Composition of bis(fluorosulfonyl)imide lithium salt

A composition, fluorosulfonyl technology, applied in the direction of lithium compounds, nitrogen compounds, alkali metal compounds, etc., can solve the problems of reducing the overall performance and stability of lithium-ion batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0014] According to one embodiment, the mass content of acetic acid in the composition is greater than or equal to 0.1 ppm, preferably greater than or equal to 1 ppm, advantageously greater than or equal to 10 ppm, relative to the total weight of the composition.

[0015] According to one embodiment, the mass content of acetic acid in the composition ranges from 0.1 ppm to 300 ppm, preferably from 0.1 ppm to 200 ppm, advantageously from 0.1 ppm to 150 ppm, even more advantageously from 0.1 ppm to 100 ppm, relative to the composition of total weight.

[0016] The above compositions may also include:

[0017] - less than or equal to 20 ppm, preferably less than or equal to 15 ppm, advantageously less than or equal to 10 ppm of Cl by weight - the content of ions relative to the total weight of the composition; and / or

[0018] - less than or equal to 200 ppm by weight, preferably less than or equal to 50 ppm, advantageously less than or equal to 30 ppm of F - content, relative ...

Embodiment 1

[0130] A solution of 134 g LiFSI in 823 g butyl acetate (obtainable eg according to the method described in WO 2015 / 158979). The LiFSI concentration was about 10% by weight, and the water content of the solution was 3% by weight. The water content of this solution is higher than the solubility of water in butyl acetate due to the association of the lithium salt with water. The first concentration by evaporating the solvent was performed with a rotary evaporator at 40° C. under reduced pressure (P<30 mbar). A solution was obtained with a solids content of 42% by weight and a water content (measured by titration) of 430 ppm by weight. The final concentration is carried out in a WFSP (wiped film short path) evaporator at a temperature of 80° C. and a vacuum of 0.5 mbar. The concentrate was taken up in dichloromethane. LiFSI crystallizes rapidly. After 1 hour of contact time, solid LiFSI was obtained and recovered by filtration and dried under vacuum for at least 24 hours. Th...

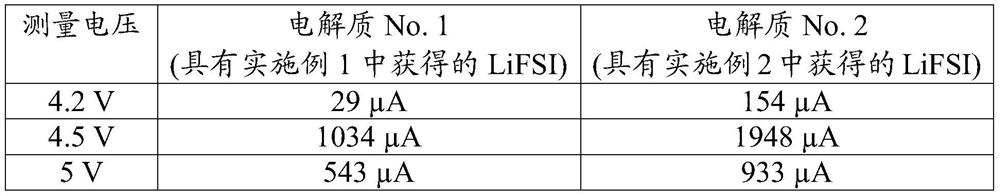

Embodiment 2

[0133] Example 2 (Compared):

[0134] A solution of 53 g LiFSI in 640 g butyl acetate (obtained eg according to the method described in WO 2015 / 158979). The water content was 3.2% by weight. The solution was evaporated under vacuum at 70°C. A solution was obtained with a solids content of 40% by weight and a water content of 1050 ppm by weight. The final concentration is carried out in a WFSP (wiped film short path) evaporator at a temperature of 80° C. under a vacuum of 0.5 mbar.

[0135] The concentrate was taken up in dichloromethane. LiFSI crystallizes rapidly. After 1 hour of contact time, 44 g of LiFSI were obtained and recovered by filtration and dried under vacuum for at least 24 hours.

[0136] Residual solvent analysis was as follows:

[0137] weight% headspace NMR Butyl acetate 0.15 0.16 Dichloromethane 0.07 0.07 Acetic acid not detected 0.055 Butanol not detected not detected

[0138] Headspace measurements ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com