Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

140results about How to "Wide range of industrial applications" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

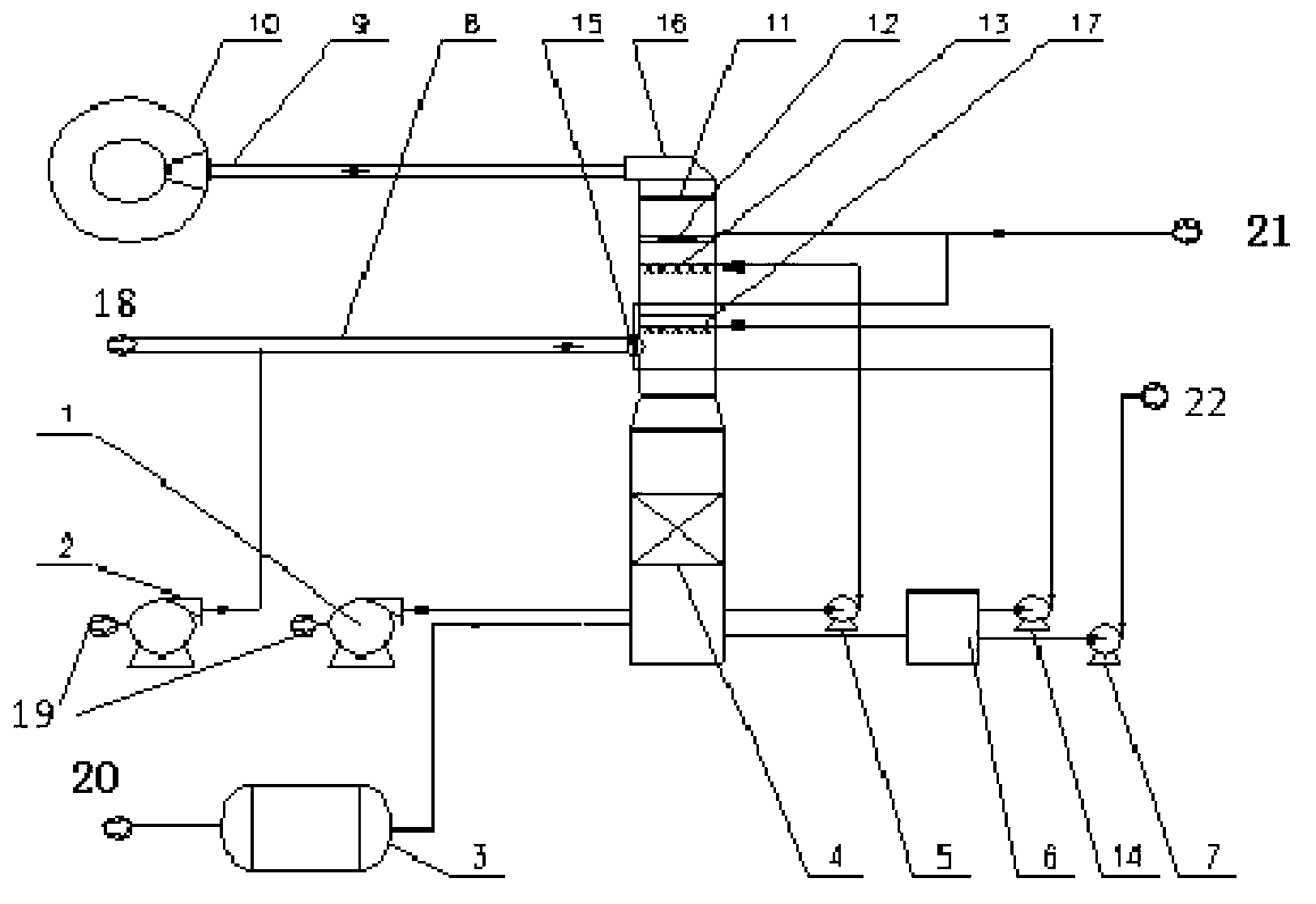

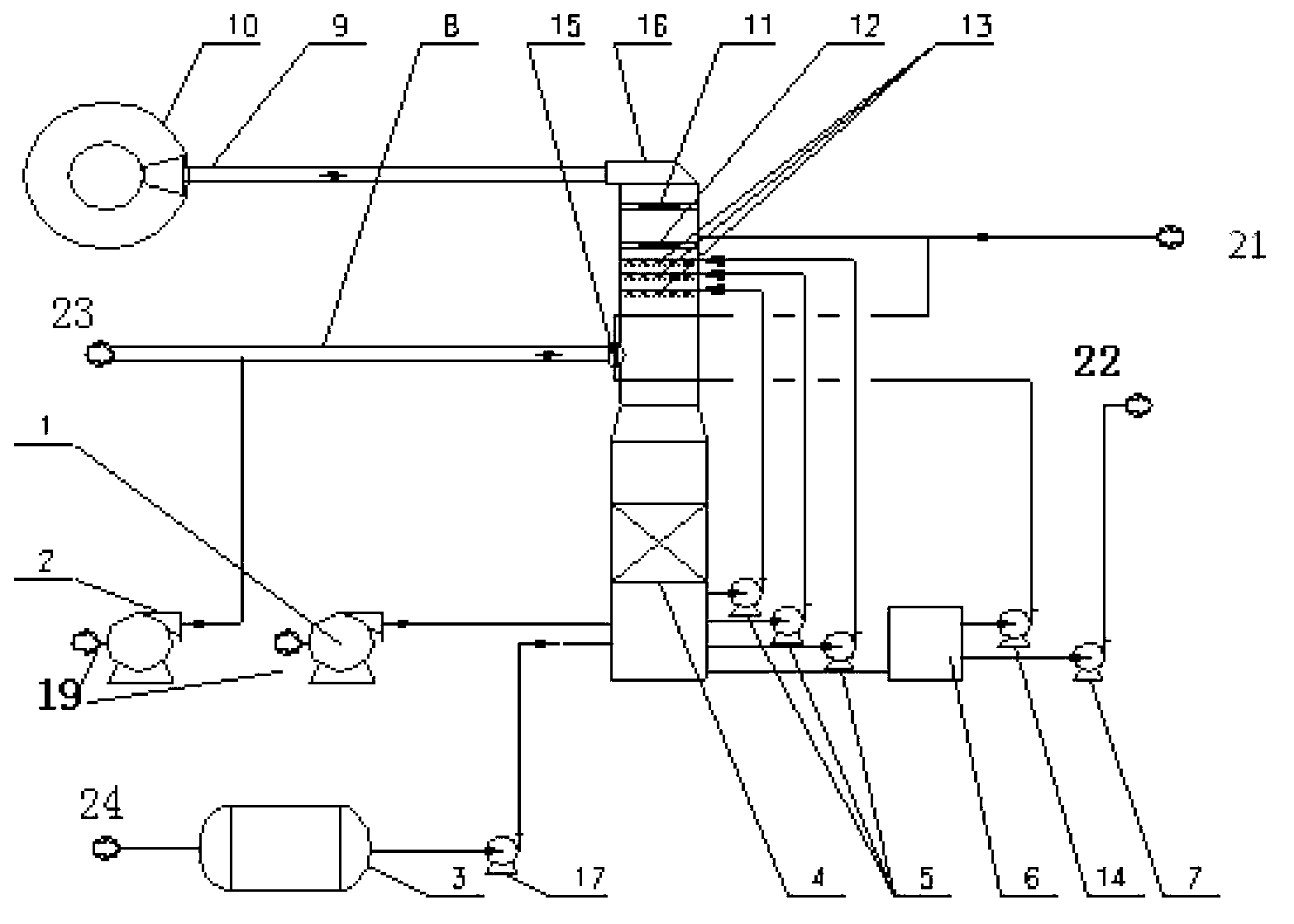

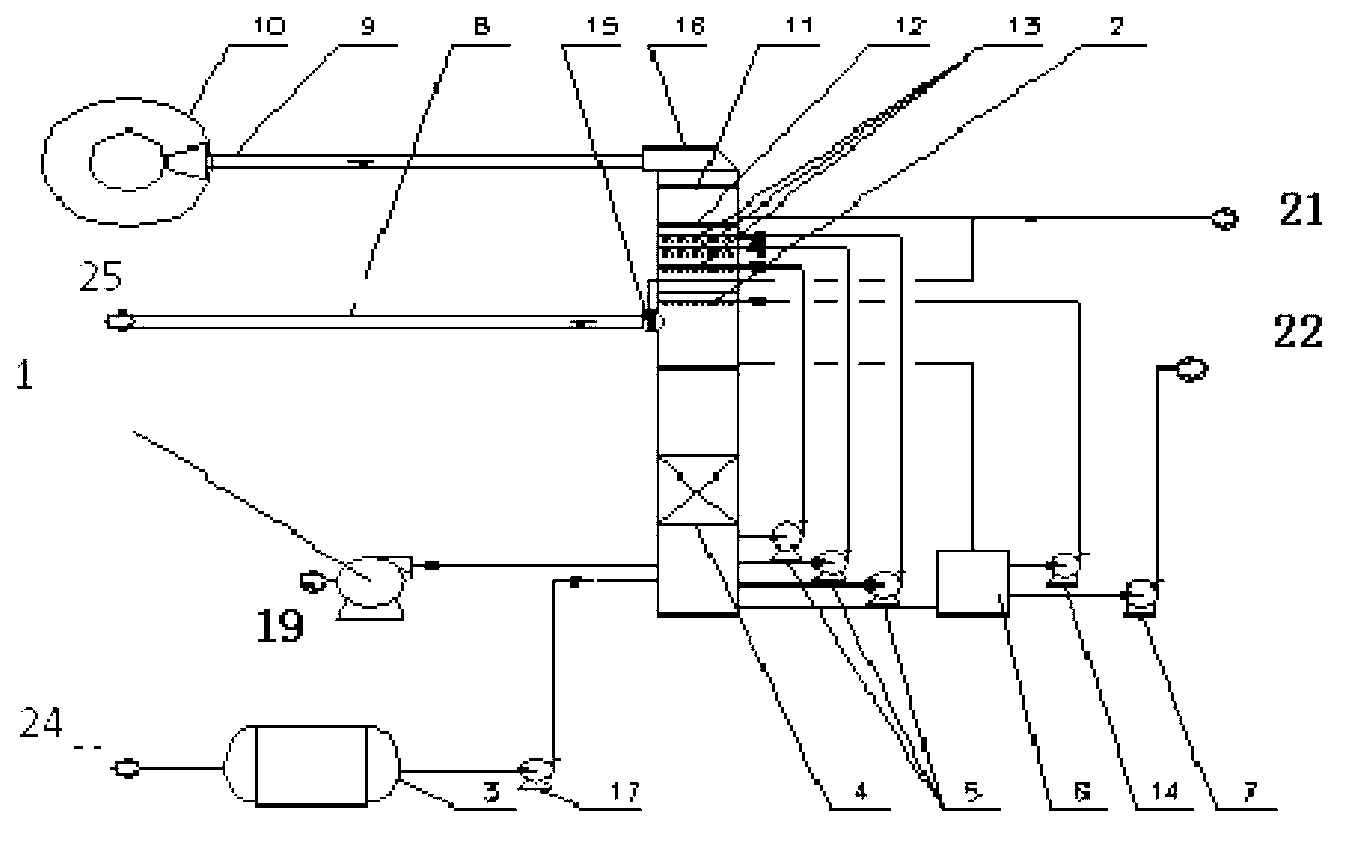

Ammonia process flue gas treatment method for acidic tail gas and device

ActiveCN103223292AIncreased self-concentrationGood desulfurization absorptionDispersed particle separationAmmonium sulfatesEnvironmental resistanceAmmonia storage

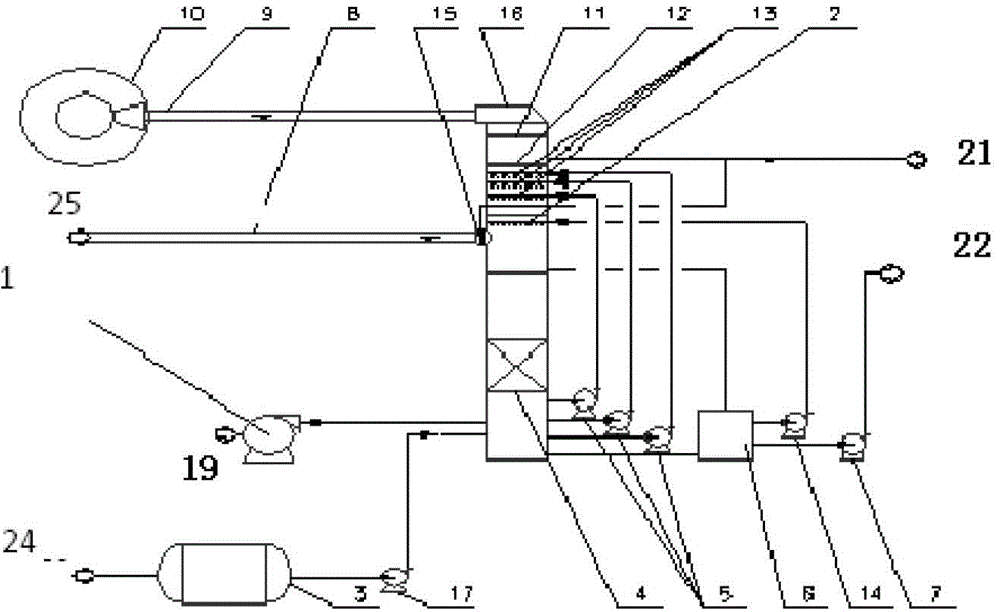

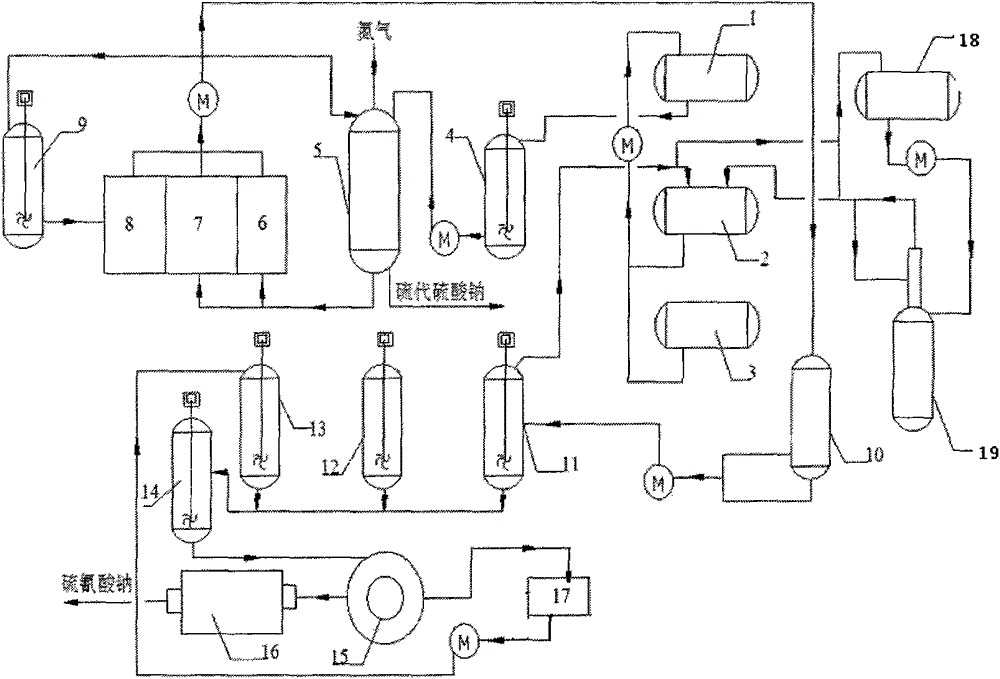

The invention relates to an ammonia process flue gas treatment method for acidic tail gas. The method includes the steps of: 1) controlling the sulfur dioxide concentration of tail gas entering an absorption tower at a level of less than or equal to 30000mg / Nm<3>; 2) arranging process water in an absorption tower entrance flue or in the absorption tower or cooperating with a ammonium sulphate solution to perform spray cooling; 3) disposing an oxidation section in the absorption tower, setting an oxidation distributor at the oxidation section to achieve oxidation of a desulfurized absorption liquid; 4) arranging an absorption section in the absorption tower, utilizing an absorption liquid distributor in the absorption section to realize desulfurization spray absorption by an ammonia-containing absorption liquid, which is fed through an ammonia storage groove; 5) arranging a water washing layer at an absorption section upper part in the absorption tower, washing the absorption liquid in the tail gas by the water washing layer and reducing the absorption liquid escape; and 6) setting a demister at the upper part of the water washing layer in the absorption tower to control the mist drop content in the purified tail gas. Employment of the Claus sulfur recovery and ammonia process desulfurization integrated desulfurization technology in the coal chemical industry can reduce the investment cost of after-treatment, the process can be simpler, and factory environmental protection treatment can form an intensive advantage.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

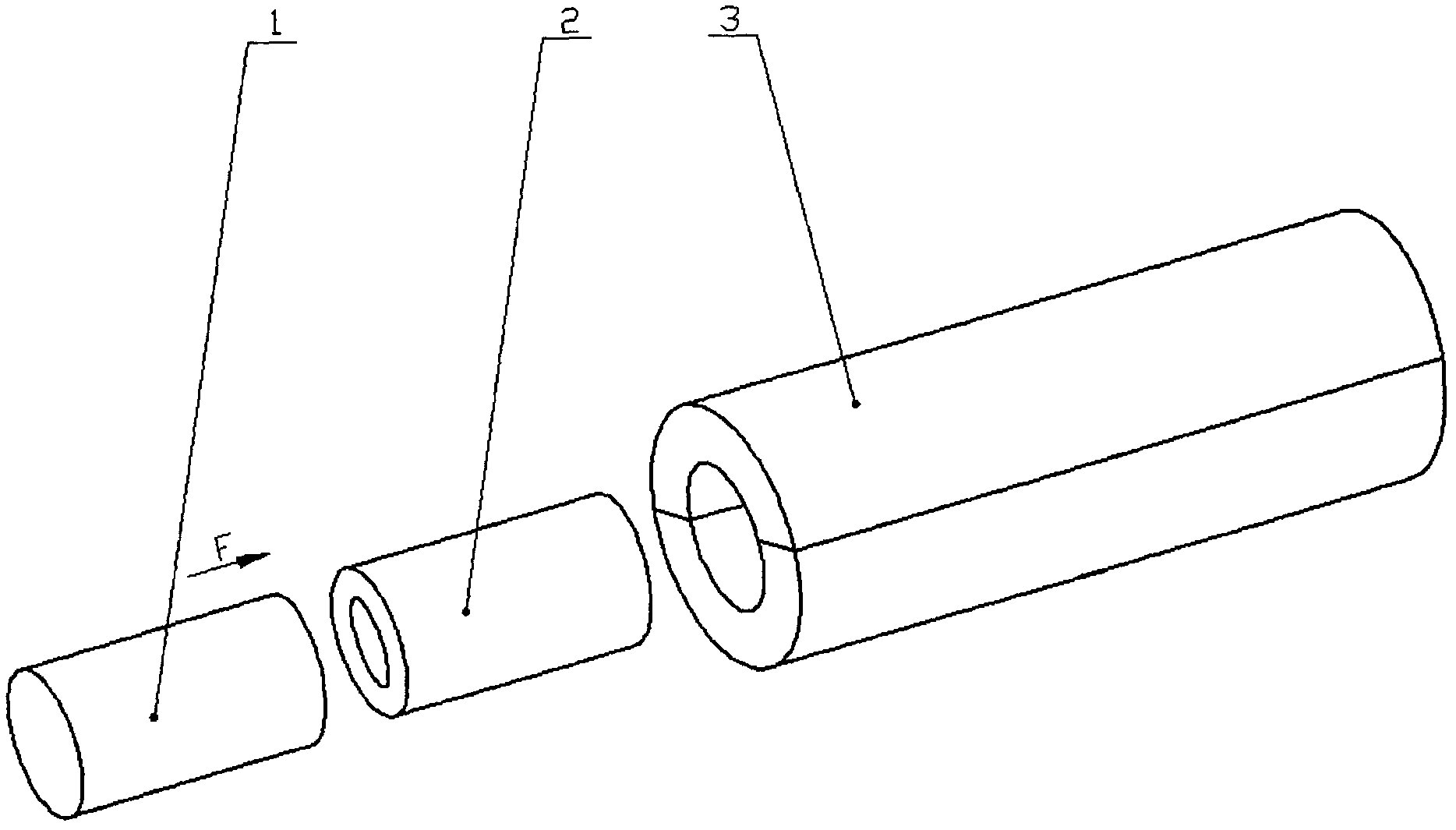

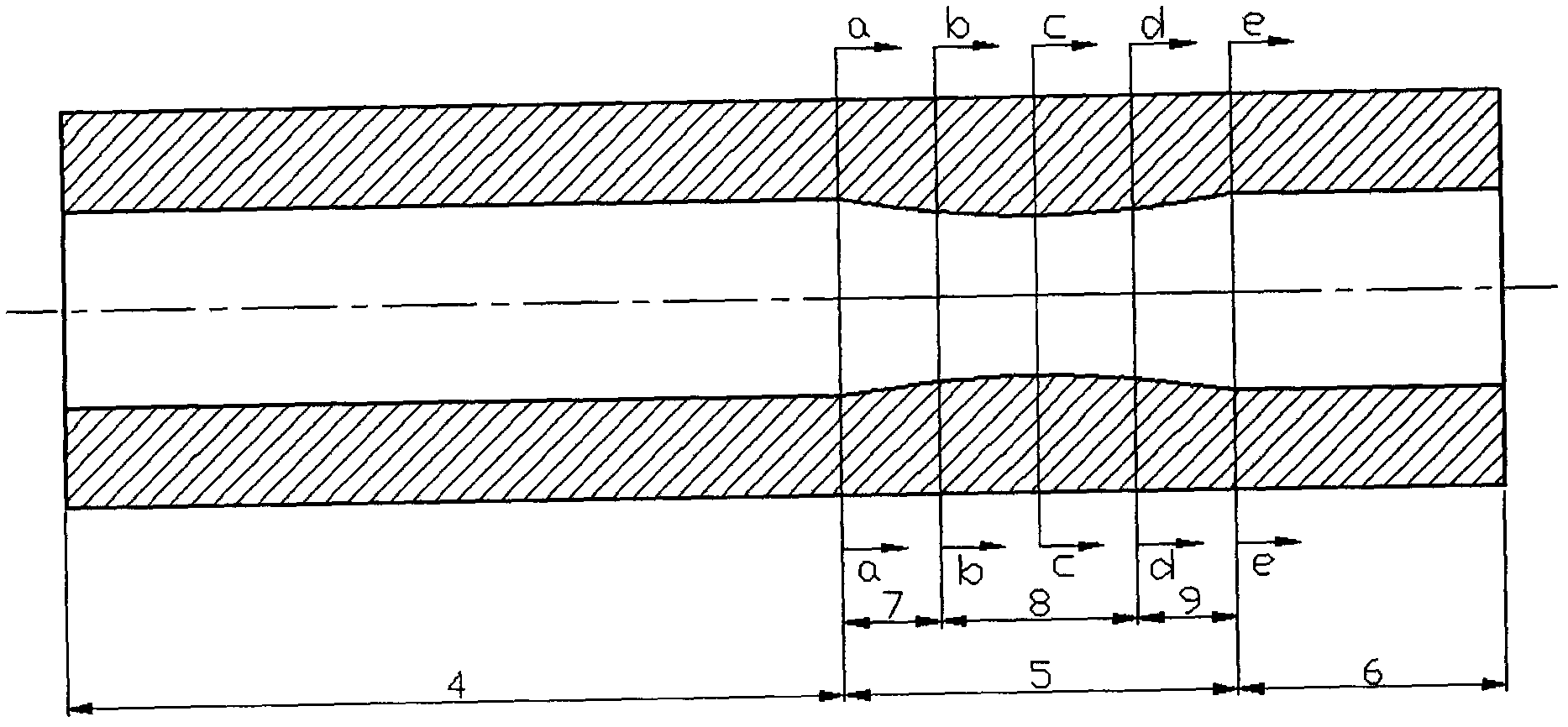

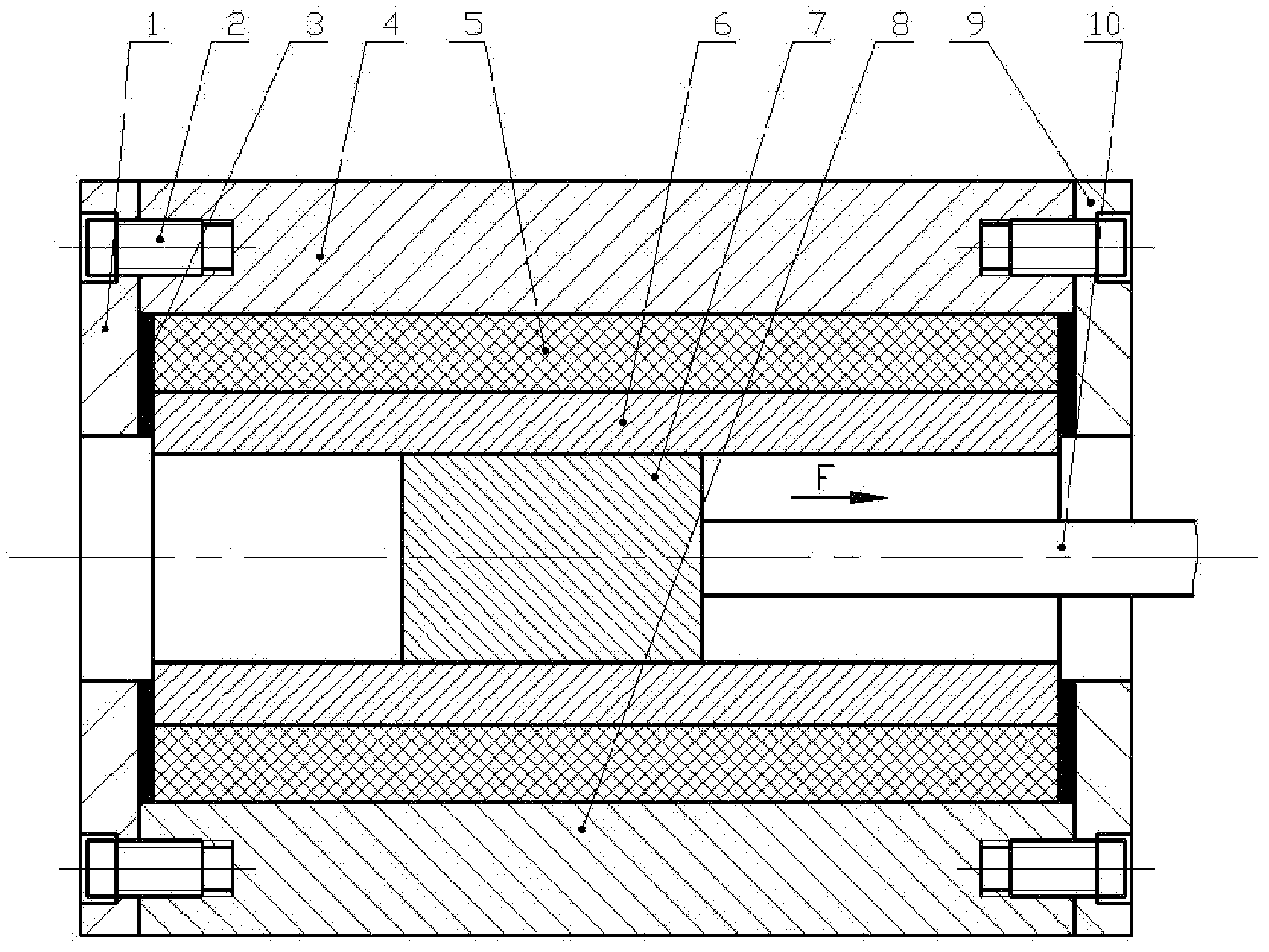

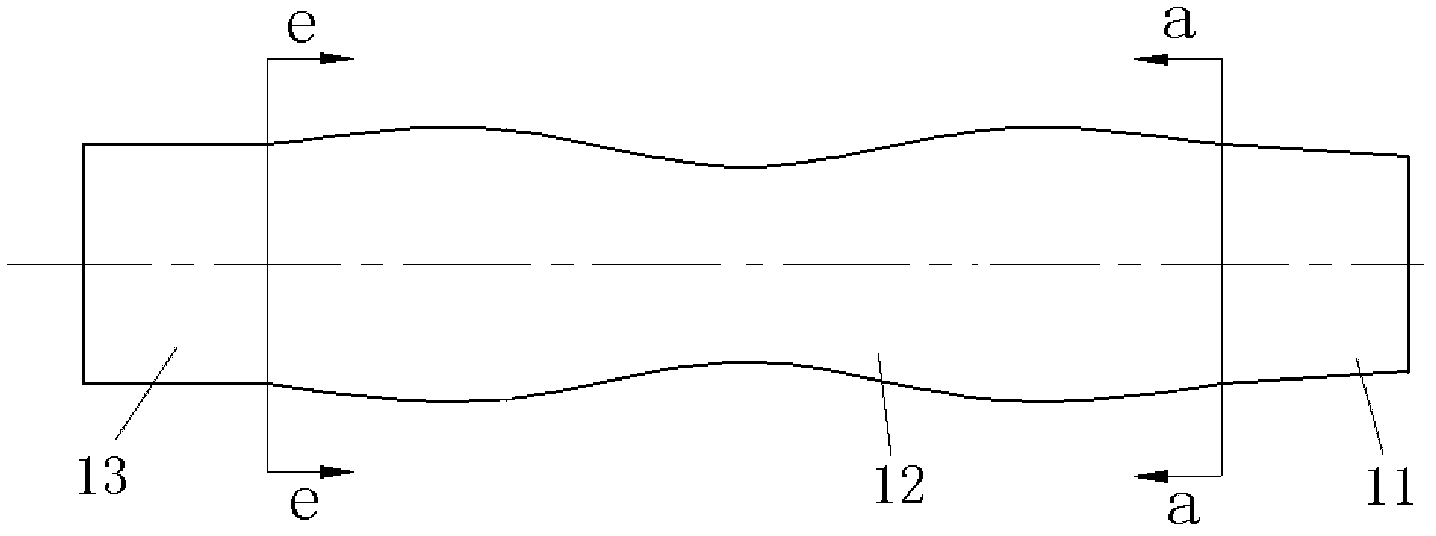

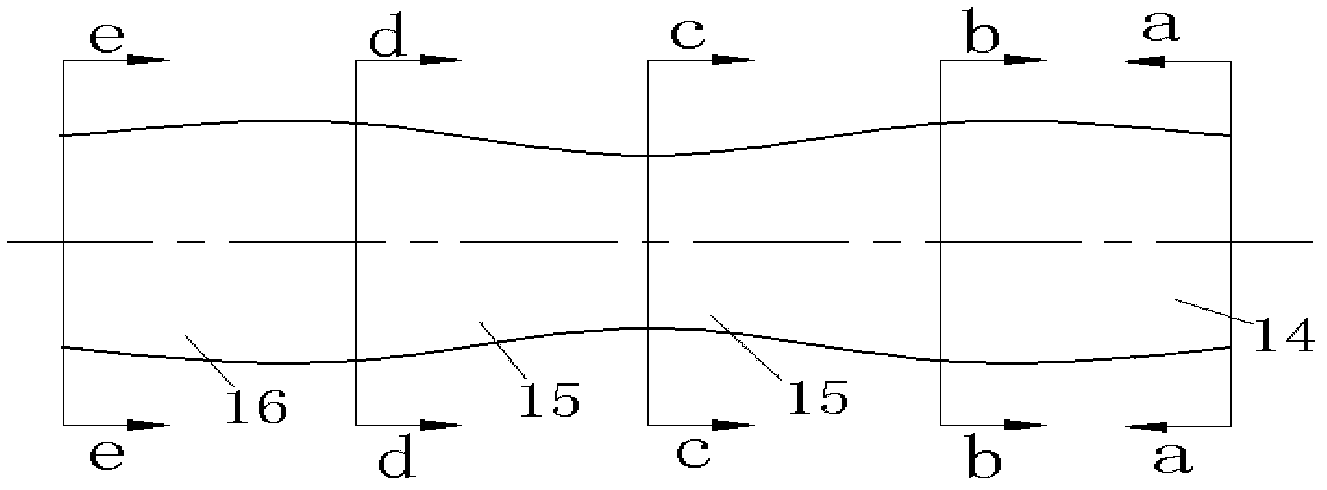

Equal-passage variable-cross-section extruding mold and extrusion forming method for pipes

InactiveCN102430609AImproved strain distributionIncrease stressExtrusion diesExtrusion mandrelsStress distributionShear stress

The invention relates to an equal-passage variable-cross-section extruding mold and an extrusion forming method for pipes. The equal-passage variable-cross-section extruding forming is adopted, so the extruding forming of the pipes is formed through the twisting shearing deformation and the upsetting deformation on the cross section, and the combination of various deformation modes in one extruding process is realized. The pipe walls are in a strong three-direction press stress state through being limited by die cavities and polyurethane foam filling agents, in the deformation stage of circle-ellipse-circle and ellipse twisting change, materials enter twisting shearing deformation zones of the metal transition regions, the material internal tissues generate rotation and shearing stress under the effect of the shearing stress, the orientation of the material tissue structure is caused, i.e. a new tissue structure is formed, and the material tissue structure under the same deformation degree is improved. The mold and the method have the advantages that deformation degree higher than that of the traditional forming process can be obtained, the strain distribution and the stress distribution inside the pipes are improved, residue casting tissues of the pipes can be favorably crushed, the forms and the distribution of inclusions are changed, and the internal tissue defects of the pipes are eliminated.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method for preparing sodium thiocyanate by using desulphurization waste liquid of coke oven gas

InactiveCN101597073AHigh purityHigh selectivityChemical industryThiocyanic acidLiquid wasteSodium thiocyanate

The invention discloses a method for preparing sodium thiocyanate by using desulphurization waste liquid of coke oven gas, and belongs to the technical field of utilization of desulphurization waste liquid of the coke oven gas. The method comprises the following steps: using the desulphurization waste liquid of the coke oven gas as a raw material, firstly, filtering the waste liquid in vacuum, using tributyl phosphate to extract thiocyanate radicals in the waste liquid, then using sodium hydroxide solution to back-extract the extract, and finally concentrating and crystallizing the extract, and washing and drying the crystals to obtain sodium thiocyanate crystals. The method uses the desulphurization waste liquid of the coke oven gas to prepare a sodium thiocyanate product with the purity as high as 93 to 95 percent so as to change waste into valuable and makes full use of waste resources; and the method is simple, saves energy, has no three-waste discharge, is favorable for environmental protection, has low production cost and good economic benefit, and develops a new path for the utilization of the desulphurization waste liquid resources of the coke oven gas. The sodium thiocyanate product prepared by the method can be widely applied in the industries of medicaments, textile, printing and dyeing, pesticide, chemistry and the like.

Owner:CHONGQING UNIV

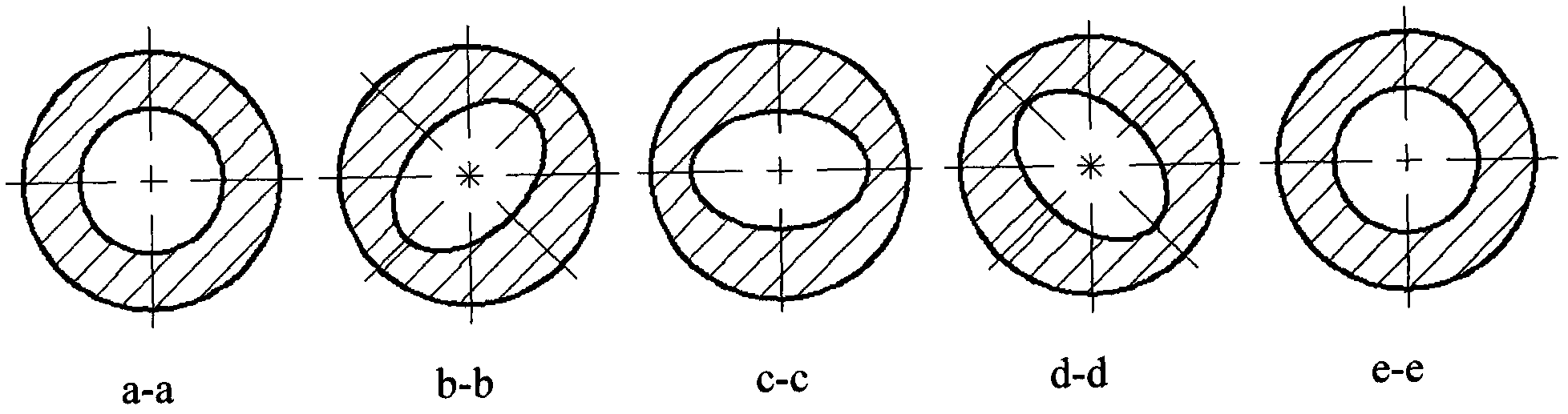

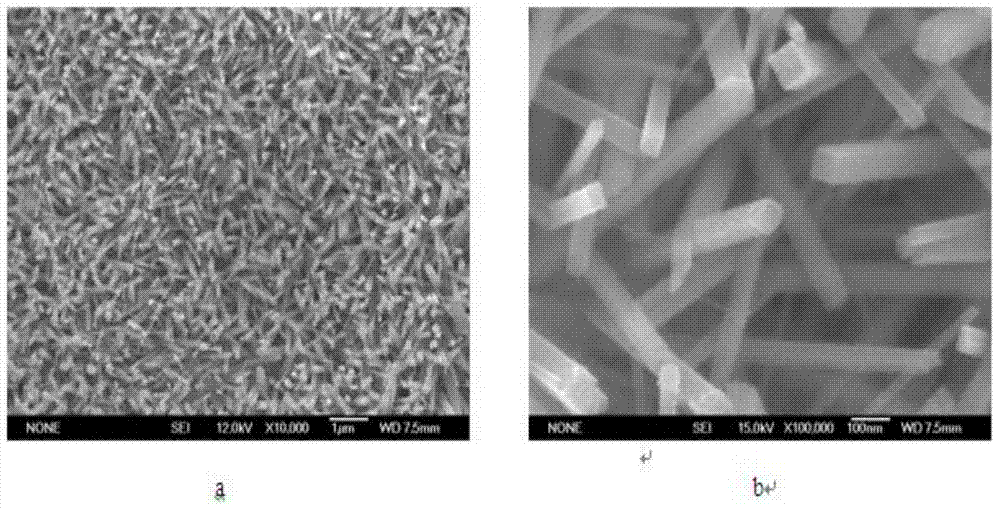

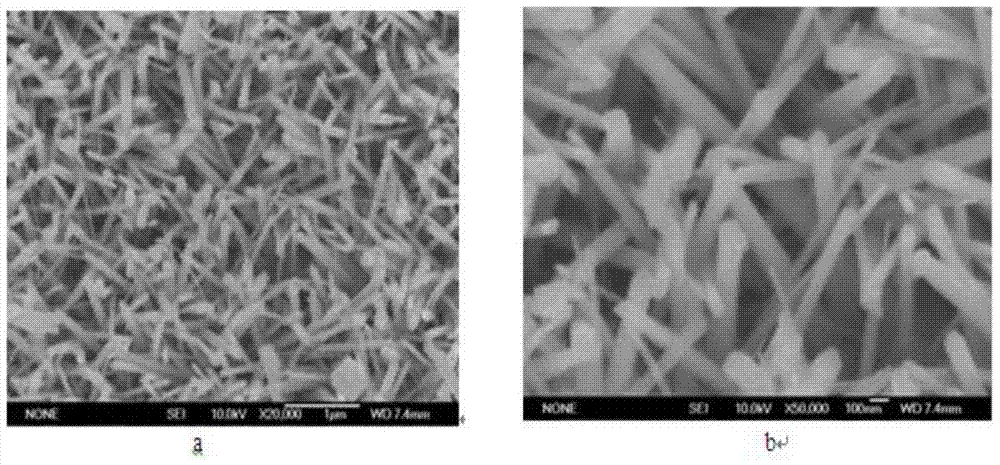

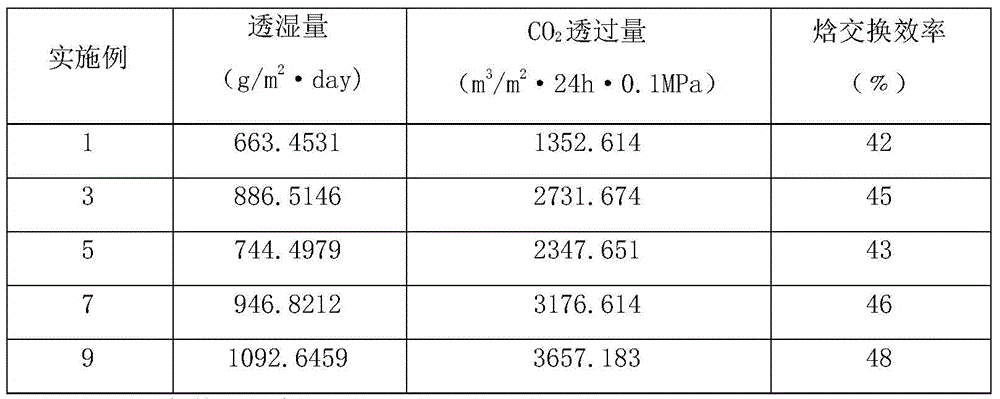

Nano-fiber composite ultrafiltration membrane preparation method based on electrostatic spinning technology

ActiveCN103386257AHigh water flux and retentionWide range of industrial applicationsSemi-permeable membranesUltrafiltrationIon

The invention relates to a nano-fiber composite ultrafiltration membrane preparation method based on an electrostatic spinning technology. According to the invention, a high-molecular polymer used for spinning is dissolved in a solvent, such that a spinning solution A with a concentration of 10-30wt% is obtained; a PVA spinning solution with a mass percentage of 7-10% is prepared; a PVA water solution with a mass concentration of 1-6% is prepared; through crosslinking treatment, a PVA coating liquid is obtained; the spinning solution A and the PVA spinning solution is subjected to composite electrostatic spinning, such that a nano-fiber composite membrane is obtained; the membrane is processed under water vapor, and is soaked with a crosslinking bath; the PVA coating liquid is used for coating by using a spin coater; a sealed reaction is carried out under room temperature; the membrane is soaked by using deionized water, and is suspended and air-dried, such that the ultrafiltration membrane is obtained. The surface of the prepared nano-fiber composite ultrafiltration membrane comprises large amounts of hydrophilic groups and active groups. The membrane has good mechanical performances and anti-pollution performances, and is especially suitable for ultrafiltration under ultra-low pressure or even no power. The membrane has high flux and retention rate under low pressure.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

Ammonia process flue gas treatment method for acidic tail gas and device

ActiveCN103223292BImprove efficiencyLess investmentDispersed particle separationAmmonium sulfatesAmmonia storageEnvironmental engineering

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

Detection system and method thereof

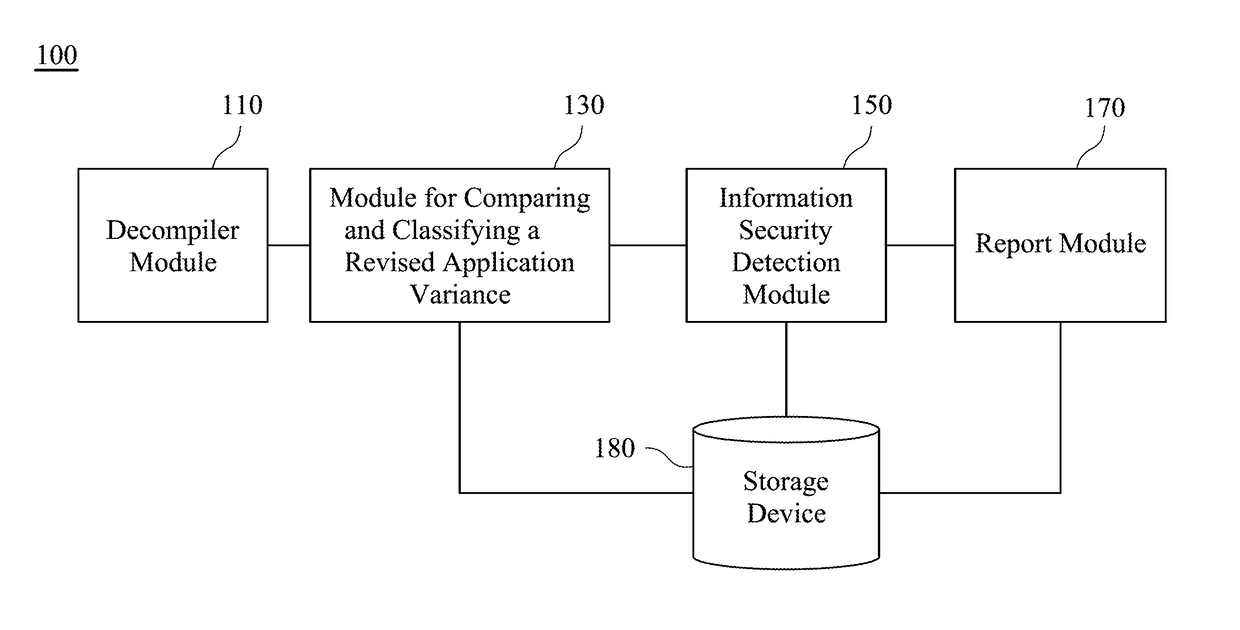

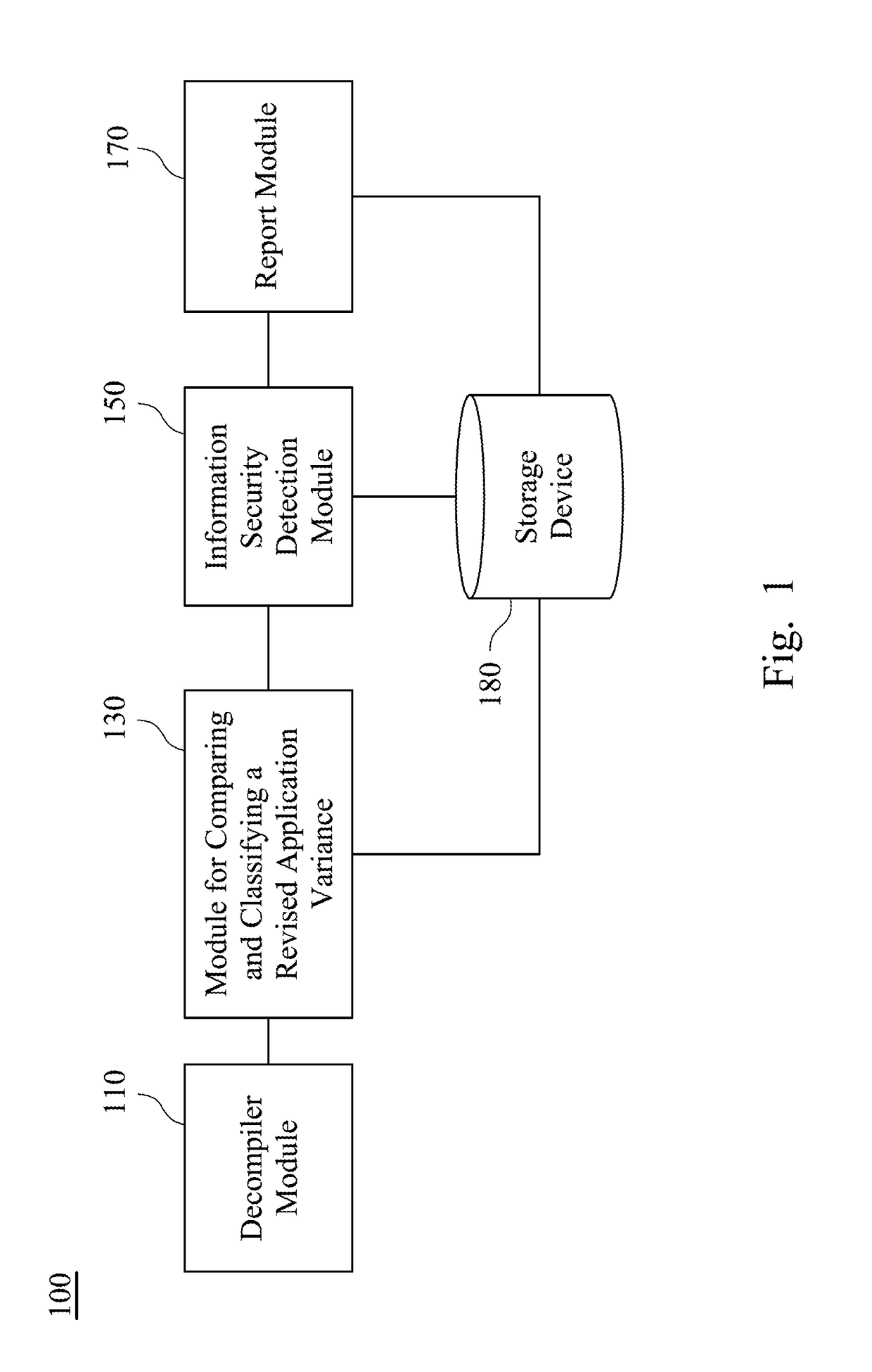

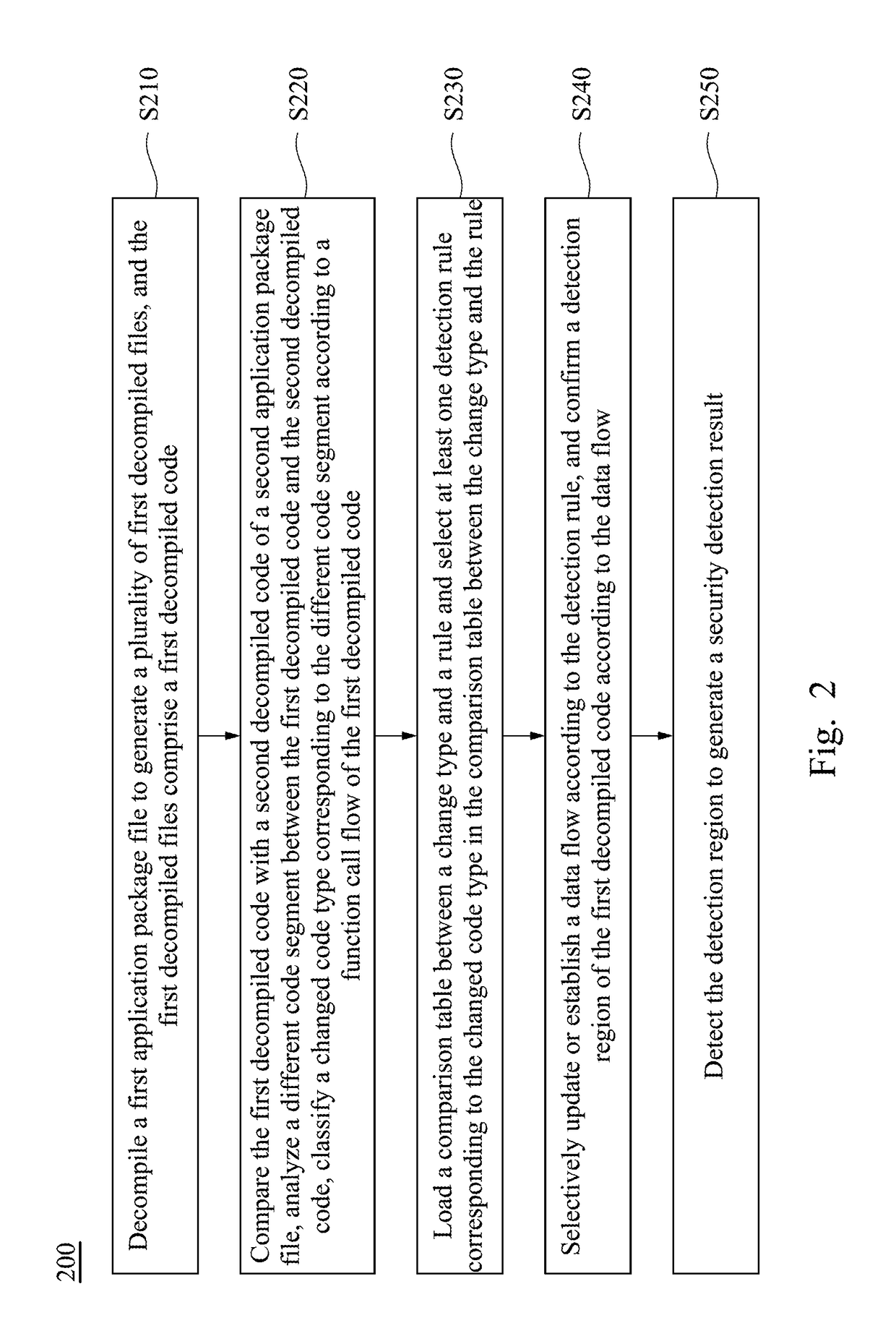

ActiveUS20170169223A1Extensive industrial applicabilityAvoids repeated consumptionDecompilation/disassemblyError detection/correctionCode segment

A detection system and method thereof are provided. The detection method comprises the following steps: decompiling a first application package file to generate a plurality of first decompiled files, and the first decompiled files comprising a first decompiled code; comparing the first decompiled code with a second decompiled code of a second application package file to analyze a different code segment between the first decompiled code and the second decompiled code; classifying a changed code type corresponding to the different code segment according to a function call flow of the first decompiled code; loading a correspondence table and selecting at least one detection rule corresponding to the changed code type in the correspondence table; confirming a detection region of the first decompiled code according to the at least one detection rule; and detecting the detection region to generate a security detection result.

Owner:INSTITUTE FOR INFORMATION INDUSTRY

Method for reinforced ultrafiltration treatment of phenol-containing waste-water by ultrafiltration membrane

InactiveCN101157492AIncrease the amount of solubilizationHigh removal rateWater contaminantsWater/sewage treatment bu osmosis/dialysisFiltration membranePhenol

The invention discloses a method for ultra-filtration membrane strengthened ultra-filtration treatment of phenol-containing sewage. The method comprises: first adding cetylpyridinium chloride which is a cationic surfactant, and sodium carbonate into the phenol-containing sewage, stirring uniformly and standing for reaction where cetylpyridinium chloride monomer molecules produce micelles by self-assembly and then solubilize the phenol contained in the water; pumping the water to an ultra-filtration component for filtration where the cetylpyridinium chloride micelles with being solubilized the phenol contained in the water are intercepted by the ultra-filtration membrane so that the phenol contained in the water is removed. The phenol concentration in the sewage is 5mg / L-200mg / L; the addition of cetylpyridinium chloride is 20*10<-3>mol / L-30*10<-3>mol / L; the addition of sodium carbonate is 1*10<-3>mol / L-20*10<-3>mol / L; the weight of molecules intercepted by the ultra-filtration membrane is 6000-10000Dalton; the membrane operation pressure is 0.05MPa-0.20MPa. The method is carried out in an intermittent type, and the standing reaction time is 0.5-10h. In treating the phenol-containing sewage, the invention has excellent phenol removal performance, low energy consumption, simple operation, low surfactant consumption and low cost. In addition, the surfactant and the phenol can be recycled.

Owner:HUNAN UNIV

Tube drawing forming method and forming mould

InactiveCN102423770AImproved strain distributionIncrease stressDrawing diesStress distributionShear stress

The invention discloses a tube drawing forming method and forming mould. In the forming method, extrusion-bulging deformation is performed on a tube by using a drawing torsion variable-section core to realize combination of various deformation modes in a primary forming process. The tube wall of the formed tube is subjected to the extrusion-bulging of the core and is in a strong three-way compressive stress state due to the limitation of a polyurethane filling layer; at a deformation stage of circular-elliptical-circular and elliptical torsion change, the tube enters a torsion shearing deformation zone of a metal transition region; under the action of shearing stress, the internal organization of the material is subjected to rotation and shear strain to cause the orientation of a materialorganization structure, namely a new texture is formed, thereby improving deformation texture under the equivalent deformation degree. The drawing variable-section core extrusion-bulging tube deformsto achieve larger deformation degree compared with that of the conventional forming process, so that strain distribution and stress distribution in the tube are improved, the casting organization remained in the broken tube is facilitated, the form and the distribution of inclusion are changed, and the defects of the internal organization of the tube are overcome.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

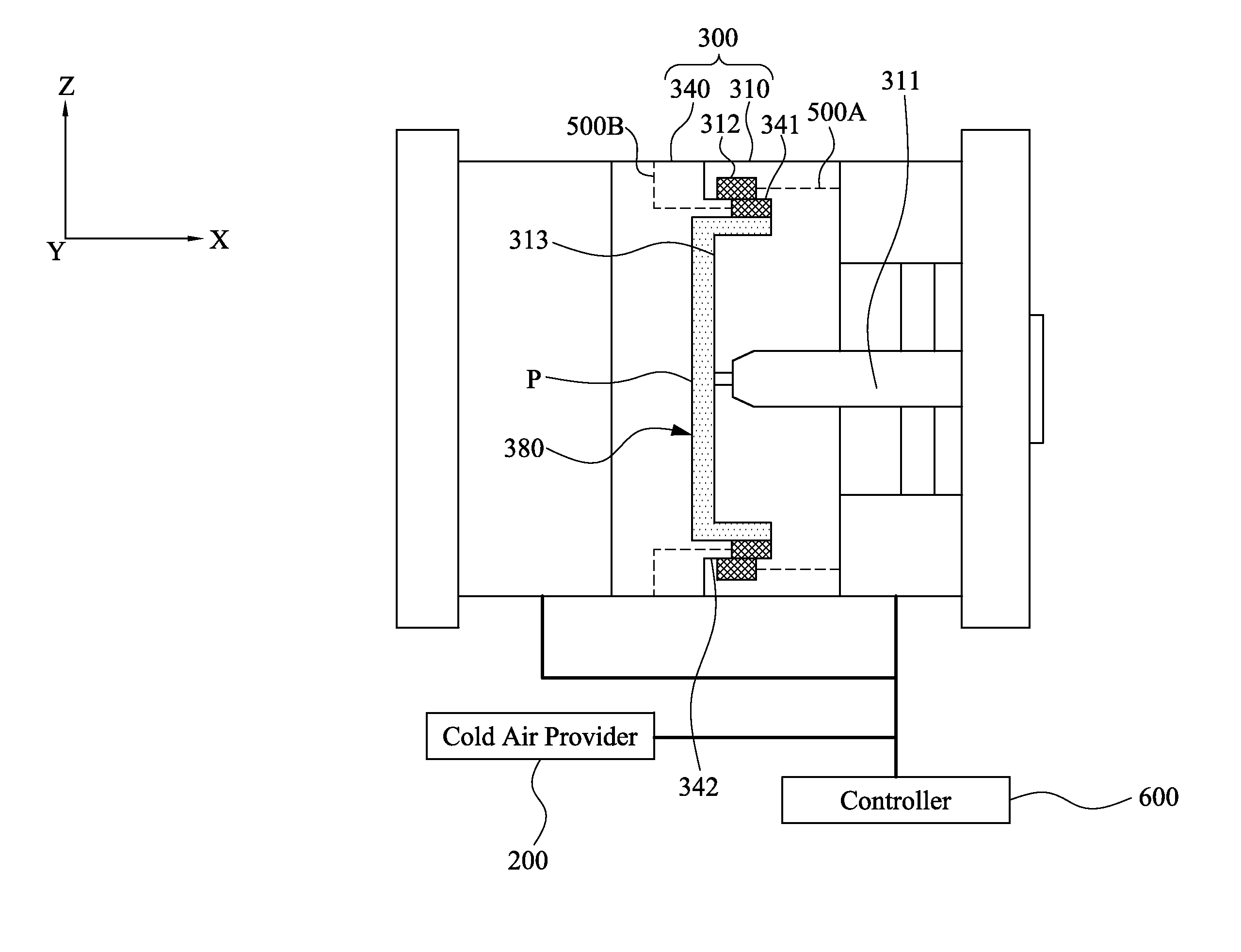

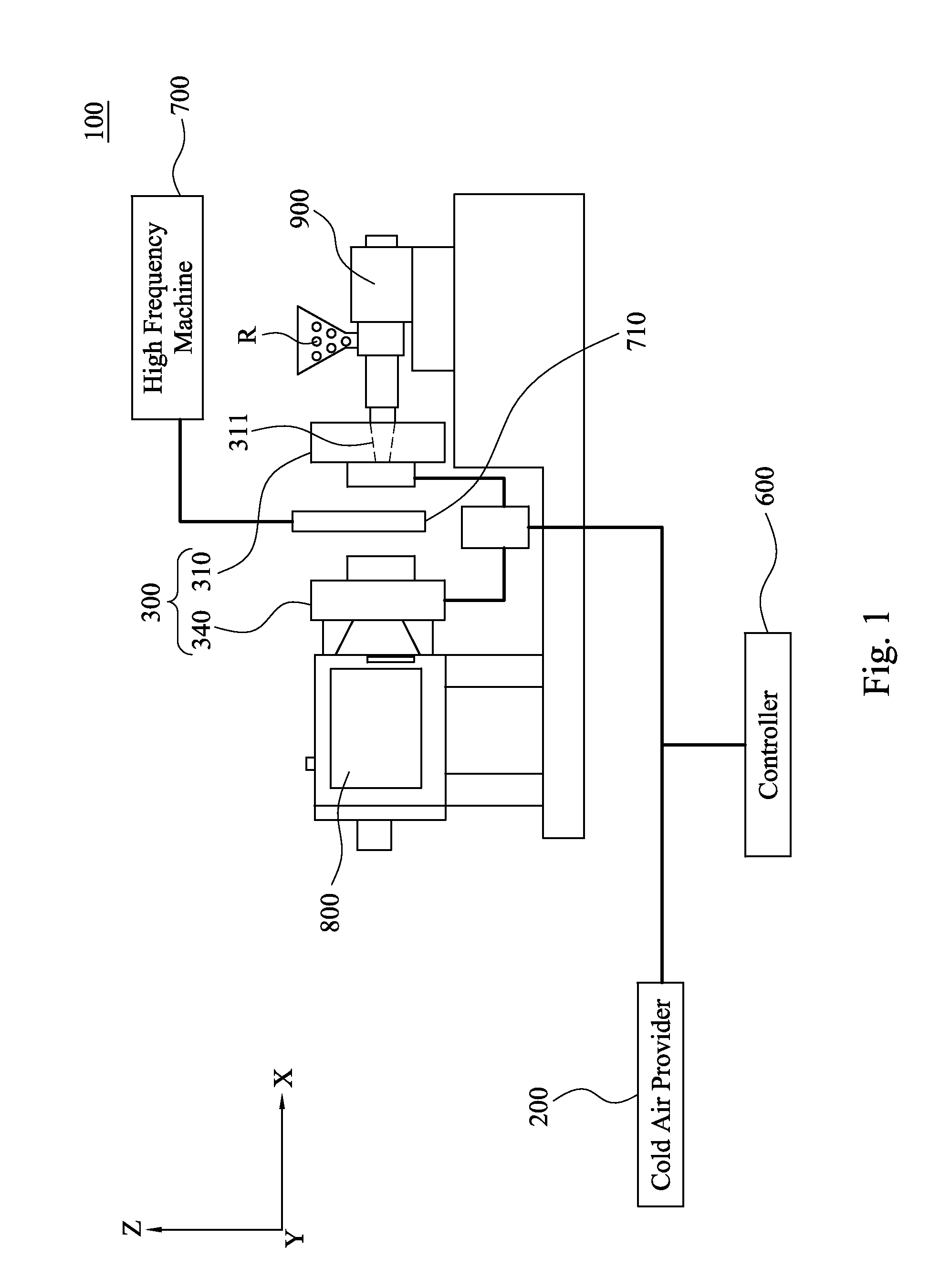

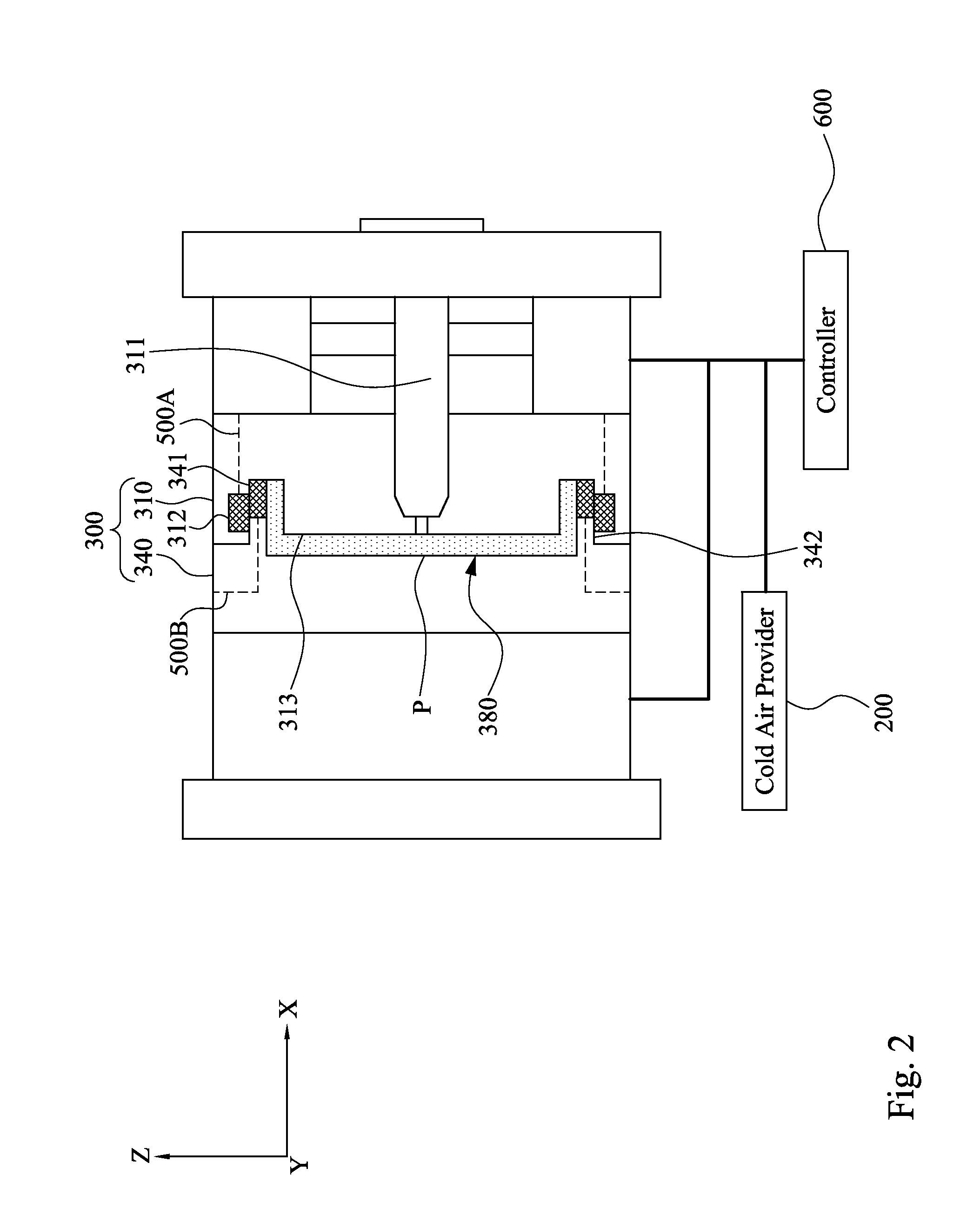

Molding system and method for directly gas-cooling a molding object

ActiveUS20160107357A1Molding cycle of the molding object is shortenedWide range of industrial applicationsAuxillary shaping apparatusCold airShell molding

A molding system for directly gas-cooling a molding object includes a cold air provider, two molding parts, a plurality of outlets, at least one air-providing molding part, at least one air passage, and a controller. The two molding parts are closed detachably to co-define a forming cavity therebetween. The outlets are arranged on the air-providing molding part. The air passage is connected to the cold air provider and the outlets. The controller drives the cold air provider to provide cold air to a molding object in the forming cavity directly when the two molding parts are separating.

Owner:QUANTA COMPUTER INC

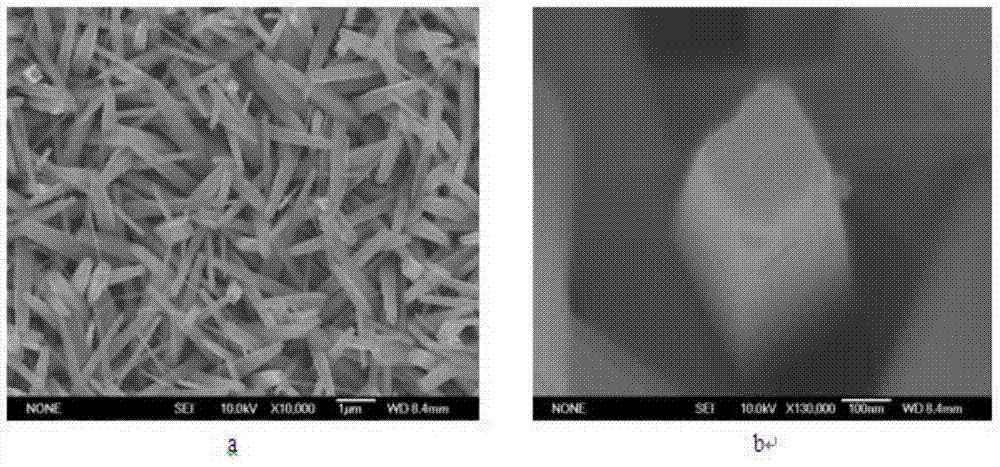

Manganese dioxide nanowire array electrode on titanium substrate and preparation method thereof

InactiveCN103896208AGuaranteed stabilityReduce interface resistanceNanostructure manufactureElectrode manufacturing processesManganeseSupercapacitor

The invention relates to a manganese dioxide nanowire array electrode on a titanium substrate and a preparation method thereof. The electrode is formed by manganese dioxide nanowire arrays on the titanium substrate, the diameter of a single manganese dioxide nanowire is 50-500 nanometers, and the manganese dioxide nanowires are vertically, uniformly and tensely distributed on the surface of titanium and are in an array form. The preparation method of the electrode comprises the following steps of fully mixing potassium permanganate, deionized water, acetone and hydrochloric acid solution to obtain mixed solution; arranging a titanium sheet in the mixed solution, arranging the mixed solution into a reactor, sealing the reactor, heating the reactor to 200 DEG C, and keeping the temperature for nine hours to ten hours; taking the titanium sheet out after the mixed solution is naturally cooled down, and obtaining the manganese dioxide nanowire array electrode on the titanium substrate. The manganese dioxide nanowire array electrode is applied to a lithium ion battery to show good circulating performance and rate capability and applied to a supercapacitor to show excellent electrochemical performance.

Owner:HUAZHONG NORMAL UNIV

Slurry bed hydrogenation catalyst, and preparation, design method and use thereof

ActiveCN104907078AHigh catalytic activityGood dispersionLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsActivated carbonRed mud

The invention discloses a slurry bed hydrogenation catalyst, and preparation, a design method and a use thereof; the catalyst includes the following components: a catalyst main body, molybdenum-containing red mud or hematite powder, a carrier and activated carbon; the molar ratio of a metal center Fe to the other metal center Mo in the red mud or hematite is 1:150 to 1:200, the mass ratio of the catalyst main body to activated carbon is 0.2:1 to 1.1:1, and the activated carbon has the pore size of 1-100 nm. The preparation method includes the following steps: firstly, preparing the molybdenum-containing red mud or hematite powder, then adding activated carbon with the particle size of 50-150 [mu]m into the molybdenum-containing red mud or hematite powder, mixing evenly, and thus obtaining the slurry bed hydrogenation catalyst. The slurry bed hydrogenation catalyst has the advantages of low cost, simple preparation method, and easy storage and transportation, can be discarded and has no need of recycling, is applied to heavy oil slurry bed hydrogenation, coal direct liquefaction and oil coal mixing, and achieves quite high residual oil / oil coal conversion rate and liquid yield.

Owner:CATECH TECH

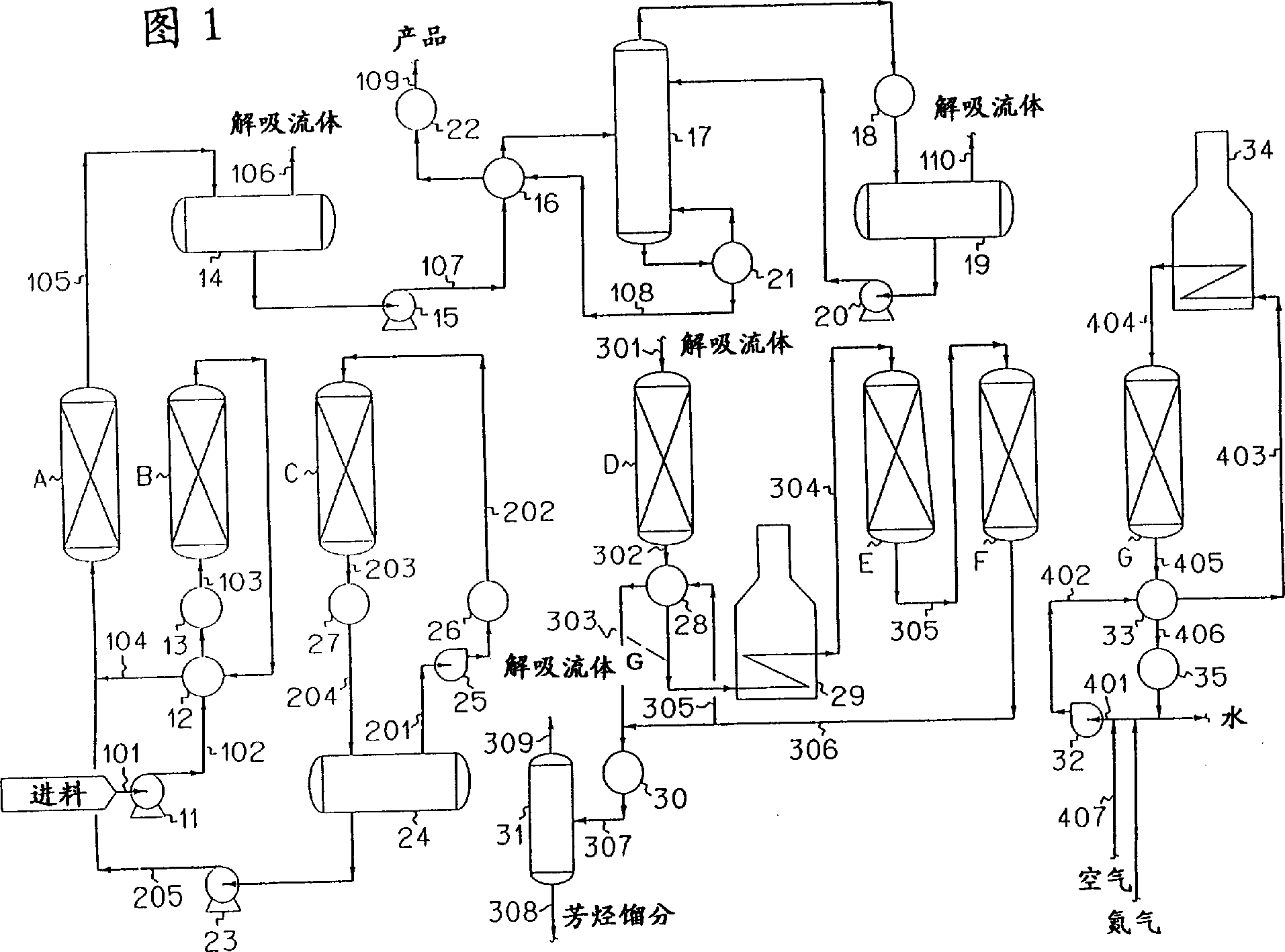

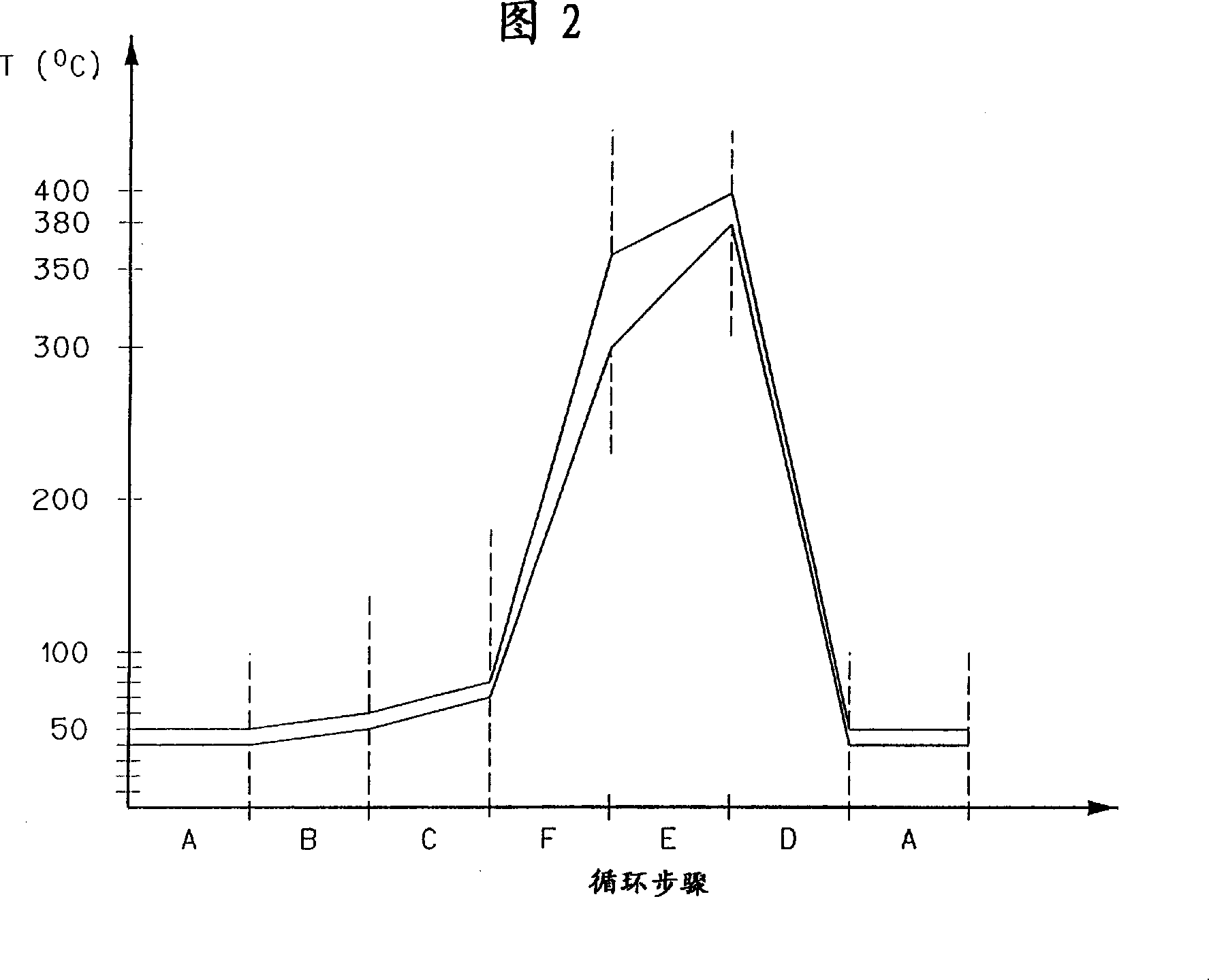

Hydrocarbon adsorption dearylating process

InactiveCN1243114ALow costHigh recovery rateAdsorption purification/separationBraking elementsMolecular sieveBoiling point

To provide an effective adsorption for separation of aromatics from hydrocarbon containing much aromatic contaminants and capable of desulfurization and energy conservation or the like by contacting serially connected beds of molecular sieves. This adsorption process includes following steps; a hydrocarbon having 45-300 deg.C boiling point and including 0.5-15 wt.% aromatic carbon (Z) is adsorbed on serially connected beds A, B, C, D, E, F and G of molecular sieves for the compound Z (e.g. silicagel, zeolite or alumina) and purged with a controlled cold desorbing liquid so as to recover paraffin / isoparaffin / naphthene-based hydrocarbons and the adsorbed compound Z is desorbed with a heated desorbing liquid by the aid of thermal swing temperature.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

Method for extracting NaSCN from thiocyanate-containing wastewater solution

InactiveCN101966996ALow priceHigh purityThiocyanic acidMultistage water/sewage treatmentElutionWastewater

The invention specifically relates to a method for extracting NaSCN from thiocyanate-containing wastewater solution. The technical scheme comprises the following steps: adsorbing the thiocyanate-containing wastewater solution by active carbon and filtering to obtain primary filtrate; adding elution agent into the primary filtrate under normal pressure at 10 to 50 DEG C, wherein the volume of the added elution agent is 1 to 8 times of that of the primary volume, and the addition seed of the elution agent is 50 to 600 mL / h; stirring at a speed of 100 to 600 r / min during the addition of the elution agent; after adding the elution agent, standing for 15 to 30 min and filtering to obtain secondary filtrate; and evaporating and crystallizing the secondary filtrate to obtain the NaSCN crystal. The method has the characteristics of low cost, environmental protection and the like, and the purity of extracted NaSCN reaches 87 to 96%.

Owner:WUHAN UNIV OF SCI & TECH

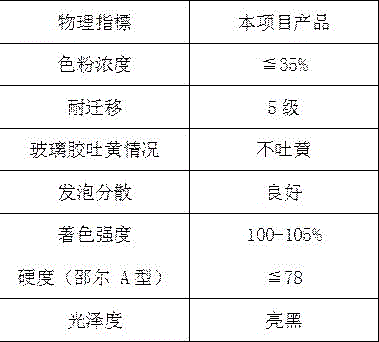

Highly dispersible black colorant rubber and preparation method thereof

InactiveCN106397886AGood color rendering physical propertiesIncreased dispersionPolymer scienceAnti ageing

The invention provides highly dispersible black colorant rubber. The highly dispersible black colorant rubber comprises, by mass, 30% of butadiene-styrene rubber, 18.5% of calcium carbonate, 8% of softening oil, 42% of carbon black, 1% of an anti-aging agent and 0.5% of a slipping agent. The invention also provides a preparation method of the highly dispersible black colorant rubber. The preparation method can ensure that the carbon black and auxiliary agents in the rubber can be uniformly supported by the carrier rubber, keep good color development physical properties and a dispersion degree of the black rubber, and satisfy colorant rubber plasticity demands in later processes such as normal rolling and extrusion.

Owner:苏州清丰兴业塑胶有限公司

Q&P steel with gradient structure and manufacturing method thereof

InactiveCN105463307AIncreased strength and plasticityEnsure process stabilitySolid state diffusion coatingCarburizingAustenite

The invention discloses Q&P steel with a gradient structure. The Q&P steel comprises, by weight percent, 0.14-0.29% of C, 1.1-2.8% of Si, 1.8-3.0% of Mn, 0.5-1.9% of Cr, 1.5-3.1% of Al, smaller than or equal to 0.01% of S, smaller than 0.01% of P and the balance Fe. A manufacturing method of the Q&P steel includes the steps of austenitizing, carburizing, quenching, tempered carbon distributing and quenching. According to the Q&P steel and the manufacturing of the Q&P steel, technology stability and organization gradient can be ensured in production of large-size products, strength of the steel is improved, good toughness of the steel is also ensured, and low alloying cost is low.

Owner:ZHONGBEI UNIV

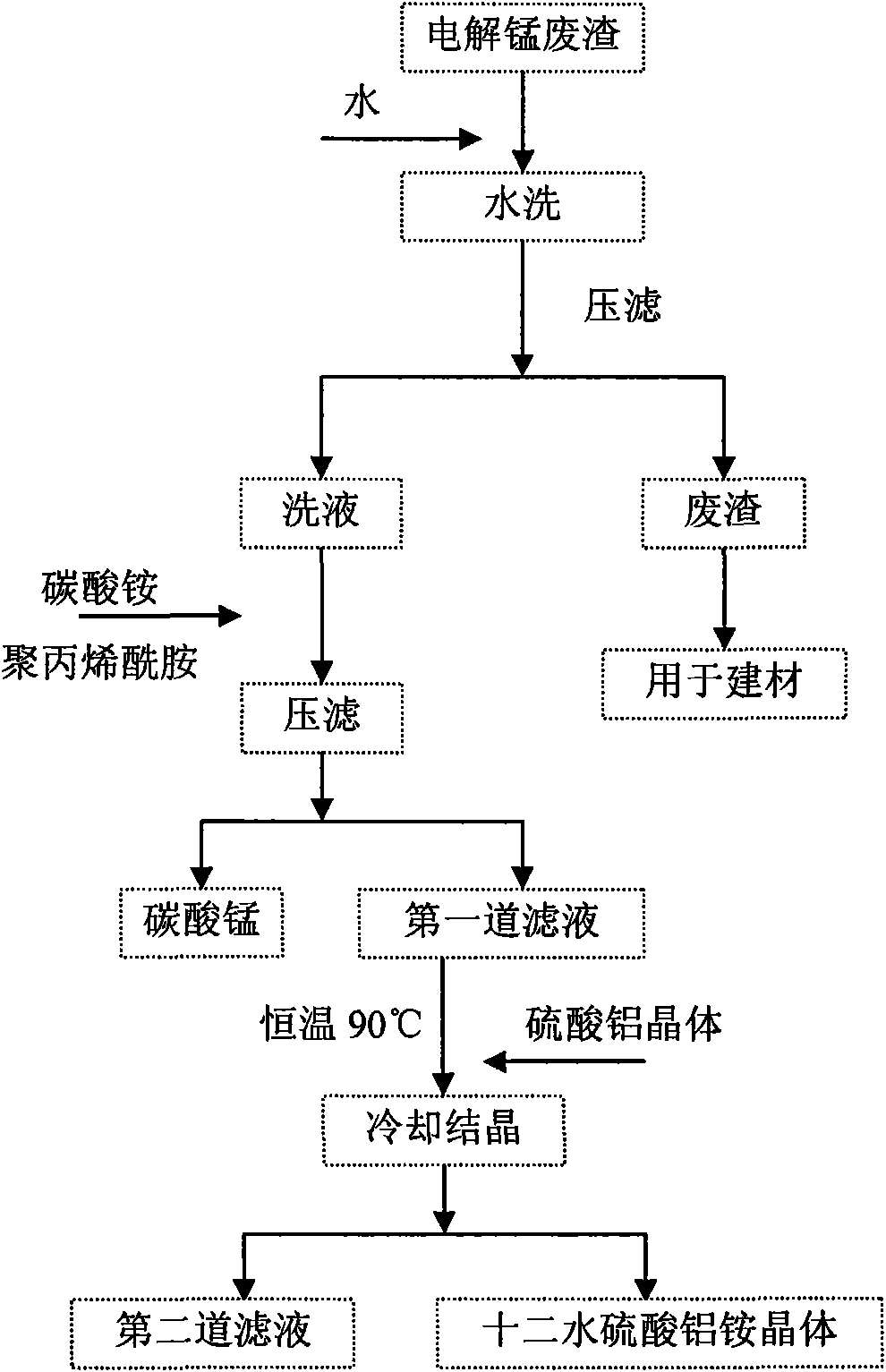

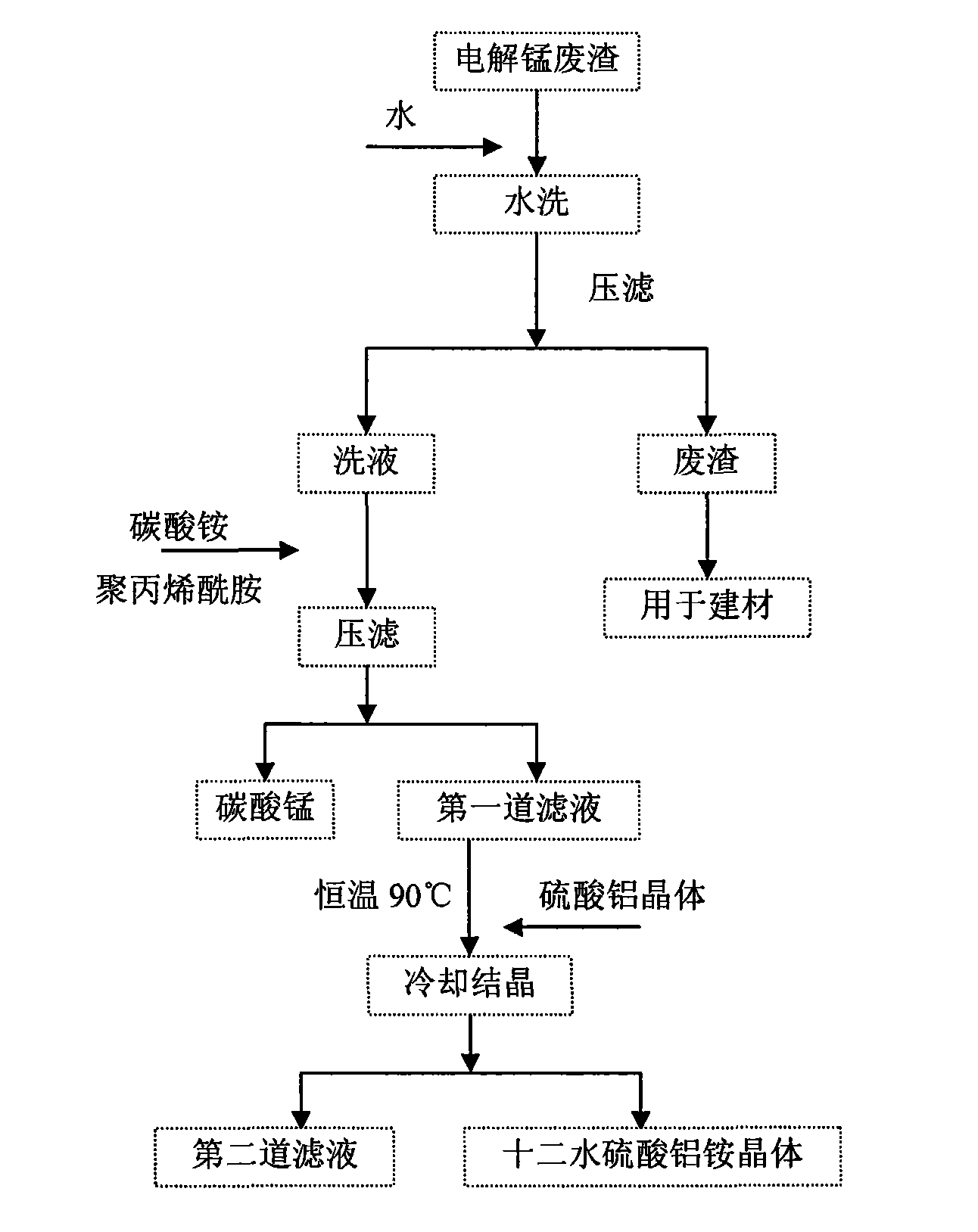

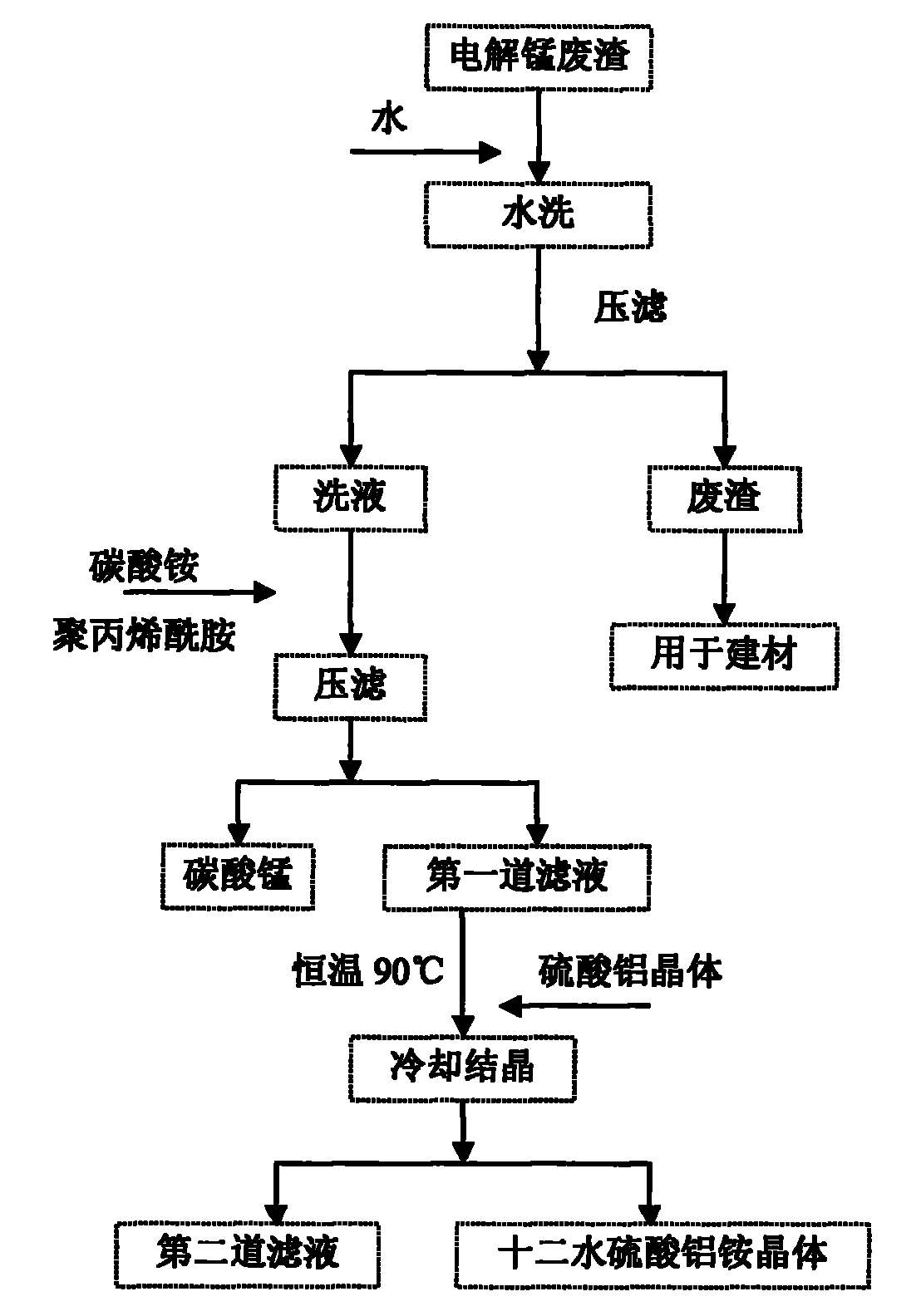

Method for processing and utilizing electrolytic manganese waste residue

The invention relates to a method for processing and utilizing electrolytic manganese waste residue, which comprises the following steps of: the electrolytic manganese waste residue is washed so as to a water washing liquid; salvolatile and flocculating agent and polyacrylamide are added so as to obtain a manganous carbonate precipitation and a first filtrate; aluminium sulphate crystal and crystal modifier borax are added into the first filtrate so as to separate out dodecahydrate aluminium ammonium sulfate crystal. The method can convert manganous sulfate in the electrolytic manganese waste residue which is difficult to isolate a manganese element into the manganous sulfate which is convenient to isolate the manganese element, can convert the manganous sulfate which is difficult to isolate a nitrogen element into the dodecahydrate aluminium ammonium sulfate crystal which is convenient to isolate the nitrogen element. The method has the low manufacturing cost, is easy to operate and convenient for realizing the commercial process.

Owner:CHONGQING UNIV

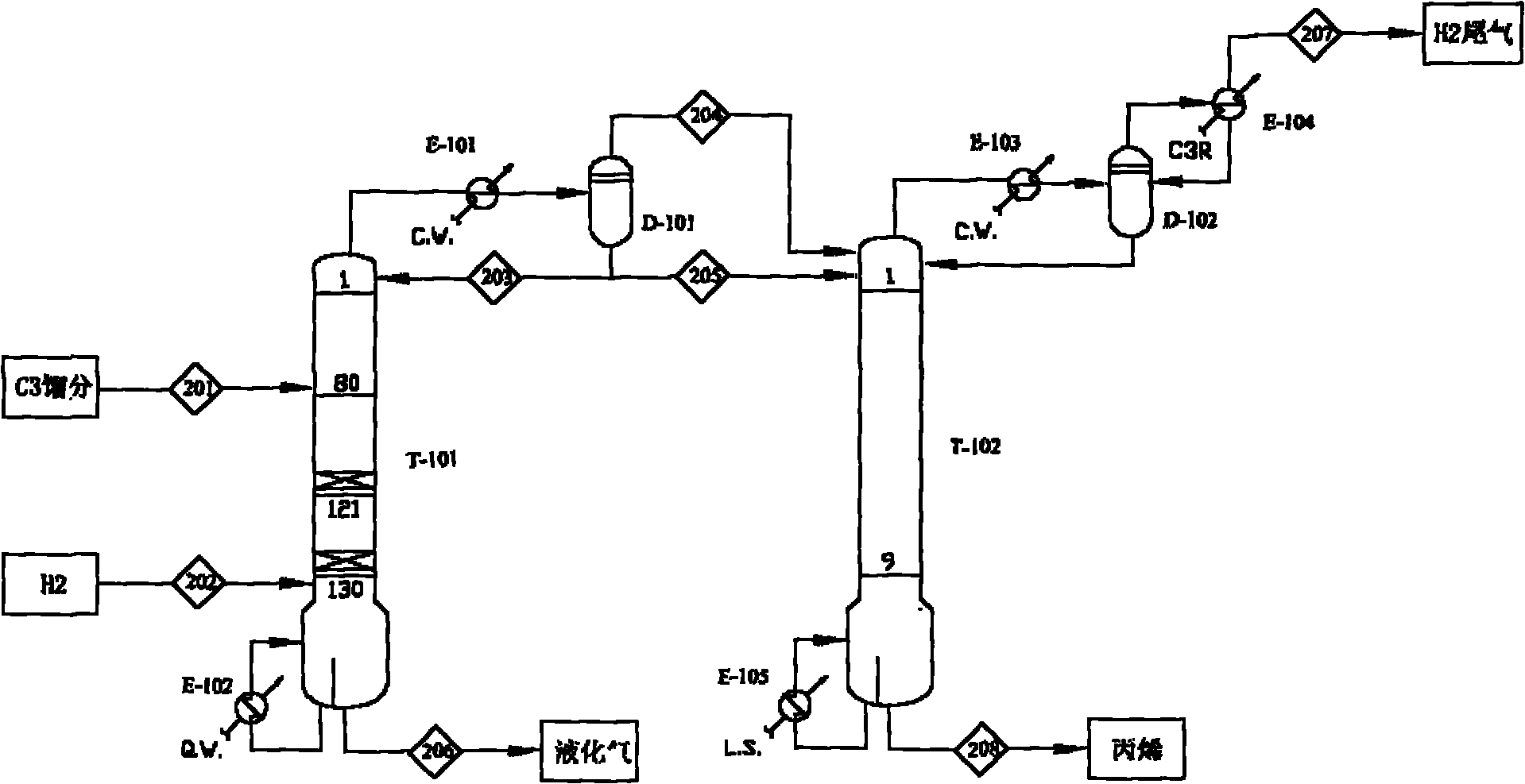

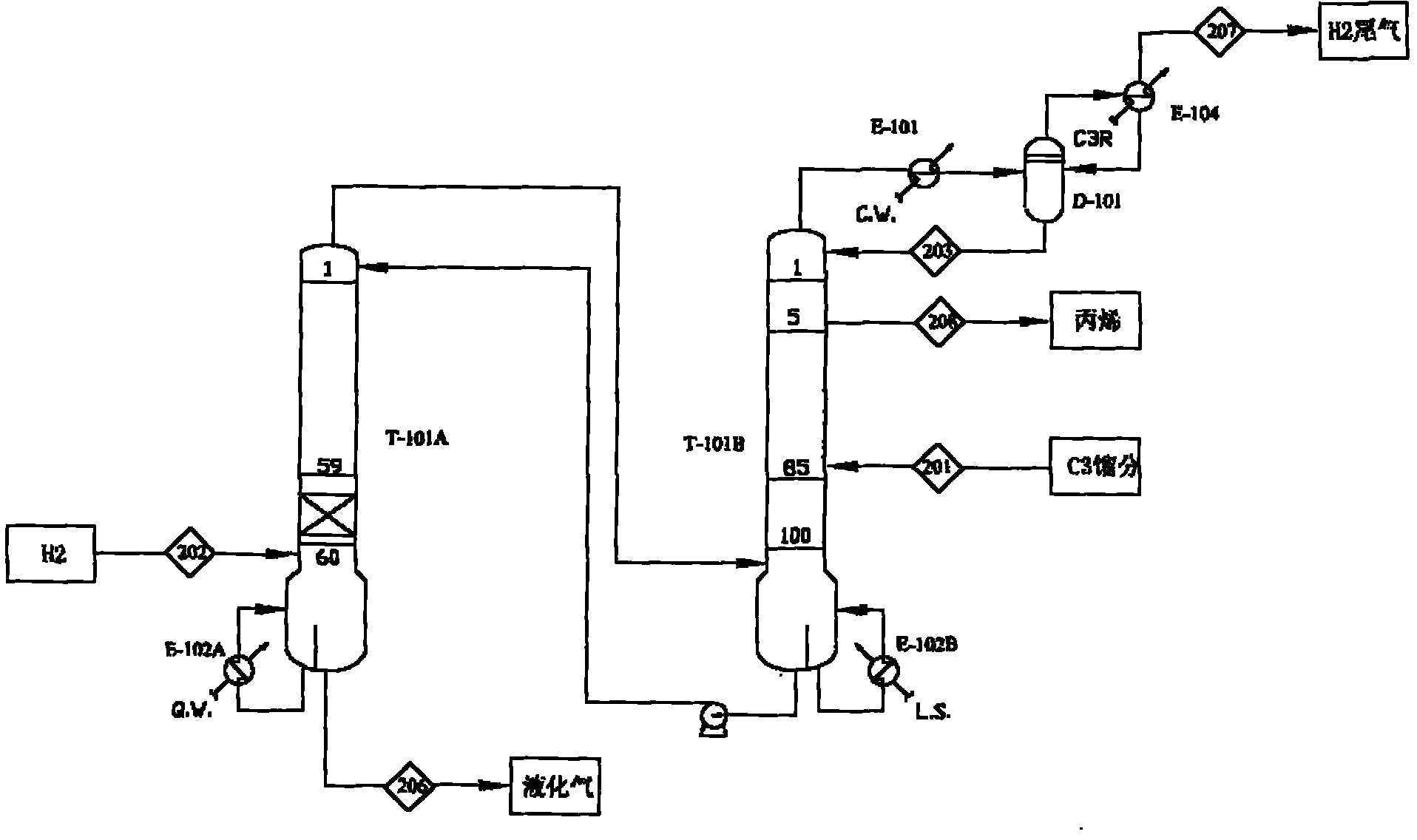

Catalytic rectification method for removing MAPD by selective hydrogenation

ActiveCN102040446AHigh conversion selectivityLow inactivation effectHydrocarbon by hydrogenationGaseous fuelsHydrogenTower

The invention provides a catalytic rectification method for removing methyl acetylene and propadiene (MAPD) by selective hydrogenation. The method comprises the following steps of: placing a catalytic rectification member below a C3 fraction feeding position of a propylene rectification tower, introducing hydrogen into the tower from the lower part of the catalytic rectification member, and making the hydrogen upwards flow through the catalytic rectification member; and directly feeding the C3 fraction containing the MAPD into the propylene rectification tower or feeding the C3 fraction whichis pre-transformed through a first MAPD reactor into the propylene rectification tower to perform catalytic rectification and remove MAPD, directly recovering propylene meeting the polymerization level requirement from a lateral line, or recovering the material from the top of the tower, and removing light components to obtain polymerization level propylene, wherein the molar fraction of the MAPDin the tower can be directly reduced to below 0.1 to 2 percent. The method is characterized in that: by using the characteristic of low concentration of the propylene in the propylene rectification tower, the probability of side reaction of transforming the propylene into propane can be reduced, the selectivity of MAPD transformation is improved, and the purpose of high propylene yield is fulfilled.

Owner:CHINA PETROLEUM & CHEM CORP +1

Anti-yellowing black color glue and preparation method thereof

The invention provides anti-yellowing black color glue. The anti-yellowing black color glue comprises the following components in percentage content by mass: 35% of styrene butadiene rubber, 18% of calcium carbonate, 8% of softening oil, 35% of carbon black, 2.5% of an antioxidant, and 1.5% of a slipping agent. The invention further provides a preparation method of the anti-yellowing black color glue. By adopting the anti-yellowing black color glue and the preparation method of the anti-yellowing black color glue, glass cement rubber outsoles generated by a client can be ensured to be not yellowed from black and produce no color shift, furthermore, the black color glue is kept in good color development physical properties and dispersion degree, and the color glue has plasticity requirements of subsequent processing procedures of capabilities of carrying out normal rolling, extrusion and the like.

Owner:苏州清丰兴业塑胶有限公司

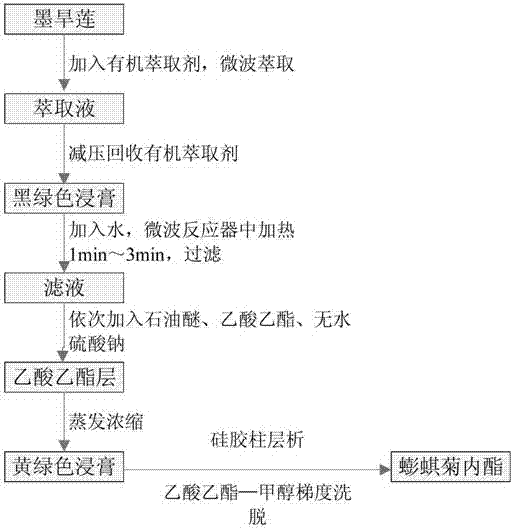

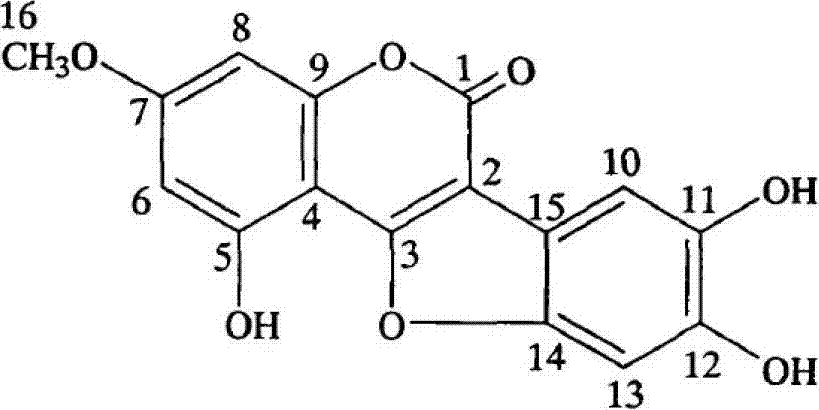

Method for extracting wedelia lactone by using microwave-assisted technology

The invention relates to a method for extracting wedelia lactone by using microwave-assisted technology, which comprises the following steps of: crushing eclipta grass, adding an organic extractant, extracting with microwave for 2-3 times, filtering the extract, combining filtrate, recovering organic extractant with a rotary evaporator by reduced pressure evaporation to obtain dark green extract, adding 2-5 times the volume of water, heating in a microwave reator of 70-80 DEG C for a period of time, filtering as soon as possible, adding petroleum ether to the filtrate to remove fat-soluble ingredients such as chlorophyll, adding ethyl acetate to extract, adding anhydrous sodium sulfate to remove water, concentrating under reduced pressure to obtain yellow-green extract, taking certain amount of extract on the silica gel column, using ethyl acetate-methanol with polarity ascending for the gradient elution, obtaining off-white solid when the volume ratio of ethyl acetate-methanol is appropriate, and recrystallizing with methanol for 2-4 times to obtain the product. The microwave extracting technology can shorten the time, reduce the solvent dosage and energy consumption, and also can improve the yield and purity of the extract. The technology can meet the requirement of the green environmental protection and has significance of industrialization.

Owner:TIANJIN UNIV

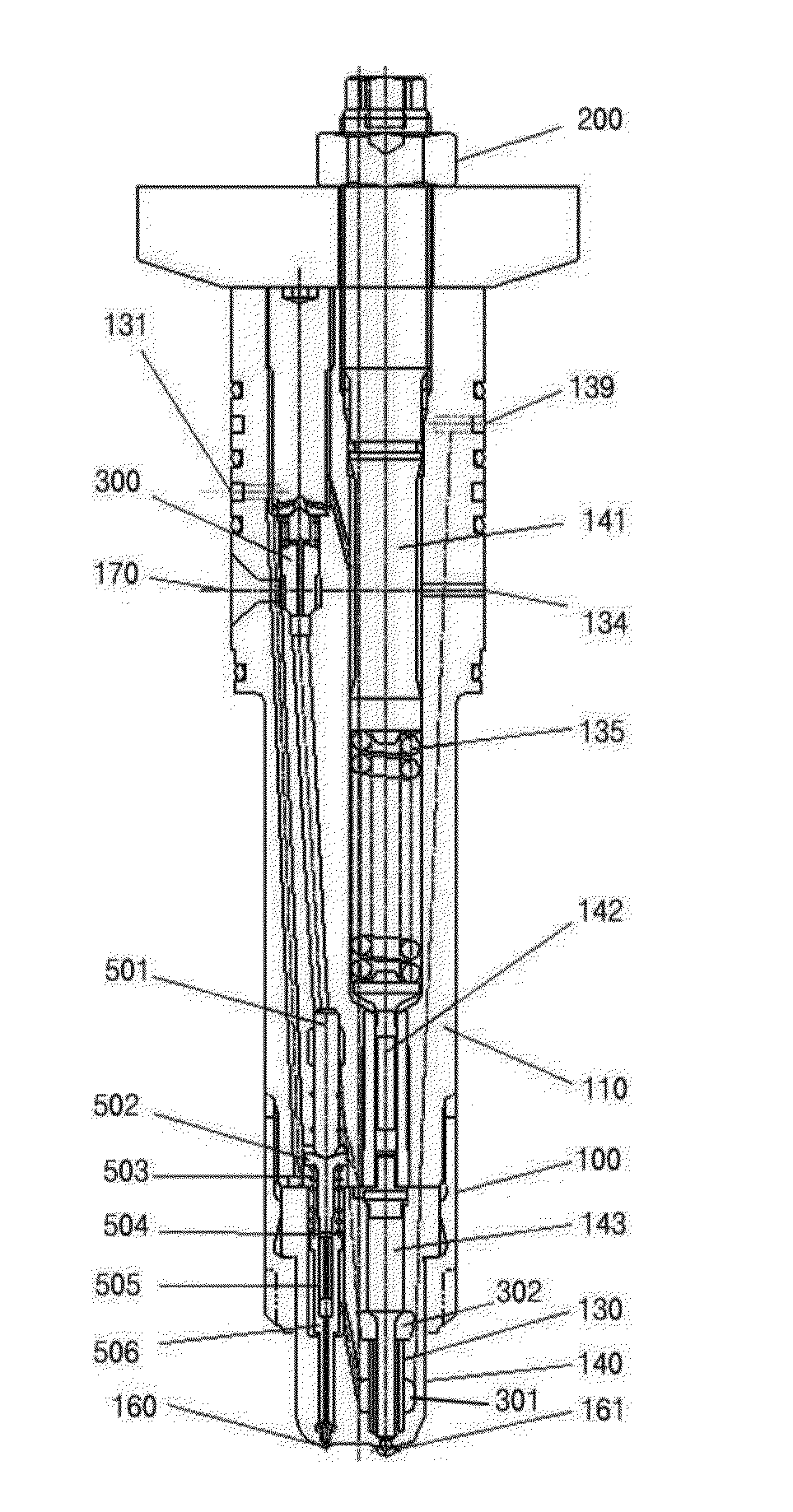

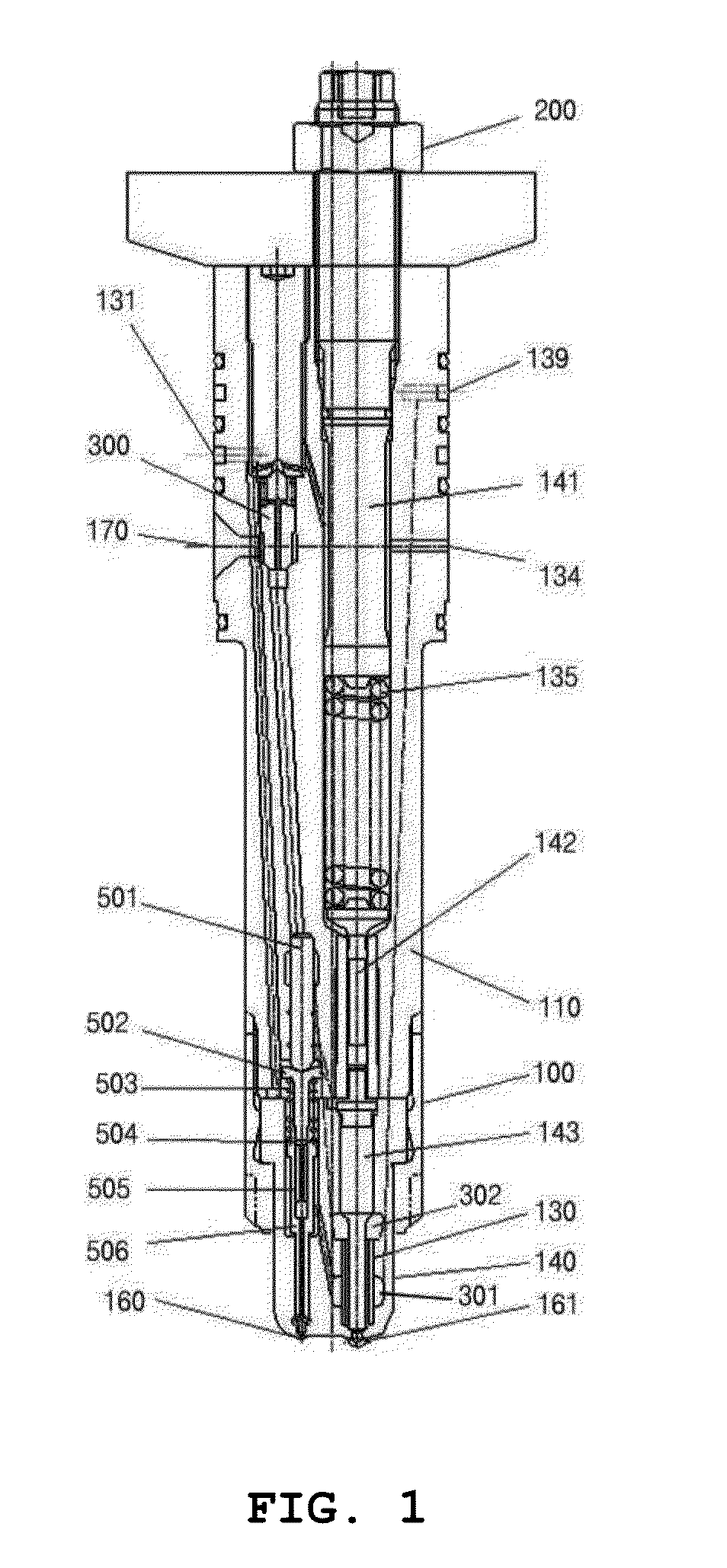

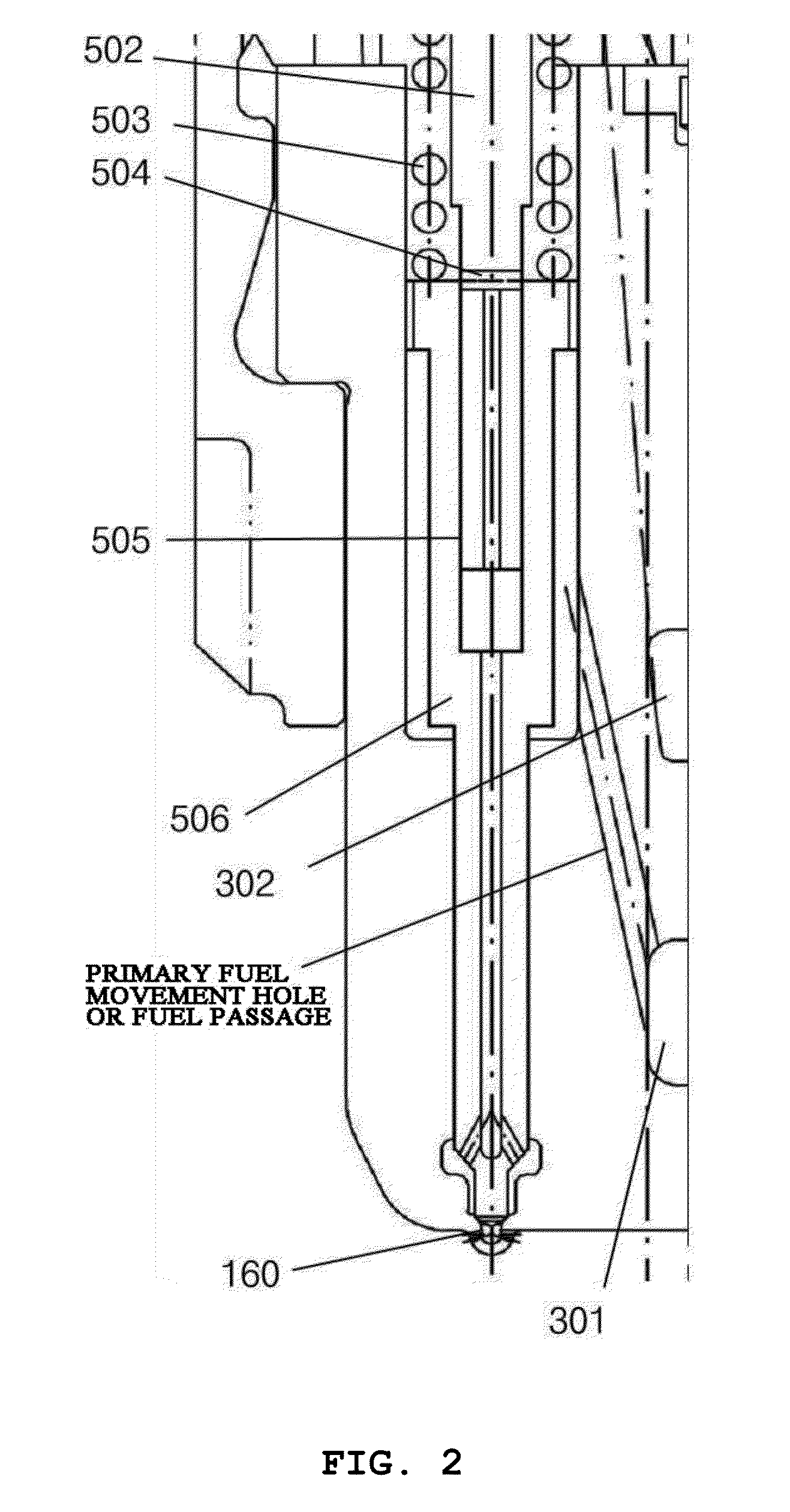

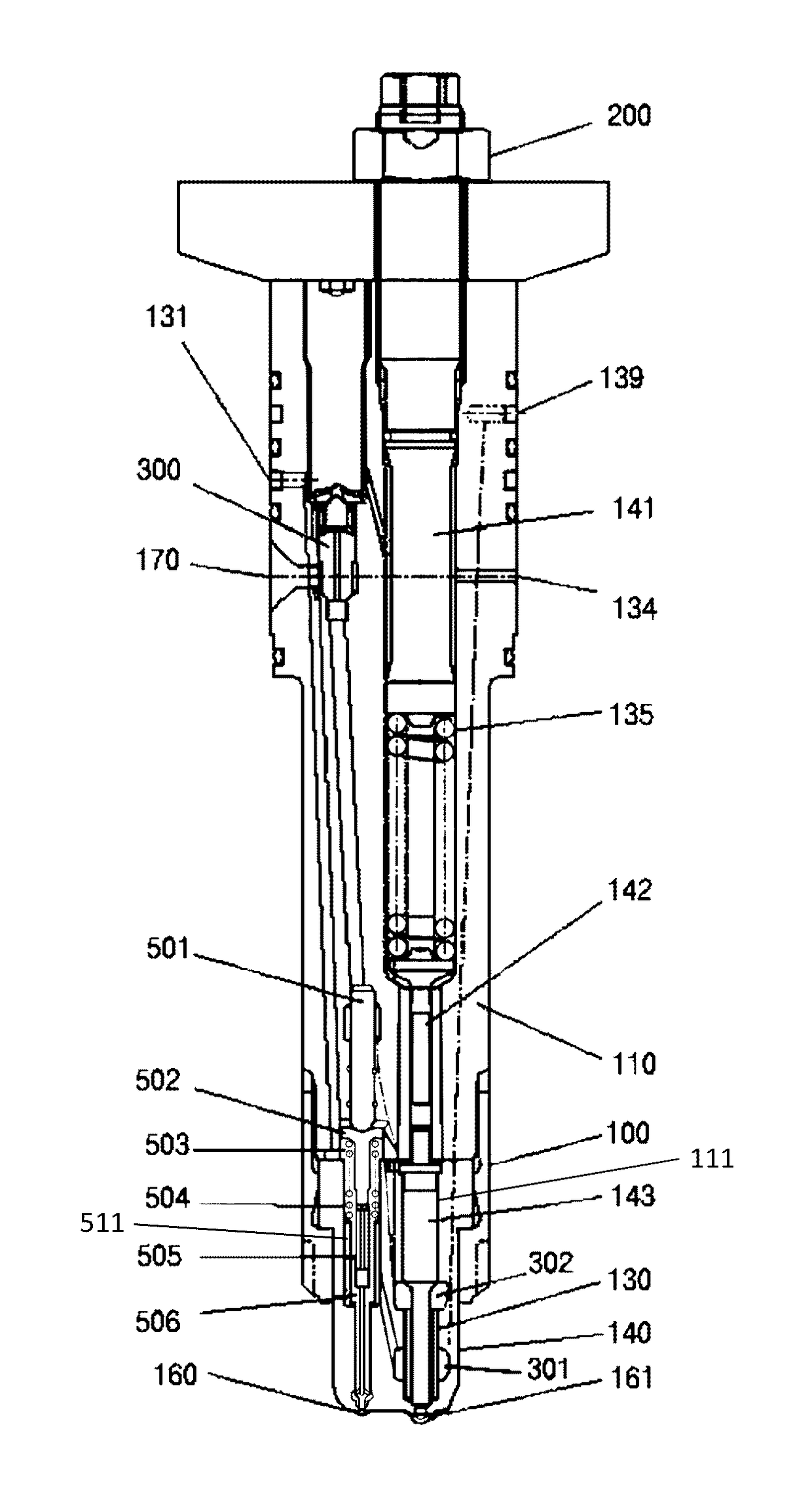

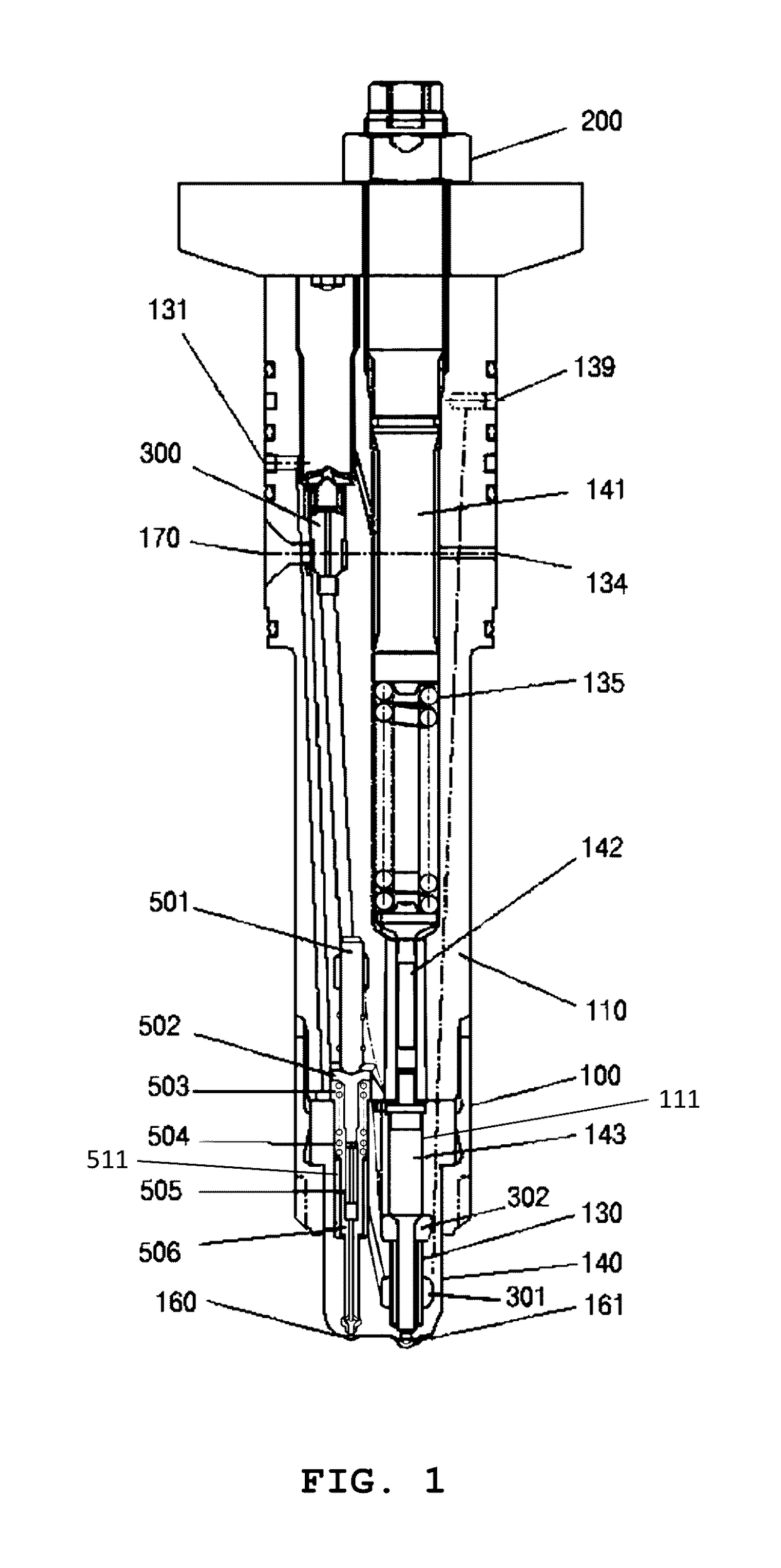

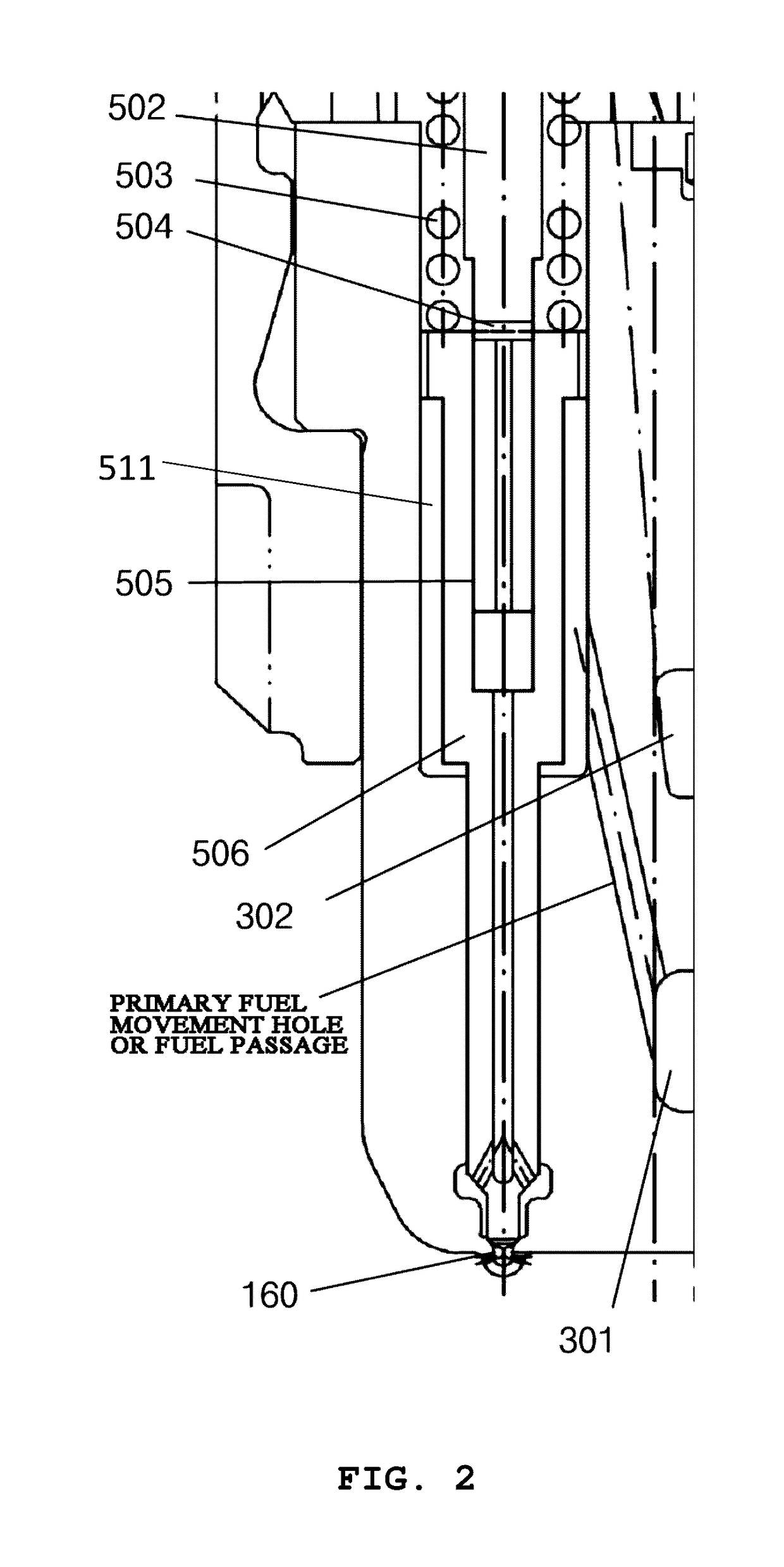

Two-phase fuel injection valve for diesel engine and gas engine including nozzle having pumping function

ActiveUS20130139790A1Needle can moveWide range of industrial applicationsInternal combustion piston enginesLow-pressure fuel injectionEngineeringPressure difference

The present invention relates to a dual fuel injection valve having a pumping nozzle for a diesel engine and a gas engine, and an objective of the present invention is to provide a fuel injection valve in which, by using two kinds of fuel entering into a fuel valve, a warming up and injection of pilot fuel may be performed in an initial injection and injection of main fuel may be performed subsequently such that subsequent dual fuel is used for combustion, thereby increasing fuel injection performance.In a fuel injection valve for a diesel engine or a gas engine for injecting fuel to a cylinder, provided is a dual fuel injection valve having a pumping nozzle for the diesel engine and the gas engine including: the dual fuel injection valve including a fuel valve block (110) in which a fuel passage to which first and secondary fuel is introduced through a high pressure pipe is formed inside thereof, the first and secondary fuel being the same fuel system or different fuel systems; a cylinder / needle valve (506) which moves upward by a pressure difference of the secondary fuel introduced through the fuel passage formed in the fuel valve block (110) to inject the primary fuel to a pilot nozzle hole; and a main needle valve (143) which, after injecting the primary fuel by pressing the cylinder / needle valve (506), moves upward by the pressure difference of the secondary fuel introduced through a connected fuel passage to inject the primary fuel to a main nozzle hole (161).

Owner:HYUNDAI HEAVY IND CO LTD

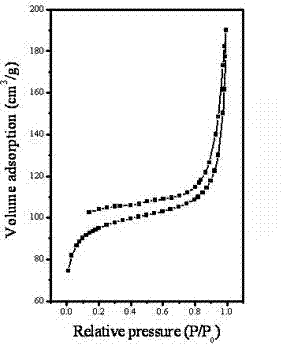

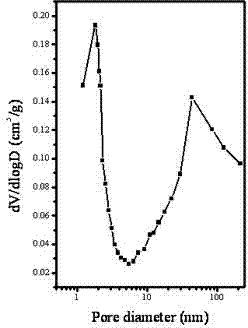

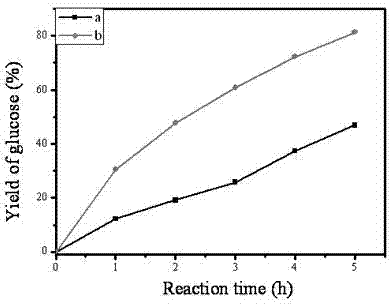

Porous carbon-based solid acid catalyst and preparation method thereof

InactiveCN103537324ALarge specific surface areaSimple methodOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystPorous carbon

The invention belongs to the technical field of material science, and discloses a porous carbon-based solid acid catalytic material with a large specific surface area and a mesoporous structure and a preparation method thereof. The catalyst takes a non-ionic surfactant F127 or P123 as a template agent and furfural as a carbon source, volatilization self assembly is carried out in the presence of isethionic acid so as to obtain a soft film type material, and high temperature crosslinking and carbonizing are then carried out for obtaining a sulfonate functionalization nano-porous carbon material; the template agent is removed under an ethanol reflowing condition, so that the nano porous carbon material is obtained. The material has the large specific surface area and has excellent acid catalytic performance, and the sulfonate functionalization mesoporous carbon catalytic material overcomes defects such as the low exposure degree and poor catalytic activity of an active center of a conventional acid catalytic material; moreover, the material can be used for overcoming the influences of the passivated hydrolization of the active center on the catalytic performance and regeneration capacity of the active center because the porous solid acid catalytic material of an inorganic framework is better than that of a hydrophile framework.

Owner:SHAOXING UNIVERSITY

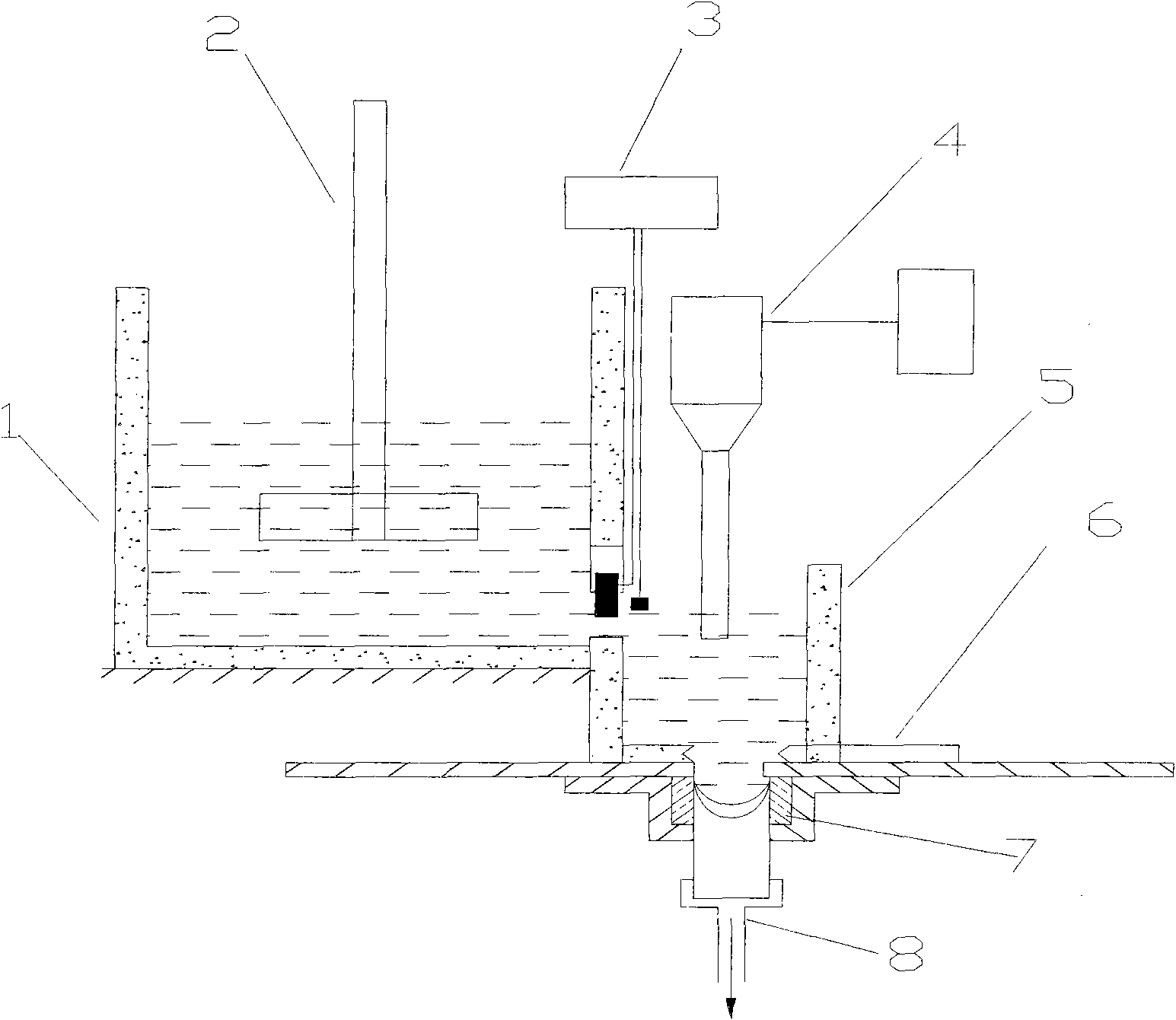

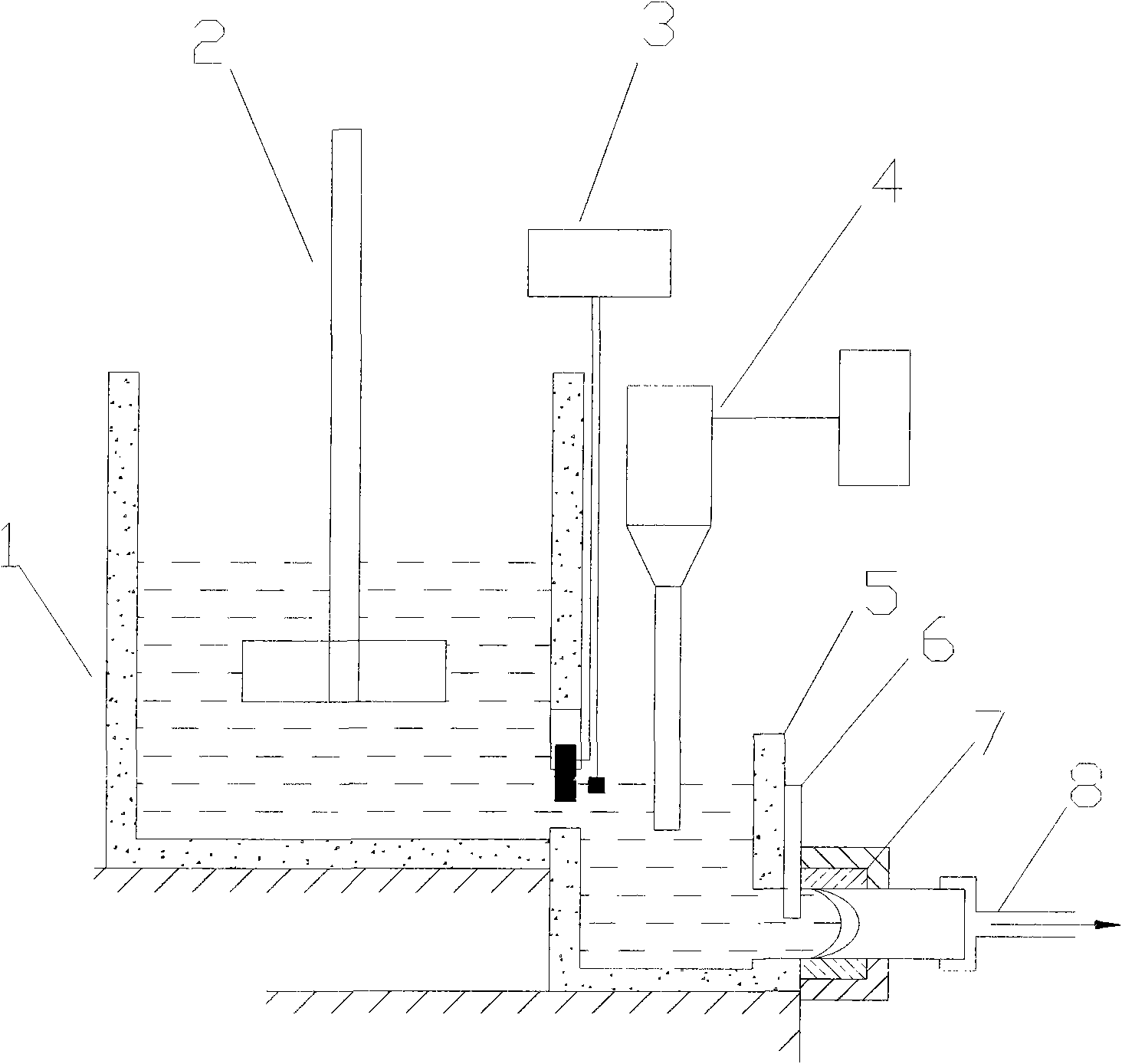

Method and device for preparing metal base nano composite material by ultrasound stirring and continuous casting

The invention relates to a method and device for preparing metal base nano composite material by ultrasound stirring and continuous casting, and the device for realizing the invention is composed of a liquid storage casting ladle, a stirring device, a liquid level controller, an ultrasonic generator, a casting ladle, a control valve, a crystallizer and a dummy bar. The method adopts stirring and ultrasonic treatment, so that nano ceramics in metallic solution are in uniform distribution state; a sensor acquires signal and the height of the liquid level of the casting ladle is controlled; and the dummy bar is used for continuous dummy ingot downward or along horizontal direction. The invention effectively prevents agglomeration of ceramic granules. The invention is especially applicable to one time preparation of material in large size and preparation of different products such as parts, plates, wires, sections and the like by secondary processing, has wide industrial application range and has a broad market prospect.

Owner:SOUTH CHINA UNIV OF TECH

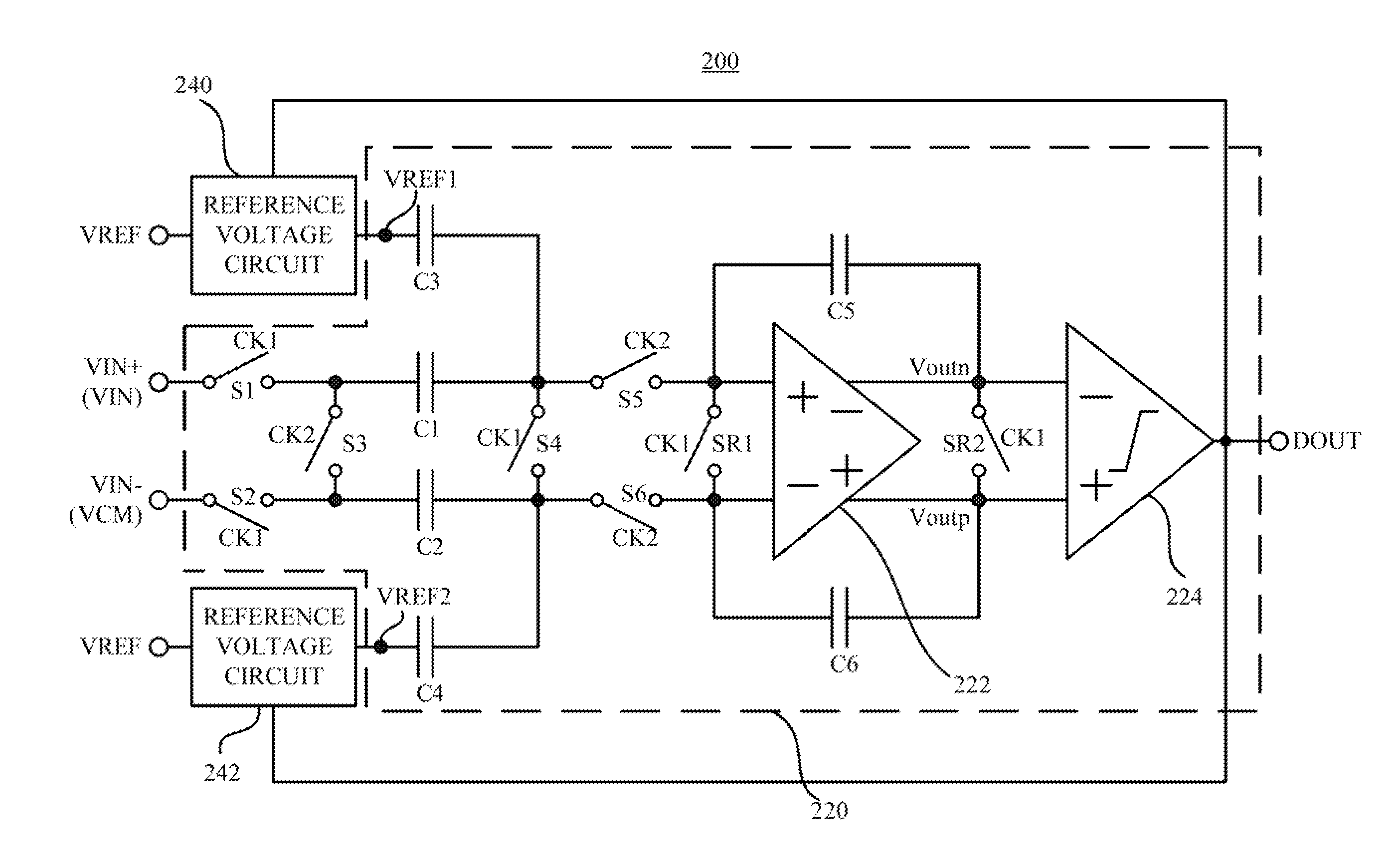

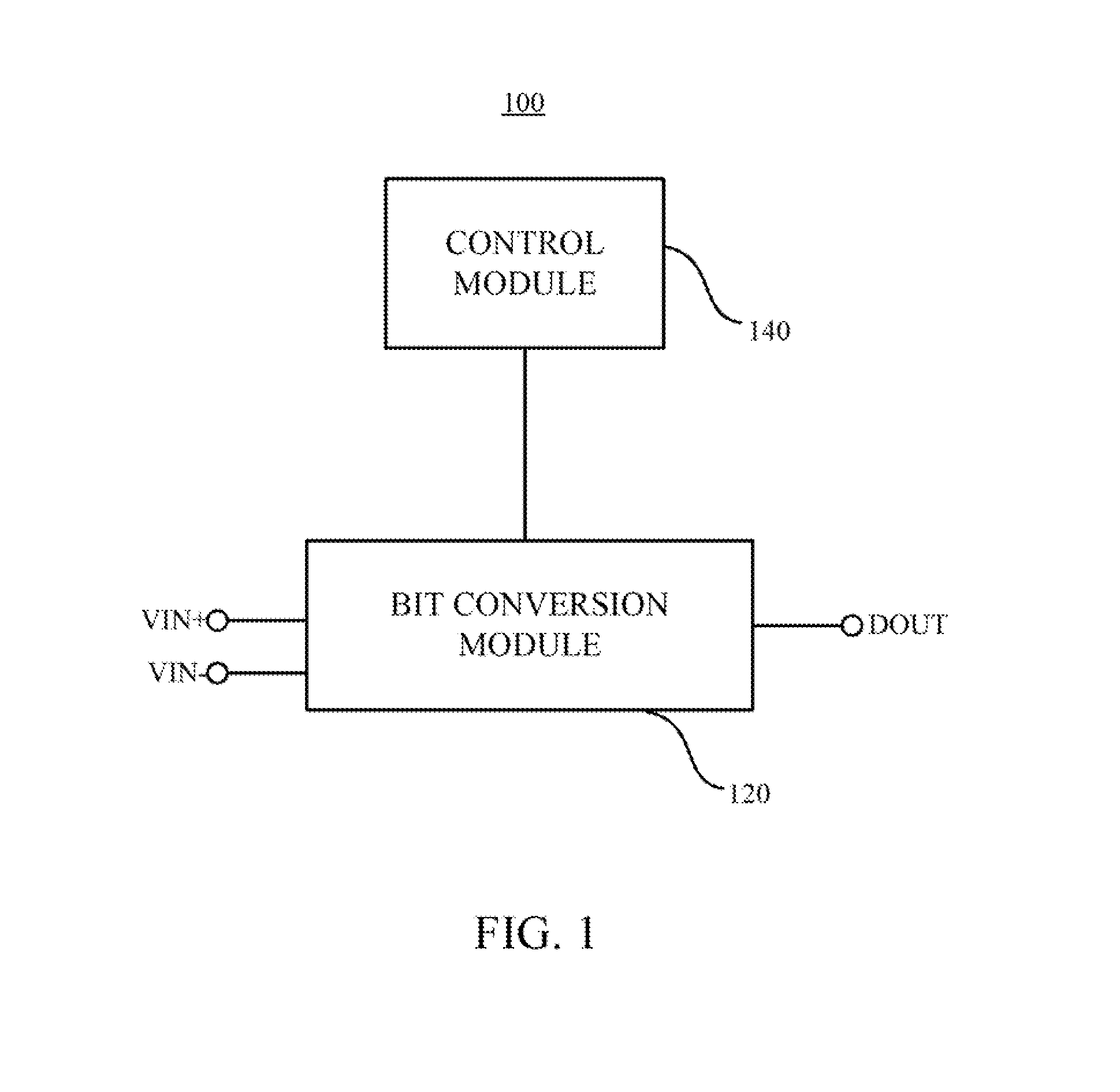

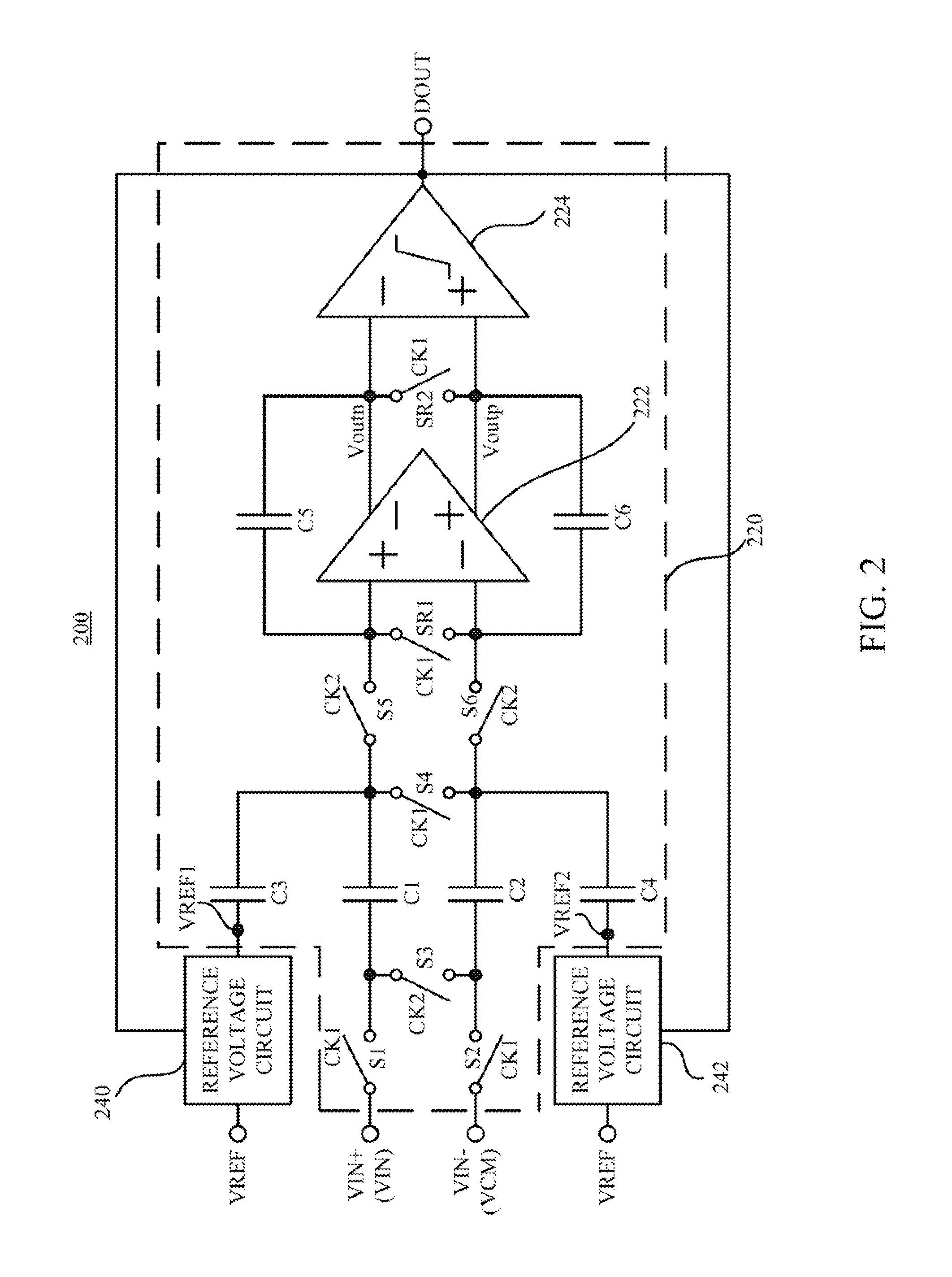

Analog to digital converter

ActiveUS20150109159A1Wide range of industrial applicationsPower saving provisionsElectric signal transmission systemsEngineeringAnalog-to-digital converter

An analog to digital converter is disclosed herein. The analog to digital converter includes a bit conversion module and a control module. The bit conversion module is configured to generate a quantization output in accordance with an input signal. The control module is configured to control the bit conversion module, so as to make the bit conversion module operate in one of a sigma delta mode and a successive approximation mode.

Owner:GLOBAL UNICHIP CORPORATION +1

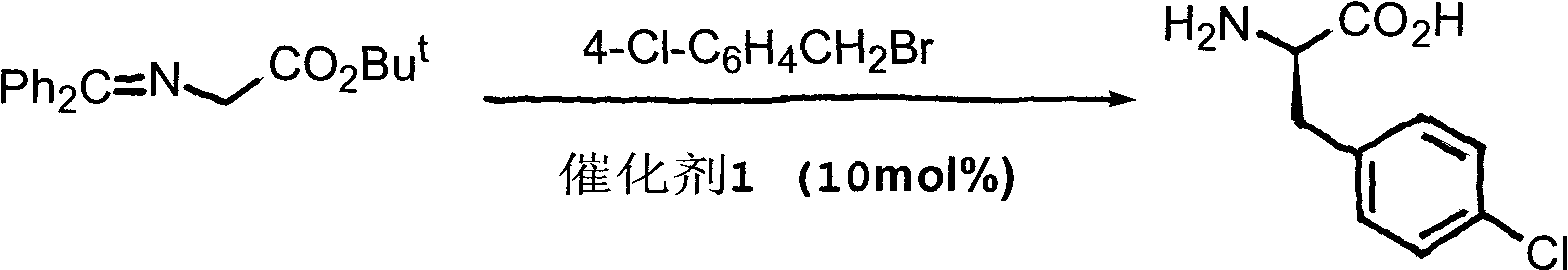

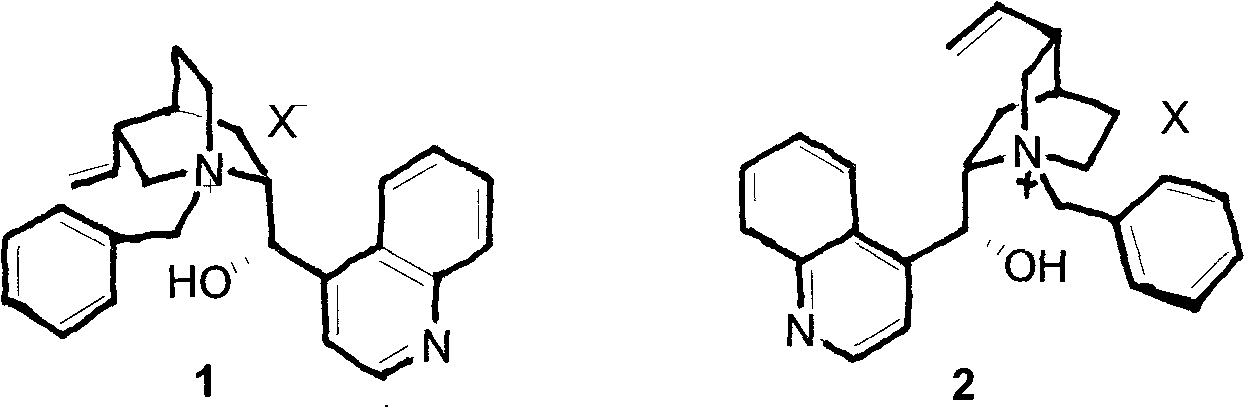

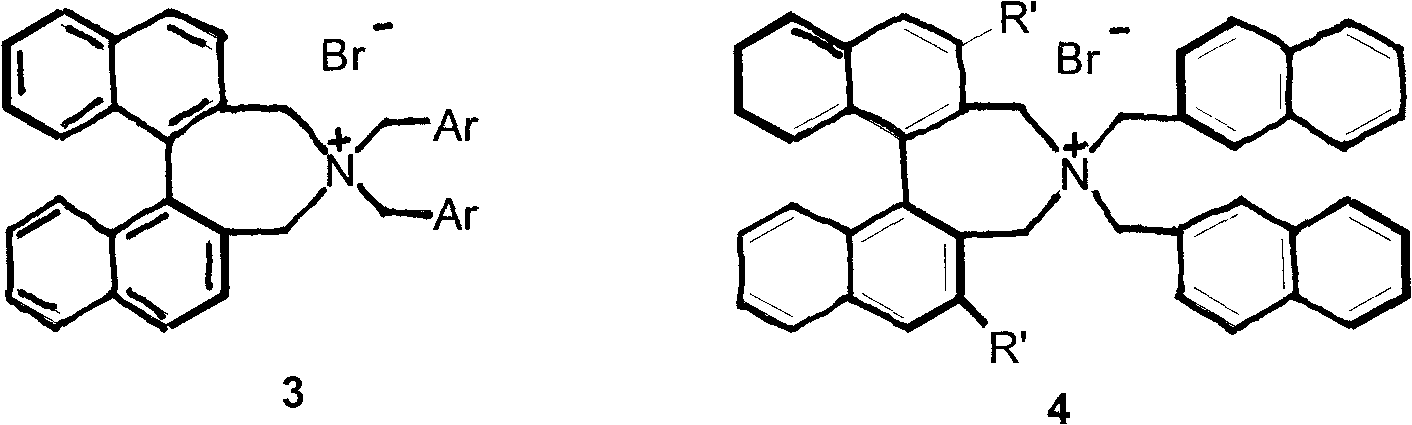

Novel asymmetric phase-transfer catalyst pentaazabicyclo and preparation method thereof

InactiveCN102658199AGood effectReduce dosageOrganic-compounds/hydrides/coordination-complexes catalystsImino compound preparationAlkanePtru catalyst

The invention discloses a novel asymmetric phase-transfer catalyst pentaazabicyclo and a preparation method thereof. A unique bran-new synthetic route is adopted: different chiral amines, which are used as the initial raw material, react with different halogenated hydrocarbons to synthesize the catalyst pentaazabicyclo with different structural formulae. The catalyst has the advantages of low consumption and high efficiency in the synthetic reaction, can easily change the structure, and thus, is suitable for various different substrates and wide asymmetric reactions.

Owner:RAFFLES PHAMRMATECH CO LTD

New process for preparing sodium thiocyanate

The invention belongs to the technical field of chemical engineering and discloses a new process for preparing sodium thiocyanate. The new process for preparing sodium thiocyanate comprises that coked gas PDS process desulphurized mixed salt is taken as a raw material, firstly sodium thiocyanate inside the raw material is extracted with methyl alcohol, then filter pressing is carried out, so that sodium thiocyanate filtrate is obtained, and finally evaporation concentration, cooling crystallization and centrifugal drying are carried out, so that sodium thiocyanate crystals are obtained. Sodium thiocyanate prepared by adopting the new process disclosed by the invention has high purity and good market prospect, desulphurization waste is effectively utilized, a waste material is changed into things of value, industrial raw material cost is greatly reduced, and occupying area is also reduced to some extent, so that an enterprise can make up the deficits and get surpluses.

Owner:徐州博创建设发展集团有限公司

Method for preparing organic-inorganic hybrid total heat exchange membrane through sol-gel method

ActiveCN105709617AImprove dispersionEnhanced interactionSemi-permeable membranesMembranesProcess synthesisSol-gel

The invention discloses a method for preparing an organic-inorganic hybrid total heat exchange membrane through a sol-gel method. The method includes the steps that an inorganic matter precursor and an organic high polymer are evenly mixed in a co-solvent, solation and gelation are conducted, and the organic-inorganic hybrid membrane is prepared. In a polymer system, nanoscale particles are obtained after hydrolytic polycondensation and evenly scattered in the polymer solution system. The preparation process is low in synthesis temperature, preparation cost is low, the pore diameter distribution is even, the agglomeration behavior of inorganic nano-particles can be effectively restrained, dispersity of the inorganic nano-particles in a polymer matrix is promoted, interaction between an organic phase and an inorganic phase is improved, the stability of the inorganic nano-particles in the polymer matrix is improved, and multiple properties such as moisture penetrability, gas blocking, pollution resistance and bacterium resistance of the separation membrane can be remarkably improved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method for processing and utilizing electrolytic manganese waste residue

The invention relates to a method for processing and utilizing electrolytic manganese waste residue, which comprises the following steps of: the electrolytic manganese waste residue is washed so as toa water washing liquid; salvolatile and flocculating agent and polyacrylamide are added so as to obtain a manganous carbonate precipitation and a first filtrate; aluminium sulphate crystal and crystal modifier borax are added into the first filtrate so as to separate out dodecahydrate aluminium ammonium sulfate crystal. The method can convert manganous sulfate in the electrolytic manganese wasteresidue which is difficult to isolate a manganese element into the manganous sulfate which is convenient to isolate the manganese element, can convert the manganous sulfate which is difficult to isolate a nitrogen element into the dodecahydrate aluminium ammonium sulfate crystal which is convenient to isolate the nitrogen element. The method has the low manufacturing cost, is easy to operate and convenient for realizing the commercial process.

Owner:CHONGQING UNIV

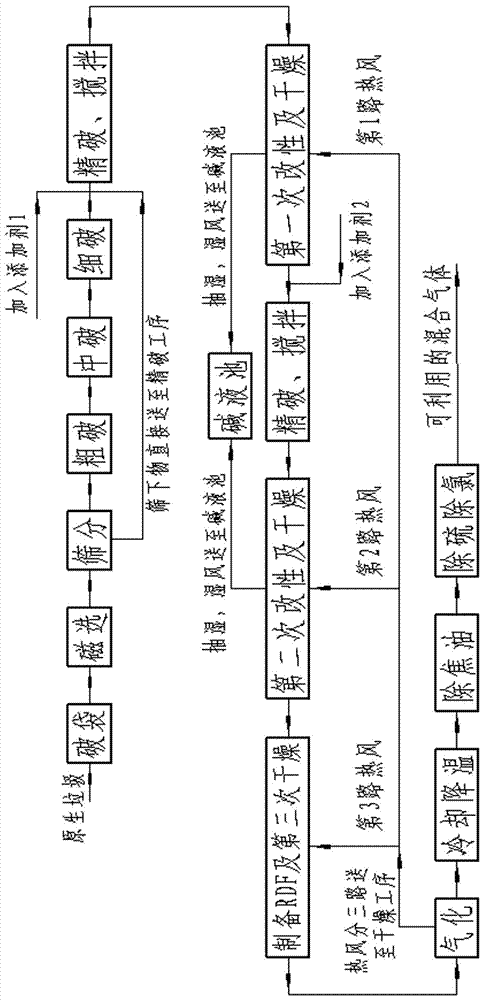

Modified molding and gasifying method for household garbage

The invention discloses a modified molding and gasifying method for household garbage. The method comprises steps as follows: the household garbage is subjected to bag breaking, magnetic separation, screening, coarse crushing, medium crushing and fine crushing, and the difference from the prior art is that procedures are added as follows: refined crushing and stirring are performed after fine crushing and an additive 1 is added; primary modification and drying are performed; refined crushing and stirring are performed, and an additive 2 is added; secondary modification and drying are performed; RDF (refuse derived fuel) is prepared, ternary drying is performed; gasification is performed; a product is cooled; tar is removed; chlorine and sulfur are removed, wherein CaO is added and reacts with water in the initial stage of treatment, and reaction heat is released. The reaction of added caustic soda and cellulose is also an exothermic reaction. After addition of sodium chloroacetate, a viscose glue-like mixture is produced through the reaction, and RDF is better in molding effect, is higher in strength and is not prone to dispersing at the high temperature; during modified molding and gasifying of the household garbage, no sewage and waste gas are discharged to the outside; combustible gas is produced after gasification of the household garbage, and the purposes of recycling resources and completely treating the household garbage are achieved.

Owner:桂林聚能环保科技有限责任公司

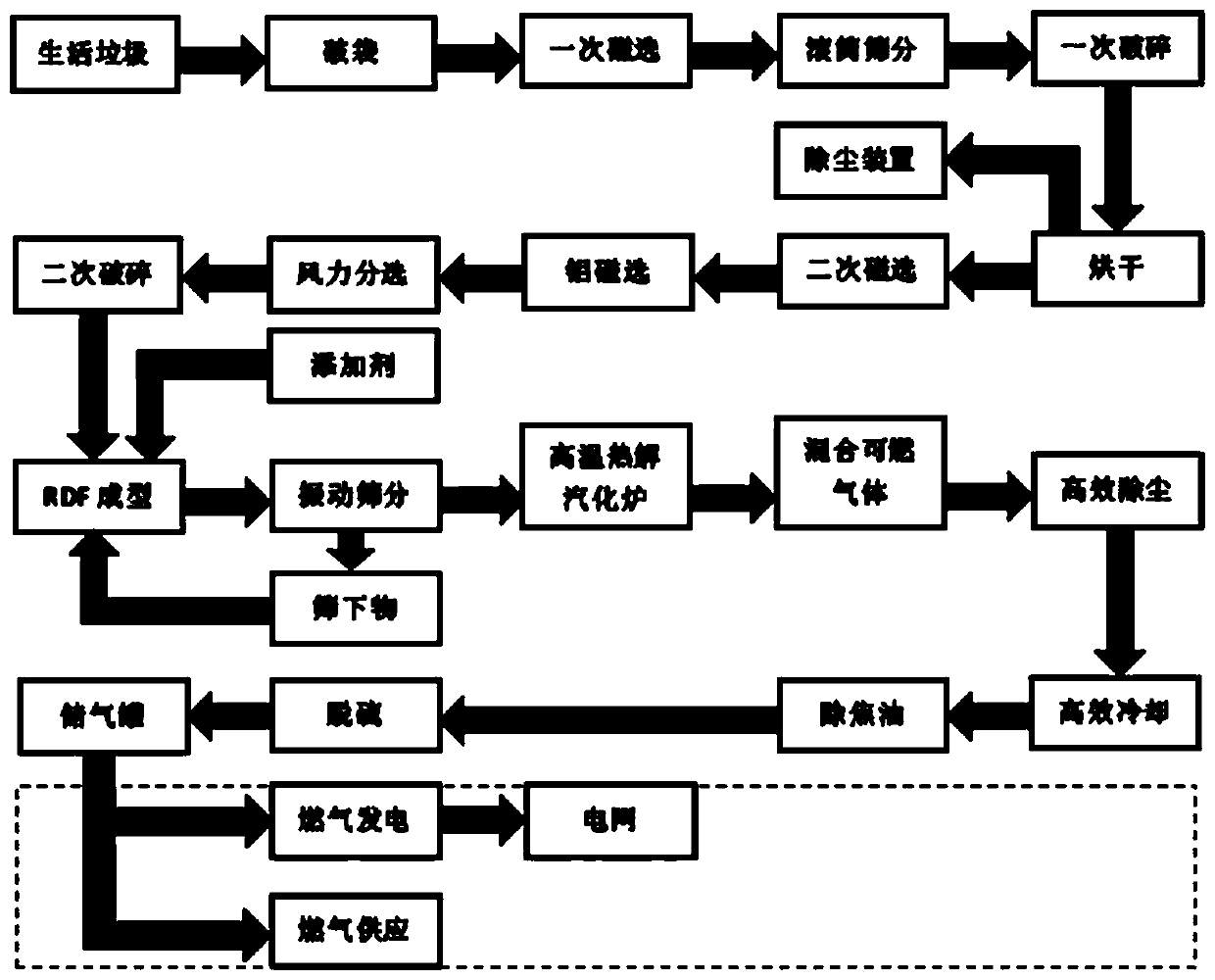

Process for making RDF from domestic garbage and high-temperature pyrolysis gasification treatment

InactiveCN110551550AWide range of industrial applicationsHigh economic valueBiofuelsSolid fuelsSustainable economyAir separation

The invention discloses a process for making RDF from domestic garbage and high-temperature pyrolysis gasification treatment. The process comprises the following procedures of domestic garbage, bag breaking, primary magnetic separation, drum screening, primary breaking, drying, secondary magnetic separation, aluminum magnetic separation, air separation, fine breaking, additives adding, stirring, RDF molding, cooling, screening, gasification, dust removal, cooling, oil removal and dechlorination and desulfurization. Metal, glass, high-value plastic, sand, stone, soil and the like in household waste are completely separated, and the effects of resource recycling and sustainable economic development are achieved.

Owner:浙江华环环境有限公司

Two-phase fuel injection valve for diesel engine and gas engine including nozzle having pumping function

ActiveUS9605635B2Wide range of industrial applicationsReducing harmful gasInternal combustion piston enginesLow pressure fuel injectionMaster cylinderFuel treatment

A dual fuel injection valve includes a primary fuel treatment space and a secondary fuel treatment space formed extending the fuel valve block and the hybrid nozzle block in the longitudinal direction and side by side with each other. The primary fuel treatment space includes a primary cylinder passage, a primary fuel passage and a primary nozzle hole. The secondary fuel treatment space includes a secondary cylinder passage formed separately form the primary cylinder passage, a secondary fuel passage formed separately form the primary fuel passage hole, a secondary nozzle hole. The dual fuel injection valve further includes a first chamber formed in a lower portion of the secondary cylinder passage, a second chamber disposed between the first chamber and the secondary nozzle hole and formed to surround the secondary cylinder passage, and a primary fuel movement hole connecting the primary cylinder passage and the second chamber.

Owner:HYUNDAI HEAVY IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com