Indium gallium antimonide crystal growing furnace with traveling wave magnetic field

A technology of crystal growth furnace and traveling wave magnetic field, which is applied in the directions of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of difficult generator design, etc., and achieve the effect of weakening macro segregation, facilitating uniform distribution, and low dislocation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

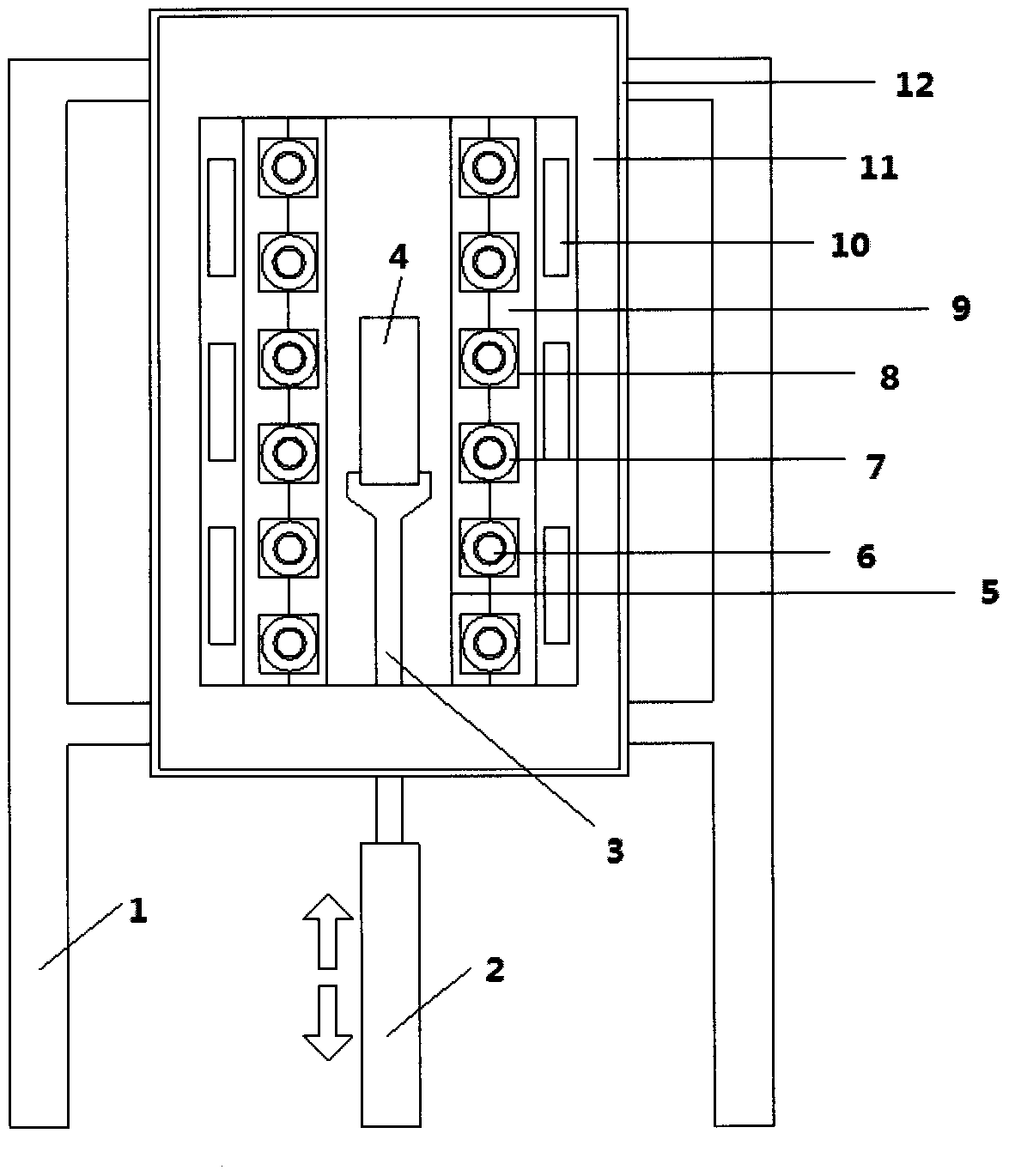

[0018] Combine below Figure 1-5 To describe this embodiment in detail, figure 1 It is a structural schematic diagram of the crystal growth furnace of the present invention, figure 2 is a schematic diagram of the magnetic field generating mechanism, image 3 It is a top view of the coil and the coil support in the furnace body of the present invention, Figure 4 It is a schematic diagram of the vertical lifting mechanism of the crystal growth furnace of the present invention, Figure 5 It is a schematic diagram of the supporting mechanism of the crystal growth furnace body of the present invention.

[0019] The invention includes a magnetic field generating mechanism, a vertical lifting mechanism and a furnace body supporting mechanism. The magnetic field generating mechanism includes an iron core 6 , three-phase conductive insulated wires 7 and an insulating protective shell 8 . There are several sets of three-phase insulated wires 7 on the iron core 6, and the three-ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com