Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

330results about "Tea alkaloid content reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for extraction, purification and enrichment of polyphenolic substances from whole grapes, grape seeds and grape pomace

InactiveUS6544581B1Maximize concentration and purificationMaximizing extractionSolid waste disposalFatty substance preservation using additivesMethacrylateFiltration

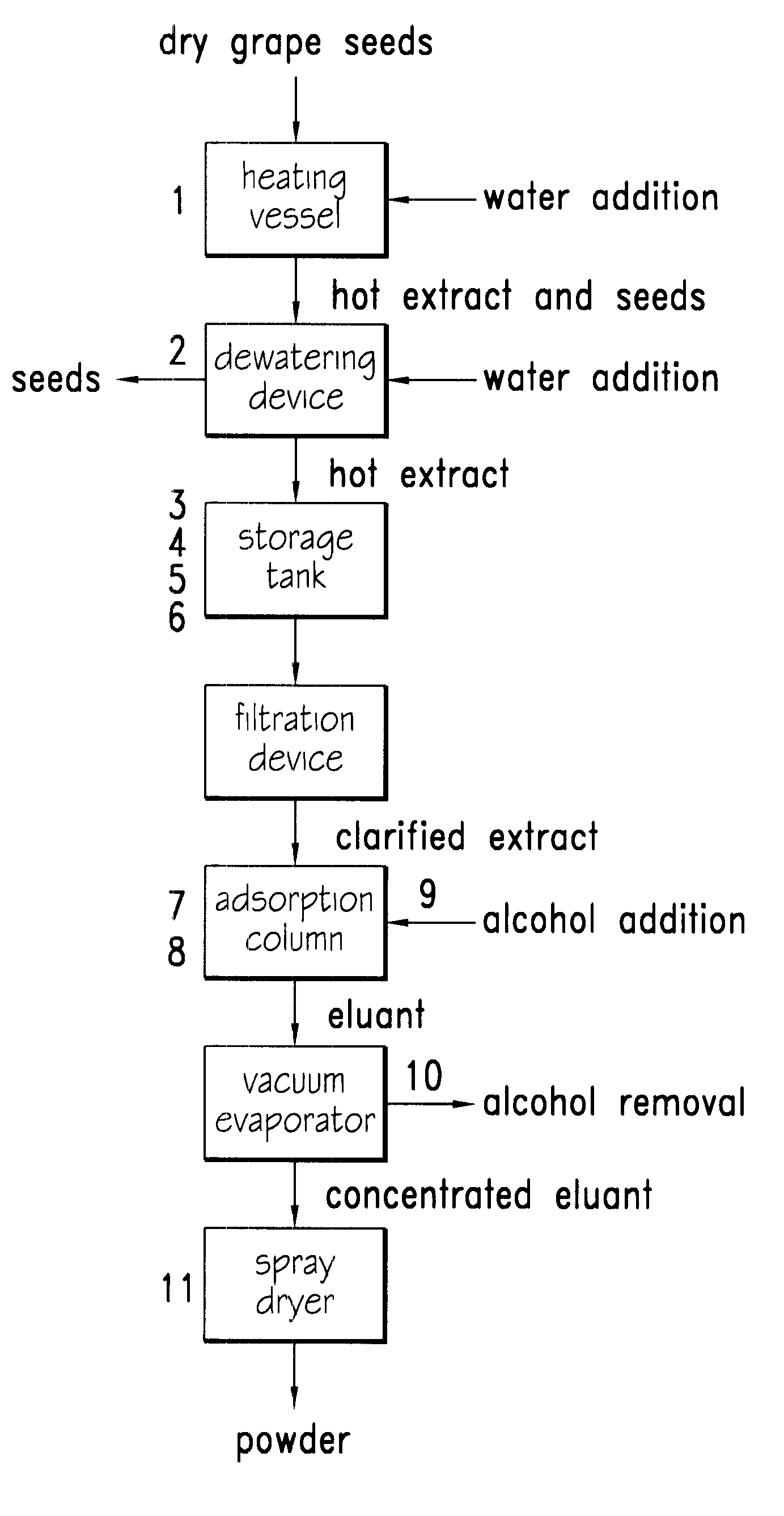

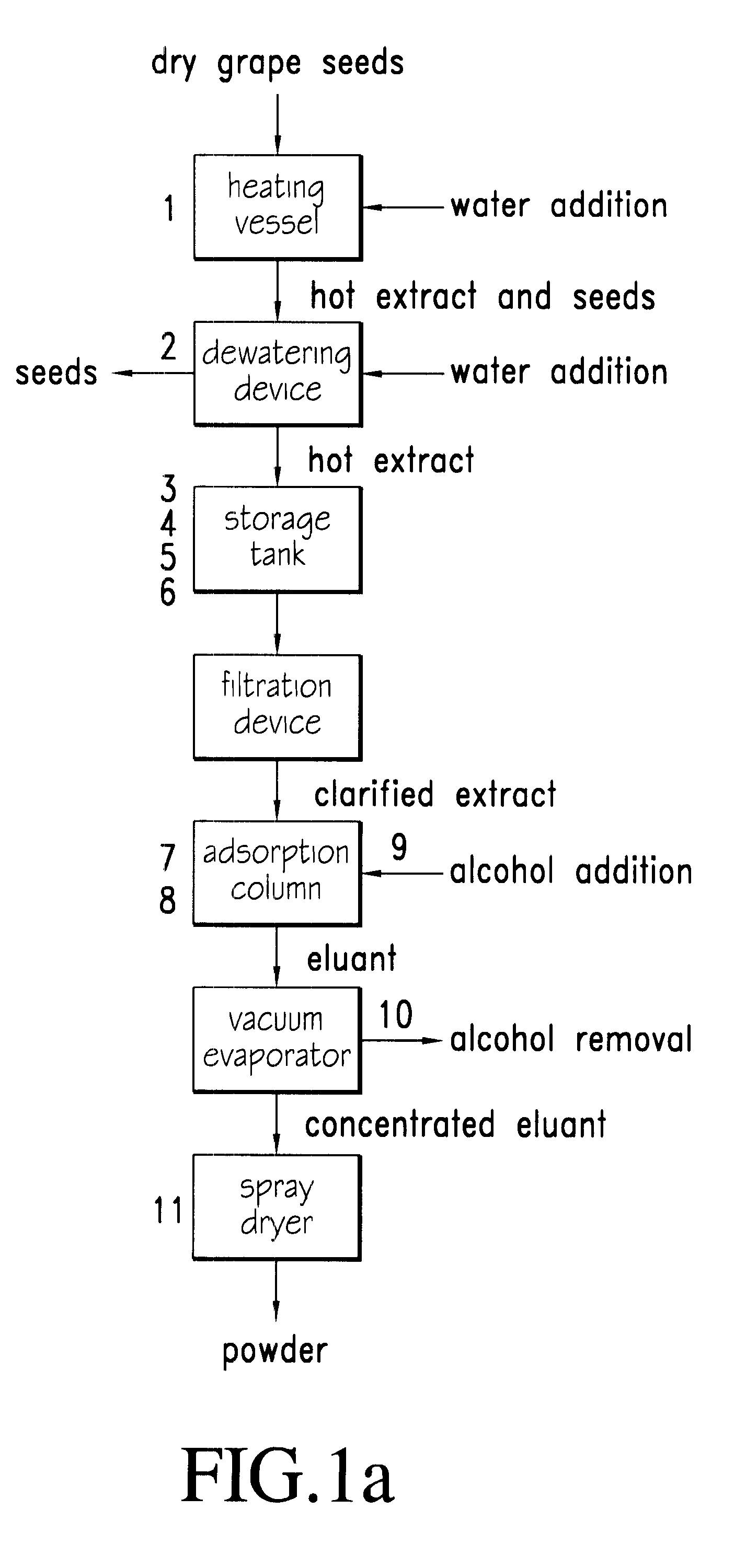

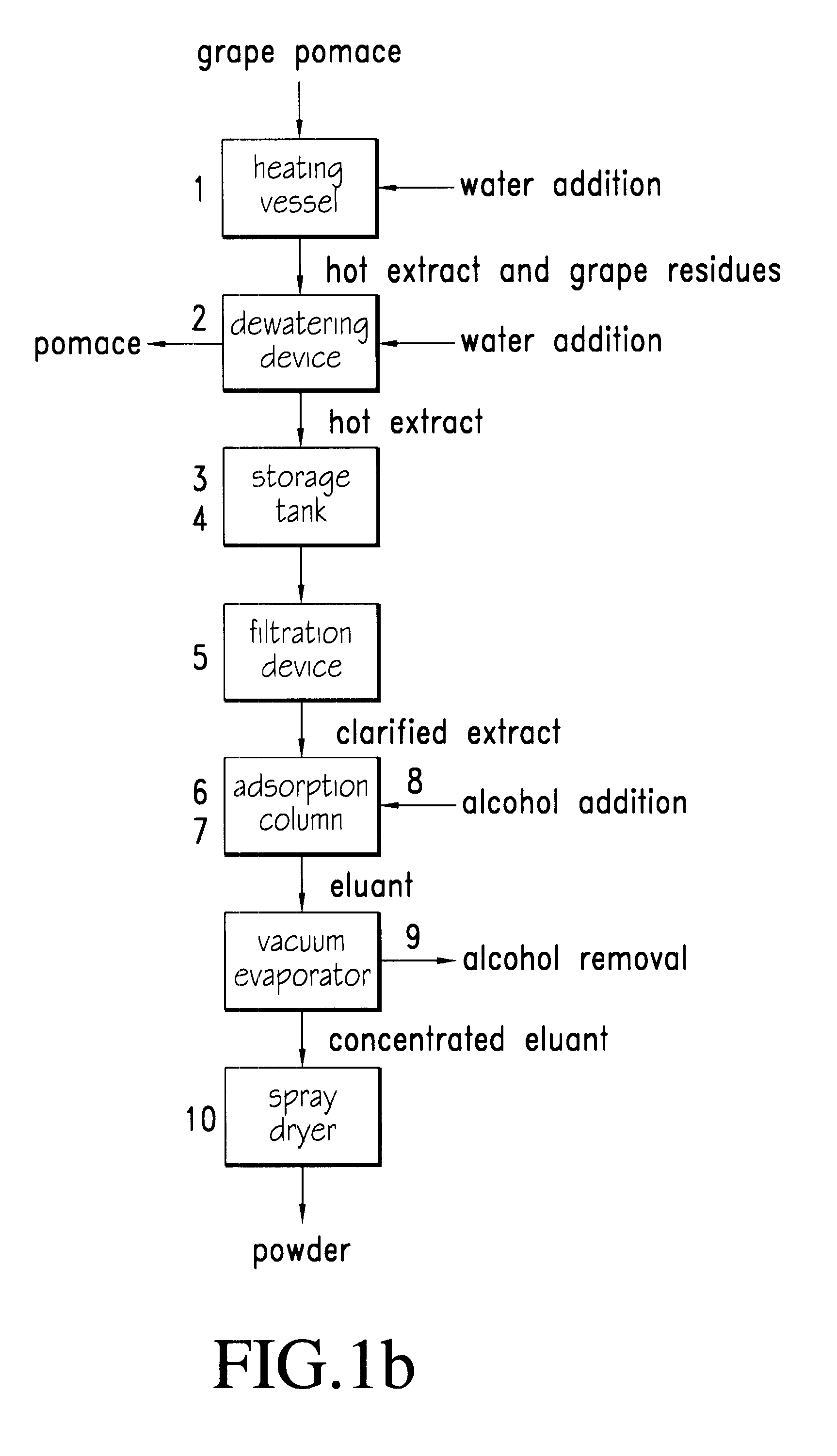

The present invention provides a novel process for extraction, purification and concentration of polyphenol substances from whole grapes, grape seeds and grape pomace without the need for membrane filtration. Aspects of several embodiments of the novel processes include hot water extraction, a dual pH treatment of the hot water extracts, and the uses of a copolymer of trimethylolpropane trimethacrylate as an adsorbent resin to maximize the concentration and purification of the beneficial polyphenolic substances.

Owner:CANANDAIGUA WINE +1

Compositions containing green tea catechins and one or more polyvalent mineral cations

InactiveUS20050003068A1Promotes cardiovascular healthLower blood pressurePre-extraction tea treatmentTea extractionTurbidityGreen tea

Owner:KELLOGG NORTH AMERICA

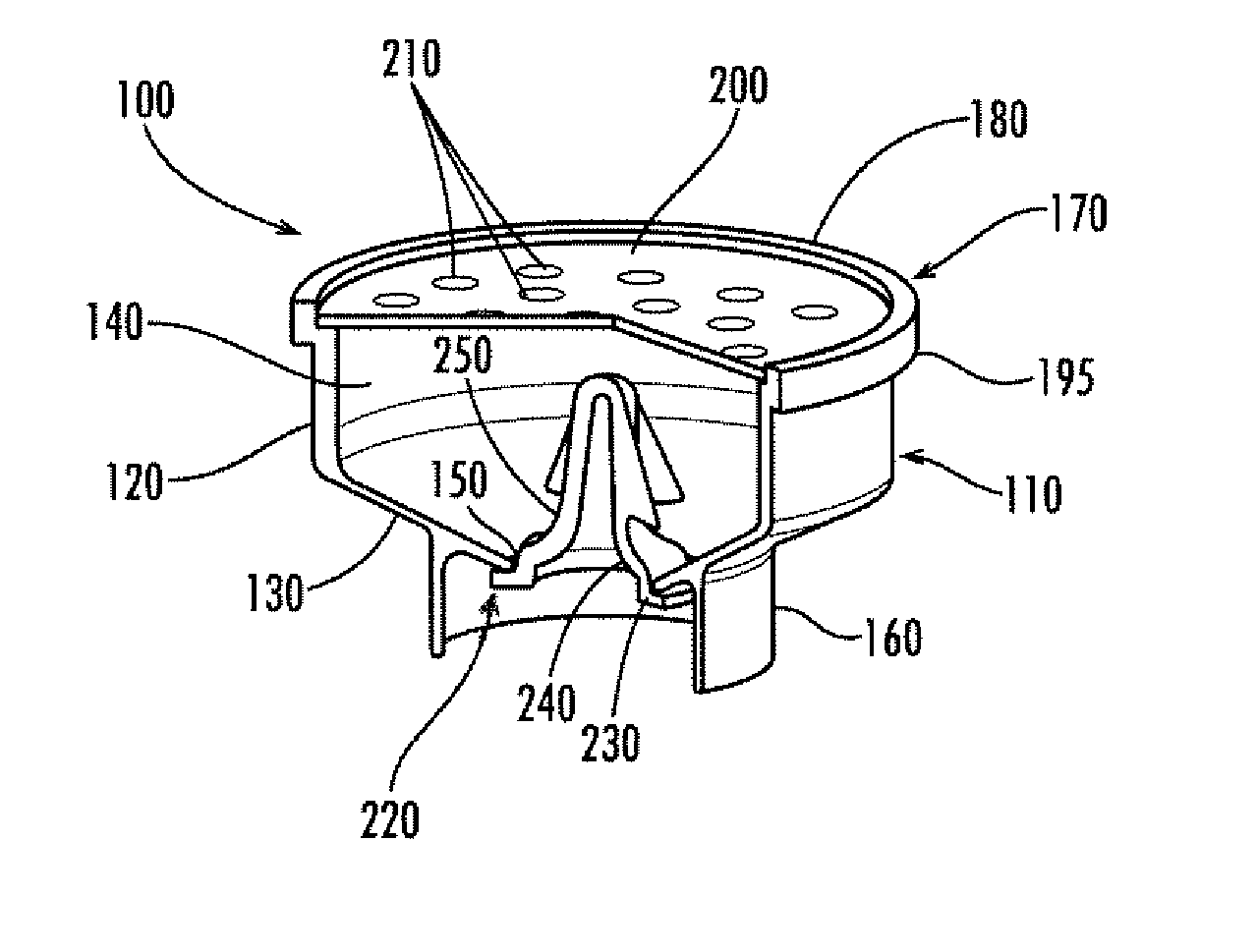

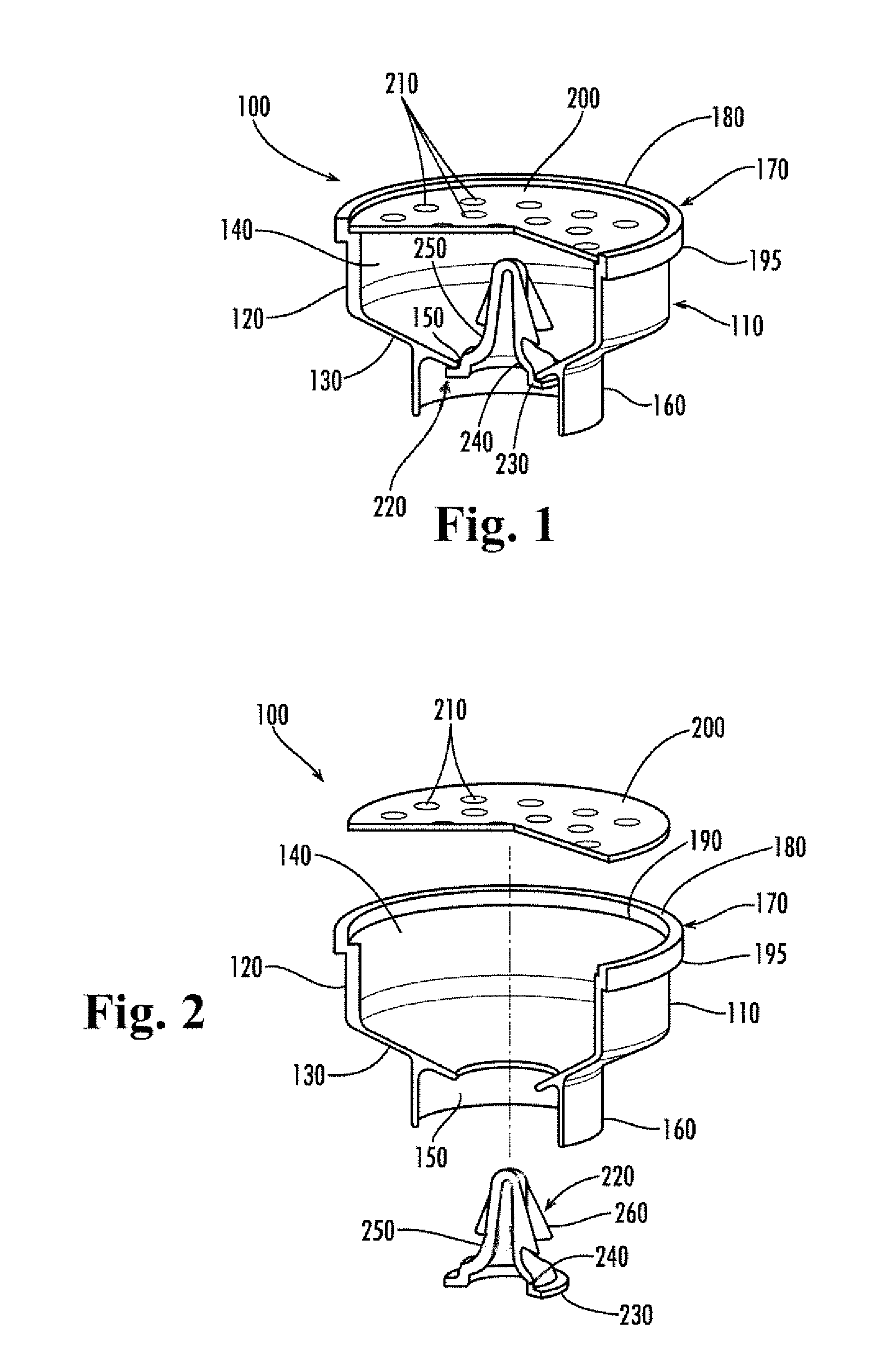

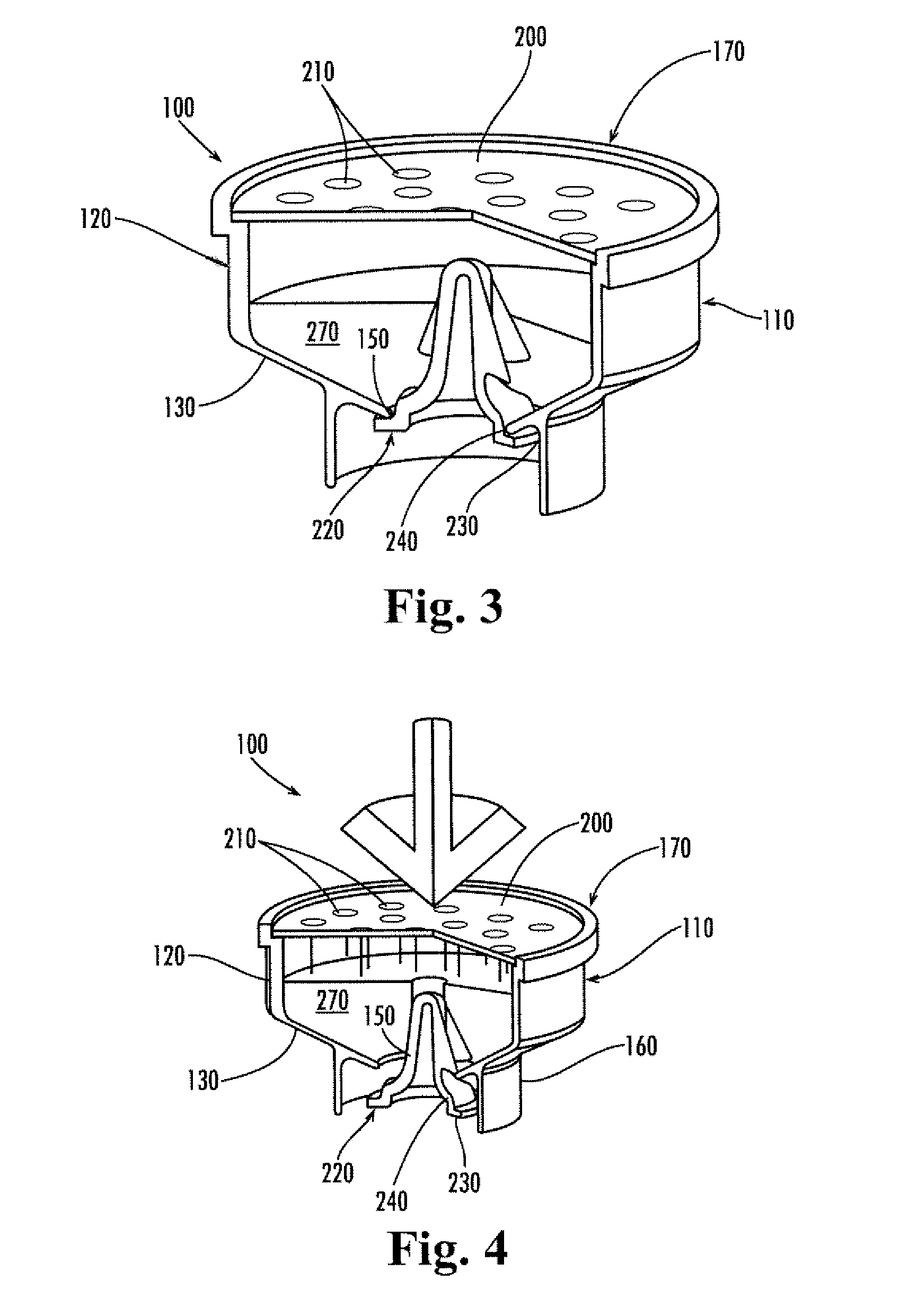

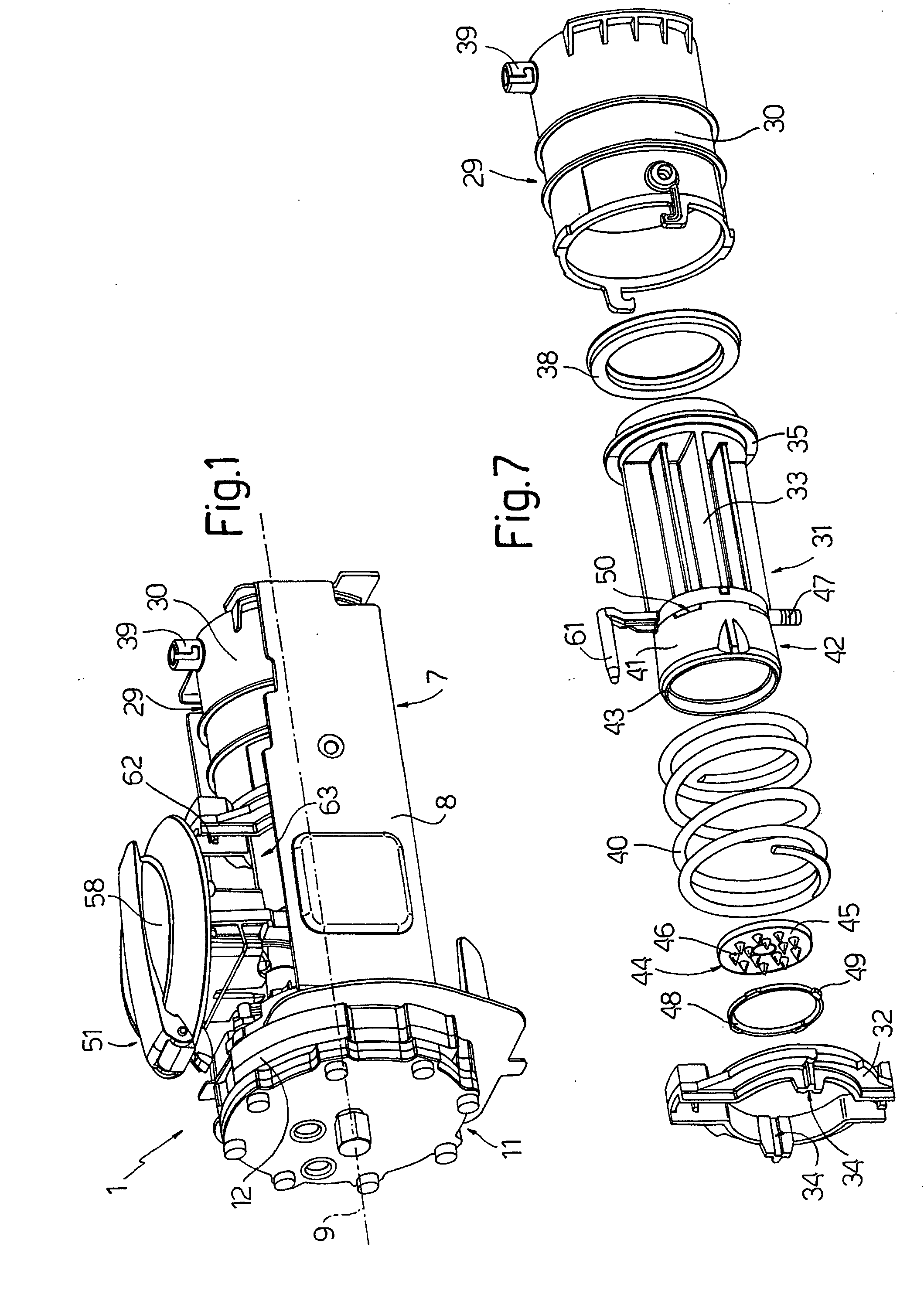

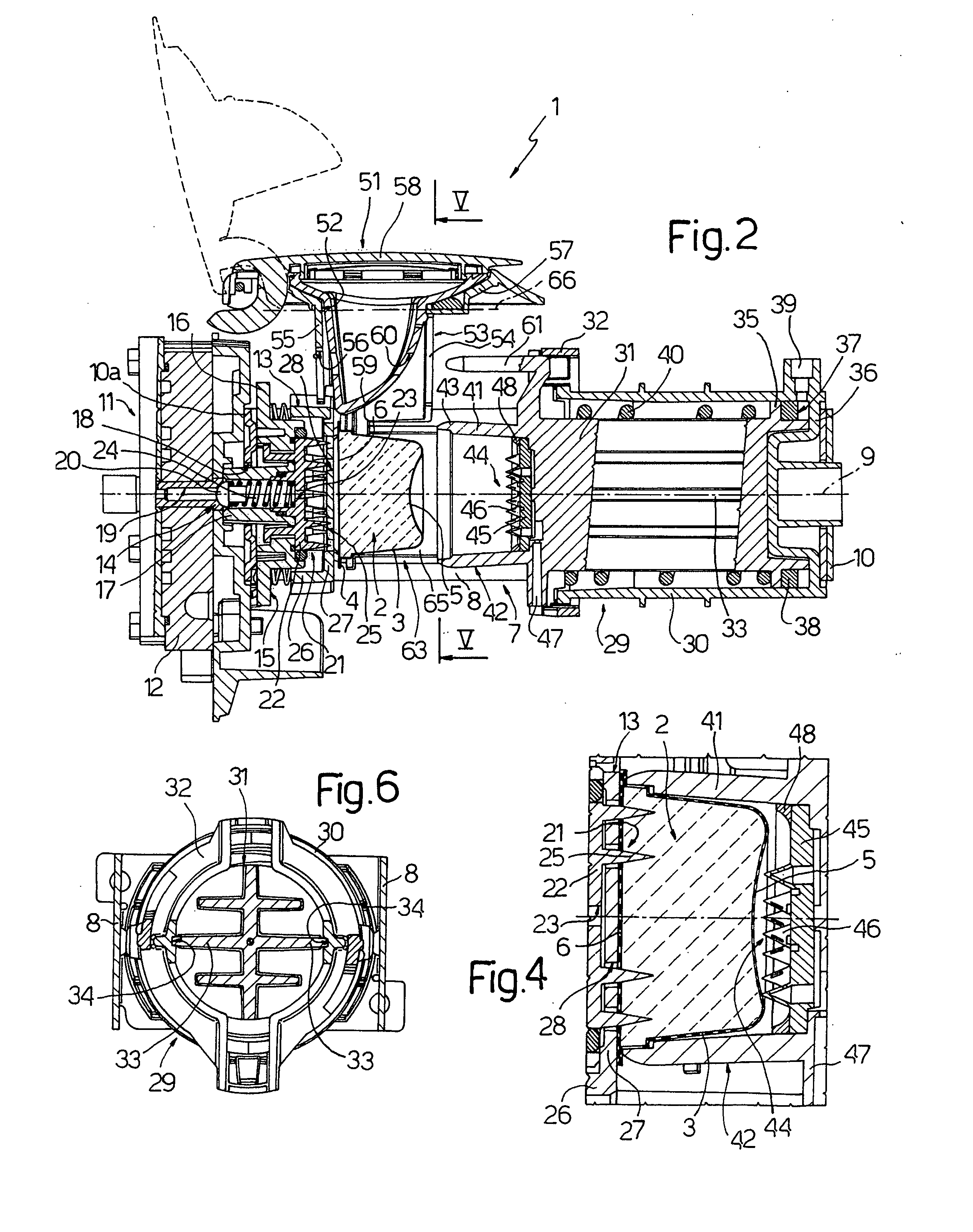

Pod for Dispersible Materials

Owner:THE COCA-COLA CO

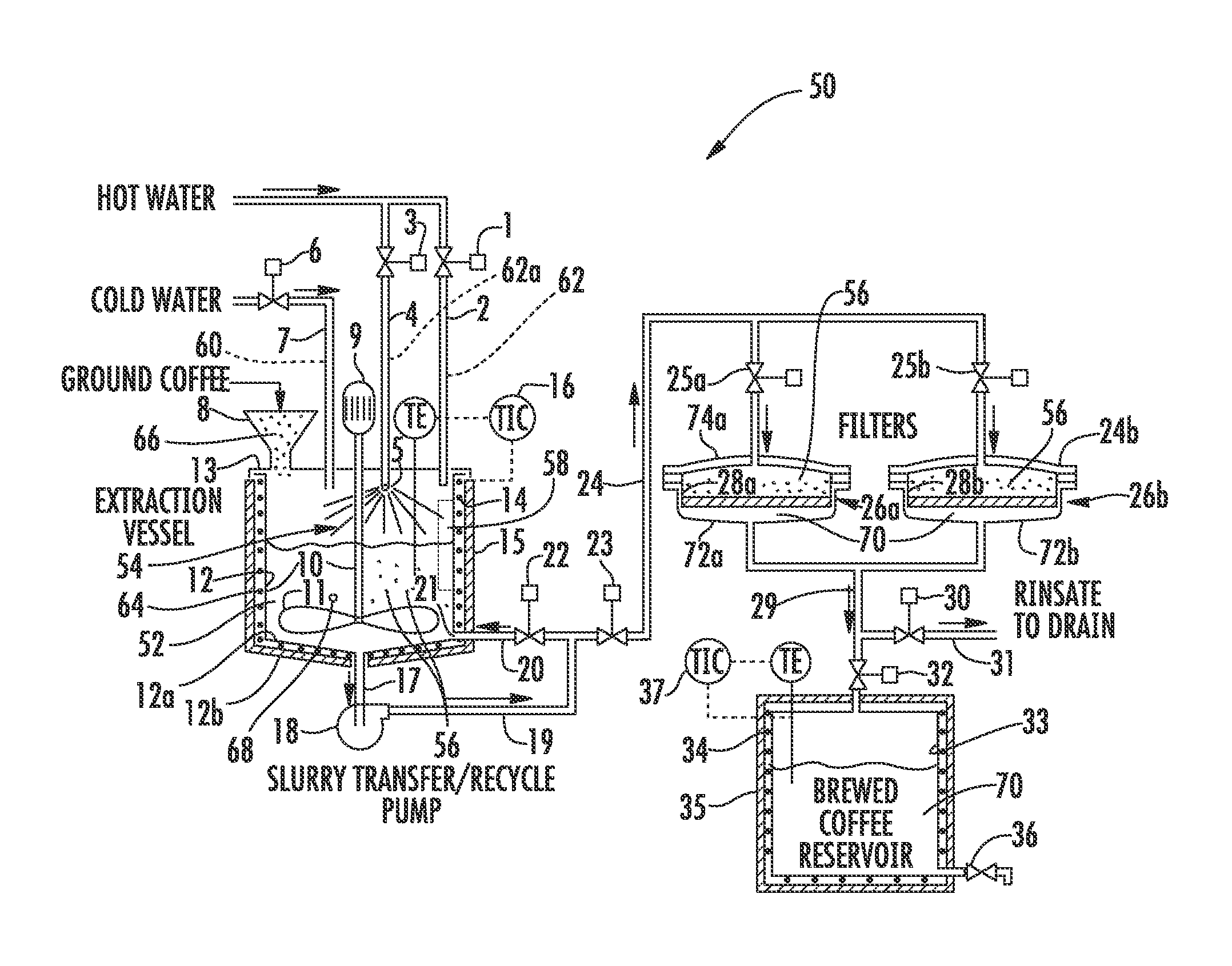

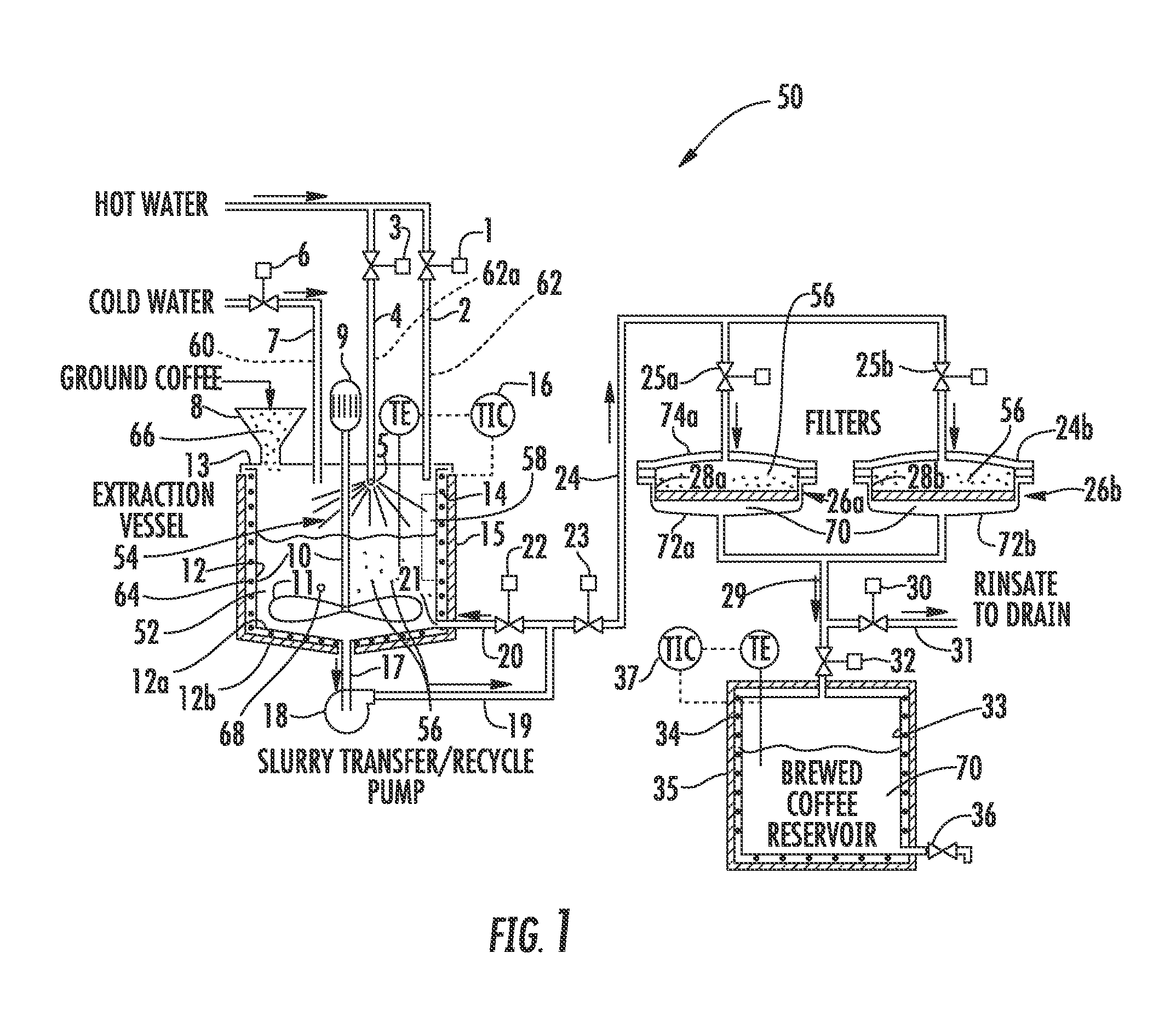

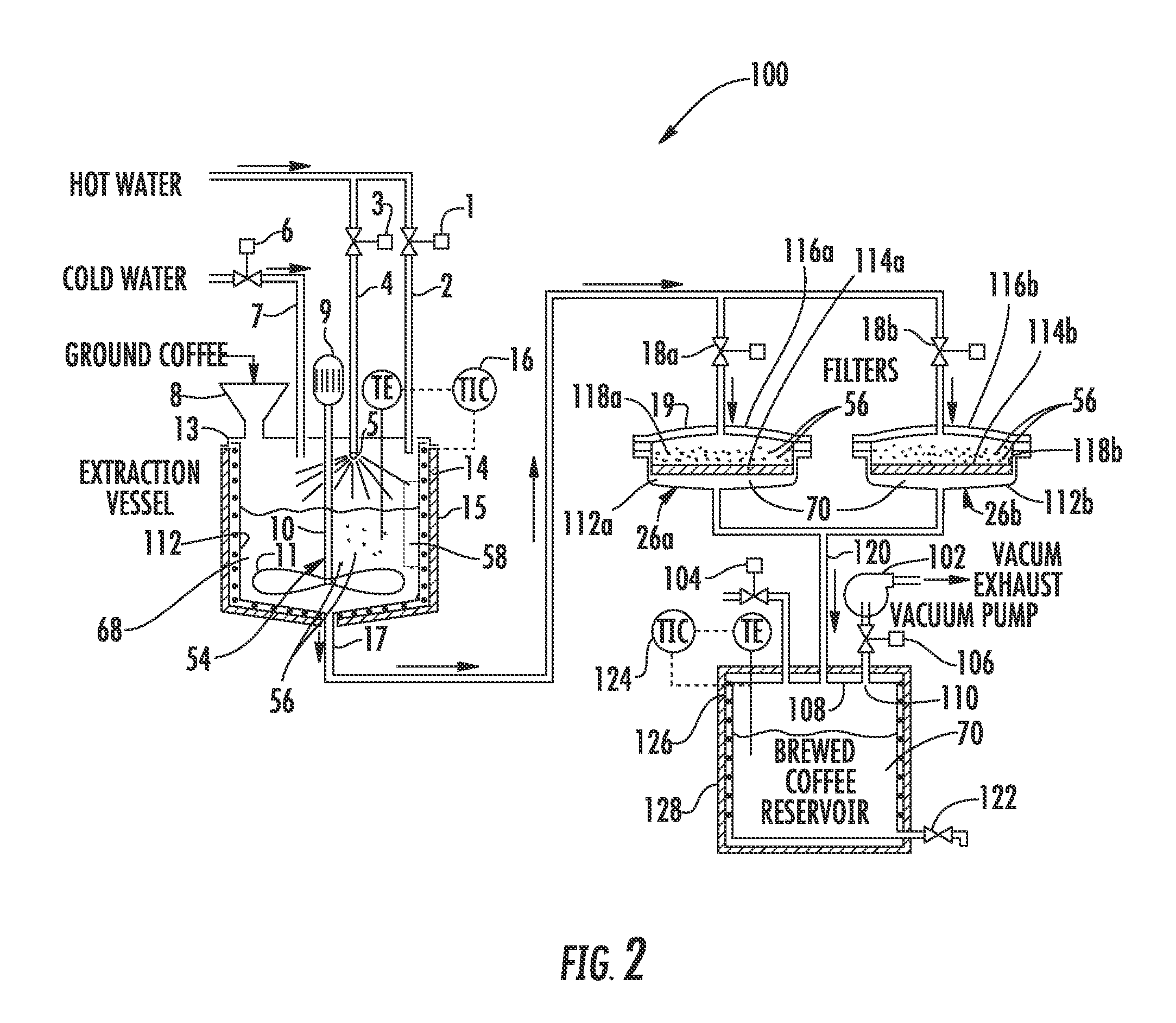

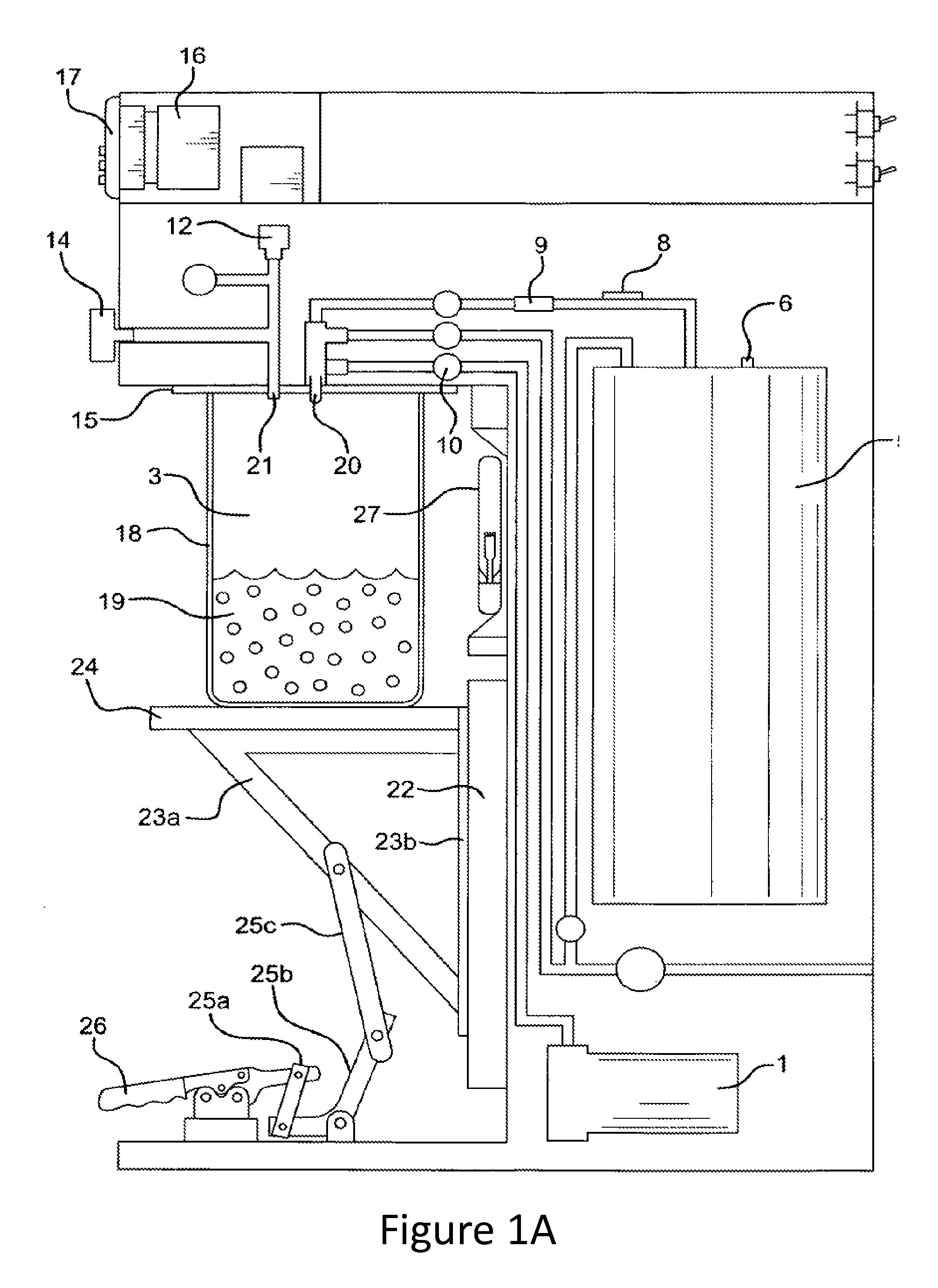

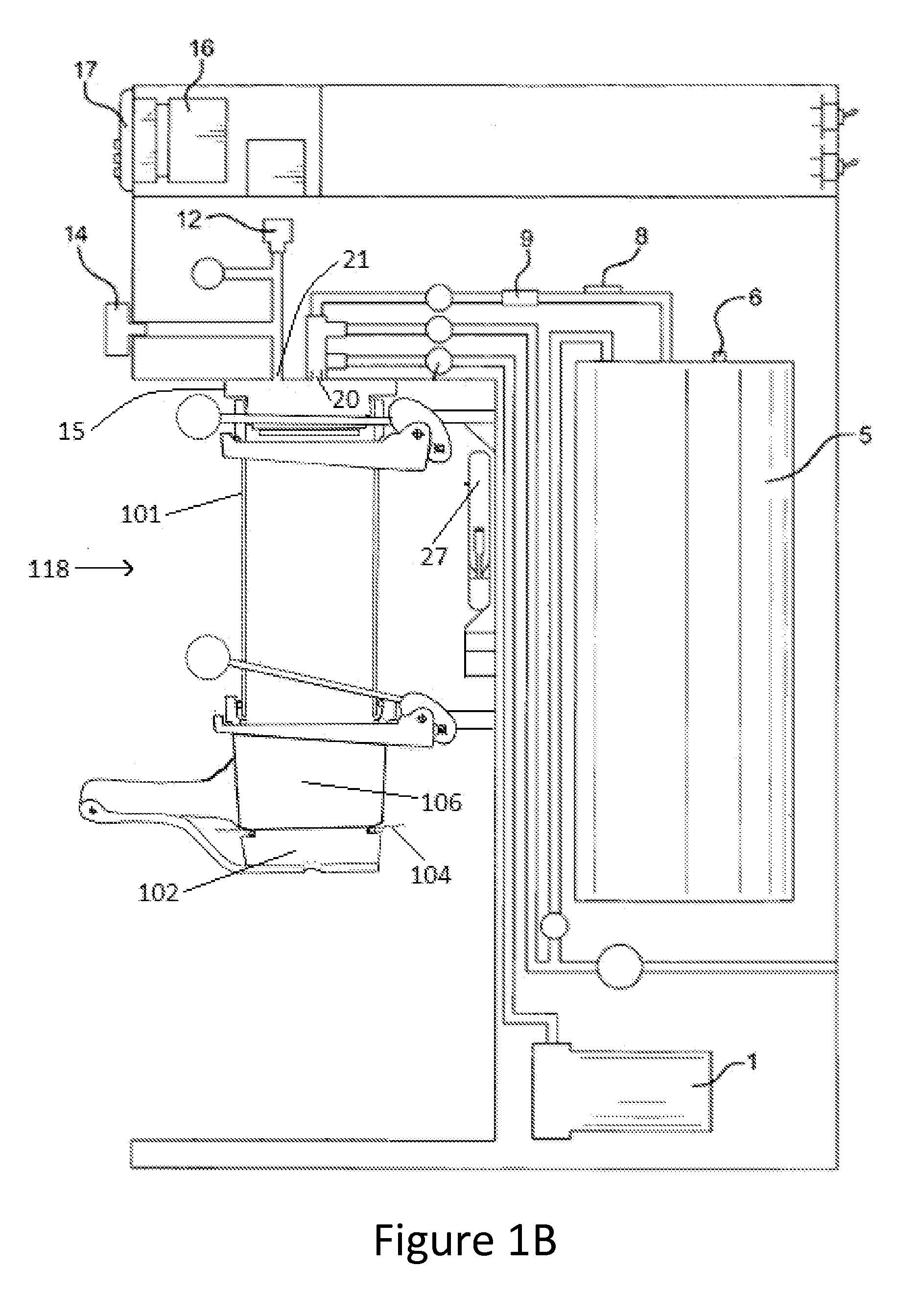

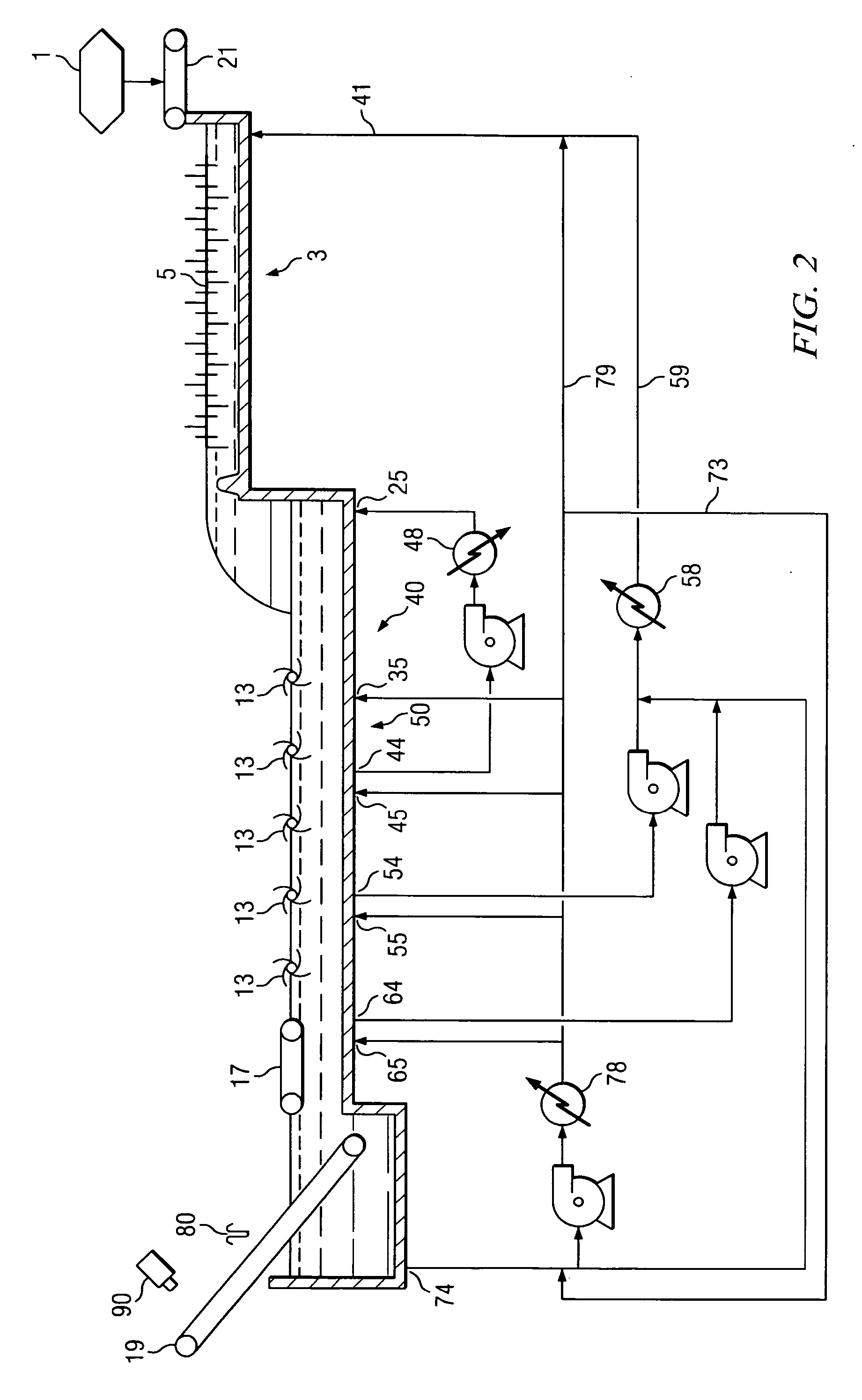

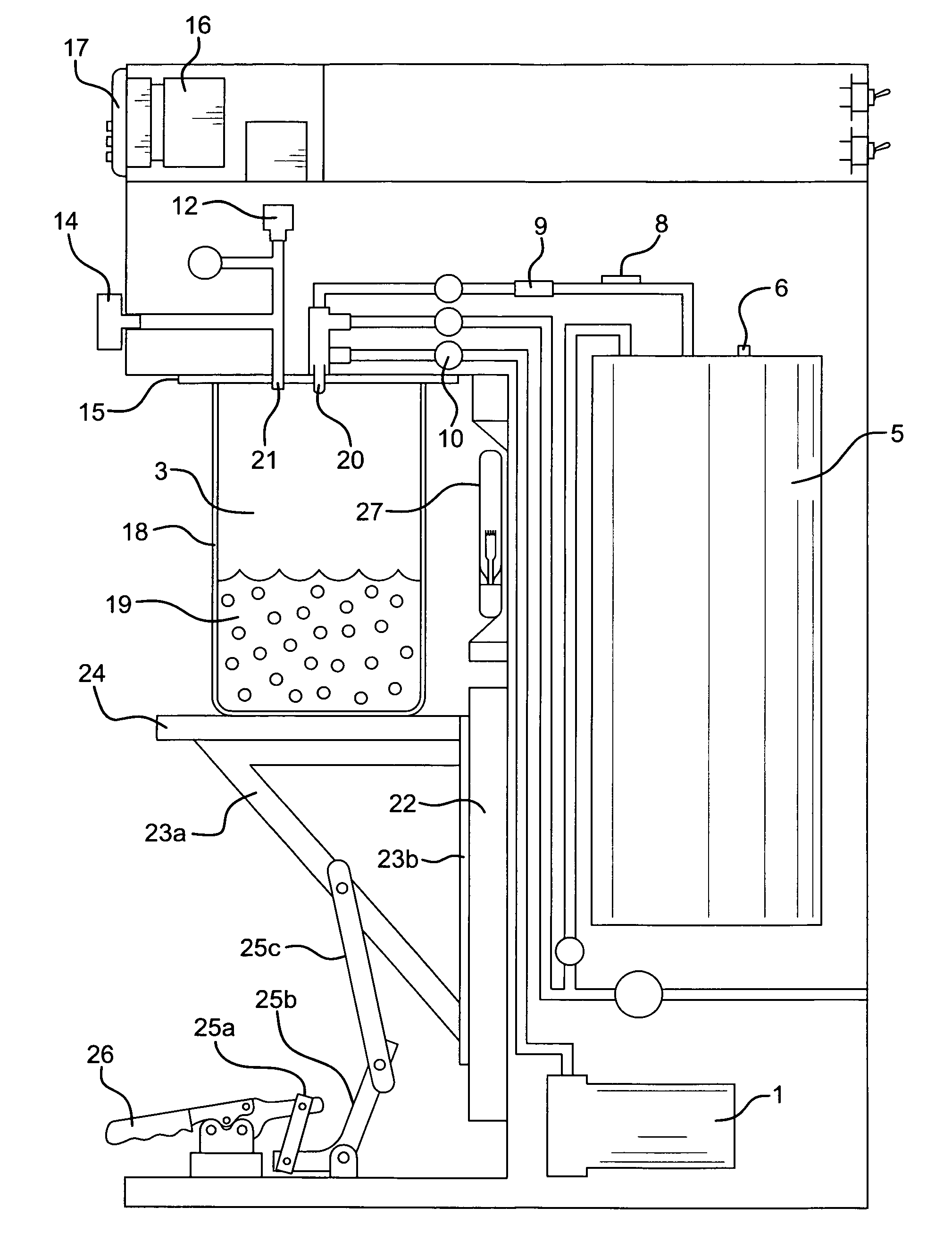

Beverage brewing process and system

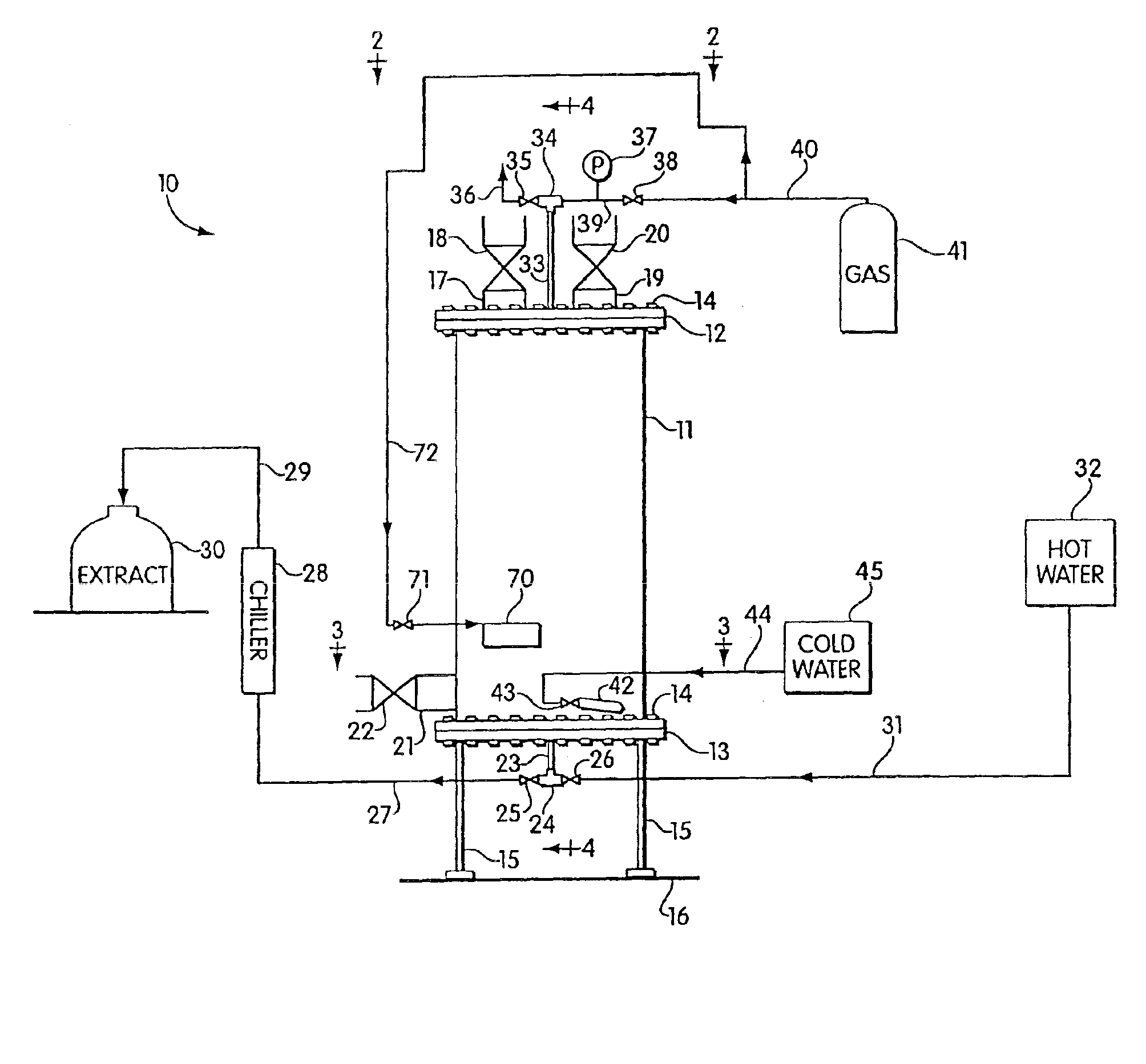

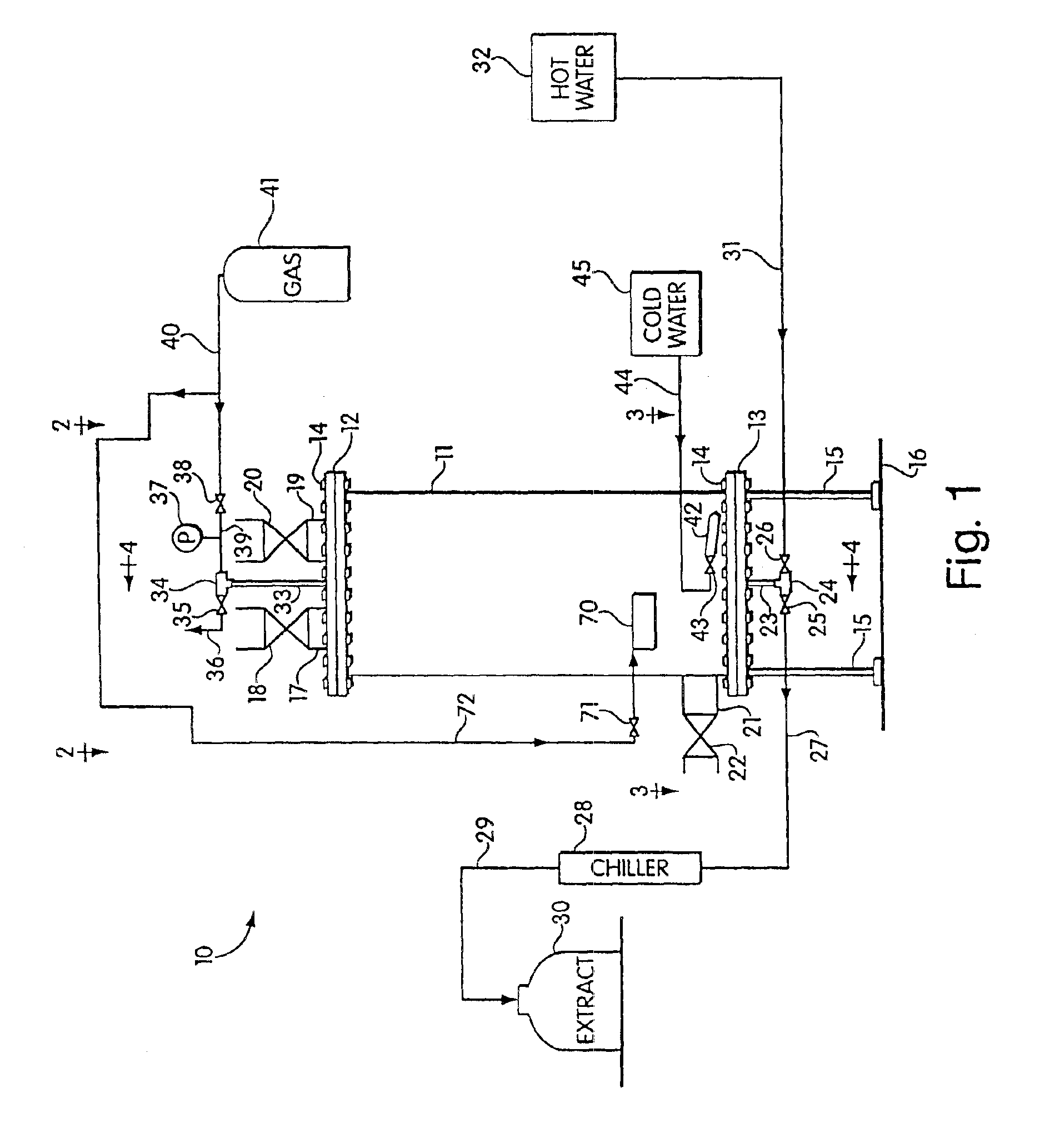

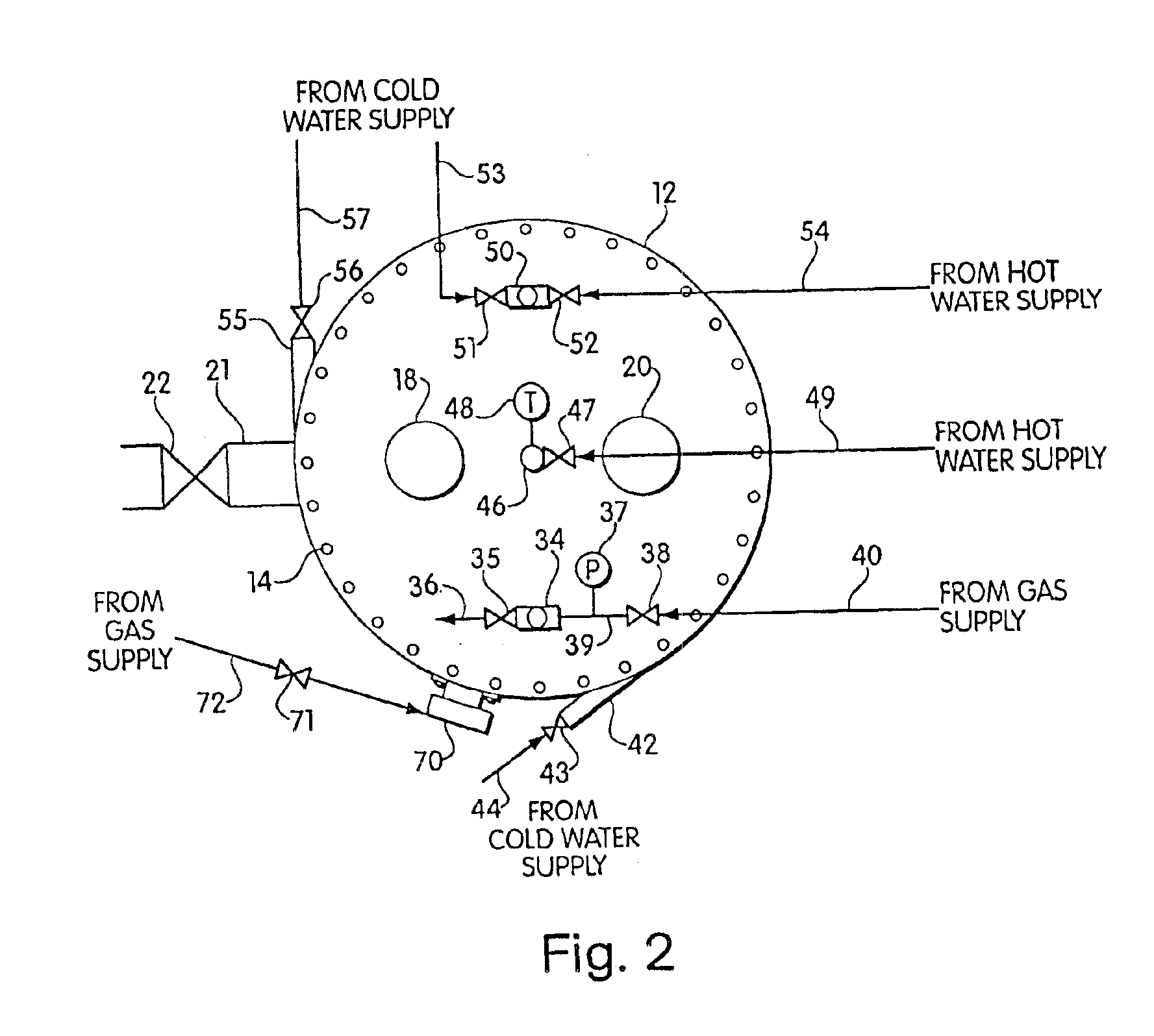

InactiveUS20100203209A1Reduce tasteGreat tasteTea substituesTea alkaloid content reductionEngineeringBrewing

The present invention provides a unique process and system for brewing beverages for retail or commercial use where the key brewing parameters are independently controlled to produce multi-cup batches of brewed beverage of optimum taste. This invention is applicable to both retail and commercial applications and is scalable in quantities ranging from one cup to three gallons or more of brewed beverage. Since the extraction and solid-liquid separation are conducted separately and independently, the present invention decouples these two operations to avoid reduction in taste quality while still being able to provide large multi-cup batches.

Owner:FISHBEIN WILLIAM +1

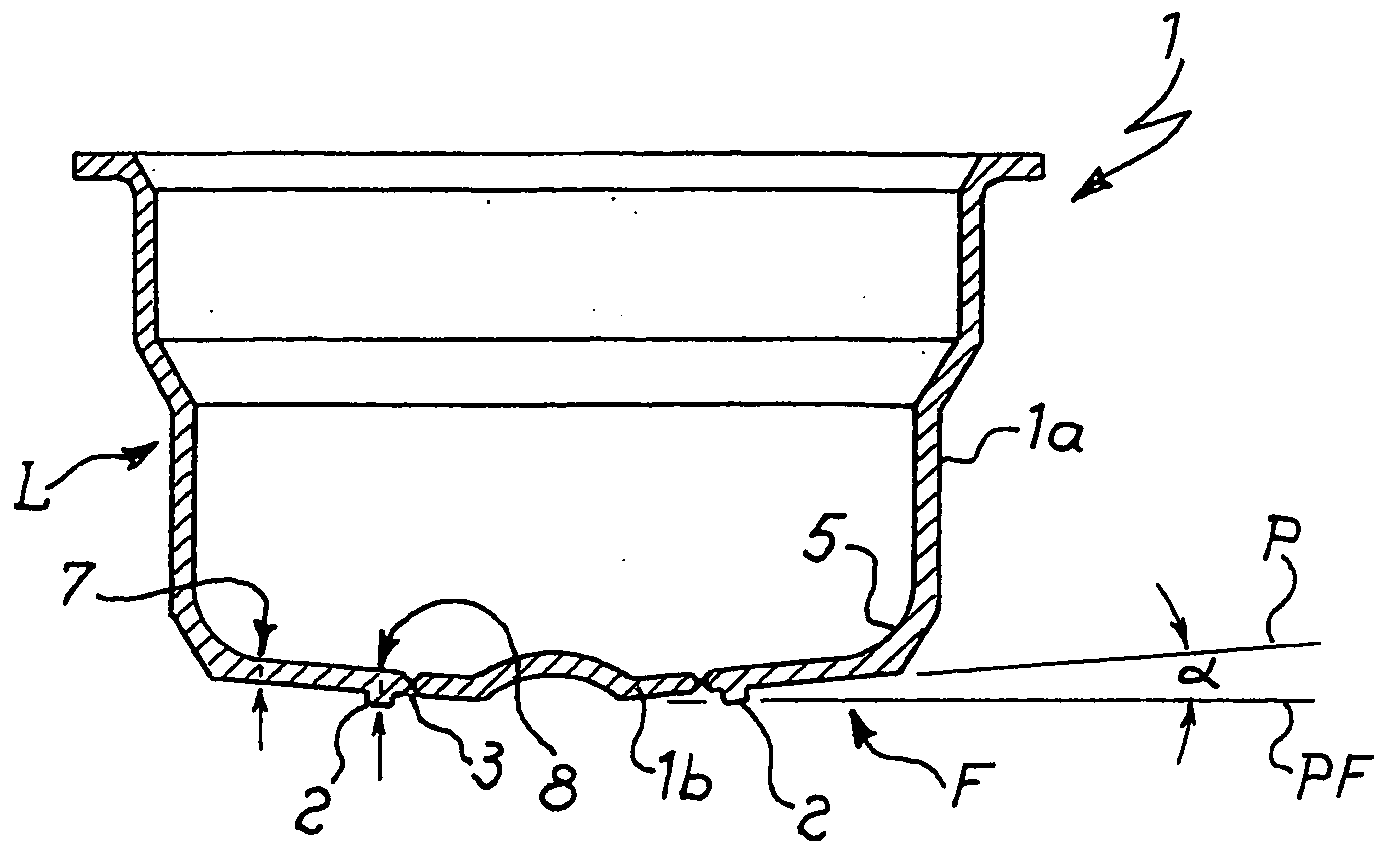

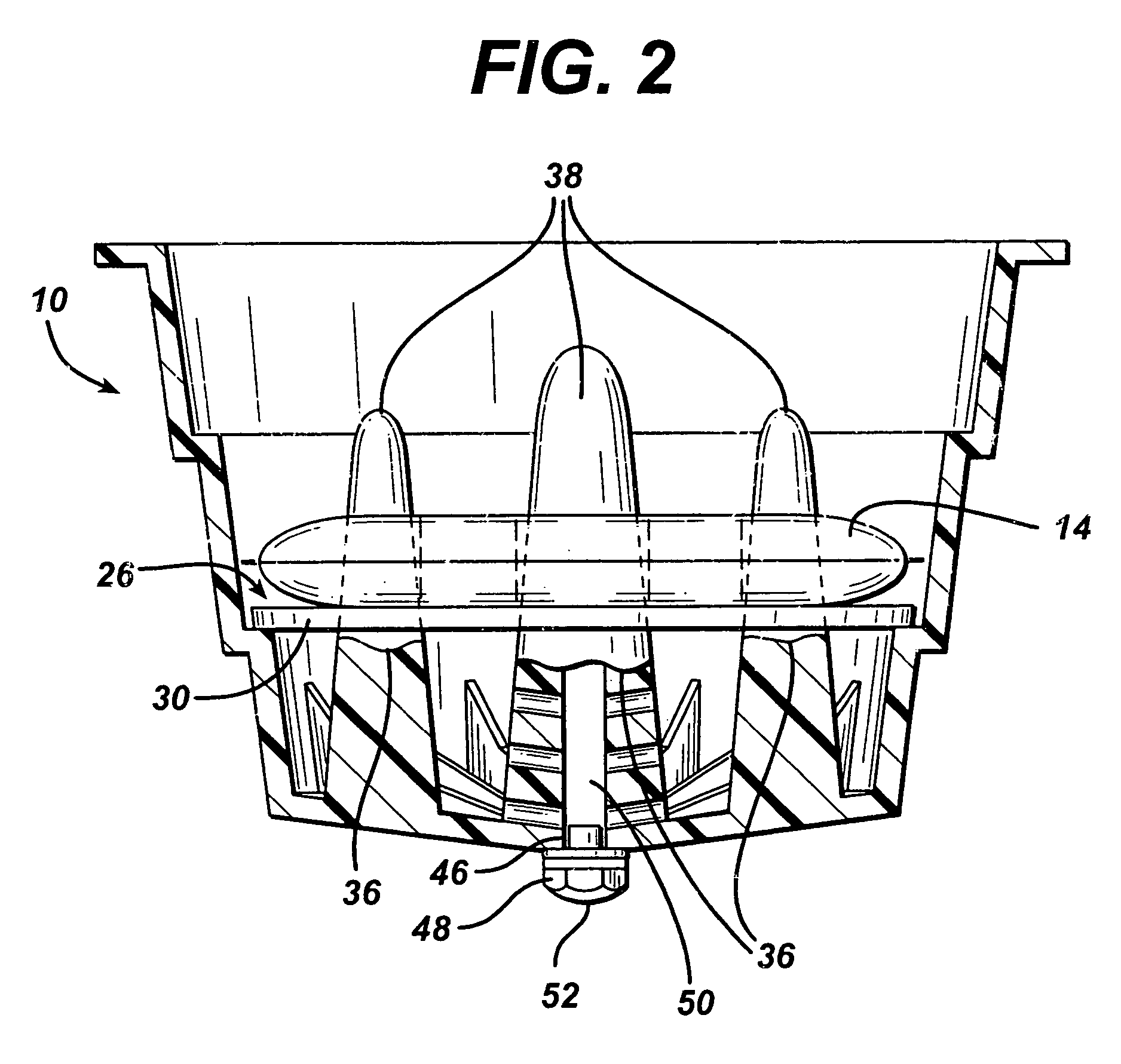

Process and capsule for preparing beverages

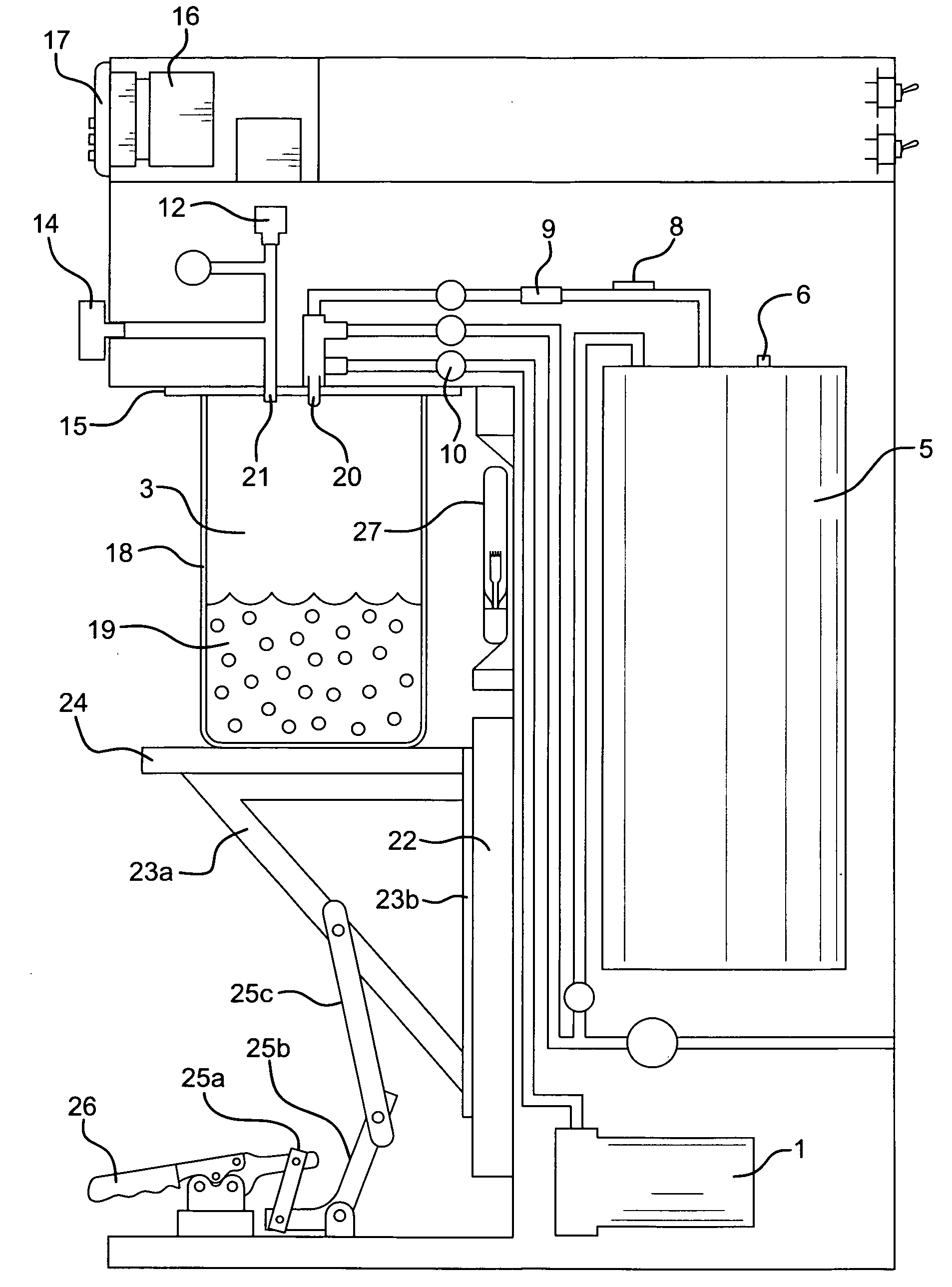

InactiveUS20090175986A1Obtain elasticityReduce pressureTea extractionTea substituesEngineeringBiomedical engineering

A single serve capsule (1) for the preparation of hot beverages such as coffee, cappuccino, tea or the like from soluble or ground preparations, having an outlet lid portion (1b) located on a dispensing wall (F) in order to form a dispensing opening (11) after a liquid has been introduced into the capsule, as well as means for changing the area of said dispensing opening during the dispensing step of the beverage.

Owner:TUTTOESPRESSO SPA (IT)

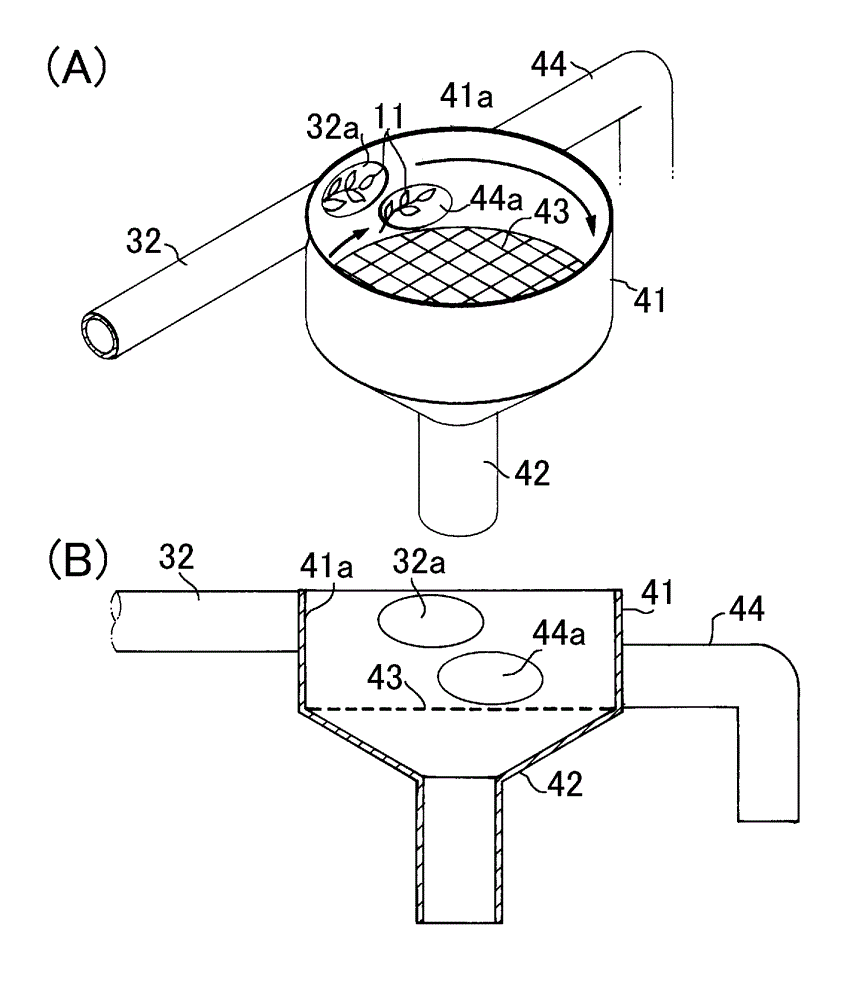

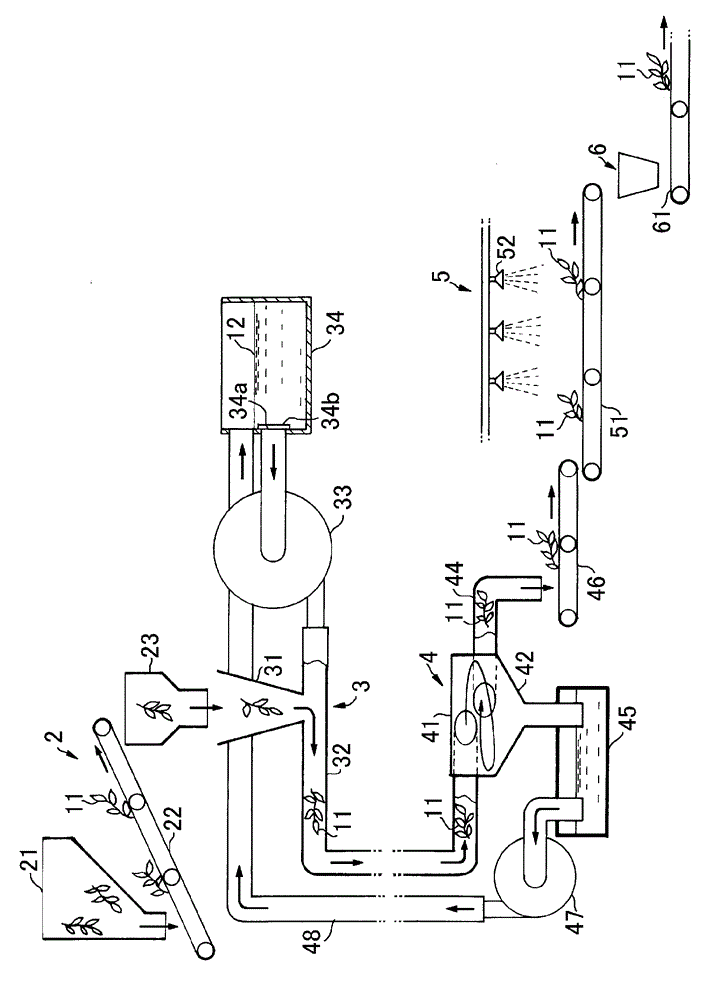

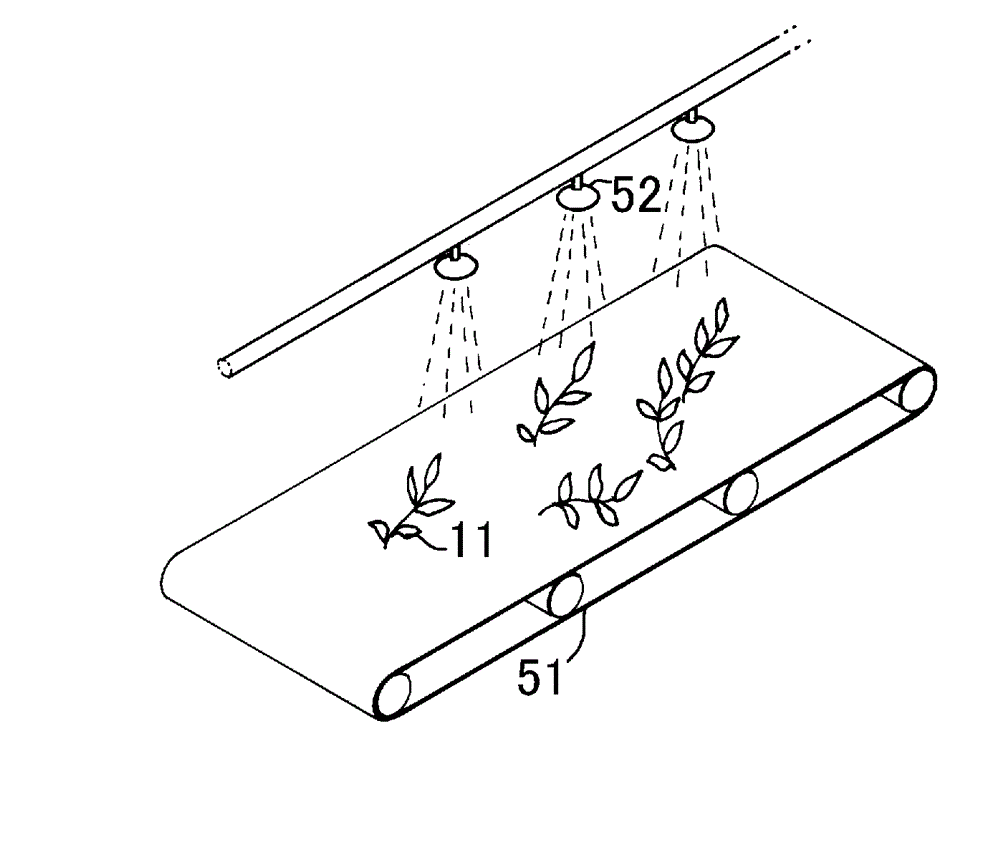

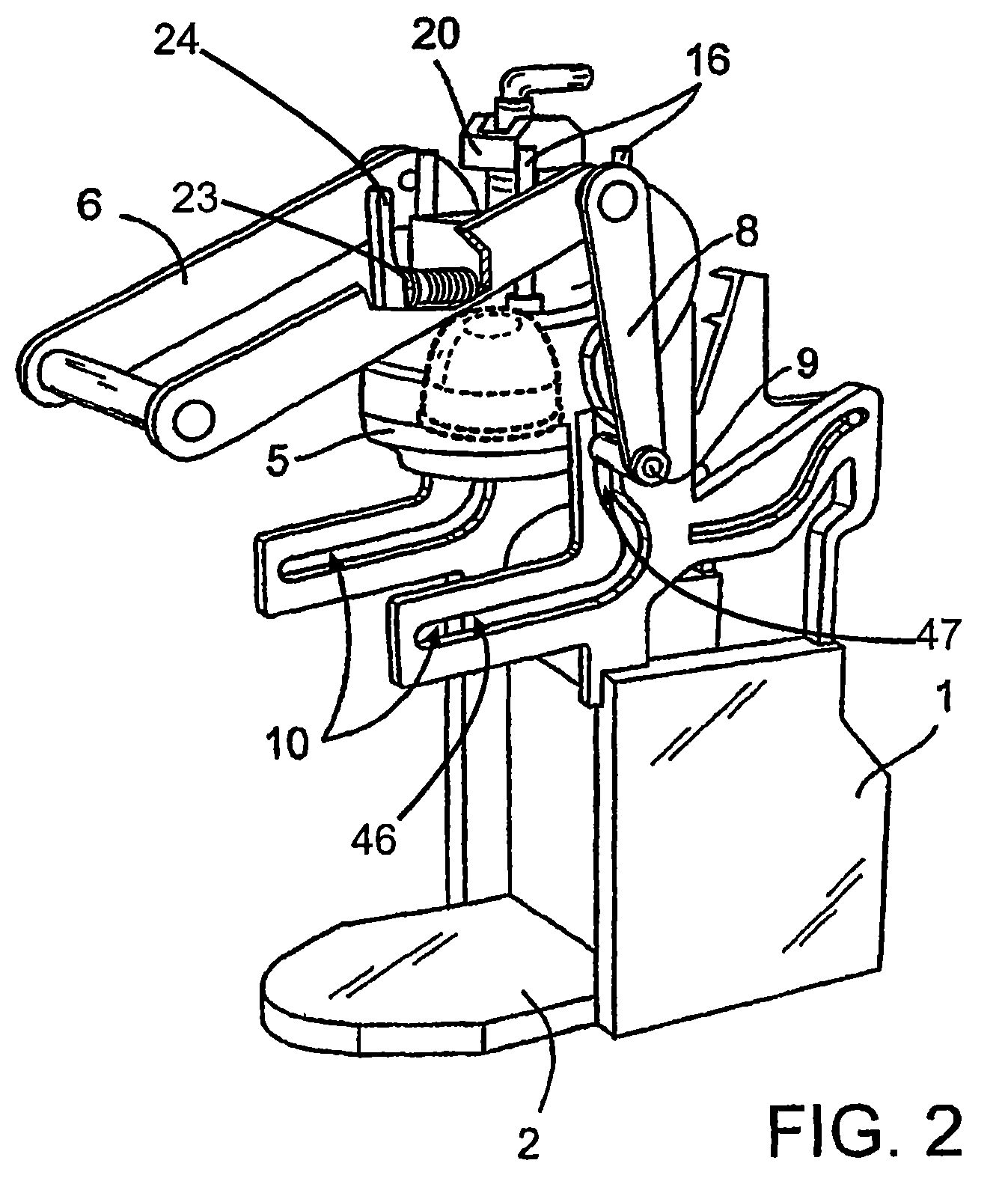

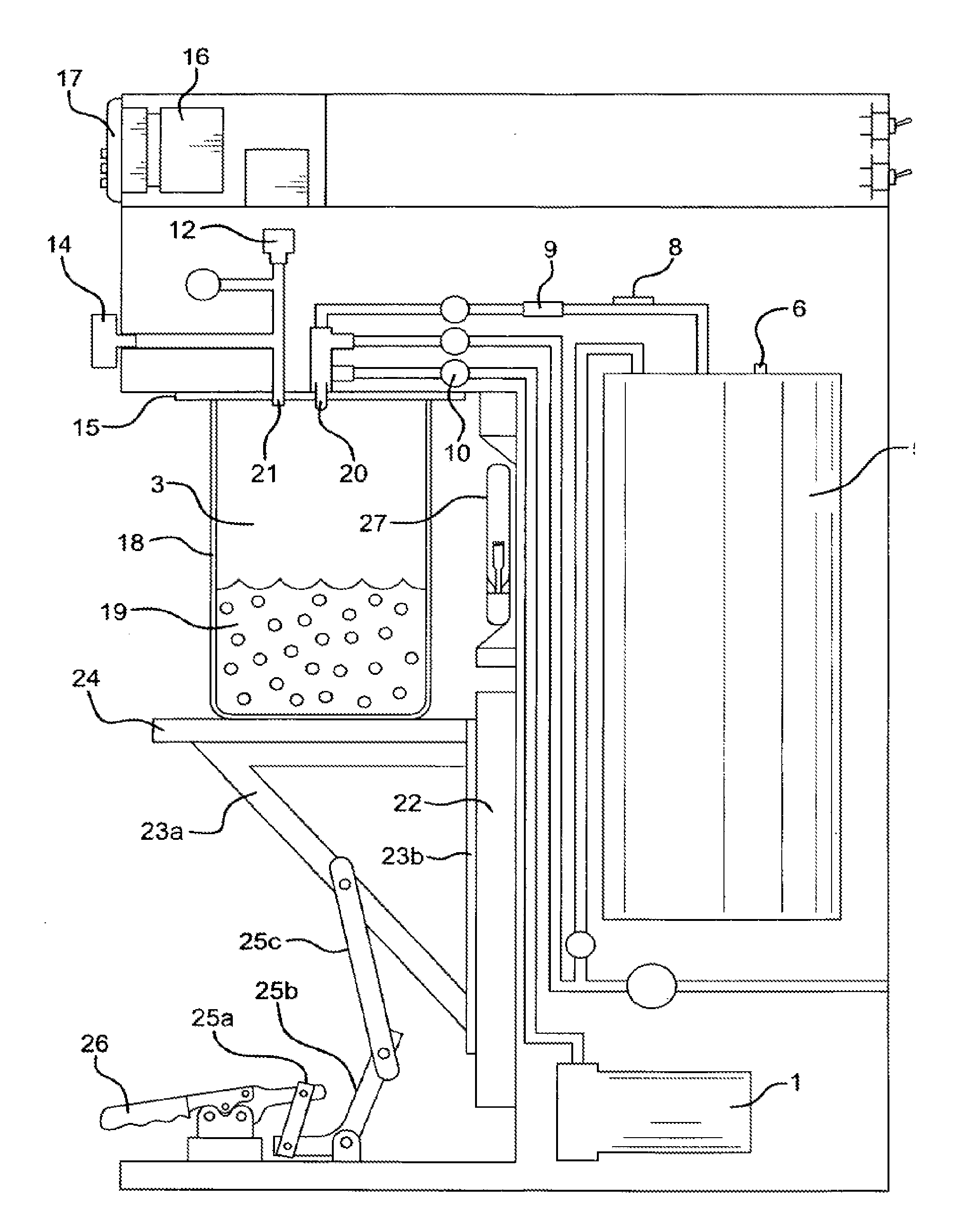

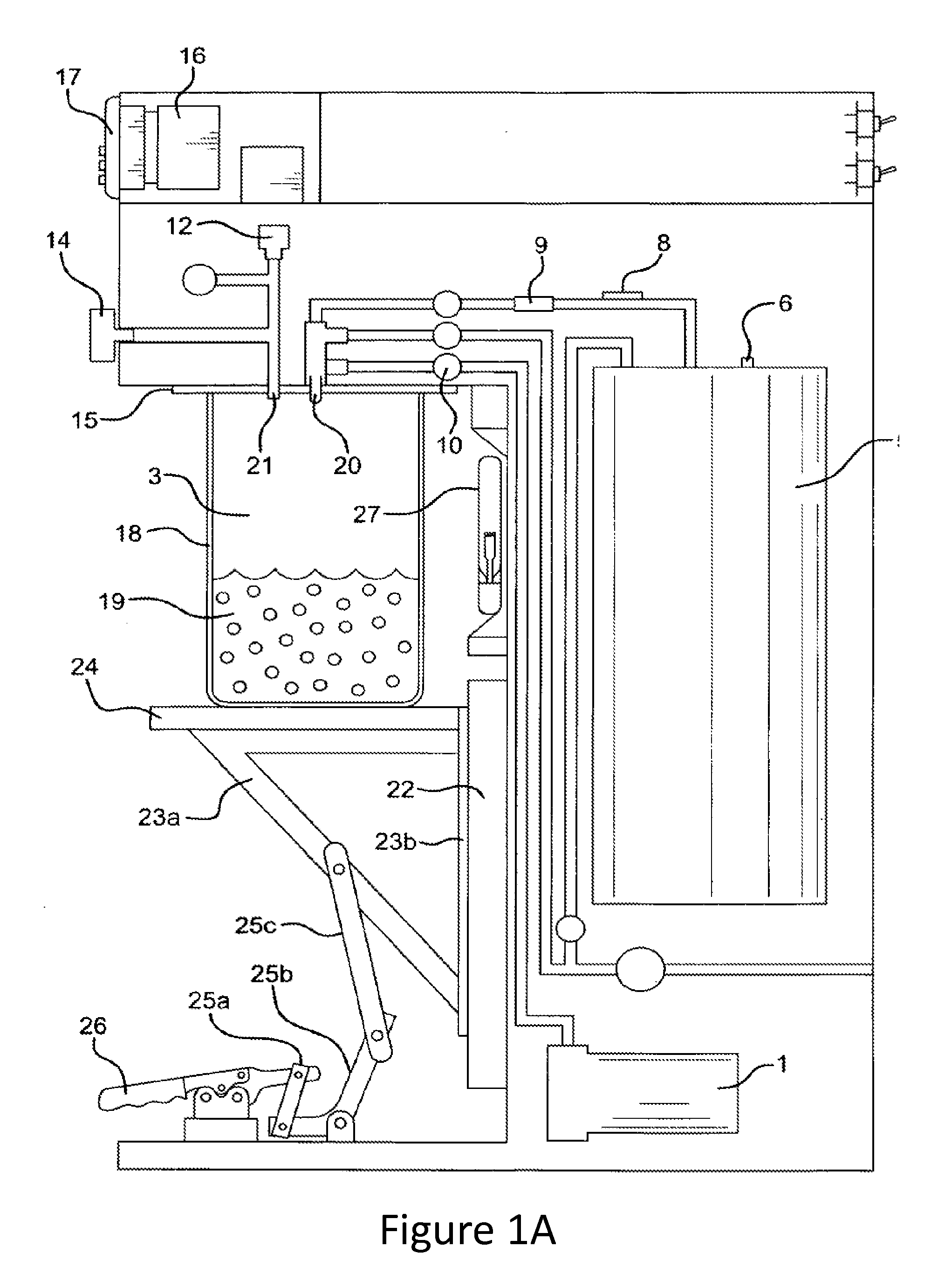

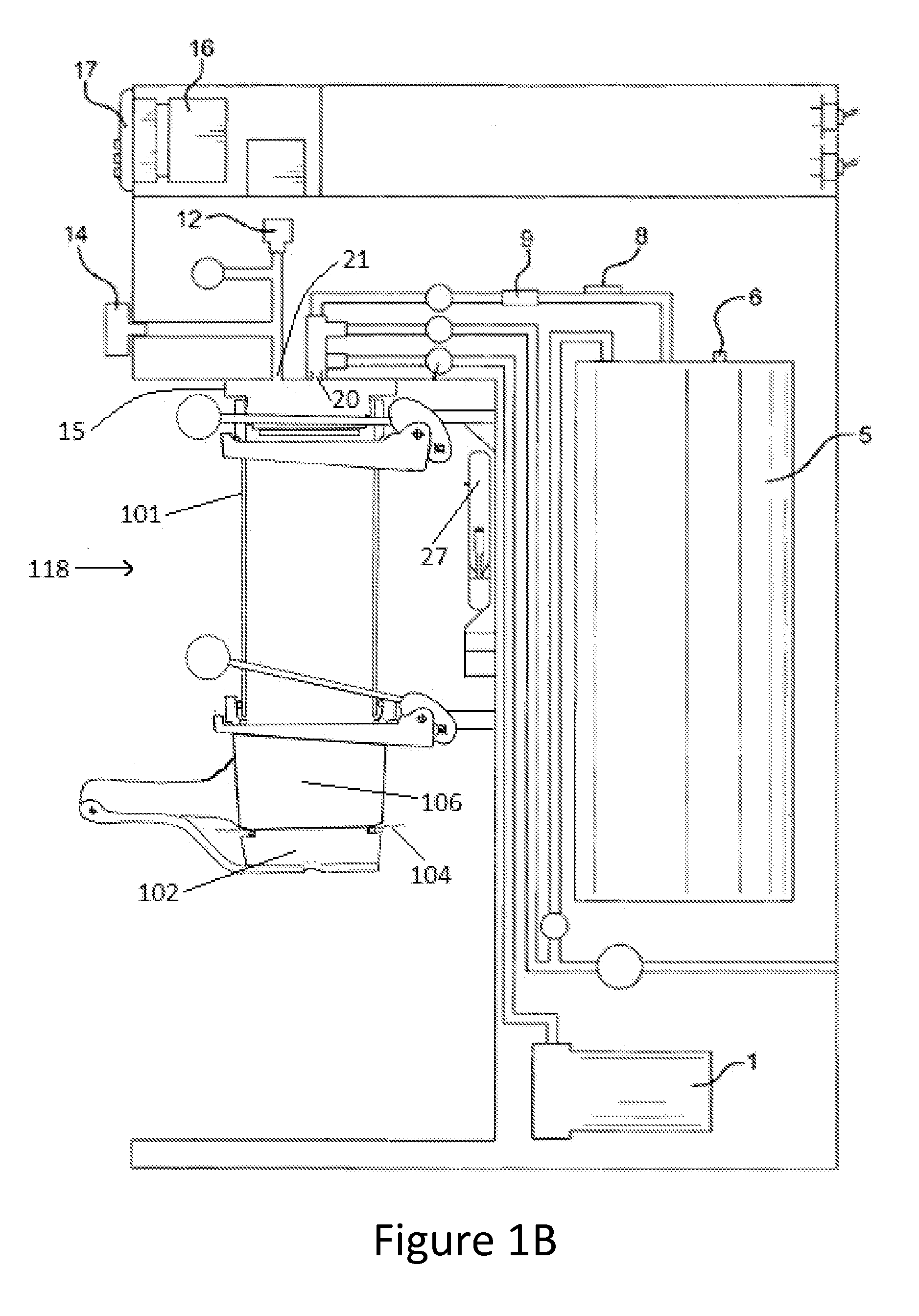

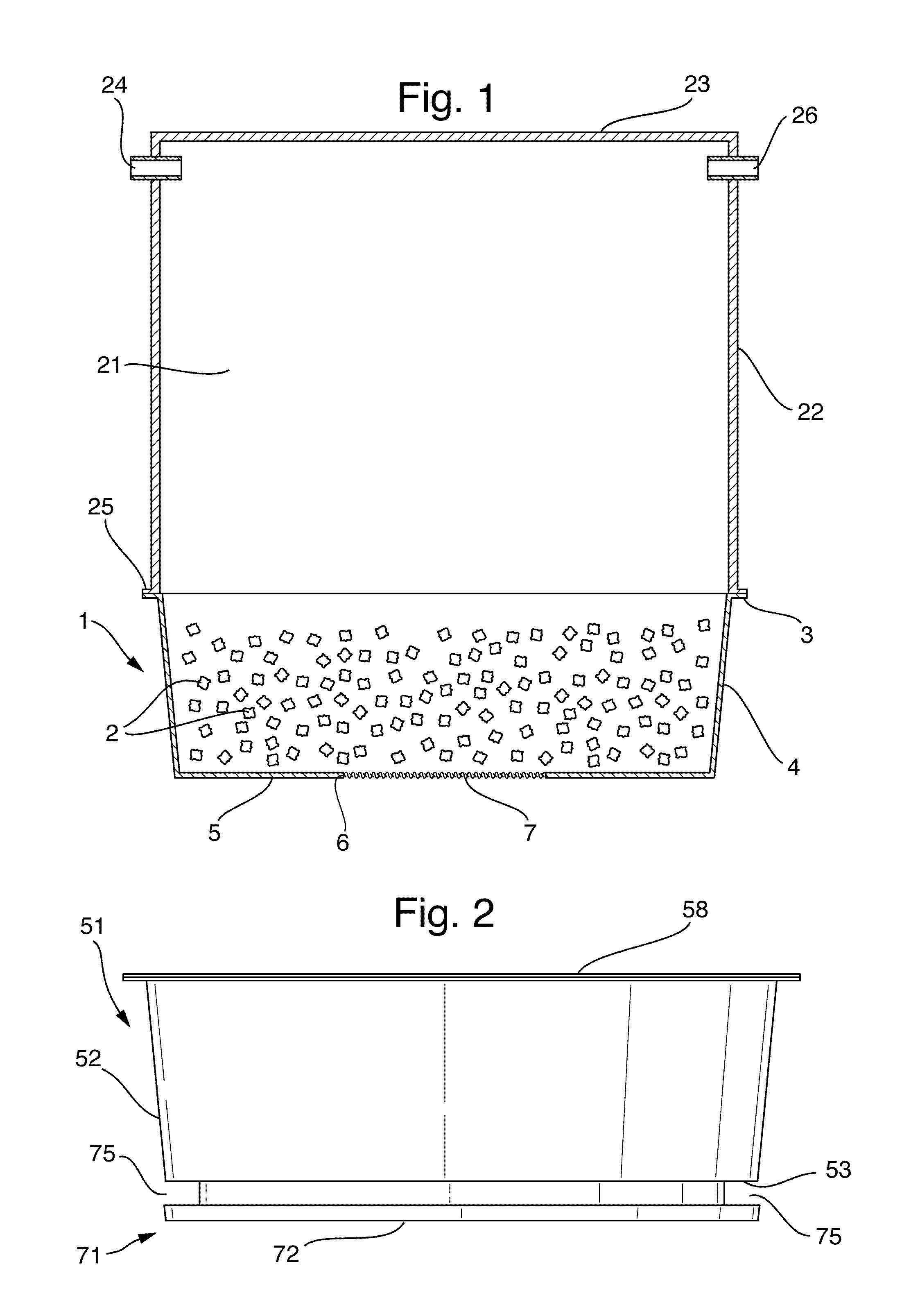

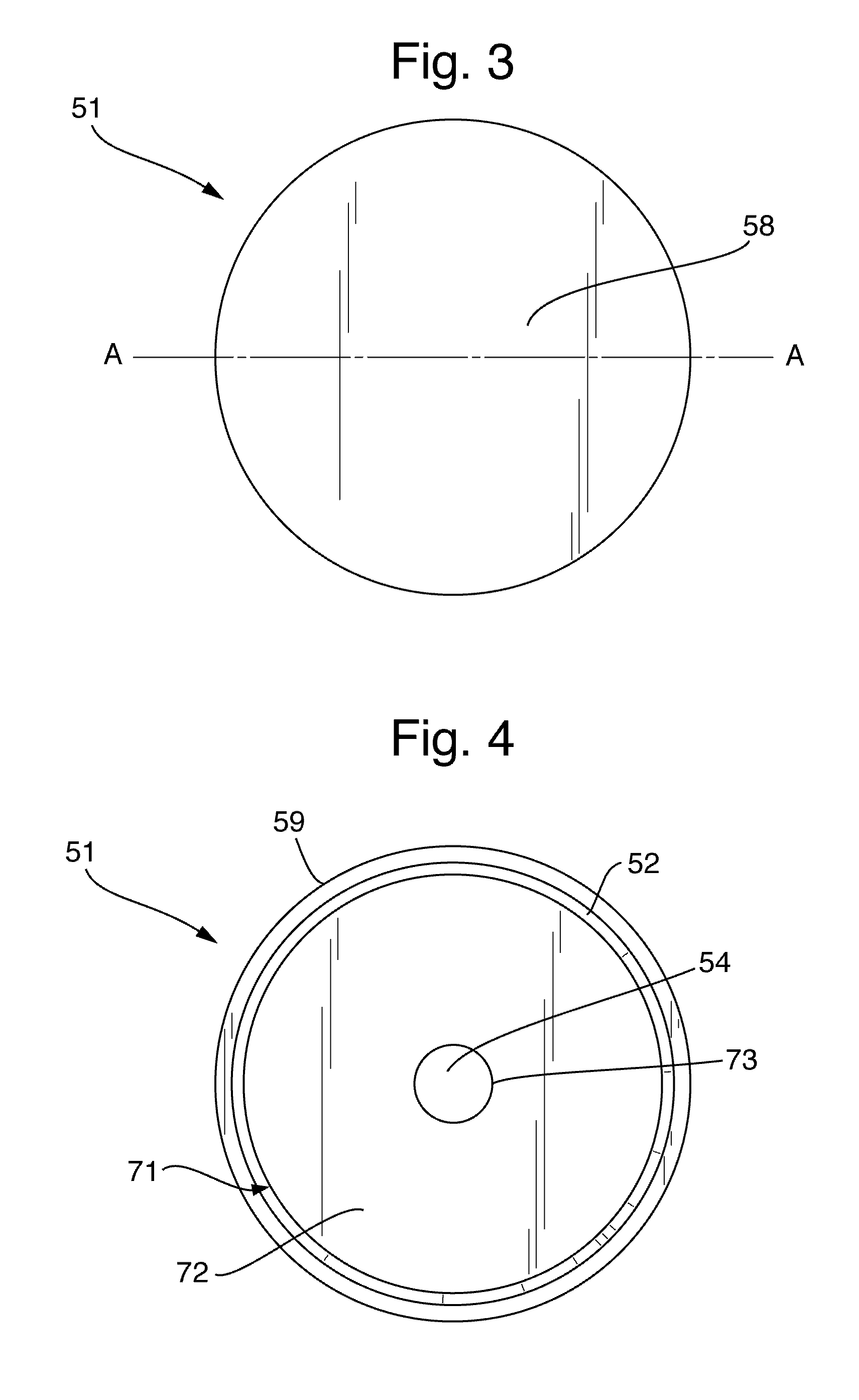

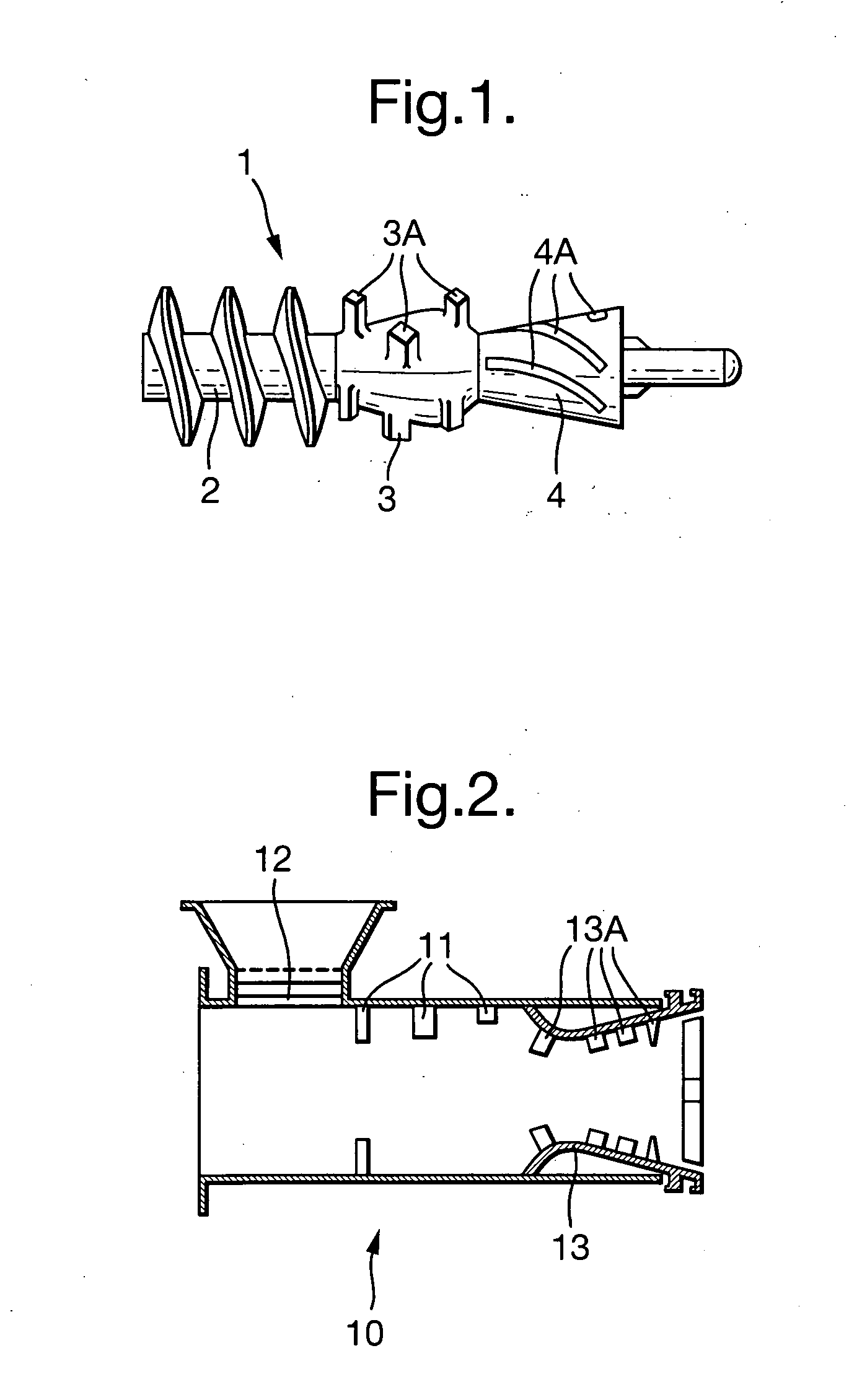

Tea leaf-transporting apparatus

InactiveCN102753029AHandling hygieneCuticle loweringPre-extraction tea treatmentTea alkaloid content reductionEngineeringThermal water

Provided is a tea leaf-transporting apparatus whereby it is possible to transport tea leaves in a sanitary manner. The tea leaf-transporting apparatus (1) is characterized by a configuration for transporting tea leaves (11) fed into a transportation pipe (32) which is configured from a metal pipe of stainless steel or the like, or a resin pipe of vinyl chloride or the like, by means of hot water (12), and a configuration for separating the hot water (12) and the tea leaves (11) which flow out of the transportation pipe (32). Additionally, adjusting factors such as the temperature of the hot water (12) or the amount of time that the tea leaves (11) remain in the transportation pipe (32) makes it possible to sterilize the tea leaves, deactivate oxidase, reduce the cuticular layer, and reduce the amount of caffeine as said tea leaves are transported.

Owner:SHOKUHIN SANGYO HIGH SEP

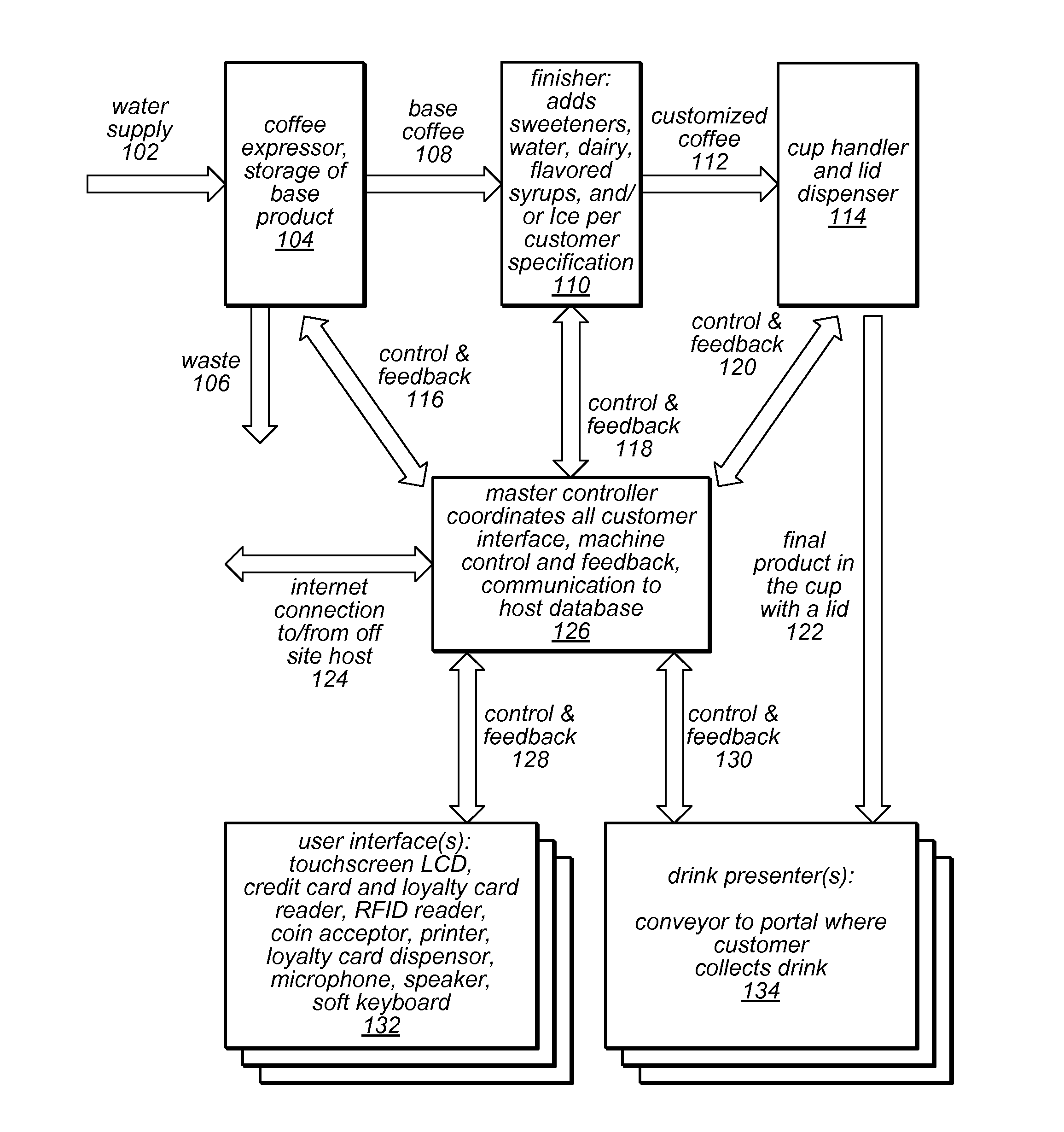

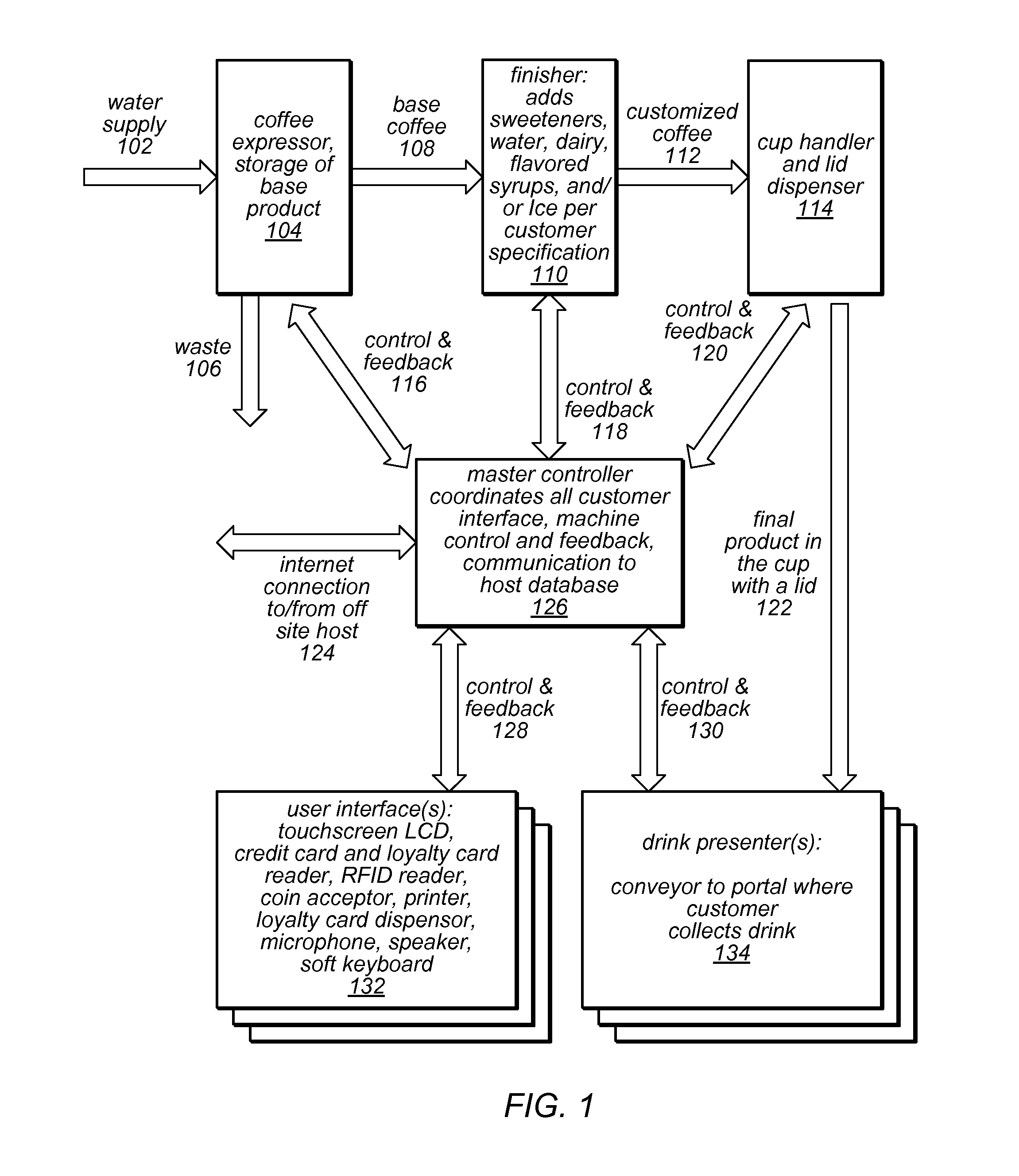

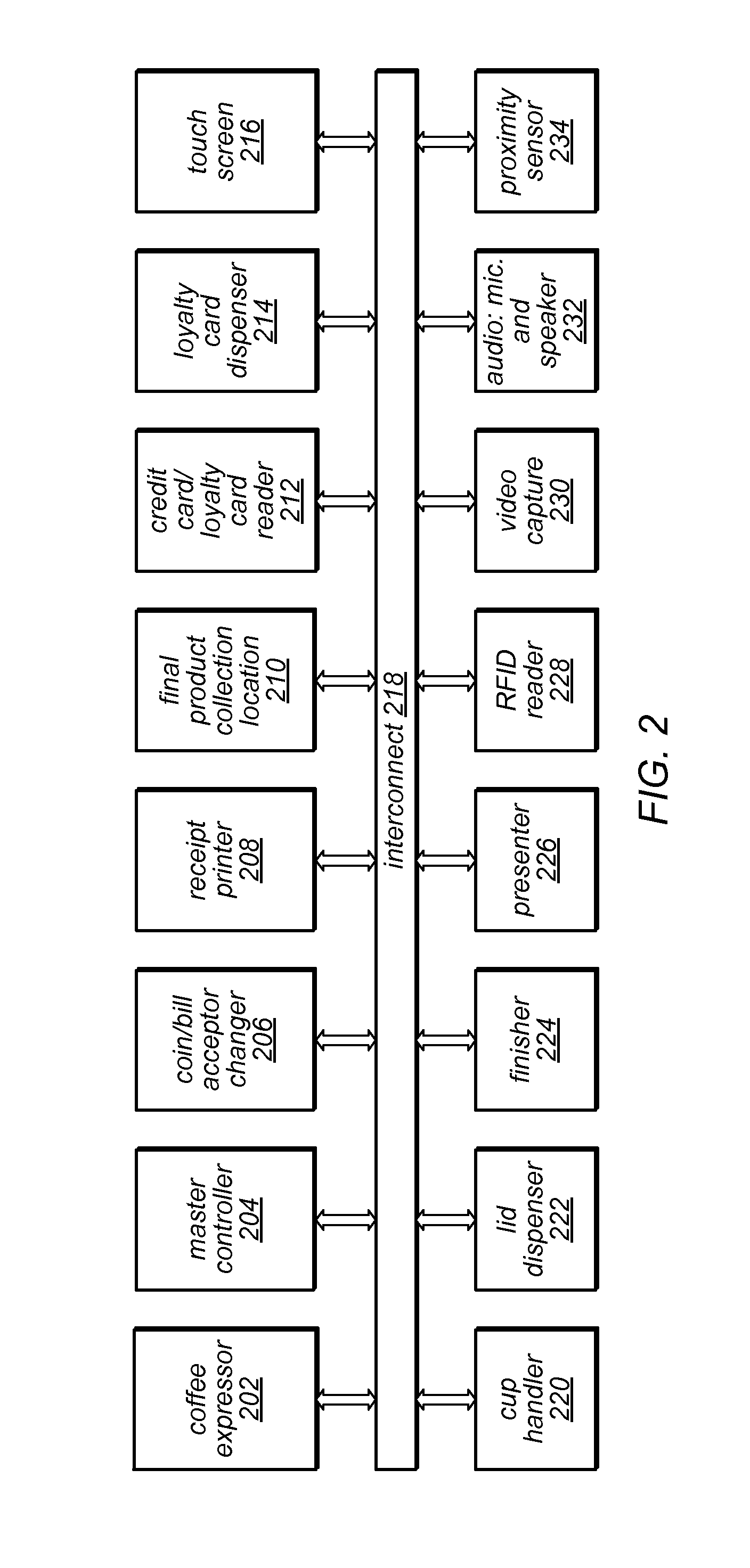

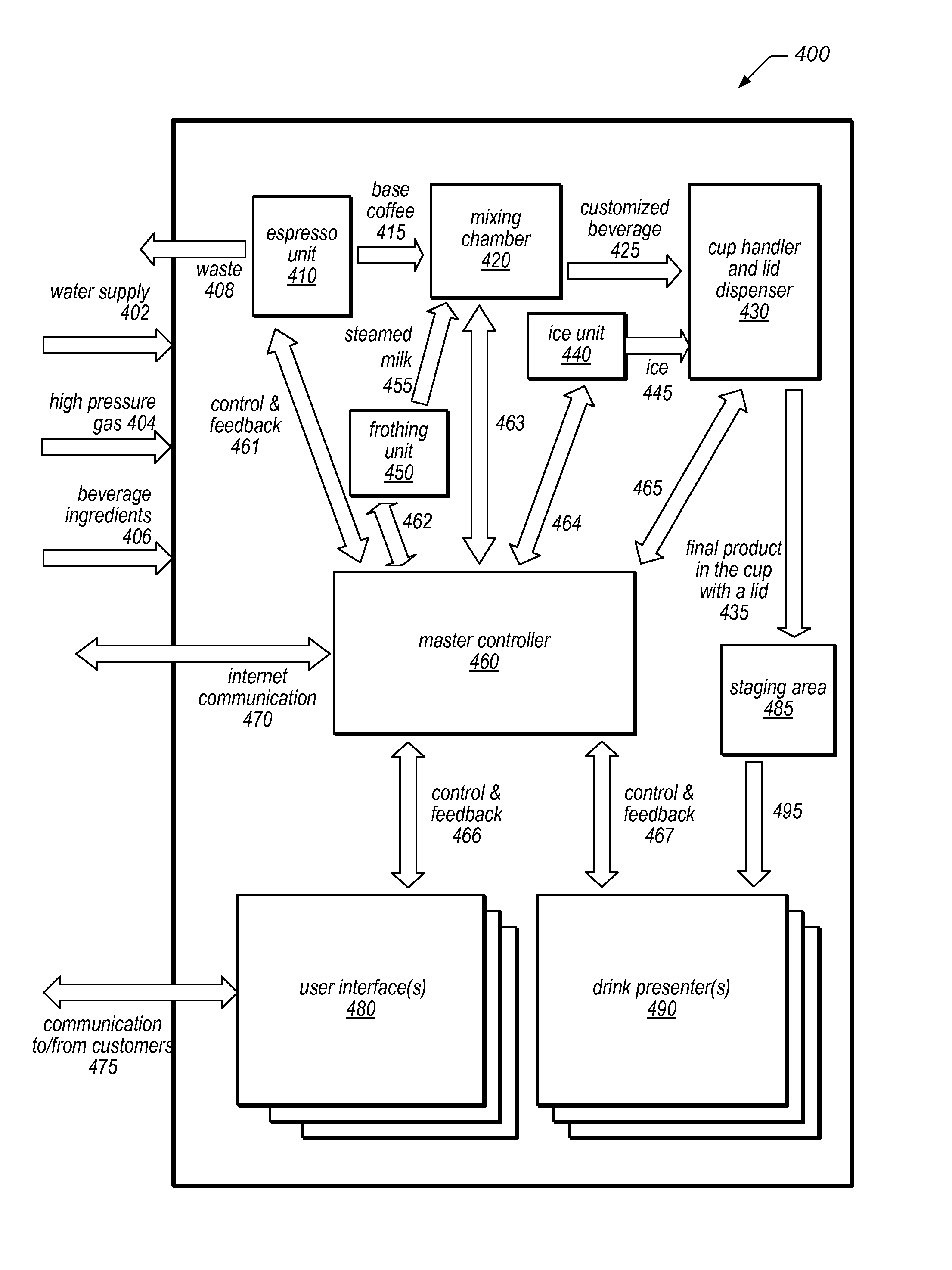

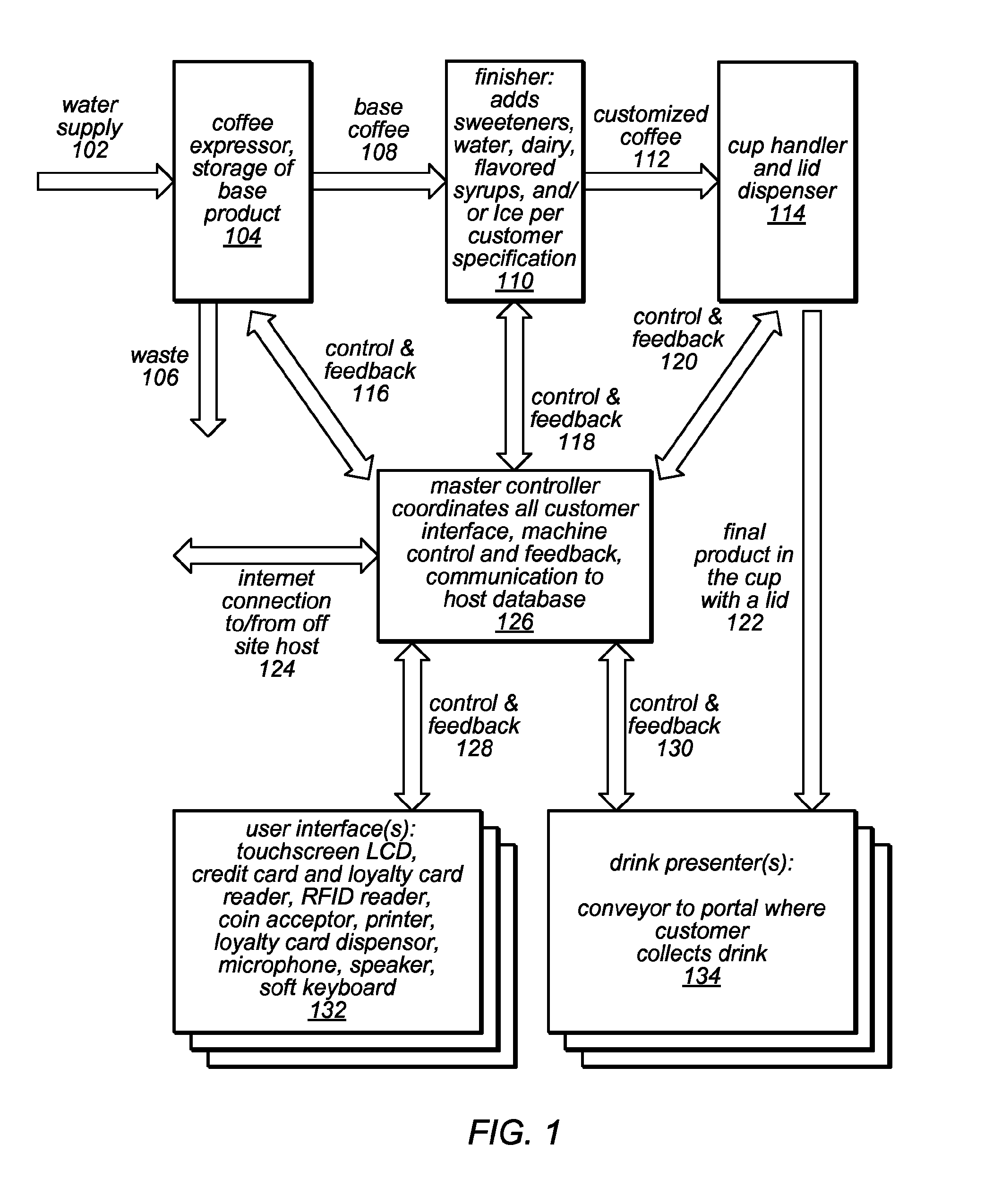

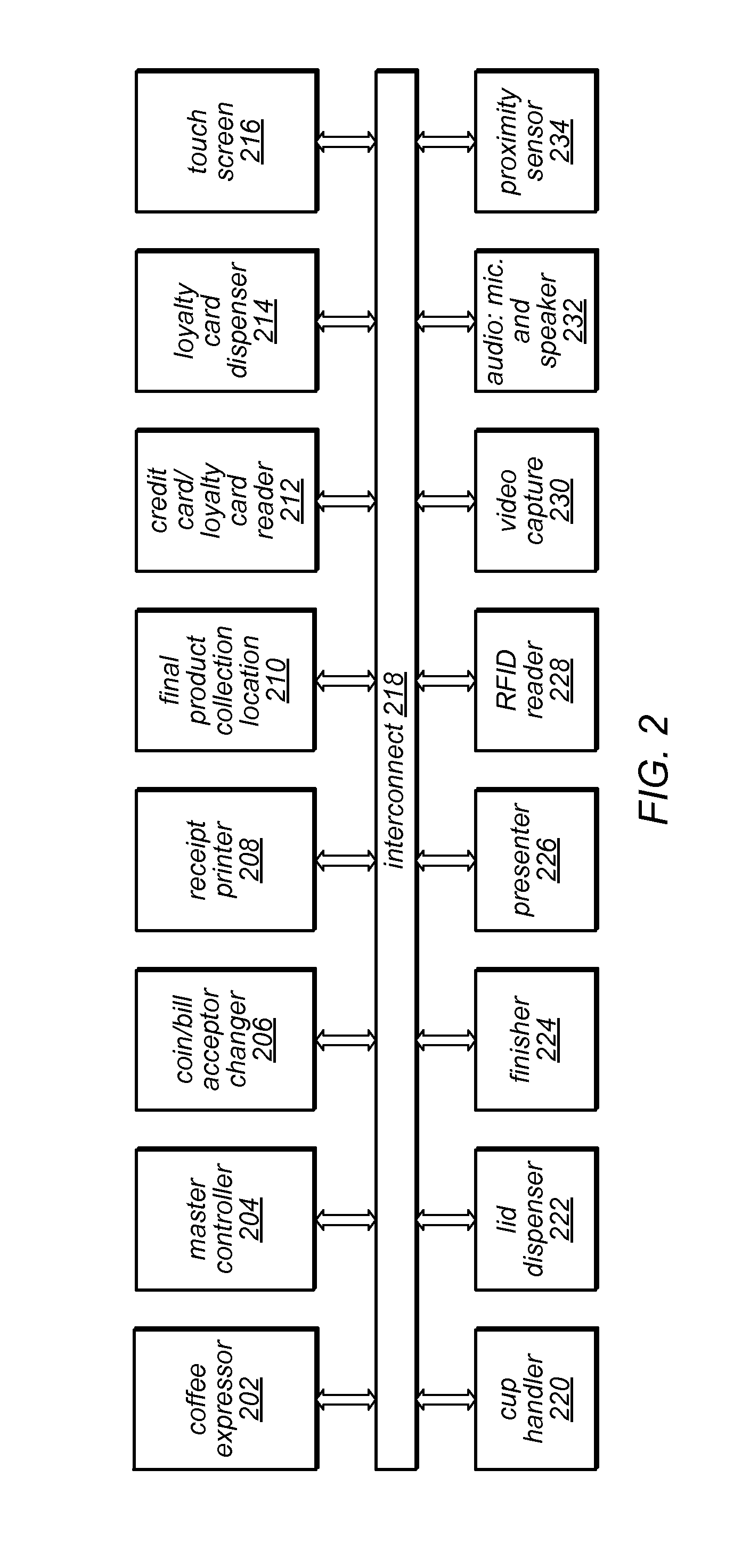

System and Method for Managing the Generation of Brewed Beverages Using Shared Resources

A system that generates brewed beverages may receive requests to produce specified brewed beverages. The system may include a scheduler that initiates and controls the performance of one or more chemical or mechanical processes to produce the beverages. While one chemical or mechanical process for producing a beverage is being performed, other processes may be performed for production of the beverage or another beverage. The scheduler may determine the time at which to perform each process, the time at which a beverage should be presented, the resources to be used to perform the processes, or the time at which to perform a cleaning process, dependent on an actual or expected demand for beverages, or dependent on a target time for beverage retrieval. Shared resources may be applied to the production of beverages for high priority orders, while partially completed beverages for lower priority orders are staged for subsequent advancement.

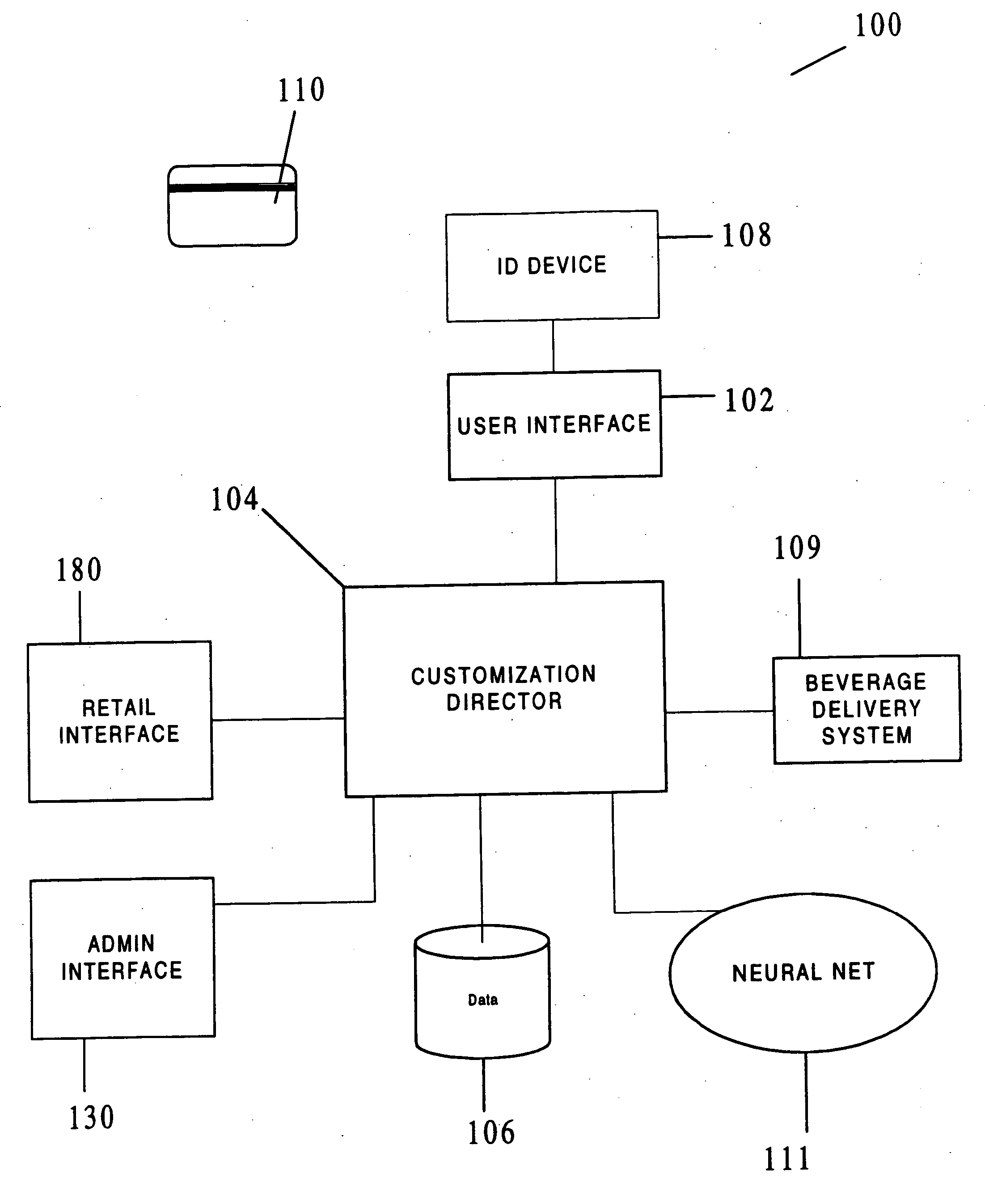

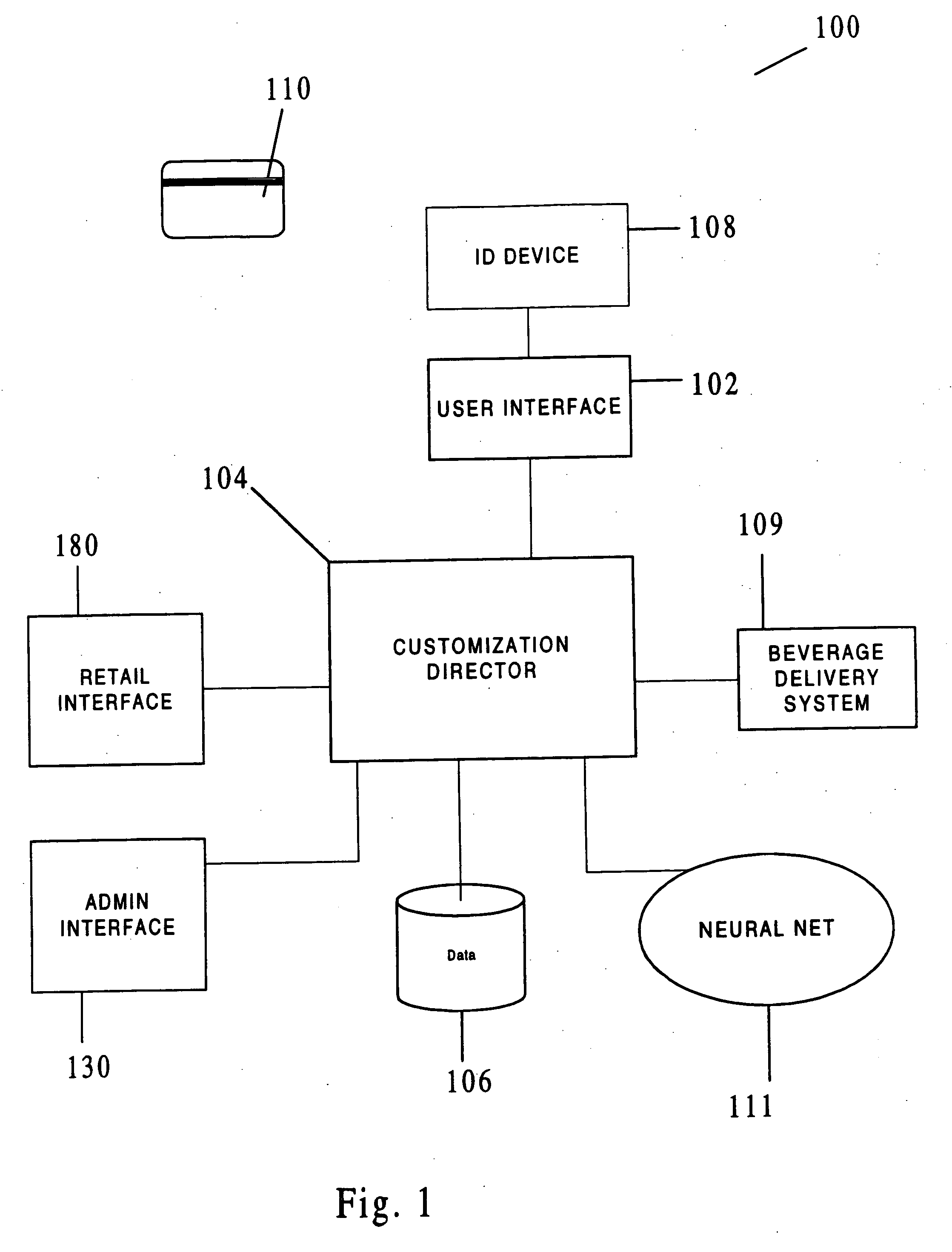

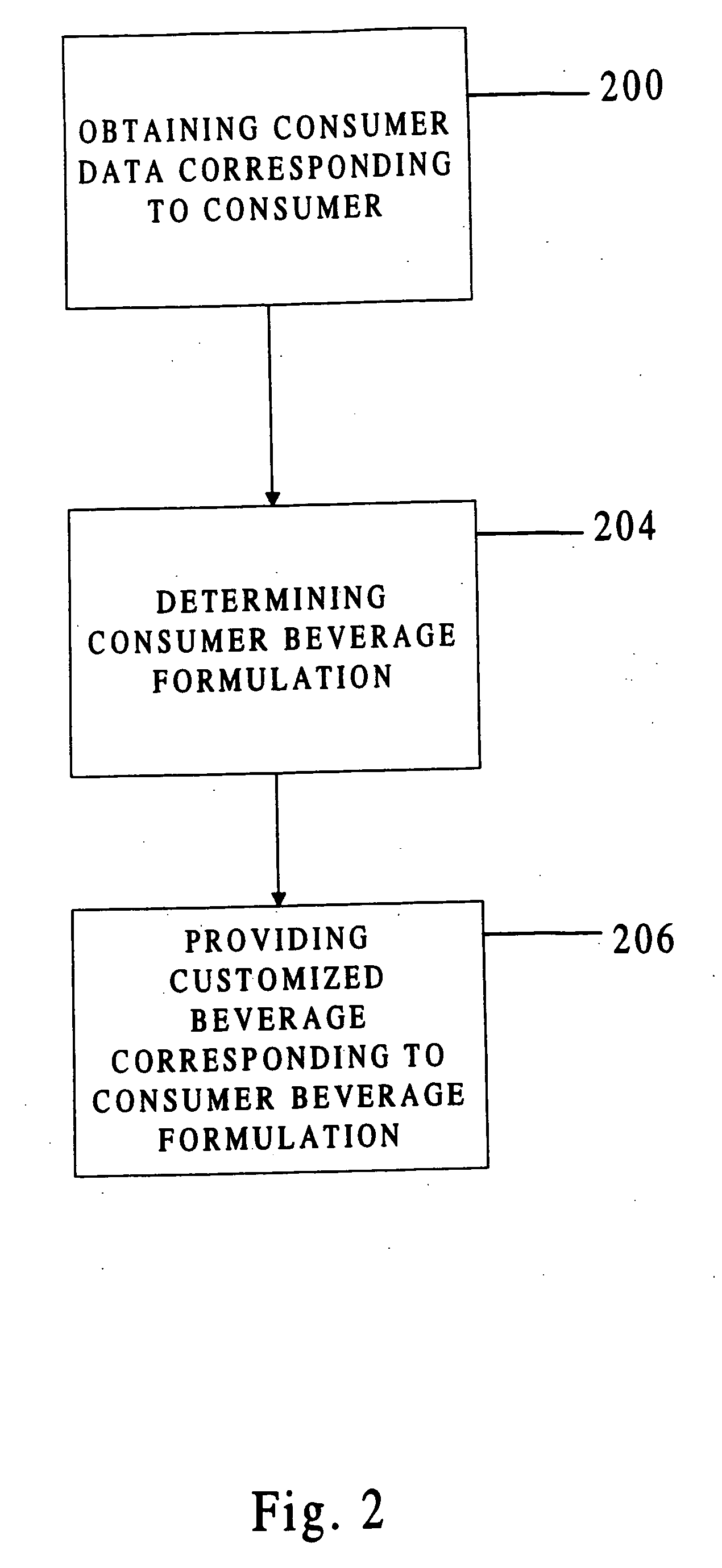

Methods and systems utilizing delayed dilution, mixing, and filtration for providing customized beverages on demand

InactiveUS20060188620A1Easy to useCredit registering devices actuationTea substituesSoftware engineeringData store

System for making and delivering a customized beverage product to a consumer having a user interface, a customization director in communication with a customization data store and the user interface, wherein the customization director includes executable instructions for determining a users customized formulation; and a beverage delivery system in communication with the customization director, wherein the beverage delivery system includes executable instructions for delivering a customized beverage product. Method for delivering a customized beverage product to an individual including the steps of obtaining consumer preference data; determining a consumer beverage formulation corresponding to the consumer preference data; and providing the consumer a customized beverage corresponding to the customized beverage formulation, utilizing one or more of delayed dilution, delayed mixing, and delayed filtering, in any order.

Owner:KNUDSEN JEANNETTE L +2

System and method for managing the generation of brewed beverages using shared resources

A system that generates brewed beverages may receive requests to produce specified brewed beverages. The system may include a scheduler that initiates and controls the performance of one or more chemical or mechanical processes to produce the beverages. While one chemical or mechanical process for producing a beverage is being performed, other processes may be performed for production of the beverage or another beverage. The scheduler may determine the time at which to perform each process, the time at which a beverage should be presented, the resources to be used to perform the processes, or the time at which to perform a cleaning process, dependent on an actual or expected demand for beverages, or dependent on a target time for beverage retrieval. Shared resources may be applied to the production of beverages for high priority orders, while partially completed beverages for lower priority orders are staged for subsequent advancement.

Owner:COSTA COFFEE

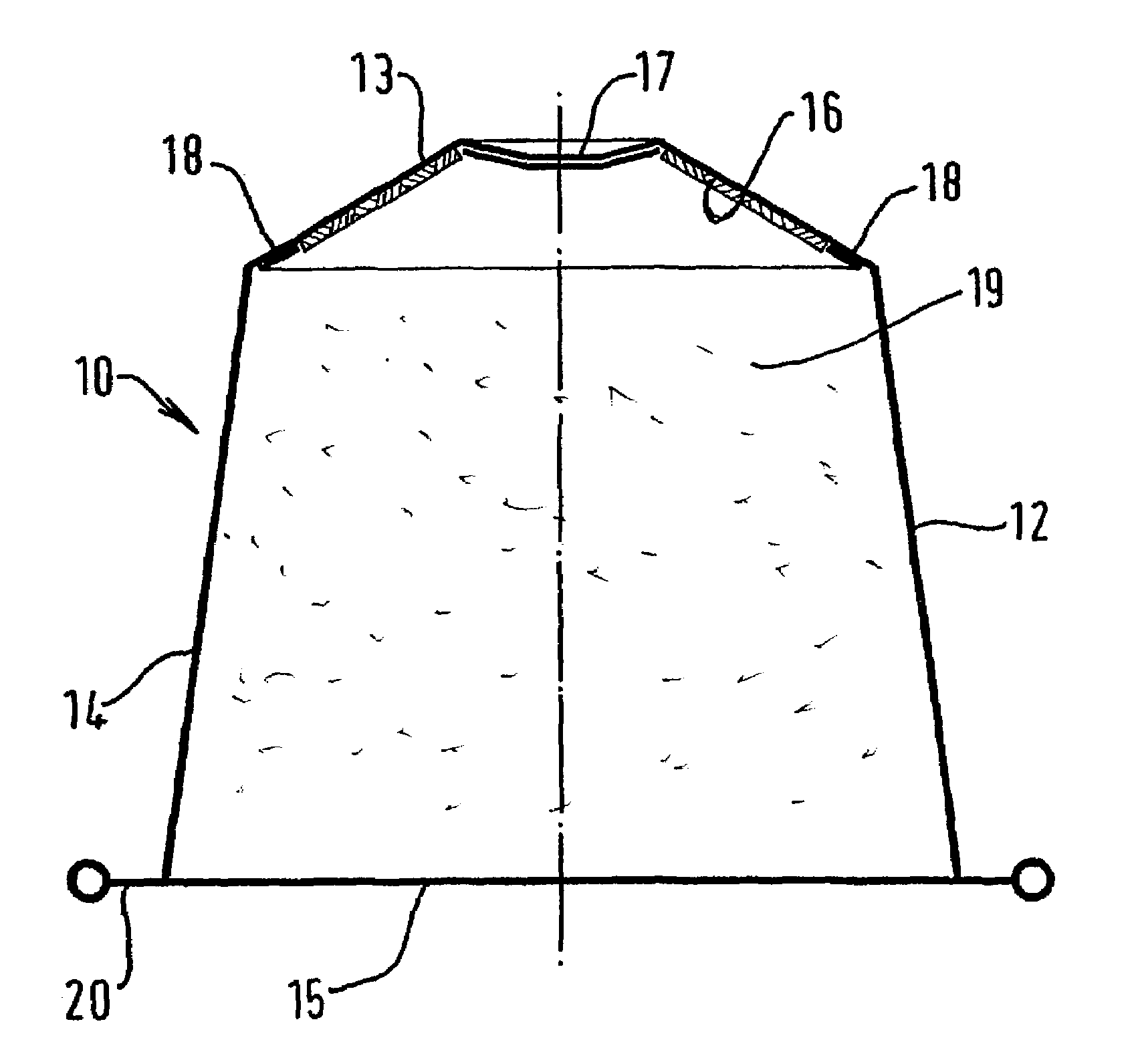

Closed cartridge for preparing a beverage for extraction under pressure

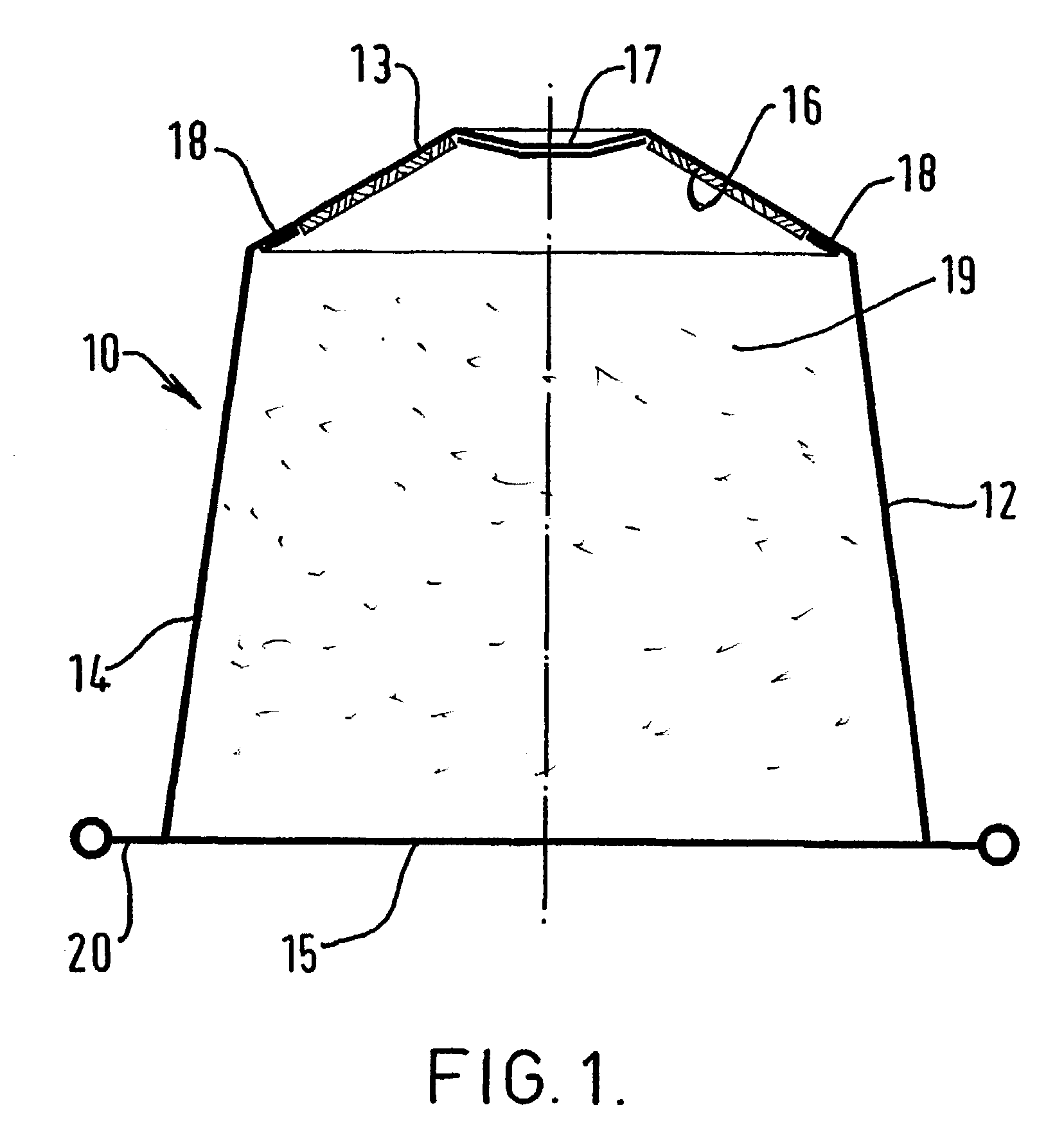

InactiveUS7153530B2Guaranteed retentionEasy to produceReady-for-oven doughsDispensing apparatusEngineeringFrustum

The present invention relates to a closed cartridge (10), for extraction under pressure, comprising a dish (12) with a bottom (13 ) with a central part and a peripheral part and a side wall having substantially the shape of a frustum of a cone and a circular edge with a diameter greater at the bottom and a cover (15) welded to the periphery of the edge of the dish and the cover is intended to be torn only through the effect of the force of the extraction fluid when extraction starts, the cartridge comprising, in the dish at the level of the bottom, a fabric (16) guaranteeing retention of the solid substance when it is opened,in which the fabric guaranteeing retention of solid substance is a sheet of fabric sealed in the bottom of the dish in two zones, on the one hand in the central part (17) and on the other hand in the peripheral part (18) of the bottom (13).

Owner:SOC DES PROD NESTLE SA

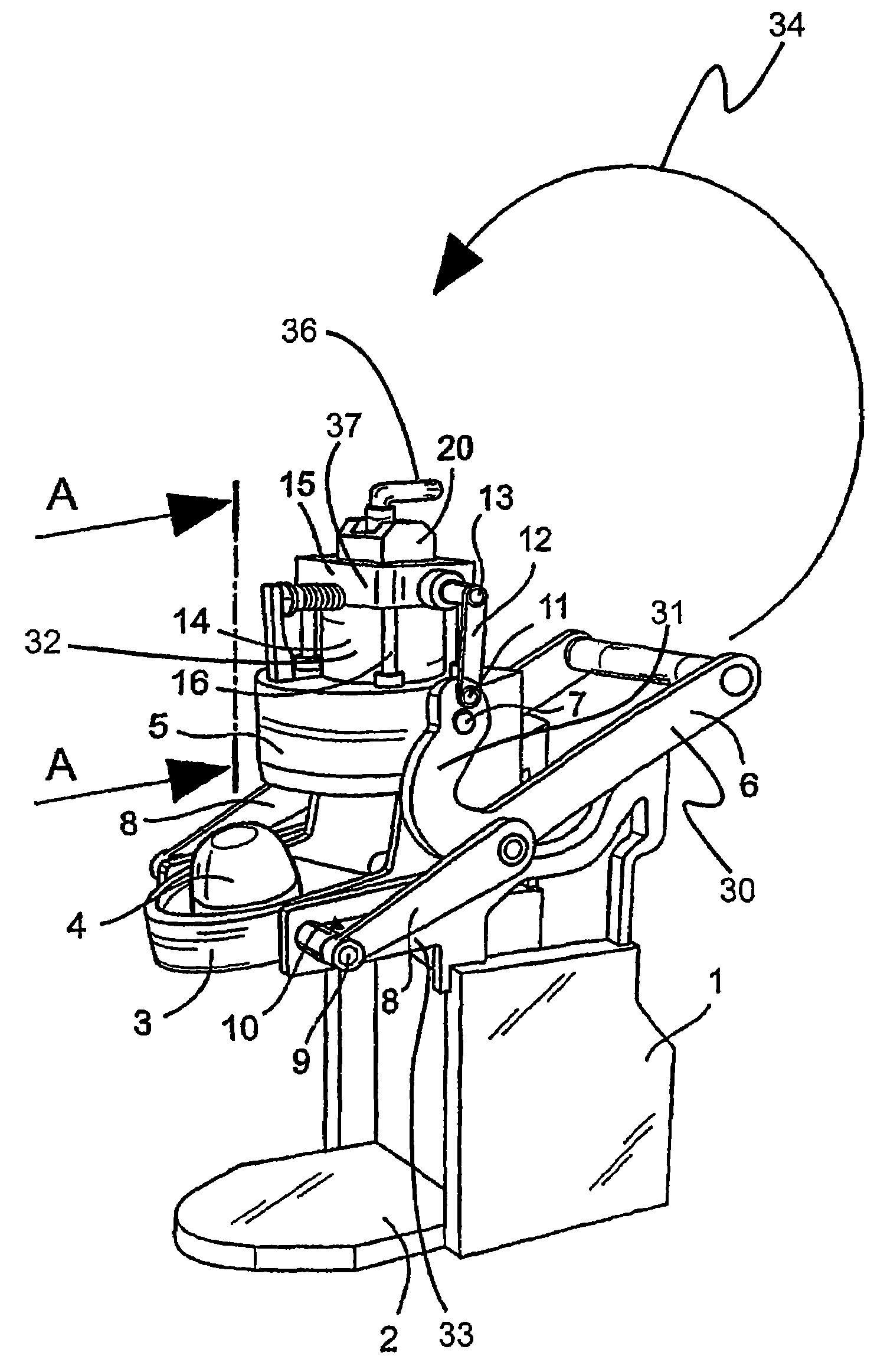

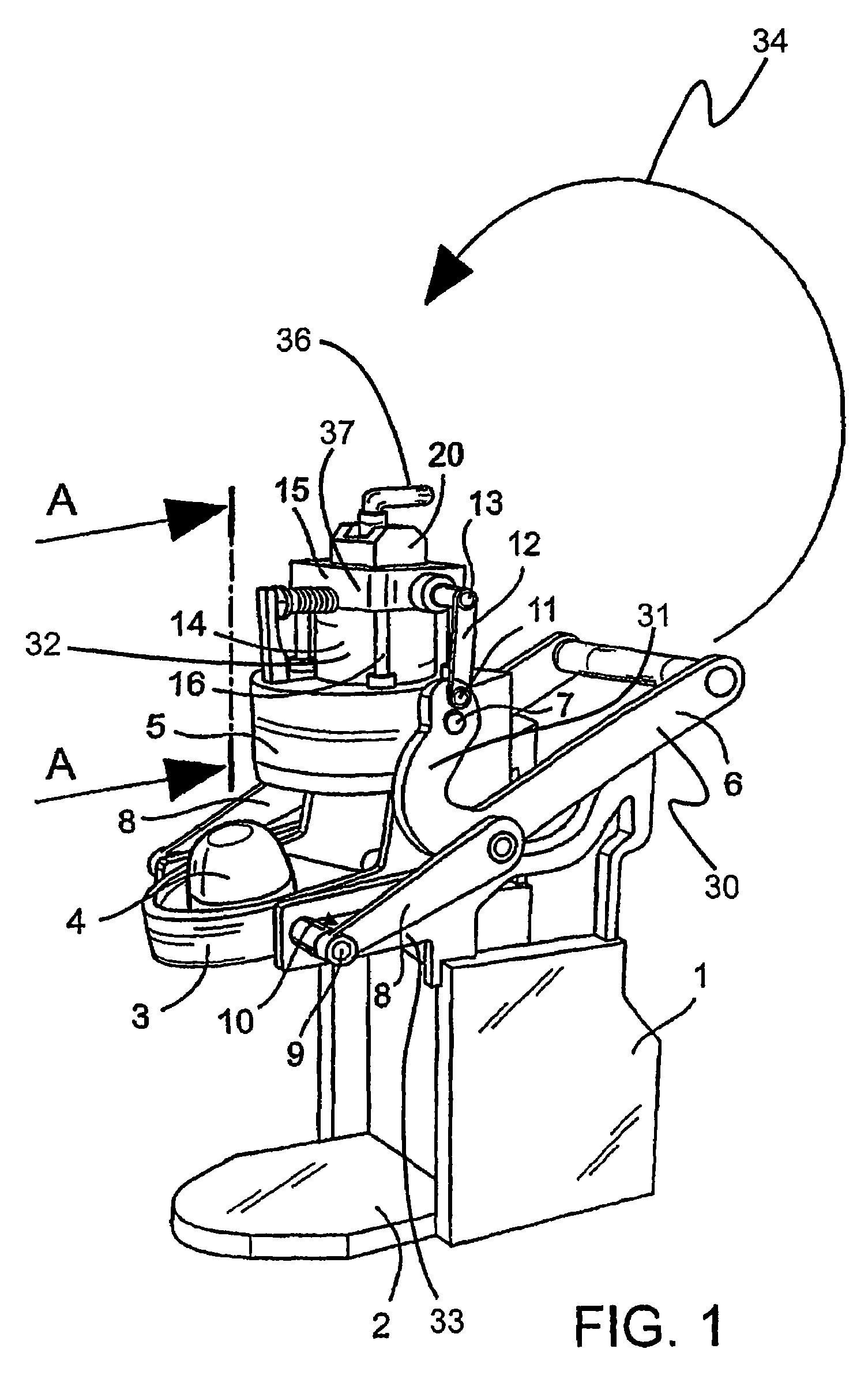

Methods of preparing a food product from a cartridge

Percolating device, for example intended to equip a coffee machine, having a percolating chamber mounted in such a way that it can carry out a displacement in the vertical direction when a control handle is operated. A cap receiving a capsule of product to be infused is also displaced, when the handle is operated, towards the inside of the percolating chamber. A percolating head sliding freely inside the percolating chamber can occupy different relative positions inside the percolating chamber according to the size of the capsule loaded into the cap. A stop device makes it possible to lock the percolating head in a definite position in order to inject steam and / or water through the percolating head.

Owner:SOC DES PROD NESTLE SA +1

Green tea formulations and methods of preparation

ActiveUS20050287278A1Large doseWell received naturalTea extractionTea substituesIntracellular substanceFood flavor

Green tea formulations and methods for the preparation thereof are disclosed and described. Generally speaking, the method of preparation includes the mixing of fresh tea leaves in an amount of cold water, followed by pulverization of the leaves to release their intracellular material from the cells of the green tea leaves into the water and form an aqueous extract component. The remaining cellular material forms a leaf residue component which is removed from the mixture. Once the leaf residue is removed, the aqueous extract component is collected and may be dried or further processed to produce a final tea extract that has good natural color, robust natural flavor, and pleasant organoleptic properties, which also is high in polyphenol content, and may be used for various purposes such as the creation of a green tea beverage.

Owner:XEL HERBACEUTICALS INC

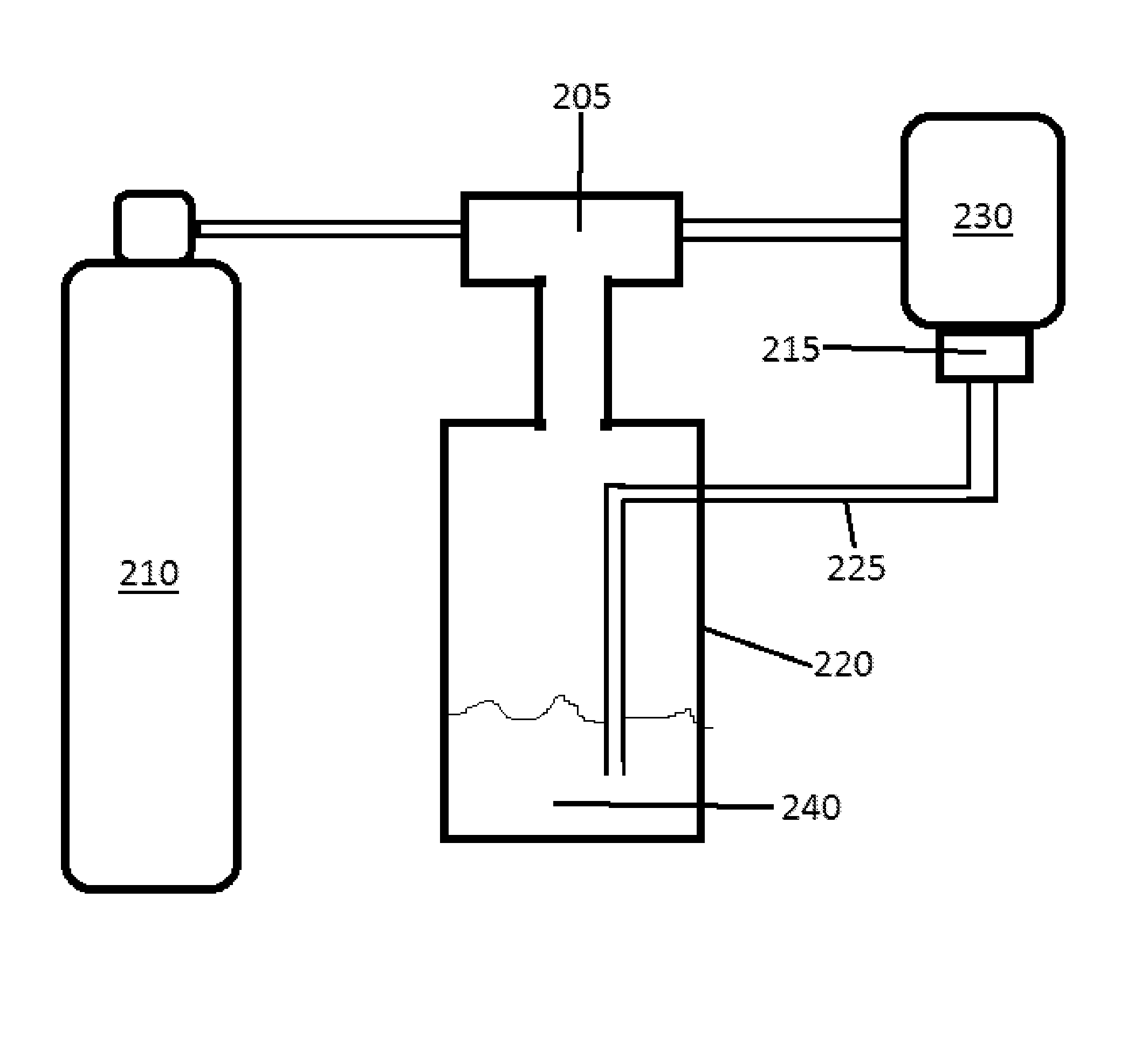

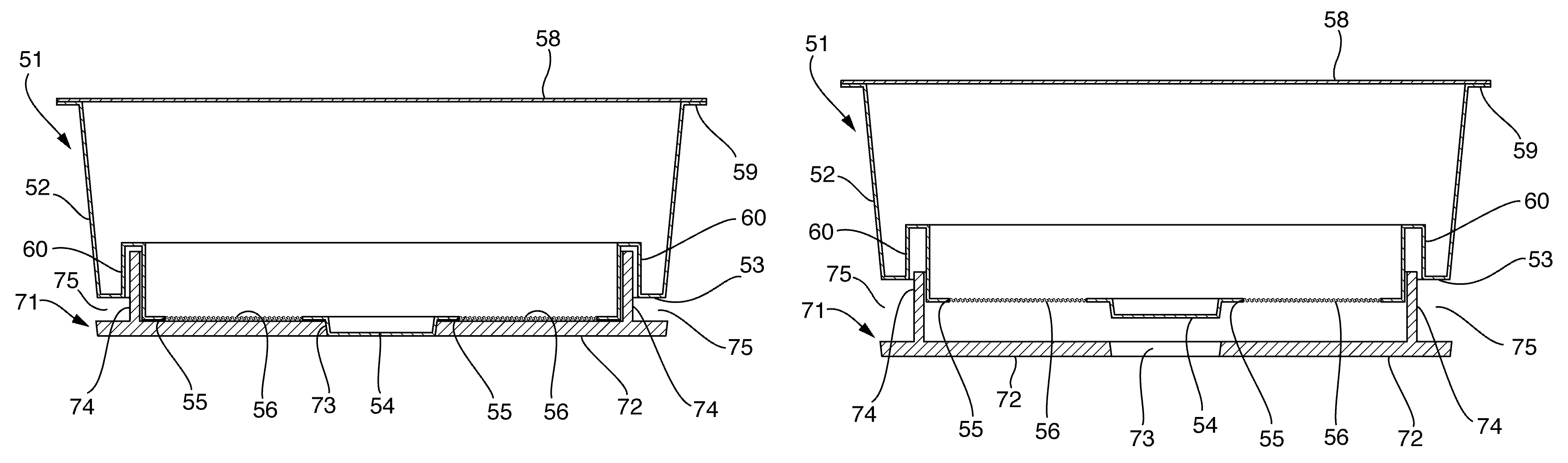

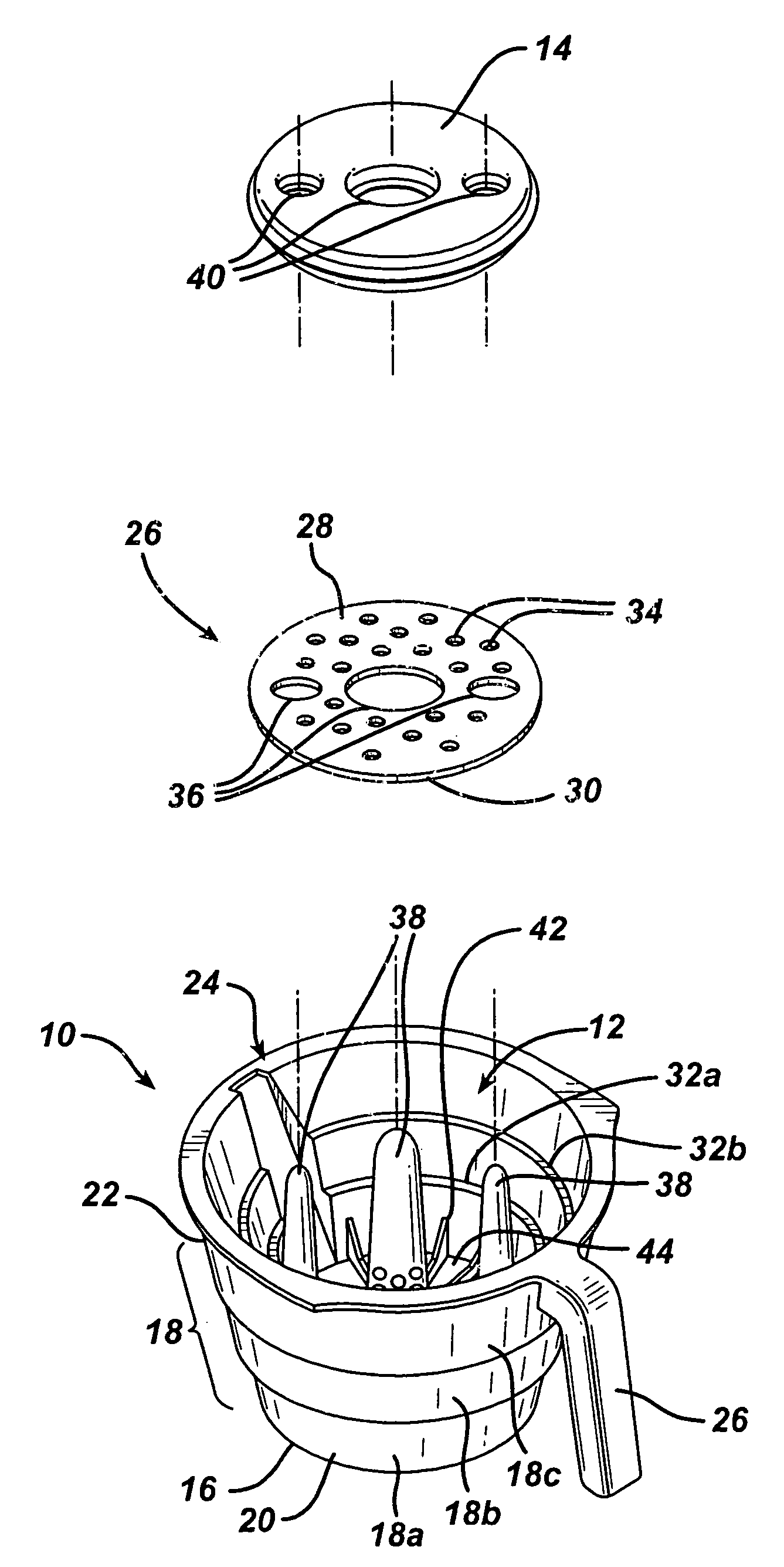

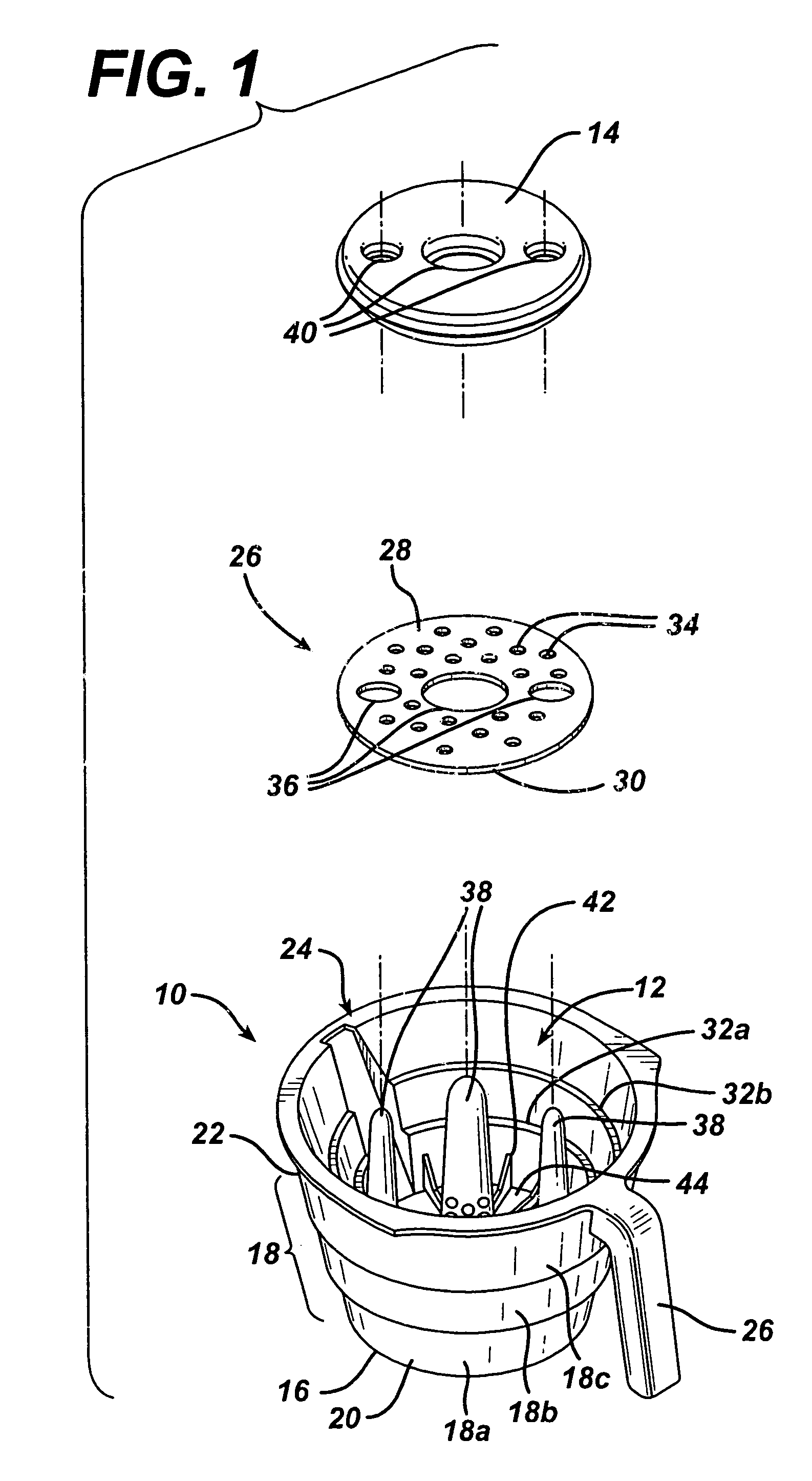

Liquid infusion process and method of brewing a beverage

ActiveUS8586117B2Enhance stirringIncrease ratingsTea extractionTea substituesPressure cycleEngineering

A liquid infusion and / or brewing process is described. The process includes the steps of placing a desired amount of an infusion material into a chamber at atmospheric pressure, placing a desired amount of liquid into said chamber, sealing said chamber from the surrounding atmosphere, and applying at least one reduced pressure cycle within said chamber, wherein said at least one cycle includes reducing pressure within said chamber to form at least a partial vacuum within said chamber and subsequently returning said chamber to about atmospheric pressure. Methods for separating the brewing media from the liquid after completion of the brewing process are also described.

Owner:BKON

Method for preparing a beverage from a capsule

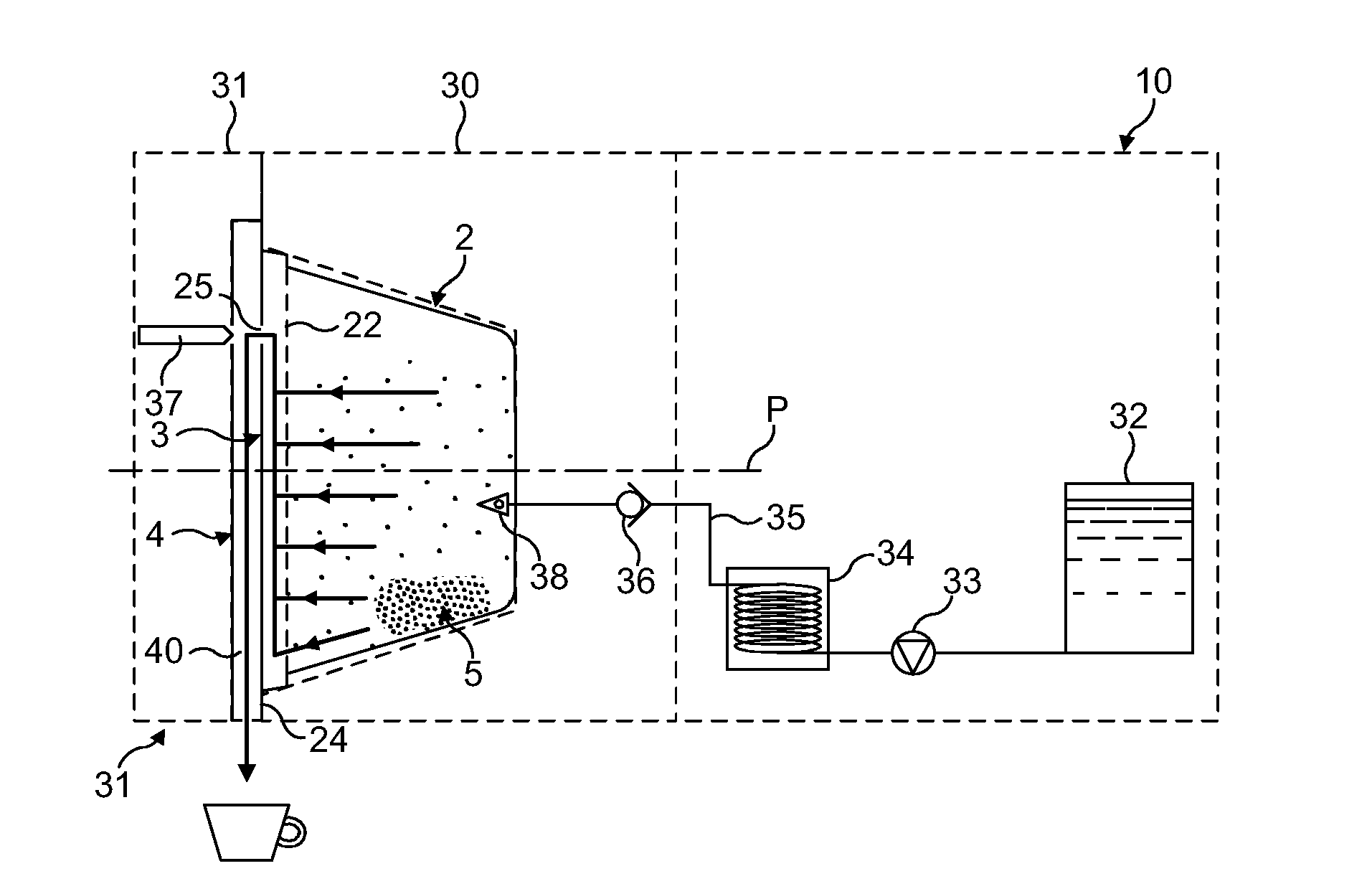

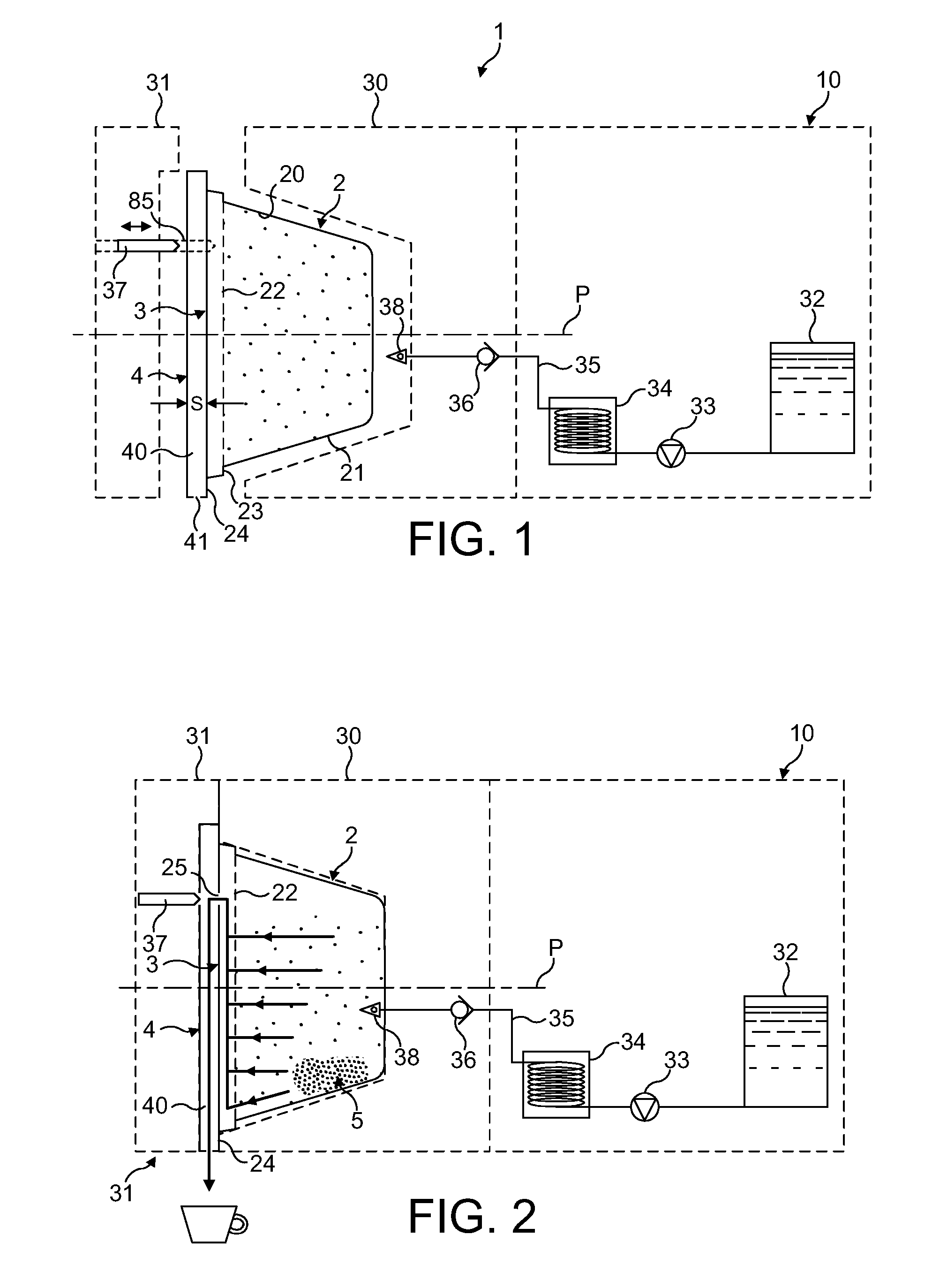

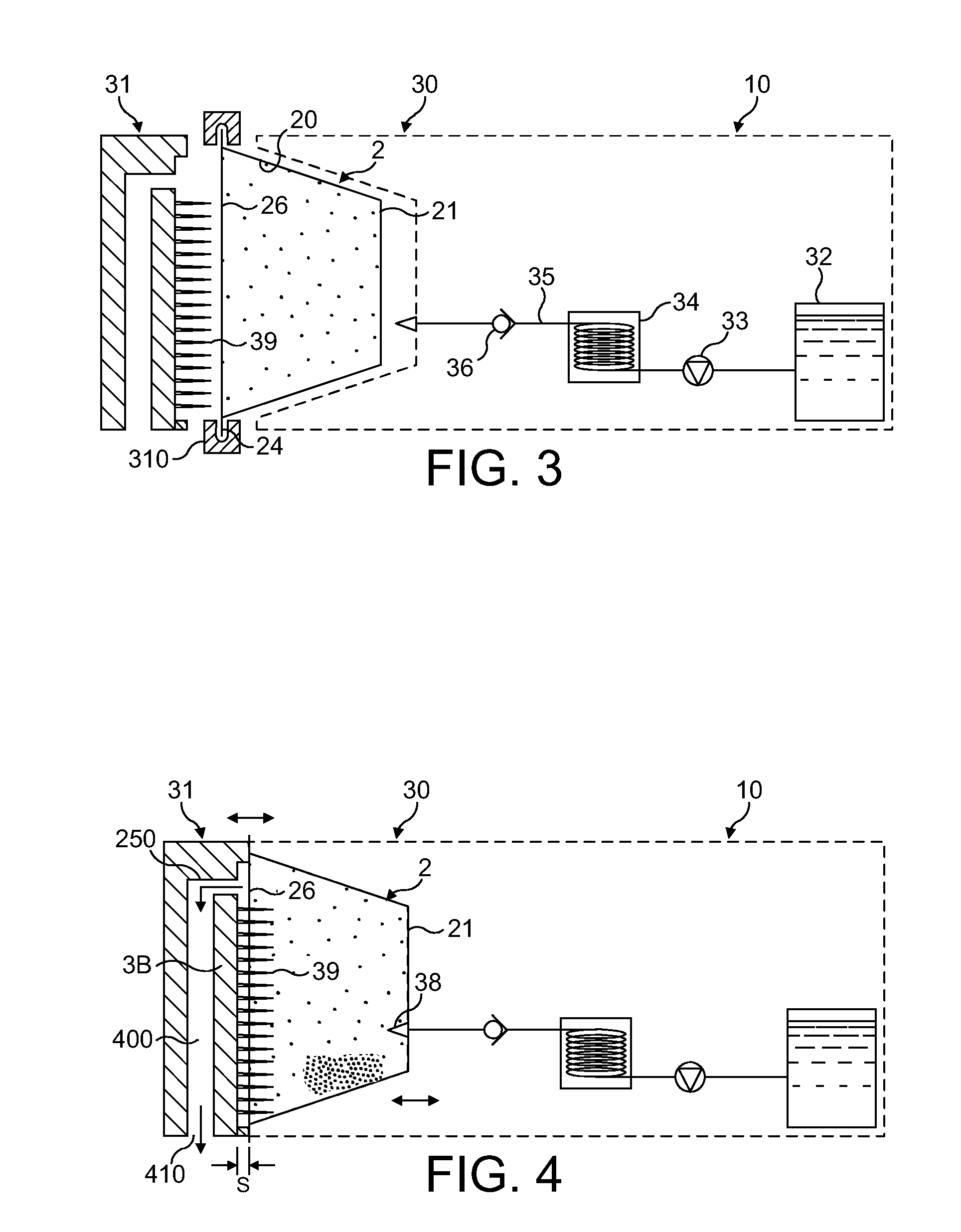

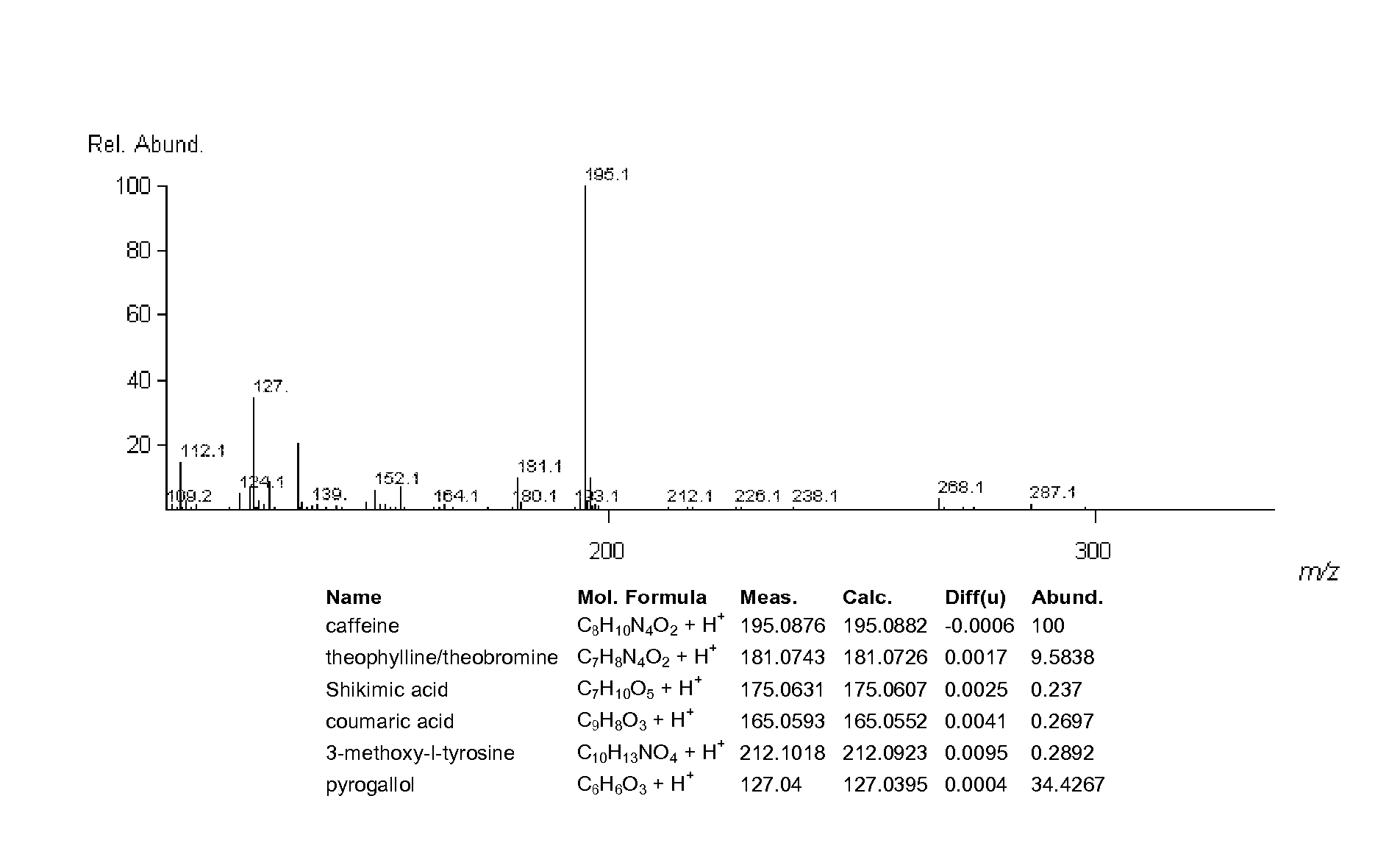

ActiveUS8039034B2Quality improvementGreat tasteTea substituesTea alkaloid content reductionAdditive ingredientEngineering

A method for preparing a beverage through a capsule (2) inserted in a beverage machine; the capsule comprising an enclosure (20) containing one or more beverage ingredients, wherein a brewing fluid is introduced in the enclosure to brew the said one or more beverage ingredients, wherein a brewed liquid is filtered by a filtering wall (22) and delivered from the capsule, wherein the filtering wall extends from substantially the bottom of the enclosure and said filtering wall is associated to an overflow wall (3) that forces the brewed liquid to traverse at least one overflow aperture (25). The method is particularly suitable for brewing a tea containing capsule.

Owner:SOC DES PROD NESTLE SA

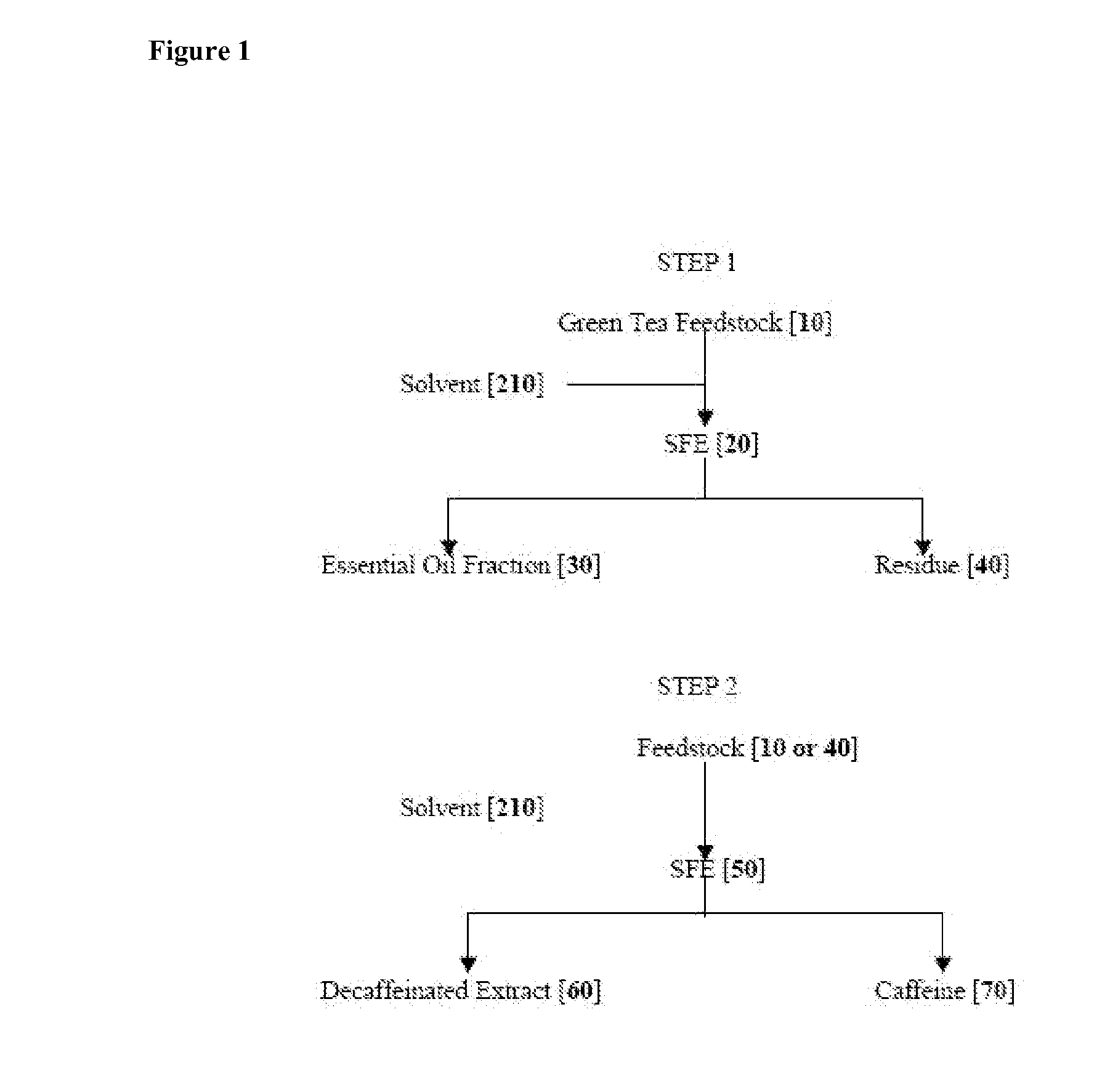

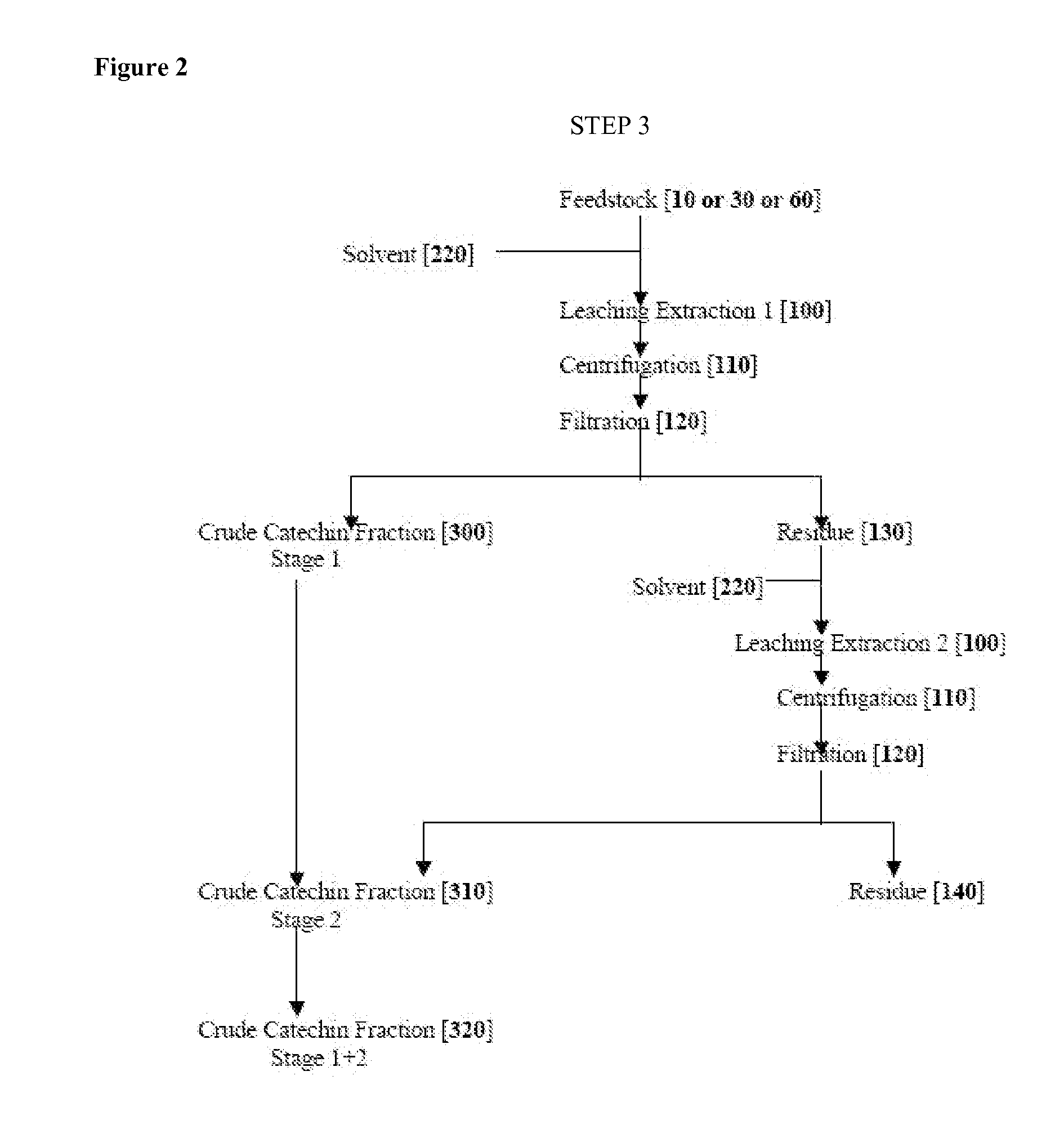

Extracts and Methods Comprising Green Tea Species

InactiveUS20080113044A1Great beneficial activityBiocideTea extractionGreen teaEpigallo-catechin gallate

Owner:HERBALSCI SINGAPORE PTE

Infusion system for enhanced flavor beverages

This invention is directed to infusible and / or water soluble material in combination with aroma compounds. The aroma compounds may be carried by a carrier compound and added to a less than conventional amount of infusible and water soluble material to make a beverage precursor. Suitable to be used to make a good tasting beverage.

Owner:UNILEVER BESTFOODS NORTH AMERICA DIV OF CONOPCO

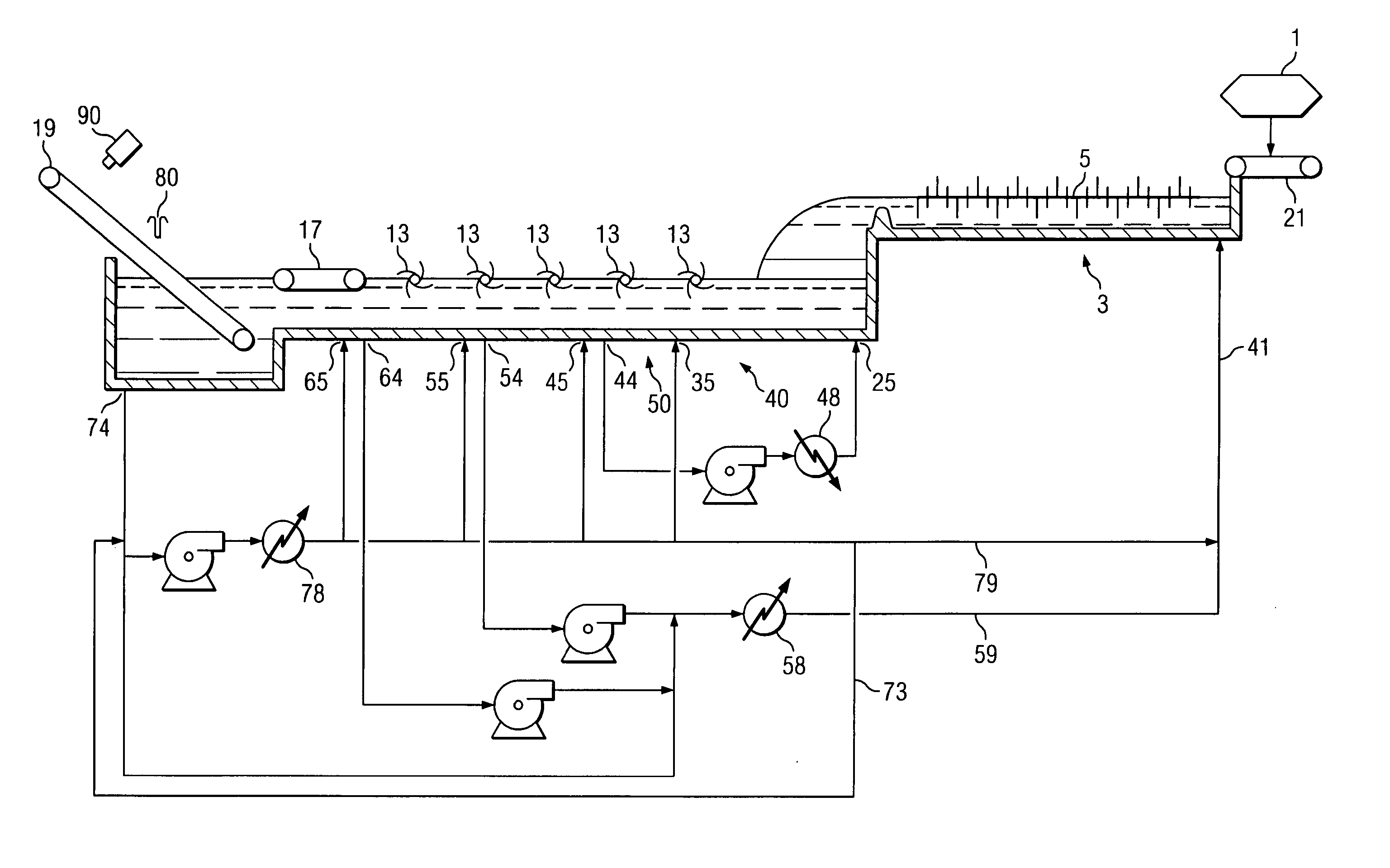

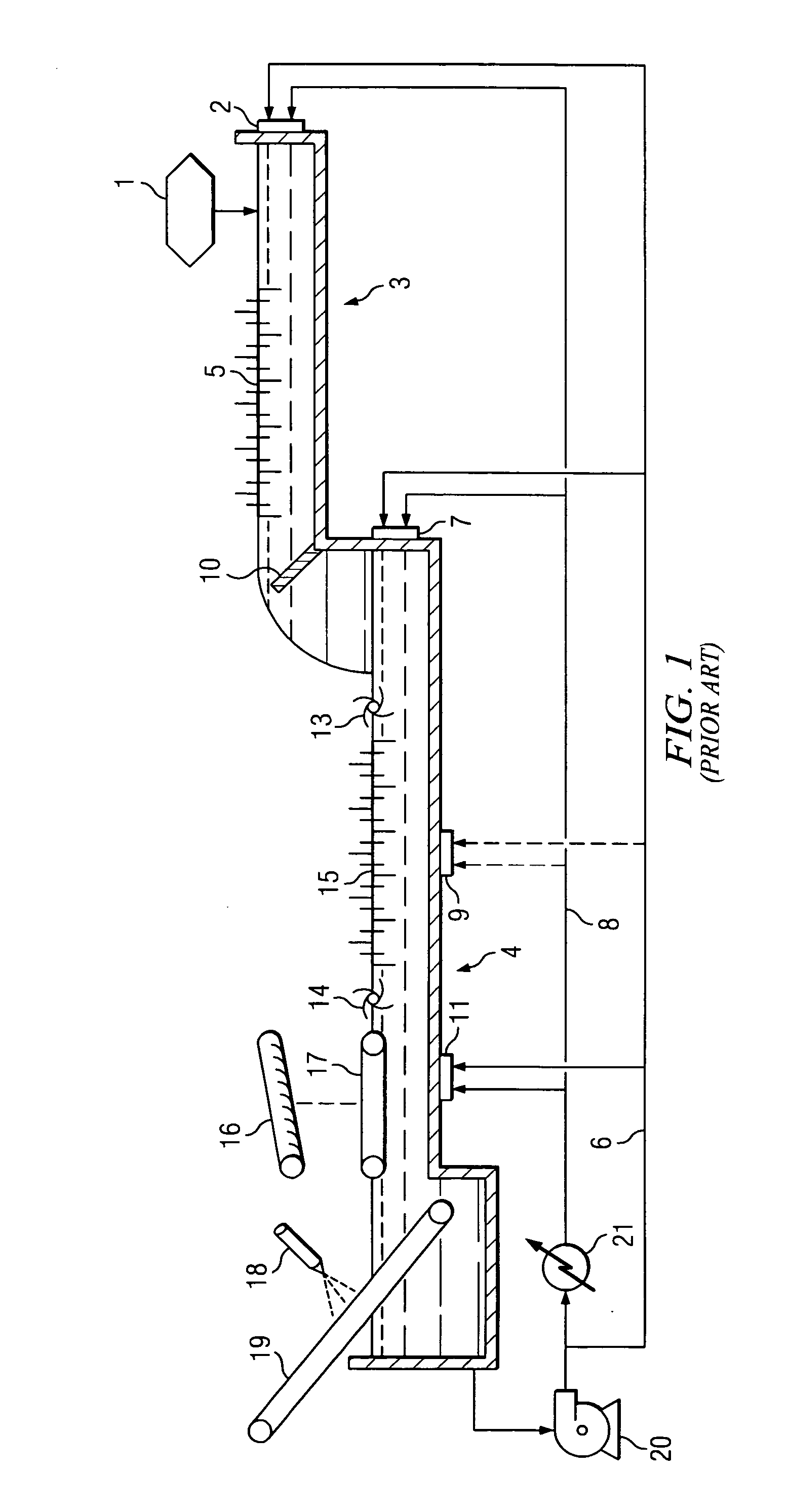

Method for continuously making kettle style potato chips

ActiveUS20060019007A1Desirable hard-bite textureDesirable taste propertyTea substituesTea alkaloid content reductionCooking processOil temperature

A continuous cooking process is disclosed that mimics the U-shaped temperature-time profile produced by a batch kettle fried potato chip operation. Potato slices are placed into hot oil in a flume portion of a continuous fryer. The potato slices exit the flume into an upstream portion of the fryer. Cooling oil is injected to the upstream portion of the continuous fryer to continuously achieve the trough portion of the U-shaped temperature-time profile. The potato slices are then further fried in the downstream portion of the fryer in a region having an increased hot oil temperature. The increased hot oil temperature occurs by injecting hot oil into the downstream portion. The temperature of injected hot oil can be controlled by the exit moisture content of the potato slices.

Owner:FRITO LAY NORTH AMERICA INC

Vacuum Brewed Beverage Machine And Vacuum Brewing Method

ActiveUS20130136833A1Enhance stirringIncrease ratingsTea extractionTea substituesPressure cycleEngineering

A liquid infusion and / or brewing process is described. The process includes the steps of placing a desired amount of an infusion material into a chamber at atmospheric pressure, placing a desired amount of liquid into said chamber, sealing said chamber from the surrounding atmosphere, and applying at least one reduced pressure cycle within said chamber, wherein said at least one cycle comprises reducing pressure within said chamber to form at least a partial vacuum within said chamber and subsequently returning said chamber to about atmospheric pressure. Methods for separating the brewing media from the liquid after completion of the brewing process are also described.

Owner:BKON

Coffee system

InactiveUS6887506B2Excellent and desirable and flavor and qualityExcellent and desirable and and fragrance qualityTea extractionTea substituesBeverage industryEngineering

Typical current methods for producing large quantities of extracts from solid raw materials such as ground, roasted coffee are designed for exhaustive extraction. Such methods are not ideally suited to producing high quality coffee extracts that are rich in flavor and fragrance, and which maintain the varietal characteristics of the roasted coffee from which they are produced. The current invention provides methods and apparatus for producing such high quality extracts. The invention provides methods that have sufficient flexibility and scalability to be used for a wide variety of applications, including for producing industrial-scale quantities of extracts for the food and beverage industry. The invention provides methods and apparatus that can produce highly concentrated, “gourmet quality” extracts for use as flavoring agents, beverage concentrates, and fragrances.

Owner:KERRY GROUP SERVICES

Vacuum brewed beverage machine and vacuum brewing method

ActiveUS20110097466A1Brewed quickly and easilyCooking-vessel materialsTea substituesGlass vesselAtmospheric pressure

The desired amount of coffee grounds, tea leaves, herbs or other beverage making material is placed in a chamber of glass vessel located on a moveable table top in its lowered position. The table top is then elevated until the upper edge of the vessel seals against a top seal. With the top sealed, the desired amount of water of about 185°-212° F. is introduced into the chamber through a port in the top. Thereafter, a vacuum is drawn in the chamber and is held within the range of about −5 to −20 Hg in. Using an external heat source, the brewing liquid is maintained at about 185°-212° F. Alternatively, the vacuum can be pulsed by turning it on and off several times during the brewing cycle. After the beverage has brewed for the desired amount of time, the heat and vacuum are removed, the chamber is returned to atmospheric pressure and the table top is lowered to release the vessel. The contents of the chamber are then strained to remove solids from the beverage.

Owner:BKON

Method of extracting volatile component from tasty material, the volatile component and foods and drinks containing the volatile component

InactiveUS20070003683A1Meat/fish preservation by heatingTea extractionSaturated water vaporSuperheated steam

Volatile components are obtained by steam extraction of tasty materials. Coffee beans following roasting or tea leaves following tea manufacturing are used as tasty materials. Steam extraction includes of processing in which steam is contacted with a tasty material followed by recovery of the steam after that contact. Saturated water vapor or super heated steam is used for the steam, while super heated steam is used preferably. The coffee beans are preferably those that have been obtained by roasting raw coffee beans using super heated steam. The food or drink contains the aromatic components, and preferably contains the volatile components as well as an aqueous extract of the tasty material.

Owner:POKKA SAPPORO FOOD & BEVERAGE

Vacuum brewed beverage method

ActiveUS8383180B2Brewed quickly and easilyCooking-vessel materialsTea substituesGlass vesselEngineering

Owner:BKON

Method for brewing beverage and cartridge containing infusible material

The present invention provides a method for brewing a beverage in a brewing apparatus, wherein a cartridge containing infusible material is connected to a brew chamber and will form the bottom of the brew chamber. By the introduction of air through the filter of the cartridge, water and infusible material are mixed, and an effective brewing process is conducted. After brewing the beverage is discharged into a receptacle through the filter of the cartridge, leaving infusible material behind in the cartridge. The invention also provides a cartridge for use in the method.

Owner:EKATERRA TEA MFG USA LLC

Green leaf tea product and a process for the manufacture thereof

A palatable green leaf tea from Camellia sinensis var. assamica is disclosed. Infusion of 2 g of the leaf tea in 200 ml water for 1.5 minutes at 90° C. produces a beverage comprising catechins in an amount of between 0.01 and 0.1% by weight of the beverage. Also disclosed is a process for manufacturing the leaf tea product wherein fresh leaf from var. assamica is macerated using a combination of a rotorvane and double-cone processor.

Owner:EKATERRA TEA MFG USA LLC

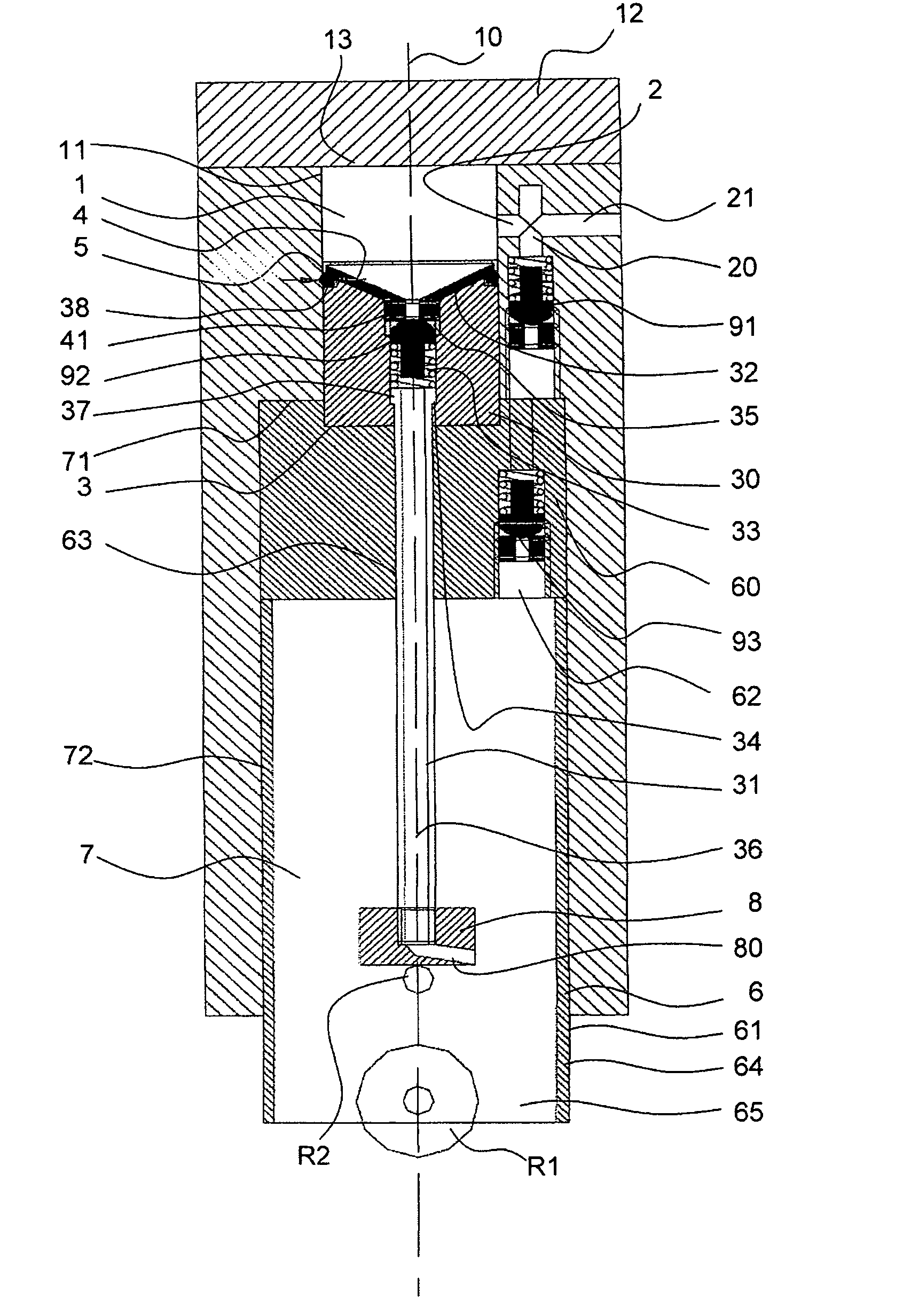

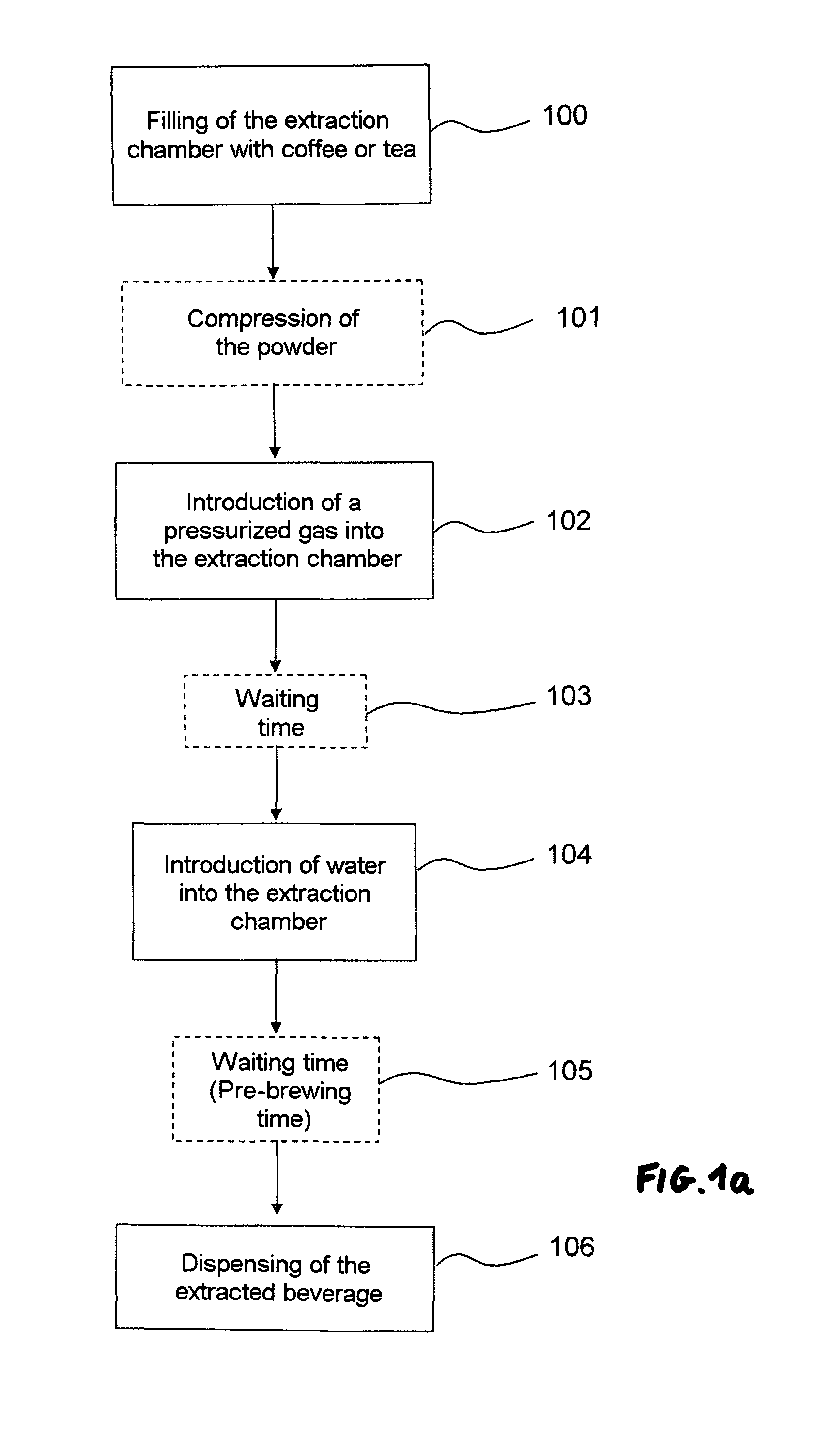

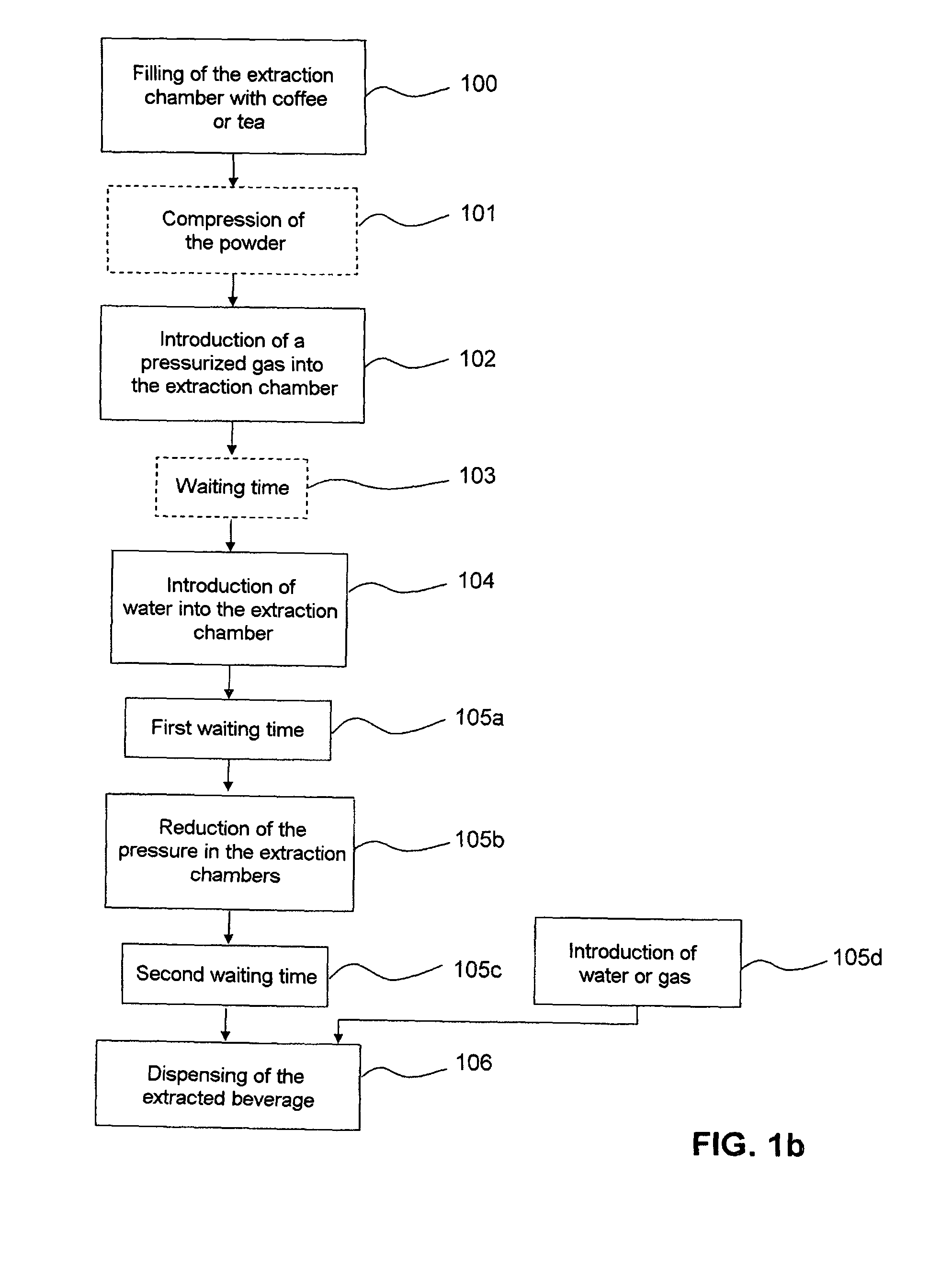

Apparatus and Method for Extracting a Hot Beverage

A method for preparing a hot beverage, in particular a coffee beverage or a tea beverage, with flavors being extracted from a flavor carrier, which is prepared from roasted coffee or dried tea, by means of water or steam having a plurality of steps: a predetermined quantity of the flavor carrier, in which the flavors are contained, is added to an extraction chamber which can be closed in a fluid-tight manner in a first step; water or steam for extracting flavors from the flavor carrier is added to the extraction chamber in a subsequent step; the extracted beverage flows out of the extraction chamber in a subsequent step; before the step of introducing water or steam into the extraction chamber, a step of introducing pressurized gas into the extraction chamber is executed. In the process, the internal pressure in the extraction chamber rises.

Owner:WHY

Method for preventing passing off of a brewed beverage

Owner:UNILEVER BESTFOODS NORTH AMERICA DIV OF CONOPCO

Package drink

ActiveUS20070128327A1Green tea flavor in the green tea leaves can be efficiently eliminatedNot to damageOrganic active ingredientsOrganic chemistryActivated carbonOrganic solvent

To provide a packaged high-catechin beverage in which a low-caffeine green tea extract is added. A packaged beverage containing from 0.03 to 1.0 wt % of non-polymer catechins, in which a low-caffeine green tea extract obtained by a method of brining a green tea extract into contact with a 91 / 9 to 97 / 3 by weight mixture of an organic solvent and water, activated carbon, and acid clay or activated clay is added.

Owner:KAO CORP

Green tea formulations and methods of preparation

ActiveUS7232585B2Well received naturalLarge doseTea extractionTea substituesFlavorIntracellular substance

Green tea formulations and methods for the preparation thereof are shown and described. Generally speaking, the method of preparation includes the mixing of fresh tea leaves in an amount of cold water, followed by pulverization of the leaves to release their intracellular material from the cells of the green tea leaves into the water and form an aqueous extract component. The remaining cellular material forms a leaf residue component which is removed from the mixture. Once the leaf residue is removed, the aqueous extract component is collected and may be dried or further processed to produce a final tea extract that has good natural color, robust natural flavor, and pleasant organoleptic properties, which also is high in polyphenol content, and may be used for various purposes such as the creation of a green tea beverage.

Owner:XEL HERBACEUTICALS INC

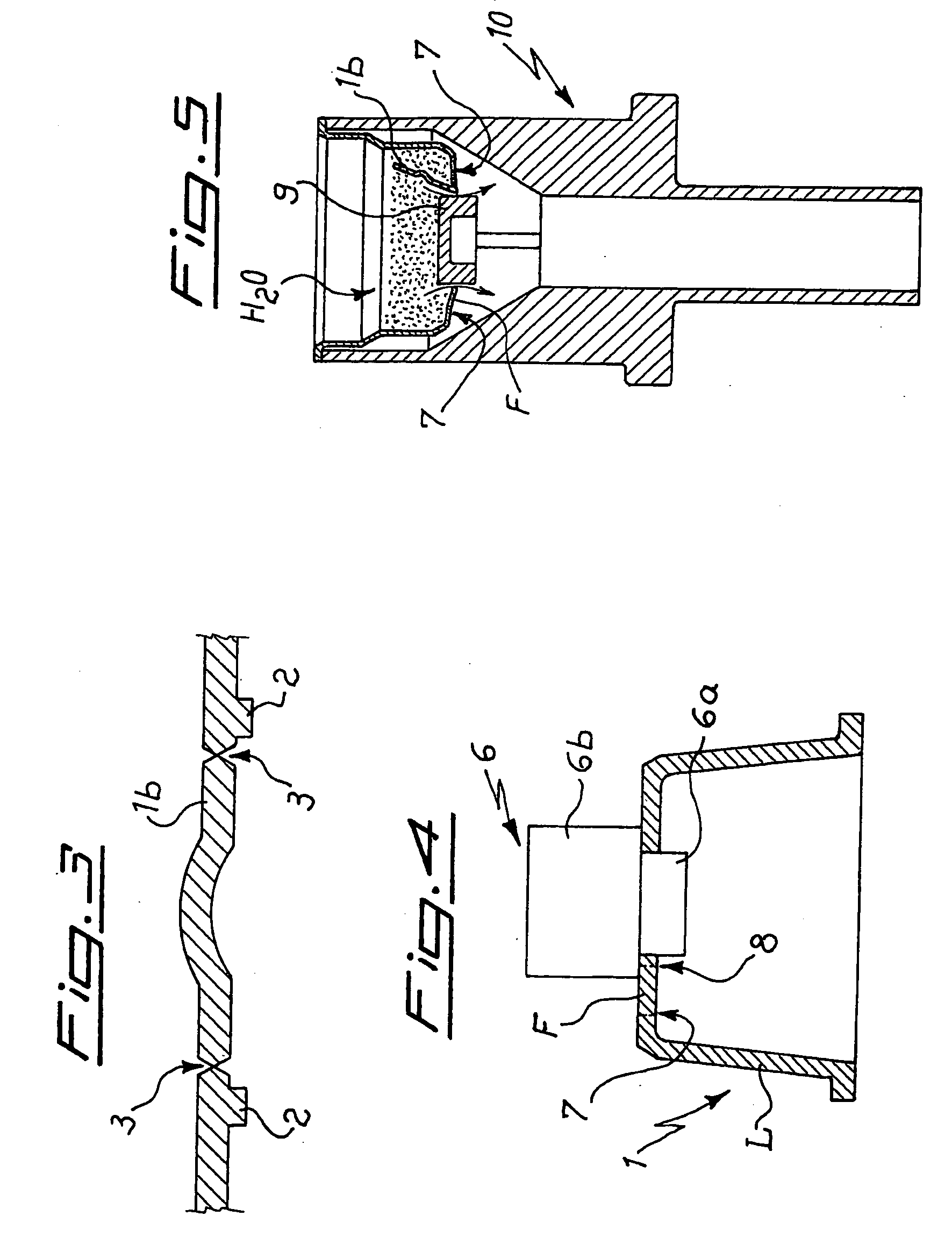

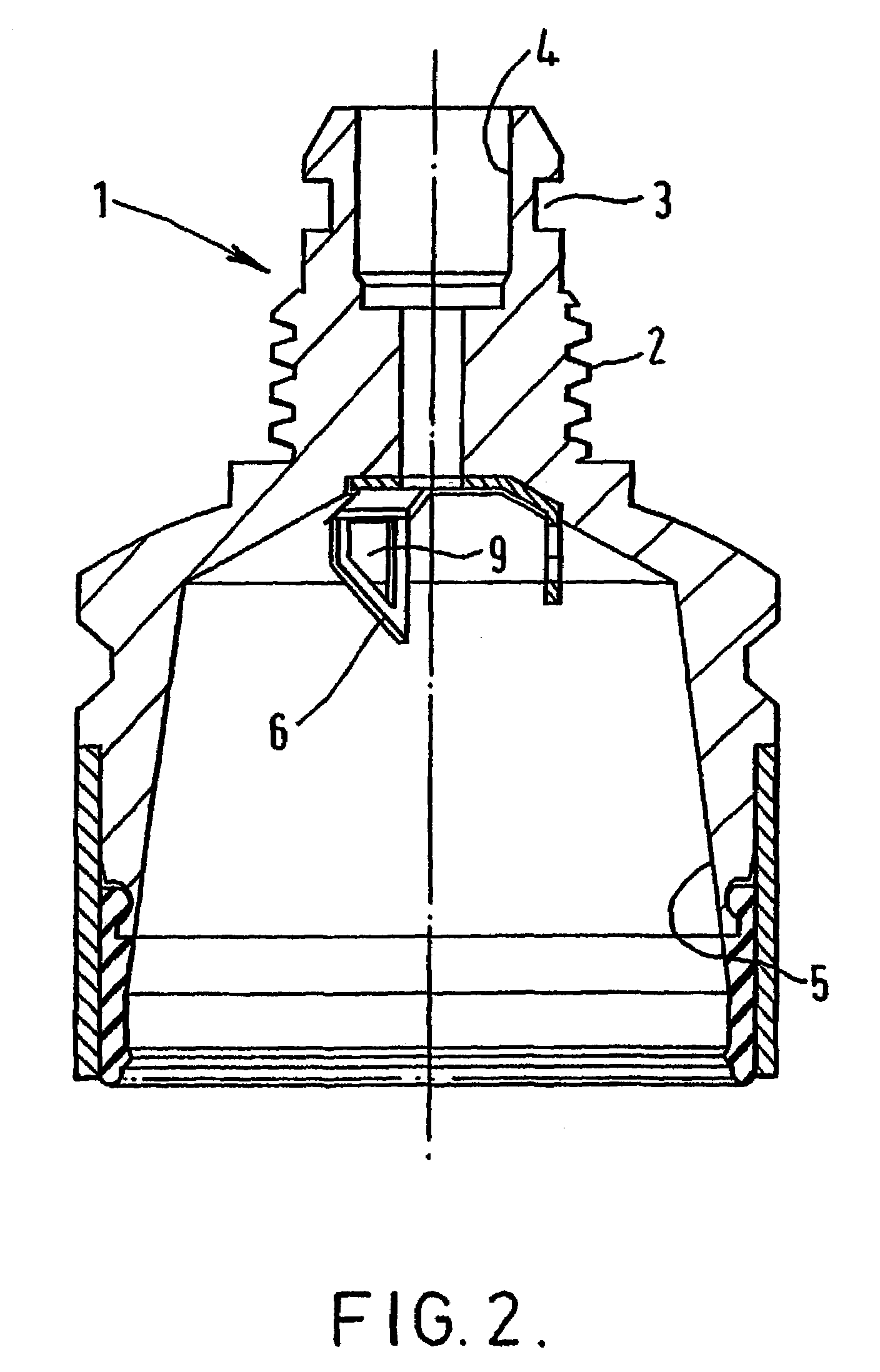

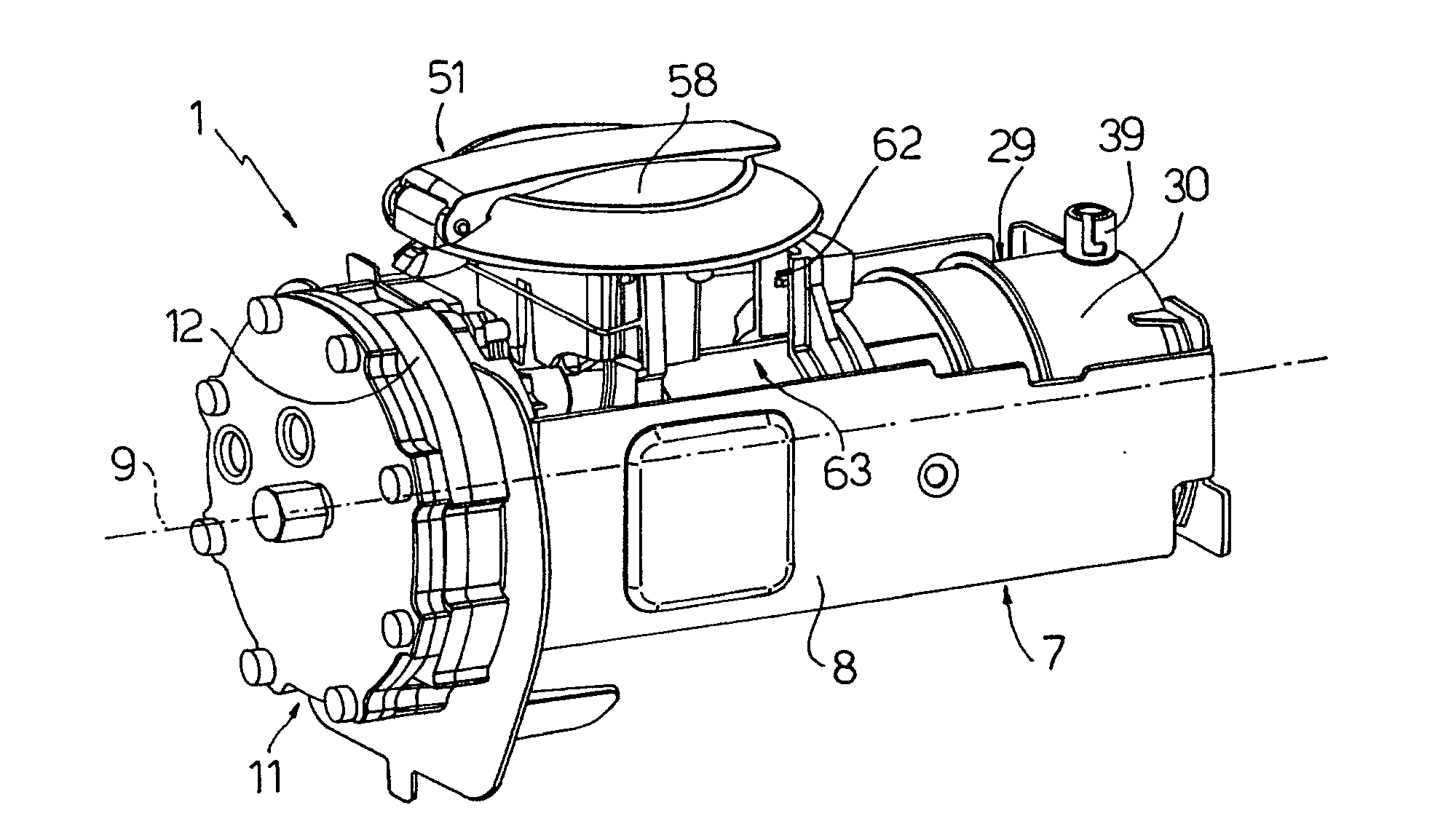

Method of making a beverage from powdered material in a sealed capsule

InactiveUS20090035438A1Affecting structural stabilityEnabling useTea substituesTea alkaloid content reductionStructural engineeringMechanical engineering

In a coffee machine, a sealed capsule is fed with a certain amount of axial clearance into a cup aligned along a horizontal axis with a pressurized-hot-water sprinkler, and is moved towards the sprinkler to press an annular flange of the sealed capsule in fluidtight manner against the sprinkler, to pierce a front sealing wall of the sealed capsule by means of a first piercing device, to feed pressurized hot water through the sealing wall to expand the sealed capsule axially and eliminate the axial clearance, and to bring an end wall of the sealed capsule into fluidtight contact with a second piercing device, and pierce the end wall against the second piercing device, so that coffee flows out through the second piercing device.

Owner:LAVAZZA

Method of producing chlorogenic acid composition

InactiveUS20090053381A1Organic active ingredientsOrganic compound preparationHigh concentrationChlorogenic acid

The present invention provides a method for obtaining a chlorogenic acid composition which contains high concentration of chlorogenic acids and a reduced amount of caffeine at a high yield.A method of producing a chlorogenic acid composition, which comprises allowing a water-soluble composition extracted from raw coffee beans or roasted coffee beans to be adsorbed to a column filled with an adsorbent and then eluting a chlorogenic acid composition by passing a 0.5 to 20 vol % ethanol aqueous solution.

Owner:KAO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com