Technology for preparing nickel sulfamate through extraction method

A technology of nickel sulfamic acid and sulfamic acid, applied in the direction of sulfamic acid, nitrogen and non-metallic compounds, etc., can solve the problems of low concentration of nickel sulfamic acid, strong hydrolysis of sulfamic acid, low solubility at room temperature, etc. The effect of small loss, high product quality, energy dependence and low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0055] Example 1, what stripping agent used for the first time is the sulfamic acid that deionized water dissolves. The concentration is 110 g / l.

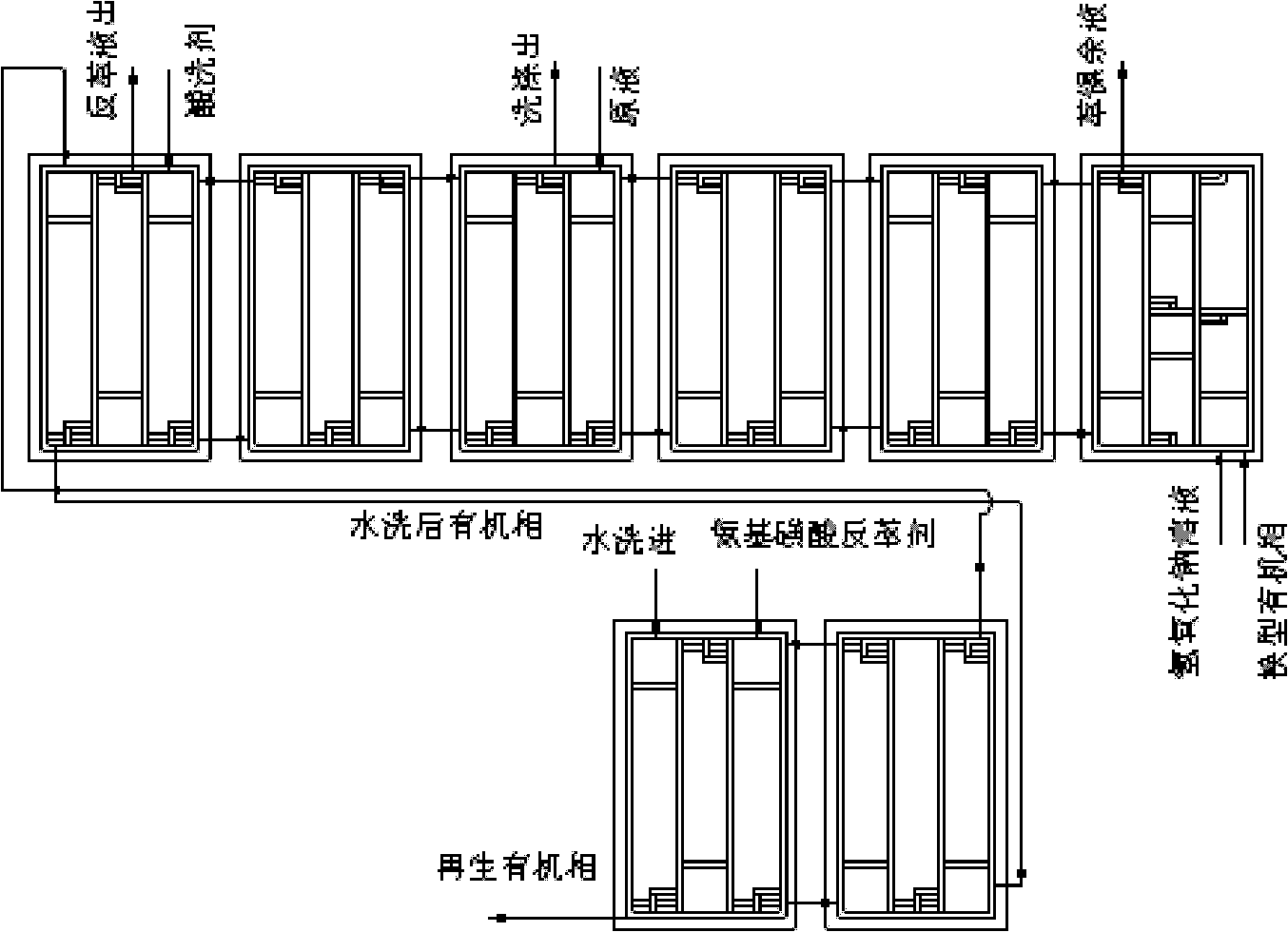

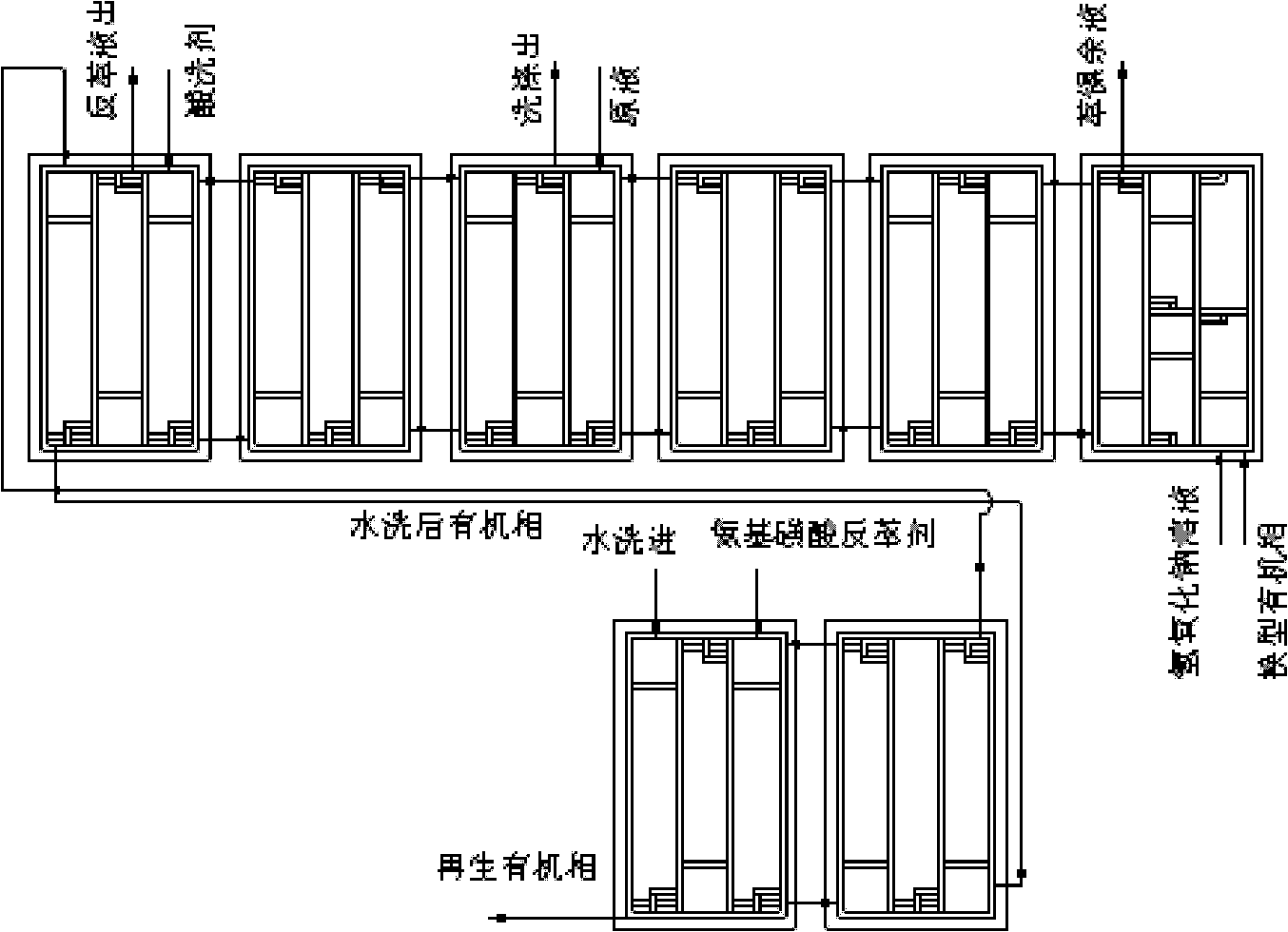

[0056] The number of extraction tank stages: 4 stages of saponification, 8 stages of extraction, 6 stages of pickling, 6 stages of sulfamic acid stripping, and 2 stages of water washing.

[0057] Specifications: Width*height*length is 600*3400*1000 (single-stage size, the same below), the volume of the mixing chamber is 0.241m 3 , clarification chamber volume 1.428m 3 In the box, the liquid intake of each section is controlled by the flow meter as

[0058] Extraction section: stock solution (nickel concentration 45g / l) inlet volume is 0.4m 3 / h, organic phase flow rate is 2m 3 / h, sodium hydroxide solution (400g / l) flow rate 0.04m 3 / h, the saponification rate is 30%,

[0059] Pickling section: sulfuric acid aqueous solution flow rate 0.35m 3 / h;

[0060] Stripping section: stripping agent (concentration of sulfamic acid is...

example 2

[0063] Example 2, what stripping agent used is to contain the sulfamic acid nickel solution that sulfamic acid concentration is 90g / l, contains nickel 50g / l, controls each section liquid inlet amount by flowmeter to be

[0064] Extraction section: stock solution (nickel concentration 60g / l) inlet volume is 0.4m 3 / h, organic phase flow rate is 2m 3 / h, sodium hydroxide solution (400g / l) flow rate 0.045m 3 / h, saponification rate 45%;

[0065] Pickling section: sulfuric acid aqueous solution flow rate 0.35m 3 / h

[0066] Stripping section: Stripping agent (concentration of sulfamic acid is 90g / l, nickel concentration is 50g / l) flow rate is 0.25m 3 / h;

[0067] Washing section: deionized water flow rate 0.05m 3 / h.

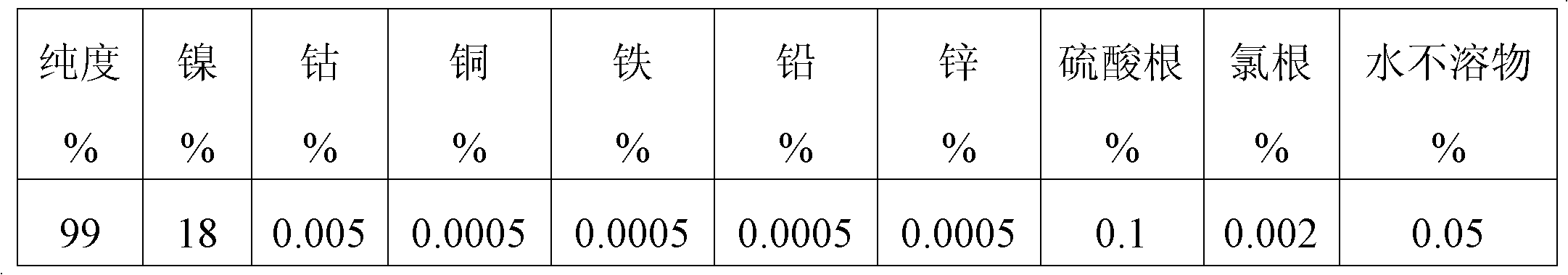

[0068] Stripping output pH value is 3.6. Contains nickel 70g / l, copper 0.0005g / l, iron 0.0005g / l, the nickel sulfamate solution of sulfate radical 3.75g / l.

[0069] Note: Through the above control conditions, the extraction section produces a raffinate conta...

example 3

[0070] Example 3, what stripping agent used is to contain the sulfamic acid nickel solution that sulfamic acid concentration is 100g / l, contains nickel 70g / l, controls each section liquid inlet amount by flow meter to be

[0071] Extraction section: the feed volume of the stock solution (nickel concentration 80g / l) is 0.25m 3 / h, organic phase flow rate is 2m 3 / h, sodium hydroxide solution (400g / l) flow rate 0.052m 3 / h, saponification rate 60%;

[0072] Pickling section: sulfuric acid aqueous solution flow rate 0.35m 3 / h;

[0073] Stripping section: stripping agent (concentration of sulfamic acid is 100g / l, nickel concentration is 70g / l) flow rate is 0.25m 3 / h;

[0074] Washing section: deionized water flow rate 0.06m 3 / h.

[0075] The pH value of the stripping output is 4.0. Nickel sulfamate solution containing 100g / l nickel, 0.0005g / l copper, 0.0005g / l iron and 5g / l sulfate radical.

[0076] Therefore, the solution is removed from the entrained organic matter, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com