Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

102results about "Amidosulfonic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

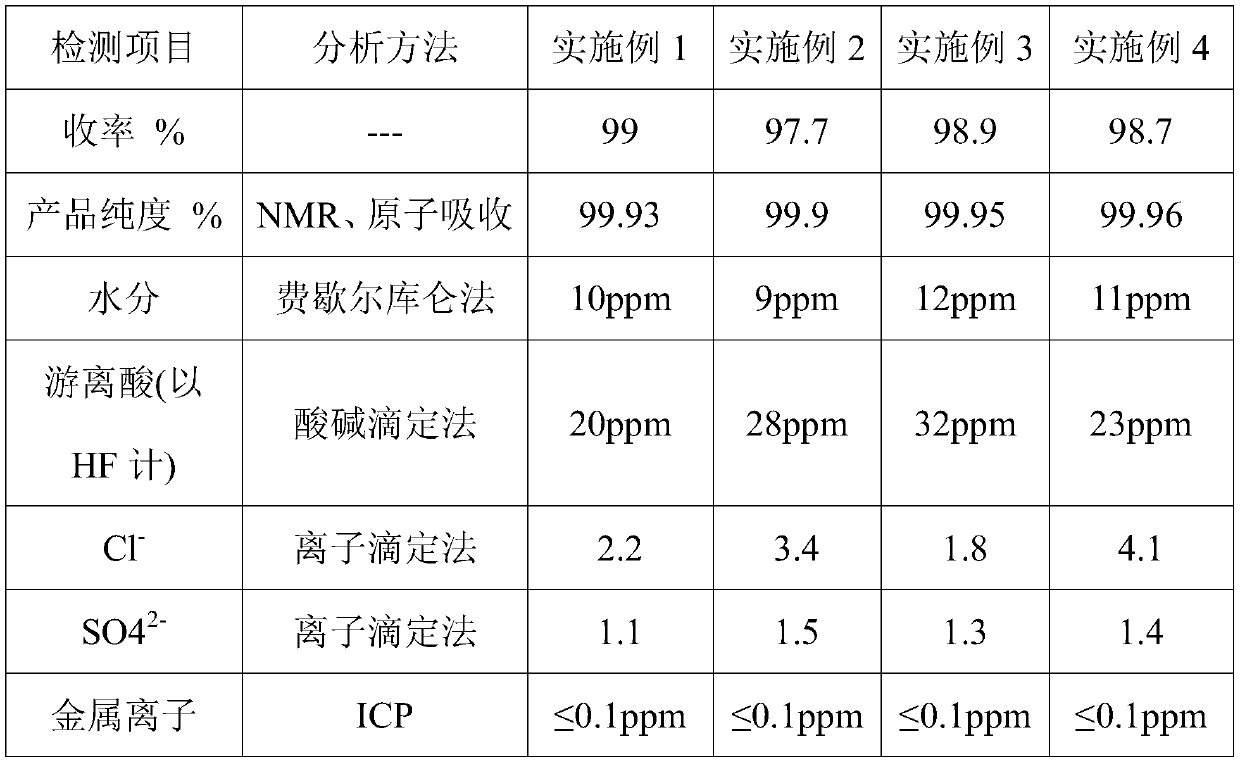

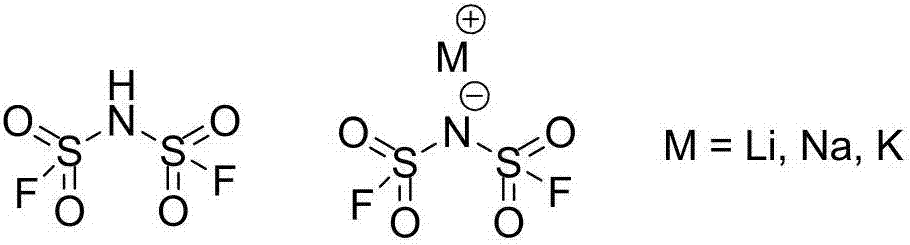

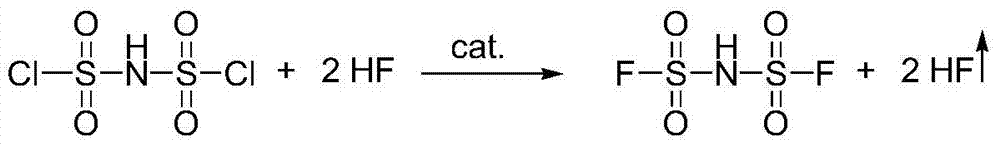

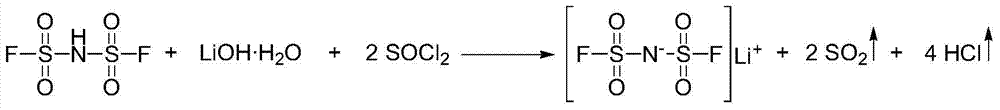

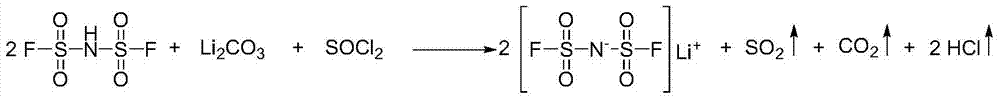

Preparation method for difluorosulfimide lithium salt

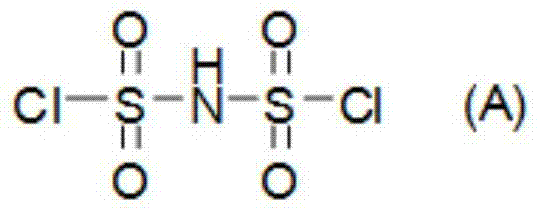

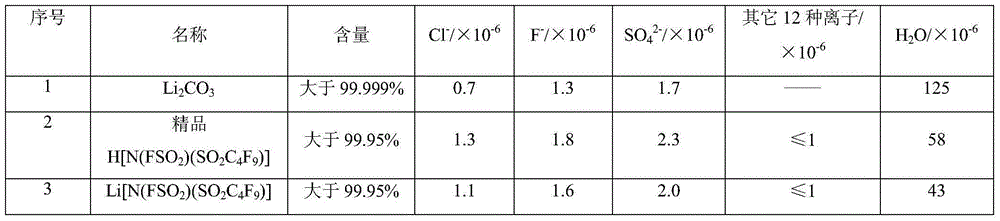

ActiveCN104925765AGuaranteed purityGuaranteed qualityNitrosyl chlorideAmidosulfonic acidHydrogen fluorideLithium-ion battery

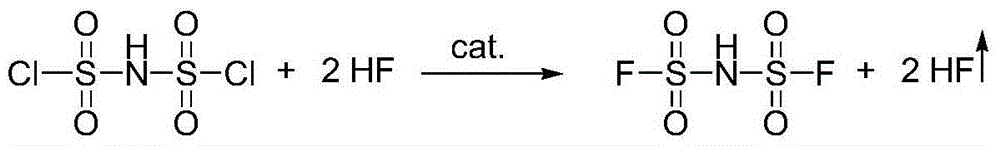

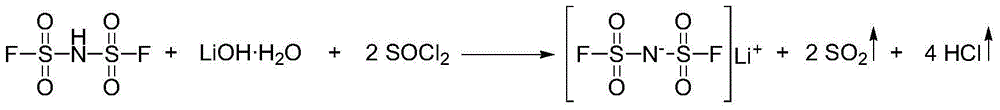

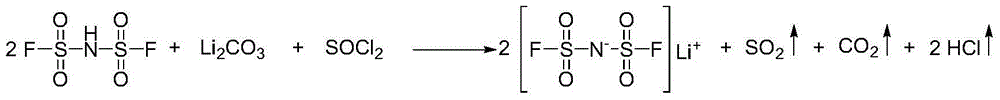

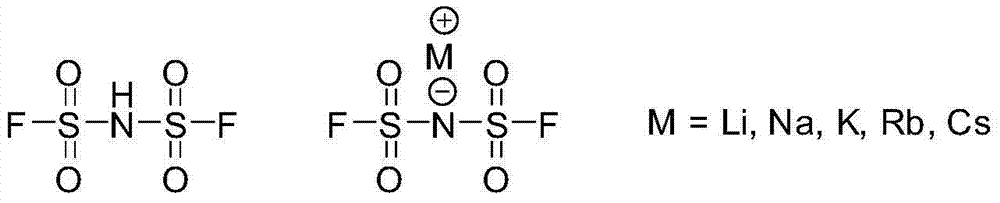

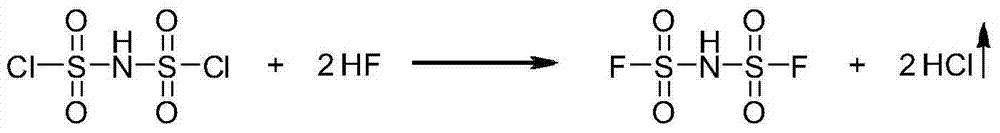

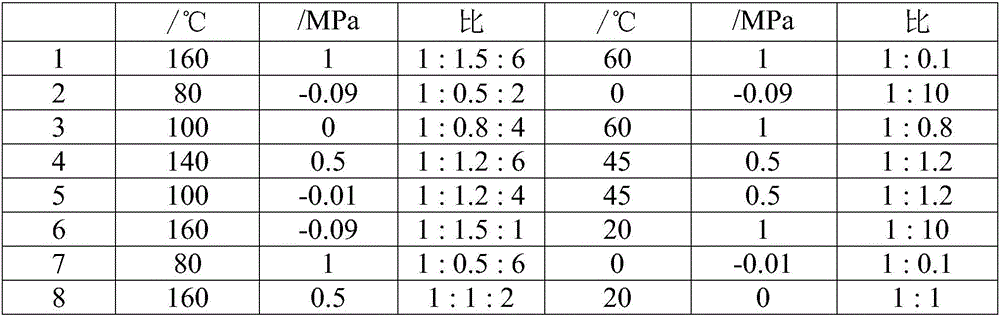

The invention relates to the field of lithium batteries and lithium capacitors, in particular to a preparation method for difluorosulfimide lithium salt and application of the difluorosulfimide lithium salt. The preparation method for the difluorosulfimide lithium salt, provided by the invention, comprises the following steps: (1) performing fluorination reaction: synthetizing midbody difluorosulfimide from dichlorosulfimide and hydrogen fluoride under the action of a catalyst; (2) performing reaction between the difluorosulfimide obtained in the step 1 and alkaline lithium, and performing solid-liquid separation after the reaction to obtain an LiFSI product. The preparation method for the difluorosulfimide lithium salt, provided by the invention, is low in cost, few in by-product and simple in post-treatment, and the quality and the purity of the product are ensured, therefore the preparation method which is capable of obtaining the high-quality and high-purity product and is economic and practical is provided; the preparation method is suitable for industrial production.

Owner:SHANGHAI CHEMSPEC CORP +1

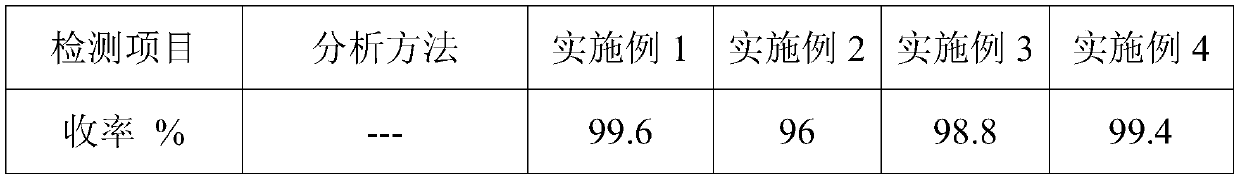

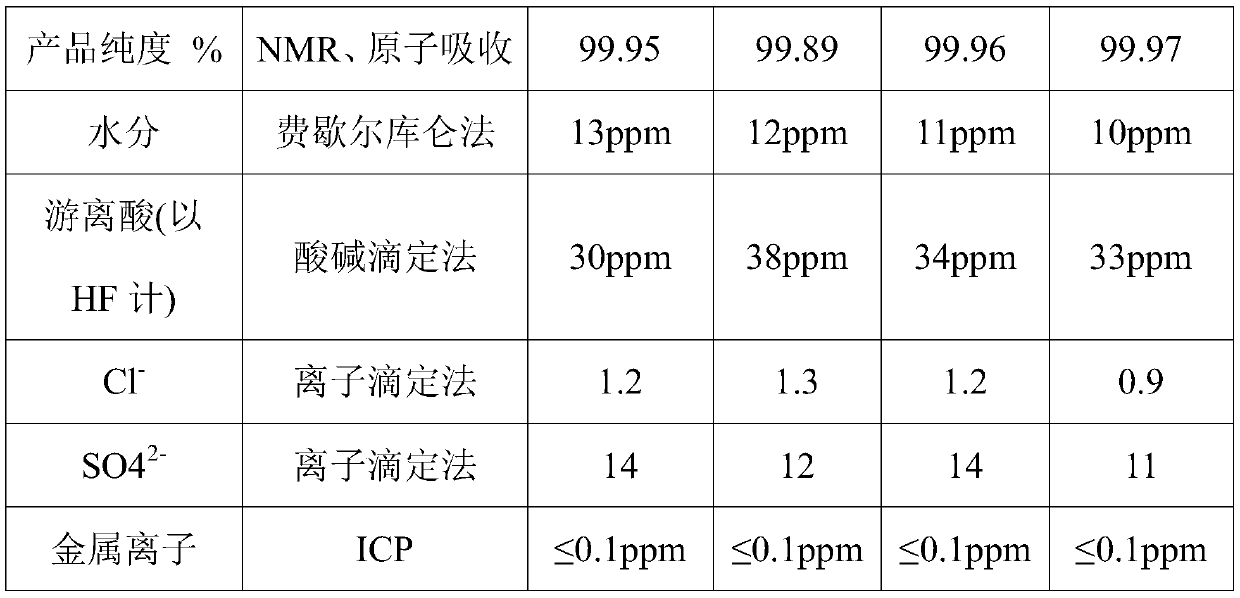

Preparation methods of bis(fluorosulfonyl)imide and alkali metal salts thereof

InactiveCN103935970AEasy to getLow costHybrid capacitor electrolytesAmidosulfonic acidImideHydrogen fluoride

The invention relates to preparation methods of bis(fluorosulfonyl)imide and alkali metal salts thereof. The bis(fluorosulfonyl)imide is prepared by subjecting bis(chlorosulfonyl)imide to react with a fluorinating agent namely hydrogen fluoride. The alkaline metal salts of bis(fluorosulfonyl)imide is prepared by subjecting bis(chlorosulfonyl)imide and alkali metal halides to react with hydrogen fluoride taken as the fluorinating agent and the solvent. The preparation methods can reduce the raw material costs, reduce the material consumption and generation of wastes, improve the raw material utilization rate, product yield, and product purity; moreover, the product purification is easier, the preparation technology process is more concise and more efficient, and the preparation methods provides a very good technical foundation for massive industrial production of bis(fluorosulfonyl)imide and alkali metal salts thereof.

Owner:SHENZHEN CAPCHEM TECH CO LTD

Preparation method of difluoro-sulfimide and lithium difluoro-sulfimide

InactiveCN106365132AFew reaction stepsSimple processNitrosyl chlorideAmidosulfonic acidChemical synthesisDistillation

The invention relates to a preparation method of difluoro-sulfimide and lithium difluoro-sulfimide, and belongs to the field of fluorine chemical synthesis. The preparation method comprises the steps that difluoro-sulfimide is obtained by adding fluoro-sulfoxide into a mixture of sulfamic acid or amino sulfonyl fluoride and fluorosulfuric acid for reacting and then subjected to recrystallization and filtration which are conducted at the temperature of minus 100 DEG C to 16 DEG C and / or reduced / normal-pressure distillation and purification which are conducted at the temperature of 60 DEG C to 169 DEG C; difluoro-sulfimide and a lithium-containing substance react in a solvent to obtain lithium difluoro-sulfimide, and then recrystallization, filtration and purification are conducted. According to the preparation method, difluoro-sulfimide can be prepared through one step, lithium difluoro-sulfimide is obtained through lithiation, and the prepared products can be purified; few steps are needed, the technology is simple, the process is easy to control, the requirement on production devices is low, the production efficiency, the product yield and the purity are high, and large-scale production and application can be achieved.

Owner:718TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Preparation method of difluorosulfimide salt

The invention discloses a preparation method of difluorosulfimide salt. The preparation method comprises the following steps: (1) adding dichlorosulfimide and a nitrogen-containing hydrogen fluoride complex which are used as reaction raw materials into an organic solvent for reaction at 0-100 DEG C, and after reaction, distilling to remove the organic solvent to obtain a difluorosulfimide and nitrogen-containing ion compound; (2) adding the ion compound obtained in the step (1) into a water solution of metal alkali or salt, neutralizing until the solution is neutral, distilling, drying, re-crystallizing by using the organic solvent, and purifying to obtain difluorosulfimide salt. According to the preparation method, the nitrogen-containing hydrogen fluoride complex is adopted as a fluorating agent, so that the whole reaction is carried out in a homogeneous system, the fluorating reaction is relatively safe, the efficiency is relatively high, and the product yield is more than 98%; a process route is simple, the yield is high, and the production cost is relatively low.

Owner:ZHANGJIAGANG HICOMER CHEM CO LTD

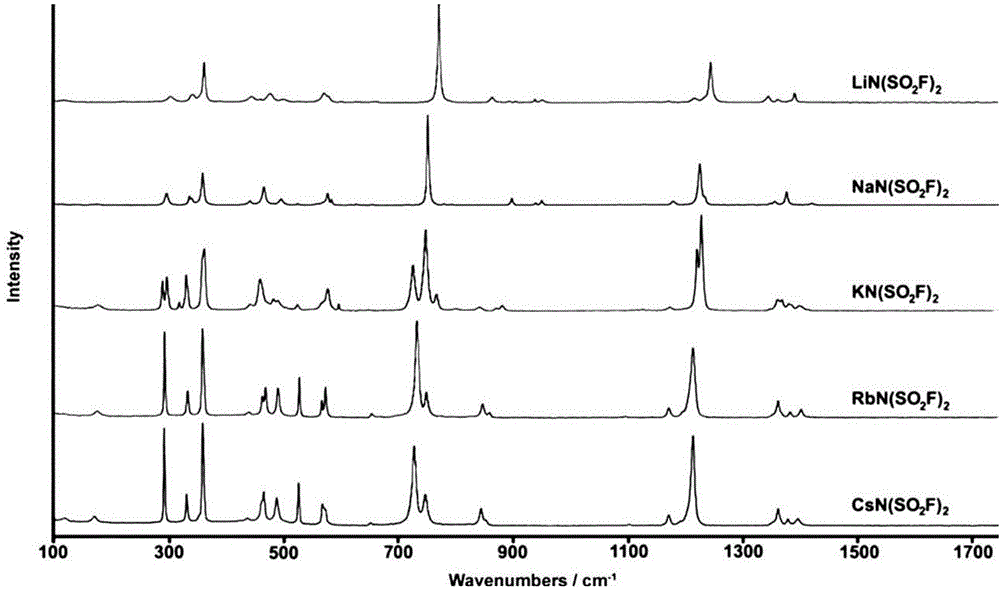

Preparation method of difluoro-sulfonyl imine salt

The invention relates to a preparation method of a difluoro-sulfonyl imine salt, and belongs to the field of fine chemical engineering. The difluoro-sulfonyl imine salt is MN(SO2F)2, wherein M is Li, Na, K, Rb or Cs. The preparation method comprises the following steps: mixing FSO2X, a nitrogen source, an acid-binding agent and an aprotic solvent to obtain a mixture, wherein X is F, Cl, Br or I, the nitrogen source is anammonium salt or anhydrous NH3, the acid-binding agent is a lithium, sodium, potassium, rubidium or cesium salt, the mole ratio of NH3 or ammonium ion to FSO2X is 1:(2-10), and the mole ratio of NH3 or the ammonium ion to the acid-binding agent is 1:(3-10); heating to perform reflux reaction on the mixture for 5-8 hours; cooling to obtain a filtrate; and removing the solvent to obtain a crude product, and performing vacuum drying to obtain the difluoro-sulfonyl imine salt. The preparation method has easily available raw material, is safe and pollution-free, is high in yield, is easy to realize separation and purification, is simple in step, is not severe in requirement of operation equipment, and is suitable for industrial production.

Owner:PERIC SPECIAL GASES CO LTD

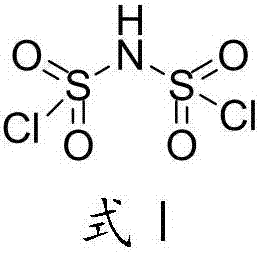

Preparation method for co-producing bis(chlorosulfonyl)imide and lithium bis(fluorosulfonyl)imide

InactiveCN111099566AReliable sourceImprove qualityNitrosyl chlorideAmidosulfonic acidImidePolymer science

The invention discloses a preparation method for coproducing bis(chlorosulfonyl)imide and lithium bis(fluorosulfonyl)imide, which comprises the following steps: S1, adding sulfuryl chloride into a first solvent, dropwisely adding octamethylcyclotetrasilazane for reaction, and carrying out purification to obtain bis(chlorosulfonyl)imide; S2, taking bis(chlorosulfonyl)imide and anhydrous hydrofluoric acid to react under the action of a catalyst to obtain bis(fluorosulfonyl)amide; and S3, taking the bis(fluorosulfonyl)amide and lithium fluoride to react in a second solvent, and carrying out purification to obtain the lithium bis(fluorosulfonyl)imide. According to the invention, proper raw materials are selected and matched with a solvent method to co-produce bis(chlorosulfonyl)imide and lithium bis(fluorosulfonyl)imide. The method has the advantages of simple preparation process, few and recyclable byproducts, high yield, no water participation in the production process, high purity of the obtained bis(chlorosulfonyl)imide and lithium bis(fluorosulfonyl)imide, no wastewater generation and green and environment-friendly process route, and is suitable for industrial production.

Owner:合肥利夫生物科技有限公司

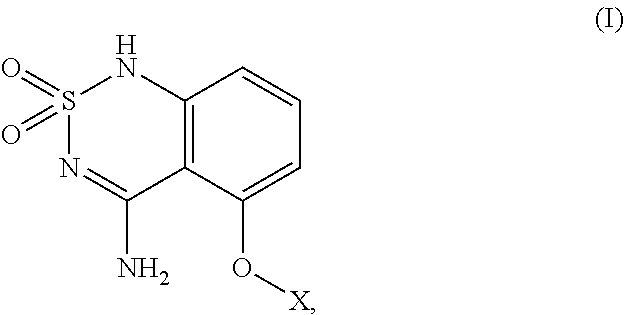

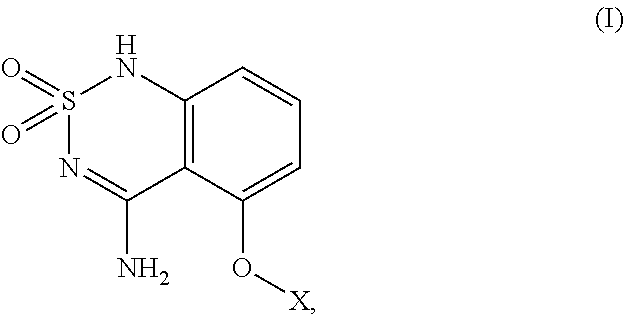

Processes and intermediates for making sweet taste enhancers

The present invention includes methods / processes and intermediates for preparing compounds having structural Formula (I):wherein X is alkyl, substituted alkyl, alkenyl, substituted alkenyl, heteroalkyl, substituted heteroalkyl, heteroalkenyl, or substituted heteroalkenyl.

Owner:SENOMYX INC

Sulfamic acid production process

ActiveCN101391759ASimple and fast operationSimplify labor intensityOrganic chemistryAmidosulfonic acidOleumAfter treatment

The invention discloses a novel sulfamic acid after-treatment process, which comprises: carbamide is adopted to be sulfonated with oleum for preparing sulfamic acid; after the reaction the dilute sulphuric acid with the concentration of 5 to 30 percent is added to regulate the concentration of the sulphuric acid in an reaction kettle to be about 70 percent, and the sulphuric acid is isolated after holding; then the dilute sulphuric acid with the concentration of 1 to 10 percent or water is added into the reaction kettle for a second time acidity regulation to regulate the concentration of the sulphuric acid in the reaction kettle to be 5 to 20 percent; then the high pure product with the purity greater than 99.9 percent can be obtained after recrystallization, filtering and drying. The after-treatment process is easy for operation and the labor hardship is lower; and the purity of the product is high and the quality is better.

Owner:中国中化股份有限公司 +1

Method for preparing disinfected-decolorized fish-squamosum organic acid calcium and non-denatured collagen

InactiveCN101792382AAvoid damagePreserve invarianceAmidosulfonic acidAnimal feeding stuffOrganic acidProteinase activity

The invention provides a method for preparing disinfected-decolorized fish-squamosum organic acid calcium and non-denatured collagen. The method comprises the following steps: adding disinfected decolorized fish squamosum solids to 10 to 20 percent organic acid in a solid-liquid ratio of 1:5-10; using energy-gathering ultrasonic wave to treat the obtained product for 4 to 24 hours; performing filtration and solid-liquid separation to obtain a crude product of collagen fish squamosum; standing filtrate at 10 DEG C for 4 to 15 hours to obtain organic acid calcium precipitate; filtering and drying the obtained product to obtain a finished product of disinfected-decolorized fish-squamosum organic acid calcium; adding 0.5 to 1 percent organic acid and / or 0.1 to 1 percent acidproof protease solution to the crude product of fish squamosum collagen in a solid-liquid ratio of 1:5-10; using energy-gathering ultrasonic wave to treat the obtained product at 10 to 35 DEG C for 2 to 4 hours until the crude product of fish squamosum collagen dissolves in the solution; removing impurities; and drying filtrate to obtain non-denatured collagen. The method has the advantages of low production cost and capability of obtaining disinfected-decolorized fish-squamosum organic acid calcium and non-denatured collagen at a time.

Owner:宋艳

Synthesis method for bis(fluorosulfonyl)imide salt

The invention discloses a synthesis method for a bis(fluorosulfonyl)imide salt, wherein the method comprises the following steps: (one) under the protection of nitrogen, dissolving a bis(chlorosulfonyl)imide salt in a nonprotic organic solvent to obtain a bis(chlorosulfonyl)imide salt organic solution; (two) under a stirring condition, adding an excess compound fluridizer into the organic solution, then heating to a temperature being 8 DEG C-20 DEG C higher than an organic solvent boiling point temperature, and making the bis(chlorosulfonyl)imide salt to undergo an effective fluorination reaction in the organic solvent, wherein the compound fluridizer is selected from at least two substances of antimony trifluoride, potassium fluoride, zinc fluoride and aluminum fluoride; (three) after the reaction is finished, filtering the reaction liquid, and concentrating the filtrate to obtain a concentrated solution; and (four) crystallizing the concentrated solution, filtering, drying, and thus obtaining the high-purity bis(fluorosulfonyl)imide salt. The synthesis method has the advantages of simple operation, high product productive rate, no toxic reagent to pollute the environment, and high purity of the product, and is suitable for large-scale production in industry.

Owner:JIANGSU GUOTAI SUPER POWER NEW MATERIALS

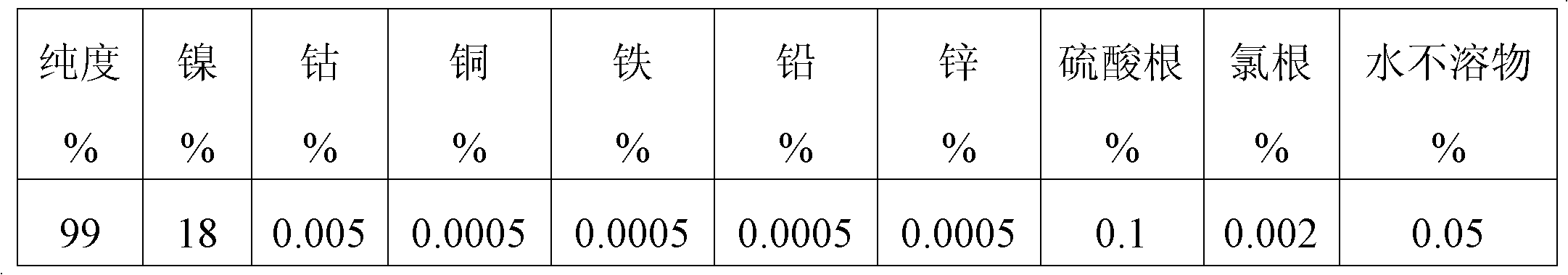

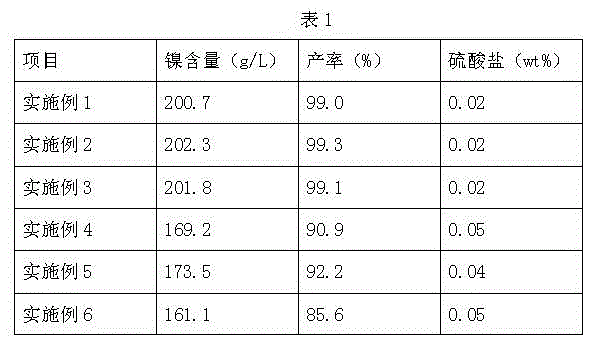

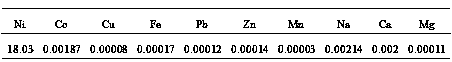

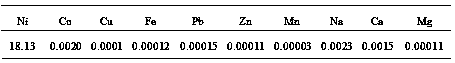

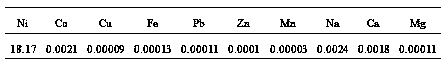

Preparation method of electronic grade high-purity nickel sulfamic acid solution

ActiveCN101704517ALow product contentLevel content decreasedAmidosulfonic acidDiammonium carbonateSodium hydroxide

The invention relates to a preparation method of an electronic grade high-purity nickel sulfamic acid solution, comprising the following steps of: (1) dissolving industrial grade nickel vitriol raw materials in purified water, filtering and concentrating a solution for crystallization to obtain a refined nickel vitriol crystal; (2) preparing the obtained nickel vitriol crystal into the solution to react with sal volatile; (3) precipitating and putting prepared alkaline nickel carbonate in a sodium oxide solution, cooking and washing the alkaline nickel carbonate to be neutral by purified water; and (4) reacting the washed alkaline nickel carbonate with sulfamic acid to obtain the nickel sulfamic acid solution. The preparation method has the advantages of high product purity, lower contents of sulfate and sodium ions than those of products prepared by an ordinary carbonate method, simple process condition, easy control and low production cost.

Owner:GUANGDONG GUANGHUA SCI TECH +1

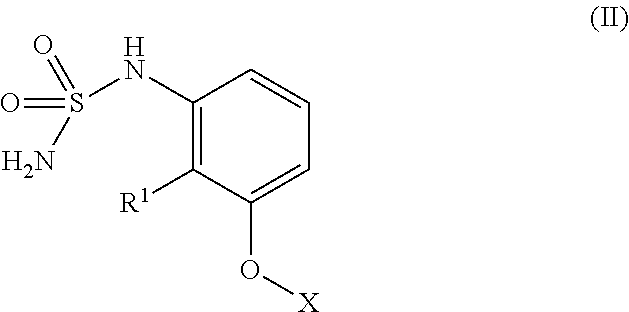

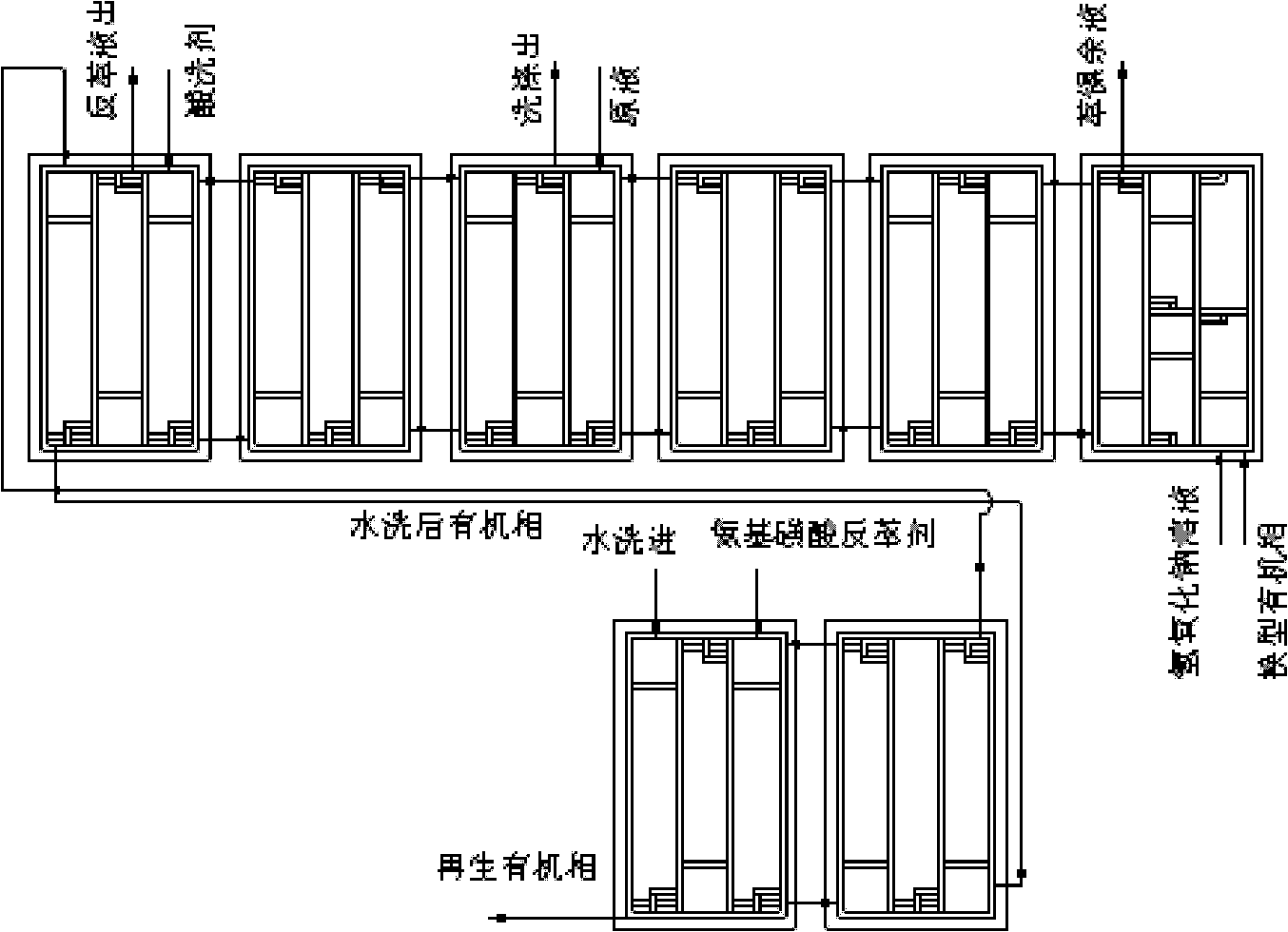

Technology for preparing nickel sulfamate through extraction method

The invention relates to a technology for preparing nickel sulfamate through the extraction method, belonging to the technical field of fine chemicals. The technology is characterized by comprising the following steps: using the raffinate obtained by extracting the two-stage countercurrent leaching liquor of high grade matte nickel and removing impurities as a stock solution to perform an extraction reaction with hard soap which is prepared from an organic phase and a sodium hydroxide solution according to a specific ratio; and washing a loaded organic phase with acid, and using aminosulfonicacid as a stripping agent to prepare a nickel aminosulfonate solution; and performing evaporation concentration, centrifugation and other working procedures to prepare the finished nickel aminosulfonate product. The invention has a simple technology and less loss of nickel. The massive consumption of resources such as water, electricity and the like can be avoided and the invention is a low-carbon production method suitable for future development.

Owner:JILIN JIEN NICKEL IND

Difluoro-sulfonyl imine preparation method and method for preparing difluoro-sulfonyl imine alkali metal salt by using prepared difluoro-sulfonyl imine

InactiveCN107381522AEasy to controlHigh purityNitrosyl chlorideAmidosulfonic acidChemical industryDistillation

The invention belongs to the technical field of fluorine chemical industry, and especially relates to a difluoro-sulfonyl imine preparation method and a method for preparing difluoro-sulfonyl imine alkali metal salt by using prepared difluoro-sulfonyl imine. The difluoro-sulfonyl imine preparation method comprises the following steps: polystyrene and antimony pentalfluoride are added in a solvent and are subjected to reaction to obtain polystyrene-loaded antimony pentalfluoride, difluoro-sulfonyl imin liquid is added for a reaction, after the reaction is completed, pumping filtration and underpressure distillation are carried out to obtain the difluoro-sulfonyl imin; the method for preparing difluoro-sulfonyl imine alkali metal salt by using the prepared difluoro-sulfonyl imine comprises the following steps: adding difluoro-sulfonyl imine, an alkali metal compound and polystyrene-loaded antimony pentalfluoride in a reaction solvent, reacting the materials for 6-10 h under the reaction temperature of 0-100 DEG C, filtering the materials after the reaction is completed to obtain a difluoro-sulfonyl imine alkali metal salt crude product, and re-crystallizing the difluoro-sulfonyl imine alkali metal salt crude product to obtain a difluoro-sulfonyl imine alkali metal salt fine product. The method has the advantages of controllable reaction, safety, high efficiency, and high yield, and is suitable for industrial production.

Owner:VALIANT CO LTD

Fast production method of high-purity metal sulphamate

The invention discloses a fast production method of high-purity metal sulphamate. The fast production method comprises the following steps of: adopting excess metal powder and sulphamic acid, wherein the average particle size of the metal powder is less than 100nm; introducing pure water at the temperature of 40-60 DEG C; grinding and stirring for reaction in a drum type closed reaction tank with a grinding device under the participation of high-pressure oxygen; filtering to obtain a sulphamate solution with the concentration which can be up to 180g / L (by weight of metal); and recovering the filter residue (the metal powder) for reutilizing nickel sulphamate and cobalt sulphamate. As raw materials are simple and strong acid, base and other initiators are not added during the production process, the pollution caused by other hetero ions is avoided, and the purity of the sulphamate is only affected by the metal powder and the purity of the sulphamic acid; the smaller the average particle size of the metal powder, the higher the yield; and sulfate radicals are less than 600ppm, and the content of sodium ions and other metal ions is very low, which can not be detected by a conventional method.

Owner:郑景宜

Preparation method of bis(fluorosulfonyl)amide alkali metal salt

ActiveCN110407184ASolving Sublimation Residue ProblemsReduce generationAmidosulfonic acidSolubilityMetal chloride

The invention discloses a preparation method of a bis(fluorosulfonyl)amide alkali metal salt. A trivalent metal fluoride is used for fluoridizing a bis(chlorosulfonyl)amide alkali metal salt in an organic solvent into the bis(fluorosulfonyl)amide alkali metal salt, then, a trivalent metal chloride and the bis(fluorosulfonyl)amide alkali metal salt are separated and purified by means of differencesof solubilities of the trivalent metal chloride and the bis(fluorosulfonyl)amide alkali metal salt in different solvents, the method avoids generation of hydrogen chloride gas in the fluorination process, and the fluorination efficiency is high.

Owner:刘大凡

A kind of method for preparing lithium fluorosulfonyl imide

ActiveCN103664712BHigh purityReduce contentAmidosulfonic acidSulfonic acid amide preparationImideReaction temperature

The invention relates to a method for preparing fluorine sulfimide lithium and belongs to the field of fine chemical industries. The method comprises the steps as follows: lithium salt and deionized water are prepared into a turbid liquid with the mass concentration of the lithium salt in a range of 20-50% in a reaction still, a refined fluorine sulfimide acid solution is added dropwise to obtain a reaction solution under the condition of stirring, the mass content of the deionized water in the fluorine sulfimide acid solution is in a range of 5-20%, the reaction temperature is in a range of 50-150 DEG C, and the reaction is stopped when the pH value of the reaction solution is in a range of 6-8. Non-vacuum drying is performed on the reaction solution firstly, and when the mass content of the deionized water is lower than or equal to 0.5%, vacuum drying is performed. The method is easy to operate, higher in process safety and capable of effectively improving the purity of products and satisfying requirements of lithium battery industries for the high purity.

Owner:PERIC SPECIAL GASES CO LTD

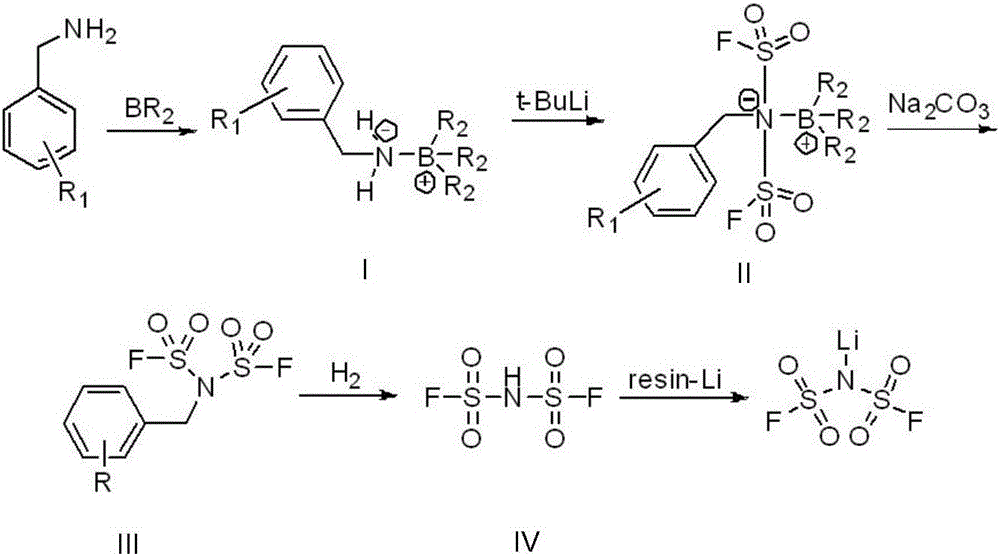

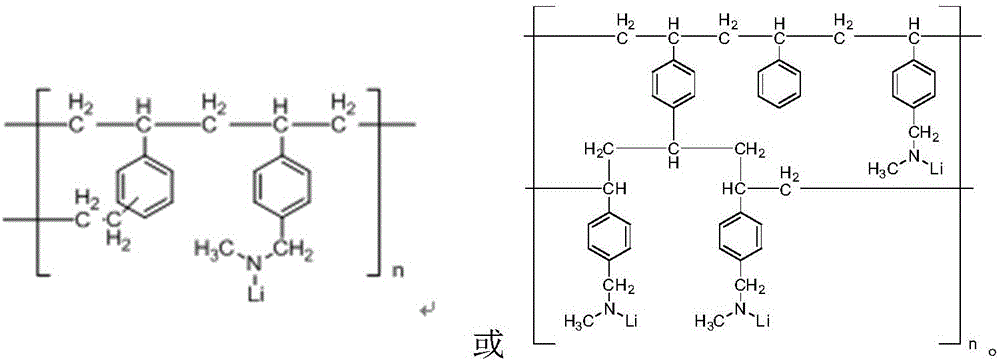

A preparing method of lithium bis(fluorosulfonyl)imide

A synthetic method of novel lithium bis(fluorosulfonyl)imide is provided. Compared with the prior art, the method is characterized in that the lithium bis(fluorosulfonyl)imide is prepared through reacting an aromatic methylamine that is adopted as an initial compound with organoboron, reacting with halogen sulfonyl to obtain a sulfonyl-containing aromatic methylamine, performing a hydrogenation reduction reaction to obtain bis(fluorosulfonyl)imide, and performing ion exchange with resin lithium. In a final strong base reaction for preparing the lithium bis(fluorosulfonyl)imide, the method adopts a resin lithium ion exchange technique, thus breaking away from convention, and the method researches the possibility that the reaction is performed without a solvent for the first time at home and abroad and synthesizes the lithium bis(fluorosulfonyl)imide in an ion exchange manner. The method has advantages of a simple process, convenience, simple after-treatment, no complex operation, and cyclic use of the resin lithium, and the like.

Owner:NANJING YUANSHU MEDICAL TECH CO LTD

Method for preparing lithium bis (fluorosulfonyl) imide by using organic metal lithium reagent

InactiveCN111573639AHigh yieldImprove product qualityNitrosyl chlorideAmidosulfonic acidImideSulfate radicals

The invention discloses a method for preparing lithium bis (fluorosulfonyl) imide by using an organic metal lithium reagent. The method comprises the following steps: S1, using the organic metal lithium reagent as a raw material, carrying out mixed reaction with bis (fluorosulfonyl) imide acid to obtain a lithium bis (fluorosulfonyl) imide crude product; S2, performing vacuum pumping on the crudeproduct, adding a poor organic solvent of lithium bis (fluorosulfonyl) imide for multiple times of washing, and then performing vacuum pumping to obtain a solid; and S3, adding an organic solvent intothe solid, extracting, filtering, concentrating, adding a low-polarity aprotic solvent into the concentrated solution, standing, crystallizing, filtering, and carrying out vacuum drying on the crystal to obtain the lithium bis (fluorosulfonyl) imide. The preparation steps are carried out without water under the protection of inert gas. According to the preparation method, high-purity lithium bis(fluorosulfonyl) imide can be prepared, the yield is high, the product quality is stable, and the content of impurities such as potassium ions, sodium ions, calcium ions, fluorine ions, chloride ions,sulfate ions and water in the product is effectively reduced.

Owner:LEE & MAN CHEM CO LTD

Energy-saving environment-friendly co-production process of cyanuric acid, food-grade sulfuric acid and sulfamic acid

InactiveCN105524006ASolve defects in independent production linksEasy to produceOrganic chemistryAmidosulfonic acidChemical industrySulfur

The invention relates to the technical field of chemical industry production, and specifically relates to an energy-saving environment-friendly co-production technology of cyanuric acid, food-grade sulfuric acid and sulfamic acid. The co-production process comprises the steps of (1) cyanuric acid production; (2) food-grade sulfuric acid production including sulfur melting, sulfur burning, conversion, absorption and drying, and residual heat recovery; and (3) sulfamic acid production. With the co-production process, defects in independent production links of cyanuric acid, food-grade sulfuric acid and sulfamic acid are solved, and no additional environmental treatment equipment is needed, such that the production process is greatly simplified, and the production period is shortened. The process is safe, energy-saving and environment-friendly.

Owner:SHANDONG MINGHUI NEW MATERIAL CO LTD

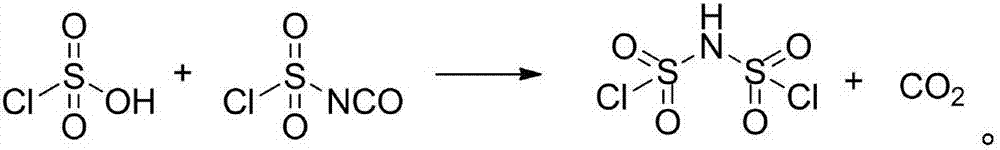

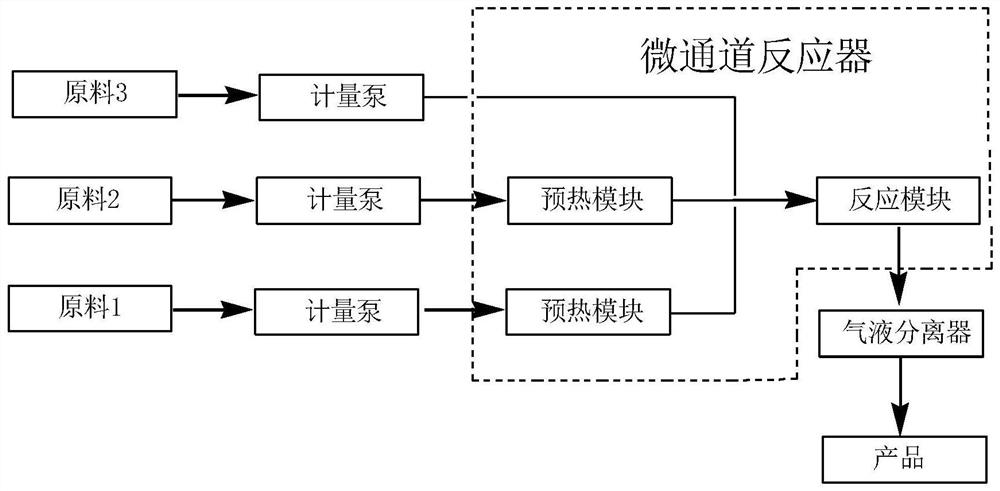

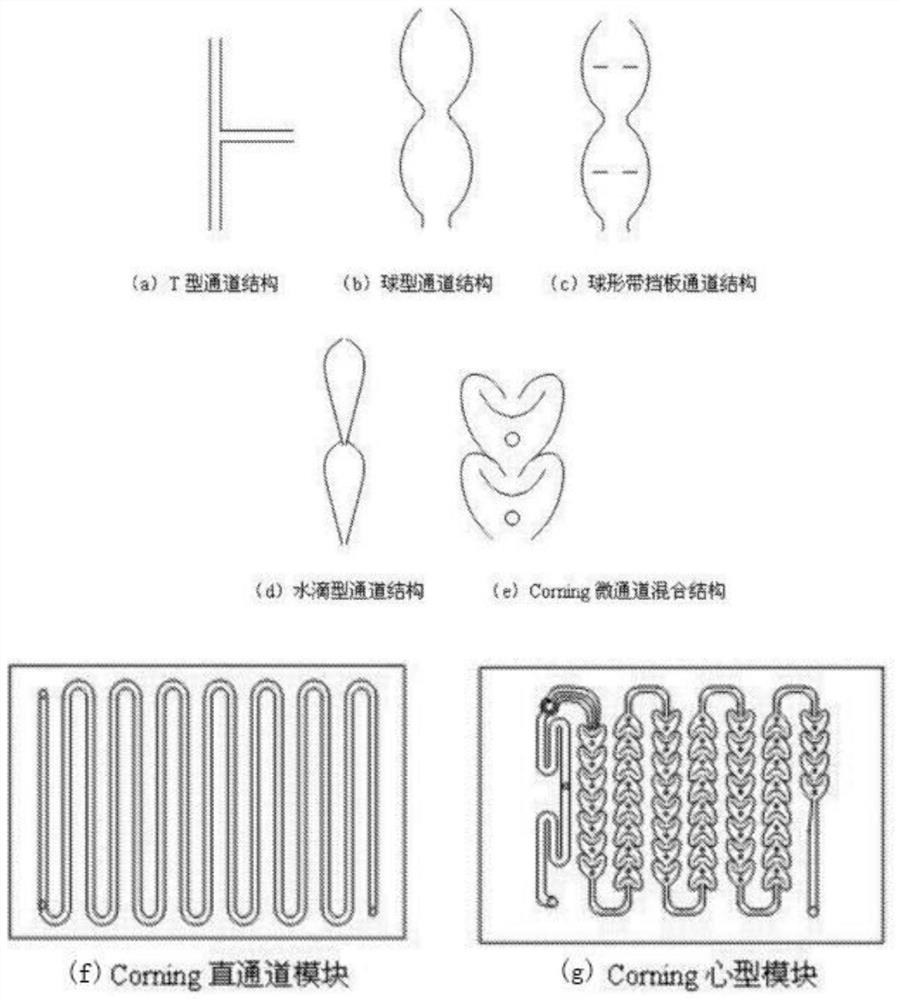

Continuous preparation method of bis(fluorosulfonyl)imide

The invention discloses a continuous preparation method of bis(fluorosulfonyl)imide. The continuous preparation of bis(fluorosulfonyl)imide is carried out in a microchannel reactor, and comprises the following steps: A1, preheating a first raw material chlorosulfonic acid and a second raw material chlorosulfonyl isocyanate in a preheating module at the preheating temperature of 30-150 DEG C; A2, feeding a third raw material hydrogen fluoride, the preheated first raw material chlorosulfonic acid and the preheated second raw material chlorosulfonyl isocyanate into a reaction module for mixed reaction, wherein the molar ratio of the hydrogen fluoride to the chlorosulfonic acid to the chlorosulfonyl isocyanate is (2-2.5):1:1, the flow rate of the chlorosulfonic acid is 1-100g / min, the flow rate of the chlorosulfonyl isocyanate is 1-100g / min, the reaction temperature is 30-150 DEG C, the reaction pressure is 0-0.5 MPa, and the retention time is 1-100s; and A3, carrying out gas-liquid separation on the product at the outlet of the reaction module to obtain bis(fluorosulfonyl)imide. The method has the advantages of simple process, low equipment loss, high yield and the like.

Owner:ZHEJIANG LANTIAN ENVIRONMENTAL PROTECTION HI TECH +1

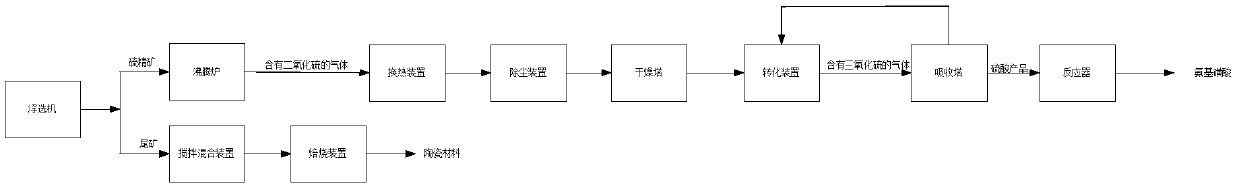

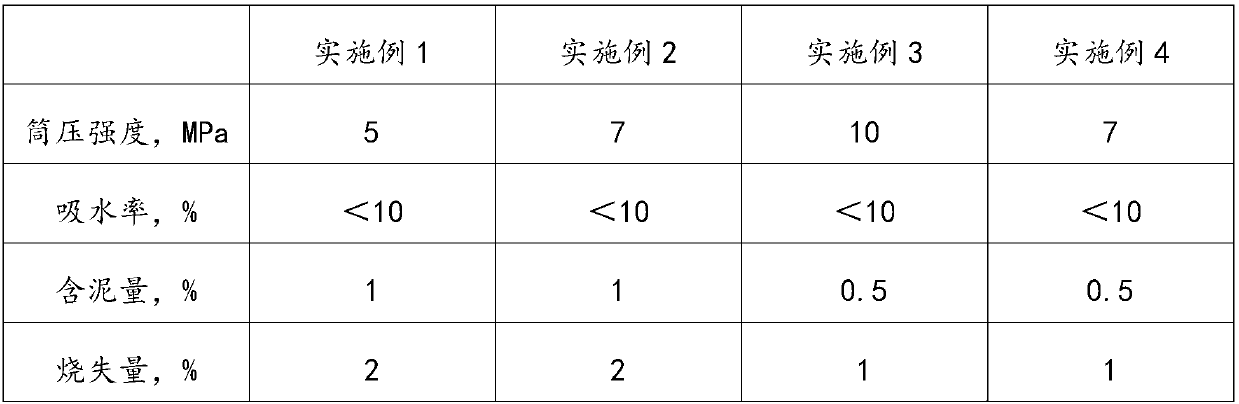

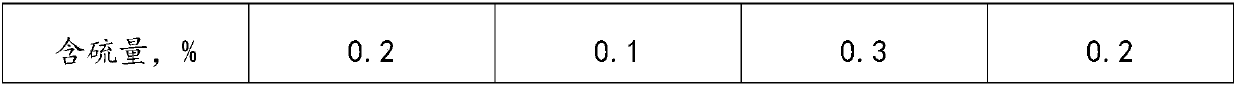

Method for comprehensive utilization of cyanide tailings and device

ActiveCN108017374AImprove purification effectEasy to reuseAmidosulfonic acidSulfur compoundsEconomic benefitsCyanide ion

The invention provides a method for comprehensive utilization of cyanide tailings. According to the method, sulfur concentrates with the sulfur content greater than or equal to 46% are screened out, and sulfuric acid is prepared from the sulfur concentrates, so that the quality of the sulfuric acid is guaranteed; by mixing the tailings, fly ash and clay according to a specific ratio and carrying out roasting at high temperature, cyanide ions and organic agents contained in the tailings can be decomposed, and thus, the tailings are changed into non-toxic products; the tailings contain a small amount of sulfur during roasting, internal structures of ceramsite can have gaps along with the volatilization of the sulfur, and crystal forms are changed, so that the strength of the ceramsite is greatly improved. According to the method for the comprehensive utilization of the cyanide tailings, provided by the invention, the cyanide tailings are completely utilized while virulent cyanide ions are removed from the cyanide tailings, so that the method is environmentally friendly, the prepared ceramsite and sulfuric acid are excellent in quality, and huge economic benefit is brought.

Owner:GO HIGHER ENVIRONMENT GRP CO LTD +1

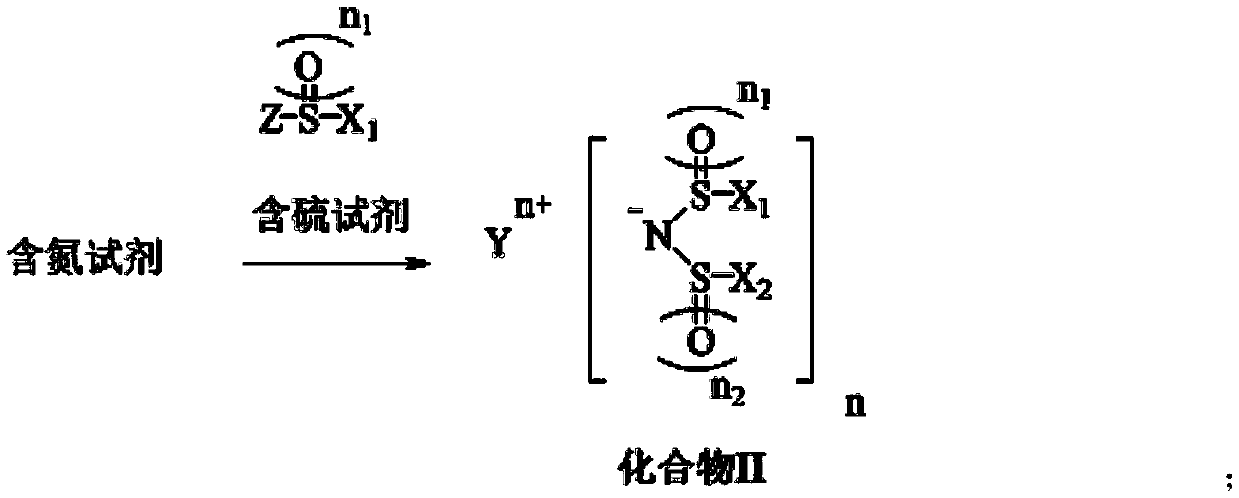

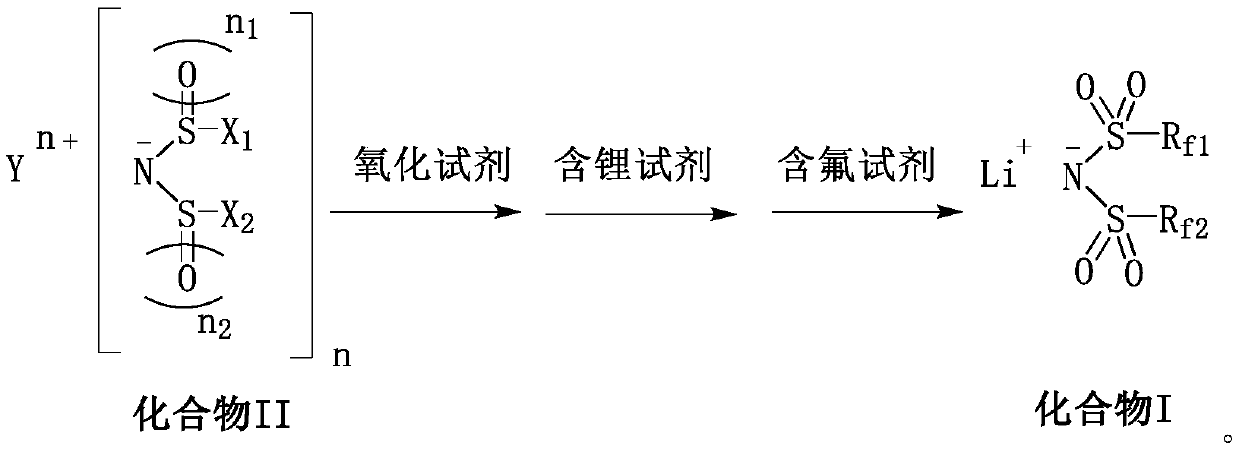

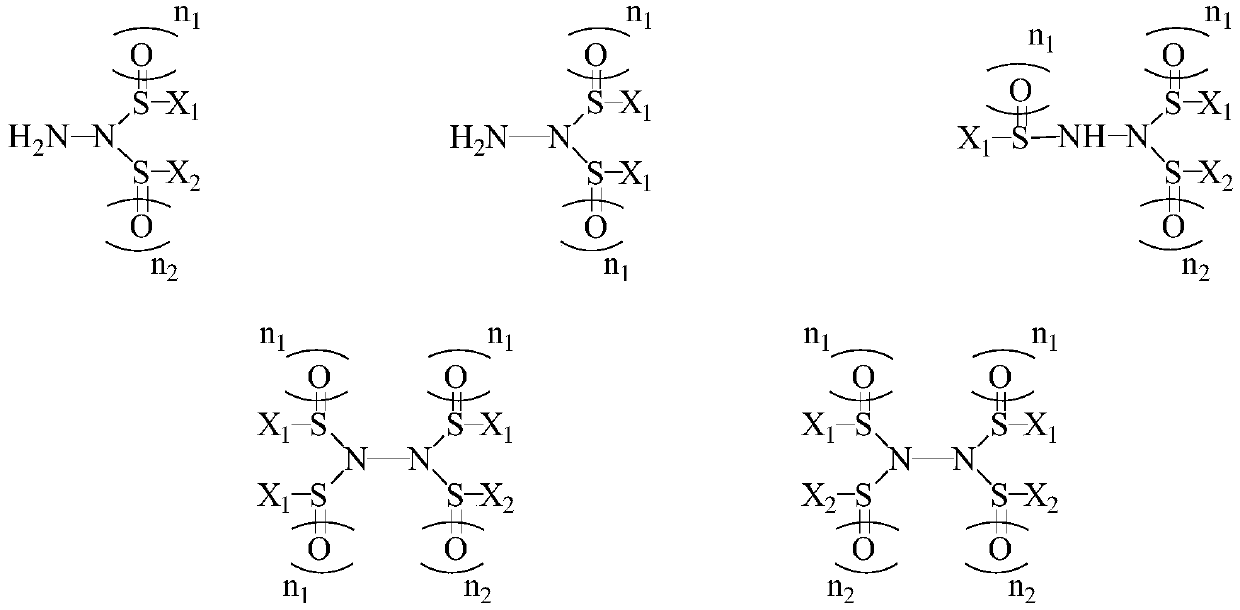

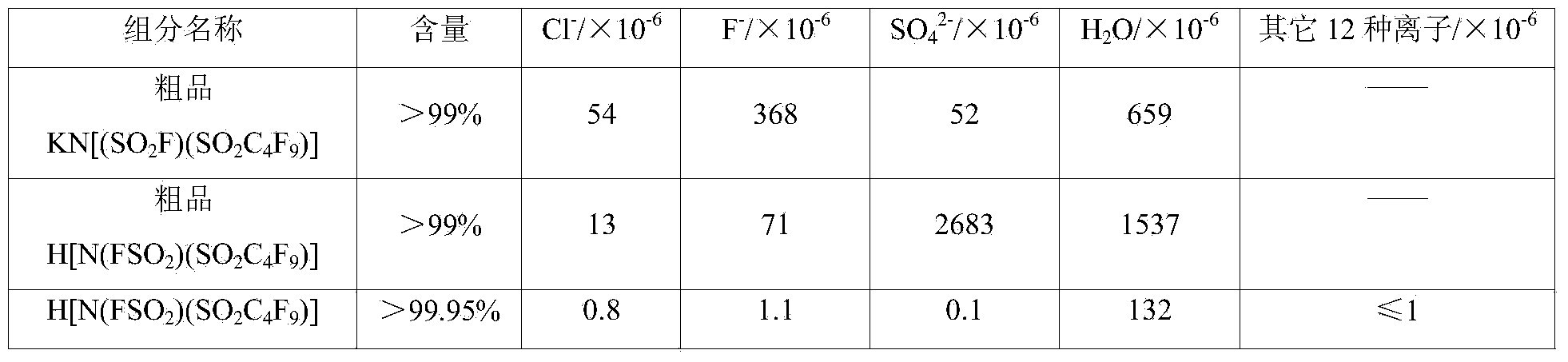

Preparation method and purification process of fluorine-containing lithium sulfimide

The invention discloses a preparation method and a purification process of fluorine-containing lithium sulfimide, and belongs to the technical field of lithium ion battery electrolytes. The preparation process is divided into three steps: (1) a first preparation step: reacting a nitrogen-containing reagent with at least one of a sulfur-containing reagent and a Y-containing reagent to obtain a compound II; and (2) a second preparation step: reacting the compound II with at least one of an oxidation reagent, a lithium-containing reagent and a fluorine-containing reagent to obtain a compound I, namely fluorine-containing lithium sulfimide. Finally, the prepared fluorine-containing lithium sulfimide crude product is subjected to the purification process to obtain a high-purity fluorine-containing lithium sulfimide refined product, and the prepared fluorine-containing lithium sulfimide can be used as an electrolyte lithium salt and an electrolyte additive of a lithium ion battery.

Owner:苏州固锂新能源科技有限公司

Production of electroplating-grade nickel aminosulfonate or electroplating-grade cobalt aminosulfonate through ion exchange method

InactiveCN105523531AHigh strengthIncrease contentIon exchange regulation/controlIon-exchange column/bed processesPhysical chemistryIon exchange

The invention discloses production of nickel aminosulfonate or cobalt aminosulfonate through an ion exchange method; the production of nickel aminosulfonate or cobalt aminosulfonate through the ion exchange method relates to ion exchange resin, an ion exchange column, amino sulfonic acid, a pure alkali solution and deionized water. The production comprises the production steps of ion exchange resin transformation, adsorption, elution and the like. The implementation scheme having the advantages of simple process route, low cost and continuous production is provided for production of nickel aminosulfonate or cobalt aminosulfonate.

Owner:江西核工业兴中科技有限公司

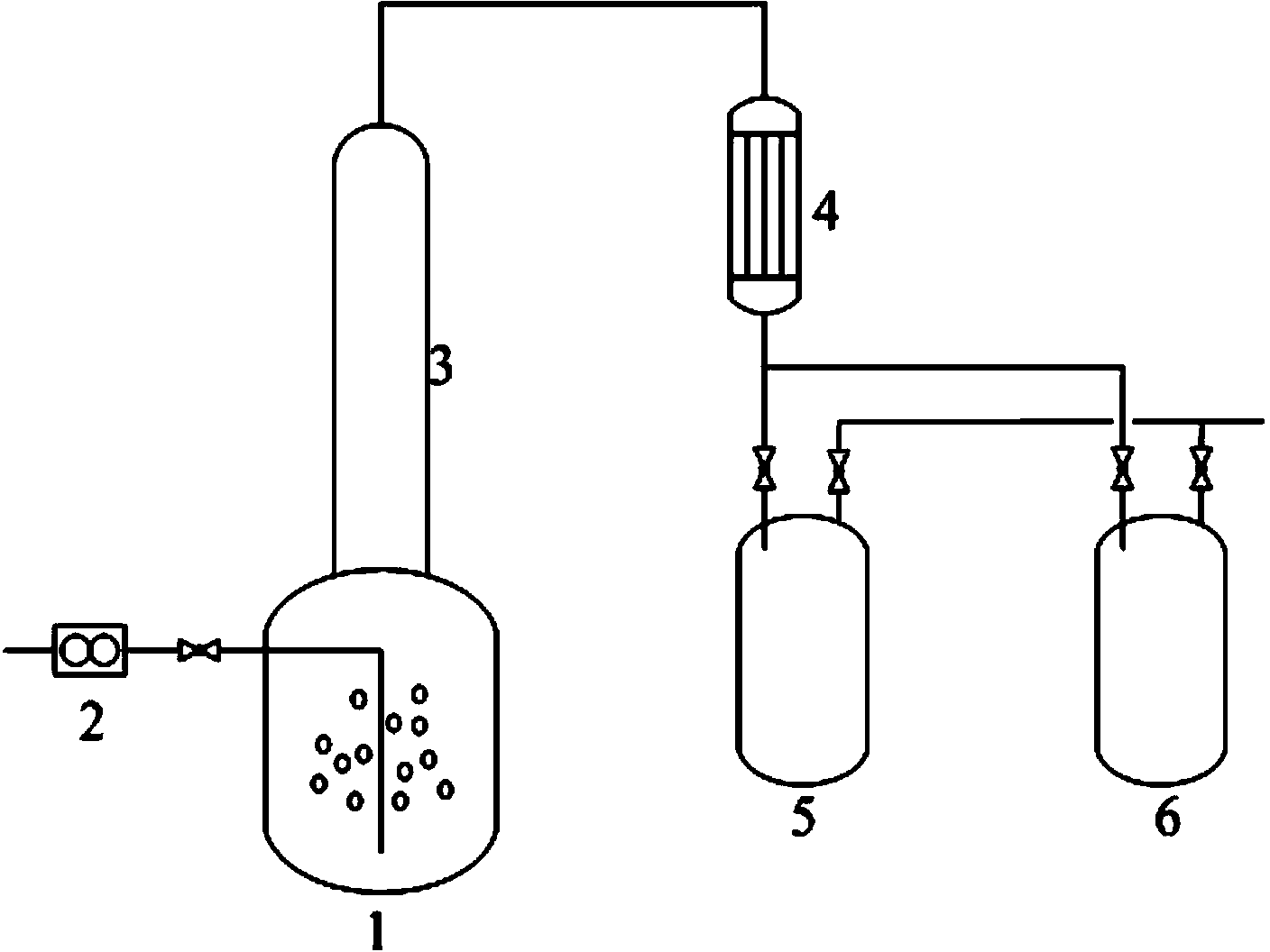

Method and device for preparing fluorine sulfimide acid

ActiveCN103664713AReduce contentImprove efficiencyAmidosulfonic acidSulfonic acid amide preparationDistillationReaction temperature

The invention relates to a method and a device for preparing fluorine sulfimide acid and belongs to the field of fine chemical industries. The method comprises the steps as follows: a crude product of fluorine sulfimide salt reacts with sulfuric acid with the mass concentration in a range of 98-105% with the presence of silicon dioxide at the reaction temperature in a range of 85-150 DEG C for 1-4 h, nitrogen is fed before the reaction, and a crude product of the fluorine sulfimide acid is prepared through atmospheric distillation after the reaction; and then the crude product of the fluorine sulfimide acid is led into a rectifying tower, and the fluorine sulfimide acid is obtained through refinement. According to the method, the content of impurities in the fluorine sulfimide acid is effectively reduced, the operability of the production process is improved, and the purity of the fluorine sulfimide acid is increased.

Owner:PERIC SPECIAL GASES CO LTD

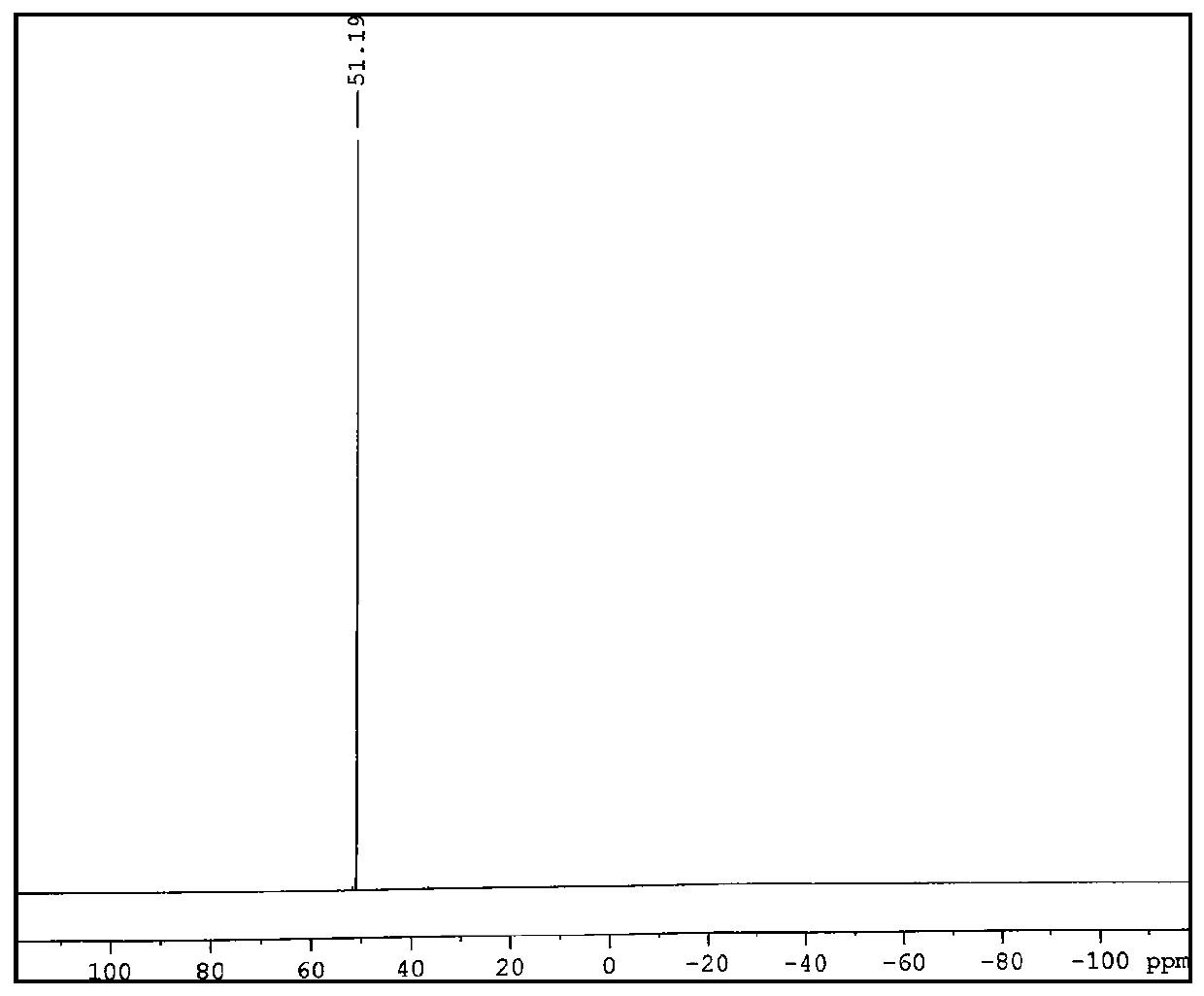

A kind of preparation method of bisfluorosulfonimide lithium salt

ActiveCN104925765BGuaranteed purityGuaranteed qualityNitrosyl chlorideAmidosulfonic acidImideHydrogen fluoride

Provided is a preparation method for lithium bis-(fluoro-sulfonyl) imide, comprising the following steps: (1) carrying out fluorination: synthesizing an intermediate bis-(fluoro-sulfonyl) imide by using bis-(chloro-sulfonyl) imide and hydrogen fluoride in presence of a catalyst; and (2) enabling the obtained bis-(fluoro-sulfonyl) imide and alkaline lithium to react, and carrying out solid-liquid separation after the reaction to obtain the lithium bis-(fluoro-sulfonyl) imide. The preparation method is low in cost, fewer in by-products and simple in aftertreatment, and is capable of guaranteeing the quality and purity of products, thereby being suitable for industrial production.

Owner:SHANGHAI CHEMSPEC CORP +1

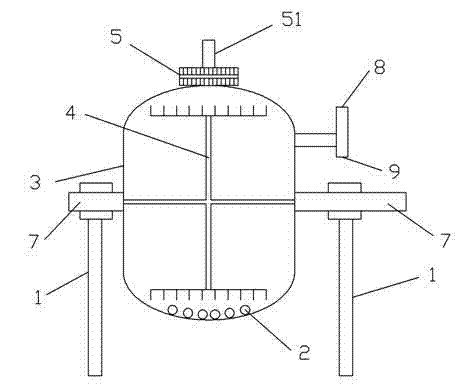

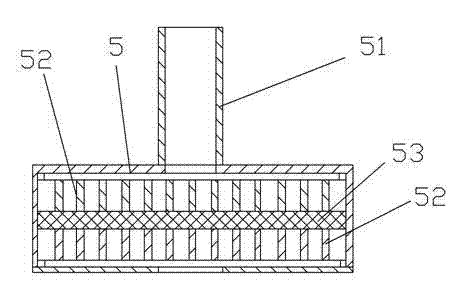

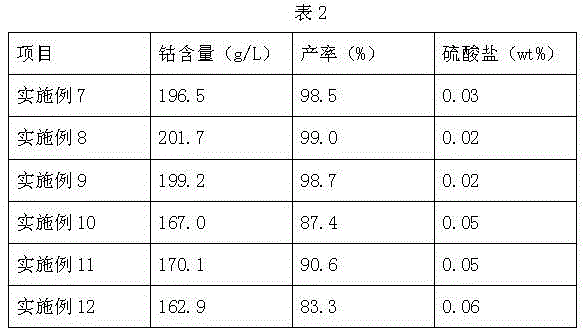

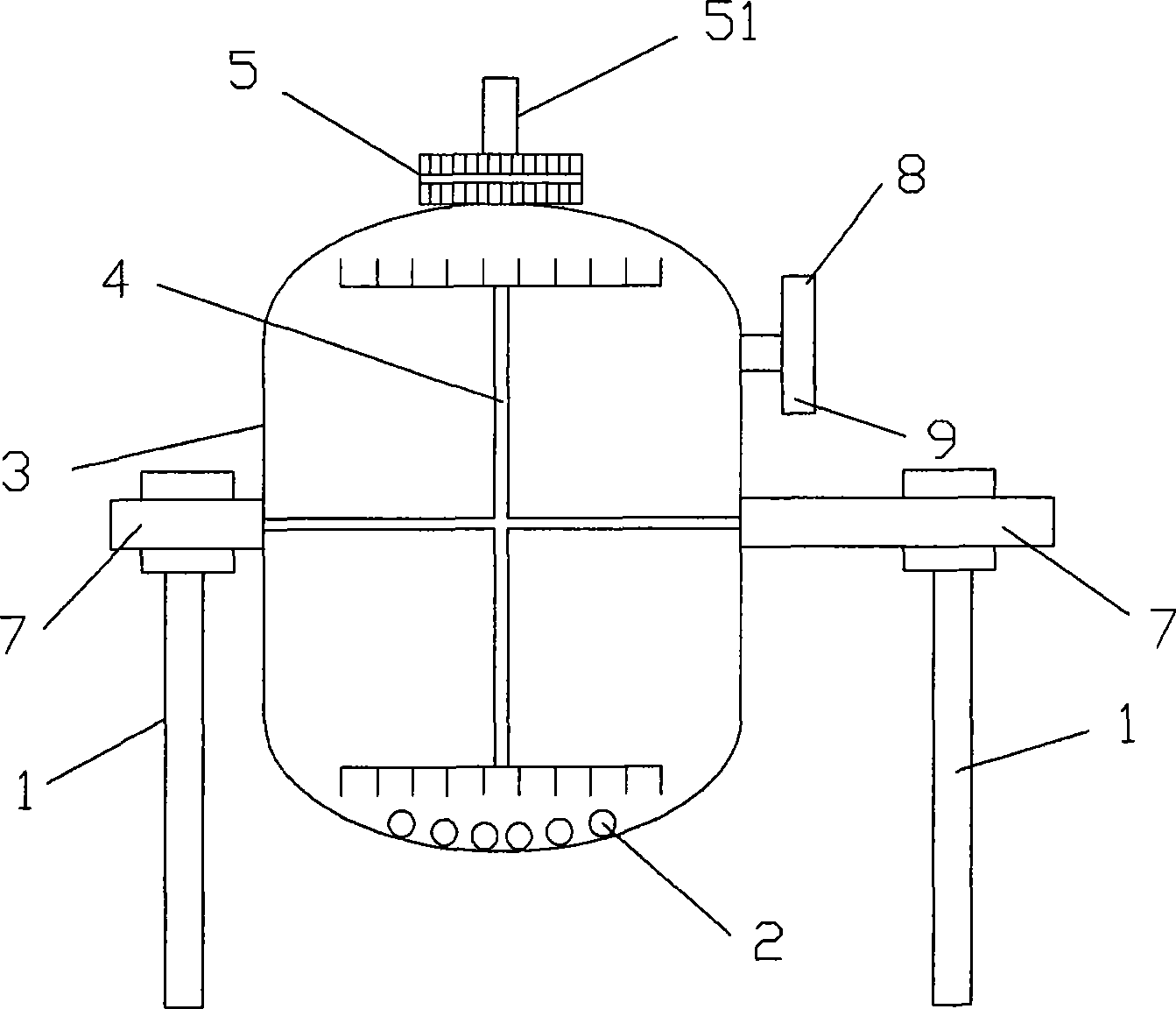

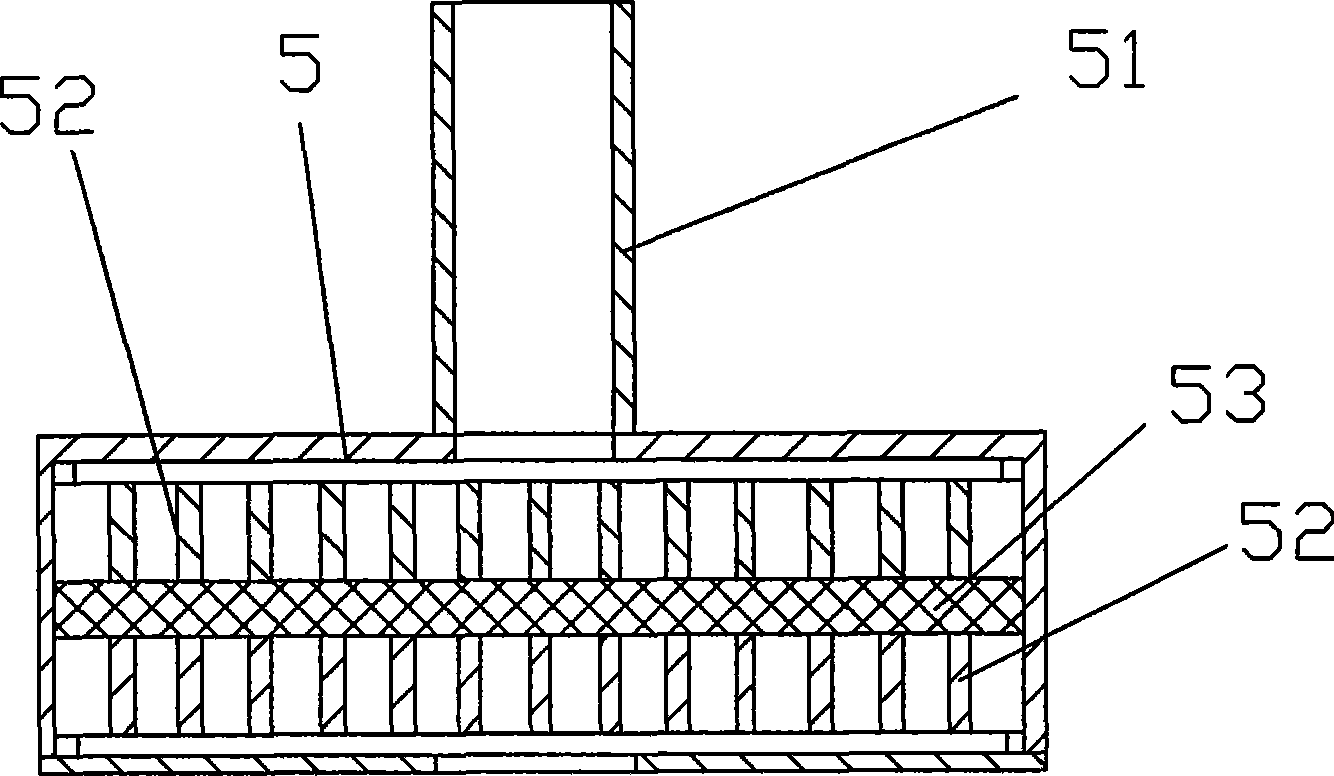

Low-sulfate radical sulfamate concentrated liquid preparation method and device thereof

InactiveCN101445225APromote decompositionShort reaction timeAmidosulfonic acidReaction timingChemistry

The invention discloses a low-sulfate radical sulfamate concentrated liquid preparation method and a device thereof. The method comprises: taking 1 to 3 portions of nickel carbonate, or cobalt carbonate, or nickel hydroxide or cobalt hydroxide (counted in metal weight) and 3 to 9 portions of dry powder sulfamic acid; stirring uniformly in a reaction can, then adding 5 to 15 portions of pure hot water with the temperature of 30-40 DEG C and stirring for 50 to 70 minutes in the closed reaction can; a mode of rotating the reaction can is employed by the stirring; a fixed stirring device is arranged in the closed reaction can for stirring, and ball milling grinding, stirring while grinding, pressurizing and filtering are carried out to collect the concentrated liquid of nickel sulfamic acid or cobalt sulfamate; the concentration can achieve about 210g / L; the sulfate radicals are less than 600PPM; and crystallization can be obtained by heating and vaporizing for a while. The special device designed for the method integrates reaction and filtering, shortens the reaction time and improves the reaction effect.

Owner:郑景宜

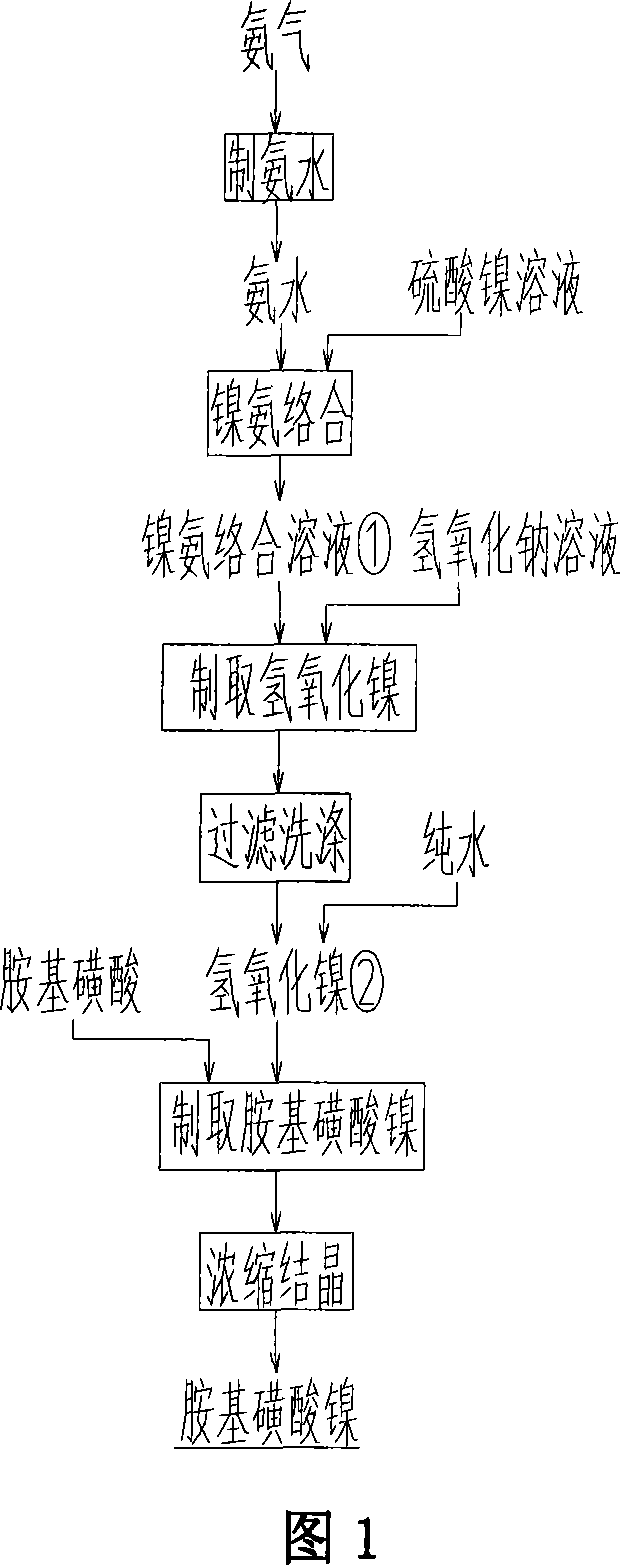

Method for producing amido nickel sulphonic acid

The invention relates to a process for producing nickel sulfamic acid, which is characterized in that the preparation process comprises (1) nickel sulfate or nickel chloride is carried on nickel ammonia complex reaction with ammonia to obtain nickel ammonia complex solution, (2) nickel hydroxide is prepared by the reaction of the produced nickel ammonia complex solution and sodium hydrate, (3) the produced nickel hydroxide solution is washed and filtered, (4) nickel sulfamic acid solution is produced by the reaction of the filtered nickel hydroxide solution and sulfamic acid, and (5) nickel sulfamic acid is prepared by condensing and crystallizing nickel sulfamic acid solution. The process of the invention has the advantages that the cost is reduced by producing through combining with nickel sulfate, the product purity is high, the process condition is simple and the reaction endpoint is clear.

Owner:JINCHUAN GROUP LIMITED

Method for preparing nickel aminosulfonate with solid sulfamic acid

ActiveCN103818888AQuality improvementEfficient use ofAmidosulfonic acidPhysical chemistryAcid dissolution

The invention discloses a method for preparing nickel aminosulfonate with solid sulfamic acid, comprising the following steps: carrying out P204 extraction on a nickel-containing solution to obtain a nickel-containing loaded organic phase; directly carrying out back extraction on the nickel-containing loaded organic phase with solid sulfamic acid to convert the nickel-containing loaded organic phase to a high concentration of a nickel aminosulfonate solution, evaporating, crystallizing, centrifuging, drying and screening to obtain a nickel aminosulfonate product. The invention has beneficial effects as follows: as resources are fully utilized and solid sulfamic acid is directly used in the reaction, an acid dissolution process is reduced, cost is saved and labor intensity of operators is also minimized; due to over-dose of sulfamic acid during the back extraction, the prepared nickel aminosulfonate solution has a high concentration (150g / L-200g / L), evaporation time is short, steam consumption is reduced, and production cycle is shortened.

Owner:JINCHUAN GROUP LIMITED

Production process of bis (chlorosulfonyl) imide

ActiveCN113800486ALow costIncrease profitNitrosyl chlorideAmidosulfonic acidChemical industryChlorosulfuric acid

The invention relates to the technical field of production of bis (chlorosulfonyl) imide, in particular to a production process of bis (chlorosulfonyl) imide. The production process of the bis (chlorosulfonyl) imide comprises the steps of adding sulfamic acid and thionyl chloride into a reaction kettle until solids are completely dissolved, then adding sulfur trioxide into the reaction kettle at a constant speed, after the sulfur trioxide is completely added, heating to the temperature of 90-120 DEG C, continuing to react for 5-10 hours, restoring to normal pressure, opening a condensate outlet valve of a condenser, continuing to react for 1-3 hours, carrying out reduced pressure rectification until no condensate flows out of the condenser, and obtaining the target product bis (chlorosulfonyl) imide. Compared with an original chlorosulfonic acid method process, the production process has the advantages that the hydrogen chloride waste gas amount is reduced by 1 / 3, the sulfur dioxide tail gas can be recycled and reused in a thionyl chloride production device, the yield of three wastes is further reduced, and the production process belongs to an innovative process meeting the development requirements of the green chemical industry.

Owner:SHANDONG KAISHENG NEW MATERIALS

Preparation method of lithium bis (fluorosulfonyl) imide

PendingCN114506829ALow costAvoid environmental pollutionNitrosyl chlorideAmidosulfonic acidImideOrganic solvent

The invention belongs to the technical field of lithium ion battery electrolyte salt synthesis, and particularly relates to a preparation method of lithium bis (fluorosulfonyl) imide. Comprising the following steps: (1) in the presence of an organic solvent, mixing bis (fluorosulfonyl) imide triethylamine salt and an alkaline lithium salt, carrying out a stirring reaction, carrying out reduced pressure distillation, and removing triethylamine and water generated in the reaction until no bis (fluorosulfonyl) imide triethylamine salt exists in a reaction solution; and (2) filtering the reaction liquid after the reaction in the step (1) under the protection of nitrogen, concentrating the filtrate, adding a poor solvent, crystallizing, filtering and drying to obtain the product lithium bis (fluorosulfonyl) imide. The preparation method disclosed by the invention is simple and convenient to operate, the lithium ion exchange reaction is thorough, and the product is easy to crystallize and separate, so that the generated lithium bis (fluorosulfonyl) imide is high in yield and high in purity.

Owner:SINOPHARM CHEM REAGENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com