Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

438results about How to "Reduce spoilage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

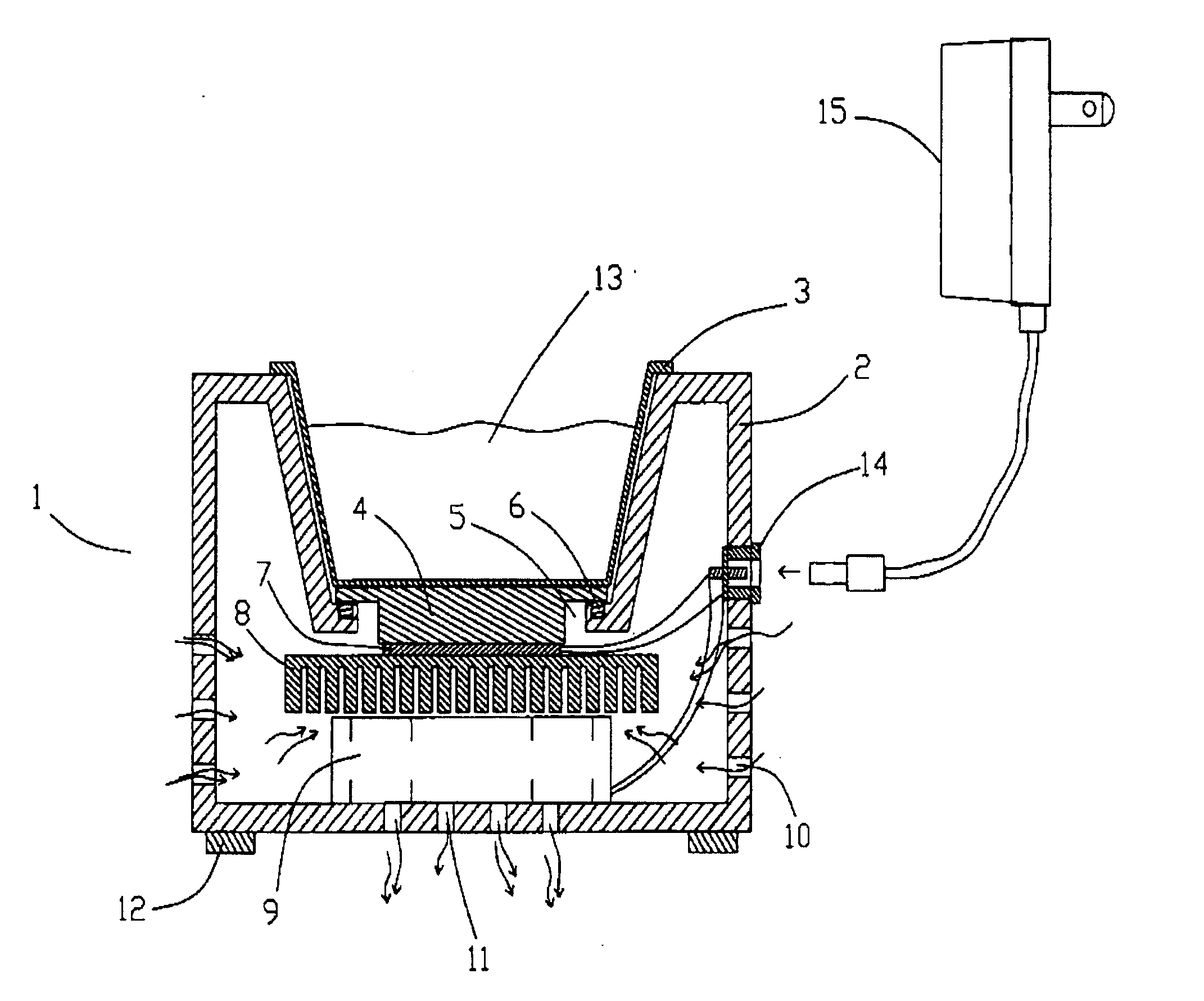

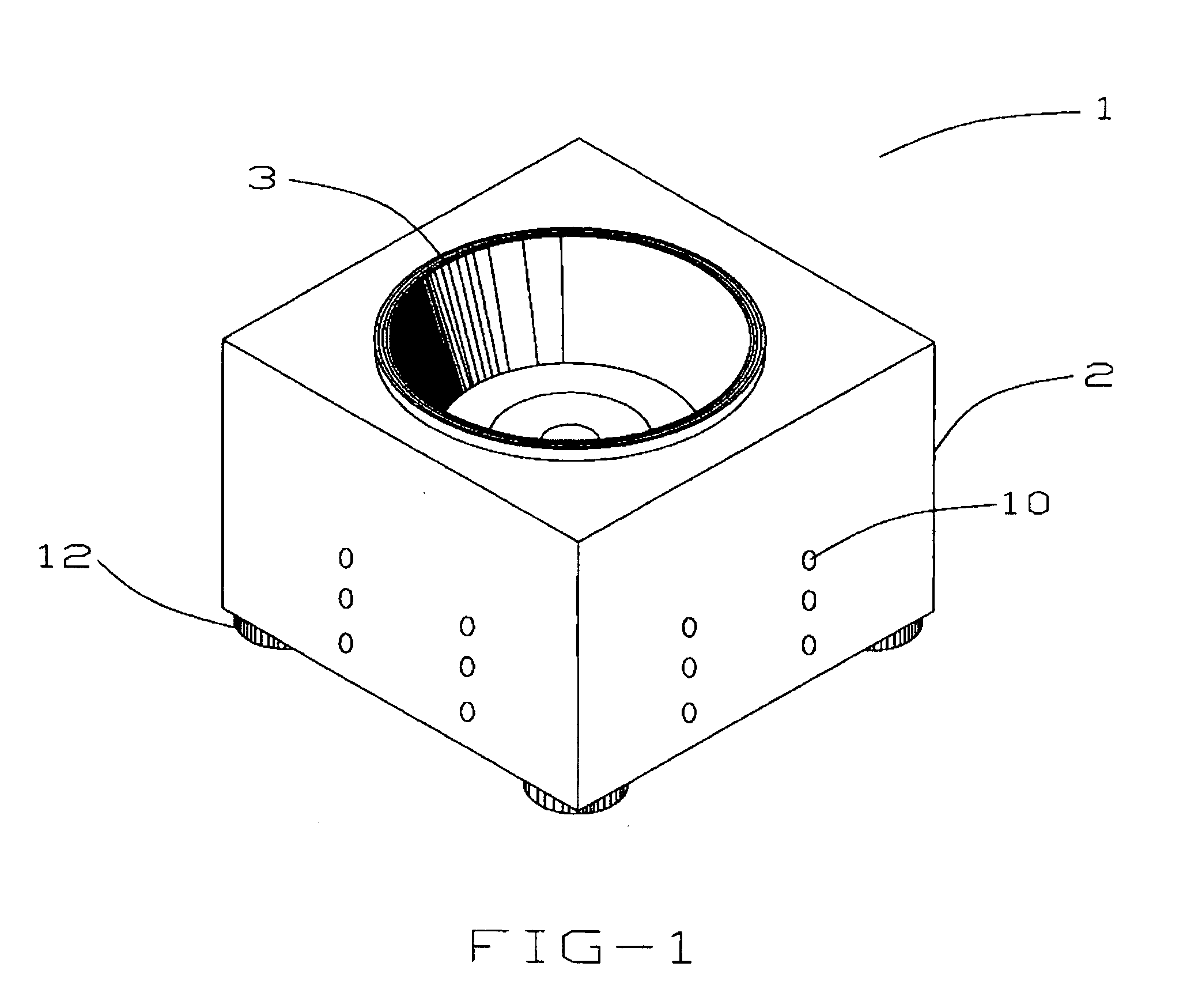

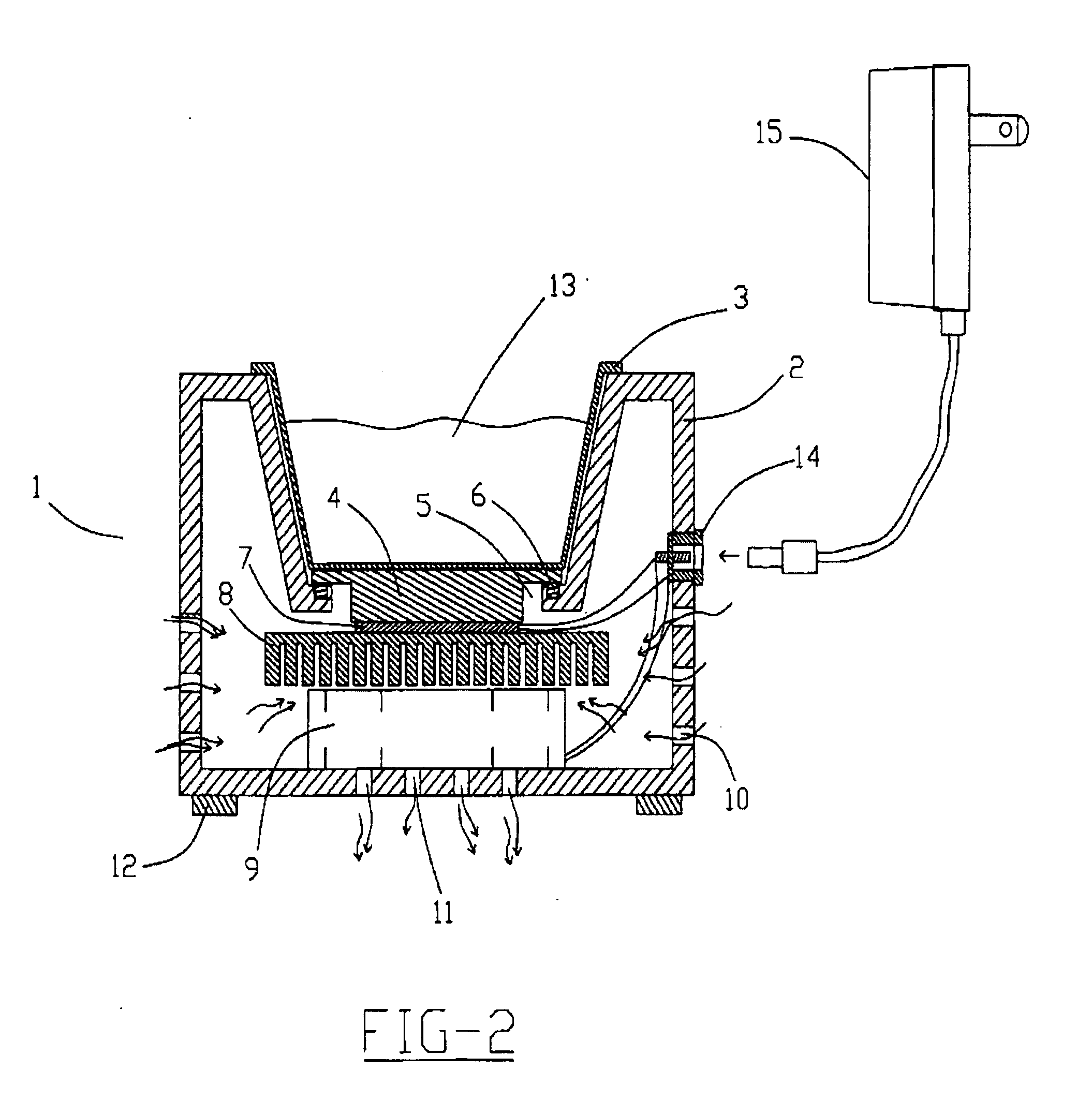

Refrigerated pet feeding dish

InactiveUS20070227456A1Reduce spoilageReduce corruptionAnimal watering devicesAnimal feeding devicesRefrigerated temperatureWall mount

A refrigerated pet feeding assembly with a removable thermally conductive dish designed to contain food, water or both that is continuously cooled by a thermoelectric Peltier-effect conditioning source and powered by an external dc voltage source such as a wall mount power supply or battery. The invention will maintain the contents of the feeding dish at cool refrigerated temperatures slowing the growth of bacteria.

Owner:BOREY CARL NORMAN

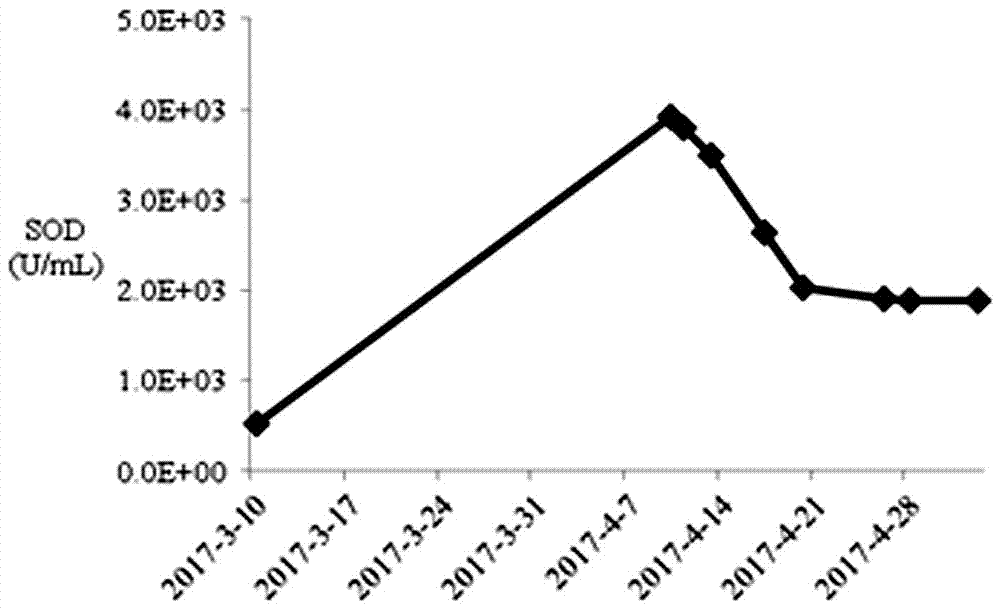

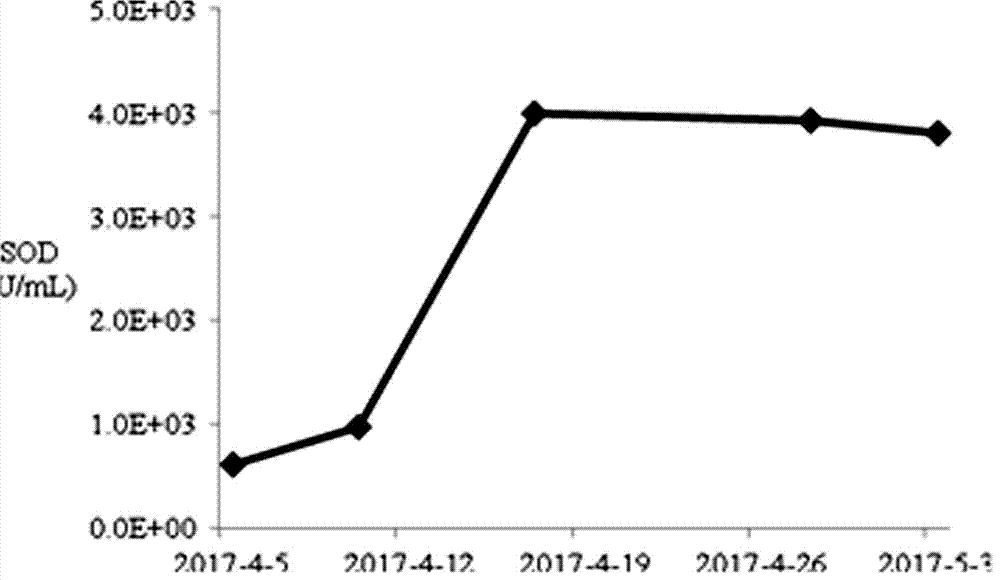

Probiotic fruit and vegetable enzyme drink and preparation method thereof

PendingCN107348272AHigh activityHigh nutritional valueFood ingredient for microbe protectionNutritive valuesLactobacillus paracasei

The invention provides a probiotic fruit and vegetable enzyme drink and a preparation method thereof. Fruits and vegetables as well as four-in-one PPHR Lactobacillus powder (including Lactobacillus paracasei, L. plantarum, L. helveticus and L. rhamnosus) are mixed and the obtained mixture is fermented, and the obtained fermented product is the probiotic fruit and vegetable enzyme drink. Compared with the prior art, the preparation method has the advantages that the fermentation process can be shortened, the fermentation process can be simplified, the nutritional value of fruit and vegetable juice can be increased, the fruit and vegetable juice is endowed with higher oxidation resistance, and the application range of Lactobacillus in food, particularly drinks, is broadened.

Owner:恒利康生物科技股份有限公司

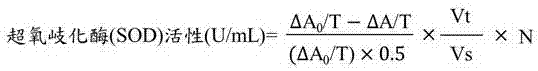

Steamed egg cake and preparation method thereof

InactiveCN104585809AReduce spoilageSolve the problem of anti-mildew preservationSugar food ingredientsFood preparationVegetable oilGlycerol

The invention relates to the technical field of foods, in particular to a steamed egg cake and simultaneously discloses a preparation method of the steamed egg cake. The steamed egg cake is prepared from the following raw materials in parts by weight: 55-65 parts of low-gluten wheat flour, 30-40 parts of white granulated sugar, 40-55 parts of egg, 8-12 parts of edible vegetable oil, 7-15 parts of edible glucose, 7-11 parts of glucose syrup, 16-24 parts of modified starch, 0.3-0.8 part of edible salt, 1-3 parts of sorbitol, 4-6 parts of glycerol, 0.2-0.4 part of glycerin monostearate, 0.5-1.5 parts of baking powder, 0.1-0.4 part of soda powder, 0.7-1.3 parts of potassium sorbate, 0.02-0.05 part of sodium dehydroacetate, 0.15-0.35 part of edible citric acid and 0.05-0.15 part of edible essence. The steamed egg cake provided by the invention keeps the most original and fresh taste of the food, is fine in cake texture, soft in texture, rich in elasticity, soft in mouth feeling and rich in nutrition and is suitable for both the old and the young.

Owner:HENAN HENGRUI STARCH TECH CO LTD

A kind of processing method of tea drink with low bitterness and astringency and high catechin

ActiveCN102265953AAntioxidantAntioxidant delayTea extractionTea alkaloid content reductionCyclodextrinBitter tastes

The invention provides a processing method of high catechin beverage with low biter taste and belongs to the processing field of food. The processing method comprises the following steps of: 1) taking green broken tea, extracting three times continuously with water so as to obtain an extract liquid I, an extract liquid II and an extract liquid III; 2) coarsely filtering the extract liquid I, the extract liquid II and the liquid III so as to remove tea leaves; 3) respectively processing the extract liquid II and the extract liquid III by use of tannase so as to obtain the corresponding enzymolysis liquid I and enzymolysis liquid II; 4) mixing the extract liquid I, the enzymolysis liquid I and the enzymolysis liquid II to obtain a tea mixed liquid; 5) performing film separation process on the tea mixed liquid so as to obtain clarified tea water; 6) adding VcNa and cyclodextrin into the clarified tea water for mixing so as to obtain the tea beverage; and 7) filtering, sterilizing and bulking the tea beverage to obtain finished products. The tea beverage obtained by the processing method is a green-yellow tea beverage, wherein the content of catechin is more than or equal to 800mg / l; and the tea beverage belongs to a functional tea beverage with pure taste and crisp mouth feel and without obvious bitter taste.

Owner:TEA RES INST CHINESE ACAD OF AGRI SCI

Comprehensive treatment method for pollution of livestock and poultry aquaculture, special feedstuff bridging agent, biological edible warm pad and biological organic fertilizer

InactiveCN101317625AFully digested and absorbedInhibition of heterogeneous decompositionClimate change adaptationExcrement fertilisersNatural organic matterFeces

The invention belongs to the technical field of agricultural cultivation, which comprises a comprehensive treatment method for livestock and poultry breeding industry pollution, a special feed bridging agent, a biological edible warm pad and biological organic fertilizer; wherein, the comprehensive treatment method for livestock and poultry breeding industry pollution is realized by the steps as follows: (1) the livestock and poultry are fed by the feed bridging agent which is prepared by that probiotic bacterial flora is enlarged for cultivation and inoculated to natural organic matter for fermentation; (2) the livestock and poultry cultivation ring is padded by the biological edible warm pad which is prepared by the fermentation by matching the probiotic bacterial flora and the biological organic raw material; (3) the biological edible warm pad mixed with the dejecta of the animals is added into microbial flora so as to prepare the completely rotten biological organic fertilizer. The treatment method of the invention has the advantages that the feed is sufficiently absorbed in the animal body, the nutrition drainage is reduced, the feed is saved and the pollution is reduced; no waste gas and no waste matter are generated during the cultivation process; the pollution source is thoroughly eliminated; the pollution of the cultivation on the environment is radically solved; the dejecta of the animals is processed in situ and the organic fertilizer is produced.

Owner:刘新虎

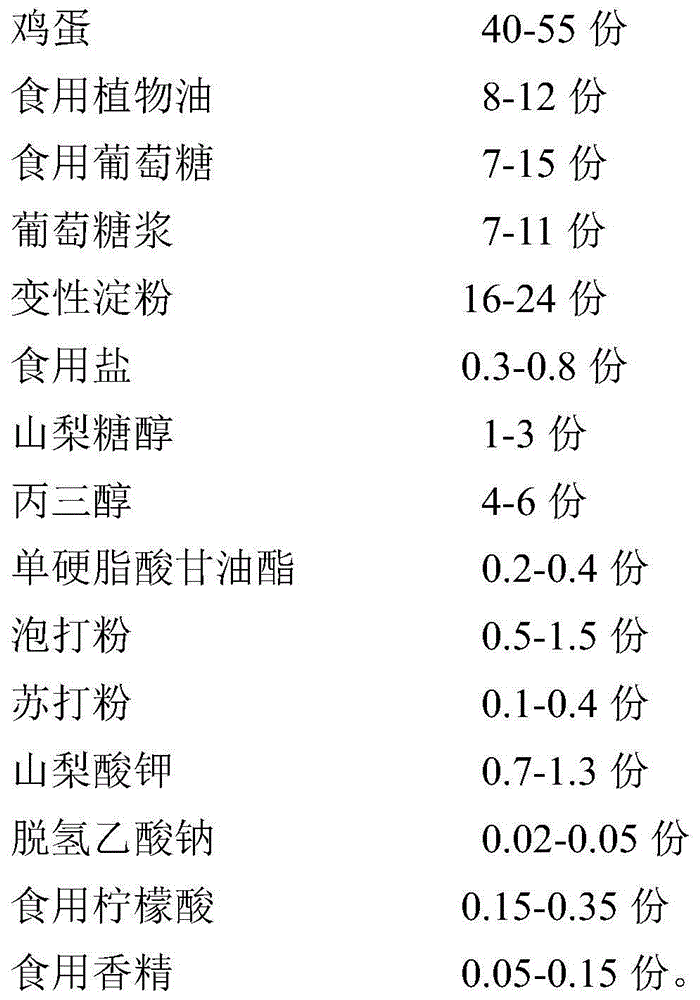

Water quality purification method in source-free water area and facilities

InactiveCN101041539AReasonable stockImprove water qualityWater cleaningWater aerationAutomatic controlPurification methods

The invention discloses a water purifying method of waterless source waters and device, which comprises the following steps: including recharge craft, hydrologic cycle craft, water quality physical disposing craft; water quality chemical disposing craft, accelerate vertical motion of water and aerate craft, rainwater collecting and purifying craft, ecological restoring craft and composite control device; proceeding automatic control; installing make-up water pump room, device room, element depositing tank, filtering tank, purifying tank, catch frame, pump, make-up water pipe, circulating pump, disposing pump, charging pump and air blower; installing make-up water pump room, device room, element depositing tank, filtering tank, purifying tank, clean water pump under floor.

Owner:BEIJING DRAINAGE GRP CO LTD

Preparation method of dried day lily

ActiveCN103918775AMaintain nutrientsBalance internal and external moistureFruits/vegetable preservation by heatingFruits/vegetable preservation by dehydrationCooking & bakingFlavor

The invention belongs to the field of food processing, and particularly relates to a preparation method of dried day lily. The dried day lily is prepared by the working procedures of with fresh day lily buds as raw materials, destemming, rinsing by running water, leaching, putting into dishes, carrying out microwave heating for deactivating enzymes, cooling, carrying out once microwave drying for dehydrating, cooling, carrying out secondary microwave drying for dehydrating, cooling, carrying out three-segment far infrared rotary baking, and packaging. According to the invention, microwave heating for deactivation of enzymes for three times, dehydration and three-segment far infrared rotary baking and drying modes are adopted, the day lily is subjected to enzyme deactivation, dehydration and drying, and sterilization, and the prepared dried day lily can be directly eaten or can be eaten after rehydrated. The method provided by the invention is beneficial to preservation of the dried day lily, also keeps the color, fragrance, flavor and shape of the day lily well, and effectively solves the problem of nutritional ingredient loss in the processes of deactivating enzymes and drying. The dried day lily prepared by the method provided by the invention is straight and uniform in shape, is golden yellow and green in color, and can be preserved for 18 months with perfect packages under the normal temperature condition.

Owner:渠县琦鑫源花卉苗木开发有限公司

Microbial agent for Chinese silvergrass ensilage as well as preparation method and application thereof

The invention relates to a microbial agent for Chinese silvergrass ensilage as well as a preparation method and application thereof. The microbial agent is composed of 0.3*10<9>-1.5*10<9> cfu / g Lactobacillus casei, 0.3*10<9>-1.5*10<9> cfu / g of Lactobacillus plantarum, 0.4*10<9>-2*10<9> cfu / g of Saccharomyces cerevisiae and 0.4*10<9>-2*10<9> cfu / g of Trichoderma viride, wherein the total amount ofmicroorganisms is 0.68*10<9>-3.4*10<9> cfu / g. By using the microbial agent to manufacture the Chinese silvergrass ensilage, the maturation time of the Chinese silvergrass ensilage is shortened, the probability of feed deterioration is reduced, the protein content is increased, the cellulose content is reduced, and the palatability is enhanced.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

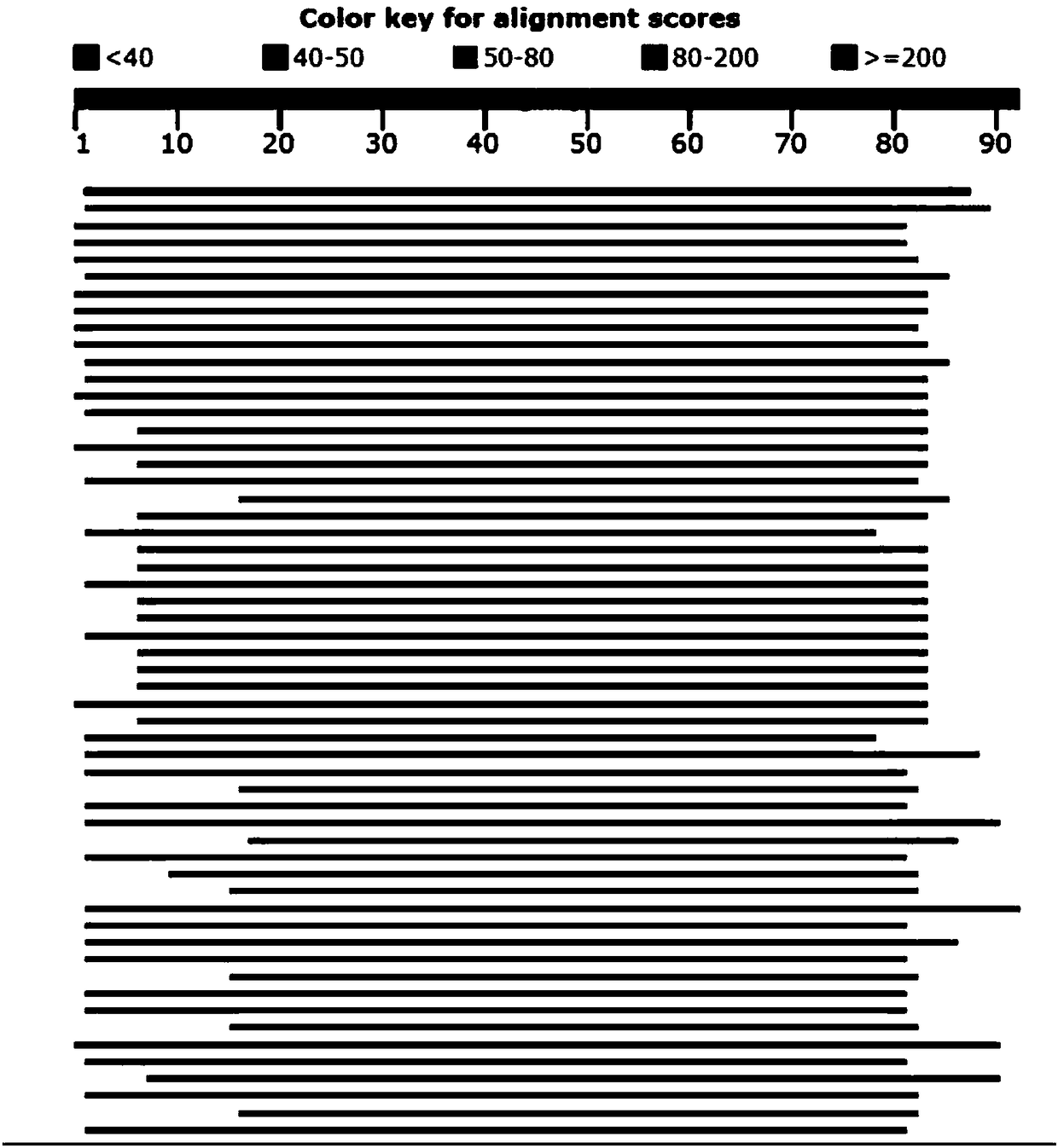

Salmonella phage LPSE34 and application thereof in food

ActiveCN108588037AImprove the bactericidal effectOvercoming the disadvantages of isotype specificityLectin superfamilyMeat/fish preservation by coatingFood borneSalmonella Phage

The invention discloses a salmonella phage LPSE34. The preservation number of the salmonella phage LPSE34 is CCTCC NO 2018121. The phage is a broad-spectrum salmonella phage and can crack drug-tolerant salmonellas, it is identified that the phage belongs to myoviridae, and the phage is named as LPSE34. The phage LPSE34 is stable in titer at the pH of 4-12 and the temperature of 30-60 DEG C. The invention further discloses application of the salmonella phage in food, especially in chicken and ham systems; and in addition, the invention further discloses a compound edible coating film formed bytaking the phage as an antibacterial substance to be combined with sodium alginate, and compared with antibiotics and chemical preservatives, the phage cannot affect the texture and flavor of food andhas the characteristics of high specificity, no residue and safety. The salmonella phage LPSE34 can serve as a bacteriocidal substance / the antibacterial substance to control pollution of food-borne pathogens to the food and is a very promising biological agent for guaranteeing the food safety.

Owner:HUAZHONG AGRI UNIV

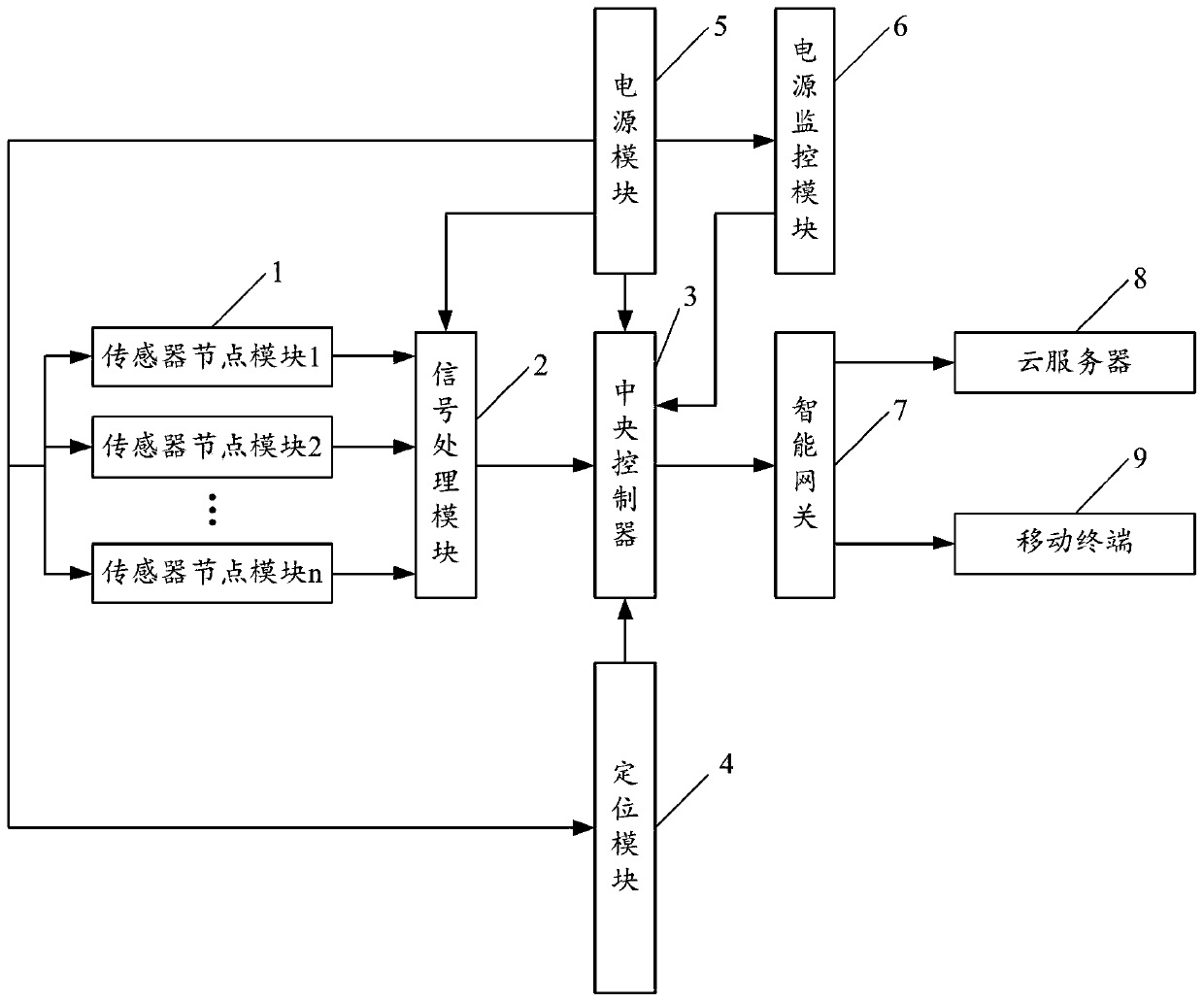

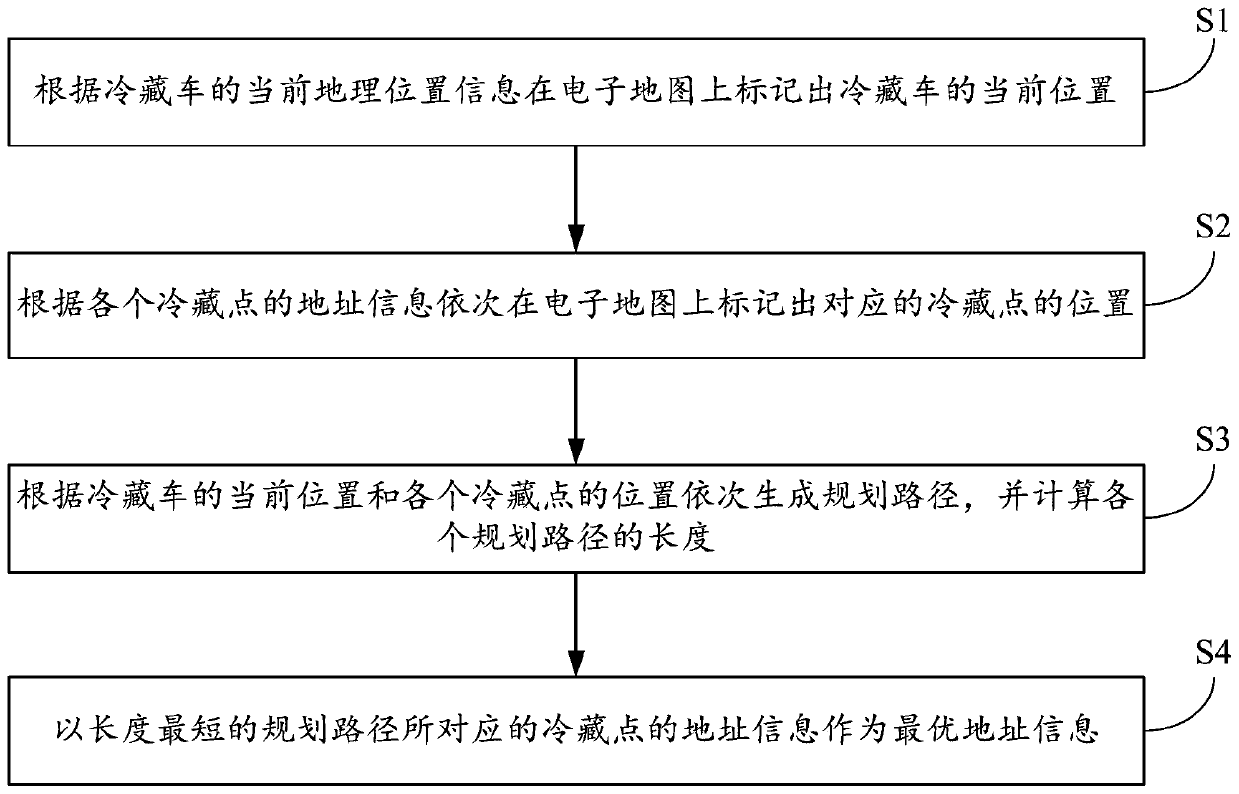

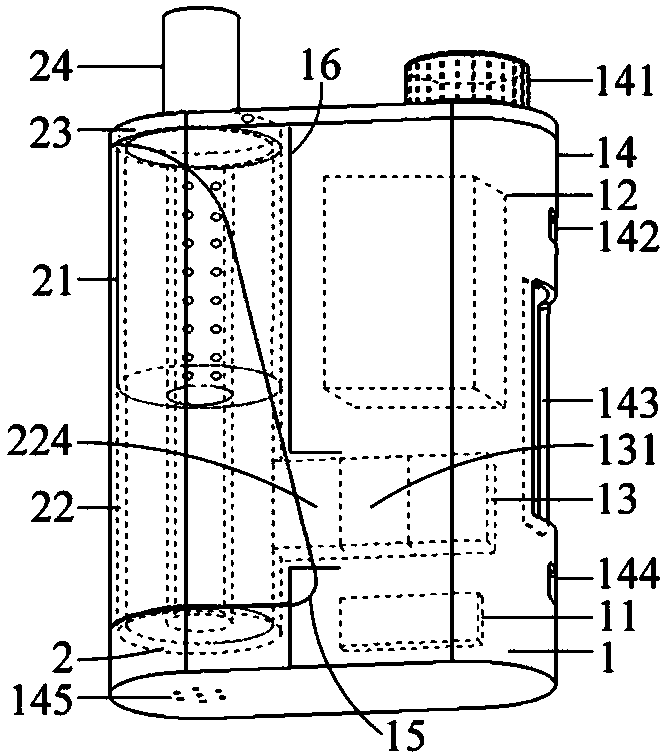

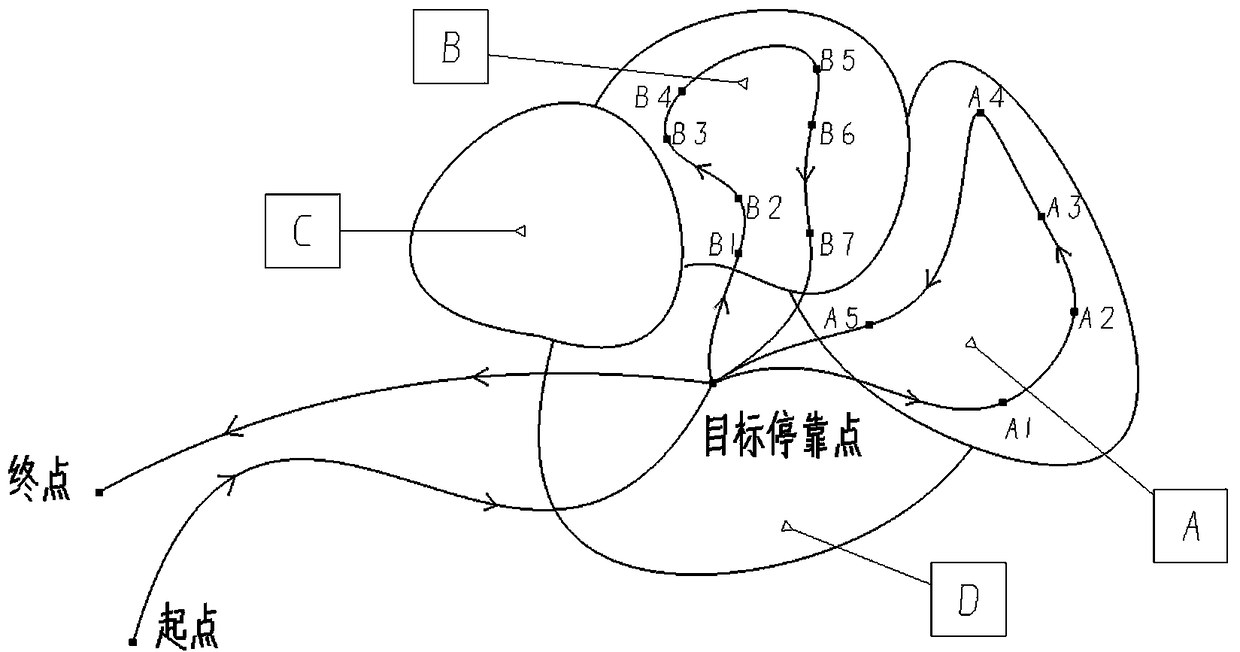

Refrigerated transport monitoring system for cold-chain logistics

InactiveCN110221562AAvoid spoilageReduce product spoilageProgramme controlComputer controlTruckMoisture

The invention relates to a refrigerated transport monitoring system for cold-chain logistics. The refrigerated transport monitoring system is characterized in that a sensor node module is used for transmitting an electric signal corresponding to acquired environmental data to a signal processing module; the signal processing module is used for transmitting digital signal converted from the electric signal to a central control unit; the central control unit is used for judging whether the digital signal is larger than a threshold or not; if so, the central control unit reads current geographical position information of a refrigerated truck through a positioning module, and determines optimal address information; and meanwhile, the central control unit transmits alarm information generated through a gateway to a cloud server and a mobile terminal respectively. Through adoption of the refrigerated transport monitoring system, the environmental parameters of temperature, moisture and air pressure can be monitored in real time in order to prevent cold-chain products from deteriorating in a refrigerated transport process. Meanwhile, the mobile terminal also displays the address of a refrigeration station closest to the current position of the refrigerated truck in real time, so that transport personnel can transfer the cold-chain products immediately, and product deterioration due tounexpected failure of refrigeration equipment is further reduced, thereby reducing economical loss.

Owner:JILIN TEACHERS INST OF ENG & TECH

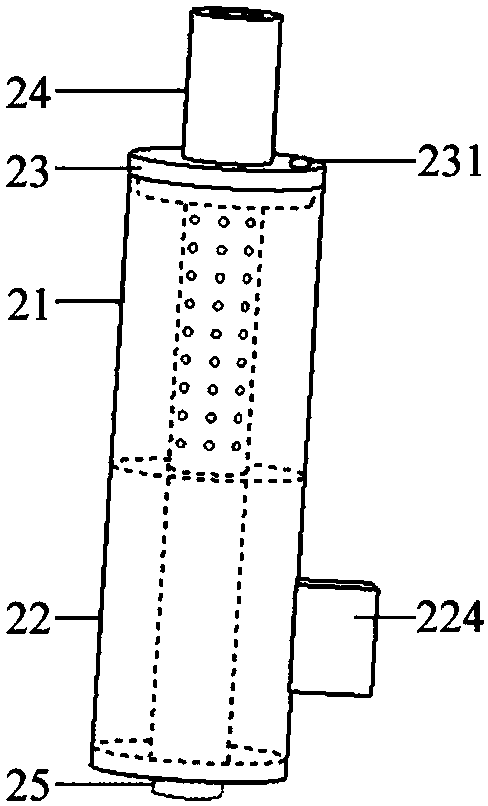

Microwave resonant atomizer for electronic cigarette

InactiveCN108552614AAvoiding patent infringementIncrease energy densityTobacco devicesTarInterior space

The invention discloses a microwave resonant atomizer (2) for an electronic cigarette. The microwave resonant atomizer comprises an oil storage unit (21), an atomizing unit (22), an upper cover plate(23) and a suction nozzle (24), wherein a microwave resonant cavity (221) is formed in the internal space of the atomizing unit (22); and a coupling hole (225) is formed in the side wall of the microwave resonant cavity (221), and the outer side wall of the microwave resonant cavity (221) with the coupling hole (225) can be covered with an energy coupling (224). When being applied to the electronic cigarette, the microwave resonant atomizer has the advantages that instant heating is realized, the efficiency is high, heat uniformity is good, non-contact atomization is realized, the low temperature sterilization of tobacco tar can be realized, and the like.

Owner:CHINA TOBACCO YUNNAN IND

Freight transport system based on unmanned child-mother vehicle and freight transport method thereof

InactiveCN109447547AImprove securitySolve the unloading problemForecastingLogisticsTransport systemControl system

The invention relates to the technical field of logistics distribution, in particularly to freight transport system based on unmanned child-mother vehicles and a freight transport method thereof. Thegoods vehicle comprises a driverless bus, a self-driving sub-vehicle and a control system for controlling the parent vehicle and the sub-vehicle, a set of deck lifting motors and a deck mounted on thelifting motors are arranged in the carriage of the bus car, the rear part of the bus car is provided with a lifting type car door. The shipping method comprises a preparation process, a boarding process, a transport process, a discharging process, a distribution process and a returning process. The invention has the advantages that no freight driver, porter and freight distribution worker is needed, the problem of freight handling is solved, the handling damage of the goods is reduced, the safety factor and logistics efficiency of the freight are greatly improved, and the deterioration problem of the food goods to be distributed is reduced.

Owner:JILIN UNIV

Fat-soluble nutrient microcapsules and preparation method thereof

ActiveCN107594597AReduce lossesHigh retention rateVitamin food ingredientsAccessory food factorsAntioxidantNutrient

Owner:ZHEJIANG NHU CO LTD +1

Microwave resonant cavity for electronic cigarette

InactiveCN108552612AAvoiding the Risk of Patent InfringementIncrease energy densityTobacco devicesResonant cavityMicrowave

The invention discloses a microwave resonant cavity (221) for an electronic cigarette. The microwave resonant cavity is of a cylinder shape, wherein a second oil guiding component (223) is arranged inthe microwave resonant cavity (221) along the axial direction; and a coupling hole (225) is formed in the side wall of the microwave resonant cavity (221). When being applied to the electronic cigarette, the microwave resonant cavity has the advantages that instant heating is realized, the efficiency is high, heat uniformity is good, non-contact atomization is realized, the low temperature sterilization of tobacco tar can be realized, and the like.

Owner:CHINA TOBACCO YUNNAN IND

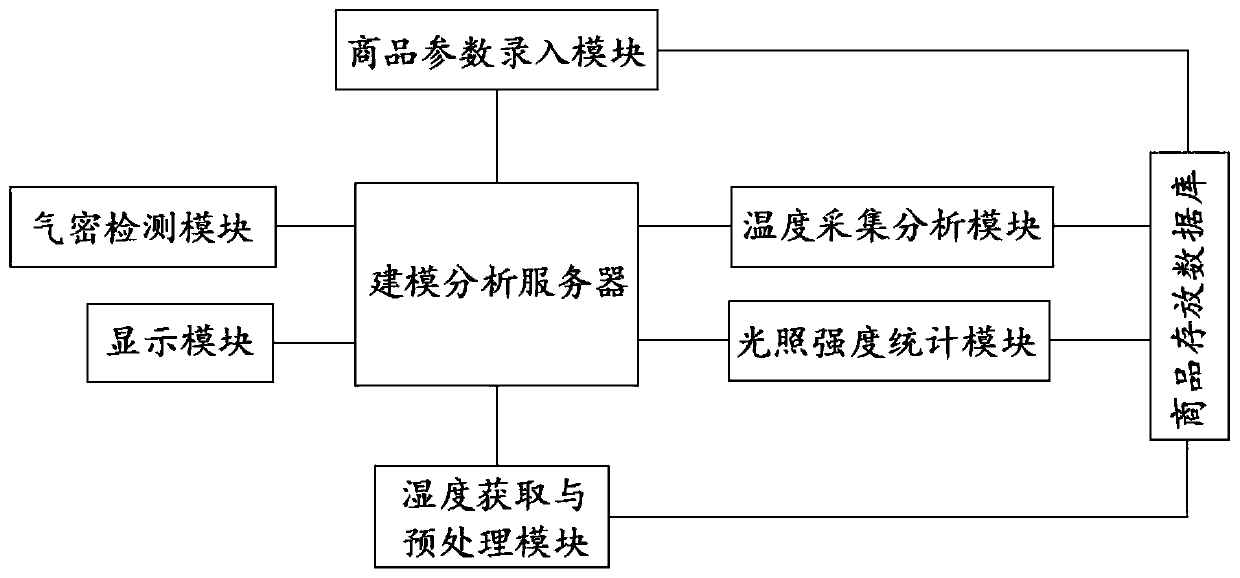

Commodity quality detection system based on big data

ActiveCN110455343ADetermining the Coefficient of Altitude VariationQuality improvementDatabase queryingMeasurement devicesModelling analysisData science

The invention discloses a commodity quality detection system based on big data. The system comprises an airtight detection module, a temperature acquisition and analysis module, an illumination intensity statistics module, a humidity acquisition and pretreatment module, a commodity storage database, a modeling and analysis server and a display module, wherein the modeling and analysis server is connected with the airtight detection module, the temperature acquisition and analysis module, the illumination intensity statistics module, the humidity acquisition and pretreatment module, the commodity storage database and the display module; the commodity storage database is connected with the temperature acquisition and analysis module, the illumination intensity statistics module and the humidity acquisition and pretreatment module. According to thecommodity quality detection system, quality of each commodity in different storage environments is evaluated by detecting the temperature, humidity and illumination intensity in the commodity storage environments and combining the height of packaging bags, the commodity deterioration evaluation coefficient of each commodity type is analyzed,reference is provided for commodity storage, and accordingly, the deterioration speed of the commodities is reduced, and quality of thecommodities is improved.

Owner:浙江云禾健康管理有限公司

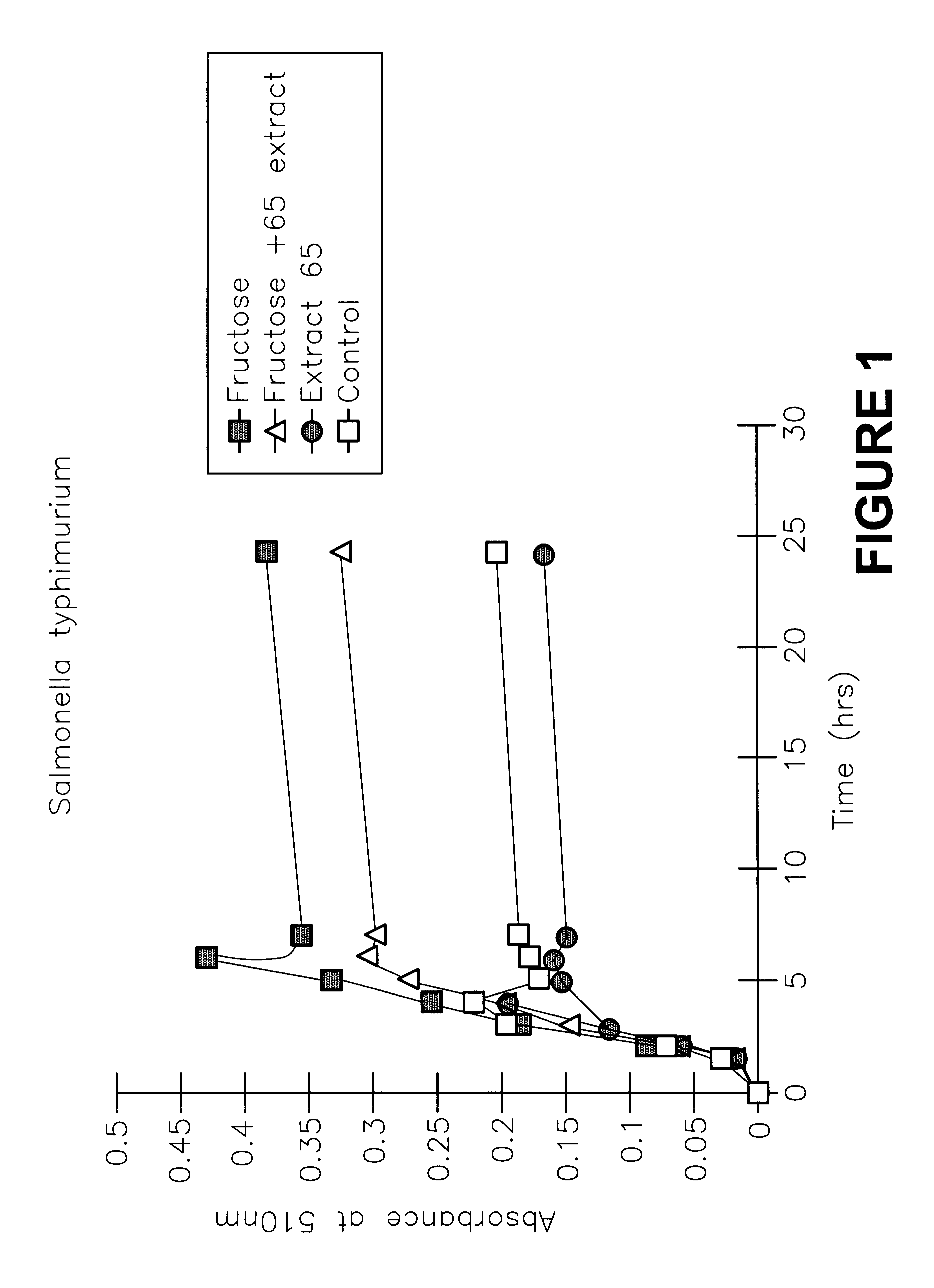

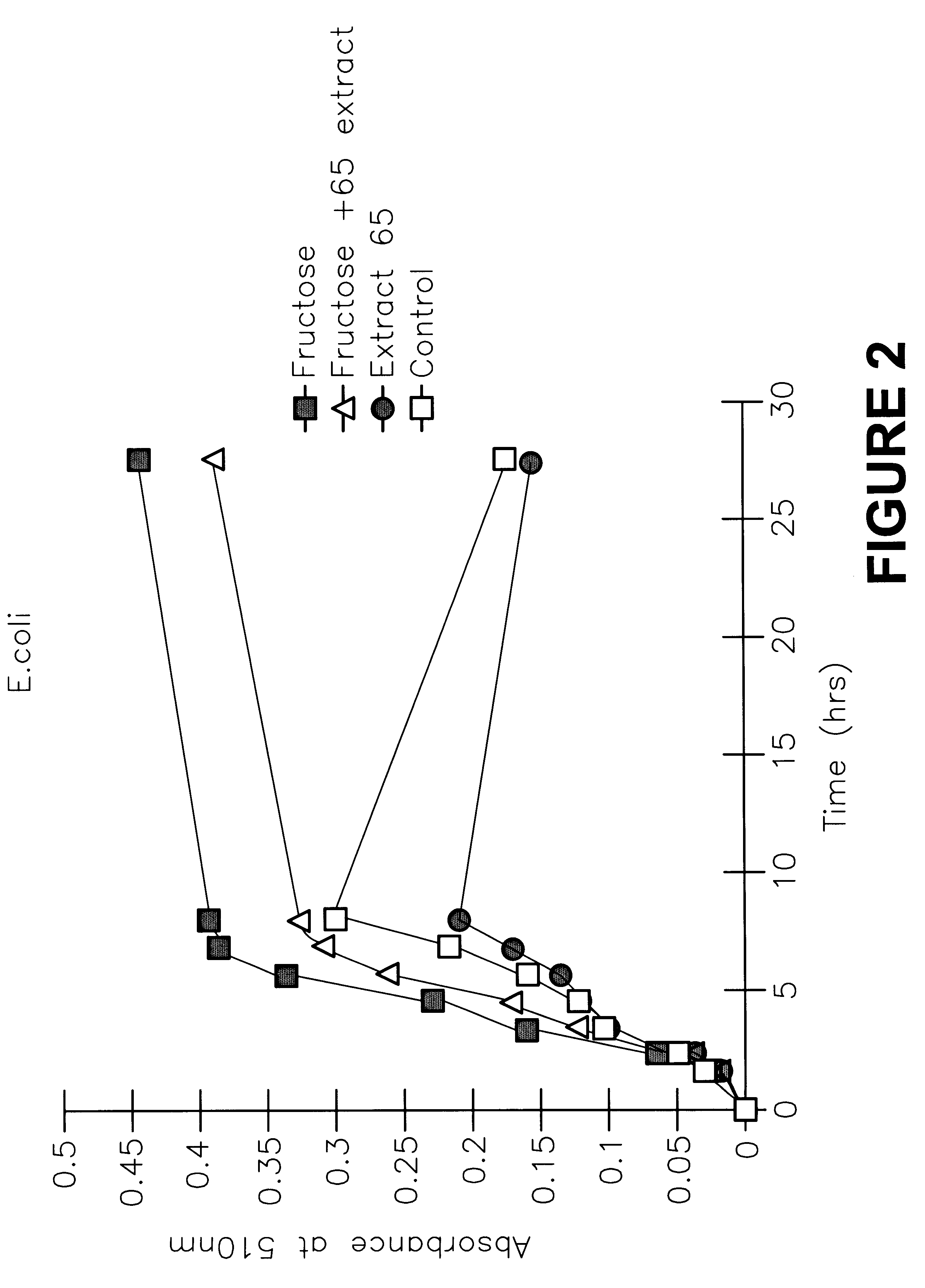

Reduction of pathogenic bacteria in food products

InactiveUS6210678B1Reducing viable bacterial contentReduce bacterial growthBiocideMicroorganismsBiotechnologyBacteroides

A composition is provided for reducing bacterial growth in food products. The composition includes a wood extract containing polyphenols and may contain arabinogalactan. The composition suppresses or prevents the growth of E. coli and of Salmonella sp. The wood extract imparts little or no residual taste to the food product. However, it can readily be removed if desired by washing before use of the food. The composition may be essentially arabinogalactan-free to further reduce bacterial growth.

Owner:MONTANA THE UNIV OF

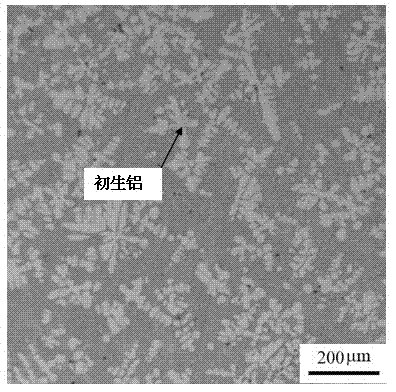

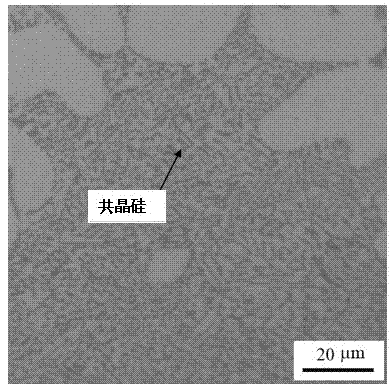

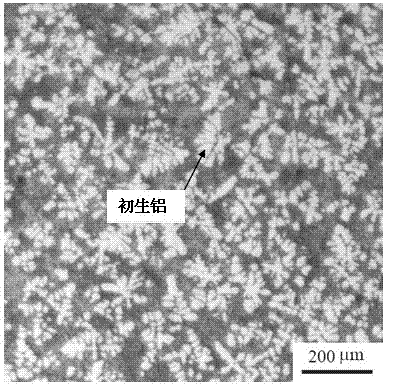

Tissue control method for near-eutectic cast aluminum-silicon alloy

The invention relates to a tissue control method for near-eutectic cast aluminum-silicon alloy. The method comprises the following steps: preparing raw materials, namely commercially pure aluminum, ZL102, Al-Sr, Al-B and one of Al-La, Al-Ce and Al-Re, in a manner that the raw materials contain the following ingredients in percentage by mass: 9-12% of Si, 0.05-0.5% of B, 0.01-0.1% of La, Ce or RE, 0.02-0.03% of Sr and the balance of Al; then carrying out smelting of the following steps: preheating the raw materials, heating an empty furnace, then, adding ZL102 and the commercially pure aluminum, and heating for melting; adding a sodium-free refining agent of which the mass accounts for 0.4-0.6% the total mass of the raw materials; treating a melt treated in the step (2) by adopting a boron and rare-earth combined refining method; carrying out secondary refining treatment on the melt; cooling to 690-700 DEG C, adding an Al-Sr alterant after temperature is stabilized, pressing the alterant into the bottom of the melt, and stirring, so as to enable the alterant to be thoroughly dissolved into the melt; carrying out heat preservation for 10-20 minutes at the temperature of 700 DEG C, then, heating to 720-730 DEG C, casting the melt into a metal mold which is preheated at the temperature of 200-250 DEG C, cooling, and then, taking out a casting.

Owner:SOUTHEAST UNIV

Sprouted beans and preparation method thereof, and processed foodstuff with sprouted bean as raw material

InactiveCN103211176AReduce churnGood transferabilityCheese manufactureCultivating equipmentsFood materialSprouting

The invention relates to sprouted beans and a preparation method thereof. Existing sprouted bean products cannot satisfy market requirements and expectations. According to the invention, beans are processed with the methods such as impregnating, sprouting, freezing, and the like, such that frozen sprouted beans with sprout lengths from 1mm to bean length are obtained; specific spectral radiation and nutrition enhancing treatments are carried out according to different requirements, such that sprouted beans suitable for different populations and with good nutritional and dietotherapy values are obtained. The beans include soybeans, black beans, mung beans, chickpeas, coffee beans, and the like. The sprouted beans can be eaten as bean foods, and can be used as raw materials of various processed bean foodstuffs and applied in processed foodstuffs and health-care foodstuffs.

Owner:赵钧永

Laminated material laminating glue and preparation method thereof

ActiveCN106867427AImproved storage stabilityReduce dosageMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesDefoamerIsocyanate

The invention discloses laminated material laminating glue and a preparation method thereof. The laminated material laminating glue comprises components A and B. The component A comprises, by mass, 17.7% to 25.4% of deionized water, 39% to 63% of a water-based emulsion, 1% to 5% of a plasticizer, 2% to 4% of polyvinyl alcohol, 0.1% to 0.2% of a chelating agent, 0.1% to 0.2 % of a dispersant, 0.05% to 0.1% of a defoamer, 16% to 26% of calcium carbonate and 0.05% to 0.1% of a bactericide. The component B comprises polyaryl polymethylene isocyanate. The preparation method comprises preparing a modified polyvinyl alcohol solution from deionized water, polyvinyl alcohol and the chelating agent, orderly adding the water-based emulsion, the plasticizer, the dispersant and the defoamer into a dispersion kettle, slowly adding calcium carbonate into the dispersion kettle, carrying out dispersion to obtain uniform glue slurry, adding a polyvinyl alcohol modification solution and a bactericide into the glue slurry to obtain the component A and mixing the component A and the component B. The laminated material laminating glue is used for splicing of various laminated materials, has high splicing strength, a long application period, excellent heat resistance and excellent water resistance, resists water boiling and can reach the wood breaking strength.

Owner:北京市创新玮地科贸有限公司

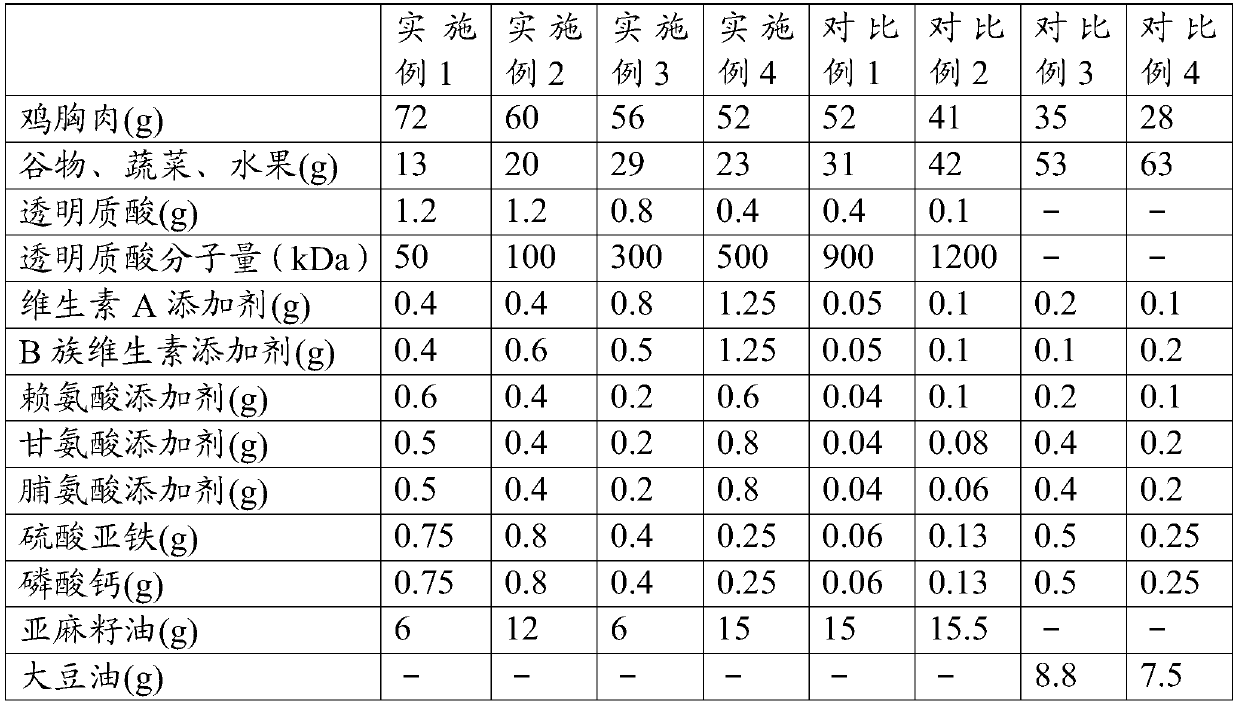

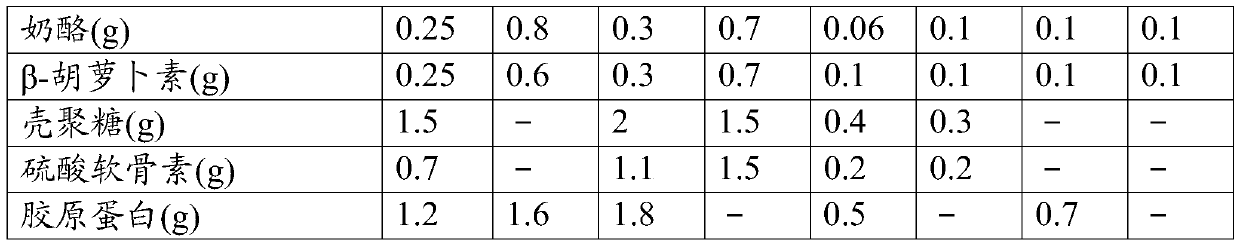

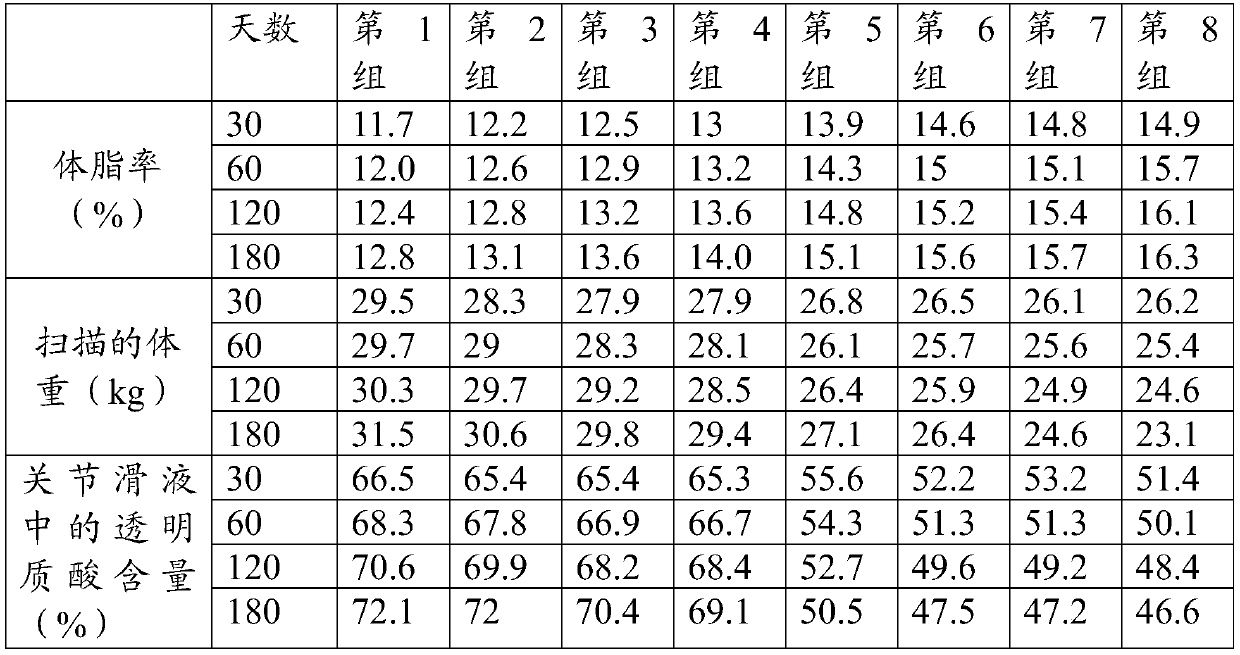

Pet food and preparation method thereof

InactiveCN109965124ASolve the problem of single health care functionReduce incidenceAnimal feeding stuffAccessory food factorsHyaluronic acidChemistry

The invention discloses a pet food. The pet food is characterized in that on the basis of the total weight of the pet food, the pet food is composed of 75-85% by weight of a main material and 15-25% by weight of an auxiliary material, wherein the main material comprises 60-85% by weight of meat on the basis of the total weight of the main material; and the auxiliary material comprises 0.3-8% by weight of hyaluronic acid on the basis of the total weight of the auxiliary material. The invention also discloses a method for preparing the pet food. The pet food contains the hyaluronic acid, and thepet food with balanced nutrition is obtained through the mutual synergistic effect among the components, so that the anorexia of a pet can be improved, the fur of the pet can be smooth, and the bonejoint disease can be improved.

Owner:BLOOMAGE BIOTECHNOLOGY CORP LTD +1

Preparation method of edible and nutrient composite fruit-vegetable coating preservative

ActiveCN103609670AMake up for the lack of poor water resistanceImprove film formationFruits/vegetable preservation by coatingOperabilitySpoilage microorganisms

The invention relates to a preparation method of an edible and nutrient composite fruit-vegetable coating preservative. The method comprises the following steps: adding pectin into deionized water so as to prepare a pectin solution; adding whey protein into the deionized water so as to prepare a whey protein solution; mixing the pectin solution with the whey protein solution; stirring and emulsifying; adding a plasticizer, tripotassium citrate anhydrous and calcium propionate; stirring; and performing vacuum degassing so as to prepare the composite coating preservative. The method is simple, strong in operability and low in cost; and the coating preservative is rich in nutrition. A preservative film prepared from the coating preservative is good in stability, high in strength and good in water resistance and has a good effect for inhibiting spoilage microorganisms so as to prolong the shelf life of fruits and vegetables.

Owner:BOHAI UNIV

Oil-proof wrapping paper and preparation method thereof

ActiveCN109680556APromote environmental protectionExpand the scope of applicationNatural cellulose pulp/paperFlexible coversDimethyl formamideChemistry

The invention relates to oil-proof wrapping paper and a preparation method thereof and belongs to the technical field of food wrapping paper. According to the invention, a double oil-proof technologyis adopted, fluorobenzoyl chloride, dimethyl formamide and plant fiber microfilaments are mixed according to a certain proportion, oil-proof plant fiber microfilaments are prepared under certain reaction conditions, nanometer celluloses are subjected to fluorine-containing modification preparation by using the same method, and the double oil-proof wrapping paper is prepared by paper-making and surface application. The oil-proof wrapping paper and the preparation method thereof provided by the invention have the beneficial effects that the interior oil-proof performance and the surface oil-proof performance of the oil-proof wrapping paper are improved, and through double oil-proof treatment on the interior and the surface of pulp, the product achieves high oil-proof performance; in addition, the oil-proof wrapping paper is good in oil-proof performance, enhancement performance and barrier performance, so that the product grade and the value added are improved; moreover, the oil-proof wrapping paper prepared by the preparation method provided by the invention needs not be coated or waxed, so that the environmental protection performance, the safety, the oil-proof efficiency and the strength of the oil-proof wrapping paper are improved, and the application range is expanded.

Owner:ZHEJIANG HENGDA NEW MATERIAL CO LTD

Efficient sorting method and efficient sorting system

The invention relates to an efficient sorting method which comprises the following steps: displaying pre-sorted cargo information comprising pre-delivery warehouse information; if the received current sorted cargo information is matched with the pre-sorted cargo information, driving indicating equipment of a warehouse position corresponding to the pre-delivery warehouse information to work to indicate the warehouse position of the current sorted cargo according to the pre-delivery warehouse information in the pre-sorted cargo information. The problems that the existing sorting process is complicated and has a long period are solved. In the cargo sorting process, a specific indication can be given to an operator, so that the sorting error is prevented and the sorting efficiency is improved. The sorted commodities are photoelectrically indicated, so that the stacking and arrangement process of cargo is shortened. Therefore, the sorting time is shortened, the manual taking step is simplified, the possibility of deterioration of fresh commodities, especially for products of which the quality is greatly influenced by temperature, is reduced, and the timely sorting of cargo is ensured, and thus the logistics period and the transaction validity are improved.

Owner:北京任我在线电子商务有限公司

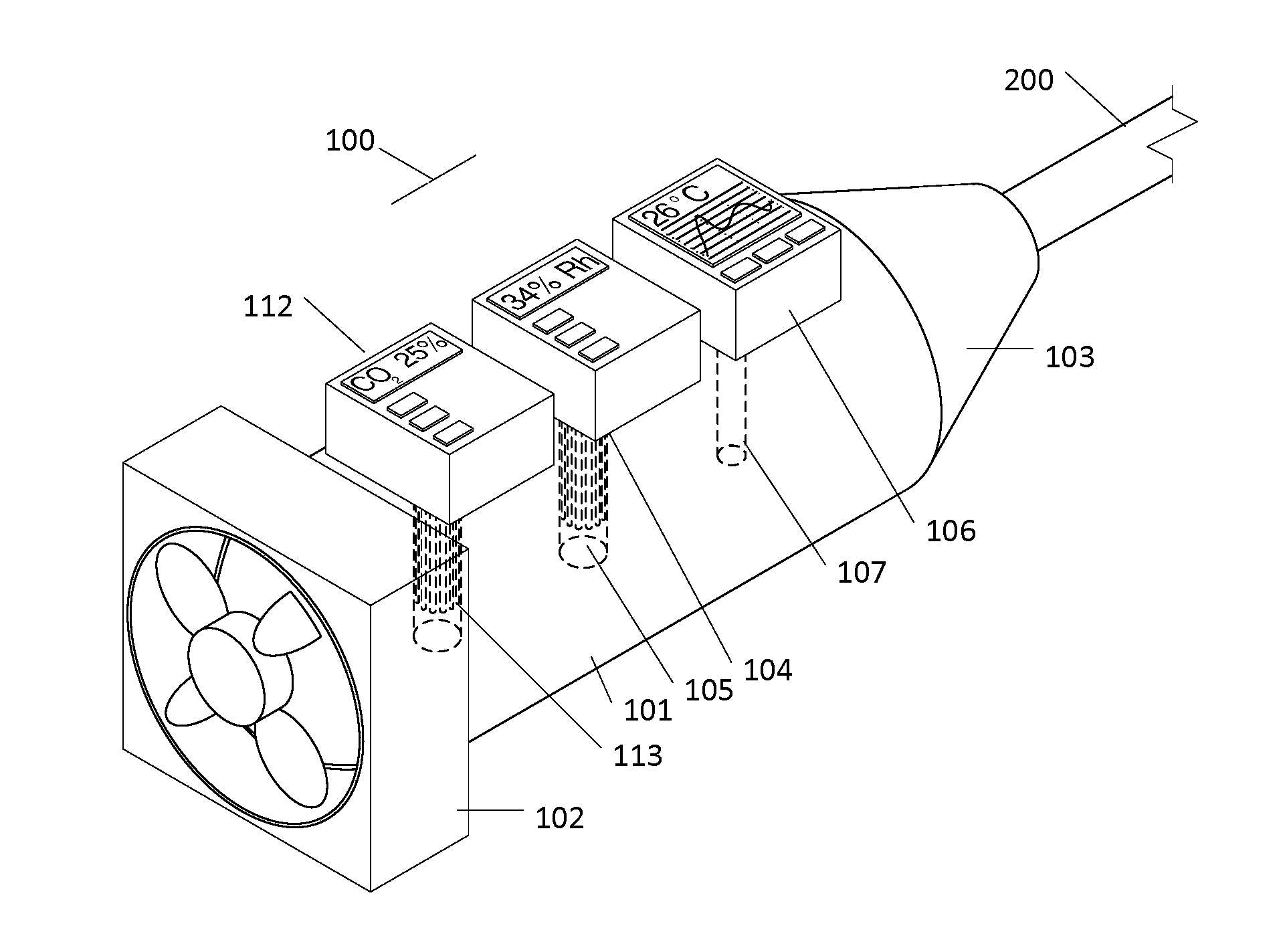

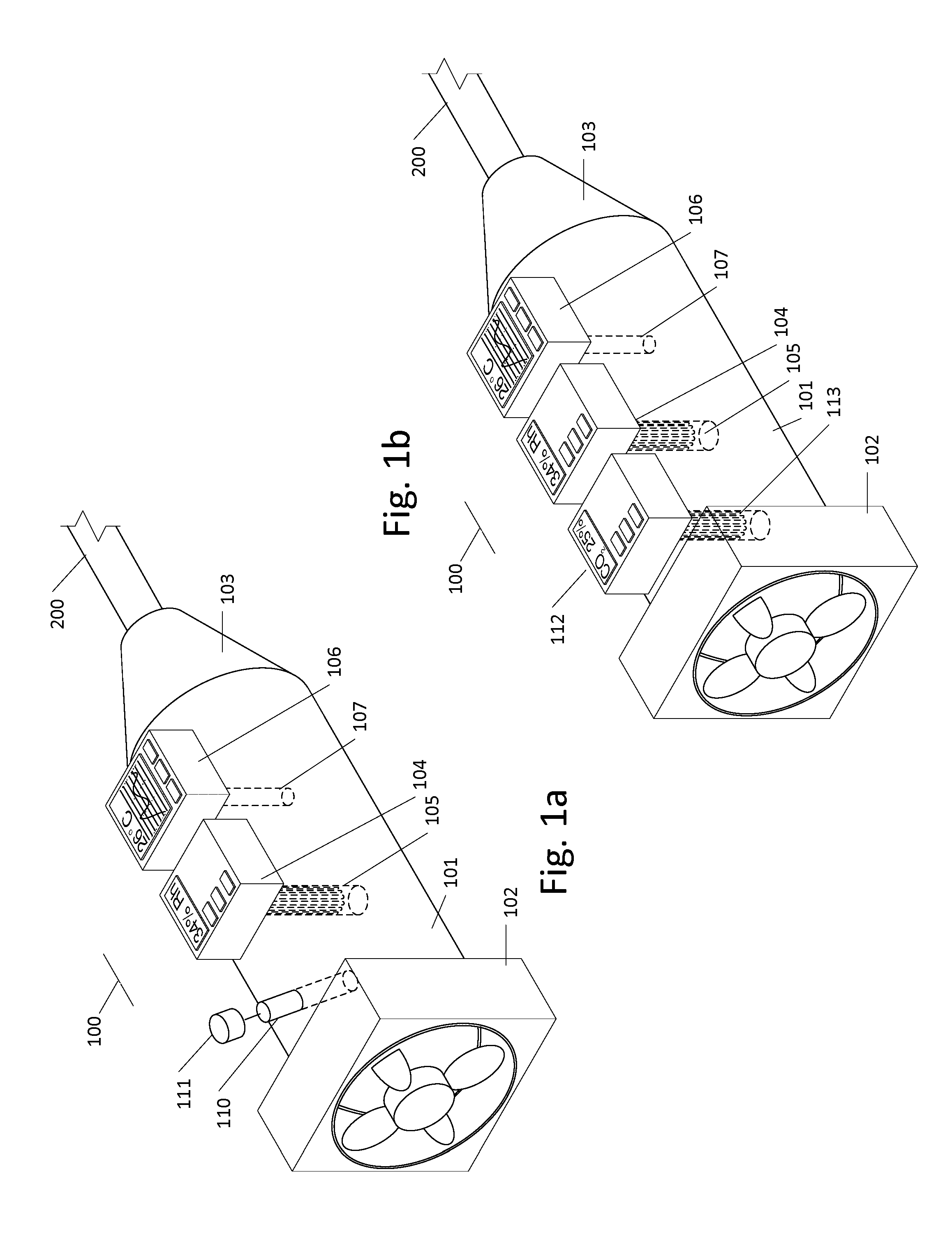

Pumped Air Relative Humidity and Temperature Sensing System with Optional Gas Assay Functionality

InactiveUS20140102175A1Prevent sproutReduce spoilageWithdrawing sample devicesUsing mechanical meansComplex networkTemperature sense

A distributed relative humidity and temperature sensing system with optional gas assay functionality, comprising a sample head internally equipped with: 1) A relative humidity sensor; 2) A temperature sensor; 3) A gas sample port for the attachment of a gas assay device, or, an integral gas assay device; and, 4) A fan. The sample head is attached to a semi-rigid sample tube embedded in a stored mass of agricultural product and the aforementioned fan causes air from within the stored mass to be drawn through the sample head where its relative humidity, temperature, and optionally, chemical composition may be studied. An alternative embodiment allows for the deployment of a complex network of sample tubes so that samples may be drawn as required from a number of points within the stored mass.

Owner:WASDEN KENT

Superhigh-pressure fresh keeping method for fresh rosa roxburghii

InactiveCN105360277AReduce inactivationReduce impact qualityFruit and vegetables preservationReverse osmosisRosa roxburghii fruit

The invention discloses a superhigh-pressure fresh keeping method for fresh rosa roxburghii. The superhigh-pressure fresh keeping method comprises the following steps of cleaning the rosa roxburghii: cleaning the rosa roxburghii with ultrasound high-pressure water cleaning equipment for 15-25 minutes; removing stabs of the rosa roxburghii: removing the external stabs of the rosa roxburghii fruits with a rotary mill; weighing the rosa roxburghii and loading the rosa roxburghii in bags: based on the unit of 3-8 kilograms of the rosa roxburghii in each bag, loading the rosa roxburghii in HDPE bags; injecting water for vacuum sealing: injecting reverse osmosis water to the HDPE bags loaded with the rosa roxburghii, and performing vacuum sealing to form rosa roxburghii water bags; using a superhigh-pressure processing technique, putting the rosa roxburghii water bags in a processing container of a high-pressure processing machine, and applying stationary liquid pressure of 100-800MPa, wherein the processing time is 5-10 minutes; and taking out the processed rosa roxburghii water bags, and preserving the rosa roxburghii water bags under normal atmospheric temperature. According to the superhigh-pressure fresh keeping method disclosed by the invention, the original flavor and the nutrient value can be maintained, the refrigeration and circulation shelf life can be prolonged, and the superhigh-pressure fresh keeping method has the same food safety grade as a conventional thermization method, and maintains the characteristics of flavor and the like.

Owner:贵州华南理工生物工程有限公司

Method for producing chrysanthemum tea

InactiveCN102696823AIncrease coverageImprove water qualityTea substituesHarvestersScientific managementQuality management

The invention aims to overcome the defects in the prior art and provides a method for producing chrysanthemum tea. The method comprises a planting method, a picking method and a processing method. The method has the advantages of overcoming the defects of high cost, low quality, low yield and poor conditions and further realizing the all-around '4GMP-10 Production Standard' of chrysanthemum tea, namely ecological standard, planting standard, picking standard and processing standard, therefore, the aims of producing chrysanthemum strictly in accordance with pharmaceutical standards, implementing the quality management in the whole production process, taking scientific quantitative planting means and implementing all-around scientific management are really fulfilled.

Owner:湖北明钼健康科技有限公司

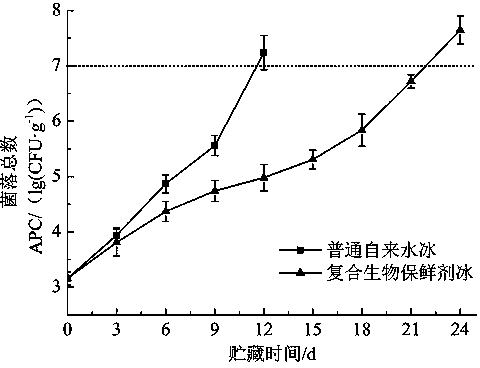

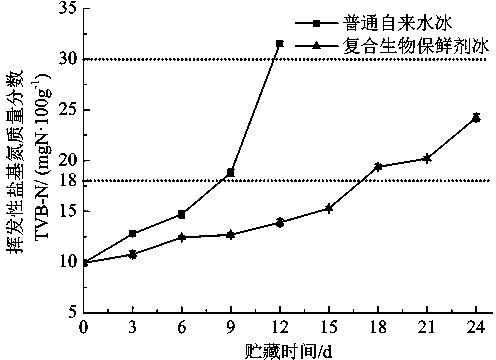

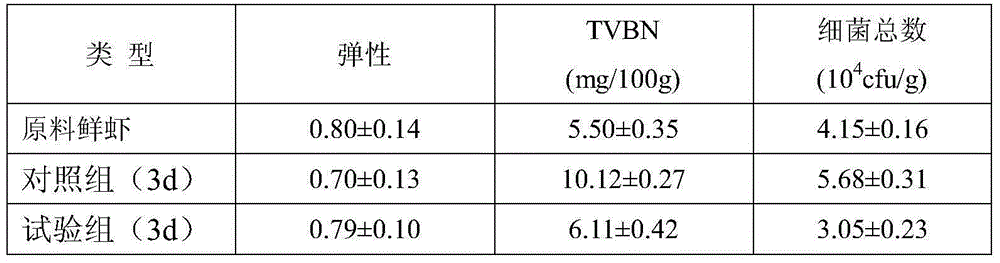

Penaeus Vannamei ice temperature fresh keeping method combining with ice cube refrigeration

ActiveCN102423100ASlow down the speed of blackeningExtended shelf lifeFood preservationChemistryRefrigerated temperature

The invention discloses a Penaeus Vannamei ice temperature fresh keeping method combining with ice cube refrigeration. The method comprises the following steps: 1, preparing a biological fresh keeping agent solution, and dividing it into two parts; 2, preparing ice cubes from one part of the biological fresh keeping agent solution by an ice making machine; 3, flushing screened Penaeus Vannamei bodies by sterile water, cooling the Penaeus Vannamei bodies by crushed ice for 5-10min, and immersing the cooled Penaeus Vannamei bodies in the biological fresh keeping agent solution for 1-3min; 4, putting the ice cubes containing the biological fresh keeping agent in a stainless steel cylinder to realize a case that the Penaeus Vannamei bodies are surrounded by the ice cubes; 5, covering Penaeus Vannamei surfaces with a small amount of the crushed ice to fully cover Penaeus Vannamei by the ice cubes; 6, storing the stainless steel cylinder in a 2-8DEG C refrigerator; and 7, timely supplying the ice cubes containing the biological fresh keeping agent during the storage. Compared with the storage which is carried out only under pure water ice cube refrigeration conditions, the fresh keeping agent allows the shelf life of Penaeus Vannamei to be obviously prolonged by 7-8 days. The fresh keeping method of the invention, which is simple and easy to carry out, can accurately realize the ice temperature control and has a good fresh keeping effect, has a very good application value.

Owner:SHANGHAI OCEAN UNIV

Method for refreshing pomfrets by using ice containing composite biological refreshing agent

InactiveCN104322649AReduce spoilageExtended shelf lifeMeat/fish preservation by freezing/coolingIce waterPhytic acid

The invention discloses a method for refreshing pomfrets by using ice containing a composite biological refreshing agent. The method comprises the following steps of: (1) preparing composite biological refreshing liquid containing tea polyphenol and phytic acid; (2) adding glycerinum into the composite biological refreshing liquid; (3) freezing the composite biological refreshing liquid containing the glycerinum into ice blocks at the temperature of -18 DEG C; (4) cleaning the selected pomfrets with ice water, and draining for 2-3 minutes; (5) crushing the ice blocks containing the composite biological refreshing agent by using an ice crushing machine, and storing layered pomfrets and layered ice in a foam box to realize surrounding of crushed ice for the pomfrets; (6) putting the foam box in a refrigerated cabinet with the temperature of 1-4 DEG C for storage; and (7) supplementing the ice containing the composite biological refreshing agent at proper time during the storage period. Compared with the method for refreshing pomfrets by using common ice, the shelf life of the pomfrets can be prolonged for 9-10 days by using the ice containing the composite biological refreshing agent. The method disclosed by the invention is simple and easy, is obvious in refreshing effect, reduces the waste of the pomfrets to a great extent, is a good method which can replace the common iced storage for refreshing the pomfrets, and has large potential for market application.

Owner:SHANGHAI OCEAN UNIV

Evaporation crucible and evaporation equipment

InactiveCN107058958AGood evaporation uniformityReduce spoilageVacuum evaporation coatingSputtering coatingCrucibleHeat conducting

The invention provides an evaporation crucible and evaporation equipment. The evaporation crucible comprises a body and a cover with an opening. The cover is arranged on the top of the body. A heat conducting column is arranged on the bottom wall of the body. The top end of the heat conducting column is located at the opening position. In the evaporation process, the heat conducting column can conduct heat to evaporation materials around the heat conducting column, and the evaporation materials in the body are heated and evaporated. Compared with a manner that heating is conducted only through the outer wall of a body, the evaporation uniformity of the evaporation materials is better, deterioration of the evaporation materials in the body can be reduced, and accordingly, the film forming quality of the vacuum evaporation technology is improved. Meanwhile, the distance between the side wall of the heat conducting column and the side wall of the opening is short, the heat conducting column can conduct enough heat to the side wall of the opening, the temperature of the side wall of the opening is high, and therefore the evaporation materials can be prevented from being condensed and stacked on the side wall of the opening, and accordingly stability of the evaporation rate of the evaporation materials is improved.

Owner:BOE TECH GRP CO LTD

Film preservative, preparation method thereof, and application thereof in preservation of euphausia superba

InactiveCN105028602APrevent spoilageGuaranteed quality and tasteMeat/fish preservation by coatingChemistryHoneysuckle

The invention relates to a film preservative. The film preservative is composed of the following components in percentage by mass: 0.8 to 1.5 percent of soybean polysaccharide, 0.6 to 1.0 percent of sodium alginate, 0.2 to 0.5 percent of citric acid, 0.1 to 0.3 percent of phytic acid, 3 to 5 percent of a waxberry extract, 5 to 7 percent of a honeysuckle extract, 0.08 to 0.2 percent of magnesium salt and the balance of pure water. The invention also relates to a preparation method of the film preservative and application of the film preservative in preservation of euphausia superba. Compared with the prior art, the film preservative has the advantages that a film can be formed on the surface of the euphausia superba so as to inhibit the invasion and the growth of pathogenic bacteria such as bacteria and fungi, the decaying deterioration of an euphausia superba body is prevented, the euphausia superba treated by the film preservative can be stored at the temperature of 0 to 4 DEG C, the taste and the quality of shrimp meat are guaranteed, and compared with the storage energy consumption of a conventional low-temperature storage method, the storage energy consumption of the film preservative is reduced.

Owner:ZHEJIANG OCEAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com