Film preservative, preparation method thereof, and application thereof in preservation of euphausia superba

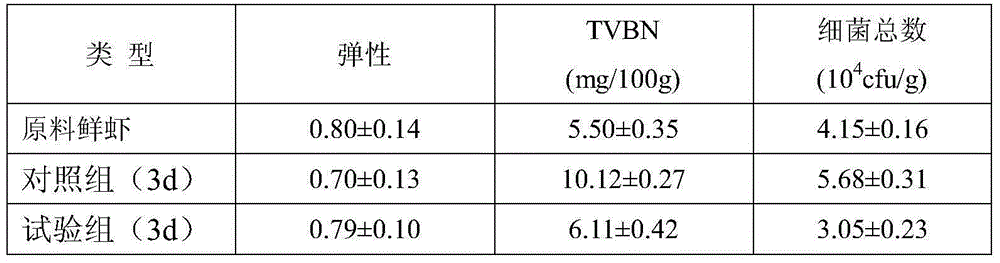

A film-coating preservative and technology of Antarctic krill, which is applied in the direction of preserving meat/fish with a coating protective layer, can solve the problem that the autolysis of Antarctic krill cannot be completely inhibited, the sensory quality of Antarctic krill is affected, and the refrigeration of Antarctic krill can be improved. Energy consumption and other issues, to achieve the effect of delaying spoilage, inhibiting bacterial reproduction, and reducing storage energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1.1 Preparation of coating preservative

[0019] Soybean polysaccharide preparation: take dried okara, add pure water 10 times the mass of dried okara according to the mass-volume ratio (g / ml) of dried okara to water, stir and adjust the pH value to 4, cook at 110°C for 2.5h, then cool to room temperature , and then filter and separate the cooking product to obtain a soybean soluble polysaccharide solution, then purify and dry to obtain soybean polysaccharide.

[0020] Preparation of bayberry extract: take fresh bayberry fruit, dry and crush, add 3 times the mass of 95% ethanol to soak for 24 hours, ultrasonically assisted extraction for 20 minutes to obtain an extract, and concentrate to obtain an extract; disperse the extract in water, wash with ethyl acetate Extraction is carried out, adsorbed by D101 macroporous resin, eluted with 15%-65% ethanol, and the eluate is vacuum-dried and crushed to 200 meshes to obtain a bayberry extract.

[0021] Preparation of honeysuc...

Embodiment 2

[0029] 2.1 Preparation of coating preservative

[0030] Soybean polysaccharide preparation: take dried okara, add pure water 20 times the mass of dried okara according to the mass-volume ratio (g / ml) of dried okara to water, stir and adjust the pH to 5, cook at 130°C for 1.5h, then cool to room temperature, Then, filter and separate the cooked product to obtain soybean soluble polysaccharide solution, and then purify and dry to obtain soybean polysaccharide.

[0031] Preparation of bayberry extract: take fresh bayberry fruit, dry and crush, add 5 times the mass of 95% ethanol to soak for 32 hours, ultrasonically assisted extraction for 25 minutes to obtain an extract, and concentrate to obtain an extract; disperse the extract in water, wash with ethyl acetate Extraction is carried out, adsorbed by D101 macroporous resin, eluted with 15%-65% ethanol, and the eluate is vacuum-dried and crushed to 200 meshes to obtain a bayberry extract.

[0032] Preparation of honeysuckle extra...

Embodiment 3

[0040] 3.1 Preparation of coating preservative

[0041] Soybean polysaccharide preparation: take dried okara, add pure water 15 times the mass of dried okara according to the mass-volume ratio (g / ml) of dried okara to water, stir and adjust the pH to 4, cook at 120°C for 2 hours, cool to room temperature, and then Filtrating and separating the cooked product to obtain a soybean soluble polysaccharide solution, followed by purification and drying to obtain soybean polysaccharide.

[0042] Preparation of bayberry extract: take fresh bayberry fruit, dry and crush, add 4 times the mass of 95% ethanol to soak for 28 hours, ultrasonically assisted extraction for 22 minutes to obtain an extract, concentrate to obtain an extract; disperse the extract in water, wash with ethyl acetate Extraction is carried out, adsorbed by D101 macroporous resin, eluted with 15%-65% ethanol, and the eluate is vacuum-dried and crushed to 200 meshes to obtain a bayberry extract.

[0043] Preparation of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com