A kind of method for preparing lithium fluorosulfonyl imide

A technology of lithium fluorosulfonimide and fluorosulfonimide acid, which is applied in the field of preparing lithium fluorosulfonimide, can solve the problems of poor safety, inconvenient operation of the method, and low purity of lithium fluorosulfonimide, and achieves Effects of preventing excessive temperature rise, improving operability, and reducing the content of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

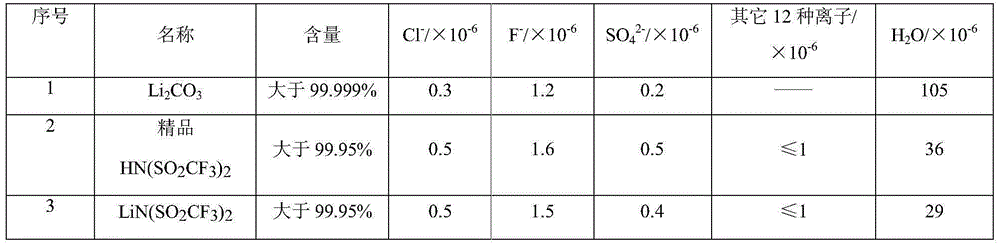

[0054] In a 200L reaction kettle sprayed with polytetrafluoroethylene, put 15kg of lithium carbonate and 60kg of deionized water to form a suspension with a lithium salt mass concentration of 20%. Under stirring, drop deionized water with a mass content of 5 %HN(SO 2 CF 3 ) 2 The reaction solution is obtained from the solution, the reaction temperature is between 50-53°C, the reaction is stopped when the pH value of the reaction solution is 6.0-6.3, and the reaction solution is spray-dried in the spray drying equipment that has been sprayed with polytetrafluoroethylene. The obtained solid powder has a deionized water mass content of 3520ppm, and the solid powder is vacuum-dried at a temperature of 196-200°C and a pressure of 1-6Pa. After 3 hours, 112.6kgLiN(SO 2 CF 3 ) 2 , the yield is 96.8%. Lithium carbonate, high-quality HN(SO 2 CF 3 ) 2 And finally get LiN(SO 2 CF 3 ) 2 The mass content of the components is shown in Table 2.

[0055] Various material components...

Embodiment 2

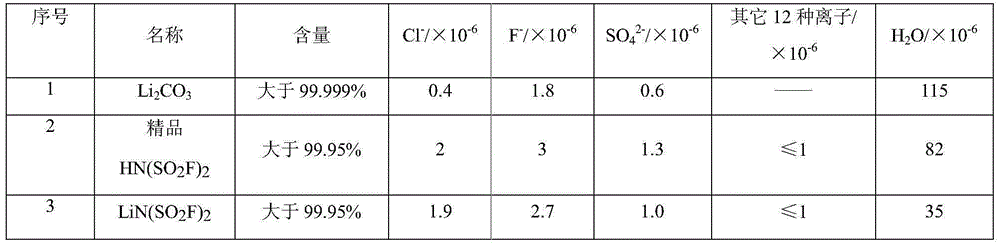

[0058] In a 200L reaction kettle sprayed with polytetrafluoroethylene, put 15kg of lithium carbonate and 15kg of deionized water to form a suspension with a lithium salt mass concentration of 50%. Under stirring, drop deionized water with a mass content of 20% %HN(SO 2 f) 2 The reaction solution is obtained from the solution, the reaction temperature is between 145-150°C, the reaction is stopped when the pH value of the reaction solution is 7.7-8.0, and the reaction solution is spray-dried in the spray drying equipment that has been sprayed with polytetrafluoroethylene. The mass content of deionized water in the obtained solid powder was 4261ppm. The solid powder was vacuum-dried at a temperature of 100-106°C and a pressure of 493-500Pa. After 15 hours, 73.7kg LiN(SO2F)2 was obtained, with a yield of 97.2%. Lithium carbonate, high-quality HN(SO 2 CF 3 ) 2 And finally get LiN(SO 2 f) 2 The mass content of the components is shown in Table 3.

[0059] Various material comp...

Embodiment 3

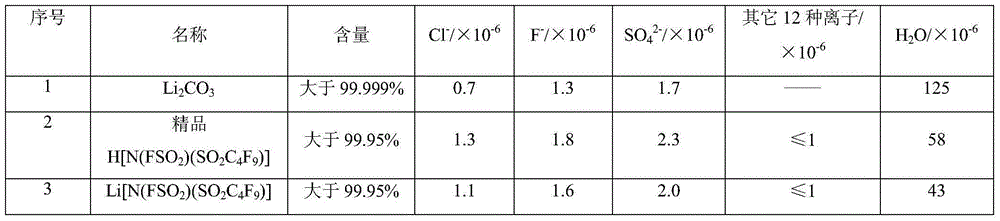

[0062] In a 200L reaction kettle sprayed with polytetrafluoroethylene, put 15kg of lithium carbonate and 45kg of deionized water to form a suspension with a lithium salt mass concentration of 25%, and add dropwise deionized water with a mass content of 10% under stirring. %H[N(FSO 2 )(SO 2 C 4 f 9 )] to obtain the reaction solution, the reaction temperature is between 80~84°C, the reaction is stopped when the pH value of the detection reaction solution is 7.7~8.0, and the reaction solution is spray-dried in the spray drying equipment through polytetrafluoroethylene spraying treatment , the obtained solid powder deionized water mass content is 3861ppm, the solid powder is vacuum-dried at a temperature of 120-123°C and a pressure of 100-108Pa, and after 10h, 146.9kgLi[N(FSO 2 )(SO 2 C 4 f 9 )], the yield is 93.6%. Lithium carbonate, fine H[N(FSO 2 )(SO 2 C 4 f 9 )] and finally Li[N(FSO 2 )(SO 2 C 4 f 9 )] The mass content of the components is shown in Table 4.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com