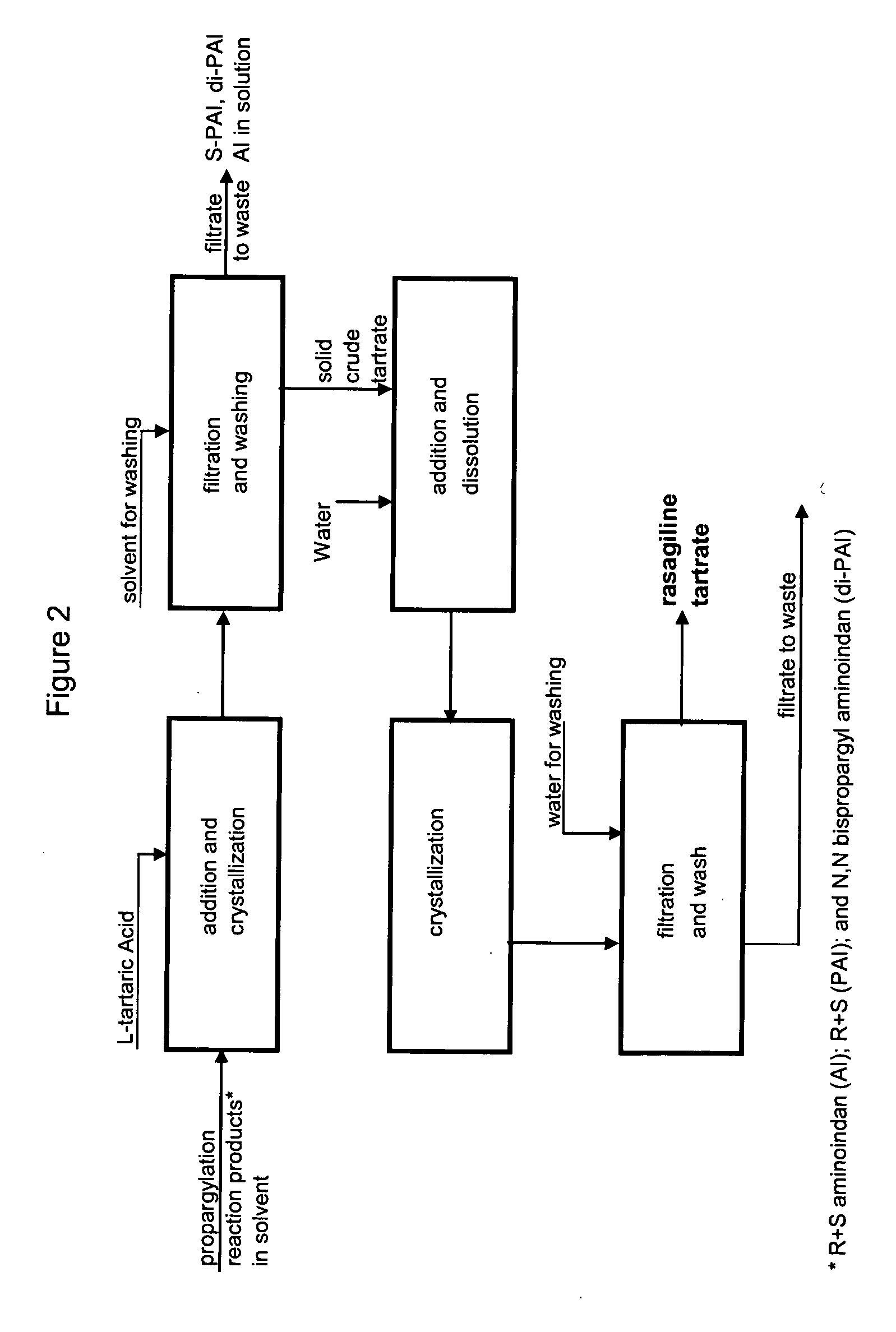

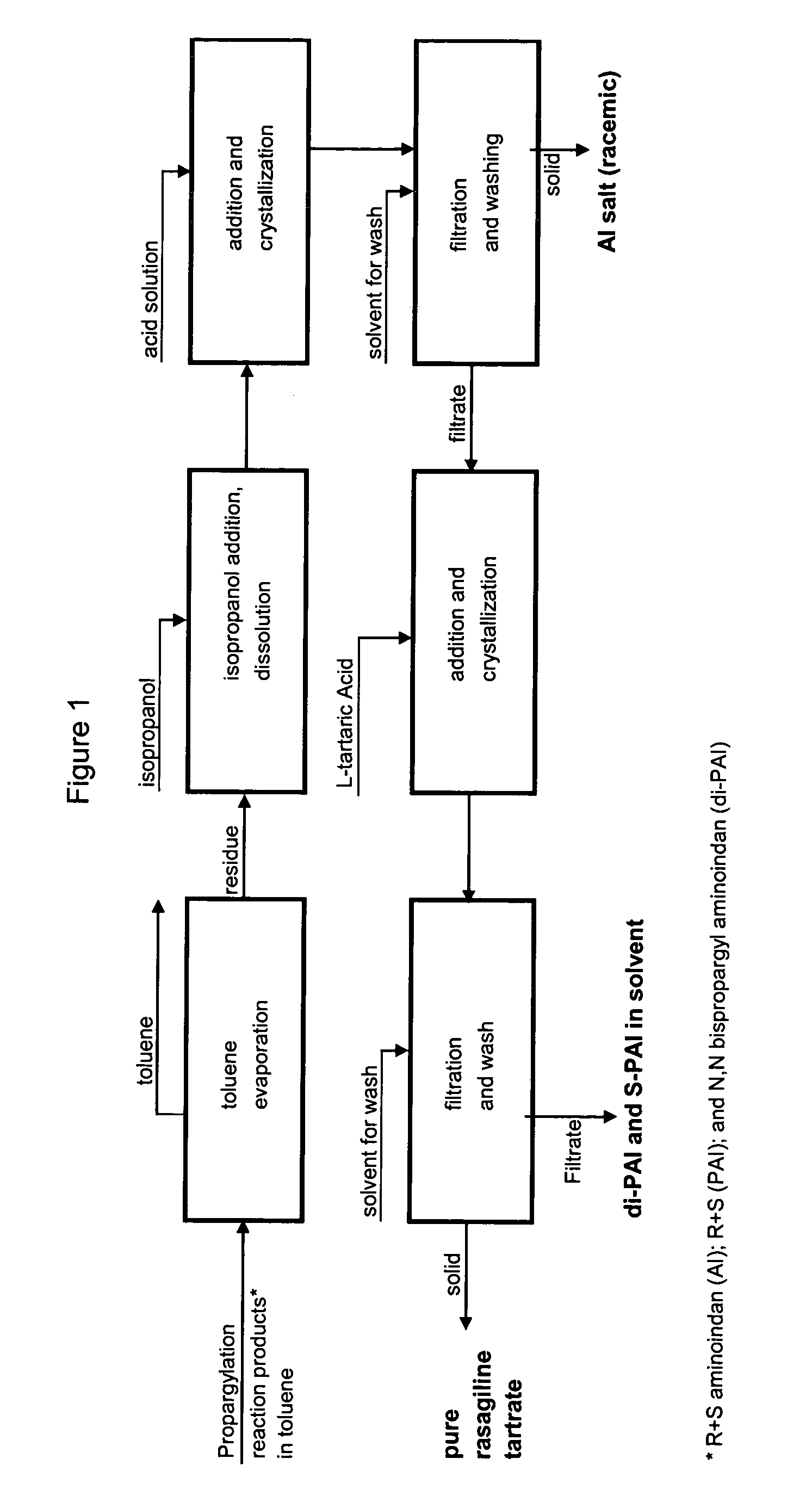

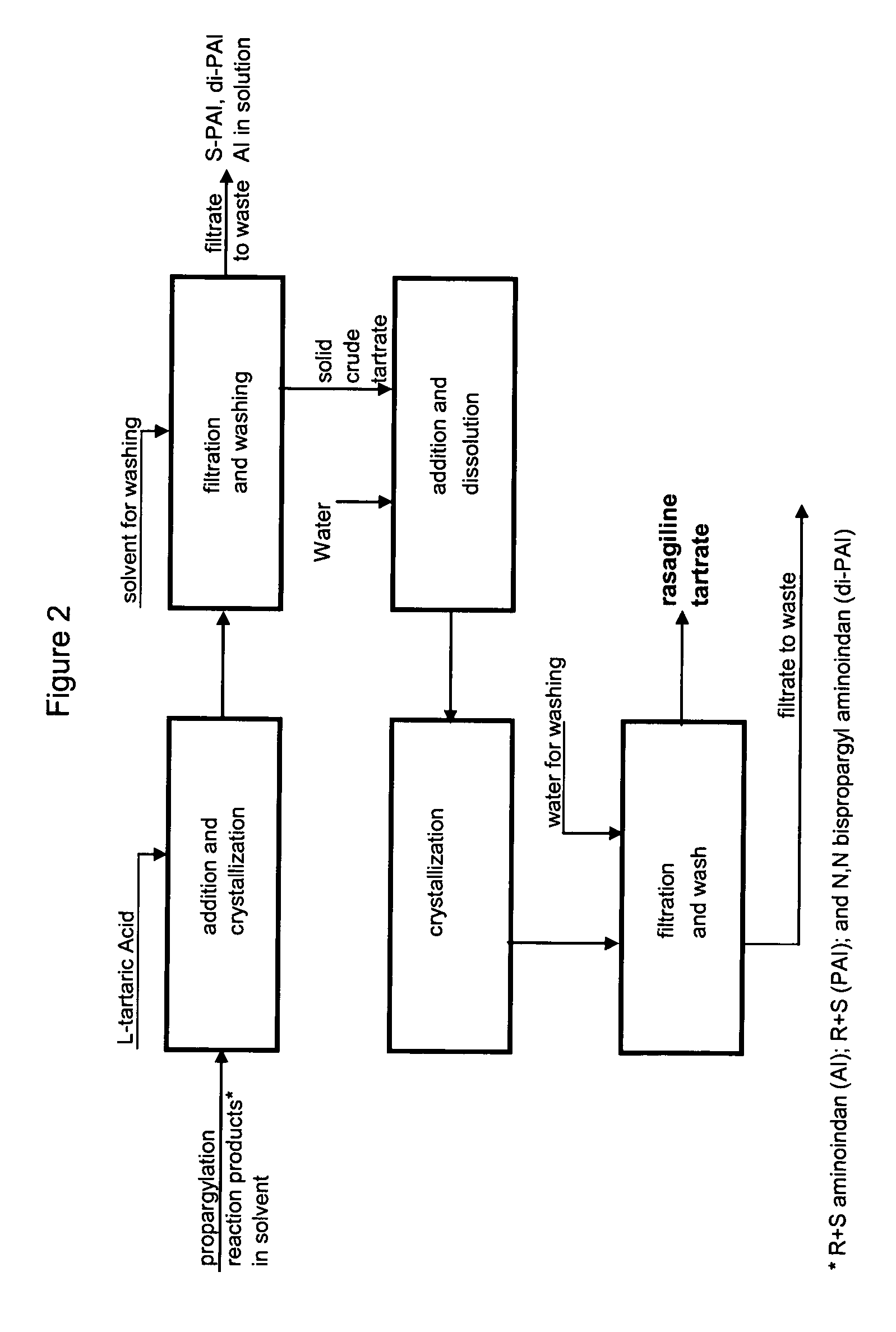

Methods for isolating propargylated aminoindans

Disclosed is a process for isolating from a reaction mixture a salt of a mono-propargylated aminoindan having the structure wherein R1 is H, hydroxyl, alkoxy or wherein Y is O or S; R2 and R3 is each, independently, C1-8 alkyl, C6-12 aryl, C6-12 aralkyl, each optionally halo substituted, or hydrogen; where the reaction mixture further comprises a solvent, a primary aminoindan having the structure wherein R1 is defined as above, and a tertiary aminoindan having the structure the process comprising d) adding an acid to the reaction mixture; e) crystallizing the mono-propargylated aminoindan under conditions suitable for the formation of a crystalline salt of the mono-propargylated aminoindan; and f) recovering the crystalline salt of the mono-propargylated aminoindan, wherein the process is performed without addition of an organic solvent. Also disclosed are the crystalline diastereomeric salts produced by the process and pharmaceutical compositions containing the salts.

Owner:TEVA PHARMA IND LTD

Methods for isolating propargylated aminoindans

A process for isolating from a reaction mixture a salt of a mono-propargylated aminoindan, a process for isolating from a reaction mixture a crystalline diastereomeric salt of a mono-propargylated aminoindan, and a process for isolating from a reaction mixture a salt of enantiomerically pure N-propargyl-1-aminoindan or a salt of enantiomerically pure 6-(N-methyl, N-ethyl-carbamoyloxy)-N′-propargyl-1-aminoindan. The corresponding products are also disclosed.

Owner:TEVA PHARMA IND LTD

Agglomerated zeolitic adsorbents, method for obtaining same uses thereof

InactiveUS6884918B1Amino compound purification/separationOrganic compound preparationSorbentSimulated moving bed

The present invention relates to agglomerated zeolitic adsorbents based on zeolite X with an Si / Al ratio such that 1.15<Si / Al≦1.5, at least 90% of the exchangeable cationic sites of the zeolite X of which are occupied either by barium ions alone or by barium ions and potassium ions whose Dubinin volume is greater than or equal to 0.240 cm3 / g.They are obtained by agglomerating zeolite powder with a binder, followed by the zeolitization of the binder, the exchange of the ions of the zeolite by barium ions (and potassium ions) and the activation of the adsorbents thus exchanged.These adsorbents are particularly suited to the adsorption of the para-xylene present in C8 aromatic hydrocarbon fractions in the liquid phase in processes of simulated moving bed type but also to the separation of sugars, polyhydric alcohols, cresols or substituted toluene isomers.

Owner:ARKEMA FRANCE SA

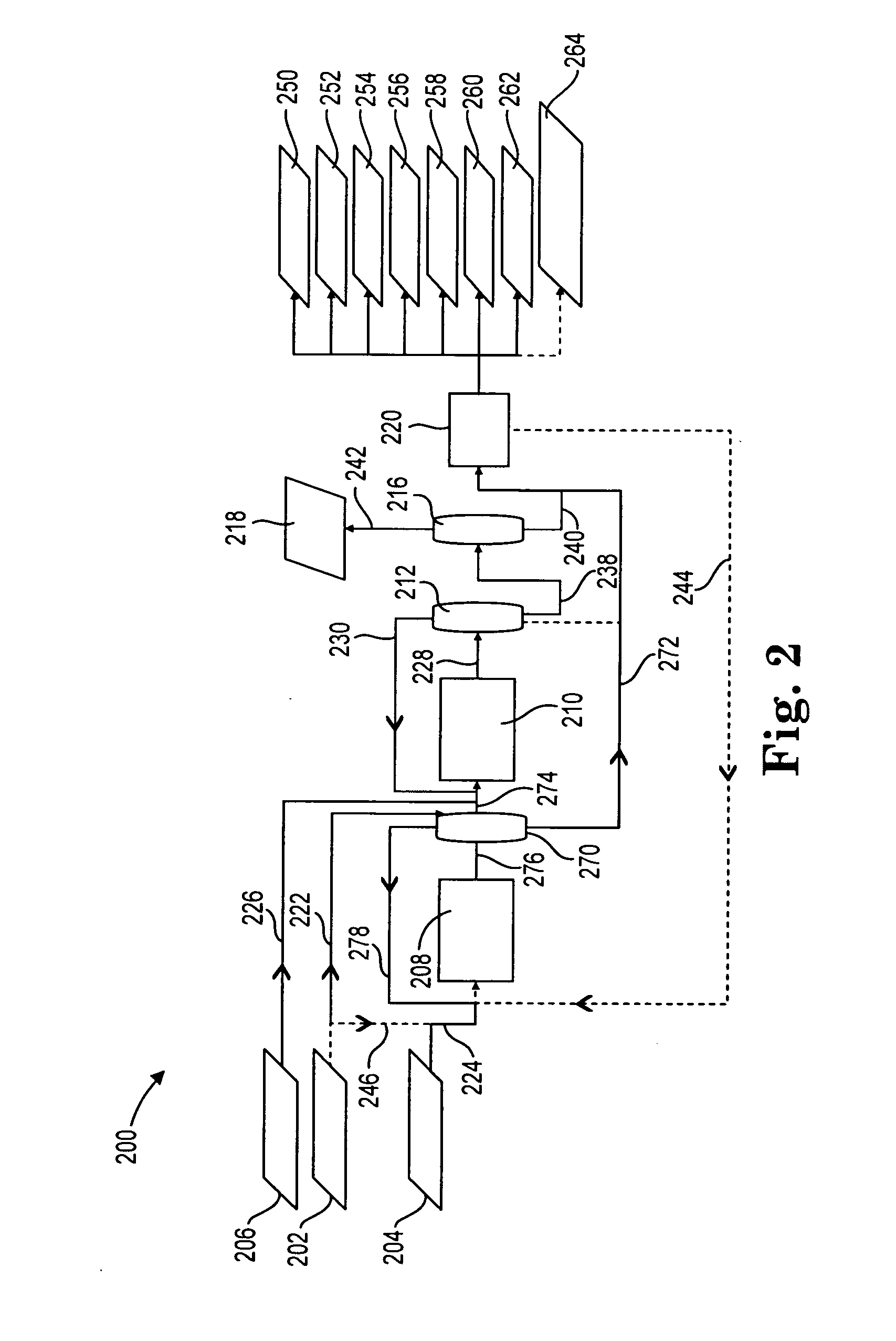

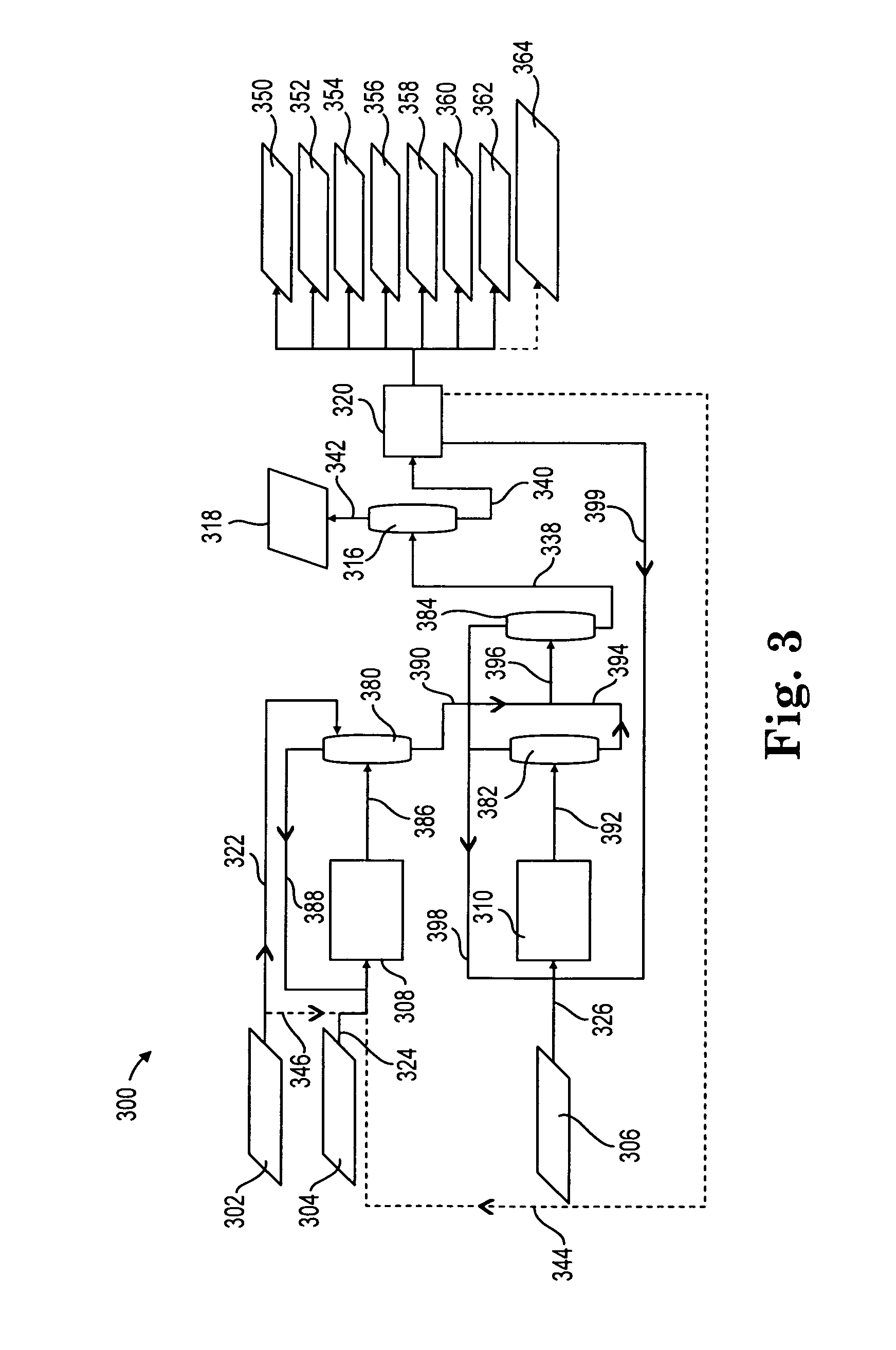

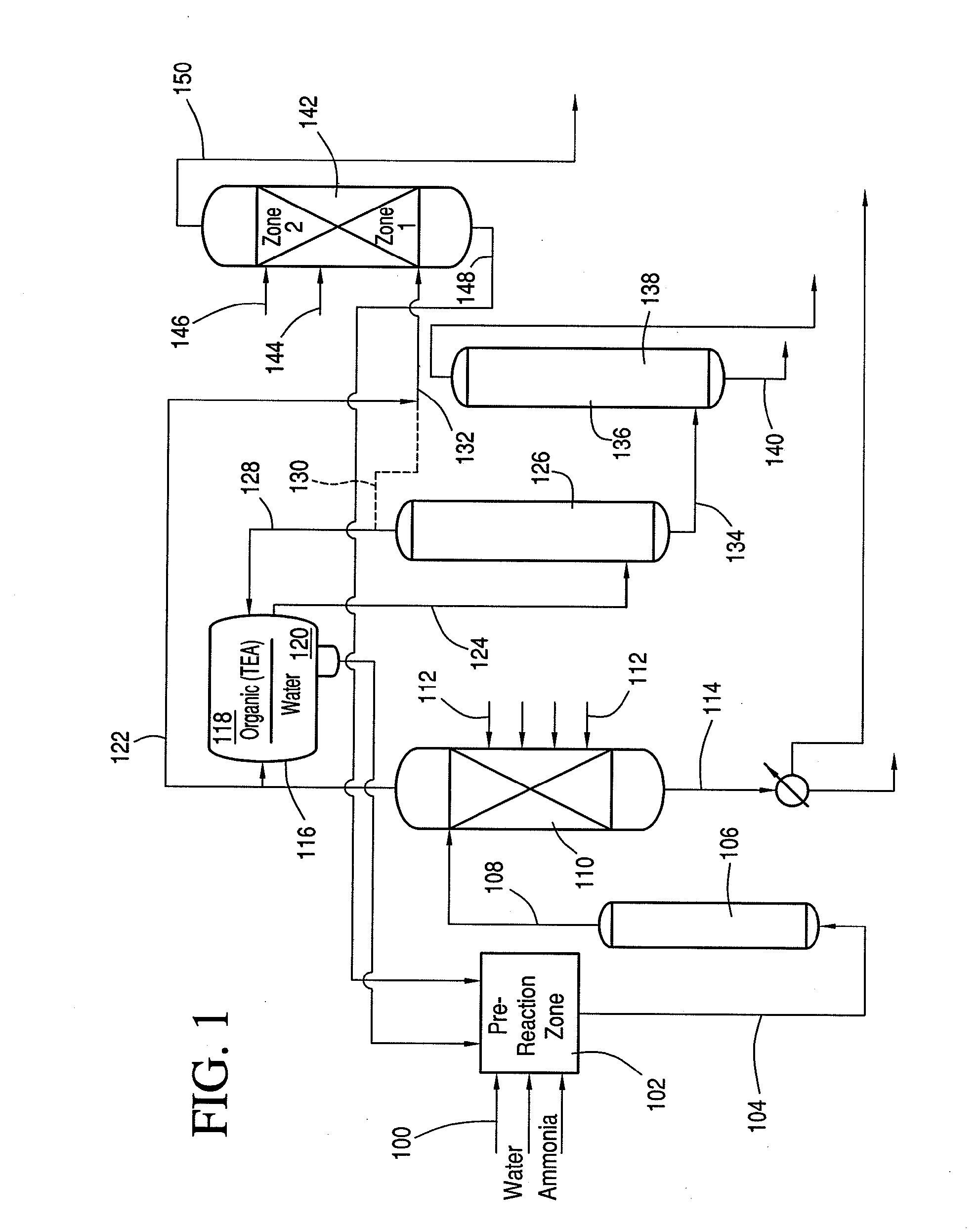

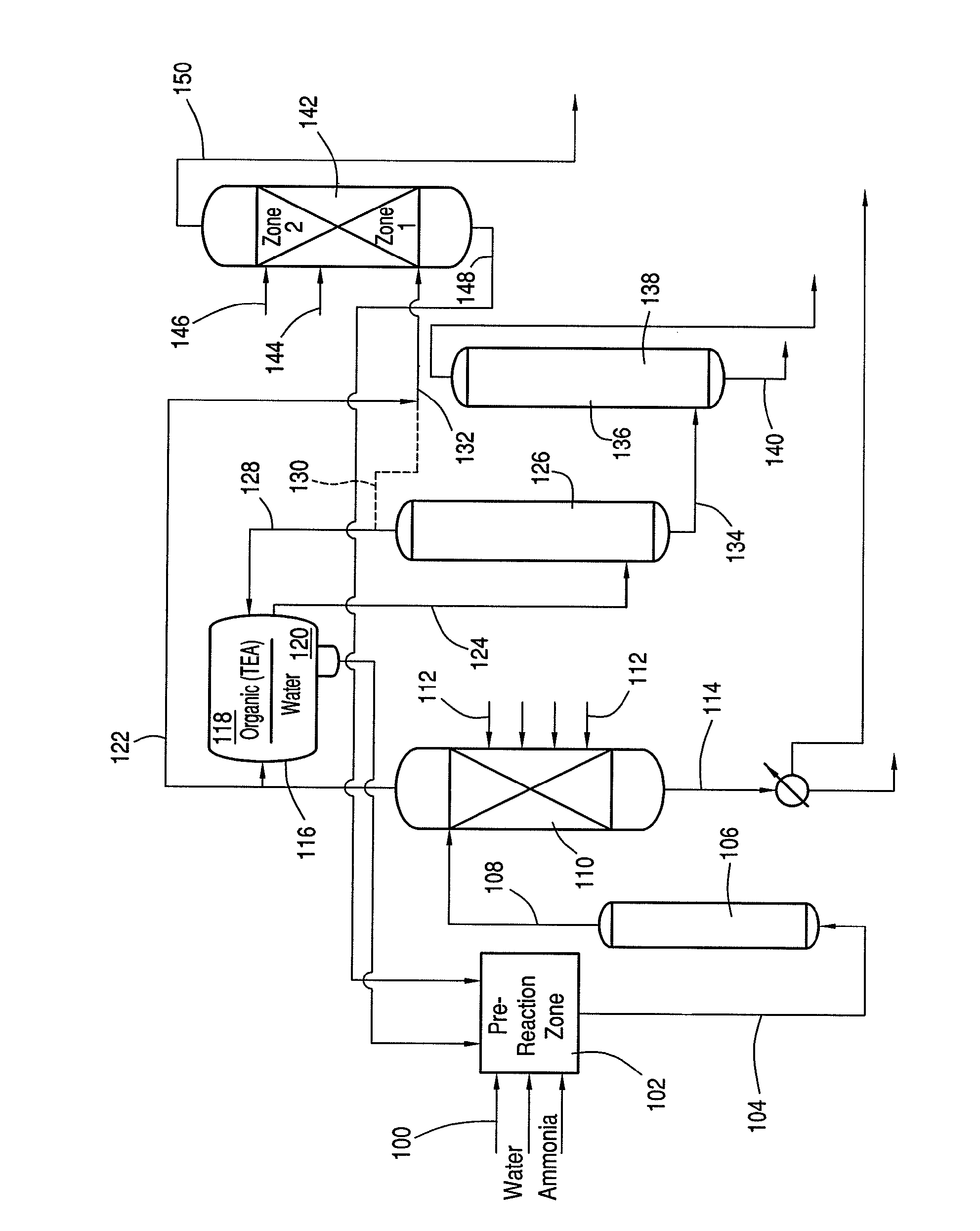

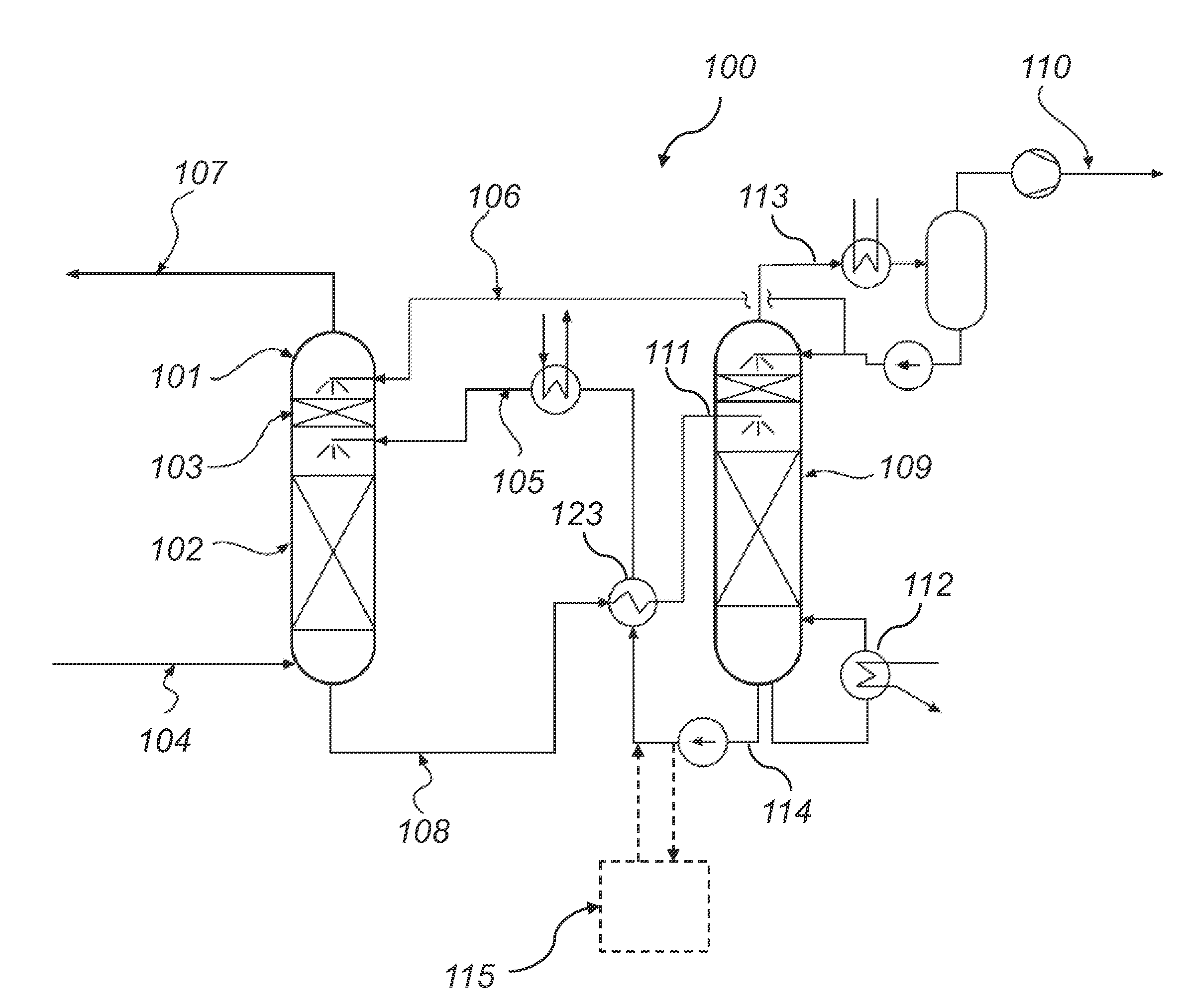

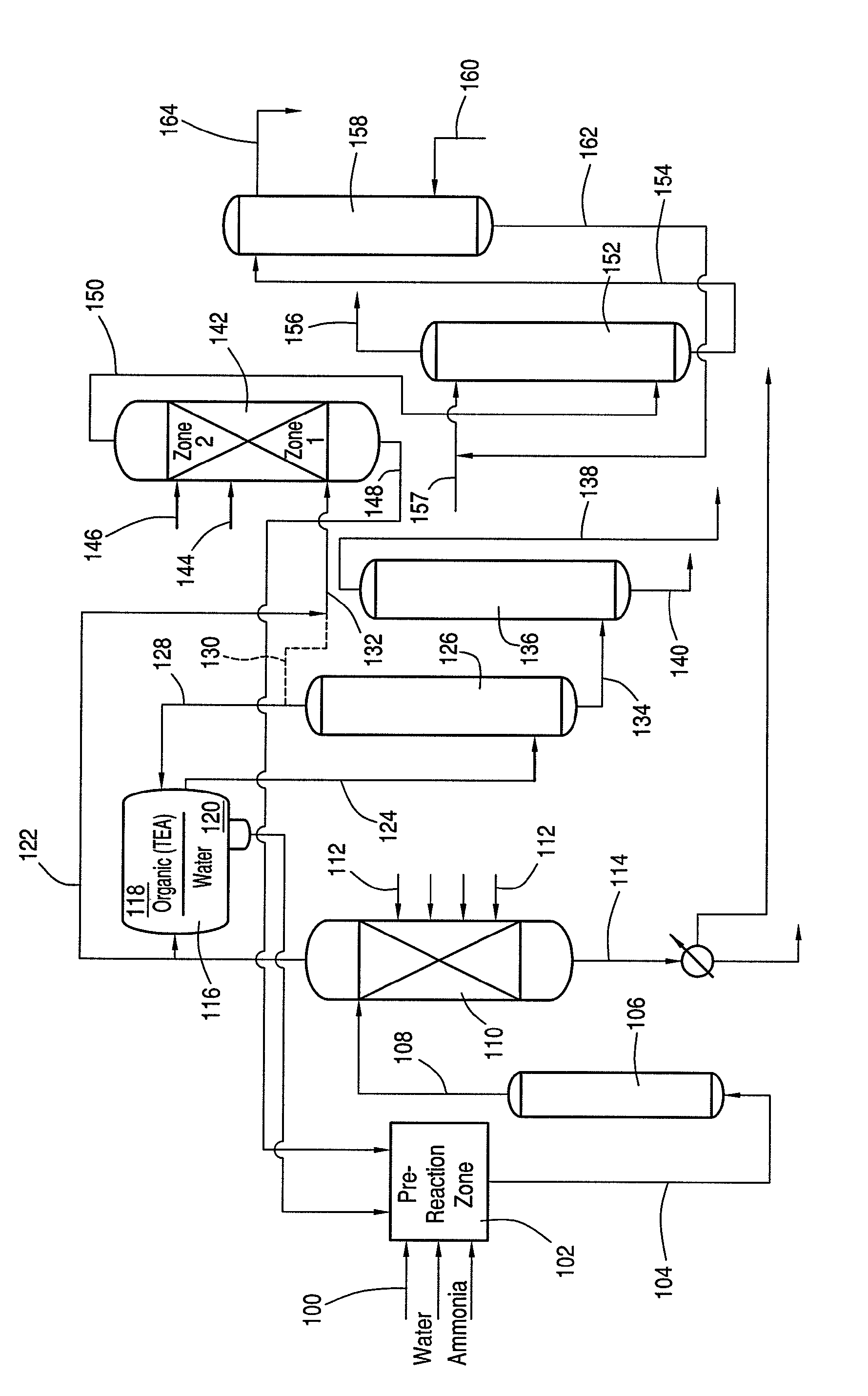

Methods for making ethanolamine(s) and ethyleneamine(s) from ethylene oxide and ammonia, and related methods

ActiveUS20100087684A1Minimizes numberReduce equipment footprintAmino compound purification/separationOrganic compound preparationEthylenediamineEthylene oxide

The present invention relates to processes for the manufacture of one or more ethanolamines and one or more ethyleneamines starting from the reaction of ethylene oxide with ammonia to produce one or more ethanolamines and the conversion of the ethanolamine(s) to ethyleneamine(s). The present invention also relates to separating alkylethyleneamines from ethyleneamines.

Owner:DOW GLOBAL TECH LLC

Process for production of pentamethylenediamine, and process for production of polyamide resin

ActiveCN102056889AEmission reductionAmino compound purification/separationAmino preparation from aminesDistillationCarbonate

Disclosed are: a process for producing purified pentamethylenediamine by simple production steps and in high yield; and others. The process for producing purified pentamethylenediamine comprises: a thermal decomposition step of heating pentamethylenediamine carbonate to yield crude pentamethylenediamine and carbon dioxide; and a distillation step of distilling the crude pentamethylenediamine produced in the thermal decomposition step to yield pentamethylenediamine, wherein the concentration of pentamethylenediamine in the crude pentamethylenediamine is 30 mol% or more relative to the total concentration of pentamethylenediamine and pentamethylenediamine carbonate.

Owner:MITSUBISHI RAYON CO LTD

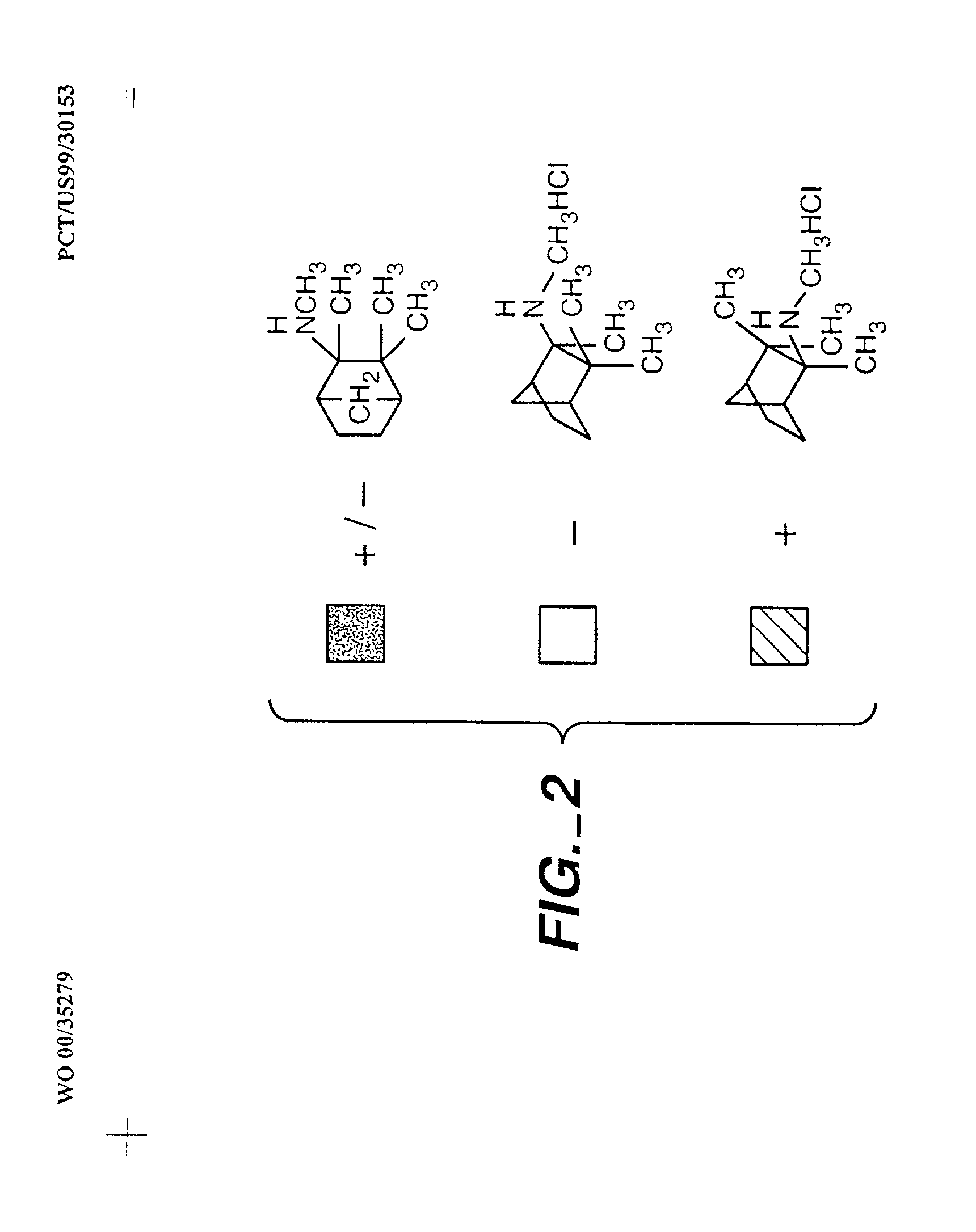

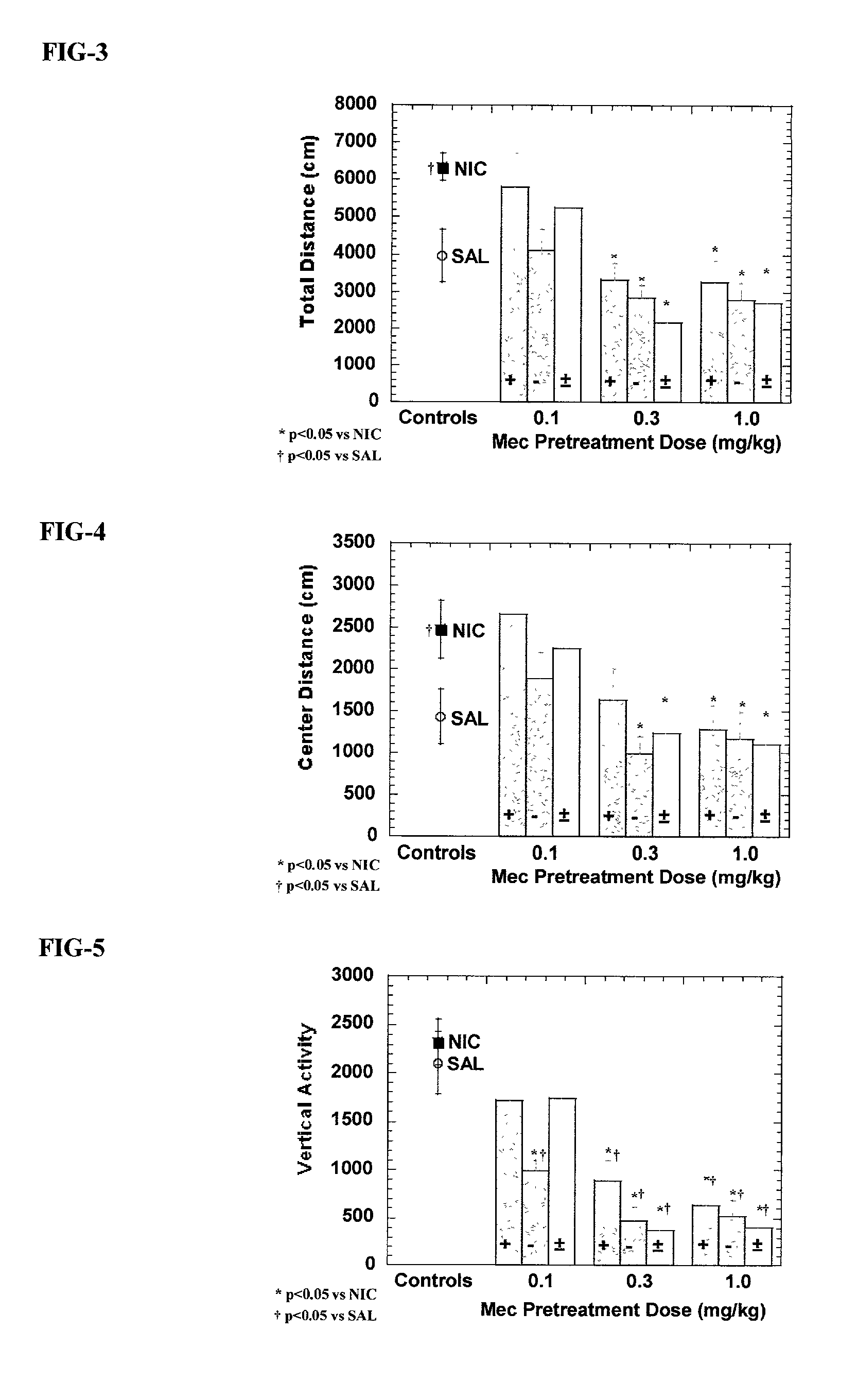

Exo-R-mecamylamine formulation and use in treatment

InactiveUS20020016370A1Convenient treatmentImprove Medication AdherenceBiocideUrea derivatives preparationStimulantS syndrome

A pharmaceutical composition includes a therapeutically effective amount of exo-R-mecamylamine or a pharmaceutically acceptable salt thereof, substantially free of exo-S-mecamylamine in combination with a pharmaceutically acceptable carrier. Preferably the amount is about 0.5 mg to about 20 mg. Medical conditions are treated by administering a therapeutically effective amount of exo-R-mecamylamine or a pharmaceutically acceptable salt thereof, substantially free of its exo-S-mecamylamine, said amount being sufficient to ameliorate the medical condition. The medical conditions include but are not limited to substance addiction (involving nicotine, cocaine, alcohol, amphetamine, opiate, other psychostimulant and a combination thereof), aiding smoking cessation, treating weight gain associated with smoking cessation, hypertension, hypertensive crisis, Tourette's Syndrome and other tremors, cancer (such as small cell lung cancer), atherogenic profile, neuropsychiatric disorders (such as bipolar disorder, depression, an anxiety disorder, schizophrenia, a seizure disorder, Parkinson's disease and attention deficit hyperactivity disorder), chronic fatigue syndrome, Crohn's disease, autonomic dysreflexia, and spasmogenic intestinal disorders.

Owner:UNIV OF SOUTH FLORIDA

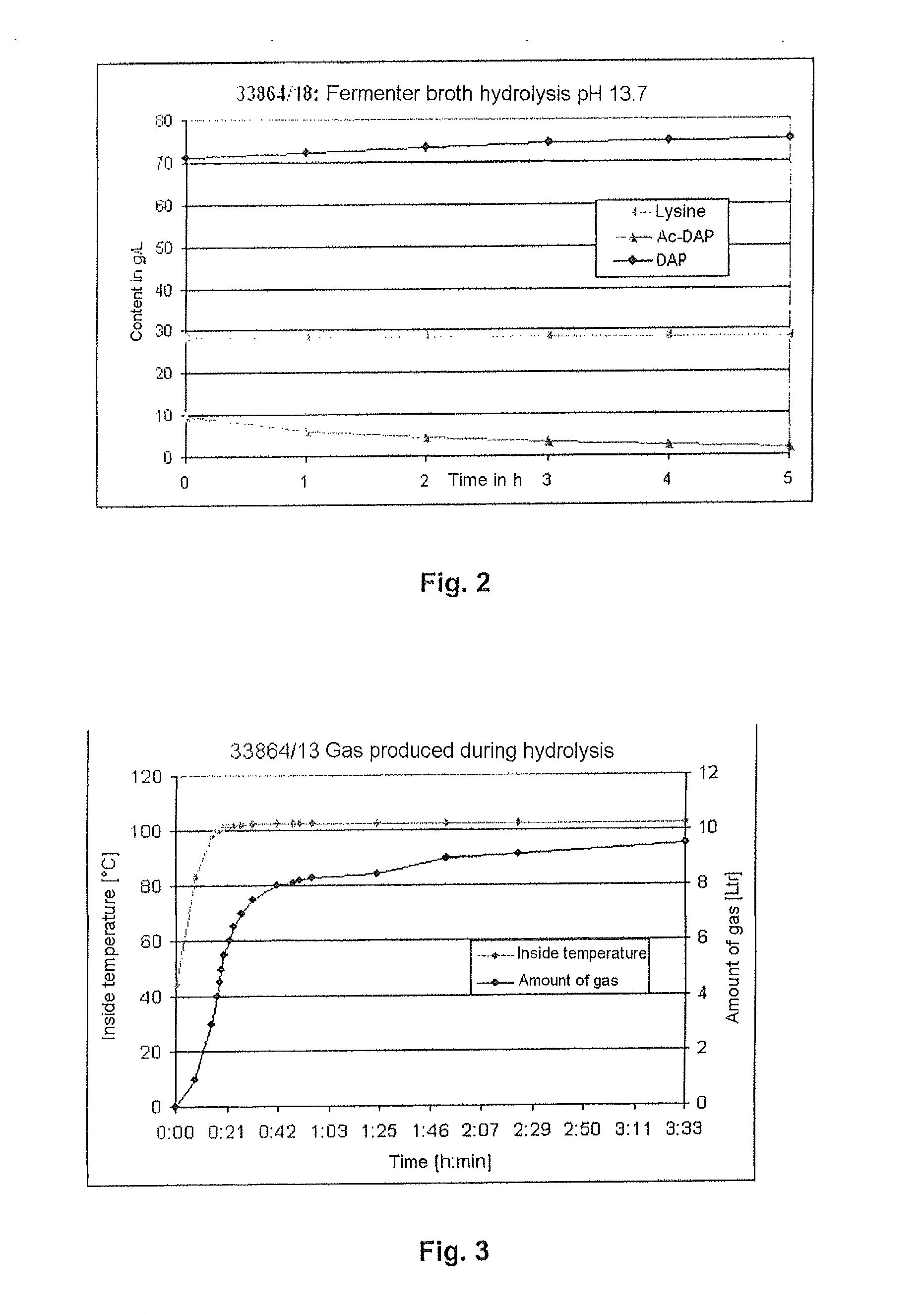

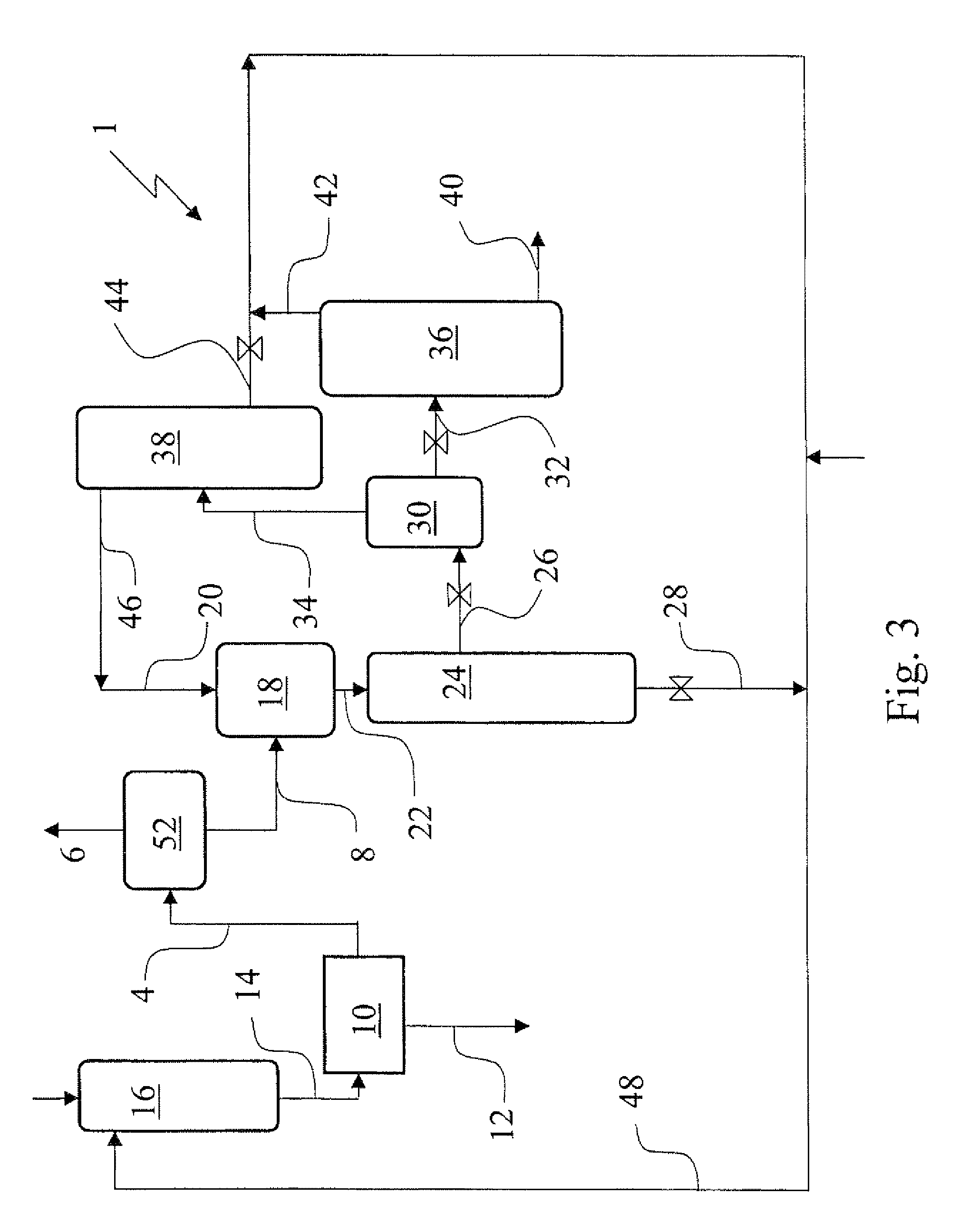

Method for Fermentatively Producing 1,5-Diaminopentane

ActiveUS20100292429A1Facilitate phase separationIncrease probabilityAmino compound purification/separationOrganic compound preparationBiotechnologyFermentation broth

The invention relates to a method for isolating 1,5-diaminopentane (DAP) from DAP-containing fermentation broths, to a method for the fermentative production of DAP using said isolating method and to a method for producing DAP-comprising polymers by using the DAP isolated or fermatively produced DAPs according to said methods.

Owner:BASF AG

Method for producing fine spherical particles of carbonate or hydroxide of nickel, cobalt or copper

InactiveUS6197273B1Amino compound purification/separationOxide/hydroxide preparationSal ammoniacCobalt metal

The invention provides a process for production of fine spherical particles of a carbonate or a hydroxide of nickel, cobalt or copper which comprises: dissolving a carbonate or a hydroxide of nickel, cobalt or copper having the general formula (I)wherein M represents Ni, Co or Cu, and x and y are numerals satisfying the followings: 0<=x<=2, 0<=y<=2 and x+y=2, in aqueous ammonia, converting the resulting solution to a W / O emulsion containing droplets of the solution in a non-aqueous medium, and then removing volatile components including ammonia from within the droplets, thereby precipitating a basic carbonate or a hydroxide of a metal selected from nickel, cobalt and copperin the droplets.The fine spherical particles of a carbonate or a hydroxide of nickel, cobalt or copper obtained according to the process of the invention are especially useful as a precursor for the manufacture of uniform, fine spherical particles of nickel, copper or cobalt metal, as well as useful as themselves as a catalyst for use in organic synthesis, a carrier, a pigment, a filler or a glaze.

Owner:SAKAI CHEM IND CO LTD

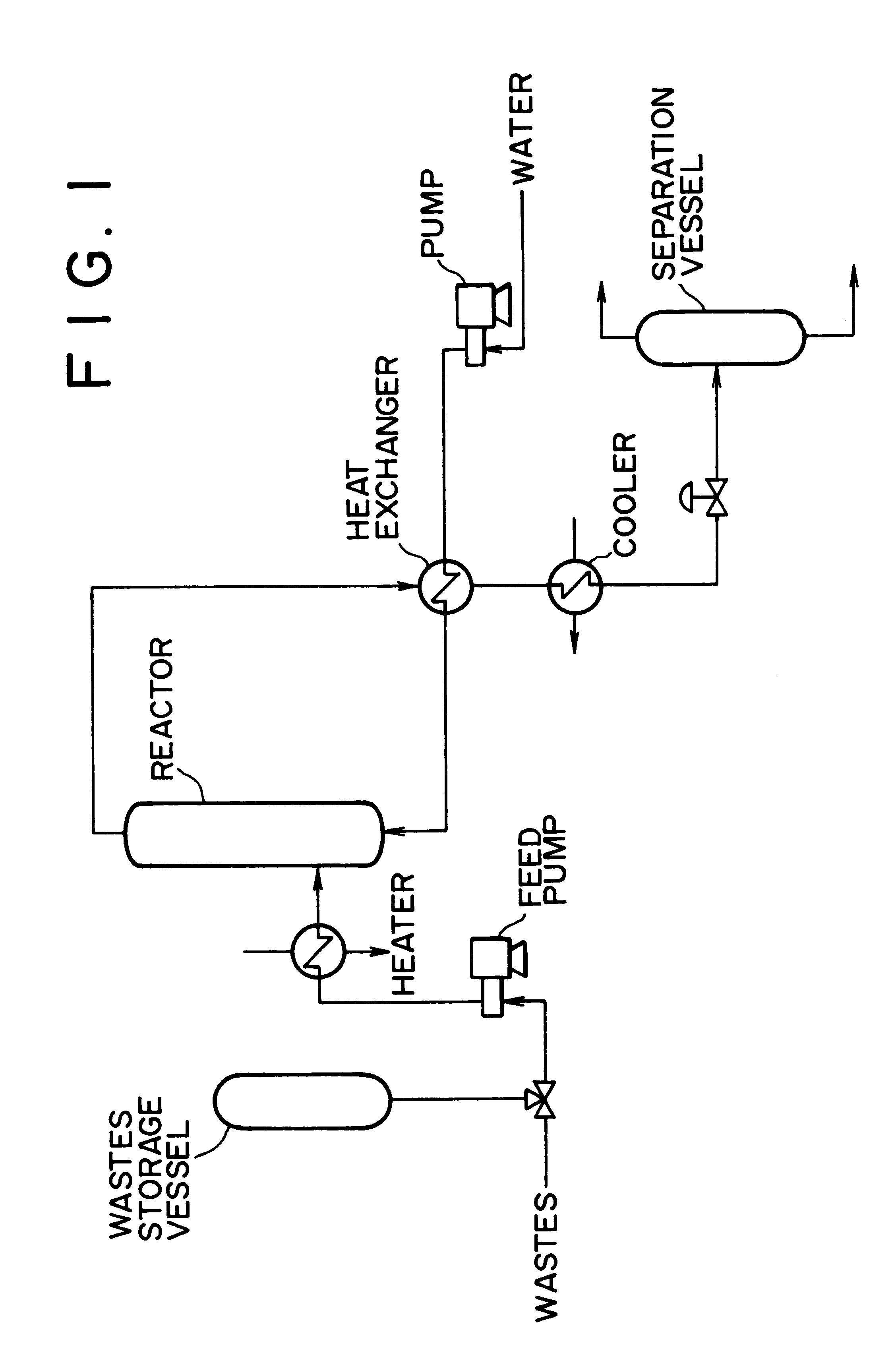

Method of and apparatus for decomposing wastes

InactiveUS6255529B1Useful operationResultant decomposition products can be utilized effectivelySolid waste disposalIndirect heat exchangersMolten stateLiquid state

A method of decomposing wastes containing target compounds having one or more of hydrolyzable bonds of ether bond, ester bond, amide bond and isocyanate bond wherein the method comprises continuously supplying the wastes in a molten state or liquid state to a reactor, continuously supplying super-critical water or high pressure / high temperature water to the reactor, bringing the water into contact with the wastes, thereby decomposing the target compounds and then recovering them as raw material compounds or derivatives thereof for the target compounds. Target compounds contained in wastes in chemical plants which could not be utilized but merely incinerated or discarded so far are continuously decomposed into raw material compounds or derivatives thereof for the aimed compound and can be reutilized effectively.

Owner:TAKEDA CHEM IND LTD 50

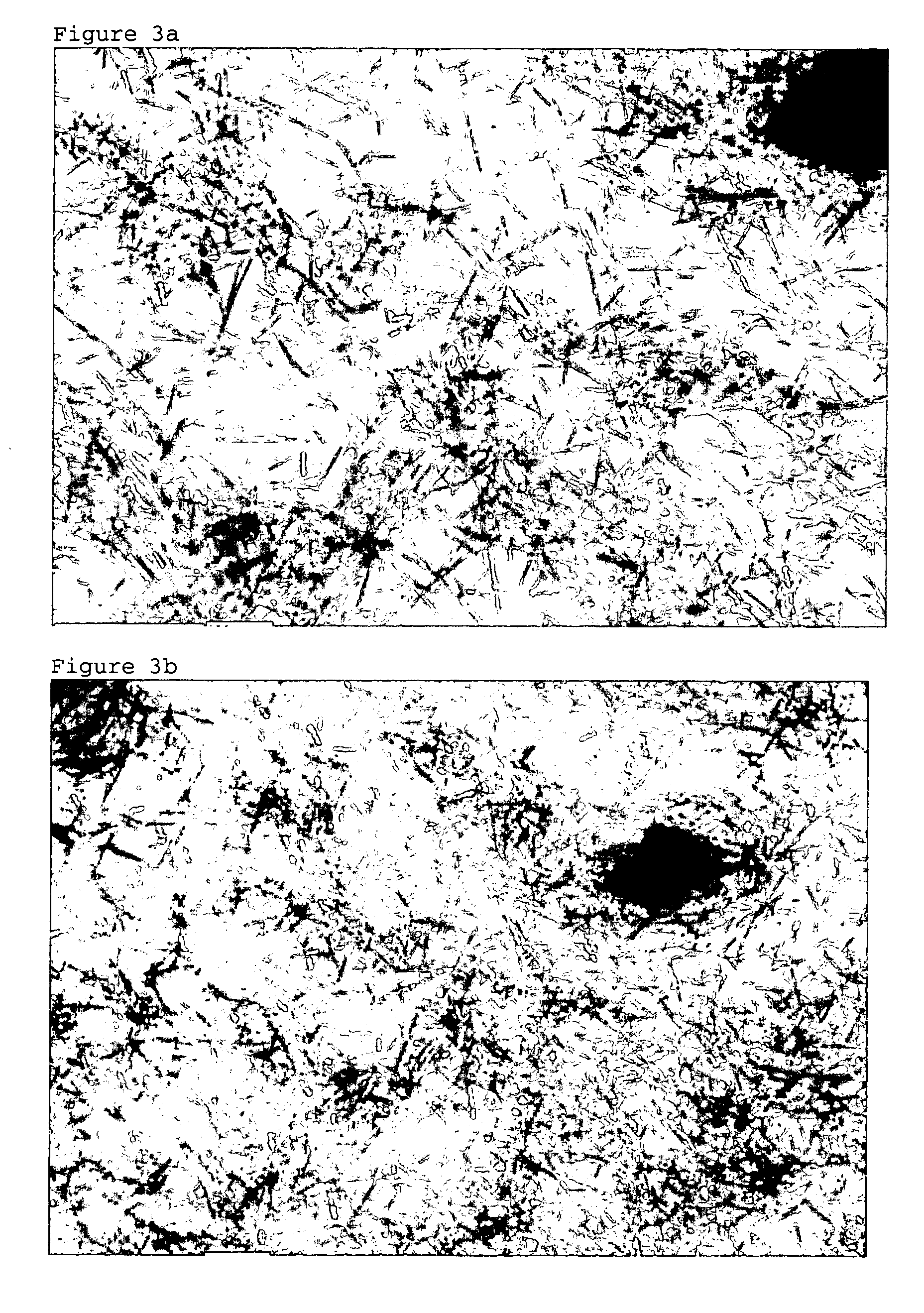

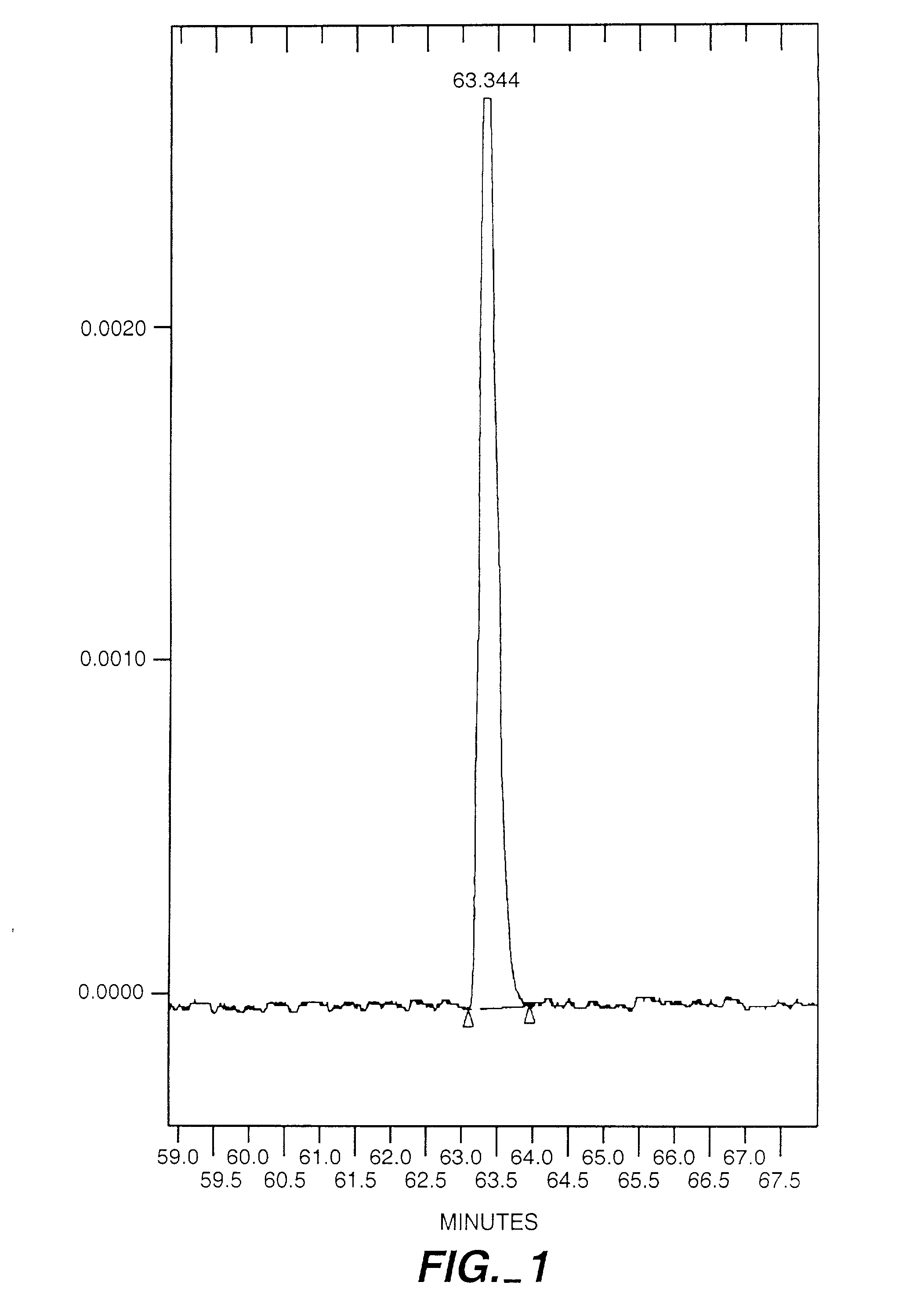

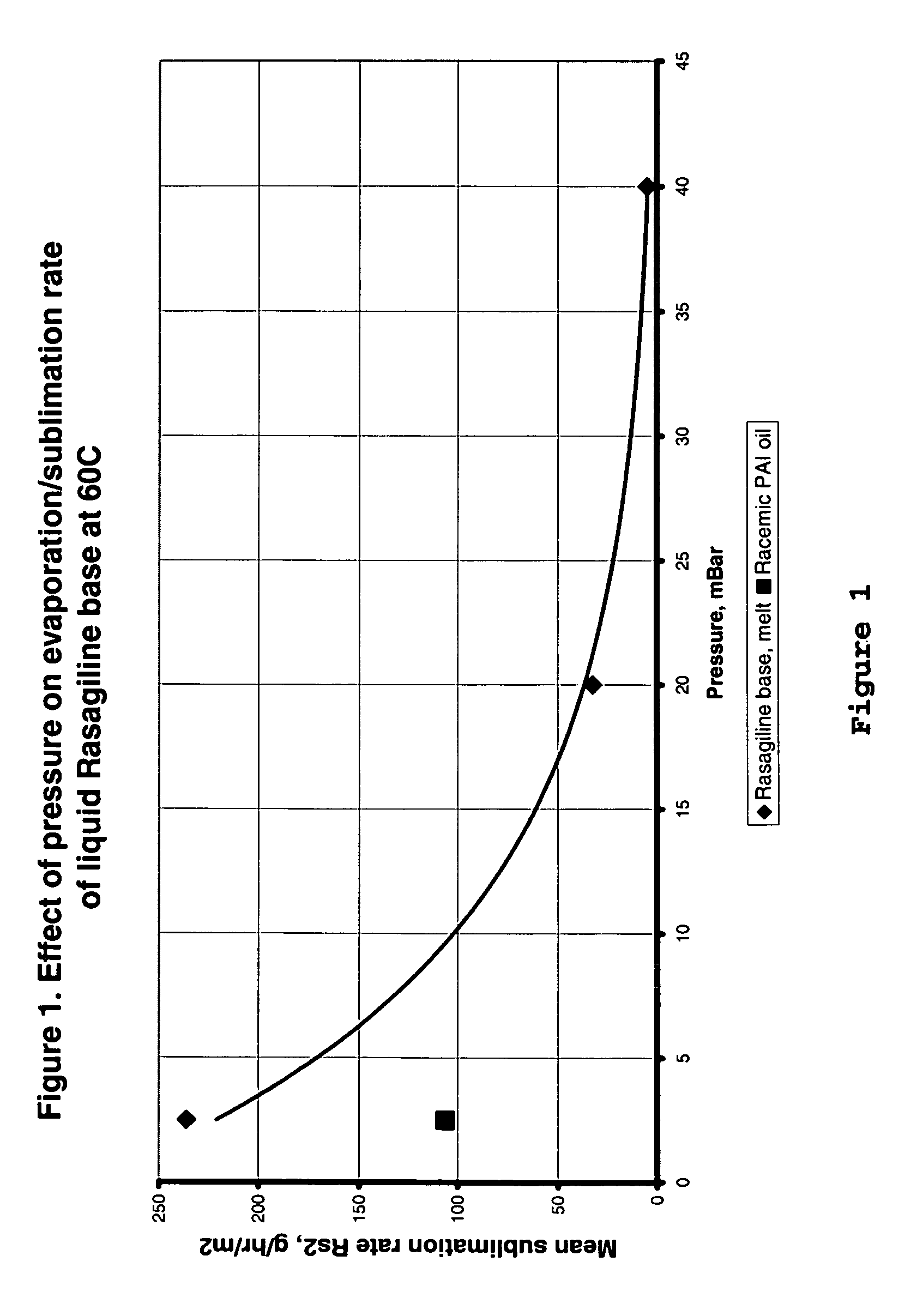

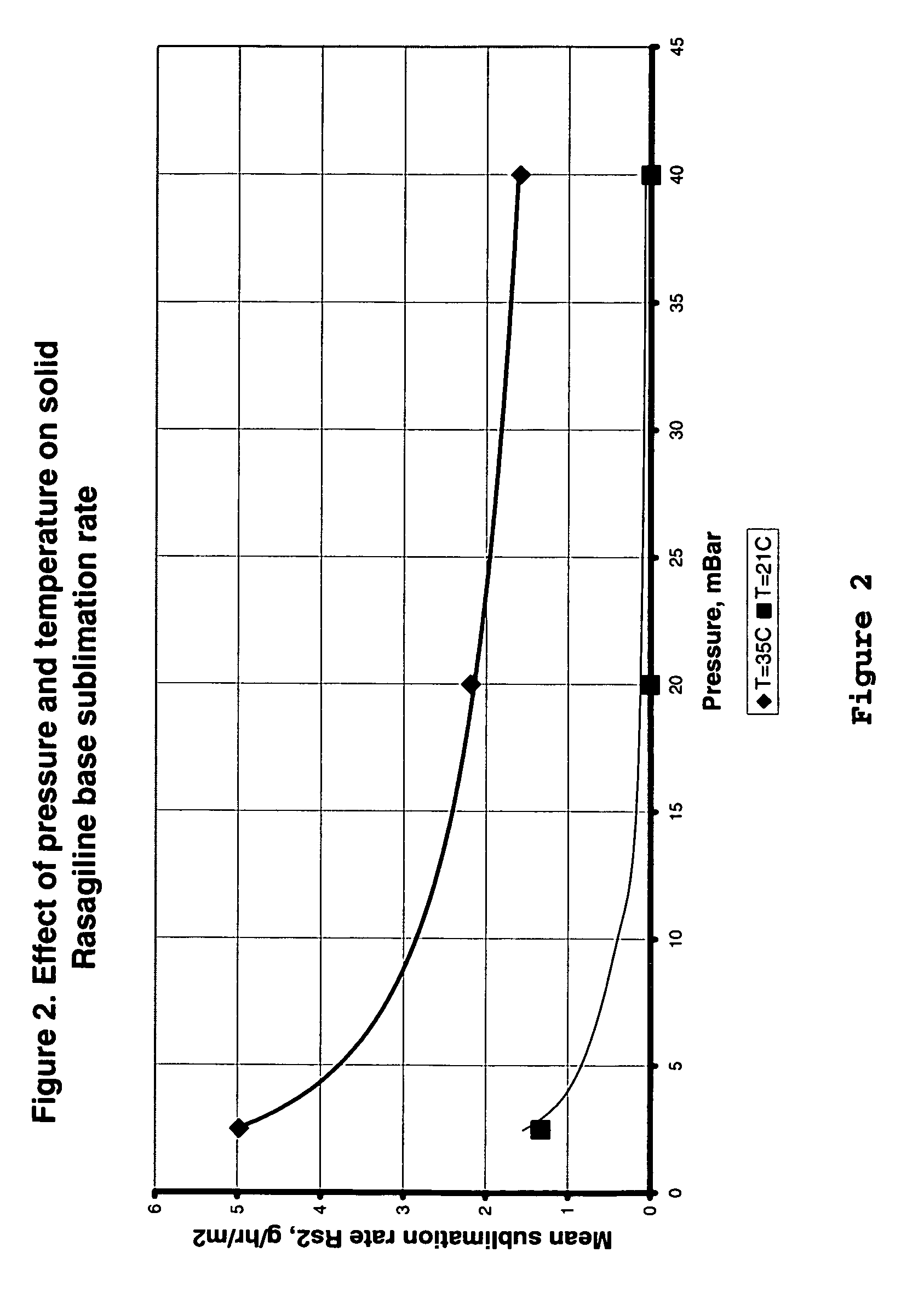

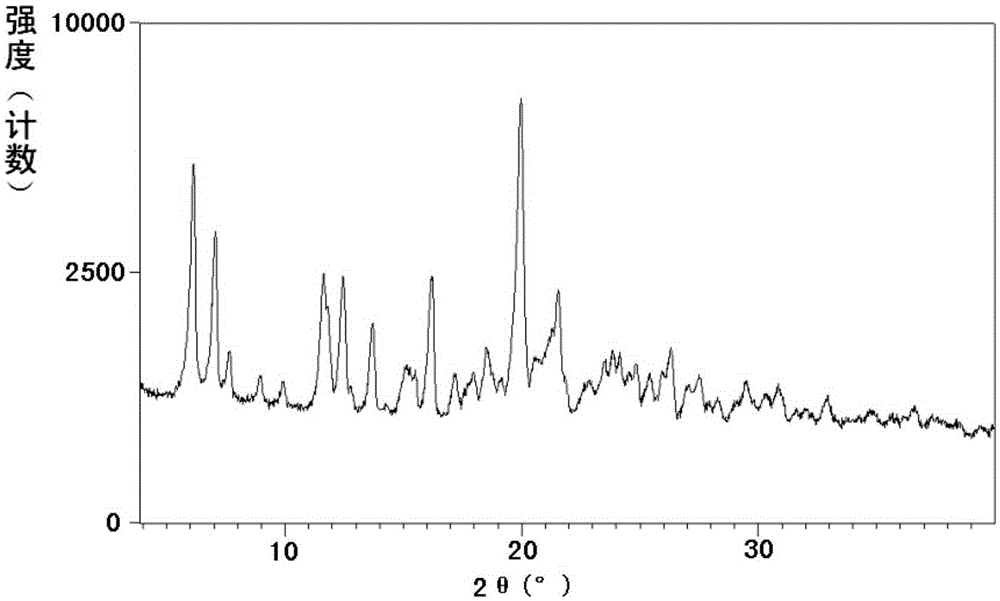

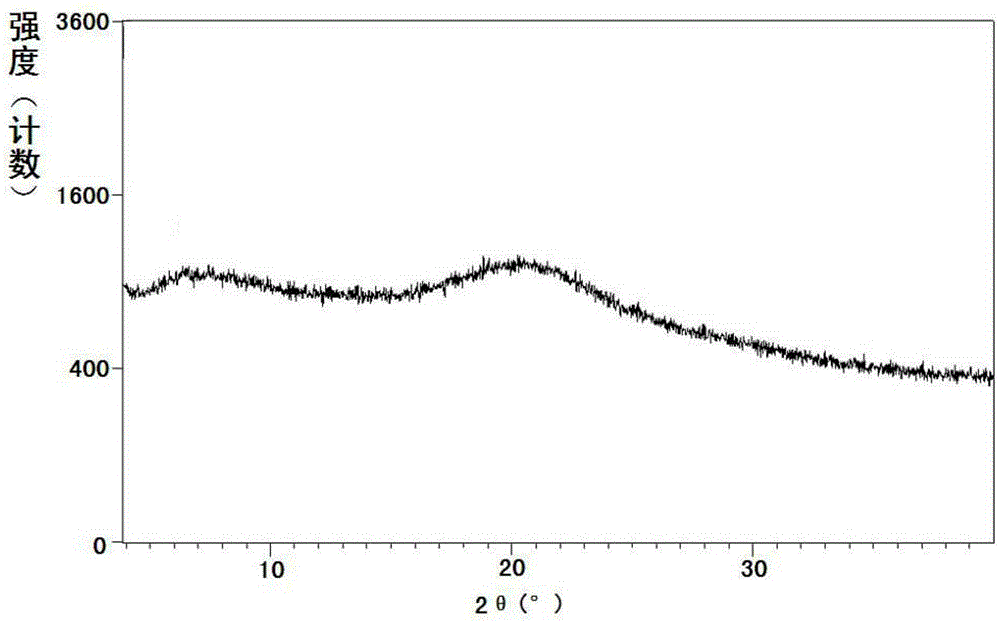

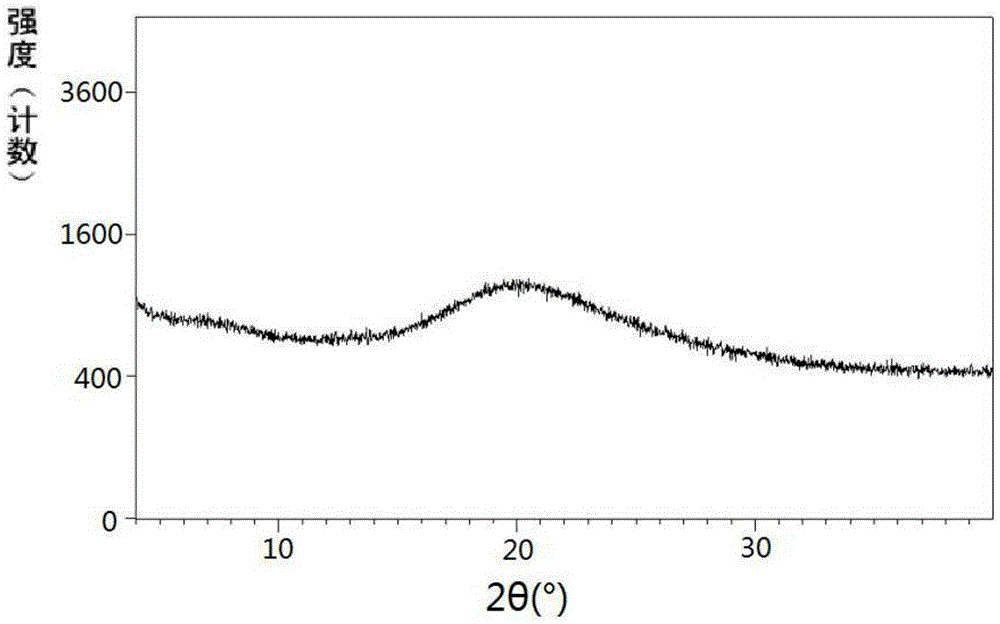

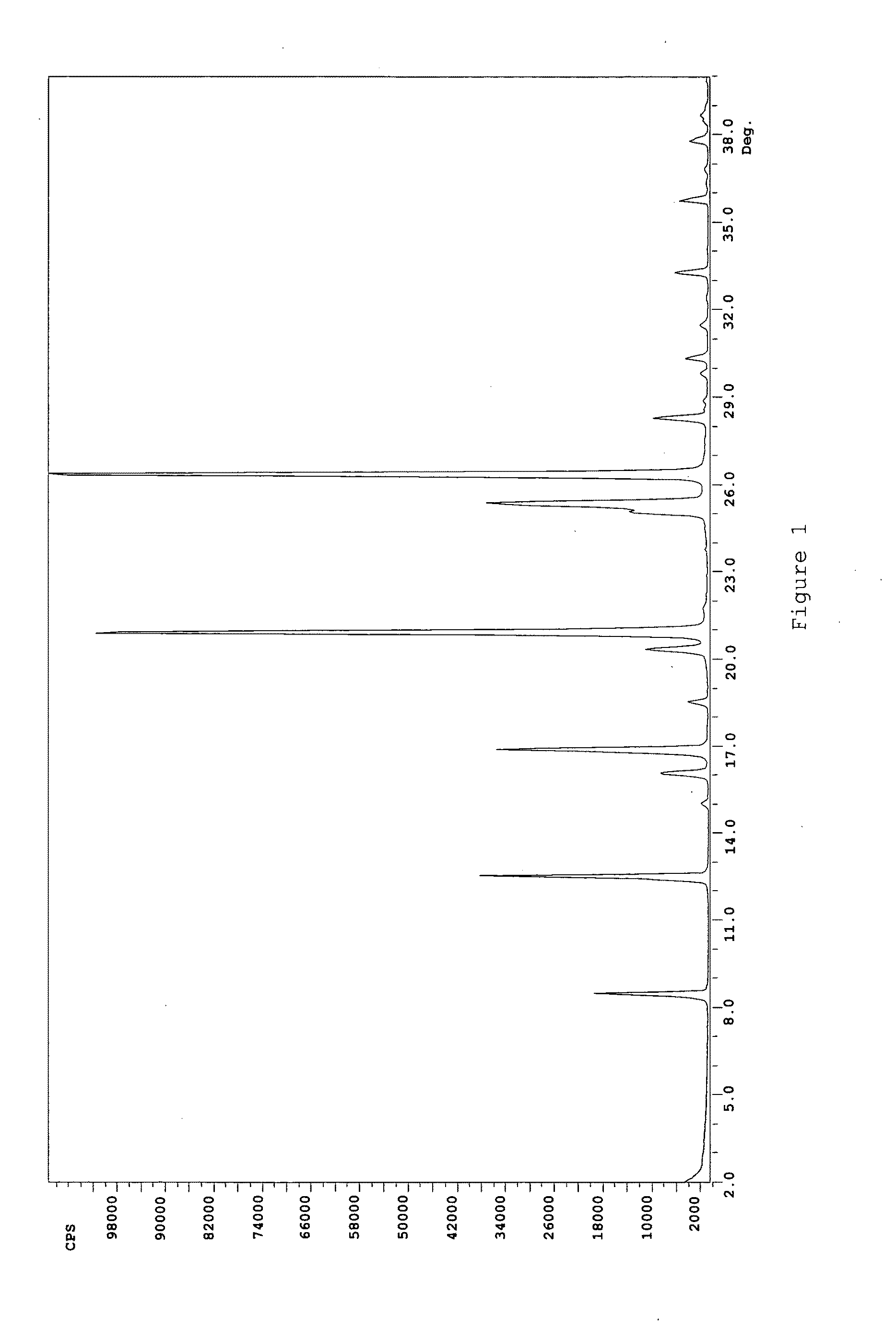

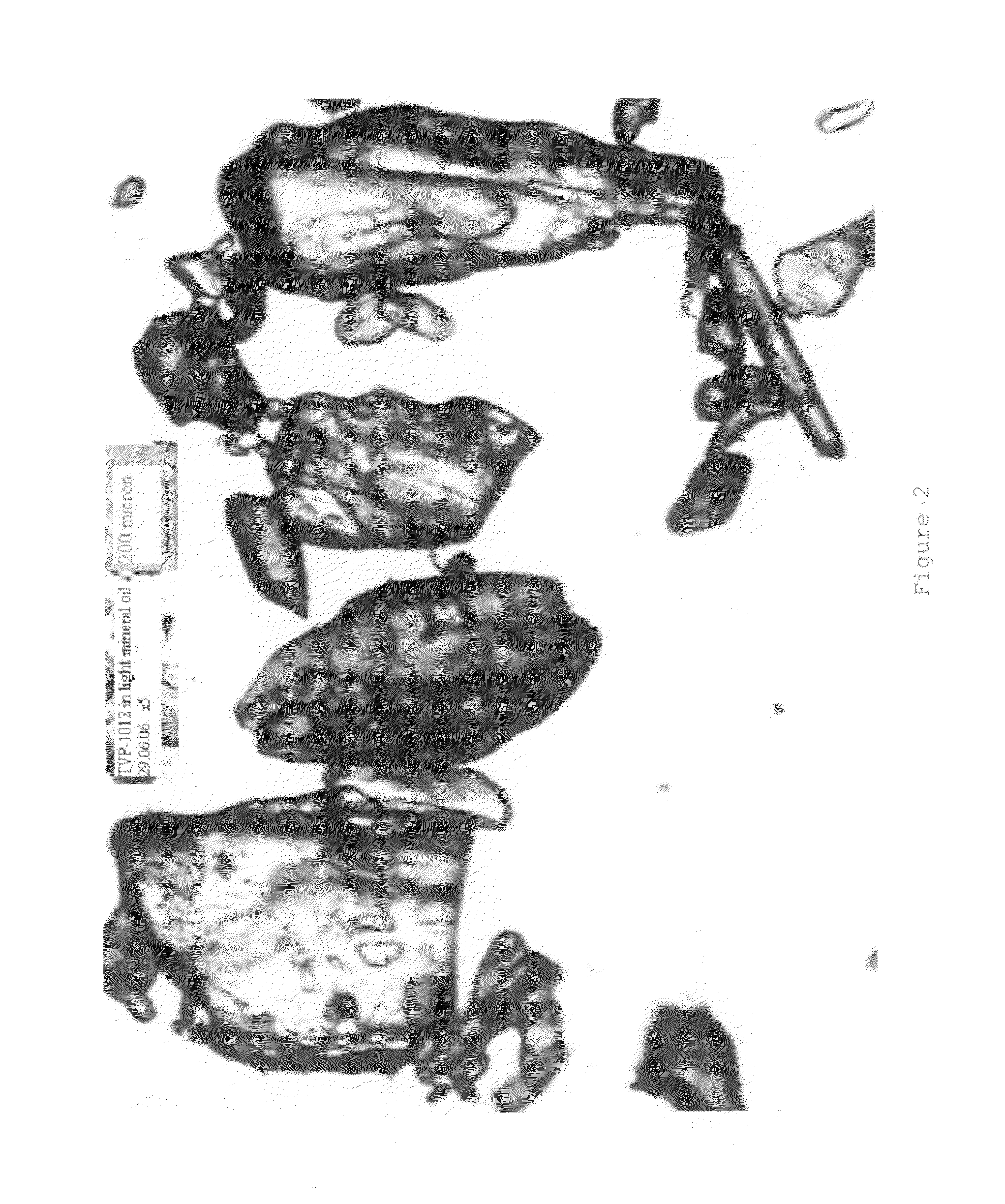

Process for purifying rasagiline base

Disclosed is crystalline R(+)-N-propargyl-1-aminoindan and racemic N-propargyl-1-aminoindan characterized by colorless crystals a pharmaceutical composition comprising the same, and the process for the manufacture and the validation thereof. Also disclosed is pure liquid R(+)-N-propargyl-1-aminoindan and a pharmaceutical composition comprising the same, and the process for the manufacture thereof.

Owner:TEVA PHARMA IND LTD

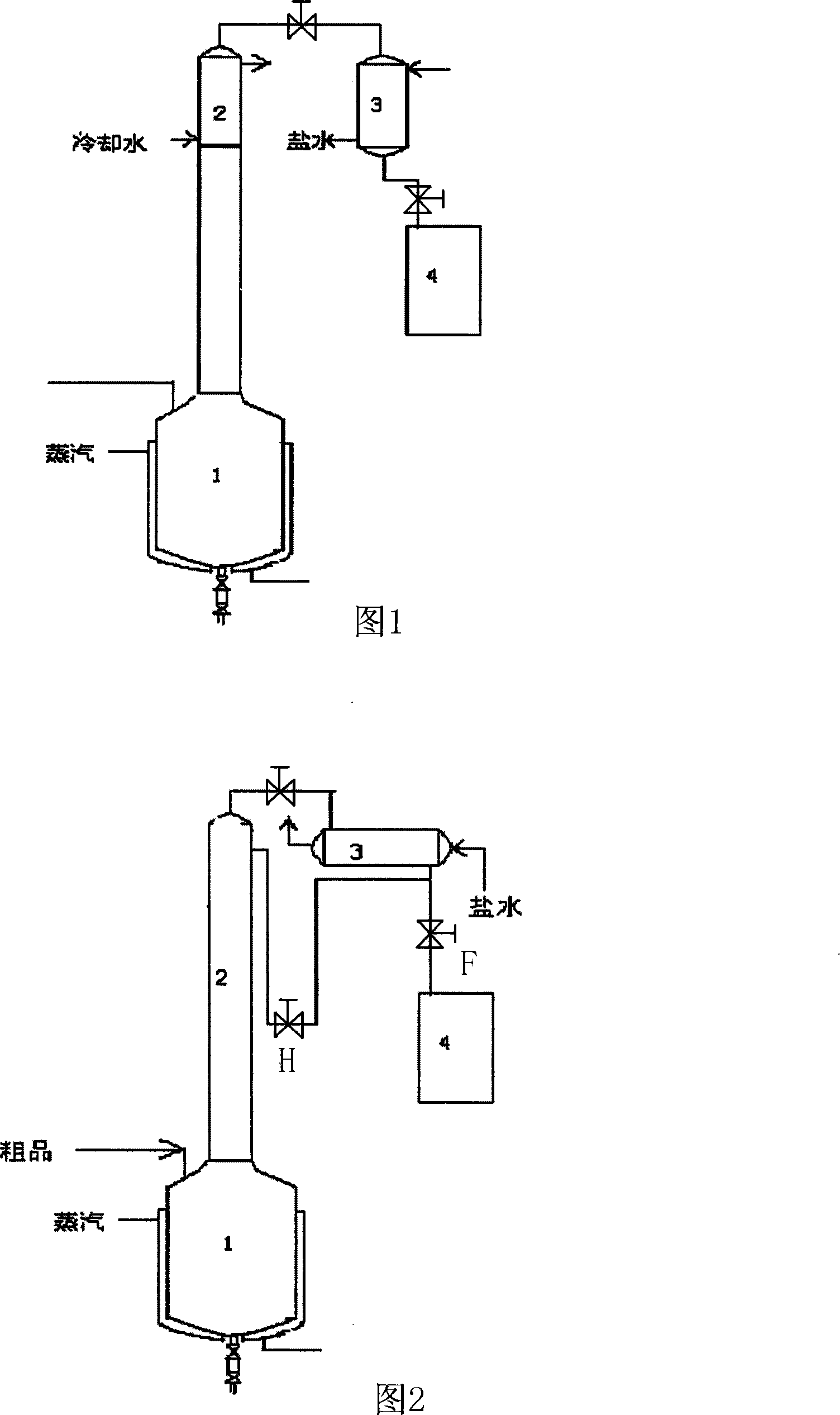

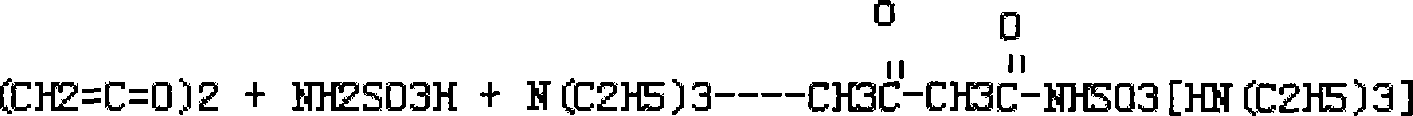

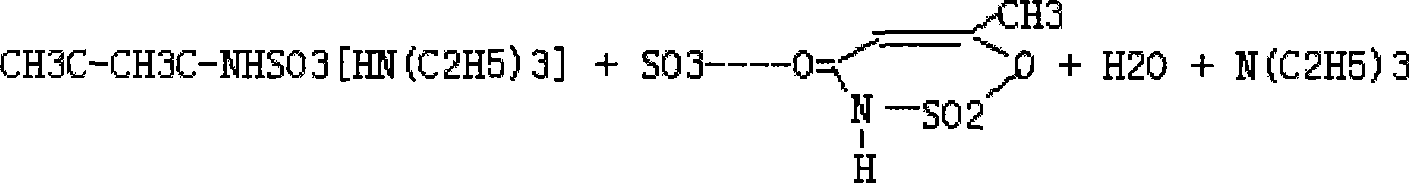

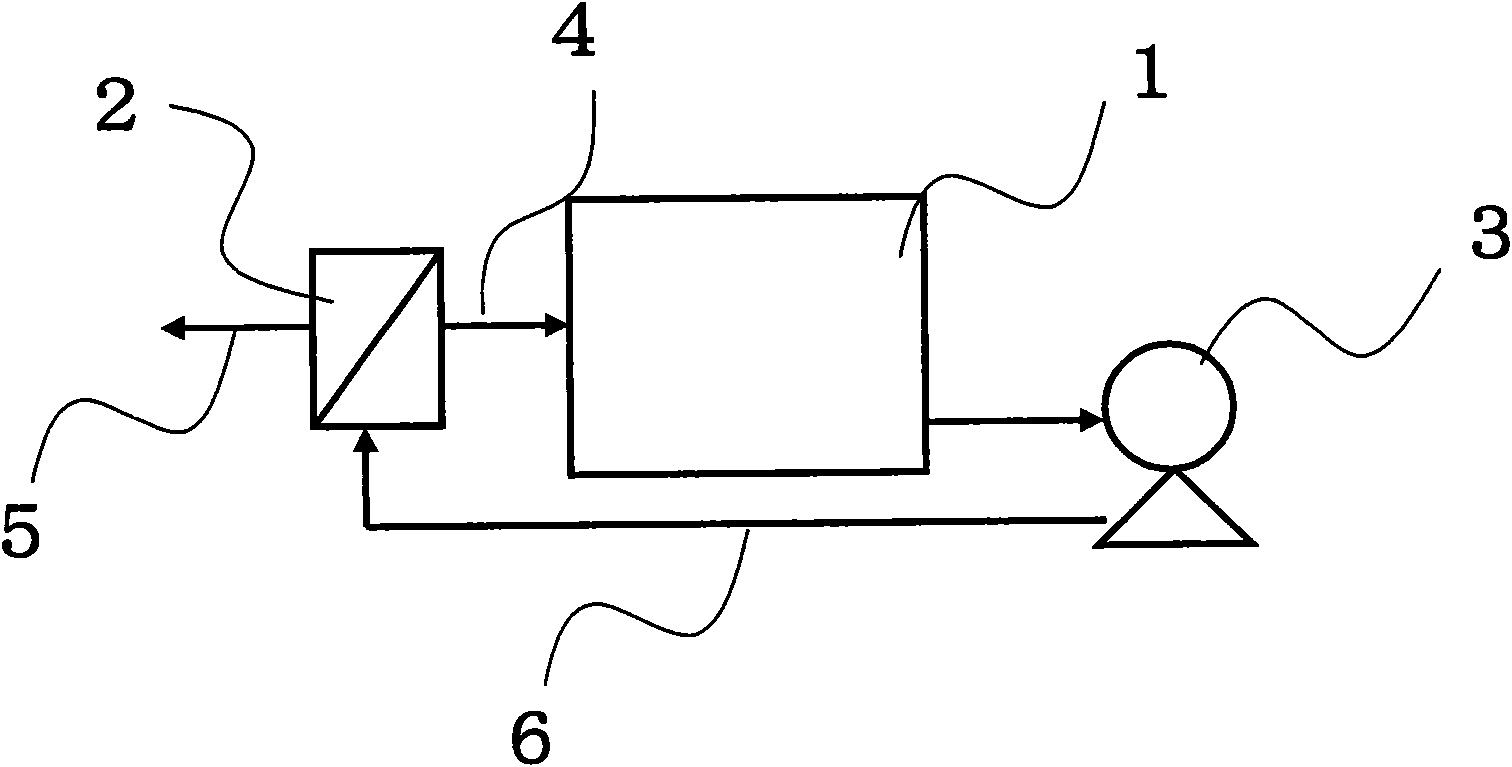

Triethylamine recovery processing method and device for production of acesulfame potassium

ActiveCN101157666AEasy to operateLow costAmino compound purification/separationMolecular sieveBoiling point

The invention relates to a triethylamine reclaim treatment method and the devices in the production of acesulfame-K, which is characterized in that the method includes the following steps: a. the crude triethylamine containing water is put into a distillation kettle (1), which is heated to the temperature of 38 DEG C to 42 DEG C, the time is about 20 to 40 minutes, the dichloromethane and other impurities with the low boiling points which are contained in the crude triethylamine are firstly evaporated, collected and then are condensed and collected by a condenser (3); b. the heating is carried out continually to about 83 DEG C, the temperature is kept for more than 30 minutes, which ensures that the water and triethylamine are placed still for layer separation, a lower layer is water, an upper layer is triethylamine, and triethylamine of the upper layer can be collected after the water is drained completely from the bottom of a kettle. Finally, the collected triethylamine is dried by the solid potassium hydroxide or a molecular screen, so the water content of triethylamine can be lower than 0.1 percent. The invention has the advantages of simple using equipment, convenient operation, safety, reliability, low cost, improved reclaim ratio of the product and significantly reduced operating cost.

Owner:ANHUI JINGHE IND

Method for controlling amine solvent regeneration system

InactiveCN101642629ARealize automatic controlReduce investmentAmino compound purification/separationDispersed particle separationControl systemReboiler

The invention provides a method for controlling an amine solvent regeneration system, belongs to the technical field of amine solvent recovery, and comprises an amine recovery tower. The method is characterized in that a heat supply regulating valve of a tower bottom reboiler is related to system pressure; and a distilled line regulating valve of a tower top product is related to the gas-phase temperature of the tower top. The method can meet the requirement on purification degree of an amine solvent product on the tower bottom only by presetting a system pressure value and a tower top gas-phase temperature vale; and the control system can trace variations of feeding flow rate, feeding quality and feeding temperature to realize automatic regulation and obtain perfect tower bottom products.

Owner:SHANDONG SUNWAY PETROCHEMICAL ENGINEERING CO LTD

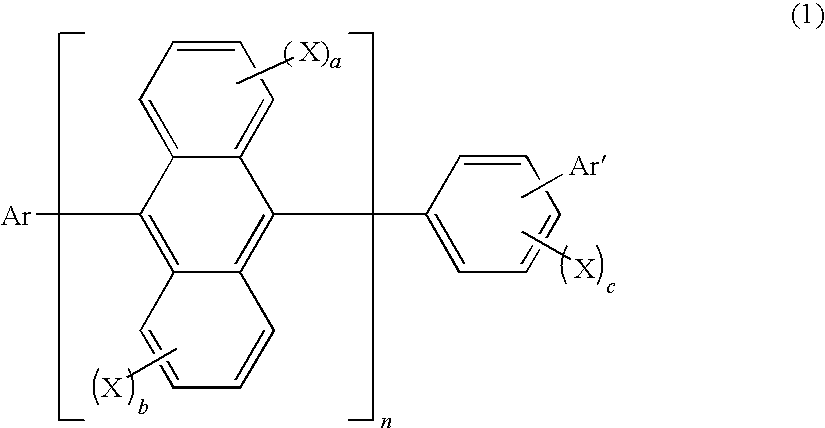

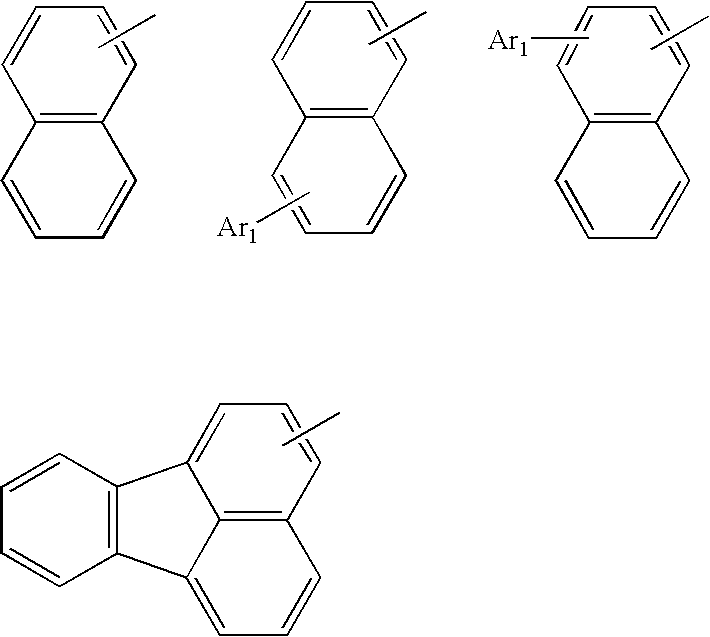

Method for producing aromatic compound and aromatic compound

InactiveUS20090206748A1Prolong lifeReduce contentAmino compound purification/separationDischarge tube luminescnet screensCompound aHalogen

A process for producing an aromatic compound which can effectively decrease the contents of halogen elements in the aromatic compound and an aromatic compound which is produced in accordance with the process and useful as the material for obtaining an organic electroluminescence device having a long life are provided. The process for producing an aromatic compound comprises bringing an aromatic compound which is produced via an intermediate compound having halogen elements and has contents of halogen elements of 10 to 1,000 ppm by mass into reaction with a dehalogenating agent to decrease the contents of halogen elements to 10 ppm by mass or smaller, and an aromatic compound which is produced in accordance with the process.

Owner:IDEMITSU KOSAN CO LTD

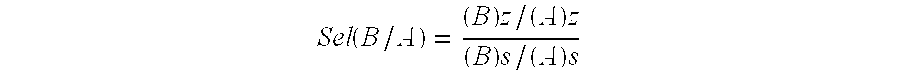

Agglomerated zeolitic adsorbents, their process of preparation and their uses

InactiveUS20050170947A1Amino compound purification/separationMolecular sieve catalystsSorbentSimulated moving bed

The present invention relates to agglomerated zeolitic adsorbents containing zeolite X and an inert binder, the inert binder containing at least 80% by weight of clay which has undergone zeolitization by the action of an alkaline solution, the zeolite X having with an Si / Al ratio such that 1.15<Si / Al≦1.5, at least 90% of the exchangeable cationic sites of the zeolite X of which are occupied either by barium ions alone or by barium ions and potassium ions whose Dubinin volume is greater than or equal to 0.240 cm3 / g. They are obtained by agglomerating zeolite powder with a binder, followed by the zeolitization of the binder, the exchange of the ions of the zeolite by barium ions (and potassium ions) and the activation of the adsorbents thus exchanged. These adsorbents are particularly suited to the adsorption of the para-xylene present in C8 aromatic hydrocarbon fractions in the liquid phase in processes of simulated moving bed type but also to the separation of sugars, polyhydric alcohols, cresols or substituted toluene isomers.

Owner:ARKEMA FRANCE SA

Separation of amine from a phenolic compound

InactiveUS20050080294A1Amino compound purification/separationOrganic compound preparationCompound aAlcohol

A process comprises contacting a product mixture with a base, optionally in the presence of a polyhydric alcohol, to produce a base-treated mixture and distilling the base-treated mixture in which the product mixture comprises an aromatic amine and a phenolic compound.

Owner:THE CHEMOURS CO FC LLC

Process for producing diamine and polyamide

ActiveCN101970393AEfficient removalEasy to operateMembranesAmino compound purification/separationOrganic solventPolyamide

Disclosed is a process for producing a diamine, comprising the step of purifying a diamine from an aqueous solution containing a diamine salt. Specifically, the process comprises the step of adding an alkaline substance to the aqueous solution and then filtering the aqueous solution through a nanofiltration film to remove the salt and thus to obtain an aqueous diamine solution, whereby a diamine suitable as a starting material for a polyamide can be obtained by a simpler operation than a conventional extraction operation with an organic solvent.

Owner:TORAY IND INC

Recovery method of catalyst triethylamine in acesulfame potassium production

ActiveCN104193625ANo lossEfficient use ofAmino compound purification/separationCalcium/strontium/barium sulfatesPtru catalystMethylene Dichloride

The invention belongs to the technical field of acesulfame potassium production and relates to a recovery method of catalyst triethylamine in the acesulfame potassium production. A one-step one-kettle reaction is changed into a two-kettle three-step reaction, and the purpose of recovering triethylamine is achieved by the following steps: (1) preheating, and recovering methylene dichloride; (2) carrying out neutralization reaction; (3) reacting in an alkali separation kettle and dropwise adding sulfuric acid; (4) carrying out heat preservation and water distribution. Compared with a traditional method, the recovery method has the advantages that the recovery rate is greatly improved, the labor intensity of workers is reduced at the same time, and produced wastes also reach the environmental treatment standards.

Owner:ANHUI JINGHE IND

Sacubitril derivatives and medicine compositions, preparation methods and application thereof

ActiveCN105693543AEasy to prepareCrystal form controllableAmino compound purification/separationOrganic compound preparationEthylenediamineArginine

The invention provides sacubitril derivatives and medicine compositions, preparation methods and application thereof and belongs to the fields of medicine compounds and preparation thereof. The sacubitril derivatives comprise sacubitril lithium salt, sacubitril kali salt, sacubitril magnesium salt, sacubitril calcium salt, sacubitril strontium salt, sacubitril zinc salt, sacubitril ferric salt, sacubitril ammonium salt, sacubitril diethylamine salt, sacubitril ethylenediamine salt, sacubitril piperazine salt, sacubitril N-(2-ethoxyl)-pyrrolidine salt, sacubitril choline salt, sacubitril cholamine salt, sacubitril diethanol amine salt, sacubitril triethanolamine salt, sacubitril tromethamine salt, sacubitril meglumine salt, sacubitril diisopropylamine salt, sacubitril tert-butylamine salt, sacubitril N, N'-bis-benzyl ethylenediamine salt, sacubitril L-lysine salt, sacubitril L-arginine salt or sacubitril L-histidine salt.

Owner:SICHUAN HAISCO PHARMA CO LTD

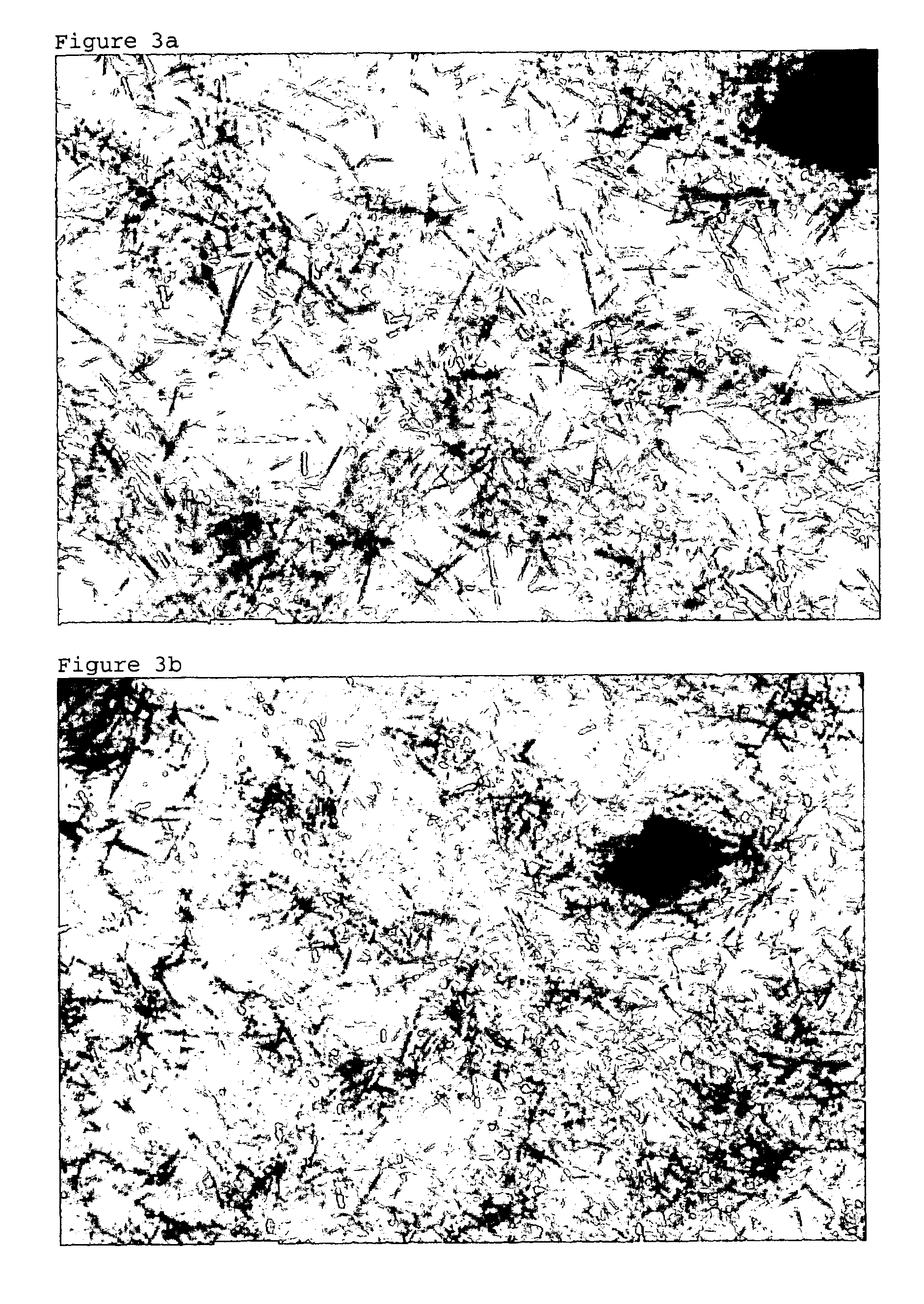

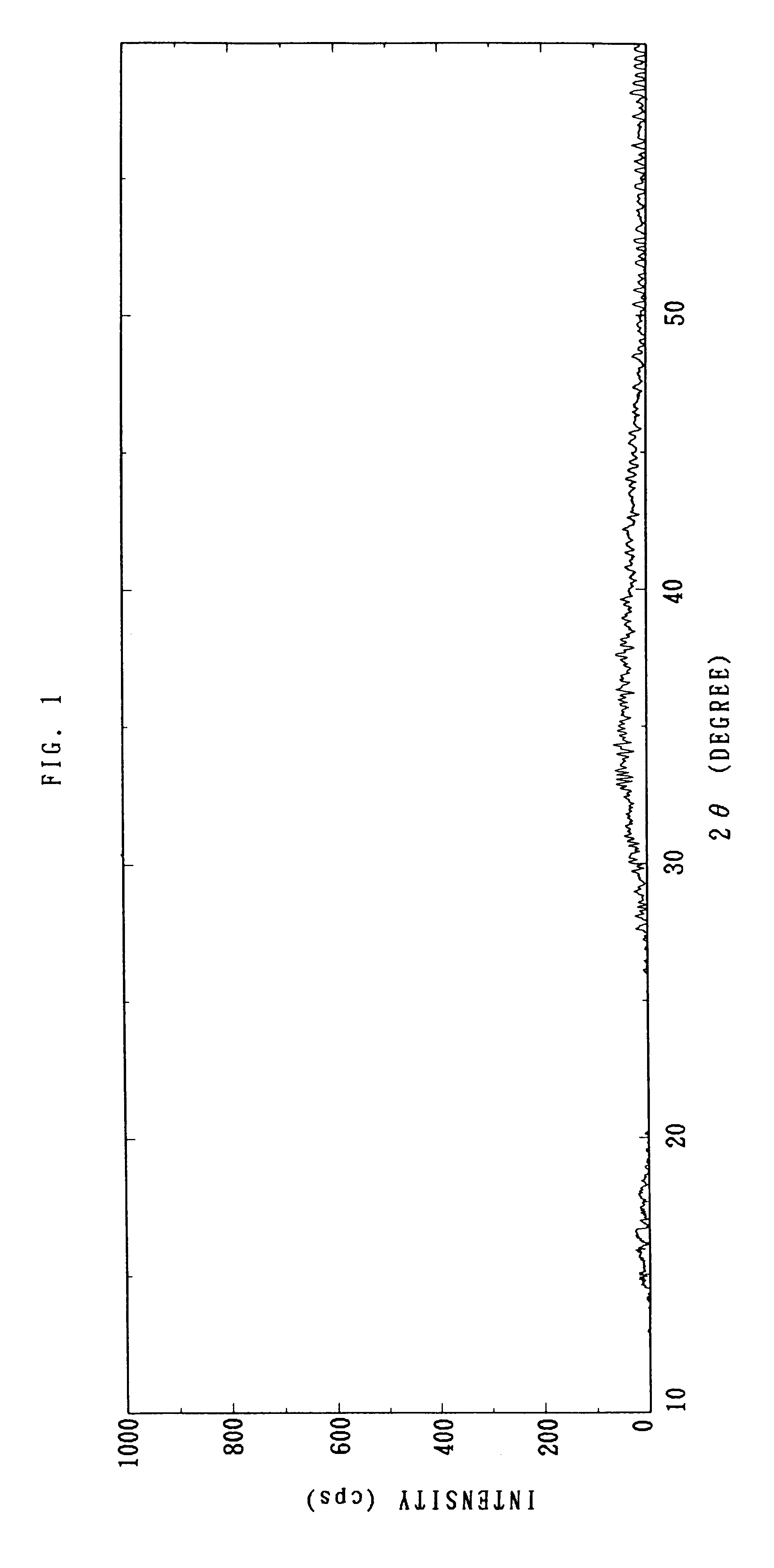

Crystalline solid rasagiline base

Owner:TEVA PHARMA IND LTD

Process for isolation of an organic amine

ActiveUS7977514B2Increasing organic amineIncreasing acidAmino compound purification/separationOrganic compound preparationHydrazine compoundAmmonia

The invention relates to a process for the isolation of an organic amine from a composition comprising the organic amine and an acid, or a salt of the organic amine and the acid, wherein the process comprises steps wherein ammonia or hydrazine is added to the composition thereby forming a multi-phase system comprising an organic amine-rich phase and an acid-rich phase, the organic amine-rich phase and the acid-rich phase obtained in step (i) are separated, and the organic amine is isolated from the organic amine-rich phase.

Owner:DSM IP ASSETS BV

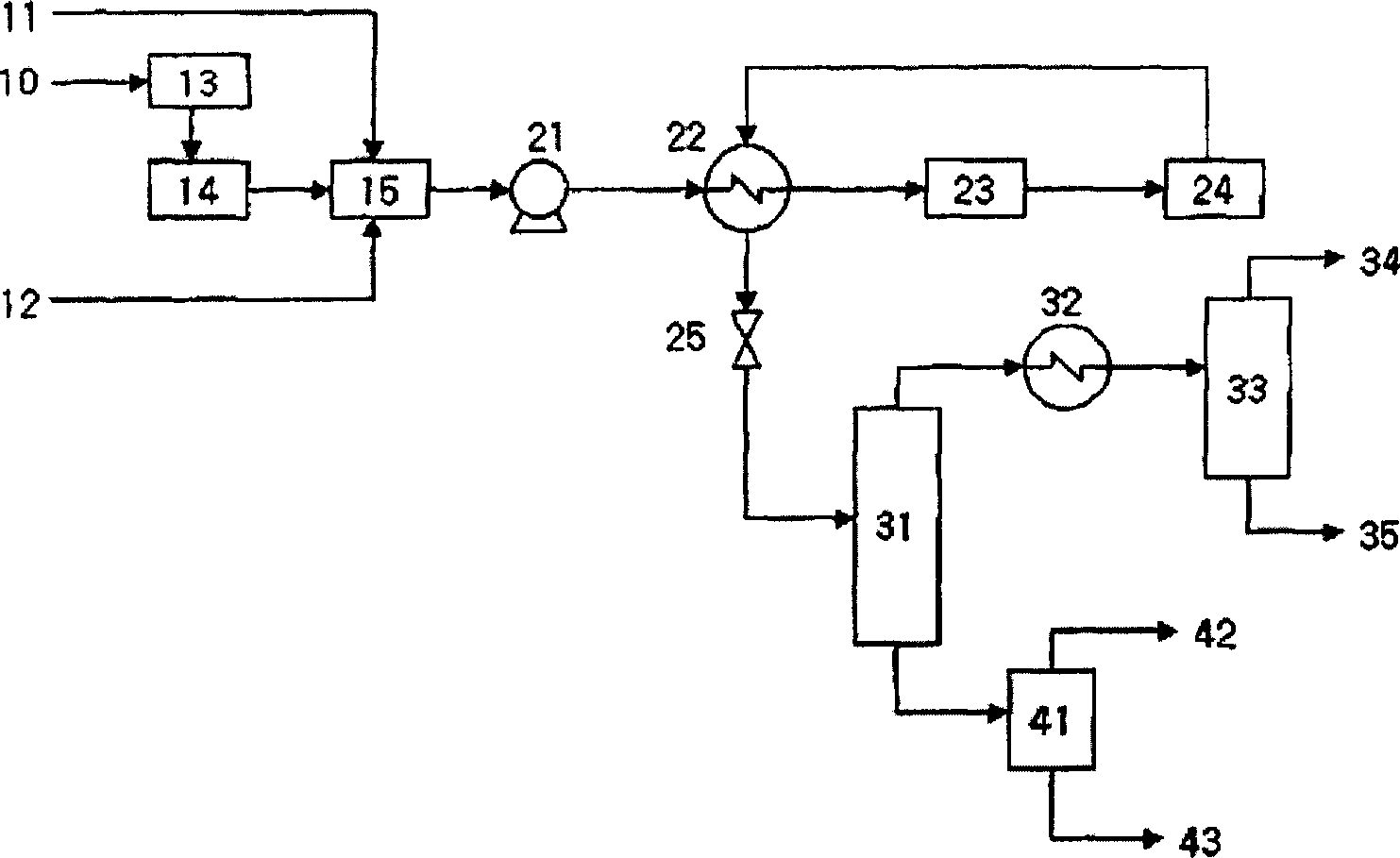

Process for producing ammonium salts

ActiveUS20110256045A1Reduce the amount requiredAmino compound purification/separationGas treatmentSulfuric acidAmmonium

In one embodiment, the invention is to a process of producing an ammonium salt composition. The process comprises the step of providing a process stream comprising sulfuric acid and at least one tertiary amine. The process further comprises the step of contacting the process stream with ammonia under conditions effective to form a waste stream and a product stream. The waste stream comprises water, the tertiary amine, and ammonia and the product stream comprises a first amount of ammonium salt. The process further comprises the step of deriving from the waste stream an off gas stream comprising a preliminary amount of ammonia. The process also comprises the step of contacting the off gas stream with an acid under conditions effective to form an ammonium salt stream and a purge stream. The ammonium salt stream comprises a second amount of ammonium salt and the purge stream comprises a reduced amount of ammonia, which is less than the preliminary amount.

Owner:CELANESE INT CORP

Crystalline solid rasagiline base

InactiveUS20100145101A1Organic active ingredientsAmino compound purification/separationN-propargyl1-aminoindan

The subject invention provides crystalline R(+)-N-propargyl-1-aminoindan, pharmaceutical compositions and methods of manufacture thereof.

Owner:TEVA PHARMA IND LTD

Process for producing ammonium salts

ActiveUS8303921B2Reduce the amount requiredAmino compound purification/separationGas treatmentWaste streamAmmonia

The invention relates to a process of producing an ammonium salt composition. The process comprises the step of providing a process stream comprising sulfuric acid and at least one tertiary amine. The process further comprises the step of contacting the process stream with ammonia to form a waste stream and a product stream. The waste stream comprises water, tertiary amine, and ammonia and the product stream comprises a first amount of ammonium salt. The process further comprises the step of deriving from the waste stream an off gas stream comprising a preliminary amount of ammonia. The process also comprises the step of contacting the off gas stream with an acid to form an ammonium salt stream and a purge stream. The ammonium salt stream comprises a second amount of ammonium salt and the purge stream comprises a reduced amount of ammonia, which is less than the preliminary amount.

Owner:CELANESE INT CORP

Method for the removal of heat stable amine salts from an amine absorbent

InactiveUS20120235087A1Good removal effectElectrolysis componentsCarbon compoundsCarbon dioxideReduced concentration

The proposed invention relates to a method and a system for the removal of heat stable amine salts from an amine absorbent used in a carbon dioxide (CO2) capture process, the method comprising: withdrawing amine absorbent containing heat stable amine salts from the CO2 capture process; subjecting the withdrawn amine absorbent containing heat stable amine salts to a residual CO2 removal step; subjecting the amine absorbent from the residual CO2 removal step to a separation step to separate heat stable amine salts from the amine absorbent; and returning the amine absorbent having a reduced concentration of heat stable amine salts to the CO2 capture process.

Owner:GENERAL ELECTRIC TECH GMBH +1

Synthetic method for high-purity quaternary ammonium salt

InactiveCN103351301AImprove solubilitySimple process routeAmino compound purification/separationOrganic compound preparationAlkyl transferQuaternary ammonium cation

The invention discloses a synthetic method for a quaternary ammonium salt, especially to a synthetic method for a high-purity quaternary ammonium salt. The synthetic method comprises the following steps: adding a certain amount of a solvent, tertiary amine and an alkylation reagent into a reaction vessel with reaction temperature being 20 to 105 DEG C and reaction time being 2 to 24 h; and after a reaction is ended, carrying out direct cooling, centrifugation and drying so as to obtain the high-purity quaternary ammonium salt. The solvent used in the method can be used indiscriminately and repeatedly, so production cost is reduced, and the method has a high industrial practical value.

Owner:安徽奔马先端科技有限公司

Process for producing ammonium salts

ActiveUS8309048B2Reduce the amount requiredAmino compound purification/separationGas treatmentMethylene DichlorideWaste stream

The invention relates to a process for producing an ammonium salt composition. The process comprises the step of providing a process stream comprising sulfuric acid, methylene dichloride, and a tertiary amine or a precursor thereof. The process further comprises the step of contacting the process stream with ammonia to form a product stream and a waste stream. The product stream comprises the ammonium salt and the waste stream comprises water, methylene dichloride, ammonia, and the tertiary amine. The process further comprises the step of deriving from the waste stream an off gas stream comprising ammonia and a first amount of methylene dichloride. The process also comprises the step of contacting at least a portion of the off gas stream or a derivative thereof with an adsorbent to separate at least a portion of the off gas into a methylene dichloride stream comprising methylene dichloride.

Owner:NUTRINOVA NETHERLANDS BV

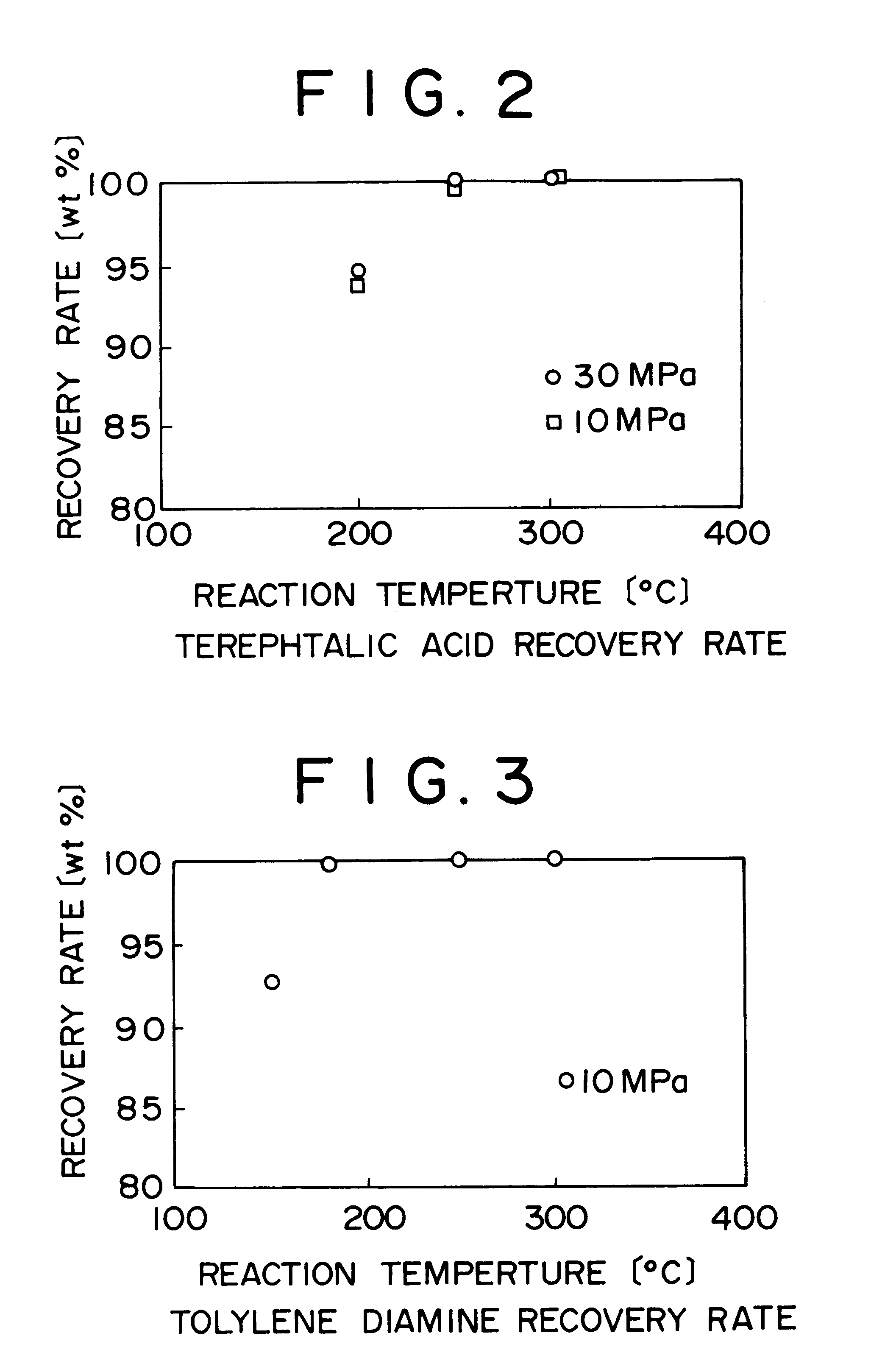

Method for recovering toluene diamine from high boiling tar residue discharged from toluene diisocyanate preparation process

ActiveCN1802344ANo negative impactAmino compound purification/separationTherapeutic coolingDiamineTar

Disclosed is a method for recovering toluene diamine from a fluid, high-boiling tar residue discharged from TDI preparation processes. After free TDI is separated and recovered from the tar residue, the remaining solid residue is pulverized, slurried and hydrolysis-treated in the presence of a catalyst under the condition of the liquid phase region near a critical point of water to produce toluene diamine, and then the resulting toluene diamine is effectively recovered.

Owner:HANWHA CHEMICAL CORPORATION

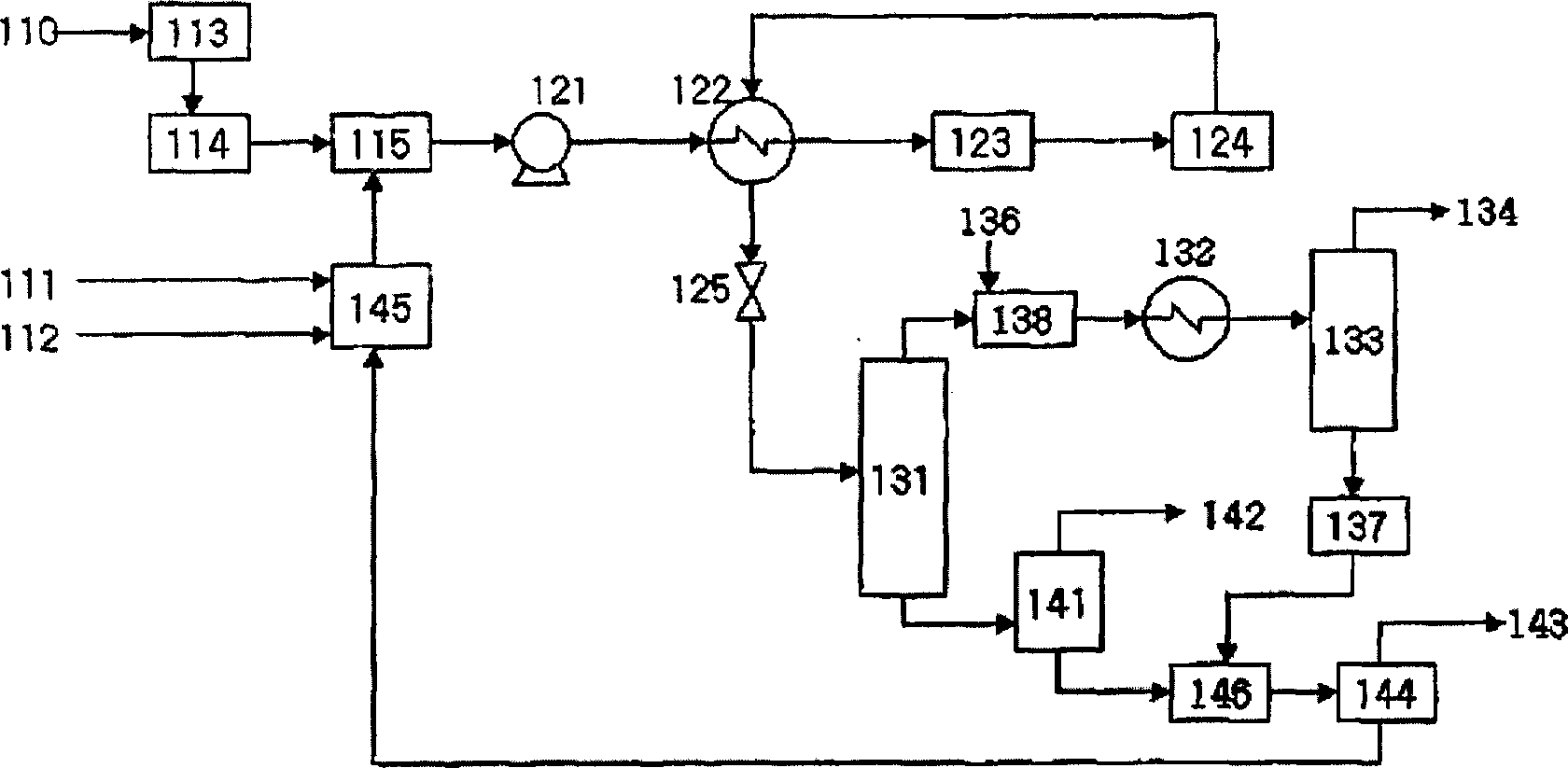

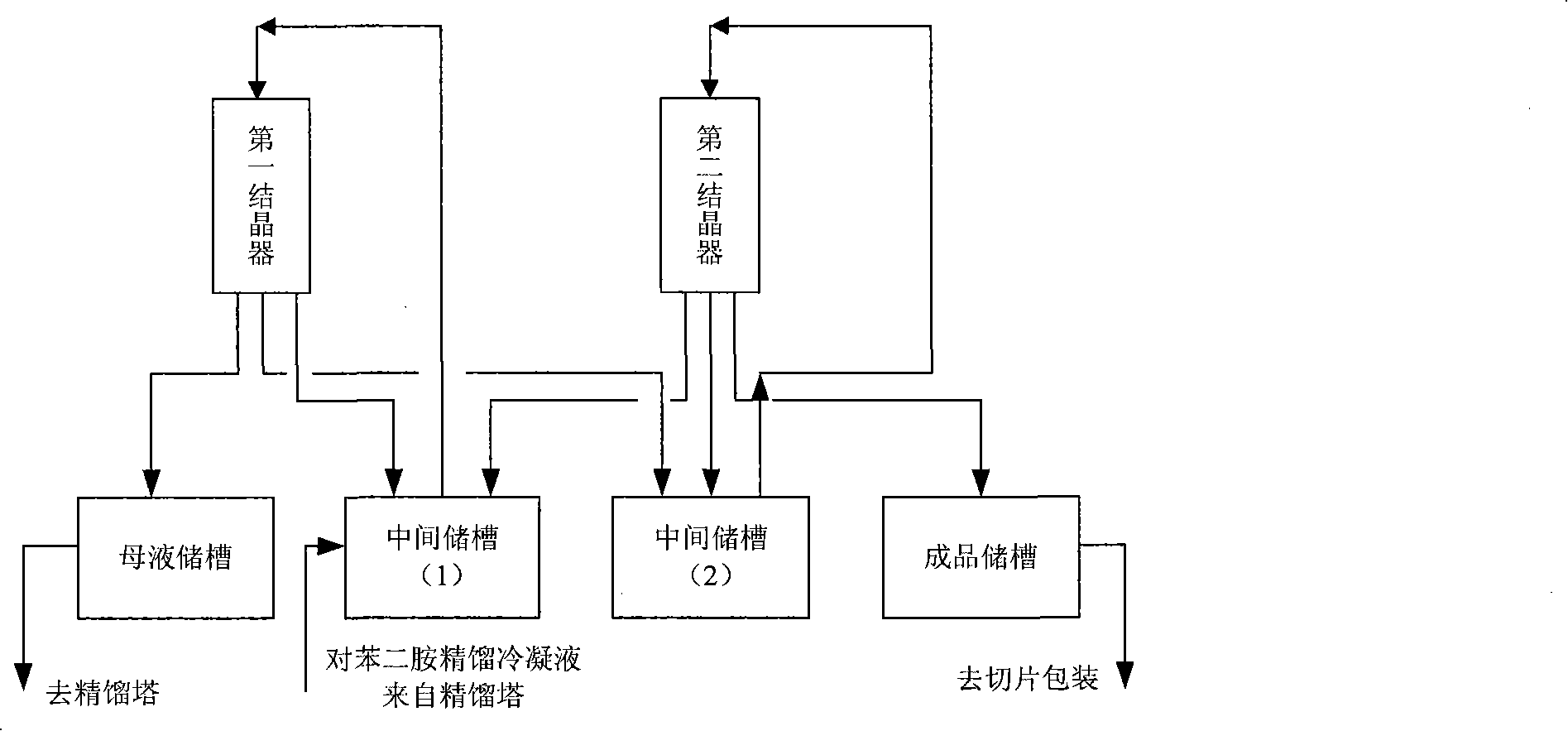

Method for refining p-phenylene diamine

The invention provides a refining method of p-phenylenediamine, which combines distillation and melting crystallization, uses the distillation product condensate to directly process melt crystallization for purification and processes fractional crystallization composed of one crystallization at least and one transpiration to obtain high-purity product. The invention combines distillation and melting crystallization to refine p-phenylenediamine and the invention can obtain high-purity and high-qaulity p-phenylenediamine product whose purity can reach 99.99-99.999% via controlling operation parameters, while the product quality can satisfy the quality demand of polymerization level product and the high-quality p-phenylenediamine can not be produced only by distillation. The refining method of p-phenylenediamine has the advantages of high product purity and flexible production set according to different standards, high yield of high-quality product and low cost, while the operation is processed without solvent to reduce pollution.

Owner:上海鸿源鑫创材料科技有限公司 +2

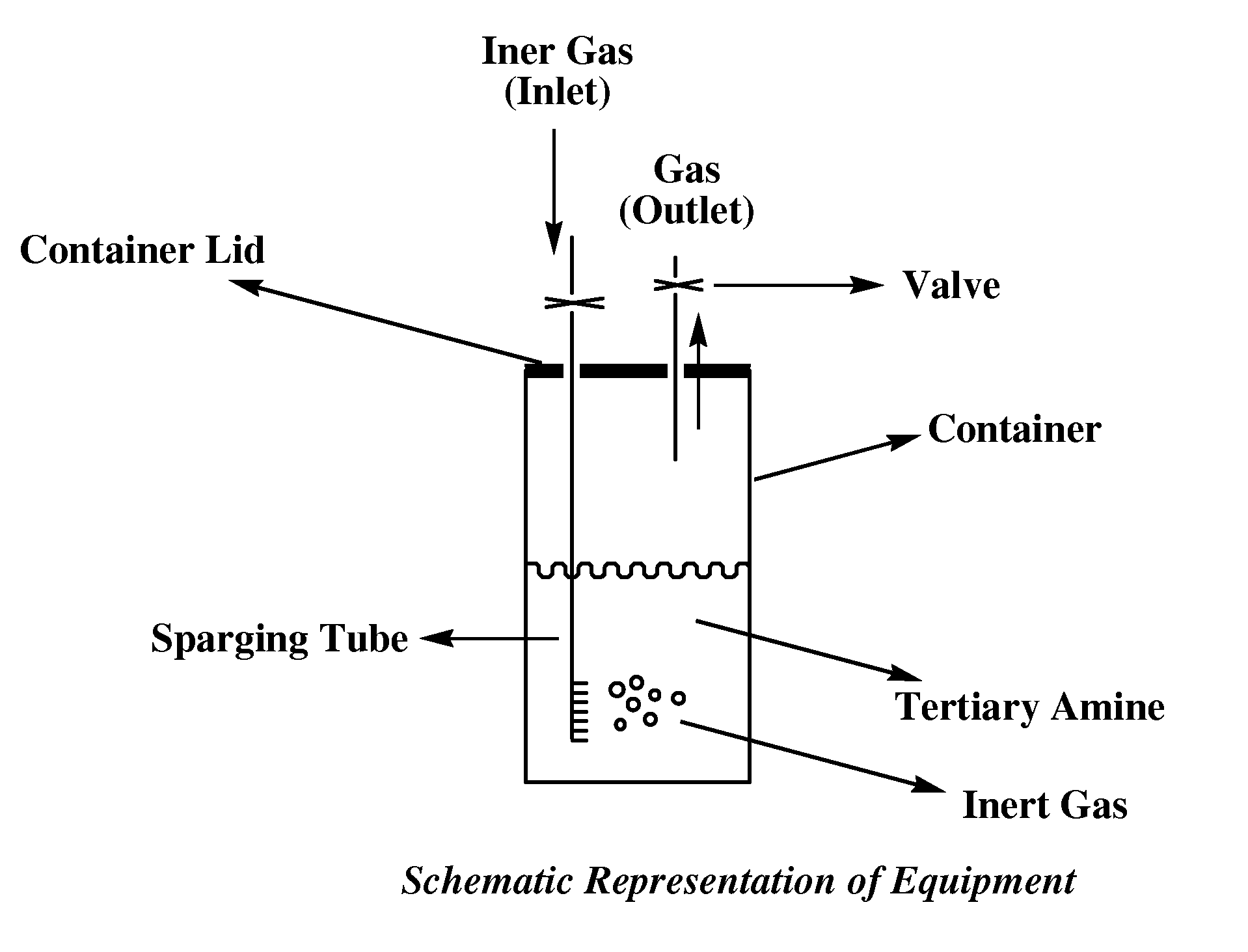

Tertiary amine composition and method for making the composition

ActiveUS20130085193A1Simple and cost-effective solutionAvoid concentrationAmino compound purification/separationOrganic-compounds/hydrides/coordination-complexes catalystsNitrogenNitrogen gas

A composition and method for producing a tertiary amine is disclosed. The tertiary amine is contacted with an inert gas. The inert gas is nitrogen or more preferably argon. The amine composition is useful in producing polyurethane foam with lower levels of chemical emissions particularly lower emissions of toxic chemicals.

Owner:EVONIK OPERATIONS GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com