Method for refining p-phenylene diamine

A p-phenylenediamine and refining method technology, which is applied in the purification/separation of amino compounds, organic chemistry, etc., can solve the problems of crystallization that is difficult to reach an equilibrium state, molecular mobility hindrance, and adhesion to the crystal surface, etc., to reduce labor costs and maintenance costs, to protect the health of employees, the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

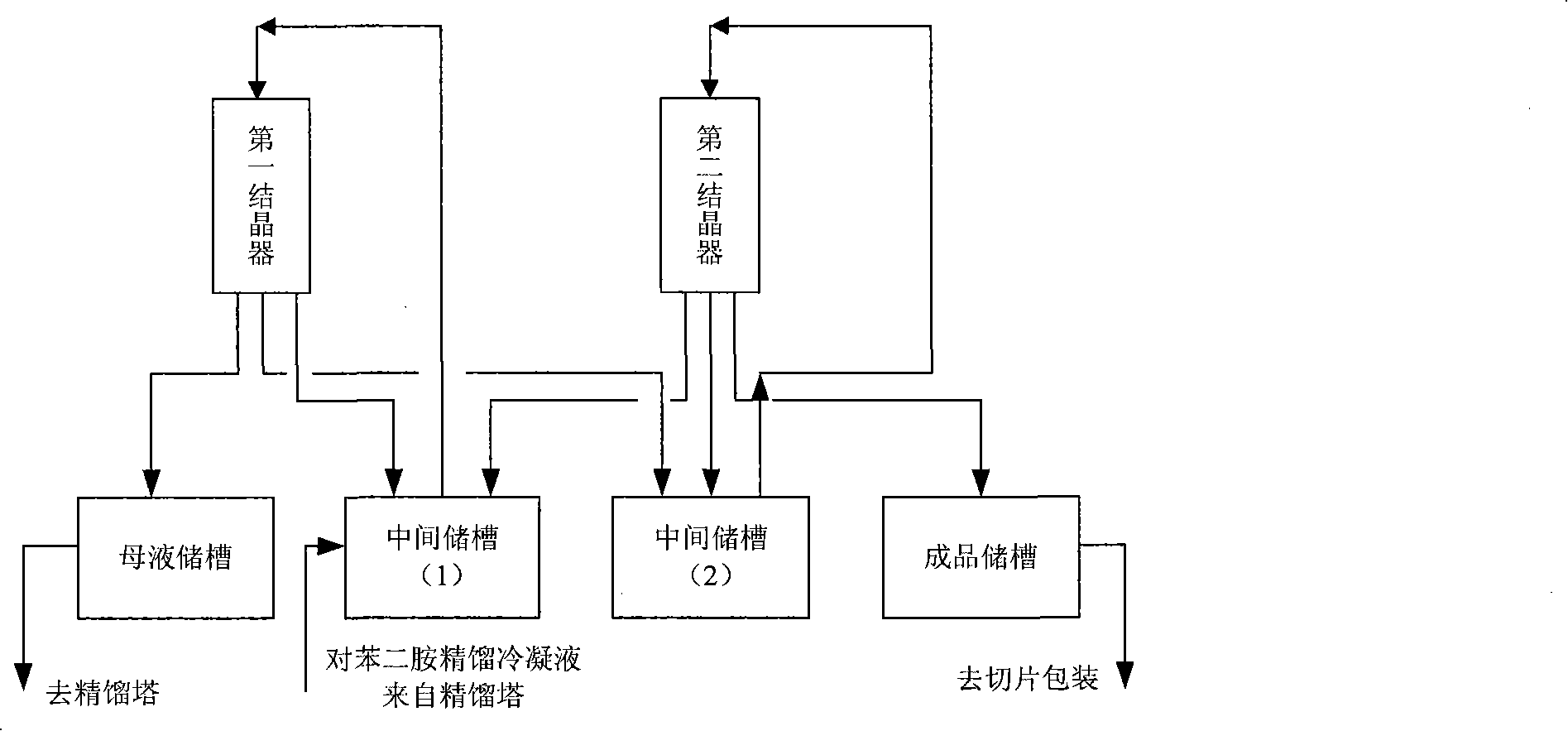

[0036] The product of catalytic hydrogenation of p-nitroaniline removes water and solvent, mixes with the mother liquor of the first-stage molten crystallization and enters the rectification tower, and removes low boiling substances and other front fractions through vacuum distillation at a vacuum degree of about 0.096MPa. The tower bottom liquid enters the second rectification tower, rectification steams p-phenylenediamine, condenses to obtain p-phenylenediamine with a purity of 99%, and puts it into No. (1) intermediate tank for subsequent crystallization and purification (flow process see figure 2 ); all crystallizers, storage tanks and pipelines used are sealed, and the original air is replaced with nitrogen.

[0037] In 3000L stainless steel shell and tube falling film crystallizer, storage tank and piping system (see figure 1 ): put the p-phenylenediamine condensate obtained from the rectification of No. (1) intermediate tank, the second-stage sweating liquid of the pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com