Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53results about How to "Eliminate organizational defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

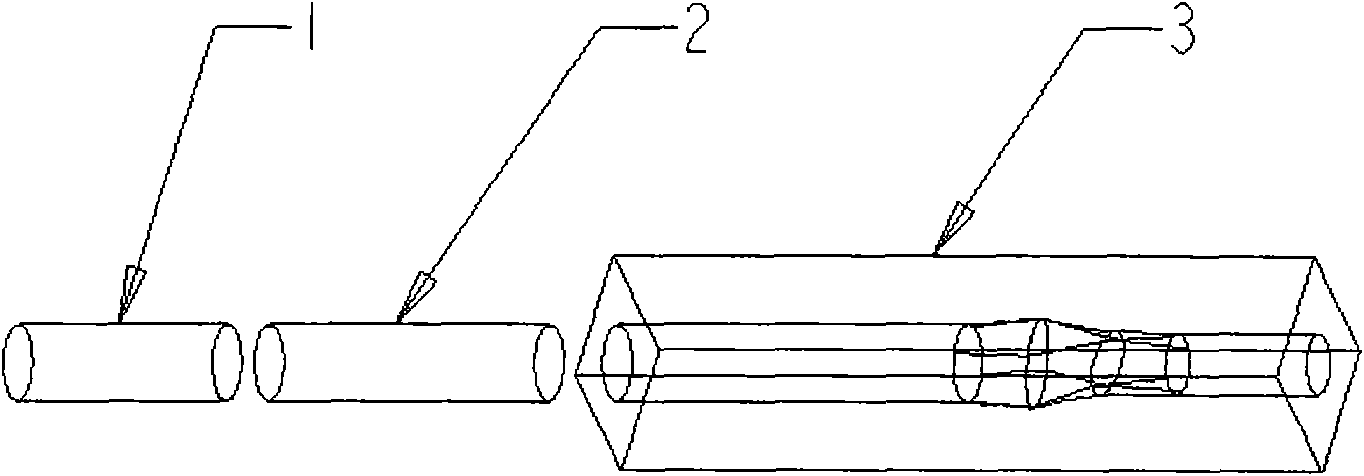

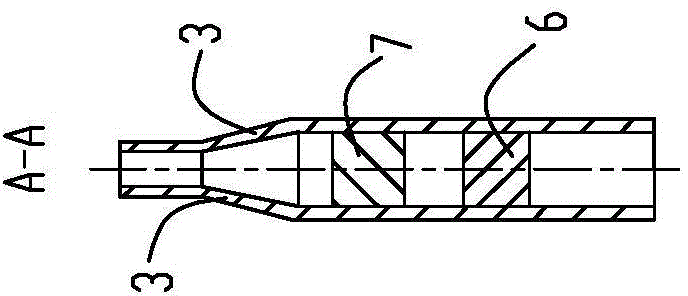

Equal-passage variable-cross-section extruding mold and extrusion forming method for pipes

InactiveCN102430609AImproved strain distributionIncrease stressExtrusion diesExtrusion mandrelsStress distributionShear stress

The invention relates to an equal-passage variable-cross-section extruding mold and an extrusion forming method for pipes. The equal-passage variable-cross-section extruding forming is adopted, so the extruding forming of the pipes is formed through the twisting shearing deformation and the upsetting deformation on the cross section, and the combination of various deformation modes in one extruding process is realized. The pipe walls are in a strong three-direction press stress state through being limited by die cavities and polyurethane foam filling agents, in the deformation stage of circle-ellipse-circle and ellipse twisting change, materials enter twisting shearing deformation zones of the metal transition regions, the material internal tissues generate rotation and shearing stress under the effect of the shearing stress, the orientation of the material tissue structure is caused, i.e. a new tissue structure is formed, and the material tissue structure under the same deformation degree is improved. The mold and the method have the advantages that deformation degree higher than that of the traditional forming process can be obtained, the strain distribution and the stress distribution inside the pipes are improved, residue casting tissues of the pipes can be favorably crushed, the forms and the distribution of inclusions are changed, and the internal tissue defects of the pipes are eliminated.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Lost foam casting production low-carbon steel upper core disc and impact seat processing method

InactiveCN104162633AAvoid crackingImprove compromiseFoundry mouldsFoundry coresManufacturing technologyHigh volume manufacturing

The invention discloses a lost foam casting production low-carbon steel upper core disc and impact seat processing method. The method comprises the following steps: making foam polystyrene EPS into a foaming member, which has the same shape as a cast and is a little bigger than the cast; painting a plurality of fireproof coatings on the surface of the foaming member, placing the foaming member in non-adhesive moulding sands, carrying out casting on the foaming member, wherein during the casting process, the foam polystyrene EPS foaming member is burnt and gasified under the assistance of vacummizing and vibration during the casting process, and finally the molten liquid replaces the foaming member as the cast. The lost foam technology is used to manufacture upper core disc and impact seat, is capable of reducing the metal tissue defects and improving the compactness and anti-fatigue strength of metals, moreover has the advantages of high precision in size, reducing on cleanness, reduced processing time, compact tissue of products, suitability for massive production, and high automation, can greatly improve the operation environment, and has greater advantages and a vaster prospect, compared to the conventional manufacture technology of upper core disc and impact seat.

Owner:XIANGTAN SANTAI MACHINERY MFG

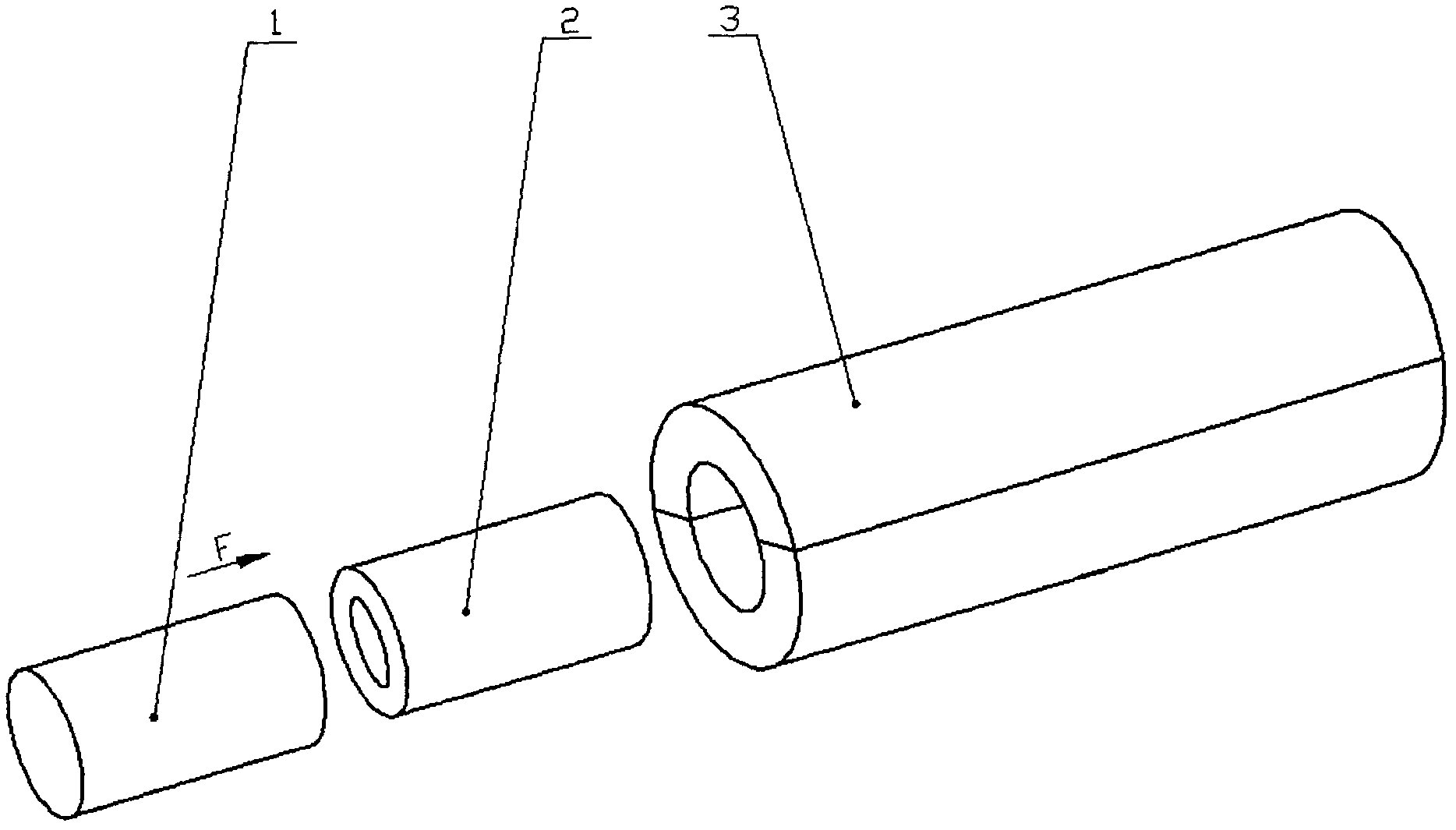

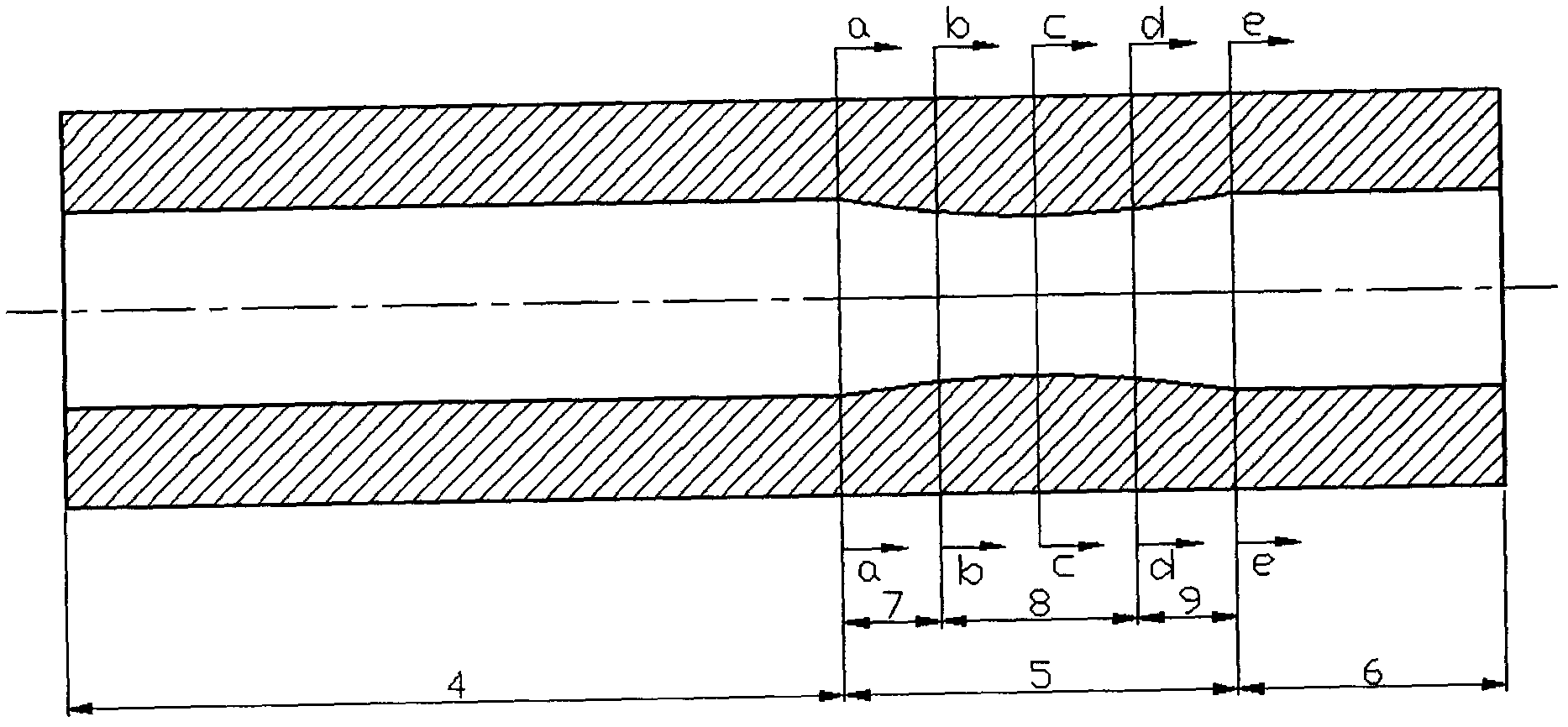

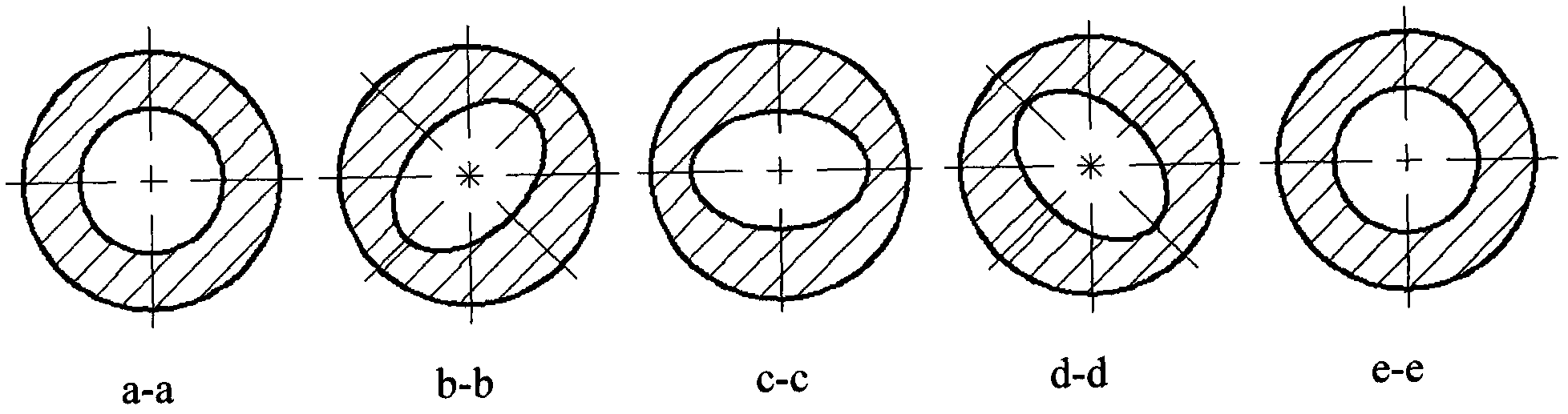

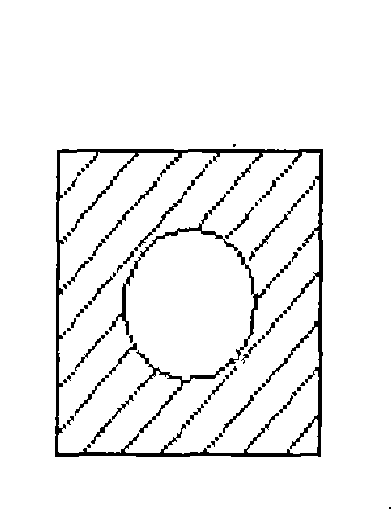

Variable-channel extrusion die and forming method

InactiveCN101823085AImproved strain distributionIncrease stressExtrusion diesExtrusion mandrelsPowder metallurgyLow load

The invention relates to a variable-channel extrusion die and a forming method. The variable-channel extrusion die comprises a male die (1) and a female die (3), a die cavity of the female die sequentially comprises a feeding section (4), a front forming section (5), a middle forming section (6), a rear forming section (7) and a discharging section (8) from an inlet of a blank (2) to an outlet of the blank (2), wherein the feeding section (4) is a circular equant channel, the front forming section (5) is a circular-elliptical transition channel, the middle forming section (6) is a prismatic elliptical channel, the rear forming section (7) is an elliptical-circular transition channel, and the discharging section (8) is a prismatic circular channel; and the blank (2) enters from an inlet of the female die (3) and is limited by the die cavity of the female die (3) to change a circular cross-section into an elliptical cross-section and change the elliptical cross-section into the circular cross-section in order to form a performed workpiece. The variable-channel extrusion die has simple structure, low load, low cost and high efficiency and can be widely applied to producing rods and wires of steel and nonferrous metal and forging and blanking difficultly deformed materials of large-scale shaft parts, high-speed steel, powder metallurgy, and the like.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Casting mold for producing high-temperature alloy single crystal blades and directional solidification device thereof

The invention provides a casting mold for producing high-temperature alloy single crystal blades. The casting mold is applied to a directional solidification device. The casting mold is in a cylindrical shape and comprises an inner-layer ceramic shell and an outer filling interlayer, wherein an inner cavity formed by the ceramic shell is used for pouring high temperature alloy melts to form high-temperature alloy castings, and the periphery of the ceramic shell is filled with heat conduction materials and thermal insulation materials alternately through a barrel-shaped hoarding to form a filling entity provided with a plurality of horizontal heat conduction layers and thermal insulation layers through bonding. According to the entity heat conduction casting mold process, pouring and directional solidification can be performed in the existing directional solidification furnace, all sides of blades can be evenly heated, and therefore the severe shadow effect and organizational defects caused by the shadow effect can be eliminated effectively; and the condition that cold and hot areas in the existing device are almost through is changed, closed isolation between hot areas and cold areas is achieved, reduction of heat losses is facilitated, temperature gradients in castings is increased greatly, and the optimal temperature condition for growth of single crystals is formed.

Owner:DONGFANG TURBINE CO LTD

Steel wire tip drawing technology and apparatus

The invention discloses a steel wire drawing technique and device, comprising that 1, clamping and drawing the front of the steel wire which needs to pass through mould and drawn, 2, heating the steel wire, 3, forcing the clamped steel wire, to extend and crack the steel wire, removing the broken waste steel wire to obtain the mould-through steel wire with sharp end. The invention can improve working efficiency and improve plasticity.

Owner:JIANGSU XIHU SPECIAL STEEL

Casting nozzle device

The invention provides a casting nozzle device which comprises an upper plate, a lower plate opposite to the upper plate, edge baffles connected with the side portions of the upper plate and the lower plate, and a bottom plate connected with the upper plate, the lower plate and the two edge baffles. A melt inlet is formed in the middle of the bottom plate, and a melt outlet is formed in the side opposite to the melt inlet. The casting nozzle device further comprises a first-level flow distributing unit and a second-level flow distributing unit which are sandwiched between the upper plate and the lower plate. Compared with the prior art, according to the casting nozzle device, the size of casting nozzle flow distributing runners is changed, two levels of flow distribution are adopted, and the shape and arrangement of flow distributing blocks are changed, so that the uniformity of molten aluminum metal in the casting nozzle device is improved, local cold points are reduced, and the cast finished product texture defects caused by slag bonding in inner cavities of casting nozzles are eliminated.

Owner:SNTO TECH GRP

Deformation method and device for gradient temperature wedge pressure for injecting and depositing porous material

Disclosed is a ladder temperature band-pressing deforming method and device, which is made of spraying settling cellular materials. The utility model puts blanks into a ladder temperature mold of which the temperature increases step-by-step from the top to the bottom, the lower surface of the blanks contacts the heating bottom board, when the blanks which are ready to be used also has temperature gradient from the top to the bottom, using wedge indenters to compress partially, and the blanks are accumulated from local deformation to integral large deformation step by step. The utility model comprises a mold with a heating and cool-off device, a bottom board with a heating tube and a wedge indenter. The utility model has the advantages of reasonable structure, simple art work. After bringing in ladder temperature, weakening resistance of deformation of the blanks from the top to the bottom, overcoming the phenomenon of compact ill effect of the bottom of the blanks which is caused by frictional force of the mold wall produced in the process of molding and compacting of the large blanks, thereby weakening the briquetting pressure. The utility model is especially applicable to the compacting manufacturing procedure of large spraying settling cellular materials, and expanding application foreground of large units of spraying settling cellular materials.

Owner:HUNAN UNIV

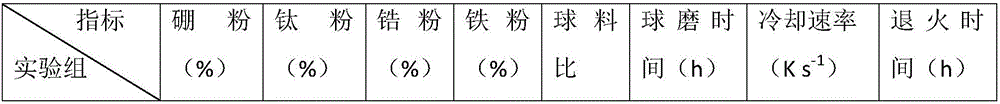

Production method for in-situ generation of titanium zirconium boride reinforced high-modulus and high-hardness steel

The invention discloses a production method for in-situ generation of titanium zirconium boride reinforced high-modulus and high-hardness steel. The production method comprises the following specific steps: firstly, weighing boron powder with the purity of 99 percent or above, high-purity iron powder, titanium powder and zirconium powder according to mass percentage and blending, placing powder into a ball milling pot and mixing the powder by using a planetary ball mill; secondly, taking the mixed powder obtained in the first step, placing the mixed powder into a copper crucible of a vacuum arc melting furnace, and smelting under an argon protecting atmosphere; meanwhile, treating a melt by continuously performing electromagnetic stirring, and enabling the melt to be completely homogenized; at the same time, refining a precipitated phase and a matrix structure, and adopting a water-cooled copper mold to cast a sample; and thirdly, annealing the sample obtained by casting in the second step at the temperature of 1050 to 1150DEG C under the argon atmosphere, and then quenching to room temperature. According to the production method disclosed by the invention, a process is relatively simple and reliable; and the manufactured high-modulus steel is high in cost performance and good in wear resistance.

Owner:KUNMING UNIV OF SCI & TECH

Part treatment process

The present invention discloses a part treatment process, which is characterized by specifically comprising: (1) normalizing; (2) annealing, wherein the annealing comprises re-crystallization annealing, destressing annealing, spheroidization annealing, and complete annealing; (3) tempering, wherein the tempering comprises low temperature tempering, medium temperature tempering, high temperature tempering, and multiple tempering; (4) quenching, wherein the quenching comprises salt bath quenching, martensite grading quenching, bainite isothermal quenching, surface quenching, and local quenching; and (5) quenching and high temperature tempering, wherein a quenching and tempering composite heat treatment process is performed. The part treatment process of the present invention has the following beneficial conditions that: the performance of the treated part is good, high hardness, high plasticity, high toughness and high wear resistance are provided, the structure defects are eliminated, and the part can work in a larger dynamic load.

Owner:ZHEJIANG WANXI PRECISION CASTING

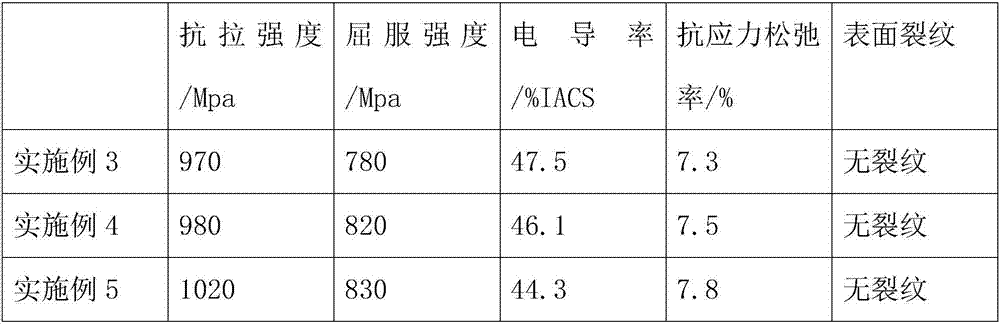

Copper alloy material and preparation method thereof

The invention provides a preparation method of a copper alloy material. The preparation method comprises the following steps: 1) carrying out copper and silver alloying: heating copper under the condition that the vacuum degree is not greater than 9.0*10<-3>Pa; stopping vacuumizing when the heating temperature is 800 to 900 DEG C; raising the temperature under the protection of inert gas and heating until the copper is completely melted; then adding silver and mixing to form a melt; casting to form a casting ingot; 2) carrying out alloy solid solution treatment: carrying out solid solution treatment on the casting ingot; 3) carrying out cold deformation processing; 4) carrying out ageing heat treatment. According to the preparation method provided by the invention, the content of the silver in a prepared alloy is less; in a preparation process, the burning loss of noble metal silver can be extremely reduced and the production cost is reduced; the copper alloy material obtained by matching proper heat treatment and a cold processing technology has the characteristics of high strength and high conductivity, uniform components and stable performance and convenience for processing various copper products, and guarantees are provided for wide application of the copper alloy material.

Owner:SHANGHAI ELECTRIC CABLE RES INST

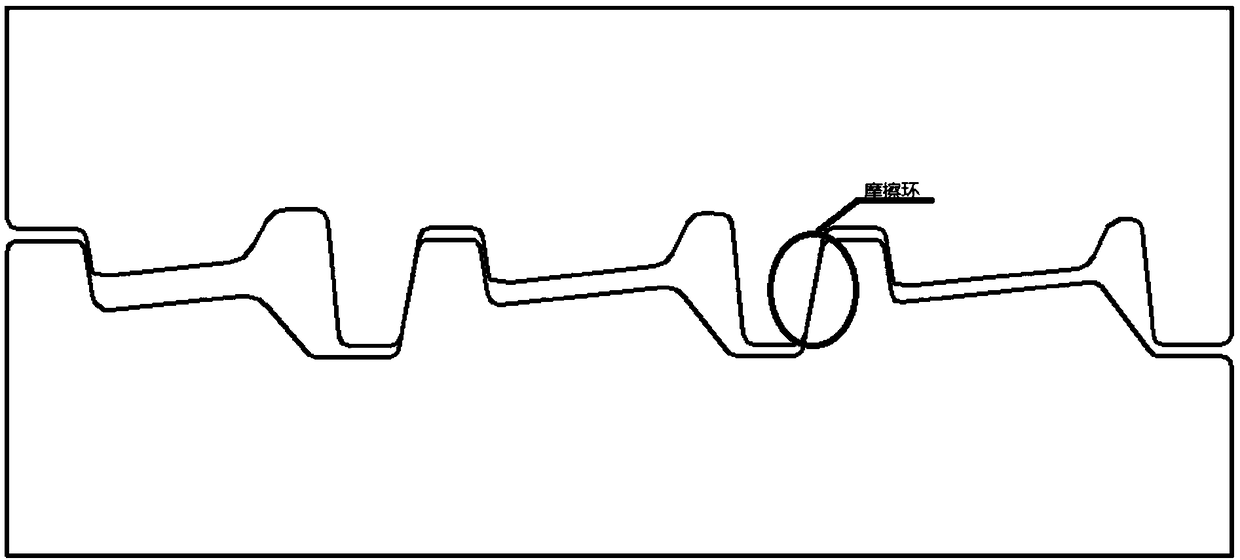

Rolling method of symmetric flat-bulb steel for large-scale shipbuilding

ActiveCN109261714AImprove mechanical propertiesEliminate organizational defectsWork cooling devicesMetal rolling arrangementsHigh pressure waterWater cooling

The invention relates to the technical field of flat-bulb steel rolling, in particular to a rolling method of symmetric flat-bulb steel for large-scale shipbuilding. The oblique rolling method is adopted for rolling. A rolling device comprises a two-roller type section mill, three to five three-roller type section mills, wherein the three-roller type section mills are arranged transversely. The specific rolling process comprises the following steps of rough rolling, moderate rolling, frictional ring arrangement, fine rolling and forced cooling after rolling, wherein high-pressure water mist issprayed by using a water cooling device, and accurate cooling is performed by accurately adjusting a bulb and the flow of web plate water mist. By adopting the oblique rolling method, the installingdifficulty of a foreplate and the labor intensity of steel rolling workers are reduced on the premise that the problem of insufficient length of each roller body is solved; the bulb metal filling amount and web plate width precision are ensured; by arranging frictional rings, web plate waves are avoided, and the surface quality of rolled pieces is improved.

Owner:ANGANG STEEL CO LTD

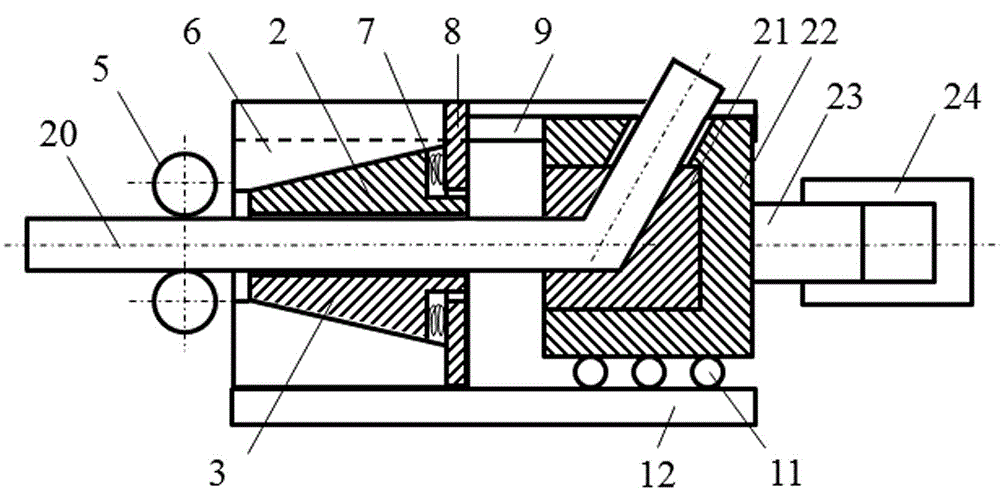

Stepping continuous extrusion device and method for metal severe plastic deformation

ActiveCN103331319AEliminate organizational defectsImprove tissue performanceExtrusion diesStart upPlastic property

The invention provides a stepping continuous extrusion device and method for metal severe plastic deformation. The device comprises a die part and a clamp part, wherein the clamp part comprises an upper clamp, a lower clamp, a clamp seat, a fixing plate and springs, the inclined planes on the outer sides of both the upper clamp and the lower clamp are connected with the inclined plane in the clamp seat, the fixing plate is mounted on the clamp seat, and the springs are fixed on the fixing plate and used for being connected with the upper clamp and the lower clamp respectively; the die part consists of a die, a die base and a die driving device, and the die is fixed on the die base connected with the die driving device. The method comprises the following steps: transmitting metal bar / plate strips to a deformable part channel as deformable parts through feeding rollers, and starting up the die driving device to enable the die to reciprocate so as to realize stepping continuous extrusion deformation of metal. By adopting the method, long superfine grained materials and materials subject to severe plastic deformation can be prepared, and the deformation load is reduced. The method has the advantages of simple process, energy saving, material saving and the like.

Owner:NORTHEASTERN UNIV

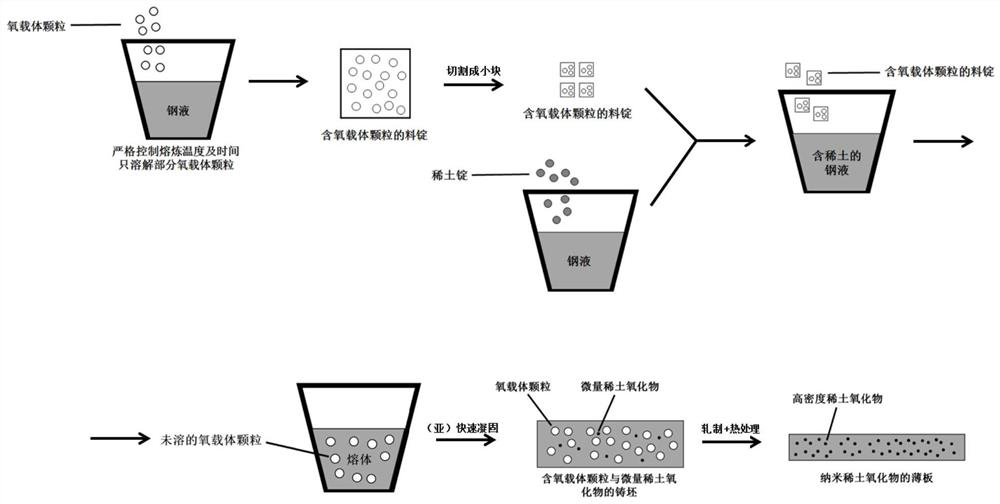

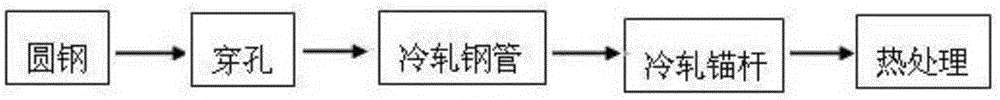

Preparation method of high-density oxide dispersion strengthened steel

The invention discloses a preparation method of high-density oxide dispersion strengthened steel, and belongs to the field of metal material preparation. The method comprises the following steps that1, a steel base body is placed in a container to be smelted into molten steel, after the steel base body is completely smelted, oxygen carrier particles are added into the molten steel, smelting is continued to be conducted to enable the oxygen carrier particles and the molten steel to be mixed, and cooling is conducted to obtain a material ingot; 2, a steel base body is placed in a container to be smelted into molten steel, and after the steel base body is completely smelted, rare earth elements are added into the molten steel to form molten steel containing the rare earth elements; 3, the material ingot is added into the molten steel containing the rare earth elements to be smelted to enable the material ingot to be dissolved, oxygen carrier particles in the material ingot are partiallydissolved to obtain a melt, and the melt is cooled to obtain a casting blank; and 4, the casting blank is subjected to rolling and heat treatment to obtain ODS steel. According to the preparation method, the ODS steel with the nano rare earth oxide with extremely high density can be prepared, and the performance of the prepared ODS steel is greatly improved.

Owner:SHANGHAI UNIV

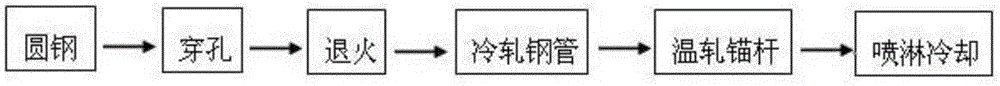

Warm rolling processing technology of low-cost high-performance hollow anchor rod

InactiveCN105032933AHigh strengthLarge amount of deformationTemperature control deviceWork treatment devicesPunchingEngineering

The invention introduces a warm rolling processing technology of a low-cost high-performance hollow anchor rod. The technological process is as follows: round steel processing, hole punching, annealing, steel pipe rolling, anchor rod warm rolling, and spraying for cooling; and the round steel punching temperature is at 1160 to 1190 DEG C. After round steel punching, complete annealing with the temperature of 850 to 890 DEG C is carried out; after annealing, primary cold-rolling moulding is carried out on a tubular pipe, wherein the rolling deformation is larger than 70%; rolling is carried out on the steel pipe after cold rolling at the temperature of 500 to 700 DEG C at the speed of 1m / min; and spraying cooling is carried out after the anchor rod is sent out of a rolling machine. According to the invention, because processes of steel pipe warming rolling and spraying cooling are carried out after cold rolling of tubular pipe annealing and tubular pipe high deformation, the texture of the obtained anchor rod is extremely fine and has the certain strength, so that problems of too high cost of the thermal-treatment high-strength anchor and too poor property of the common anchor rod can be solved. And the tensile strength can reach over 900MPa and the elongation percentage can reach over 8%.

Owner:洛阳中岩工程材料有限公司

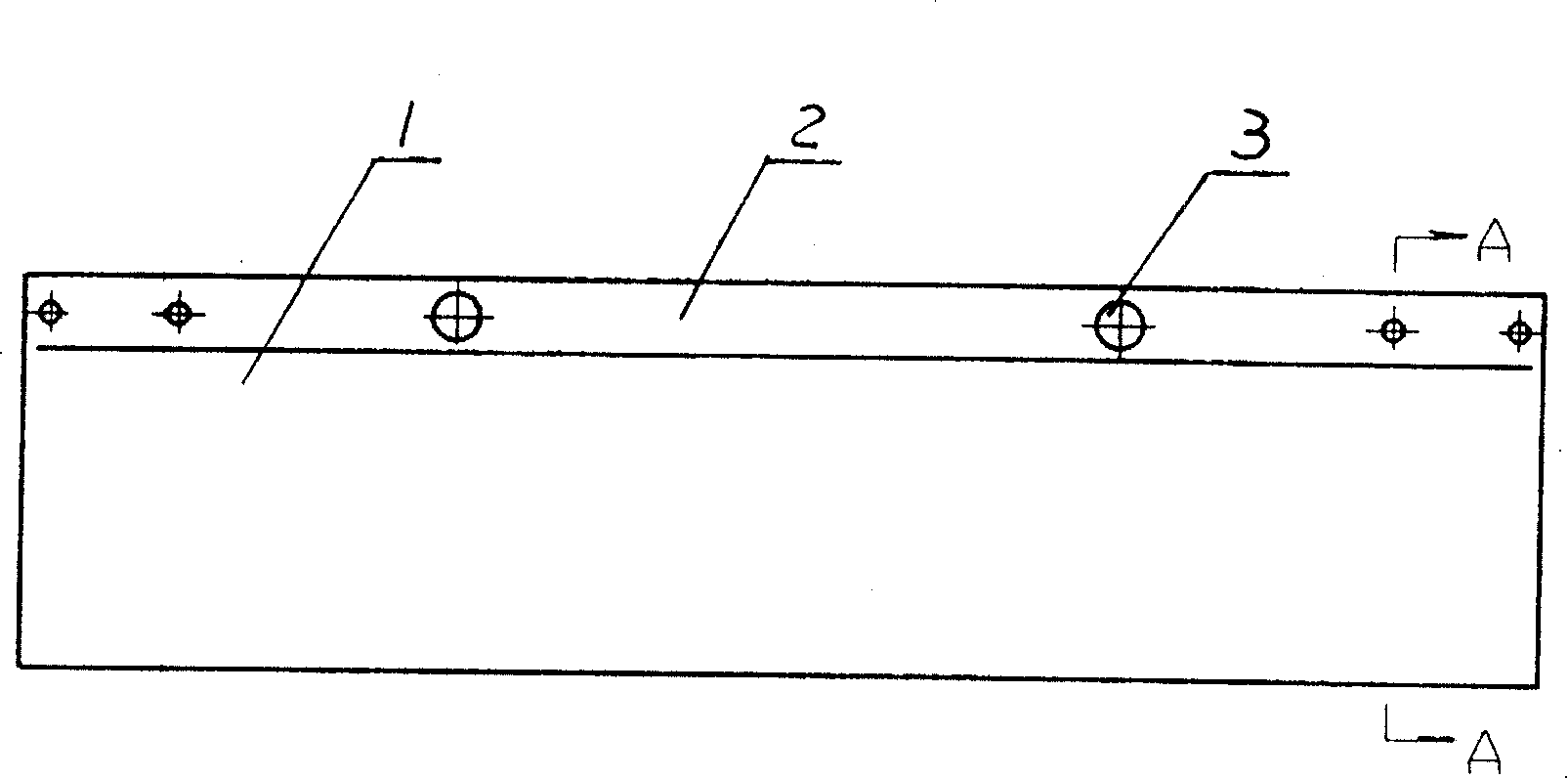

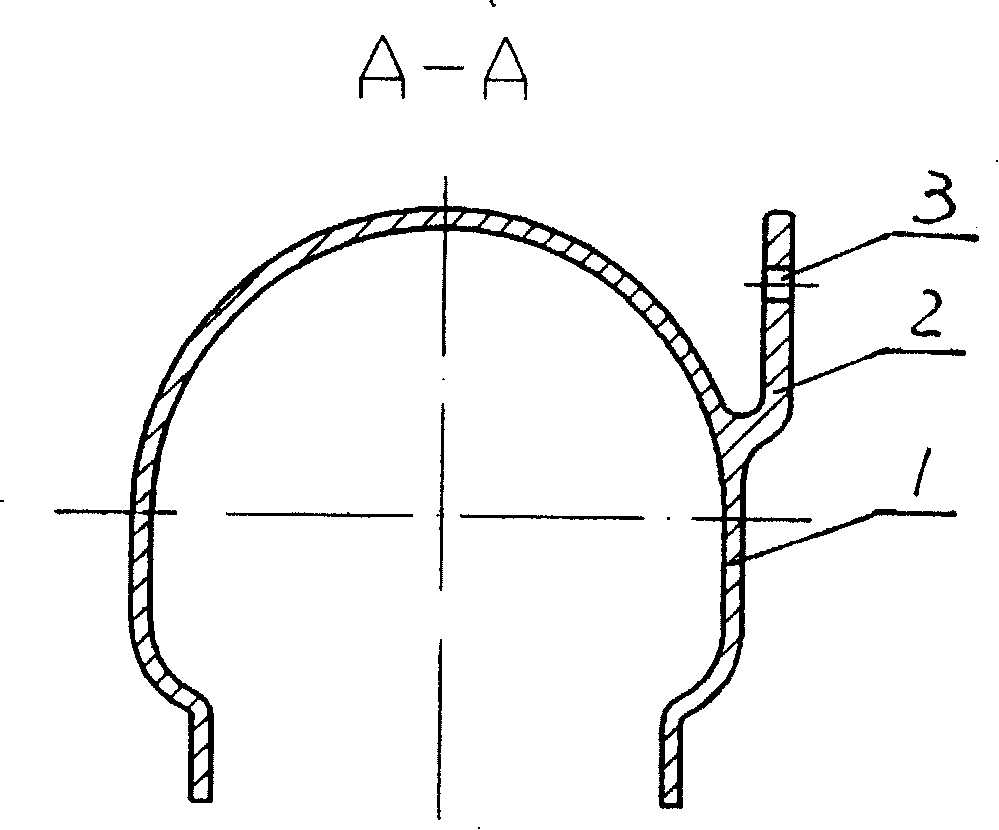

Production technology of grease cooler air chamber and its product

ActiveCN1718360ABeautiful shapeEasy to shapeMachines/enginesLubrication temperature controlSurface finishPunch press

A technology for manufacturing the air chamber of machine oil cooler includes such steps as providing a phi 100 aluminium (3A21) rod, hot pressing to become a section, cutting by needed length, milling edges, and punching holes by 100-T punching machine.

Owner:沈阳华铁异型材有限公司

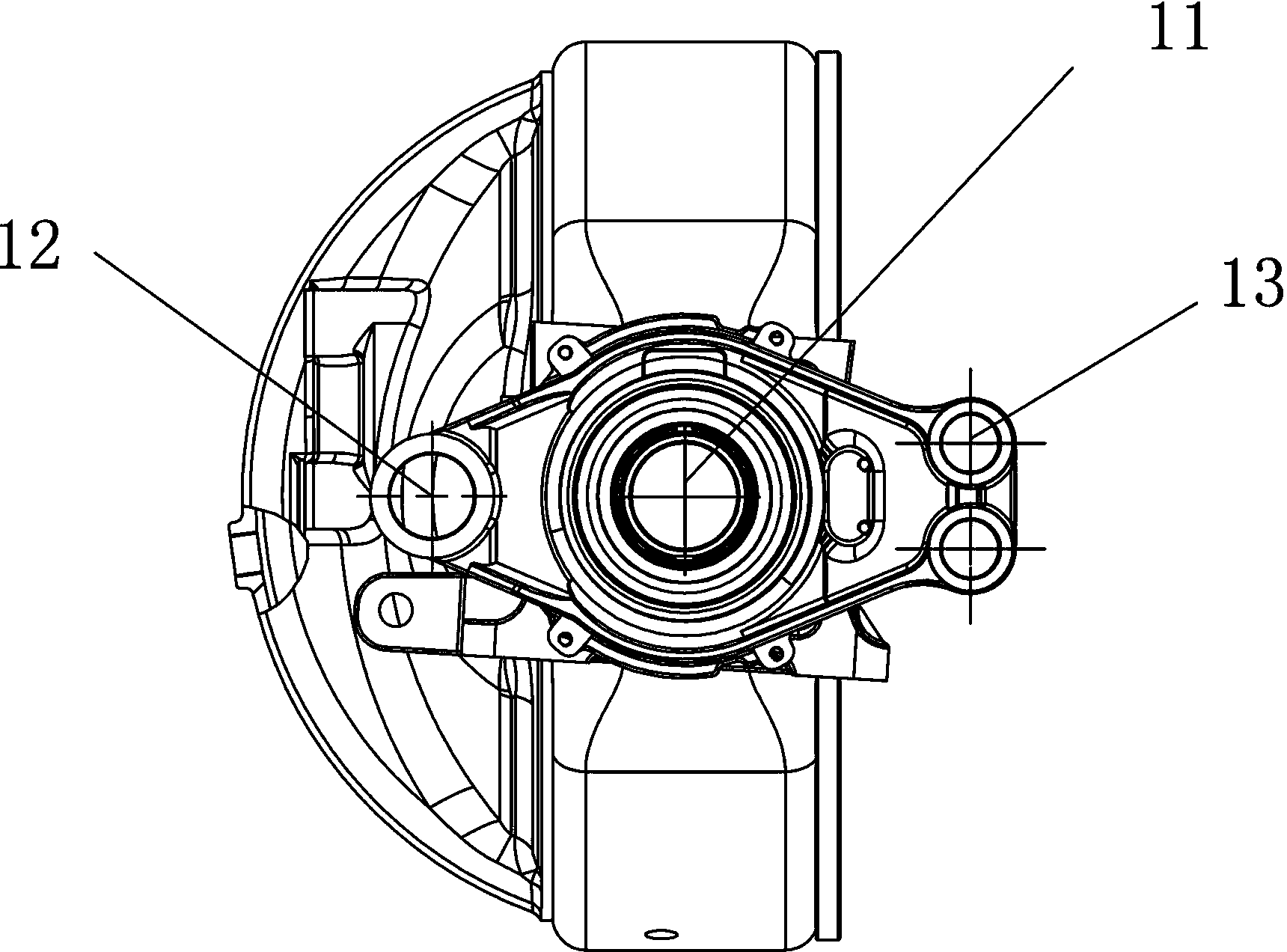

Rear axle housing with high-intensity brake bottom plates

InactiveCN103661347AImprove rigidityEliminate organizational defectsBraking membersBraking componentsTissue defectStrength of materials

The invention discloses a rear axle housing with high-intensity brake bottom plates. The rear axle housing with the high-intensity brake bottom plates comprises a housing body, the pair of brake bottom plates is symmetrically installed at the flange plate installation positions of the two ends of the housing body, each brake bottom plate is provided with a center shaft hole, the center shaft holes are in fit with the flange plate installation positions of the housing body in outer contour, one end of a plate body of each brake bottom plate is provided with a supporting pin hole, the other end of the plate body of each brake bottom plate is provided with a cam shaft installation hole in the axial direction of the housing body, and the brake bottom plates are welded to the housing body. The rear axle housing with the high-intensity brake bottom plates is better in rigidity, the tissue defect of materials is overcome in the forging process, the mechanical property is improved, and the brake bottom plates are higher than an existing casting brake bottom plate in yield strength and tensile strength of materials.

Owner:GUANGDONG FUWA HEAVY IND

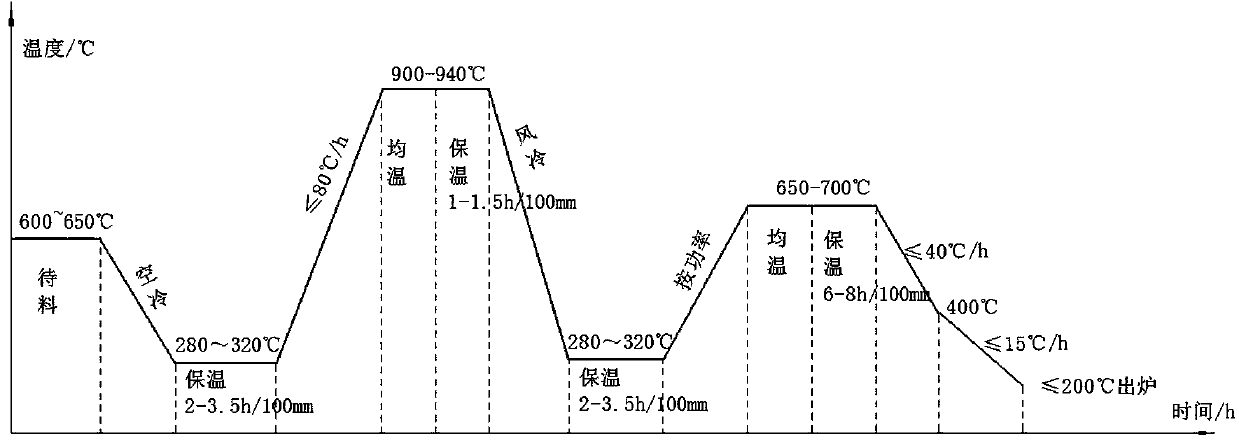

Steel for hydraulic breaking hammer piston and manufacturing technology of steel

ActiveCN107868904AEliminate organizational defectsReduce breakageManufacturing technologyElectric arc furnace

The invention relates to steel for a hydraulic breaking hammer piston and a manufacturing technology of the steel. The steel for the hydraulic breaking hammer piston is high-alloy steel SNCM26VMOD andmainly comprises the chemical components of, by weight, 0.14-0.25% of C, 0.15-0.35% of Si, 0.80-1.20% of Mn, 3.25-3.65% of Ni, 1.40-1.80% of Cr, 0.40-0.60% of Mo, 0.05-0.15% of V, 0-0.025% of S, 0-0.025% of P, and the balance Fe and inevitable impurity elements. The manufacturing technology of the steel for the hydraulic breaking hammer piston comprises the steps of electric-arc furnace smelting,LF refining, VD refining, electroslag remelting, forging and heat treatment after forging. The high-strength high-toughness piston material is manufactured through the steel and the manufacturing technology, the situation that the center of the piston is sunken is avoided, the piston breaking situation is greatly decreased, and the service life of the piston is prolonged.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

Preparation method of high-strength silver-copper alloy material

The invention discloses a preparation method of a high-strength silver-copper alloy material. The method comprises the following steps: 1) taking copper and silver as raw materials, and burdening according to the ratio of 15-20wt% of silver and the balance of copper; 2) preparing a silver-copper alloy bar by adopting a vacuum smelting technology; 3) refining the silver-copper alloy bar by adopting a vacuum consumable arc smelting technology; 4) hot extrusion, wherein the extrusion temperature is 800-900 DEG C; the heat preservation time is 2-4 hours; the extrusion ratio is 8-10, and extruding into the bar; 5) thermal treatment, wherein the annealing temperature is 200-250 DEG C; the heat preservation time is 1-2 hours, cooling along with a furnace; 6) drawing to obtain the high-strength silver-copper alloy material. A silver-copper alloy ingot is refined from the copper and the silver as raw materials in a vacuum consumable smelting furnace; the high-strength silver-copper alloy is obtained by the technologies such as hot extrusion, thermal annealing, drawing and the like. By adopting the silver-copper alloy material prepared by the preparation method disclosed by the invention, the tensile strength can be up to over 1.2 GPa, and the conductivity can be up to over 75% of international annealed copper standard (IACS).

Owner:HENAN UNIV OF SCI & TECH

Hard alloy milling cutter with high impact resistance and preparation method thereof

InactiveCN113621892AImprove impact resistanceStrong impact resistanceMolten spray coatingQuenching agentsTemperingMilling cutter

The invention discloses a hard alloy milling cutter with the high impact resistance and a preparation method thereof. According to the hard alloy for preparing the milling cutter, the hardness of the alloy is improved through a solid solution strengthening method, and the hardness and the impact resistance of the alloy are improved through heat treatment processes such as quenching and tempering; and the blending phase is added, so that different metallographic structures in the alloy can be uniformly dispersed in the alloy, and the comprehensive performance of the alloy is improved. The quenching liquid is formed by combining macromolecules, main components in the quenching liquid have an excellent cooling accelerating effect, and meanwhile, the quenching liquid has thermal stability, excellent light benign property and clean brightness. The surface of the milling cutter is treated, hardened powder can be sprayed on the alloy surface through a plasma spraying technology, a powdery coating is subjected to high-temperature baking, leveling and curing to become a final coating, the final coating has high-temperature resistance, and meanwhile the cutting capacity of the milling cutter cannot be reduced.

Owner:吉安富奇精密制造有限公司

Preparation method capable of remarkably overcoming surface defect of copper alloy material for lead frame

ActiveCN107447121AImprove surface propertiesImprove performanceSemiconductor/solid-state device detailsSolid-state devicesRare earthZinc alloys

The invention discloses a preparation method capable of remarkably overcoming the surface defect of a copper alloy material for a lead frame. The preparation method comprises the following steps that S1, a copper-iron alloy with the iron content being 7% is refined; S2, high-purity copper and wood coal are added into a high-frequency induction smelting furnace, heating is conducted until the high-purity copper is completely melted to obtain copper liquid, heating continues to be conducted, the copper-iron alloy with the iron content being 7%, a copper-zinc alloy, a copper-phosphorus alloy, a copper-tin alloy, a copper-titanium alloy and mixture rare earths are added, and stirring and smelting are conducted to obtain a copper-alloy solution; S3, the components of the copper-alloy solution are detected, and casting is conducted to obtain strips; S4, the strips are subjected to uniform annealing, the annealing temperature is 650-730 DEG C, repeated hot rolling is conducted, then the strips are transferred to be subjected to intermediate annealing finish rolling, the intermediate annealing temperature is 690-710 DEG C, and then a finish rolling product is obtained; and S5, the finish rolling product is subjected to ageing treatment and cooled with a furnace to obtain the copper alloy material, with the surface defect remarkably overcome, for the lead frame. According to the preparation method capable of remarkably overcoming the surface defect of the copper alloy material for the lead frame, uniformization of the copper alloy material for the lead frame is promoted, the surface performance of the alloy material is improved, and the comprehensive performance of the copper alloy material is improved.

Owner:安徽晋源铜业有限公司

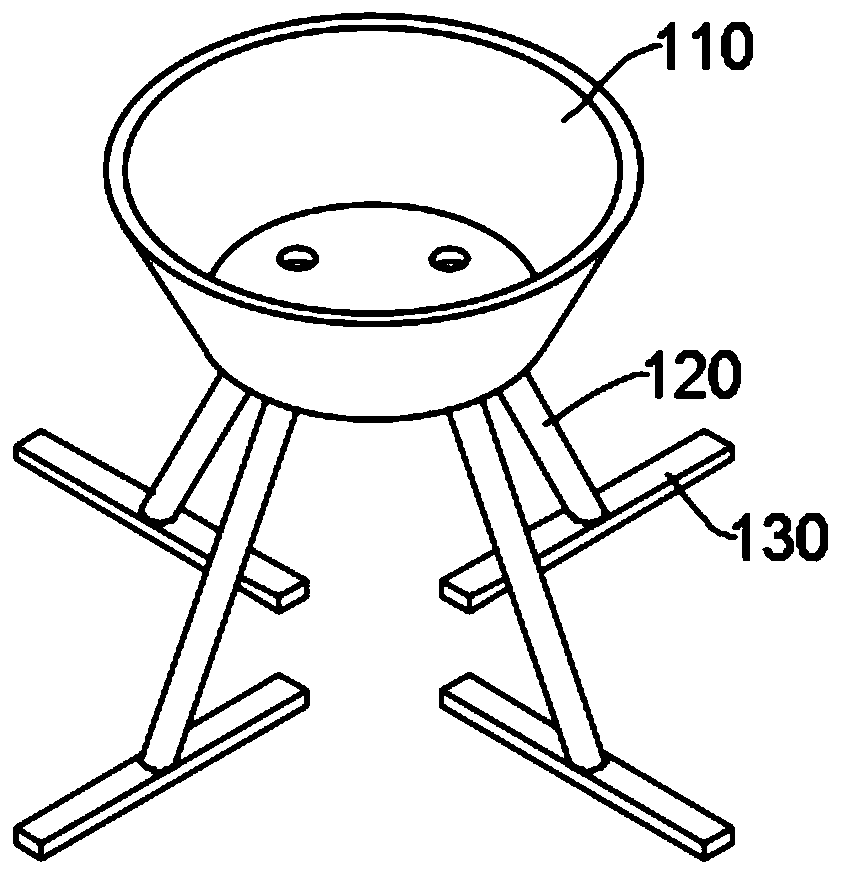

Annular ingot casting equipment and casting method thereof

ActiveCN111203521AIncrease productivityHomogeneous tissue compositionIngot casting plantsIngot castingCasting mold

The invention discloses annular ingot casting equipment and a casting method thereof, and belongs to the field of metallurgical casting. The annular ingot casting equipment comprises a pouring system,a rolling system, a casting mold and a supporting column; the casting mold comprises an inner ring and an outer ring, and a mold cavity is formed between the inner ring and the outer ring; the supporting column penetrates through the inner ring and is in threaded connection with the inner ring; the pouring system is fixedly arranged on the upper part of the supporting column and injects melt intothe mold cavity; and the rolling system is fixedly arranged on the supporting column and comprises rollers which are horizontally arranged in the mold cavity. Various defects during preparation of alarge annular ingot can be effectively reduced, the uniformity of the structural components of the ingot is increased, and therefore the mechanical performance of the ingot is improved. By adopting the annular ingot casting equipment in the casting method, the large annular ingot is prepared through continuous melt laying and rolling leveling methods, the large annular ingot can be quickly prepared through the method, and the prepared ingot has excellent mechanical properties.

Owner:SHANGHAI UNIV

A method for preparing a low-defect high-performance high-speed steel wire

InactiveCN108220583APrevent precipitationImprove organizational qualityFurnace typesHeat treatment furnacesHigh-speed steelCooling speed

The invention relates to a method for preparing a low-defect high-performance high-speed steel wire. The method can eliminate structure defects of the high-speed steel wire and can improve wire structure quality and performance. The method is mainly characterized in that after high-speed steel is heated to 840-900 DEG C and fully austenitized, the steel is rapidly cooled to 730-780 DEG C at a cooling speed of not less than 2 DEG C / min, is maintained at the temperature for 30 min to 6 h, and then is cooled in a furnace to about 500 DEG C, and then a product is discharged from the furnace. The high-speed steel wire produced by the method has advantages of few structure defects, high structure quality, and the like and has good comprehensive mechanical performance.

Owner:SOUTHEAST UNIV

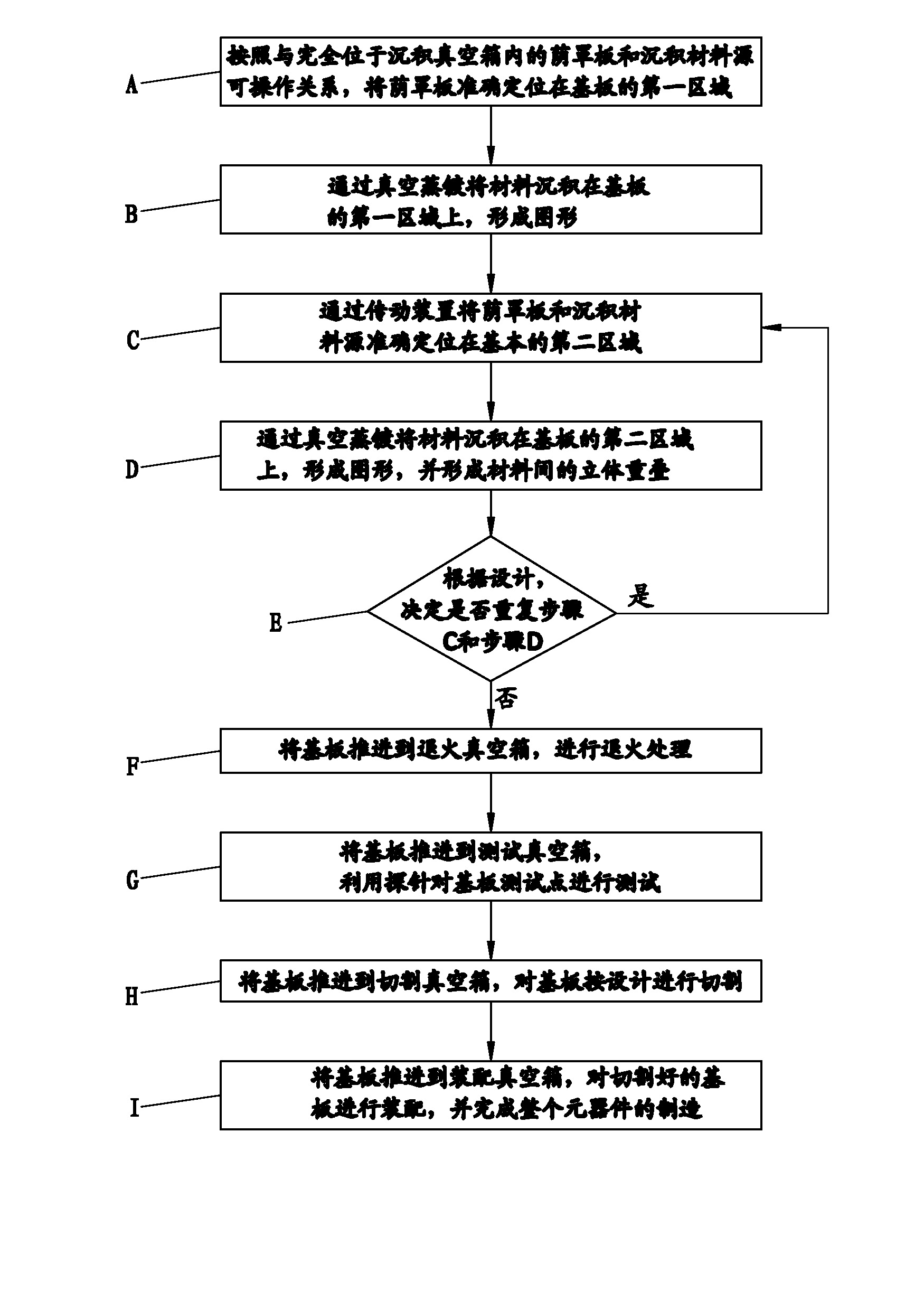

Method and system for manufacturing component by using shadow mask technological line

InactiveCN102122612AStress reliefEliminate organizational defectsVacuum evaporation coatingSputtering coatingEngineeringVacuum deposition

The invention discloses a method and a system for manufacturing a component by using a shadow mask technological line. The method comprises the following steps: A. firstly depositing materials in a vacuum deposition box, and then accurately locating shadow mask plates in a first area of a substrate according to the operable relationship between the shadow mask plates and deposited material sources which are fully positioned in the vacuum deposition box; B. depositing the materials on the first area of the substrate through vacuum evaporation to form a graph; C. accurately locating the shadow mask plates and the deposited material sources in a second area of the substrate by a transmission device; and D. depositing the materials on the second area of the substrate through vacuum evaporation to form a graph and stereoscopic overlap of the materials; repeating step C and D according to design so as to complete composition and connection of the component; and sequentially annealing, testing, cutting and assembling respectively by a vacuum annealing box, a vacuum test box, a vacuum cutting box and a vacuum assembling box, and finally forming the complete component.

Owner:潘重光

Method for manufacturng copper or copper alloy base and copper alloy pipe

InactiveCN1456406AEliminate organizational defectsImprove mechanical propertiesMachinabilityCopper alloy

A technology for producing Copper or Cu-alloy billet or tube includes such steps as flowing molten copper or Cu-alloy in crystallizer, solidifying while applying a rotary or axially alternative magnetic field to it to become billet, and cold rolling or cold drawing to become tube. Applying magnetic field can decrease micro pinhole in structure and improve its cold machinability.

Owner:江苏仓环铜业股份有限公司

Device and method for preparing metal matrix composite by adopting high-pressure gas to assist infiltration

The invention relates to a device and a method for preparing a metal matrix composite by adopting high-pressure gas to assist infiltration, and the device is formed by mutually connecting four major function systems, namely a vacuum system, a gas distribution system, a pressurizing and gas charging system and a preparation system; and the preparation method adopting the device is as follows: applying the high-pressure gas to provide pressure, driving melting matrix molten metal to effectively fill pores of a second phase or a perform and cooling so as to finally get the composite. By adopting the device and the method, structural defects can be significantly eliminated, effective control of the structure of an interface between two phases is realized through heat-keeping and pressure-keeping treatment, the performances of the composite are improved, taking the Al / diamond composite as an example, the thermal conductivity can achieve 649W / mK; through reasonable design of components of the high-pressure gas, the problems in preparation of the special metal matrix composite can be solved, and the preparation quality of the composite, including activity of matrix metal Mg, high-temperature graphitization problem of a diamond and the like, is improved; near-net-shape forming of parts in complex shapes, which are made of a large number of types of the metal matrix composites can be realized; and the preparation quality is high, and the repeatability is strong.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

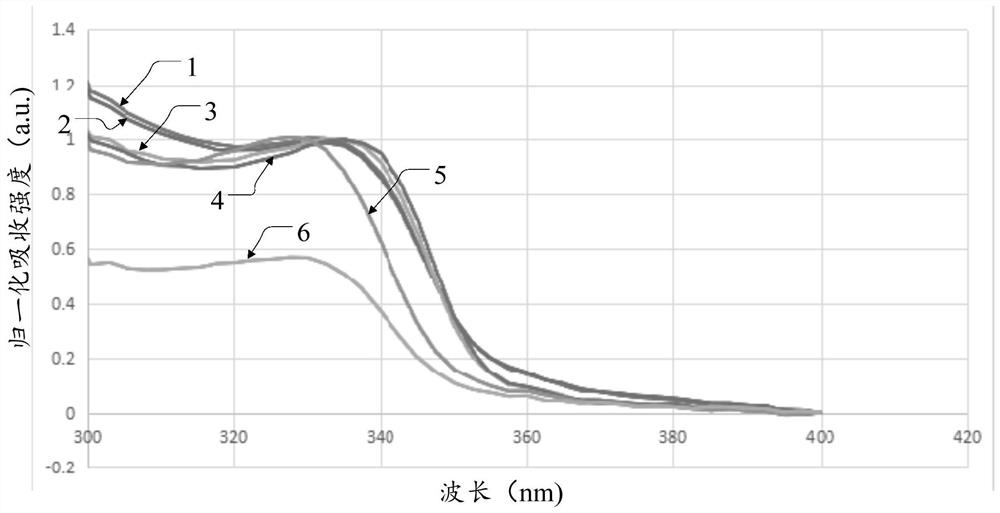

Preparation method of electronic device and display device

PendingCN112802984AImprove efficiencyReduce solubilitySolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceNano zinc oxide

The invention discloses a preparation method of an electronic device and a display device, and relates to the technical field of electronic devices, the electronic device comprises an electron injection layer, the preparation method of the electron injection layer comprises the following steps: S10, dispersing nano-zinc oxide into a solvent to form a dispersion liquid, and coating the dispersion liquid to form a thin film; and S20, carrying out light treatment on the thin film to obtain an electron injection layer. The electron injection layer prepared by the preparation method of the electronic device provided by the invention does not need to be subjected to annealing treatment, so that uneven heating of each layer is avoided, and energy is saved.

Owner:GUANGDONG JUHUA PRINTING DISPLAY TECH CO LTD

Production technology of grease cooler air chamber and its product

ActiveCN100391687CBeautiful shapeEasy to shapeMachines/enginesLubrication temperature controlSurface finishPunch press

A technology for manufacturing the air chamber of machine oil cooler includes such steps as providing a phi 100 aluminium (3A21) rod, hot pressing to become a section, cutting by needed length, milling edges, and punching holes by 100-T punching machine.

Owner:沈阳华铁异型材有限公司

Variable-channel extrusion die and forming method

InactiveCN101823085BImproved strain distributionIncrease stressExtrusion diesExtrusion mandrelsNonferrous metalLow load

The invention relates to a variable-channel extrusion die and a forming method. The variable-channel extrusion die comprises a male die (1) and a female die (3), a die cavity of the female die sequentially comprises a feeding section (4), a front forming section (5), a middle forming section (6), a rear forming section (7) and a discharging section (8) from an inlet of a blank (2) to an outlet ofthe blank (2), wherein the feeding section (4) is a circular equant channel, the front forming section (5) is a circular-elliptical transition channel, the middle forming section (6) is a prismatic elliptical channel, the rear forming section (7) is an elliptical-circular transition channel, and the discharging section (8) is a prismatic circular channel; and the blank (2) enters from an inlet ofthe female die (3) and is limited by the die cavity of the female die (3) to change a circular cross-section into an elliptical cross-section and change the elliptical cross-section into the circularcross-section in order to form a performed workpiece. The variable-channel extrusion die has simple structure, low load, low cost and high efficiency and can be widely applied to producing rods and wires of steel and nonferrous metal and forging and blanking difficultly deformed materials of large-scale shaft parts, high-speed steel, powder metallurgy, and the like.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Retainer edge-turning-free forming method based on composite working procedure

PendingCN113560504AReduce hardnessHigh hardnessFoundry mouldsFoundry coresCrazingMechanical components

The invention relates to the technical field of retainer manufacturing, in particular to a retainer edge-turning-free forming method based on a composite working procedure. According to the method, quenching is conducted, metal with the low metal melting point is put into a smelting furnace to be smelted, then metal with the high melting point is added to be smelted, cooling solidification is conducted, annealing treatment is conducted after solidification, the hardness is reduced, and the cutting machinability is improved; residual stress is eliminated, the size is stabilized, and deformation and cracking tendencies are reduced; and grains are refined, the structure is adjusted, structure defects are eliminated the quenching aims to enable supercooled austenite to be subjected to martensite or bainite transformation to obtain a martensite or bainite structure, then tempering at different temperatures is matched, the rigidity, hardness, wear resistance, fatigue strength, toughness and the like of the steel are greatly improved, then different using requirements of various mechanical parts and tools are met, quenching is conducted firstly, then annealing is conducted, and then heating is conducted to form molten metal, so that the service life of a retainer is prolonged.

Owner:浙江中精轴承有限公司 +1

A kind of forging method of superalloy gh4099

ActiveCN111604448BEliminate organizational defectsSimple processMetal-working apparatusIngotSuperalloy

The invention discloses a forging method of superalloy GH4099, which specifically includes the following steps: before forging, homogenizing the GH4099 steel ingot at a temperature of 1150° C. for 48 hours; preheating the forging furnace, and placing the homogenized steel ingot in the forging process In the furnace, the forging heating is carried out in a neutral atmosphere. At this time, the temperature in the forging furnace is less than or equal to 500 °C, then the temperature is slowly raised to 890~910 °C, and the temperature is kept for more than 1 hour. ; Forge the steel ingot after forging heating, the forging temperature is greater than or equal to 1050℃, and the final forging temperature is greater than or equal to 980℃; then place the steel ingot in the forging furnace at 1140~1160℃ and keep it at 1140~1160℃ for more than 1h, keep the temperature at 1140~1160℃. After the end, repeat the above steps to complete the forging process, each forging deformation is greater than or equal to 10%; finally, the steel ingot obtained after forging is placed in a preheated hot furnace, and the steel ingot is slowly air-cooled to room temperature. During the forging and heating process of the present invention, the steel ingot is heated evenly, the cracking of the forged steel ingot can be effectively avoided, and the finished product rate can be improved.

Owner:宝武特冶航研科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com