Continuous preparation method of bis(fluorosulfonyl)imide

A technology of bisfluorosulfonimide and chlorosulfonic acid, which is applied in the direction of sulfamic acid, nitrogen and non-metallic compounds, etc., can solve the problems of unsuitable industrial production, difficulty in obtaining raw materials, difficulty in obtaining raw materials, etc., and achieve equipment loss Small size, high product yield, avoiding the effect of non-corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

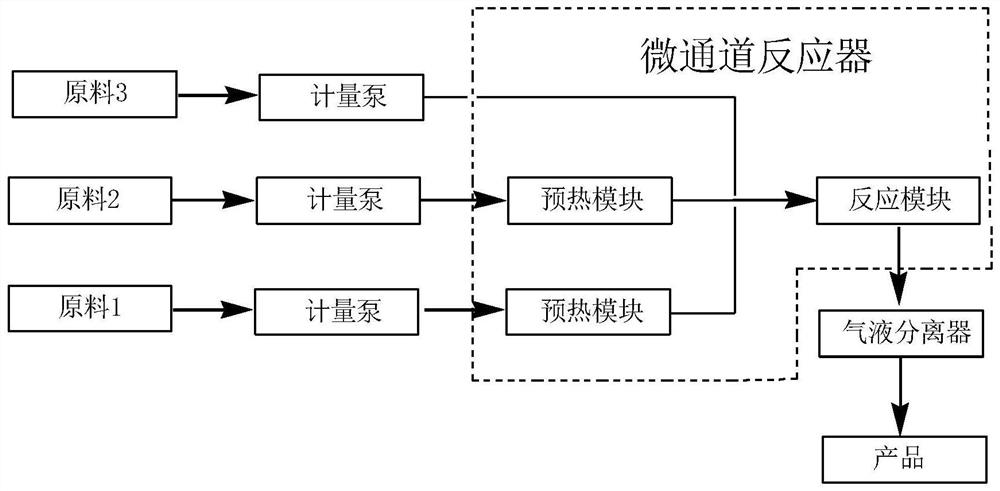

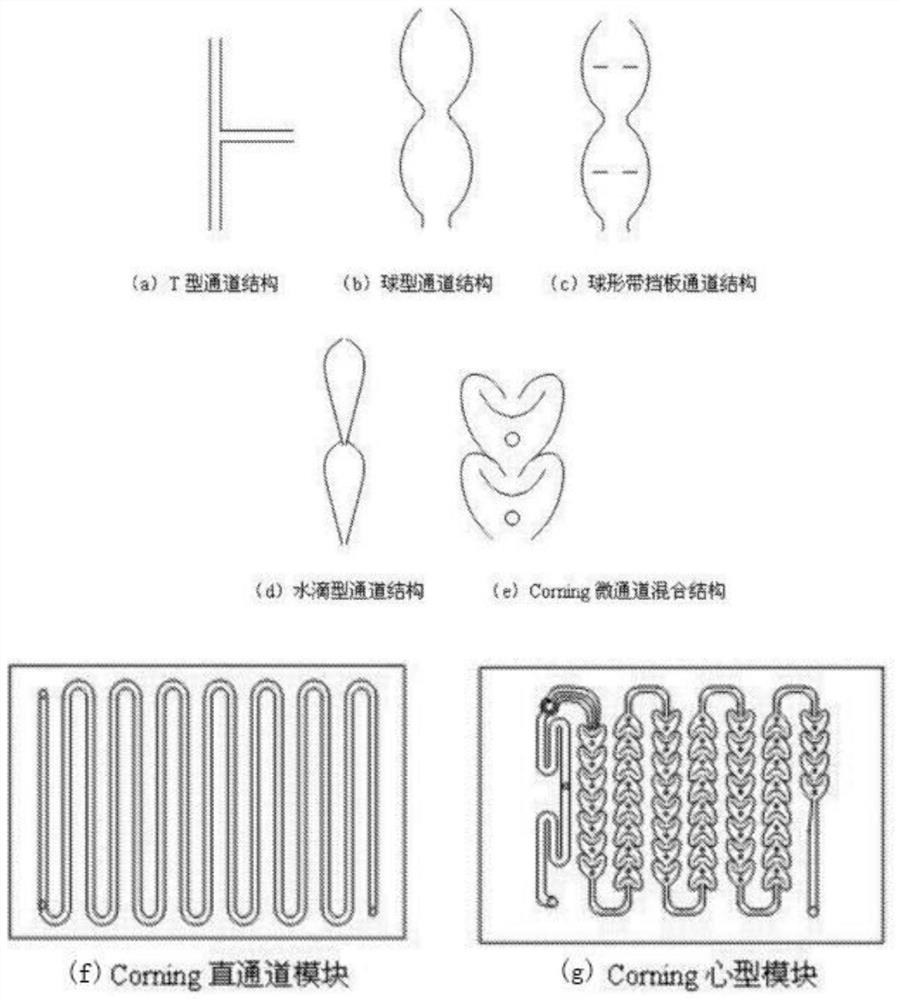

[0034] In this embodiment, the attached figure 2 Corning Microchannel Reaction Modules (Corning Straight Channel Module and Corning Cardioid Channel Module) as shown, and follow the attached figure 1 Determine the connection mode of the microchannel reactor, the number of reaction modules is determined according to the flow rate and reaction residence time, and the heat transfer medium is heat transfer oil.

[0035] Set the temperature of the heat exchanger to 100°C (ie, the reaction temperature), and the reaction pressure to 0.3MPa. Set the mass flow rate F chlorosulfonic acid=38.7g / min of each metering pump, F chlorosulfonic acid isocyanate=47.0g / min, the reaction raw material chlorosulfonic acid and chlorosulfonic acid isocyanate pass through the microchannel respectively After the module is preheated, it enters the heart-shaped microchannel reaction module. Hydrogen fluoride passes through the gas mass flow meter F hydrogen fluoride = 14.6g / min, and directly enters the h...

Embodiment 2

[0037] This embodiment adopts the same Corning microchannel reactor as Embodiment 1, and according to the same connection mode and control method.

[0038] Set the heat exchanger temperature to 150°C (ie the reaction temperature), and the reaction pressure to 0.4MPa. Set the mass flow rate F chlorosulfonic acid=65.8g / min of each metering pump, F chlorosulfonic acid isocyanate=80.0g / min, the reaction raw material chlorosulfonic acid and chlorosulfonic acid isocyanate pass through the microchannel respectively After the module is preheated, it enters the heart-shaped microchannel reaction module. Hydrogen fluoride passes through the gas mass flow meter F hydrogen fluoride = 22.6g / min, and directly enters the heart-shaped microchannel reaction module for fluorination reaction. Hydrogen fluoride, chlorosulfonic acid, and chlorosulfonic acid isonitrile The molar ratio of the acid ester is 2.0:1:1, and the reaction residence time is 13s. The reaction product was separated by a gas-...

Embodiment 3

[0040] This embodiment adopts the same Corning microchannel reactor as Embodiment 1, and according to the same connection mode and control method.

[0041] Set the heat exchanger temperature to 30°C (ie the reaction temperature), and the reaction pressure to 0.1MPa. Set the mass flow rate F chlorosulfonic acid=8.2g / min of each metering pump, F chlorosulfonic acid isocyanate=10.0g / min, the reaction raw material chlorosulfonic acid and chlorosulfonic acid isocyanate pass through the microchannel respectively After the module is preheated, it enters the heart-shaped microchannel reaction module. Hydrogen fluoride passes through the gas mass flow meter F hydrogen fluoride = 3.5g / min, and directly enters the heart-shaped microchannel reaction module for fluorination reaction. Hydrogen fluoride, chlorosulfonic acid, and chlorosulfonic acid isonitrile The molar ratio of the acid ester is 2.5:1:1, and the reaction residence time is 100s. The reaction product was separated by a gas-li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com